Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SP100ADA Series Dual-transformer

Speaker/Strobes for Fire Protective

Signaling Systems

Specifications

Mechanical

Input Terminals: 12 to 18 AWG (3.31 to 0.82 mm2)

Speaker Size: 4 inches (101 mm)

Grille Size: 5" (127 mm) square

Electrical (Speaker)

Voltage Input: 25 volts or 70.7 volts (nominal)

Frequency Range: 400 - 4000 Hz

Operating Temperature Range: 32° to 120°F (0° to 49°C)

NOTICE: This manual should be left with the owner/user

of this equipment.

General Description

The National Fire Protection Association (NFPA) has published standards and recommended practices for the speakers described in this manual. As a result, the installer must

be familiar with these requirements as well as all local

codes and special requirements of the authority having jurisdiction.

Electrical

1. Connect the speaker/strobe as shown in Figure 1. Keep

in mind that even though the speaker and strobe are a

single mechanical unit, they are electrically independent

and require separate power sources.

NOTE: Do NOT loop electrical wiring under terminal

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

screws. Wires connecting the device to the control

panel must be broken at the device terminal connection in order to maintain electrical supervision.

SP100ADA series speaker/strobes can be operated with distribution amplifiers having an output voltage of either 25

volts or 70.7 volts.

The speakers operate at any one of six input power levels.

The output sound level is selected at the time of installation, but can be changed, if necessary.

The speaker is also equipped with a capacitive input to allow for DC supervision.

The SP100ADA Series Speaker/Strobe is equipped with an

attached 15, 15/75, 75, or 110 candela (cd), UL 1971 listed

strobe. Although they are shipped as a unit, the strobe and

speaker are electrically independent and require separate

power sources. Strobes can be powered by means of a 24V

regulated or full-wave rectified unfiltered supply.

Installation - For Strobe Replacement See NFPA 72,

Chapter 6

All wiring must be installed in compliance with the National Electrical Code and all applicable local codes as well

as any special requirements of the authority having jurisdiction, using the proper wire size. This also includes all

applicable NFPA Standards, ANSI/UL 1480, and NEC 760.

2. Notice that the speaker circuit board is equipped with

two sets of posts and associated electrical jumper wires.

One set of posts is numbered 1 through 6 while the other

is labeled A and B. Both electrical leads are fitted with a

barrel connector. These two sets of posts and leads enable the installer to select any one of six sound pressure

levels with either a 25 volt or 70.7 volt amplifier.

Figure 1. Electrical connections:

D400-55-00 1 I56-691-03

Page 2

For example, Table 1 shows that to select a 1/4 Watt in-

put when a 25 volt amplifier is being used, slide the blue

lead onto post 3 and slide the yellow lead onto post B.

Similarly, to select a 4 Watt input with a 70.7 volt amplifier, slide the blue and yellow leads onto posts 2 and A,

respectively.

Table 1 also lists the UL reverberant and anechoic output

sound levels for each transformer power tap on the

SP100ADA Series Speaker/Strobes.

CAUTION

Signal levels exceeding 130% rated signal voltage can damage the speaker. Consequently, an incorrect tap connection

may cause speaker damage. This means that if a 25V tap is

selected when a 70.7V amplifier is being used, speaker

damage may result. Therefore, be sure to select the proper

taps for the amplifier voltage/input power level combination being used.

NEVER connect the yellow jumper to the posts numbered 1

through 6 or the blue jumper to lettered posts A or B.

Mechanical

Slotted head screws are included for attaching the speaker

to the electrical junction box. Insert the decorative filler

plugs supplied into the remaining two holes in the grille.

Table 1:

25 V

70.7 V

UL Reverberant

(dBA @ 10 ft.)

Anechoic

(dBA @ 10 ft.)

