Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CAUTION

PIBVEXP Explosion Proof

Post Indicator and Butterfly Valve Switch

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Specifications

Contact Ratings: One SPDT (Form C) Switch

15 A @ 125/250/480 VAC; 1/8 HP @ 125 VAC, 1/4 HP @ 250 VAC

1/2 A @ 125 VDC; 1/4 A @ 250 VDC

Dimensions: 3.75″L X 3.25″D X 4.5″H

Operating Temperature Range: –40°F - 160°F (–40°C – 71°C)

Maximum Stem Extension: 2.1875

″

Shipping Weight: 1-3/4 lb.

Enclosure Rating: UL Listed explosion proof switch enclosure for use in hazardous locations.

Class I, Groups C and D; Class II, Groups E. F and G

Important

Please Read Carefully and Save

This instruction manual contains important information

on the installation and operation of supervisory switches.

Purchasers who install supervisory switches for use by others must leave this manual or a copy of it with the user.

These instructions apply to System Sensor switches for post

indicator and butterfly type valves. Read all instructions

carefully before beginning. Follow only those instructions

that apply to the model being installed.

General Information for Post Indicator Valves and

Butterfly Valves

1. Model PIBVEXP is designed for installation in a

1

⁄2

″ NPT

tapped hole and located so that the actuating lever of the

switch engages the target or flag of the valve . The switch

actuating lever is spring loaded against the flag or target

of the valve and is released when the valve moves toward

the closed position from the fully open position.

2. Model PIBVEXP is equipped with a removable

1

⁄2″ NPT

pipe nipple which is locked in place with two set screws.

A hex wrench is provided for this feature. These models also

include an adjustable length actuating lever which elimi-

To prevent ignition of hazardous atmospheres, disconnect

nates any need for alteration of the length of the lever.

supply circuit before opening. Keep assembly tightly closed

when in operation. Do NOT leave unused wires exposed.

All supervisory switch installations must comply with local

codes and ordinances and the requirements of the authority having jurisdiction. Additional information is available

in National Fire Protection Association standards NFPA 13,

13D, 13R, 71, and 72.

