Page 1

Aspirating Smoke Detector

Pipe Installation

USER GUIDE

Page 2

Table of Contents

User Guide: Aspirating Smoke Detector Pipe Installation

Scope of this user guide ............................... 3

Designing a Pipe Network ............................3

Pipe Overview ................................................4

Pipe Network Components ............................................ 4

Pipes ..............................................................................4

Pipe Temperature...........................................................4

Fittings ............................................................ 4

Couplings and Unions ................................................... 4

Elbows ...........................................................................4

Tees ................................................................................4

End Caps ....................................................................... 5

Capillary Tubes and Sampling Ports ............................. 5

Mounting Brackets ......................................................... 5

Labels ............................................................................5

Pipe Network Installation .............................. 6

Sampling Methods ....................................... 11

Standard Pipe Network Sampling ...............................11

Capillary Tube Sampling .............................................11

Open Area Protection .................................. 12

Ceiling Sampling .........................................................12

Inter-Beam / Below-Beam Sampling ...........................13

Under Floor Protection ................................ 13

Floor Void Sampling .....................................................13

Object Protection ......................................... 14

Cabinet Sampling ........................................................14

In-Cabinet Sampling ....................................................14

Above-Cabinet Sampling ............................................14

Large Area Protection ................................. 15

Cold Area Protection ................................... 15

High Air Exchange Areas ............................ 16

Cutting Pipe ...................................................................6

Joining Components ...................................................... 6

Mounting the Pipe Network ...........................................6

Pipe Bends ....................................................................6

Drilling Sample Ports .....................................................7

Installation Stages..........................................................7

Application and Design ................................. 8

Design ............................................................................ 8

Regulatory Requirements .............................................. 9

Site Layouts and Measurements .................................10

Site Details ...................................................................10

Environmental Conditions ............................................10

System Design .............................................................10

Return Air Sampling .....................................................16

In-Duct Sampling ......................................... 17

Design Considerations for In-Duct Sampling ..............17

Small Duct Sampling ...................................................17

Large Duct Sampling ...................................................18

Port Orientation ............................................................ 18

Monitoring Voids .......................................... 18

Basic Pipe Cleaning & Maintenance .......... 19

Pipe Network Maintenance .........................................19

Filter Maintenance .......................................................19

22

Page 3

User Guide: Aspirating Smoke Detector Pipe Installation

Scope of this user guide

The purpose of this user guide is to provide details on the physical installation of the pipe network for the FAAST Fire Alarm Aspiration

Sensing Technology® aspirating smoke detector. Local codes and regulations may vary and take precedence over the information

contained in this user guide.

Designing a Pipe Network

The FAAST detector and its pipe network allow deployment of smoke detection in challenging and mission critical environments. In

order to ensure the system will operate in accordance to site specific requirements, as well as local codes and regulations, the pipe

network must be designed and verified using the PipeIQ® software. PipeIQ can be downloaded at systemsensor.com/faast.

3

Page 4

User Guide: Aspirating Smoke Detector Pipe Installation

Pipe Overview

Pipe Network Components

The FAAST detector uses standard aspiration fire detection pipe

network components, such as pipes, elbows and couplings.

The components listed in this section are not an all inclusive list,

however they represent the most commonly used items.

Pipes

The pipes used in the pipe network can be made of various

materials including copper, PVC, ABS, UPVC and CPVC. The

internal pipe diameter used with the FAAST system can range

from 0.591" to 0.827" (15 to 21 mm). Ideal dimensions vary

depending on system design requirements as well as local

codes and regulations. The FAAST detector has a built in tiered

insertion point for the pipes which allows for an outside tube

diameter of either 1.050" or 25 mm to accommodate U.S.

Customary System and Metric System Sized Pipes.

Frequently Asked Question – Can we use metal pipe instead

of plastic with FAAST?

Yes. It is acceptable to use either steel or copper pipe under the

following conditions:

Fittings

Fittings are used to connect sections of pipe together on longer

network runs and are made from the same material as the pipe.

There are several types of fittings to allow for various bends,

straight runs, branches and connections. Common fittings are

described in the following sections.

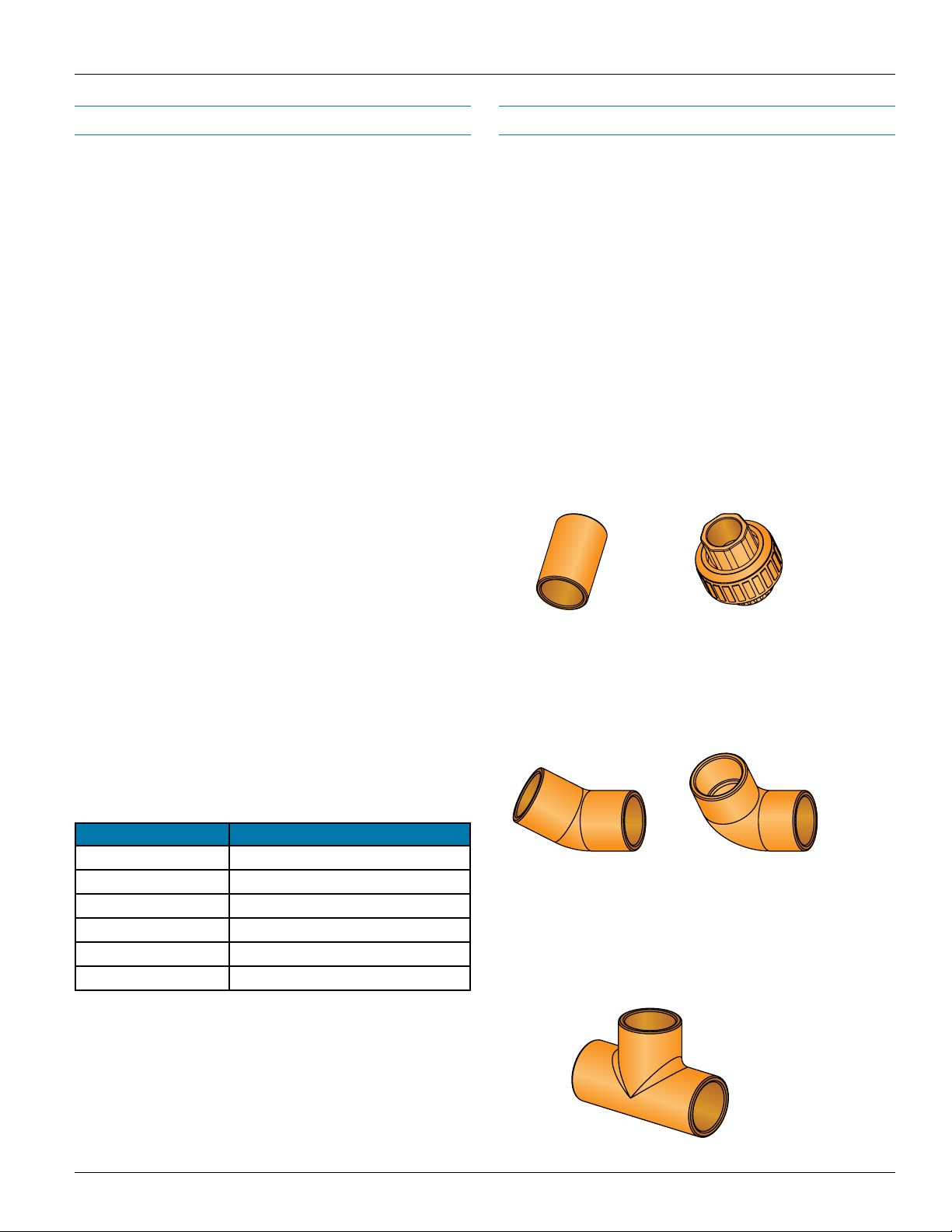

Couplings and Unions

Couplings and unions are used to connect two sections of pipe

in a straight line. A coupling is used when the section is not

intended to be taken apart.

