Page 1

System Sensor

3825 Ohio Avenue

St. Charles, IL 60174

1-800-SENSOR2

Fax: 630-377-6495

PDRP1002.CD

The PDRP-1002/PDRP-1002E

Agent Release Control System

Manual

Document 51135

I56-1358-00

03/11/99 Revision:

PN 51135:A ECN 99-017

A

Page 2

Installation Precautions

g

d

u

n

s

e

t

d

s

o

I

o

n

o

b

o

s

– Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING

fire alarm control panel. Disconnect all sources of power before

servicing. Control unit and associated equipment may be damaged by

removing and/or inserting cards, modules, or interconnecting cables

while the unit is energized. Do not attempt to install, service, or operate

this unit until this manual is read and understood.

CAUTION

ensure proper system operation, this product must be tested in

accordance with NFPA 72-1993 Chapter 7 after any programming

operation or change in site-specific software. Reacceptance testing is

required after any change, addition or deletion of system components, or

after any modification, repair or adjustment to system hardware or

wiring.

All components, circuits, system operations or software functions known

to be affected by a change must be 100% tested. In addition, to ensure

that other operations are not inadvertently affected, at least 10% of

initiating devices that are not directly affected by the change, up to a

maximum of 50 devices must also be tested and proper system

operation verified.

This system

32-120

30

and the electronic components may be adversely affected by extreme

temperature ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with a nominal

room temperature of 15-27

Verify that wire sizes are adequate

devices cannot tolerate more than a 10% I.R. drop from the specified

device voltage.

- Sever al different sources of power can be connected to the

- System Reacceptance Test after Software Changes: To

O

meets NFPA requirements for operation at 0-49

O

F and at a relative humidity of 85% RH (non-condensing) at

O

C/86O F. However, the useful life of the system's standby batteries

O

C/60-80O F.

for all initiating device loops. Most

C/

Fire Alarm System Limitati on s

An automatic fire alarm system

detectors, heat detectors, manual pull stations, audible warning devices

and a fire alarm control with remote notification capability can provide

early warning of a developing fire. Such a system, howev er, does not

assure protection against property damage or loss of life resulting from a

fire.

Any fire alarm system may fail for a variety of reasons:

Smoke detectors

detectors such as in chimneys, in walls, or roofs, or on the other side of

closed doors. Smoke detectors also may not sense a fire on another

level or floor of a building. A second floor detector , for example, may not

sense a first floor or basement fire. Furthermore, all types of smoke

detectors - both ionization and photoelectric types, have sensing

limitations. No type of smoke detector can sense every kind of fire

caused by carelessness and safety hazards like smoking in bed, violent

explosions, escaping gas, improper storage of flammable materials,

overloaded electrical circuits, children playing with matches, or arson.

IMPORTANT!

the control panel and in rooms used by the system for the connection of

alarm transmission wiring, communications, signaling and /or power. If

detectors are not so located, a developing fire may damage the alarm

system, crippling its ability to report a fire.

may not sense fire where smoke cannot reach the

Smoke detectors must be installed in the same room as

- typically made up of smoke

FCC Warning

Like all solid state electronic devices

erratically or can be damaged when subjected to lightning induced

transients. Although no system is completely immune from lightnin

transients and interferences, proper grounding will reduce

susceptibility. Overhead or outside aerial wiring is not recommende

due to an increased susceptibility to nearby lightning strikes. Cons

with the Technical Services Department if any problems are

anticipated or encountered.

Disconnect AC power and batteries

circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies

or punching of the enclosure. When possible, make all cable entrie

from the sides or rear. Before making modifications, verify that they

will not interfere with battery, transformer and printed circuit board

location.

Do not tighten screw terminals

may damage threads, resulting in reduced terminal contact pressur

and difficulty with screw terminal removal.

This system

yourself with a proper wrist strap before handling any circuits so tha

static charges are removed from the body. Use static suppressive

packaging to protect electronic assemblies removed from the unit.

Follow the instructions

programming manuals. These instructions must be followed to avoi

damage to the control panel and associated equipment. FACP

operation and reliability depend upon proper installation.

While installing a fire alarm system may make lower insurance

rates possible, it is not a substitute for fire insurance!

Audible warning devices

devices are located on the other side of closed or partly open doors

are located on another floor of a building.

A fire alarm system will

AC power f ails, the system will operate from standby batteries only f

a specified time.

Rate-of-Rise heat detectors

over time. For this reason, the rate-of-rise feature of each detector

should be tested at least once per year by a qualified fire protection

specialist.

Equipment used in the system

with the control panel. It is essential to use only equipment listed fo

service with your control panel.

T

elephone lines

central monitoring station may be out of service or temporarily

disabled.