D770-28-00 1 I56-1430-002R

Page 2

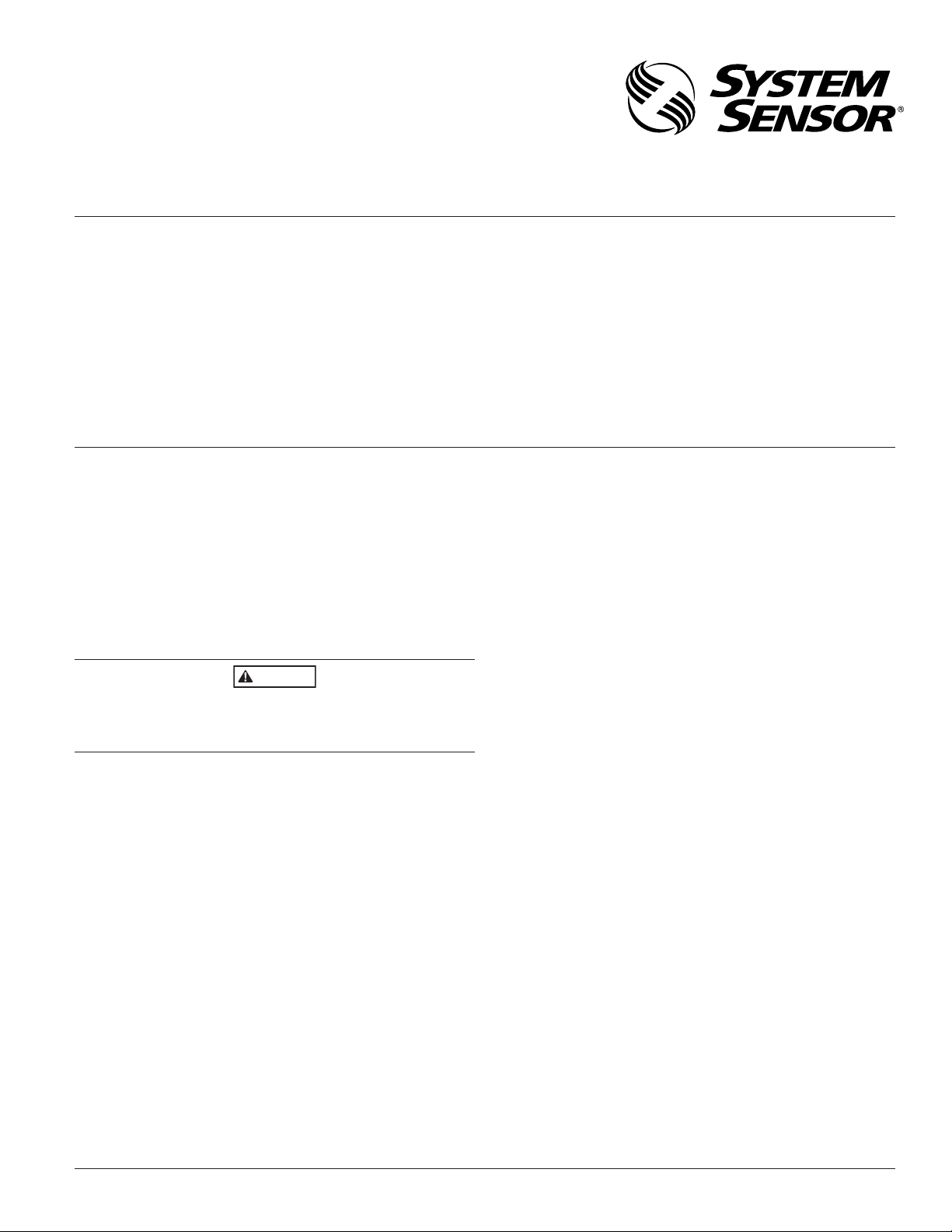

Figures 1A and 1B:

Rising Flag

Falling flag

7. Screw the nipple hand tight into the

valve and tighten the locknut against the housing to

1

⁄2

″

hole in the

secure the nipple in position.

8. Insert a probe into the hole through the nipple to measure the distance from the open end of the nipple to the

to the desired position on the target assembly. Subtract

5

⁄8

″

from the distance and set the length of the actuating lever of the PIBVEXP from the end of the enclosure

to this distance. Tighten the set screw which holds the

actuating lever.

9. Close the valve 3 to 4 revolutions.

10. Install the PIBVEXP onto the nipple and orient the

conduit entry per Section 1. Apply pressure to the

Section 1

Installation Instructions For Post Indicator Valves

1. There are two types of post indicator valves - rising

flag and falling flag. In a rising flag installation, the

PIBVEXP mounts below the target assembly, as shown

in Figure 1A. Closing the valve raises the target assembly and releases the actuating lever on the PIBV1EXP.

In a falling flag installation, the PIBVEXP mounts above

the target assembly (Figure 1B). Closing the valve lowers the target assembly and releases the actuating lever

on the PIBVEXP.

The PIBVEXP will work for either application. To

prevent binding on the actuating lever the unit

must be oriented with the conduit entry pointing

downward for a rising flag application and pointing

upward for a falling flag application. An improper

installation can cause damage to the PIBVEXP

device.

2. If the post indicator valve is predrilled with

1

⁄2

″

NPT mounting hole, remove the plug and go to step 6. If the post

indicator valve is NOT equipped with a

1

⁄2

″

NPT mounting

hole, it will be necessary to drill and tap the hole.

3. Position the valve in the fully open position (“OPEN”

should appear in the window) and remove the head and

target assembly. In doing so, ensure that the assembly

can be reinstalled with its original adjustment.

4. (a) In a falling flag installation (flag lowers as valve is

closed), measure the distance from the bottom of the

head to the upper surface of the target that will contact the actuating lever of the PIBVEXP. Add

3

⁄32

″

to

this measurement and mark the outside of the housing at that location. Drill with a

1

a

⁄2

″

NPT thread.

23

⁄32

″

drill bit and tap

(b) In a rising flag installation (flag rises as valve is

closed), measure the distance from the bottom of the

head to the lower surface of the target that will contact

the actuating lever. Subtract

3

⁄32

″

to this measurement

and mark the outside of the housing at that location.

Drill with a

23

⁄32

″

drill bit and tap a 1⁄2″

NPT thread.