A union offers the ability to screw the two pipe sections together

for future access, such as areas of the pipe network that have

to be periodically disassembled for maintenance and cleaning.

Unions can also be used to orient sample ports correctly in

a specific section of the pipe network, such as over return

air grilles (for more information on high air flow and duct

applications, see the white paper at systemsensor.com/faast).

Figure 1 shows a typical union and coupling.

• The pipe size used must be capable of fitting to a plastic

pipe upon interfacing with the FAAST device. The inner

diameter must be within the approved range of

.591" - .827" ( 15.00 - 21.00 mm ).

• The material must be approved by the local authority

having jurisdiction and must also be approved by the

insurance underwriter

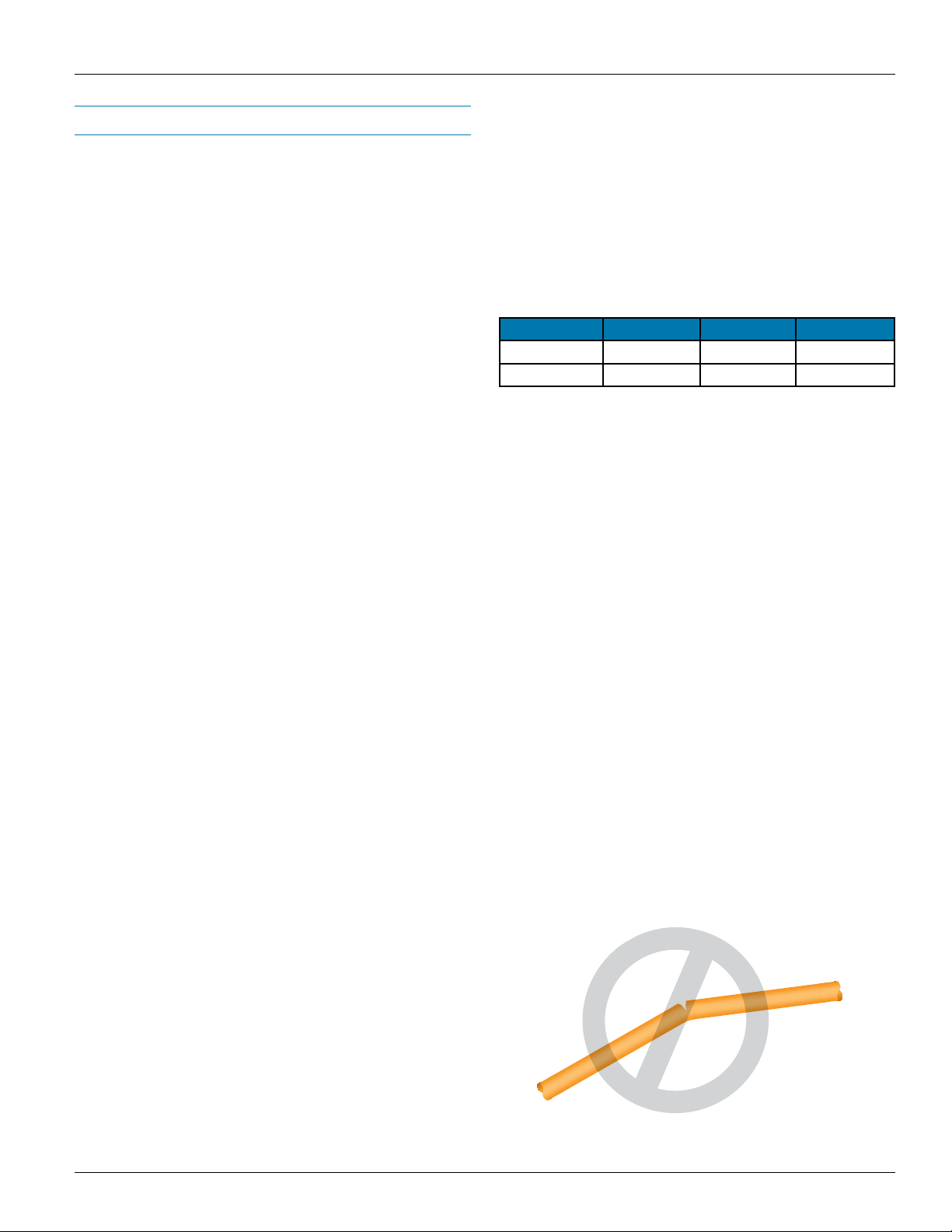

Pipe Temperature

Pipe selection may be contingent on the temperature of the

room in which the pipe will be mounted. Table 1 shows

temperature ranges for various types of pipe.

Pipe Material Service Temperature

ABS -40 – 80°C (-40 to 176°F)

PE-80 -50 to 60°C (-58 to 140°F)

PE-100 -50 to 60°C (-58 to 140°F)

CPVC -26 to 93°C (-15 to 200°F )

PVC -26 to 49°C (-15 to 120°F)

Copper -150 to 110°C (-238 to 230°F)

Table 1: Temperature ranges for various types of pipe.

ASP-76

Figure 1: Couplings and unions.

ASP-75

Elbows

Elbows are used to change the direction of the pipe network.

Both 45 degree and 90 degree elbows may be used. Both

elbow fittings are shown in figure 2.

45°

ASP-77 ASP-78

Figure 2: Elbows.

90°

Tees

Tees are also used for branching into multiple pipes from a

single pipe network. A specialized tee can be used to attach a

capillary tube and a sampling port. A tee is shown in figure 3.