The most common cause

inadequate maintenance. All devices and system wiring should be

tested and maintained by professional fire alarm installers following

written procedures supplied with each device. System inspection a

testing should be scheduled monthly or as required by National and/

local fire codes. Adequate written records of all inspections should

kept.

contains static-sensitive components Always ground

in the installation, operating and

such as bells may not alert people if the

not operate without any electrical power.

may be subject to reduced sensitivity

needed to transmit alarm signals from a premise to

of fire alarm malfunctions, however, is

, this system may operate

prior to removing or inserting

prior to any drilling, filing, reami

more than 9 in-lbs. Over tightenin

may not be technically compatible

WARNING:

frequency energy and if not installed and used in accordance with the

instruction manual, may cause interference to radio communications, It

has been tested and found to comply with the limits for class A

computing device pursuant to Subpart B of 15 of FCC Rules, which is

designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which

case the user will be required to correct the interference at his own

expense.

This equipment generates, uses and can radiate radio

2 The PDRP-1002 PN 51135:A 03/11 / 99

Canadian Requirements

This digital apparatus does not exceed the Class A limits for radiati

noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

Le present appareil numerique n'emet pas de bruits radioelectrique

depassant les limites applicables aux appareils numeriques de la

classe A prescrites dans le Reglement sur le brouillage

radioelectrique edicte par le ministere des Communications du

Canada.

Page 3

The PDRP-1002 PN 51135: A 03/11/99 3

Page 4

4 The PDRP-1002 PN 51135:A 03/11 / 99

Page 5

NFPA Standards

This control panel complies with the following NFPA standards:

NFPA 12 CO

NFPA 12A Halon 1301 Extinguishing Systems

NFPA 12B Halon 1211 Extinguishing Systems

NFPA 72 Central Statio n Signaling Systems (Automatic, M a nual, and Waterflow). Protected

Premises Unit (Requires NOTI•FIRE 911AC DACT or MS-5012 Slave Communicat or)*

NFPA 72 Local (Automatic, Manual, Waterflow and Sprinkler Supervisory) Fire Alarm Systems

NFPA 72 Auxiliary (Automatic, Manual, and Waterflow) Fire Alarm Systems. (Requires 4XTM)

NFPA 72 Remote Station (Automatic, Manual, and Waterflow) Fire Alarm Systems. Requires

4XTM, NOTI•FIRE 911AC DACT*

NFPA 2001 Clean Agent Fire Extinguish in g Sys te m s

*Applications which require the NOTI•FIRE 911AC are not FM approved.

Additional Information

Before proceeding, the installer should be familiar with the following documents and

standards:

NFPA Standards:

NFPA 12 CO2 Fire Extinguishing Systems

NFPA 12A Halon 1301 Fire Ext inguishing Systems

NFPA 12B Halon 1211 Fire Extinguishing Systems

NFPA 72 Installation, Maintenance and Use of Central Station Signaling Systems

NFPA 72 Local, Auxiliary, Remote Station and Proprietary Fire Alarm Systems

NFPA 72 Automatic Fire Detectors

NFPA 72 Installation, Maintenance and Use of Notification Appliances for Fire Alarm Systems

NFPA 72 Testing Procedures for Signaling Systems

NFPA 2001 Clean Agent Fire Extinguish in g Sys te m s

Extinguishing Systems (High Pressure Only)

2

Underwriters Laboratories Documents:

UL 38 Manual Actuated Signaling Boxes

UL 217 Smoke Detectors, Single and Multiple Station

UL 228 Door Closers - Holders for Fire Alarm Systems

UL 268 Smoke Detectors for Fire Alarm Systems

UL 268A Smoke De te c t o r s for D uc t Ap plications

UL 346 Waterflow Indicators for Fire Alarm systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Alarm Systems

UL 864 Standard for Control Units for Fire Alarm Systems

UL 1481 Power Supplies for Fire Alarm Systems

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for the Hearing Impaired

CAN/ULC-S524-M91 Standard for Installation of Fire Alarm Systems

CAN/ULC-S527-M87 Standard for Control Units for Fire Alarm Systems

Other:

NEC Article 300 Wiring Methods

NEC Article 760 Fire Alarm Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction

Notifier Device Compatibility Document, 15378

ADA Americans with Disabilities Act

The PDRP-1002 PN 51135: A 03/11/99 5

Page 6

1 The PDRP-1002/PDRP-1002E

1 The PDRP-1002/PDRP-1002E

Features

• Microprocessor-controlled

• Power-limited on all circuits except Municipal Box output

• Alarm and trouble resound

• Four Class A (Style D)/Class B (Style B) Initiating Device Circuits

• Two Class A (Style Z)/Class B (Style Y) Notification Appliance circuits

• Two Class B (Style Y) Release Circuits

• General alarm and trouble relays

• Optional module for 4 zone/function relays (4XZM)

• Optional transmitter module (4XTM). Complies with NFPA 72 Auxiliary and

Remote Station Fire Alarm systems

• Optional volt/amp meter module (4XMM)

• Optional supervised remote annunciator (RZA-4X)

• Requires LED Interface Module (4XLM)

• Optional digital communicator (NOTI•FIRE 911AC)*

• Complies with NFPA 72 Central Station and Remote Station Fire Alarm Systems

• Supervisory Input Option

• Delay timer (adjustable)