Figure 2:

4W

1B

2A

90

93

2W

1A

3B

87

90

1W 1/2 W 1/4 W

2B 2A 3B

4B 5B 6B

84 81 78

87 84 81

1/8 W

4B

6A

75

78

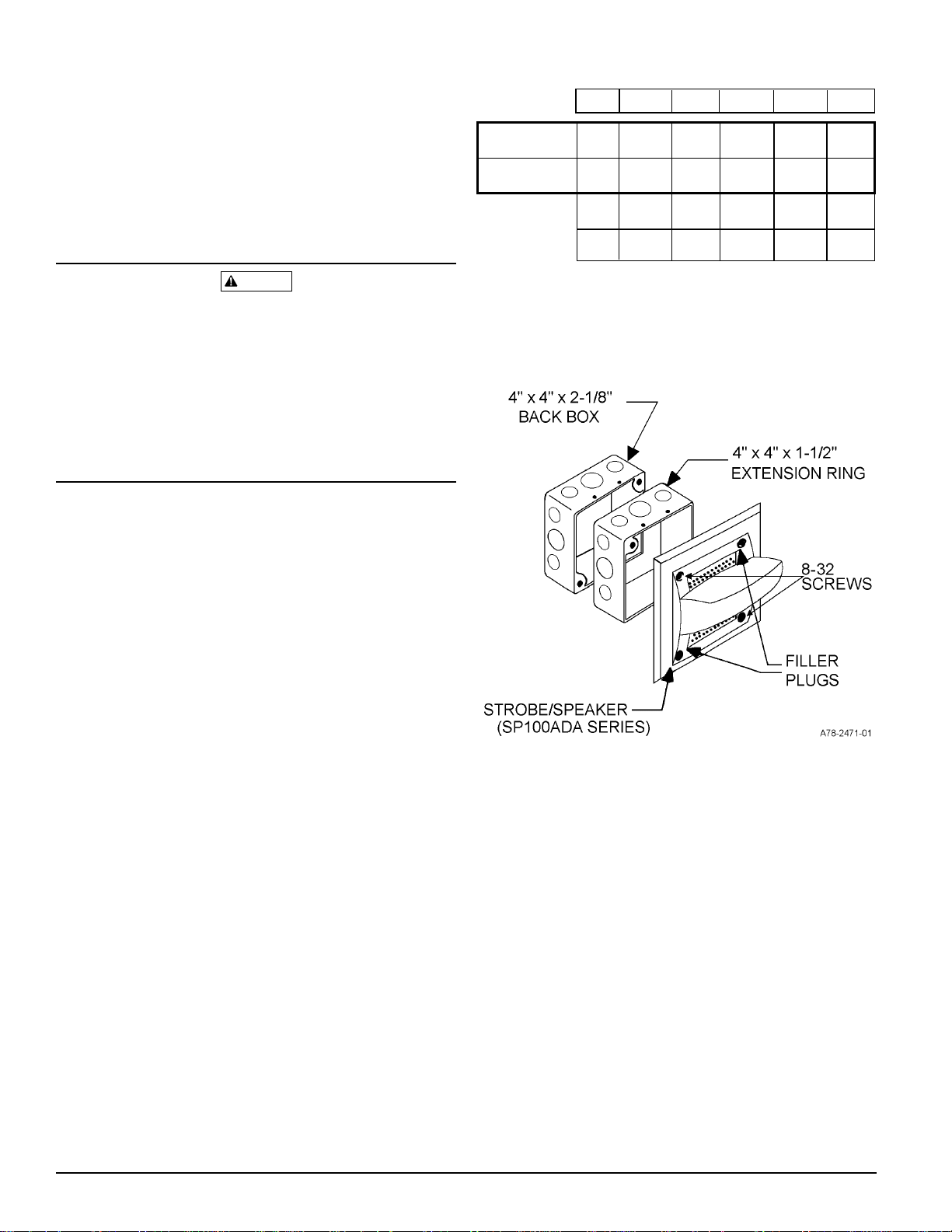

Mounting

See Figure 2. The speaker can be flush mounted on a 4" X

4" X 2-1/8" back box with a 1-1/2" extension ring, as follows:

A. Select the appropriate pair of diagonally opposite

mounting holes in the speaker grille.

B. Use the two 8-32 X 1-3/4" slotted pan head screws, pro-

vided, to attach the speaker/strobe to the back box.

C. Insert the decorative filler plugs (supplied) into the re-

maining two speaker mounting holes.

D400-55-00 2 I56-691-03

Page 3

Strobe Light Ratings

The signaling strobe is rated for 0° to 49°C and is not suit-

able for outdoor use.

The rated light output of the SP1*2415ADA and

SP1*241575ADA is 15 cd (See Figure 3).

The rated light output of the SP1*2475ADA is 75 cd (See

Figure 3).