* For specific design considerations in cold temperature

applications, download the Cold Storage White Paper from

systemsensor.com/faast

ASP-80

Figure 3: Tees

4

Page 5

User Guide: Aspirating Smoke Detector Pipe Installation

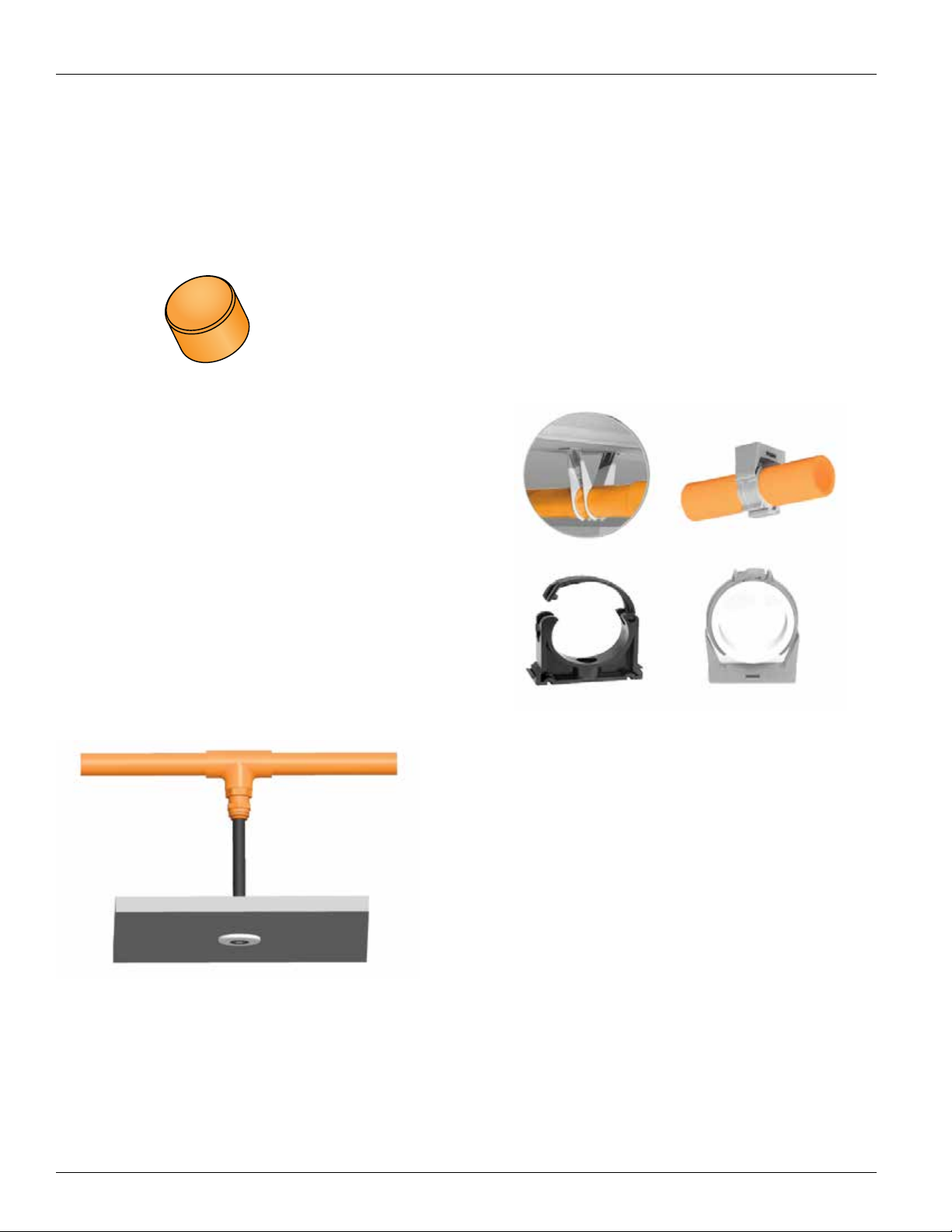

End Caps

The end of the pipe should be terminated with an end cap. The

end cap may have a sampling port depending on the system

design. The size of the port in the end cap is determined by the

PipeIQ software. An end cap is shown in figure 4.

ASP-79

Figure 4: End caps.

Capillary Tubes and Sampling Ports

A capillary tube is a length of flexible tubing that is connected

to the main sampling pipe with a sampling port at the end.

The purpose of these tubes is to extend the placement of the

area being sampled away from the main pipe network. This may

be necessary to reach in to an enclosed space, such as a

cabinet, or for aesthetic or security reasons. This allows the core

pipe network to be hidden while only a small sampling port is

located in the main space. Figure 5 shows the capillary tube extending down from the main sampling pipe with a sampling port

at the end. PipeIQ allows for capillary tubes and sampling ports

to be added to the pipe network design and will calculate the

appropriate air flow through the system.

Mounting Brackets

The pipe network is mounted to the ceiling, or other appropriate

location, using mounting brackets. A large variety of brackets

are available from a standard pipe supplier. Typical brackets

include clips, saddle clamps, or tie wraps, as shown in Figure 6.

The mounting choice will depend on the material being mounted

to, environmental temperature, and local codes and regulations. Mounting brackets are usually centered 5 ft. (1.5 m) apart

when using 3/4" schedule 40 pipe at 70°F (21°C). At 140°F this

spacing reduces to 2.5 ft. between support brackets. Open

style mounting clips should not be used in an inverted position

with the open section facing downward, because the pipe could

drop from the clip.

The maximum length for capillary flexible tubing is 26 ft. (8 m).

When multiple capillary tubes are used in a network, the length

of each capillary tube should be approximately equal.

ASP-83

Figure 5: Capillary tubes and sampling ports.

ASP-81

Figure 6: Mounting brackets.

Labels

Labels are available to identify the pipe network as a fire

detection system, both at the sampling ports and along the pipe

itself. NFPA 72® states that the pipe should be labeled:

1. At changes in direction or branches of piping

2. At each side of penetrations of walls, floors, or

other barriers

3. At intervals on piping that provide visibility, but no

greater than 20 ft. (6.1 m)

5

Page 6

Pipe Network Installation

User Guide: Aspirating Smoke Detector Pipe Installation

This section provides the basics to installing a pipe network.

Keep in mind that each system will have different characteristics, and will have variations to accommodate. The most

common issues are described in the following sections. To

ensure a pipe network performs as expected, it must be

designed in PipeIQ and installed as specified by the software.

Cutting Pipe

Proper tools must be used when cutting pipe. Pipe shears or a

wheel type plastic tubing cutter can be used for plastic pipe.

Always keep the cutting edge of the tools sharp. Ensure that

cuts are made perpendicular to the pipe length, keeping the

cuts square. Square cuts ensure maximum bonding area and

help provide a good seal when joining the components.

Remove all loose material and any burrs from the end of the

pipe after a cut. Debris and shavings from cuts must be removed in order to keep sampling ports free of obstruction.

Joining Components

The pipe network must be permanently connected once the

system has been installed and tested. The method to

accomplish a permanent connection depends upon the material

of the pipe and fittings.

NOTE: The immediate connections between the inlet pipe

and exhaust pipe and the FAAST detector SHOULD NOT be

permanently connected.

When bonding components together, never apply solvent on the

inside of a pipe or other component. Apply the solvent only to

the outside of the pipe that is being inserted into a coupling or

other component. If a solvent is applied to the inside of a pipe or

other component, the solvent can build up. This build up can

affect the air flow within the pipe network and may cause

abnormal behavior within the pipe network.

Make sure that pipes are inserted completely and butted

against the lip of the coupling or other component. If this is not

done, turbulence can be created due to the gaps, which can

cause problems with system pressures and air flow.

Frequently Asked Question – Is there a specic glue that

must be used when assembling the network piping?

Mounting the Pipe Network

The following recommendations should be taken into

consideration when mounting the pipe network.

• Minimize flexing of the pipes by securing them at proper

intervals with appropriate mounting brackets.

Maximum Support Spacing at Ambient Temperature

Pipe Diameter 60°F (16°C) 100°F (38°C) 140° F (60°C)

1/2 in. (15mm) 4.5 ft. (1.3 m) 4 ft. (1.2 m) 2.5 ft. (0.7 m)

3/4 in. (20 mm) 5 ft. (1.5 m) 4 ft. (1.2 m) 2.5 ft. (0.7 m)

Table 2: Maximum support spacing at ambient temperature.

• Typically, the pipe network should be mounted between

1 and 4 in. (25 – 100 mm), maximum of 12 in. (300 mm),

below the ceiling, subject to local codes and regulations.

• Allow for expansion and contraction of the pipe network in

areas of extreme temperature fluctuations, especially on

long straight pipe runs.

• In areas of extreme temperature fluctuations, never place

mounting brackets adjacent to couplings, unions or tees.

This can lead to interference with expansion or contraction

of the pipe network.

• To minimize the effect of pressure differentials that could

affect the air flow of the system, the sampled air must be

returned to the protected environment via exhaust tubing

wherever possible.

Pipe Bends

Never bend pipes unless absolutely necessary. Use elbows,

tees, or other fittings to change direction of the pipe.

If bending is necessary, determine how much bending the

pipe can tolerate before beginning the process. Always use

bending springs and pipe benders. Bending a pipe without heat

will cause the PVC to shatter. Never heat the pipe or bend it

around sharp objects. If a pipe creases or buckles while

bending, replace it with a new section of pipe. Conform to all

local codes and regulations for bending of pipes.

Yes, glue that is listed for the type of pipe used. When applying

the glue be cautious not to leave excess residue inside the pipe.

This can trap dust or dirt particles that can possibly affect the

airflow of the detector over time.

Prior to drilling any sample ports, the pipe network should be

checked for leaks. This can be done by pushing blank

end caps onto pipe ends and/or covering sample ports with

tape and applying low pressure air to the system to check for

pressure decay.

Figure 7: Pipe bends.

6

Page 7

User Guide: Aspirating Smoke Detector Pipe Installation

Drilling Sample Ports

Each port in a sampling pipe represents a smoke detection

location. Port placement and size are determined using the

PipeIQ software. Sample ports should be measured, marked,

and drilled before the network is installed. To prevent sampling

ports from being blocked by dust and dirt, place ports on the

bottom side of the sampling pipe, not the top side. This ensures

that any falling debris does not clog the sampling ports. This

port positioning should also be followed for voids in the ceiling

or floor.