• Three abort function options

• Designed for suppression standards NFPA 12, 12A and 12B

• Disable/enable controls per initiating zone

• Last Event Recall

• Battery/Earth fault supervision

• Fuse protection on all Notification/Release Circuits

• RMS regulated output power, 2.25 amps

• 7 amp/hour to 15 amp/hour battery options, up to 90 hours standby

• Resettable and non-resettable regulated power outputs

• Extensive transient protection

• Watchdog timer to supervise microprocessor

• Output circuits protected against false activations

• Slide-in zone identification labels

• Steel cabinet 14.5 in (368.3 mm) wid e b y 16 i n ( 406. 4 mm) high b y 5 in (127 m m)

deep

• Dead-front dress panel option (DP-4X)

• Trim ring for flush mount between 16 in (406.4 mm) center studs (TR-4XR)

• Abort and manual release circuits

• Cross-zone option

Input Circuits

Applications which require the NOTI•FIRE 911AC are not FM approved

*

.

Circuits

Input Circuits

Detector Zone 1, Class A (Style D)/Class B (Style B)

Detector Zone 2, Class A (Style D)/Class B (Style B)

Abort, Class A (Style D)/Class B (Style B)

Manual Release, Class A (Style D)/Class B (Style B)

Output circuits (optional auxiliary relays track these four circuits)

Notification Appliance Circuit 1, Class A(Style Z)/Class B (Style Y)

Notification appliance Circuit 2, Class A(Style Z)/Class B (Style Y)

Releasing Circuit 1, Class B (Style Y)

Releasing Circuit 2, Class B (Style Y)/Supervis ory Input, Class B (Style B)