The rated light output of the SP1*24110ADA is 110 cd (See

Figure 3).

Figure 3:

NOTE: The light output at 0° viewing angle for

SP1*241575ADA is 75 cd (See Figure 3).

R = Red

W = White

0˚

45˚

90˚ –90˚

–45˚

LIGHT

Degrees % of Rating

0100

5 - 25 90

30 - 45 75

50 55

55 45

60 40

65 35

70 3 5

75 30

80 30

85 25

90 25

Table 2. Strobe characteristics:

Model Supply

SP1R24110ADA

SP1W24110ADA

SP1R2475ADA

SP1W2475ADA

SP1R2415ADA

SP1W2415ADAB

SP1R241575ADA

SP1W241575ADA

Note: Inrush current lasts on the order of microseconds

Voltage

Range

20-30V 210 470/500 0 245 400/500 0.08

20-30V 170 385/400 0 200 320/370 0.04

20-30V 75 160/180 0 90 275/290 0.02

20-30V 93 210/220 0 120 275/290 1.0

Table 3:

SP100W24MC

C = Ceiling mount

LO = 1.5 cd UL 1638 Strobe

M = 15 cd UL 1638 Strobe

24 = 24 VDC Strobe

SP100W = Round Grille, White Speaker

SP101W = Square Grille, White Speaker

SP101R = Square Grille, Red Speaker

Operating Current from Regulated

Average

Operating

Current

Supply

Peak

Current

(mA)

20/30V

Inrush

Current

(mA in

access of

Peak)

Operating Current from Full-Wave Rectified

Average

Operating

Current

(mArms)

Unfiltered Supply

Peak Current

(mA)

20Vrms/30Vrms

Inrush Current

(Amps in excess

of Peak)

SP1R2415ADA

15 = 15 cd, UL 1971 Strobe

1575 = 15 cd UL 1971 Strobe

75 = 75 cd, UL 1971 Strobe

110 = 110 cd, UL 1971 Strobe

24 = 24 VDC Strobe

SP1R = Square Grille, Red Speaker

SP1W = Square Grille, White Speaker

V4R = V400 Square, Red Speaker

D400-55-00 3 I56-691-03

Page 4

WARNING

The Limitations of Speaker/Strobes

If either of the power option jumper wires is not plugged into one of the

appropriate option positions, the speaker will not sound and there will be

no trouble indication at the panel. Always make sure that the individual

speakers are tested after installation per NFPA regulations.

Underwriters Laboratories’ standard 1971 and uses an extremely reliable

xenon flash tube. The visual warning signal is suitable for direct viewing

and must be installed within an area where it can be seen by building occupants. The strobe must not be installed in direct sunlight or areas of

high light intensity (over 60 foot candles) where the visual flash might be

The speaker may not be heard. The loudness of the speaker meets (or

exceeds) the current Underwriters Laboratories standards. However, the

disregarded or not seen. The strobe may not be seen by the visually im-

paired.

speaker may not attract the attention of a sound sleeper or one who has

recently used drugs or has been drinking alcoholic beverages. The speaker

may not be heard if it is placed on a different floor from the person in hazard or if placed too far away to be heard over the ambient noise. Traffic, air

conditioners, machinery, or music appliances may prevent even alert per-

The signal strobe may cause seizures. Individuals who have positive

photic response to visual stimuli with seizures, such as persons with epilepsy, should avoid prolonged exposure to environments in which strobe

signals, including this strobe, are activated.

sons from hearing the alarm. The speaker may not be heard by persons

who are hearing impaired.

System Sensor recommends that the speaker and signal strobe always be

used in combination so that the risks from any of the above limitations are

The Signal Strobe may not be seen. The electronic visual warning signal

minimized.

that flashes at least once every three seconds meets or exceeds current

Three-Year Limited Warranty

System Sensor warrants its enclosed speaker/strobe to be free from defects

in materials and workmanship under normal use and service for a period

of three years from date of manufacture. System Sensor makes no other

express warranty for this speaker/strobe. No agent, representative, dealer,

or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this

Warranty shall be limited to the repair or replacement of any part of the

speaker/strobe which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll free

number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifica-

tions, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or conse-

quential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

D400-55-00 4 I56-691-03

© System Sensor 1996

Loading...

Loading...