The following guidelines should be followed when drilling the

sample ports in the pipe network.

• Ports must be drilled perpendicular (90 degrees) to the

pipe. If the drill is not held perpendicular, the port is not

round and not modeled properly in PipeIQ.

• Tapering the ports reduces dust collection at the

sample ports.

• Sampling ports must be drilled exactly at the positions

marked on the pipe with the exact size as determined by

the PipeIQ software.

• Ports must not be drilled through both sides of the pipe.

• Ports should be drilled with a slow speed drill with a sharp

drill bit. This minimizes dust and burrs entering the

pipe network.

It is good practice to blow compressed air through the pipe

after drilling to clear any debris before final connection to the

FAAST detector. Alternately, a shop vacuum can be used to

remove debris from the pipe network. Ensure that the pipe is

disconnected from the FAAST detector when vacuuming pipe.

Installation Stages

Table 3 lists the standard installation stages for an aspiration

pipe network.

STEP ACTION

1 Verify design documents are accurate and obtain the size

and configuration of the pipes in the network.

Note: If PipeIQ was used to design the network, a bill of

materials can be generated from the application.

2 Mark off the area where the system is to be installed and

identify the location where the FAAST detector is to be

mounted.

3 Select and mark the locations for the pipe clips in

accordance with the design.

4 Install the FAAST detector in its permanent location.

(See Installation and Maintenance Guide for details.)

5 Mount the pipe clips according to the previous markings.

6 Dry mount and assemble the pipe network according

to the pipe network design documents. CAUTION: Do not

permanently connect the pipes at this time.

7 Measure and mark the sampling ports on the pipe

network. Make sure that the spacing of the sampling

ports is in accordance with the network design. Based

upon the application, ensure that the sampling ports are

at the correct orientation to the air flow, as recommended

in the section on network pipe design.

8 Modify the design documents to agree with the actual

network, if the physical network is different from the original design, this new layout should be re-designed and

confirmed in PipeIQ prior to drilling sampling ports.

9 Verify the sampling port positions and orientations and

drill the sampling ports.

10 Drill and install end caps on all appropriate pipe ends.

11 When testing is complete and the system performance is

verified, permanently bond the pipe network together.

CAUTION: Never bond the pipes to the detector. The

detector inlet and outlet are tapered to accept the piping

without any bonding and provide an air tight seal.

12 Label all portions of the system according to local codes

and regulations. Pipe and Sampling Port labels are available – refer to the Accessories section.

13 If additional changes are made, ensure that design

documents are updated accordingly.

Table 3: Installation steps.

7

Page 8

Application and Design

User Guide: Aspirating Smoke Detector Pipe Installation

This section is intended to provide general design and

application guidelines for designing pipe networks in

conjunction with the FAAST system. It contains design

considerations and recommendations on how the FAAST

system may be installed in various applications.

Design

There are basic requirements that must be followed for a good

site design. The more information that is obtained up front, the

easier the process will be. The following list is good information

to have when designing a pipe network.

A

• Understand local codes, standards, and regulations

• Gather all relevant information about the site, including

the floor plan for the protected space. The floor plan must

also include existing or proposed fixtures, fittings, air

handlers, vents and other equipment that requires special

consideration.

• Determine the uses of the protected area to establish any

special requirements.

• Verify the protection level required for the area, i.e.

Standard, Early Warning, or Very Early Warning

Fire Detection.

• Use the PipeIQ software to design the pipe network

for the FAAST detector.

C

A

B

A. End cap with or without port

B. Air sample ports

C. Detail showing airow in sampling pipe

D. Air sample pipe

E. FAAST Aspirating Smoke Detector

Figure 8: Application and design.

B

D

E

8

Page 9

Regulatory Requirements

User Guide: Aspirating Smoke Detector Pipe Installation

Local codes and regulations can determine the size and

spacing between the sample ports in a network, making them

Transport times and obscuration levels required at each sample

port are as below:

a critical part to any pipe design. These requirements change

depending on the type of environment being monitored. Local

Very Early Warning Fire Detection (VEWFD):

codes and standards take precedence over any parameters

suggested by this document for FAAST systems.

Sample port spacing: 200 sq. ft.

Transport time: 60 seconds from further port (includes test port)

Frequently Asked Question: How should the sample ports

be spaced?

Sample port spacing varies worldwide based on regulatory

Sample port sensitivity at pre-alarm: 0.2%obs/ft.

Sample port sensitivity at alarm: 1.0%obs/ft.

Early Warning Fire Detection (EWFD):

standards. In the United States, sample ports shall be spaced

as defined per the requirements of NFPA. Each application

varies depending on the design. The requirements for sample

port square footage coverage is based on the detection

Sample port spacing: 400 sq. ft.

Transport time: 90 seconds from further port (includes test port)

Sample port sensitivity at alarm: 1.5%obs/ft.

(Very Early Warning, Early Warning, or Standard) the design

is attempting to meet.

Standard Fire Detection (SFD):

Sample port spacing: 900 sq. ft.

Transport time: 120 seconds from further port (includes test port)

Sample port sensitivity at alarm: 3.2%

½ S ½ S ½ S

SSS

½ S ½ S ½ S

Figure 9: Regulatory requirements.

This figure indicates the sample port spacing for each

S

S

S

classification requirement. The "S" indicates the maximum

distance allowed per sample port while "½ S" indicates

the maximum distance a sample port can be from a wall.

Each design will vary based on the shape of the building

but this template should be used as a starting point.

Design Classications

Classification

Type

VEWFD 200 sq. ft. 14 ft. 7 ft.

EWFD 400 sq. ft. 20 ft. 10 ft.

SFD 900 sq. ft. 30 ft. 15 ft.

Area Per

Sample

Port

Maximum

Spacing

Between

Ports (S)

Maximum

Spacing

From Wall

(½ S)

9

Page 10

User Guide: Aspirating Smoke Detector Pipe Installation

Site Layouts and Measurements

Planning of fire protection zones and relevant FAAST system

locations are needed to begin the planning process. The plan

should include measurements of the area to be protected and

any areas designated for a different use. The plan should also

show any obstacles to the flow of air in the space, i.e. partitions

or other large objects. Areas requiring special protection should

also be noted.

Locations of large machinery, equipment, cabinets or any other

large items that may affect the pipe network design also need to

be identified on the plan.

Site Details

When designing the FAAST system, there are a number of site

details that need to be taken into account:

• Air flow and the location of air handling units, returns,

exhaust systems, etc.

• Construction of areas being monitored – high ceilings,

ceiling and floor voids, soffits

• Obstructions to pipe layout – beams, walls, furniture, etc.

• Placement of equipment requiring any special protection

– electrical cabinets, etc.

• Monitoring requirements – on-site, remote

• Activities within the environment – public space,

office space, clean room, warehouse, etc.

• Room temperature of the area being monitored and the

area where the detector will be located.

• Pressure differentials of each area if monitoring multiple

rooms with one detector.

Environmental Conditions

Identify any ambient conditions that exist within the protected

area. Typically different areas have different conditions. This

includes information such as temperature, humidity, and altitude.

The more accurate the information about the protected areas,

the better the FAAST system can be designed to meet those

needs.

The environment, both internally and externally of the protected

environment (especially if air is being pulled in for heating or

cooling), may have an effect on the operation of the FAAST

detector. Areas with high air movement can cause unwanted

pressure differentials across the FAAST device if the device

is not plumbed properly. High pollution levels may cause

background levels of particulate matter in the protected area.

The Acclimate feature of the FAAST system helps to

compensate for this background level. This setting may be

chosen during configuration of the FAAST device. If the

environment is better defined by days of the week, the FAAST

detector offers a day/night/weekend mode.