6 The PDRP-1002 PN 51135:A 03/11 / 99

Page 7

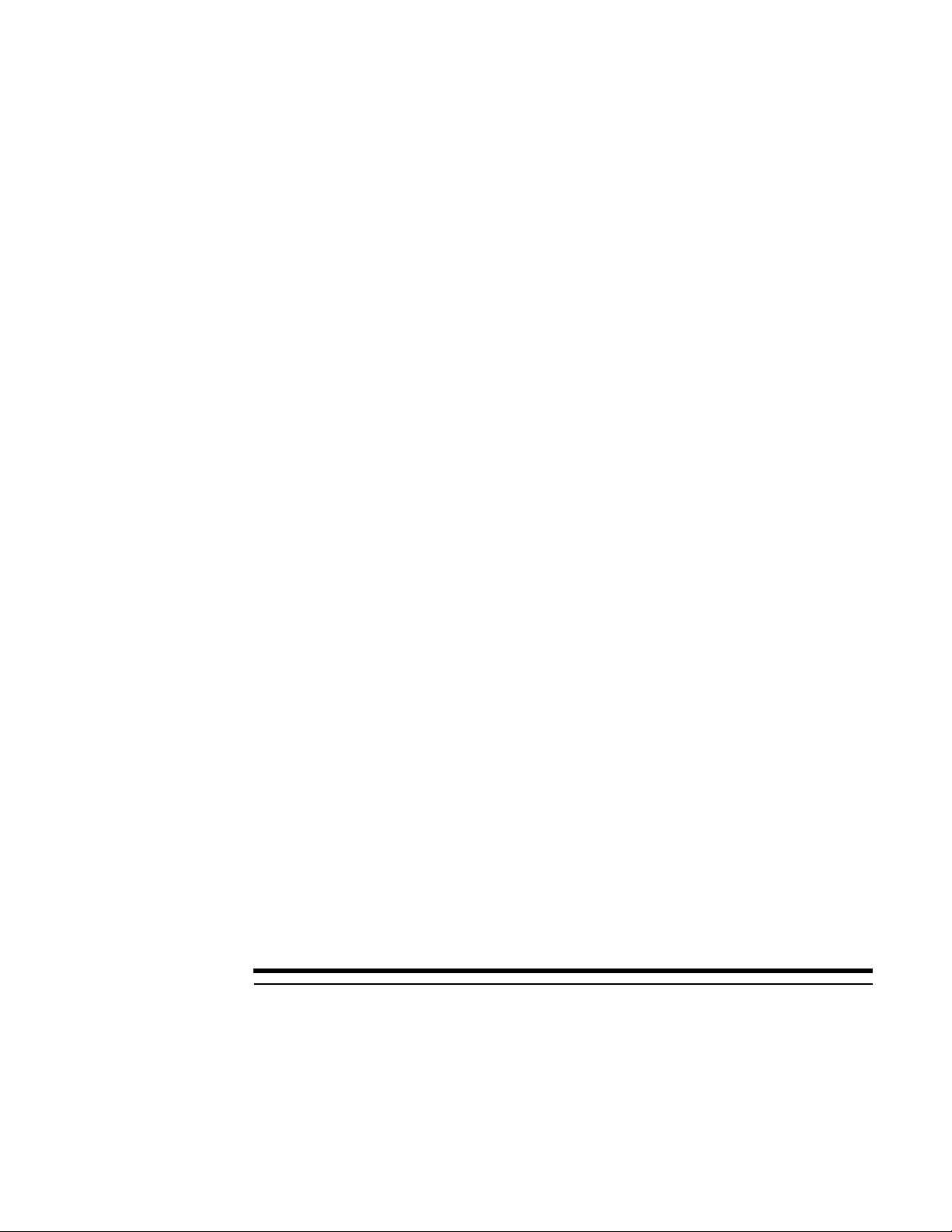

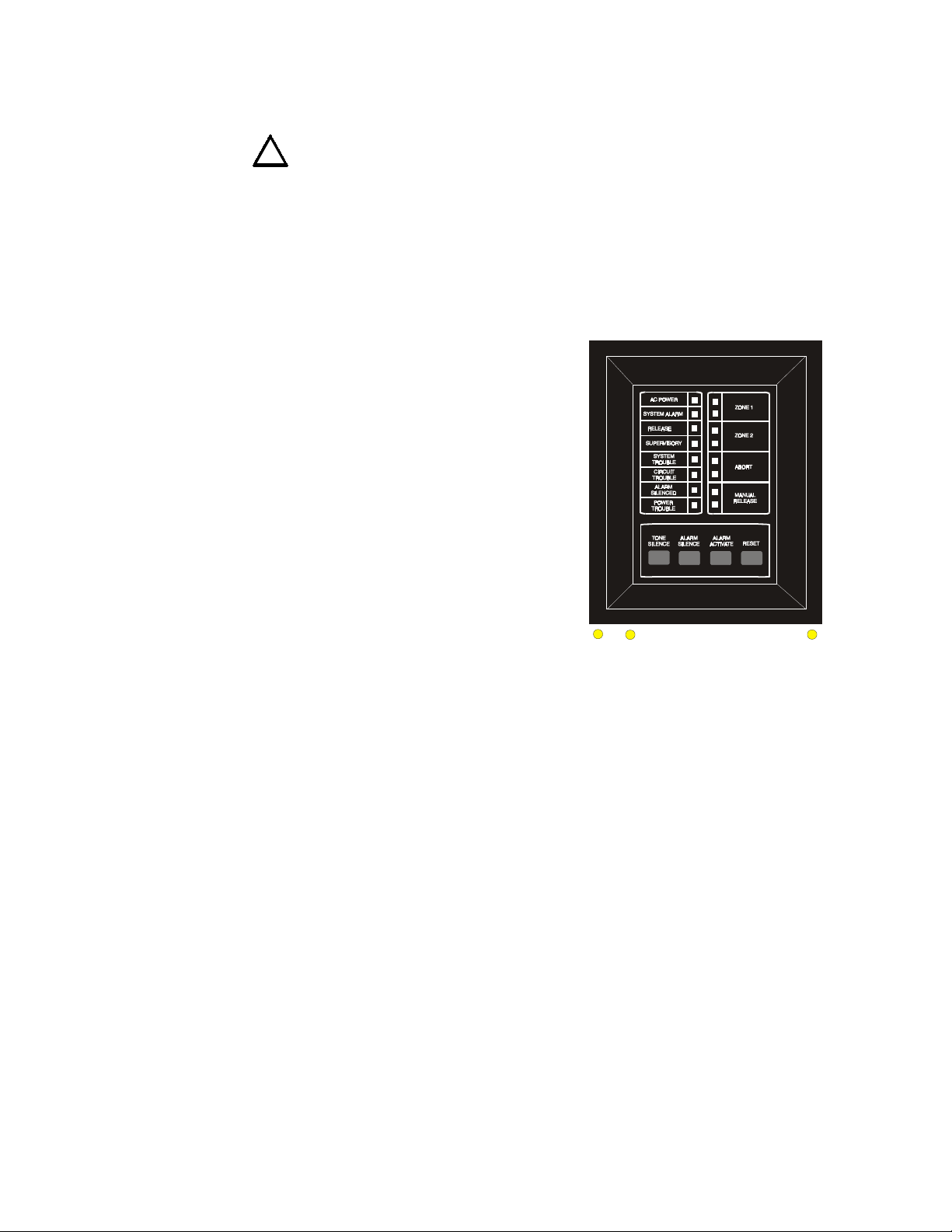

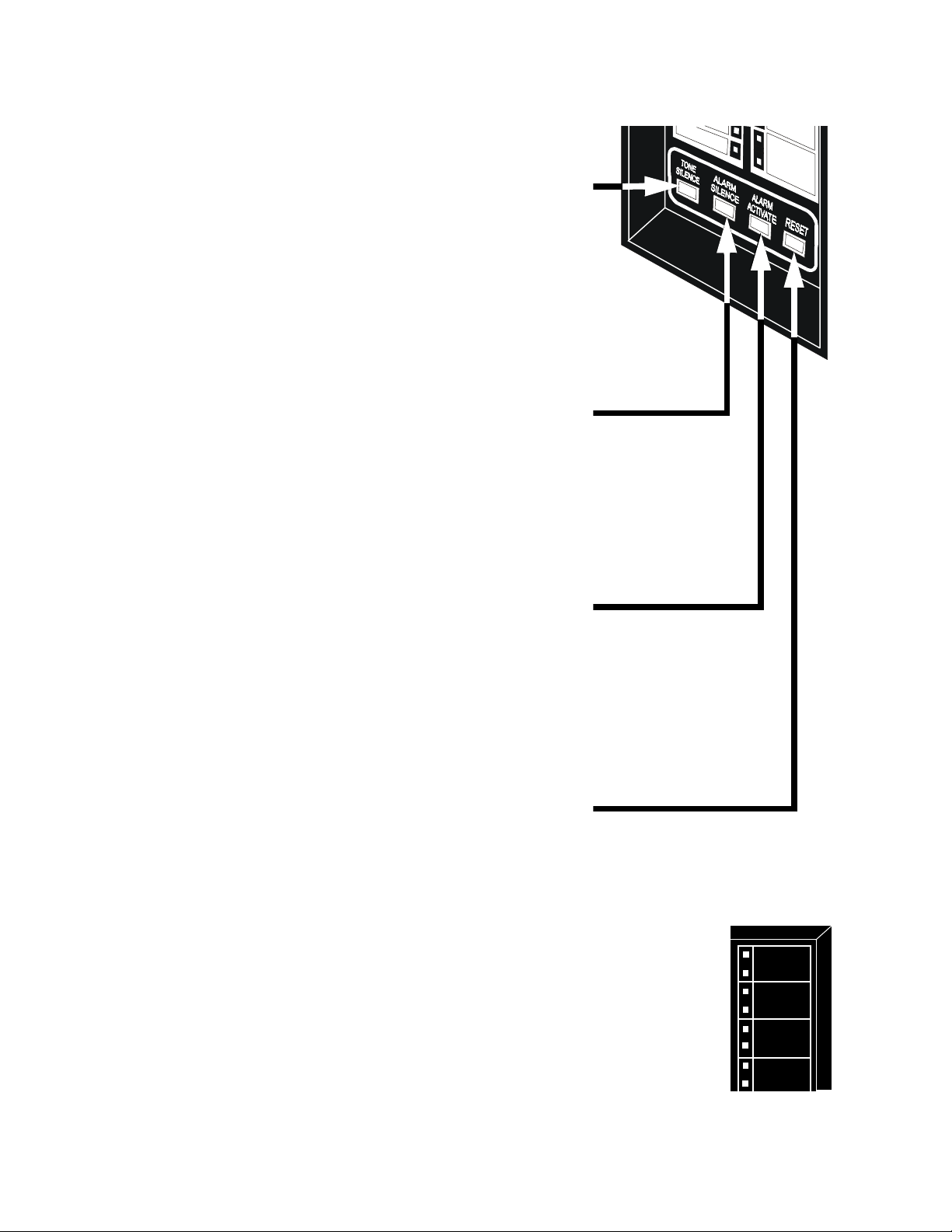

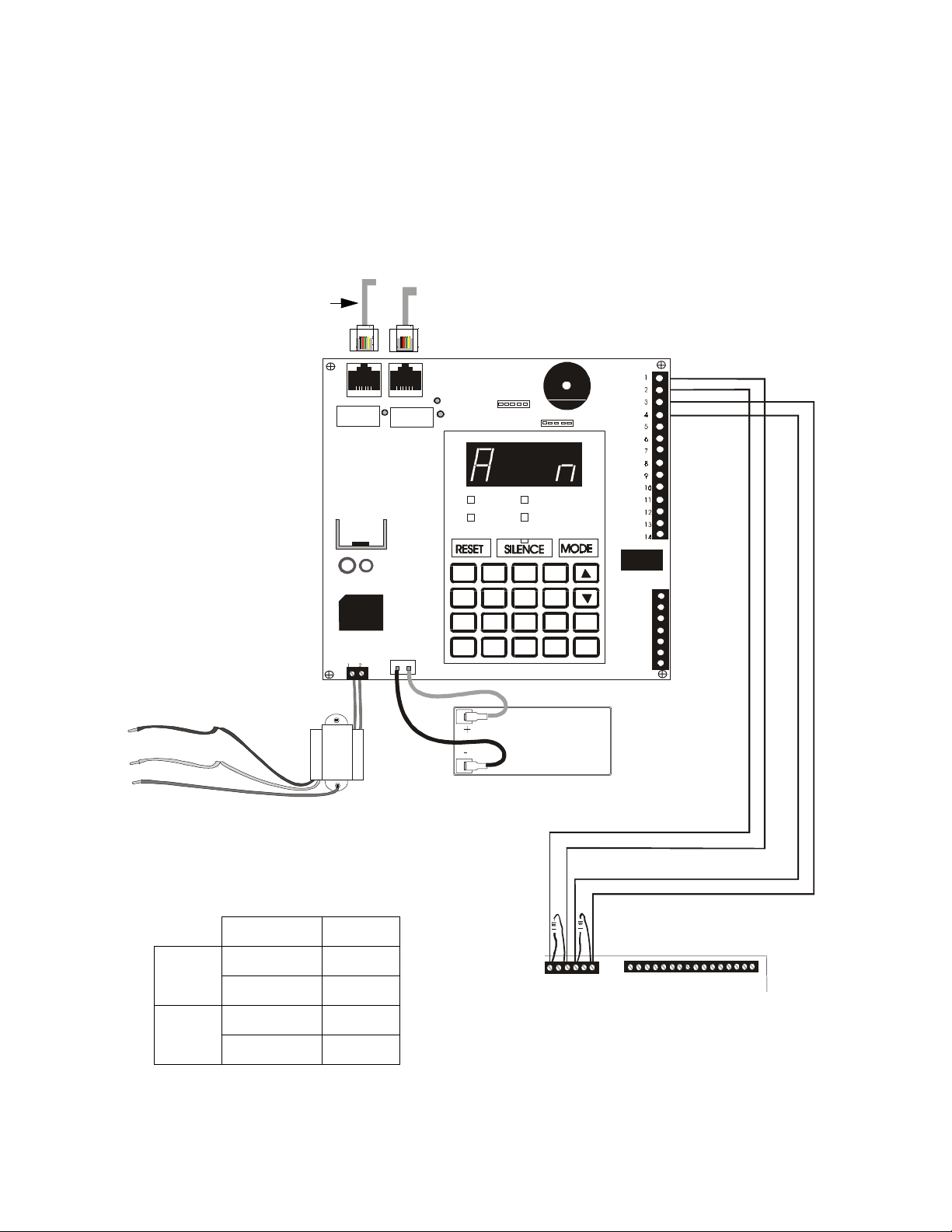

Front Panel Control Switches

1 The PDRP-1002/PDRP-1002E

Front Panel Control Switches

Switch 1 Tone Silence

Switch 2 Alarm Silence

Switch 3 Alarm Activate

Switch 4 System Reset

Ground

Neutral

Hot

Transformer

J1

TB5

J2

Optional Ammeter

Connection

J9

Batteries

+

Optional

J3

VoltmeterConnection

+24VU

+ -

+ -

TB1

AC Circuit Breaker

24 VVU

RMS-REGULATED

24 VR

+24VR

Notification Appliance

Circuits

Class A (Style Z)

Class B (Style Y)

1234

24 VNR

REGULATED

REGULATED

NON-RESETTABLE

RESETTABLE

+24VNR

B+ A+ A- B-

+ -

B+ A+ A- B-

Releasing

Circuits

B+ B-

B+ B-

Relays

TroubleAlarm

Contacts Contacts

NO NC C NO NC C

Initiating Device

Circuits

Class A (Style D)

Class B (Style B)