5. Replace the head and target assembly.

6. Screw the locknut onto the threaded nipple which is

supplied with the PIBVEXP.

D770-28-00 2 I56-1430-002R

PIBVEXP and lock the set screws to secure the nipple

to the PIBVEXP.

11. Slowly open the valve to its fully open position. The

switch should trip as the valve opens, but not force

the actuating lever against the nipple when fully open.

To check for this condition, open the valve fully and

depress the top of the actuating cam to stretch the actuating spring further. There should be some additional

movement available. If no movement is available, damage may occur to the PIBVEXP actuator lever. It will be

necessary to adjust the flag location by removing the

head and turning the handle while the valve stem is

disengaged (refer to the valve manufacturer.)

12. After checking the fully open position to ensure

adequate clearance, close the valve slowly until the

PIBVEXP contacts trip. The switches must trip within

1

⁄5 of the full travel distance of the valve.

13. If the PIBVEXP does not change states within

1

⁄5 of

the length of travel, it may be necessary to adjust the

flag up or down by removing the head and turning the

handle (refer to the valve manufacturer.)

14. Wire the switch as shown in Fig. 3.

NOTE: When removing the cover of the PIBVEXP use

provided allen wrench in box.

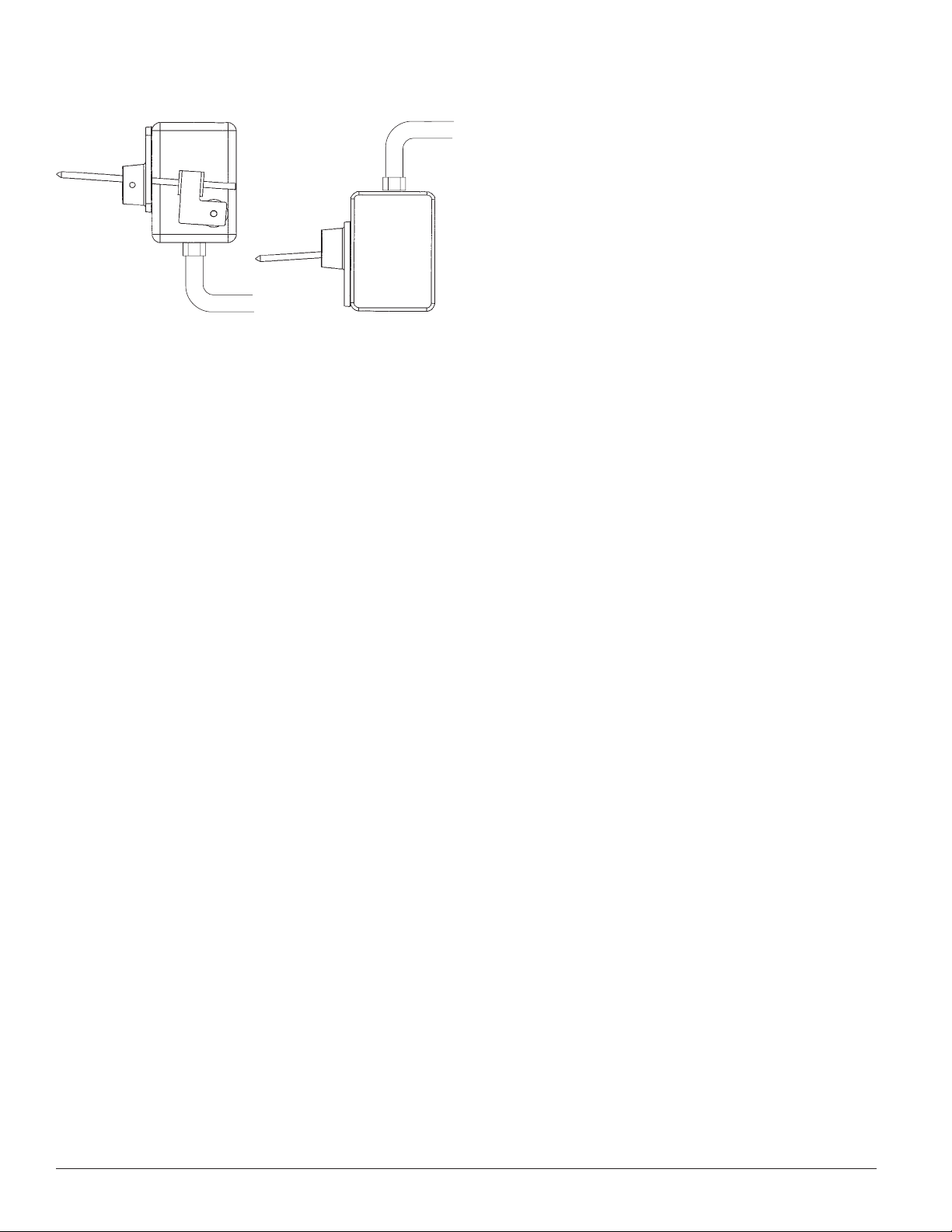

Section 2

Installation Instructions For Butterfly Valves

(See Figure 2)

1. Remove the

1

⁄2

″

NPT plug from the gear housing.

2. Loosen 2 set screws that hold the nipple on the

PIBV2EXP and remove the nipple.

3. Screw the locknut onto the nipple.

4. Screw the nipple into the

1

⁄2

″

NPT hole and hand

tighten. Tighten the locknut firmly to the housing to se cure the nipple.

5. Open the valve fully and close the valve approximately

3 revolutions, noting which direction the target moves.

6. Retract the actuating arm and install PIBVEXP onto the

nipple, orienting the PIBVEXP to trip the switch as the

valve closes. To prevent binding on the actuating lever,

the unit must be oriented so the flag falls away from the

actuating lever when the valve is closed. Apply pressure

to PIBVEXP and tighten set screws to secure the assembly.

Page 3

Figure 2:

T

O

O

P

E

N

CLOSE

CLOSE

W0244-00

Figure 3:

7. Slide the actuating arm into the valve until it bottoms

on the flag, but do not tighten the lever screw.

8. Open the valve to the full open position and tighten the

lever screw to hold actuating arm in position. (Actuat ing arm length will adjust slightly as valve is opened.)