In locations that are normally subjected to difficult environmental

conditions, such as loading docks or warehouse spaces,

the FAAST detector is typically located within a controlled

environment, while the pipe network is located in the harsh

environment. In such applications the exhaust piping shall return

to the area being monitored.

System Design

PipeIQ is designed to take the information gathered during this

initial phase and assist in designing the pipe network. There

are two design methods within the PipeIQ software. One offers

a design wizard to create a simple layout based on the

parameters provided. The other allows for customization

throughout the process. Both methods provide the opportunity

to go back and modify the system as needed to accommodate

the environment being protected.

10

Page 11

Sampling Methods

User Guide: Aspirating Smoke Detector Pipe Installation

There are two general types of sampling methods: standard

pipe network sampling and capillary tube sampling. From these

sampling methods, several design configurations can be used

to meet the needs of a particular site environment. Local codes

and standards along with site requirements will help determine

the best air sampling method.

1.

2.

3.

7. To prevent sampling ports form being blocked by dust

and dirt, taper and place the ports on the bottom side of the

sampling pipes, not on the top of the pipes. This ensures

that any falling debris does not clog the sampling ports.

8. To minimize the effect of pressure differentials, the sampled

air must be returned to the protected space wherever

possible. This eliminates any pressure differentials that

might reduce the air flow in the pipe network.

Capillary Tube Sampling

Capillary tube sampling is a method of locating sampling

ports remote from the main sampling pipe. This is particularly

useful where the main sampling pipe cannot be routed through

the area requiring protection for either technical or aesthetic

reasons. Capillary tubes are also used to sample equipment

cabinets or enclosures within the protected area.

In the absence of other guidance, it is recommended that a

minimum of two capillary sampling ports are sited in a room.

PipeIQ will allow sampling ports and capillary tubes to be added

as part of the design parameters. Local codes and standards

differ on issues, such as the minimum distance that detection

ports can be positioned from walls and ceilings. It is important

that the specific local regulatory requirements are observed.

The following guidelines are recommended for capillary tube use.

4.

Figure 10: Sampling methods.

Standard Pipe Network Sampling

The following guidelines are used for any pipe network design.

Also, some additional guidelines specific to different sampling

methods may apply.

1. Local codes and standards always take precedence over

any values specified in this document.

2. Recommended pipe network material is nominal ¾"

schedule 40 internal diameter (25 mm OD) CPVC, PVC,

ABS or UPVC pipe.

3. Sharp bends decrease airflow and performance.

4. All pipe designs must have an end cap.

5. Multiple shorter pipes provide better performance than

a single longer pipe.

6. Symmetrical (Balanced) designs in pipe length, port size,

and port distribution are preferred to optimize FAAST

system performance.

1. Try to keep the length of capillaries the same.

2. Capillary tube length should not exceed 26 ft. (8 m)

3. When sampling equipment cabinets or other enclosures,

the sampling port is typically placed at or close to the top of

the interior of the enclosure.

Frequently Asked Question – Can I paint the capillary port?

It is not recommended to paint the capillary port, but in certain

circumstances where aesthetics is a key feature, painting may

be allowed pending the approval of the local authority having

jurisdiction. If approved, the capillary port should be painted

and dried before the port is drilled. A sample port identification

label will be required to comply with NFPA.

Sampling Pipe

Capillary Tube

Ceiling Tiles

Figure 11: Capillary tube sampling.

Tee Adaptor

Reducing Connector

Sampling Port

11

Page 12

Open Area Protection

User Guide: Aspirating Smoke Detector Pipe Installation

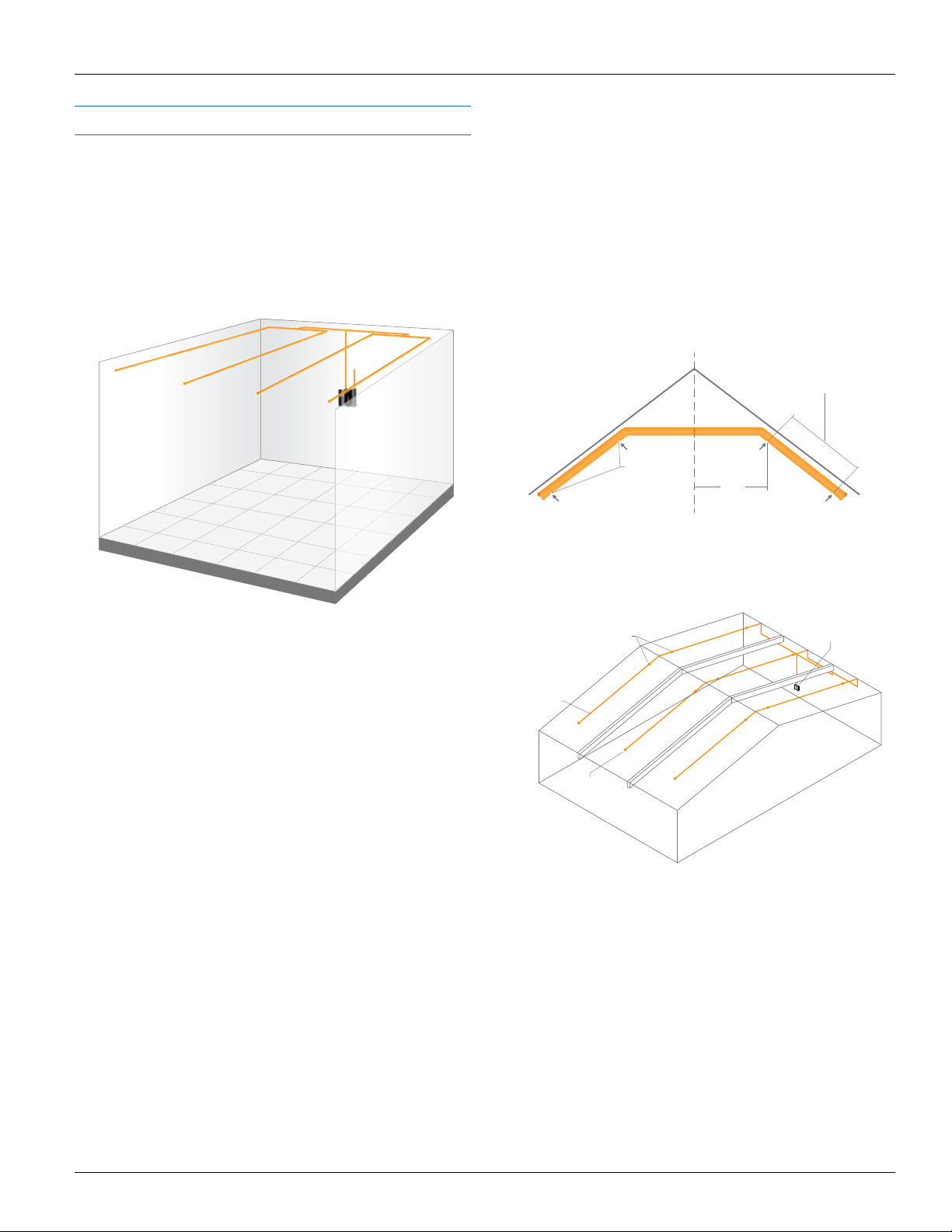

Ceiling Sampling

In typical ceiling installations, the pipe network is suspended

from 1" to 1 ft. (25 mm to 300 mm) below the ceiling level in the

protected area unless otherwise specified by local codes and

standards. This type of installation is the most common. It could

be used in offices, warehouses, equipment rooms and a variety

of other types of installations. PipeIQ can also help provide

guidance for the design.

Frequently Asked Question – How do I design for

a peak ceiling?

When designing peak ceiling applications, the spacing

requirements of NFPA-72® apply. A sample port shall be

provided within 36" from the center of the peak on both sides.