Abort

Switch

Manual

Release

1234

B+ A+ A- B-

B+ A+ A- B-

B+ A+ A- B-B+ A+ A- B-

TB4

TB2

TB3

JP 1

NO DACT

DACT

SUPV 2

4XTM

GEN ALM2

or

4XLM

or

4XZM

*Jumper “OPT 1” must

be cut if a module is

installed in this position

OPT 1

*

4XTM

or

4XLM

or

4XZM

*Jumper “OPT 2” must

be cut if a module is

installed in this position

O

123456

Cross Zone

Supervisory

Delay Timer

N

SW1

Abort Option

Abort Option

Delay Timer

Micro Fail LED

BATT

EARTH

Ground Fault LEDBattery Fail LED

Figure 1 PDRP-1002/P DRP-1002E Installatio n Di agram

The PDRP-1002 PN 51135: A 03/11/99 7

OPT 2

*

4XRP1002.cdr

Page 8

1 The PDRP-1002/PDRP-1002E

4XTM.cdr

4XLM.cdr

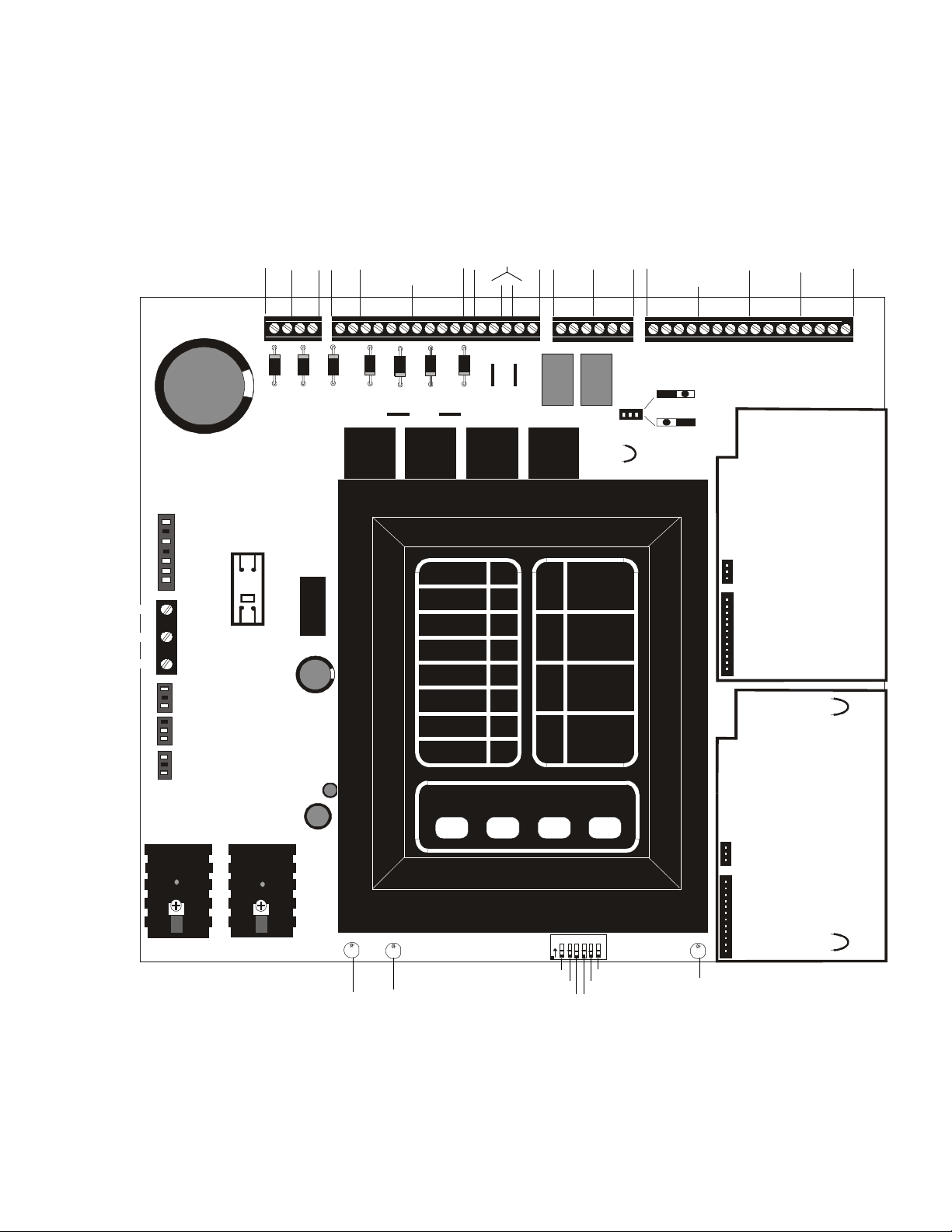

Optional Boards

The PDRP-1002/PDRP-1002E has mounting slots for two option boards. Any two of

the three option modules may be installed.

Transmitter Module (4XTM - NOTIFIER)

The Transmitter Module provides a supervised output for

local energy municipal box transmitter (for NFPA 72

Auxiliary Fire Alarm System) and alarm and trouble

reverse polarity circuits (for NFPA 72 Remote Statio n Fi re

Alarm System). Also included is a DISABLE switch and

disable trouble LED.

As a jumper option, the alarm reverse polarity circuit will

open on trouble if no alarm exists.

LED Interface Module (4XLM - NOTIFIER)

The LED Interface Module supports the RZA-4X Remote

Annunciator module. Annu nciator wi ring is superv ised for

open conditions by this module. The Annunciator Driver

Module mounts to the main board, occupying on e of the

two option connectors.

Transmitter Module (4XTM - NOTIFIER)

Zone Relay Module (4XZM - NOTIFIER)

The Zone Relay module provides Form-C contacts for the

following:

As a jumper option, the first four relays described below can

be made silenceable.

DIP 1=OFF

Either Zone

Alarm Detected First Alarm Alarm Detected First Alarm

Alarm Detected Second Alarm Alarm Detected Second Alarm

Release 1 Release 1 Release Release

Release 2 Release 2 Not Used Not Used

8 The PDRP-1002 PN 51135:A 03/11 / 99

DIP 1=ON

Cross Zone

If Supervisory (DIP 2=ON)

Either Zone Cross Zone

4XZM.cdr

Page 9

Transmitter Module (4XTM - NOTIFIER)

RZA4Xfr.cdr

voltmter.cdr

Transmitter Module (4XTM - NOTIFIER)

For Local Energy Municipal Box service (NFPA 72 Auxiliary Fire Alarm System)

Supervisory current: 5.0 mA

Trip current: 0.35 amps. (Subtracted from Notification Appliance power)

Coil Voltage: 3.65 VDC

Coil resistance: 14.6 ohms

Maximum allowable wire resistance between panel and trip coil: 3 ohms

Municipal Box wiring can leave the building

For Remote Station service (NFPA 72 Remote Station Fire Alarm

System):