Check to ensure that in the full open position the actu ating arm is not resting on the nipple.

9. Carefully close valve and note the number of handle

revolutions until the switch trips. The switch must trip

within

1

⁄5 of the total travel range of the valve.

10. Wire the switch as shown in Fig. 3.

NOTE: When removing the cover of the PIBVEXP use

provided allen wrench in box.

SUP. SWITCH SUP. SWITCH

TO NON-SILENCEABLE

INITIATING ZONE OF

LISTED FACP

W0245-00

TO POWER SOURCE

COMPATIBLE WITH BELL

W0246-00

END OF LINE

RESISTOR

TYPICAL FACP CONNECTION

LOCAL

BELL

TYPICAL LOCAL BELL CONNECTION

BREAK WIRE AS SHOWN FOR SUPERVISION

OF CONNECTION. DO NOT ALLOW STRIPPED

WIRE LEADS TO EXTEND BEYOND SWITCH

HOUSING. DO NOT LOOP WIRES.

W0247-00

D770-28-00 3 I56-1430-002R

Page 4

WARNING

The Limitations of Supervisory Switch Alarm Devices

1. Alarms generated by the actuation of the activating lever

may not be received by a central station if telephone or

other communication lines to the alarm device are out of

3. Supervisory switches are not a substitute for insurance.

Building owners should always insure property and lives

being protected.

service, disabled, or open.

2. Supervisory switch alarm devices have a normal service life

of 10-15 years.

Please refer to insert for the Limitations of Fire Alarm Systems

Three-Year Limited Warranty

System Sensor warrants its enclosed supervisory switch to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this supervisory switch. No agent, representa

tive, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obliga

tion of this Warranty shall be limited to the repair or replacement of any

part of the supervisory switch which is found to be defective in materials

or workmanship under normal use and service during the three year period

commencing with the date of manufacture. After phoning System Sensor’s

toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns

D770-28-00 4 I56-1430-002R

© System Sensor 2005

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174.

Please include a note describing the malfunction and suspected cause

of failure. The Company shall not be obligated to repair or replace units

-

which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no

-

case shall the Company be liable for any consequential or incidental dam

ages for breach of this or any other Warranty, expressed or implied what

soever, even if the loss or damage is caused by the Company’s negligence

or fault. Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not

apply to you. This Warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

-

-

Loading...

Loading...