The next sample port from the center shall comply within the

design parameters of VEWFD, EWFD or SFD. If stratification

could potentially occur, it is recommended to also provide

sample ports along the wall.

Adjacent sample port shall

be located based on spacing

requirements. (VEWFD, EWFD, SFD)

Sampling Ports

3 ft.

Figure 12: Ceiling sampling.

Air sampling pipe located 3 ft.

from the center of the peak

on both sides.

Sampling pipe

network -Typ.

Sample port -Typ.

Figure 13: Peak ceiling sampling design.

FAAST Detector

12

Page 13

User Guide: Aspirating Smoke Detector Pipe Installation

Sampling Pipe

Floor

Ground

Floor Supports

Floor VoidSampling Port

Under Floor Protection

Inter-Beam / Below-Beam Sampling

When large ceiling beams are used in construction, pockets of

space are created between the beams. In normal circumstances, the pipe network is mounted on the bottom of the beams

and does not sample the large space between the beams. If it

is necessary to cover this space, a rigid pipe in the shape of an

inverted “L” can be extended vertically from the pipe network

up into the area between the beams so that the pipe reaches up

towards the ceiling in these locations. The sampling port should

be drilled just before the end cap on the horizontal portion of the

pipe. The ends of these sampling pipes should be capped with

an end cap, which may or may not have a sample port based

on the pipe network design.

Beam Pocket

+40% (0.4H)

N/A

End cap

Sampling Port

Sampling Pipe Sampling Port

+10% (0.1H)

Sampling Pipe

Figure 14: Inter-beam sampling.

-10% (0.1H)

MAX SPACING MAX SPACING

Figure 15: Below-beam sampling.

Floor Void Sampling

The FAAST system is well suited to protect concealed voids,

either in the ceiling or under the floor. Some locations use either

ceiling and/or under floor voids as return air plenums (ducts).

A pipe network must be designed to monitor the flow of return

air through these areas. Some ceiling and floor voids are used

for cable runs or for small equipment installation. Monitoring of

these areas must be done using a pipe network designed for

operation in these areas. When installing pipe in a floor void,

keep in mind that the air sampling ports are still located at

the bottom of the pipe. This means the pipe would be located

towards the upper portion of the void.

Figure 16: Floor void sampling.

Frequently Asked Question – Can I monitor the ceiling and

under the oor with one detector?

FAAST can monitor two areas with one detector, however,

it is not recommended practice due to pressure differentials.

Areas with pressure difference of +/- 20% delta of one another

can create air flow faults. Therefore it is recommended to

provide each area with its own detector.

Floor Void Test Sample Port

Frequently Asked Question – How do I know if the beam

pocket has to be protected?

In exposed beam construction the sample port shall be spaced

based on the requirements of NFPA 72®. If the beam depth is

equal to or greater than 10% of the ceiling height and beam

spacing is greater than or equal to 40% of the ceiling height,

than detection shall be provided in each beam pocket per NFPA

72®. For beams with less than 10% of ceiling height, smooth

ceiling spacing shall be permitted.

It is recommended to install a test sample port when designing

an under floor system. A test sample port will allow an easier

commissioning process without disrupting the floor operation.

It is recommended to locate the test port at the end of each

branch pipe at a minimum of 18 in. above the raised floor. The

port diameter should be determined and verified by using the

PipeIQ Software.

Sampling Pipe

Sampling Port

Figure 17: Floor void test sample port location.

13

Floor

End cap with

Sample Test Port

18 in.

(450 mm)

Page 14

Object Protection

User Guide: Aspirating Smoke Detector Pipe Installation

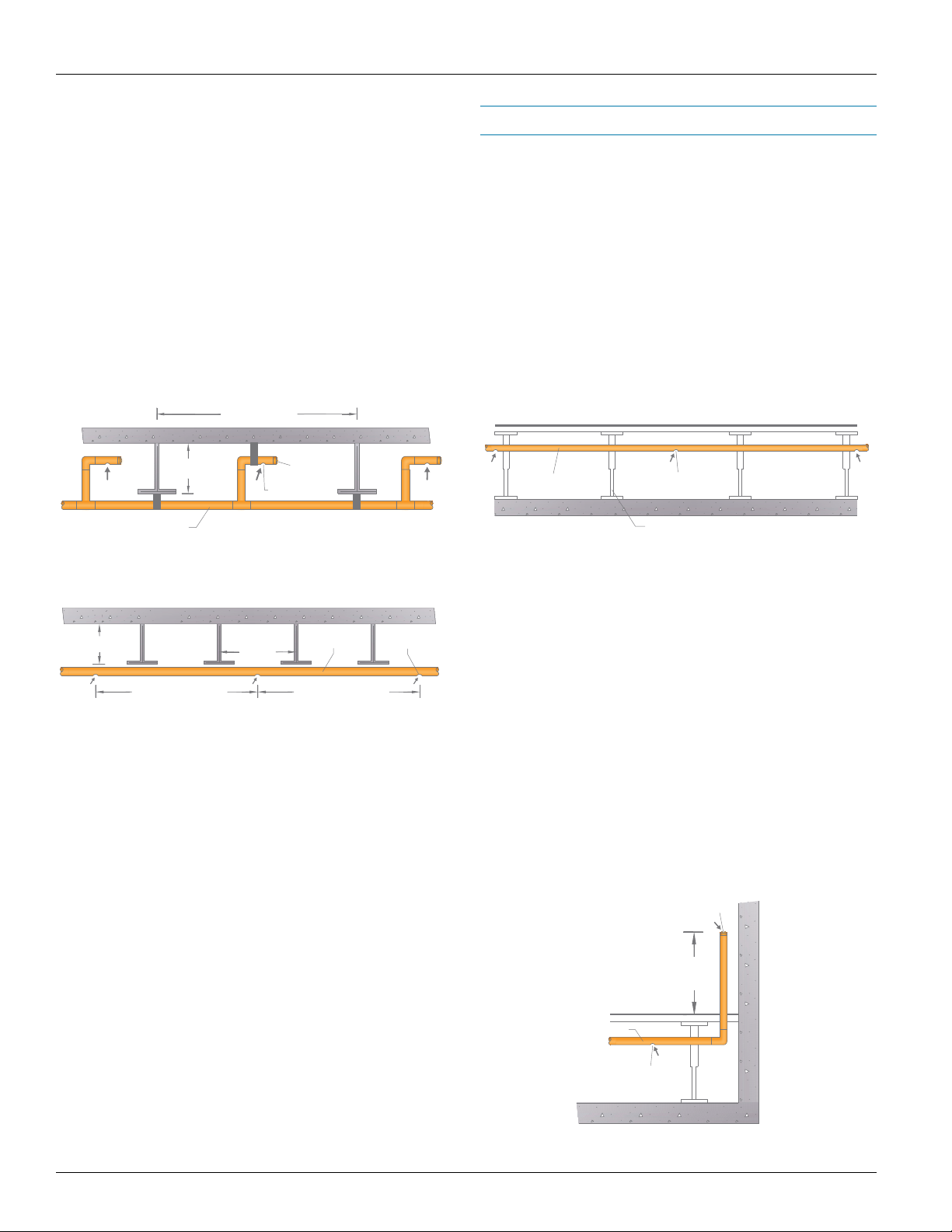

Cabinet Sampling

Equipment cabinet sampling may be accomplished in two

ways: pipe networks and sampling ports can be installed directly inside the equipment cabinet, or directly over the

equipment cabinets being monitored if the cabinets have

ventilation grills.

In-Cabinet Sampling

For in-cabinet sampling, capillary tubes can be used to enter

the equipment cabinet. The capillary tube is connected to the

pipe network via a tee connection with an adapter. The

maximum length of these capillary tubes is 26 ft. (8 m).

PipeIQ can help create an appropriate design.

An alternate to capillary tubes is a rigid drop tube. In this

application, the pipe network is run over a row of cabinets and

drop tubes are run down to each cabinet. This tube or pipe

should be less than or equal to the network pipe diameter and

is connected to the top of the cabinet and to the pipe network

via a tee connection. The pipe could also come up from under

a floor void in to a cabinet.

Cabinets with extractor fans may cause sampling problems

when the sample port is on the top of the cabinet. The

extractor fan creates a low pressure area within the cabinet that

can stop air from being drawn into the detector system at the

sampling port. This type of installation must be checked carefully for proper sampling operation. This can be accomplished

using canned smoke at the sample port location.

Above-Cabinet Sampling

In above-cabinet sampling, the pipe network should be installed

directly over the cabinets that will be protected. Sampling ports

are placed over the cabinet ventilation grills. Ports should be

oriented so that they face into the air stream coming from the

cabinet. If there is more than one exhaust from a cabinet, a

sampling port should be installed over each opening.

NOTE: With either application, it is best to locate the sampling

port in the path of the air flow near the top of the cabinet.

Top View of Cabinet

Figure 18: In-cabinet sampling.

Figure 19: Above-cabinet sampling.

14

Page 15

User Guide: Aspirating Smoke Detector Pipe Installation

Large Area Protection

Large volume areas and areas with high ceilings require

special design considerations for the pipe network design.

Stratification occurs when smoke is heated by smoldering

or burning materials and becomes less dense than the

surrounding cooler air. The smoke rises until there is no longer

a difference in temperature between the smoke and the surrounding air (see NFPA 72-2013 A.5.7.1.10). Stratification,

therefore, may occur in areas where air temperature may be

elevated at the ceiling level, especially where there is a lack of

ventilation. When stratification is likely to occur, conventional

pipe network sampling may not be effective.

One method to overcome smoke stratification is to create

vertical sampling pipes in addition to the horizontal pipe

network on the ceiling. The vertical sampling pipe should

have sampling ports at various heights to sample within any

stratification layers present in the area, as shown in figure 20.

Air sampling ports on

air sampling network -Typ.

Cold Area Protection

The FAAST detector is approved for operating temperatures

ranging from 32°F (0°C) to 100°F (38°C) and sampled air

temperature form -4°F (-28°C) to 140°F (60°C). However,

special considerations should be taken when operating at the

extreme end of these ranges.

The temperature in a cold area is typically at or just above

freezing. In designing a pipe system, the pipes should be kept

out of the immediate airflow from a chiller unit, if used, as its air

is often significantly colder than the room itself. Sample ports

should also be located away from frequently used doors

where possible.

Often, the temperature of the cold room is outside the operating

temperature of FAAST and the device must be mounted outside

of the room with the pipe network being run in to the protected

space. Depending on the temperature of the air being removed

from the room, heating elements may be required, and a

condensation trap installed to catch any condensation or

moisture that may enter the device.

For more information on deploying FAAST in cold storage

applications, see the cold storage white paper at

systemsensor.com/faast.

Air sampling test port

located at the end of

each branch pipe -Typ.

Stratification Layer

of Smoke

FAAST Detector

Air sampling ports on

vertical pipe to capture

smoke stratification -Typ.

Figure 20: Large area protection.

Frequently Asked Question – Does FAAST eliminate

stratication issues?

No, stratification occurs when smoke cools to a temperature

equal to the surrounding air. To overcome the effects of

stratification, provide sample ports on the pipe as it runs

vertically up the wall. It is recommended to provide sample

ports for stratification when the ceiling height exceeds 30 ft.

or when ceiling elevations transition, creating a jet stream.

Exhaust pipe back to

area being monitored

FAAST Detector shall be

mounted 5 ft.- 0 in. AFF.

Piping shall be pitched

accordingly based on

the natural flexibility the

pipe will allow.

Maintain a

minimum of 16 in.

of vertical pipe.

From air sampling network,

run additional horizontal piping

after exiting cold area. Sample

air temperature must be above

-4°F (-20°C) before entering

the detector.

Install drip loop on tee

fitting prior to entering

detector.

To nearest drain or

condensate collector.

Always maintain water

halfway of drip loop.

Figure 21: Cold area protection.

15

Page 16

High Air Exchange Areas

User Guide: Aspirating Smoke Detector Pipe Installation

Typically, high air exchange areas have some form of

mechanical ventilation to maintain constant or cyclical air

flow for heating, cooling or maintaining some other sort of

special environment. Smoke tends to travel with the air flow, so

positioning sampling pipes near the return of an air handling

unit or heating/air conditioning unit ensures early detection of

particulate in the area.

Normal sampling methods for high air exchange areas are a

combination of return air and ceiling sampling. The return air

sampling provides protection when the air flow is present. The

ceiling network provides protection when the air flow is off.

Local codes typically require smaller sample areas (closer

spacing of sample ports) as the air flow rate increases.

Return Air Sampling

Return air sampling provides an effective means of Very Early

Warning in a high air velocity environment. Placing the pipe

network sampling ports directly in the air stream at a return

air grill allows the system to monitor air that has circulated

throughout the protected area.

The following guidelines should be reviewed and followed to

ensure proper sampling by the detector system:

1. More than one sampling location may be required for large

air grills. NFPA 76 recommendations specify that each

sampling port can cover a maximum of 4 sq. ft. (0.4 m2)

2. Sampling ports should be aligned at an angle of 20 to 45

degrees to the direction of the maximum air flow.

3. Sampling pipes should be placed in the path of the

greatest air flow.

4. The number of bends in the pipe network should be kept

to a minimum.

5. Pipe ends should be capped with an end cap. Depending

on the pipe design and PipeIQ recommendations, the end

caps may or may not have a sampling port.

6. Socket unions should be used in locations where the pipe

network requires the removal of the pipes on a regular

basis for maintenance purposes.

7. Use of standoff fittings to keep the pipe network at least 2"

to 8" (50 mm to 200 mm) in front of the grill for high velocity

air flow locations. Installing the network any closer to the

input grill locates the sample port in an area of negative air

pressure.

8. Always keep in mind that the monitored environment

should still ensure coverage even if the manufactured air

flow gets disrupted.

Generally the FAAST detector should not monitor more than

two air handling units. When monitoring multiple units with one

device, the AHUs should have similar flow at all times. The

number of air handlers monitored is limited by the maximum

length of the pipe network. However, the degree of particle

dilution and air movement that occurs with multiple air handlers

can adversely affect system response times. Final system

testing should be done to confirm actual response times.

End cap

4ft. x 4ft.

Intake

Sample Ports

• NFPA calls for 4 sq. ft. max

per sample port

• Pipes to be positioned on 2-8"

stand-offs from grill opening

• Ports to be positioned 20" - 45"

into the direction of air ow

Figure 22: Return air sampling.

16

Page 17

In-Duct Sampling

User Guide: Aspirating Smoke Detector Pipe Installation

The FAAST detector is approved for in duct applications.

National and local safety standards and codes recognize the

ability of air duct systems to transfer smoke, toxic gases, and

flame from area to area. Sometimes smoke can be of such

quantity as to be a serious hazard to life safety unless blowers

are shut down and dampers are actuated. The primary purpose

of duct smoke detection is to prevent injury, panic, and property

damage by reducing the spread (recirculation) of smoke.

Duct smoke detection also can serve to protect the air

conditioning system from fire and smoke damage, and can

be used to assist in equipment protection applications, for

example, in the ventilation/exhaust duct work of mainframe

computers and tape drives. For additional information relating

to duct applications, refer to the duct application white paper

at systemsensor.com/faast.

Design Considerations for In-Duct Sampling

The following guidelines are necessary to obtain the best

installation results.

1. Pipes should always be supported at both duct walls –

rubber grommets can be used. Silicon sealer must also

be used to ensure an airtight seal in the duct walls.

2. Inlet pipes must be inserted between six and ten

duct widths or diameters (for round ducts) from any

disturbances to the flow generated by sharp bends,

plenums, nozzles, branch connections, etc…

3. Sampling ports should be located no closer than 2” to

the duct wall.

4. Ports on the inlet pipe should face 20-45 degrees into the

air flow with the ports concentrated at the center of the

duct as shown in figure 22.

5. The exhaust pipe must have 4, 3/8" (9.5 mm) ports. Ports

should be concentrated in the middle of the duct’s width

and spaced evenly. Ports on the exhaust pipe should be

oriented such that they face away from the air flow.

Small Duct Sampling

For ducts with a width less than 3 ft. (1 m), the inlet pipe should

be installed at the midpoint of the duct height or diameter.

Exhaust pipes should be inserted at 18" (0.5 m) downstream

from the input pipe. The exhaust pipe should be at one quarter

of the duct height or diameter, as shown in figure 23. To avoid

dilution, sampling pipes should be located before fresh air

intakes and before the exhaust air output.

Small Diameter Duct

Air Flow

Inlet Pipe

Figure 24: Small duct sampling.

Duct Width

12 in.

(300 mm)

20 in.

(500 mm)

28 in.

(700 mm)

36 in.

(900 mm)

Table 4: Port sizes for small ducts.

Number

of Ports

2

3

4

5

H/2

Port Size

1/4 in.

(6.5 mm)

1/4 in.

(6.5 mm)

11/64 in.

(4.5 mm)

5/32 in.

(4 mm)

Outlet Pipe

H/4

Nominal Pipe

Flow Rate (CFM)

1.84 cfm

(52.0 L/min)

1.83 cfm

(51.9 L/min)

1.70 cfm

(48.1 L/min)

1.81 cfm

(51.2 L/min)

H

Direction of

Air Flow

Exhaust Pipe from

FAAST Device

Figure 23: Design considerations for in-duct sampling.

Air Supply to

FAAST Device

17

Page 18

User Guide: Aspirating Smoke Detector Pipe Installation

Large Duct Sampling

For ducts with a width of 3 ft. to 7 ft. (1 m to 2 m), two branch

pipes are recommended for the inlets. Inlet pipes should enter

a quarter of the way from the top and bottom of the duct, as

shown in figure 24.

The exhaust pipe should be inserted approximately 18" (0.5 m)

from the inlet pipes and half way up the height of the duct.

To avoid dilution, sampling pipes should be located before

fresh air intakes and before exhaust air output.

Large Diameter Duct

Inlet Pipe

Air Flow

Figure 25: Large duct sampling.

Duct Width

3 ft. 4 in.

(1 m)

5 ft.

(1.5 m)

6 ft. 6 in.

(2 m)

Table 5: Port sizes for large ducts.

The information in table 4, on page 17, and table 5, above,

applies to a 15 ft. (4.6 m) inlet pipe and a 10 ft. (3 m) exhaust

pipe. Always check local codes and standards for port size

and spacing.

Number

of Ports

6

8

10

3H/4

Inlet Pipe

Port Size

9/64 in.

(3.5 mm)

1/8 in.

(3 mm)

1/8 in.

(3 mm)

Outlet Pipe

H/2

H/4

Nominal Pipe

Flow Rate (CFM)

1.77 cfm

(50.2 L/min)

1.80 cfm

(50.9 L/min)

2.10 cfm

(59.6 L/min)

Port Orientation

Sampling response time can also be improved by avoiding high

and low velocity air flows. Ports on the inlet pipes should be

facing 20-45 degrees from the airflow. The angle of the ports

can be adjusted for complete flow independence from the AHU

by following some simple steps outlined in the Duct Application

white paper on the FAAST website. Ports on the exhaust pipe

should be facing away from the airflow.

For additional information relating to duct applications, refer to

the duct application white paper at systemsensor.com/faast.

C

B

A

20° - 45°

from direction

of Air Flow

A. Airow Streamlines

B. Low velocity (high static pressure) area

C. High velocity (low static pressure) area

Figure 26: Port orientation.

Monitoring Voids

In these high air exchange environments, detection systems

should be installed in any void, unless the void is completely

empty and presents no fire risk. If the void contains cabling

and/or equipment that can initiate or contribute to a fire,

monitoring for combustion is highly recommended. The

sampling port spacing for these areas is the same as the

requirement for the rest of the area, in accordance with the

relevant local codes and standards.

When sampling pipes are installed in shallow voids having poor

ventilation, special care should be taken to position the piping

as close to the top of the void as possible. This gives the best

early warning due to the likelihood of the initial smoke layer

taking up only the top 10% of the void height.

18

Page 19

User Guide: Aspirating Smoke Detector Pipe Installation

Basic Pipe Network Cleaning

and Maintenance Procedure

Periodic maintenance of the FAAST Fire Alarm Aspiration Sensing Technology pipe network is recommended in environments

with high amounts of airborne particulate, or cold environments

where condensation may freeze on the sampling port and affect

pipe network performance. Annual maintenance of the pipe

network is recommended for all installations.

Low flow faults on devices which have been installed and operating normally for a period of time may signal the need for pipe

network cleaning.

Pipe Network Maintenance

During installation of the pipe network, it is recommended that

a valved tee fitting be installed 6 inches to 1 foot from the pipe

inlet so that the pipe entering the detector is not subject to any

flow of air during the pipe network maintenance. Forcing air in

to, or out of, the FAAST unit by any means other than the inherent fan may cause damage to the device and nullify the device

warranty.

Prior to beginning pipe network maintenance:

• Place the device in isolate or disable mode, or power

down.

• Remove the pipe network from the device, or switch the

valve on a valved tee fitting to ensure that no air can be

force in to or out of the device

• If the low flow condition persists, perform another manual

check of the pipe network against the pipe layout report

generated by PipeIQ. Also, if the exhaust pipe is not

situated in the protected space the low/high flow condition

could be the result of differences in room pressures that

have changed do to open doors, windows or upgrades to

ventilation units.

Filter Maintenance

Filter maintenance is required only when a ‘Filter’ fault is indicated by the FAAST unit. Perform the following procedure to

replace the filter assembly:

1. Remove power from the system.

2. Open the door on the right side of the device that covers

the LED system indicators.

3. Remove the plastic name card over the LEDs.

4. Remove the two screws holding the filter assembly into

the device.

5. Remove the filter assembly and replace it with a

new assembly.

6. Torque the two Phillips-head screws to 6in-lb (0.7 N-M)

or ¼ turn past “lightly snug’. DO NOT OVERTIGHTEN.

7. Replace the plastic name card over the LEDs.

8. Close the door and restore power to the system.

To perform pipe network maintenance:

• Affix a vacuum cleaner, or air compressor, to the end of

the pipe network or the entry in to the valved tee fitting.

• While the vacuum is running, use a dry brush or pipe

cleaner to swab out each sampling port in the pipe network. Leave vacuum running for 2 min following last port

cleaning.

Post pipe network maintenance:

• Reconnect pipe network to the FAAST device or switch

the valved tee tap

• Remove the device from isolate or disable mode, or

reapply power to the FAAST

• Observe the air flow pendulum on the user interface. The

two green indicators should be near center underneath

the device’s power indicator. If a low condition existed

before maintenance, this condition should be clear after

maintenance (NOTE: if the device is set to latch in fault,

the device will need to be reset to clear the fault)

19

Page 20

User Guide: Aspirating Smoke Detector Pipe Installation

Technical Support

System Sensor strives to provide our customers with outstanding support for the FAAST Fire Alarm Aspiration Sensing Technology

and all of our products. For more information, contact us using one of the methods below:

Web: E-mail: Phone:

systemsensor.com/faast systemsensor.com/contact 800.736.7672 (press 2) Mon-Fri, 7:30 a.m. – 5:00 p.m. CST

User Guide: Aspirating Smoke Detector Pipe Installation

©2014 System Sensor. ASUG32301 • 02/14

Loading...

Loading...