Maximum load for each circuit: 10mA

Reverse polarity output voltage: 24 VDC

Remote Alarm and Remote Trouble wiring can leave the b uilding

LED Interface Module (4XLM - NOTIFIER)

Maximum voltage/current, each output: 27.6V/8mA

Note: Outputs are power limited

Zone Relay Module (4XZM - NOTIFIER)

Dry Form-C contacts rated: 2.0 amps @ 30VDC (resistive), 0.5 amps @ 30 VAC

(resistive)

1 The PDRP-1002/PDRP-1002E

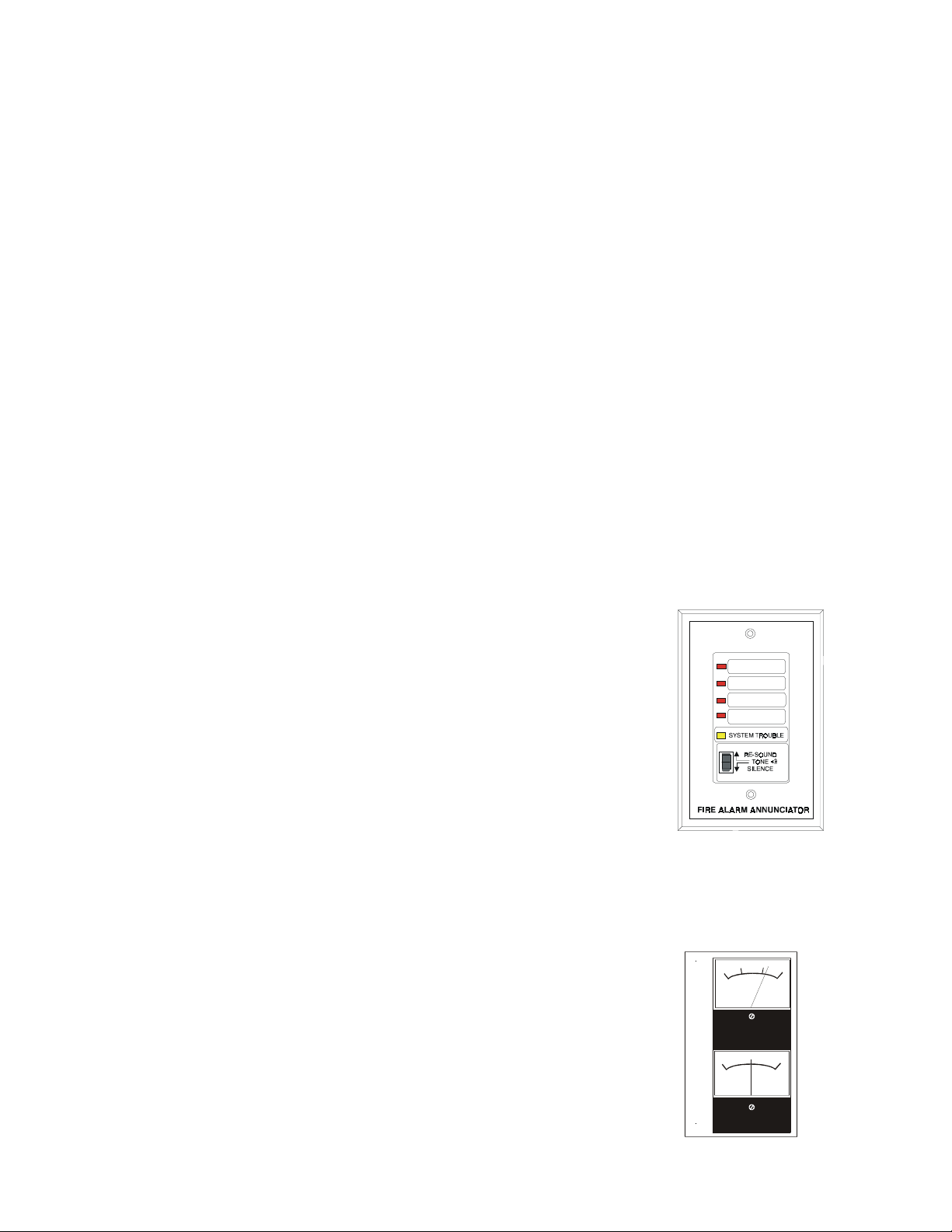

Remote Annunciator

Optional Meters

Remote Annunciator (RZA-4X - NOTIFIER)

The Remote Annunciator mounts on a standard singlegang box, and provides LED indication of the same

functions as the zone relay module. For example with

DIP 1=ON and DIP 2=OFF:

• One Zone in Alarm (red)

• Two Zones in Alarm (red)

• Releasing Circuit 1 (red)

• Releasing Circuit 2 (red)

• System Trouble (yellow)

A Local Trouble Sounder and Silence Switch are also

provided. All LED wiring is supervised for open

conditions. Any open condition will cause the System

Trouble LED to illuminate.

Note: The Remote Annunc iator requir es the use of an LED Interface m od ule (4XLM).

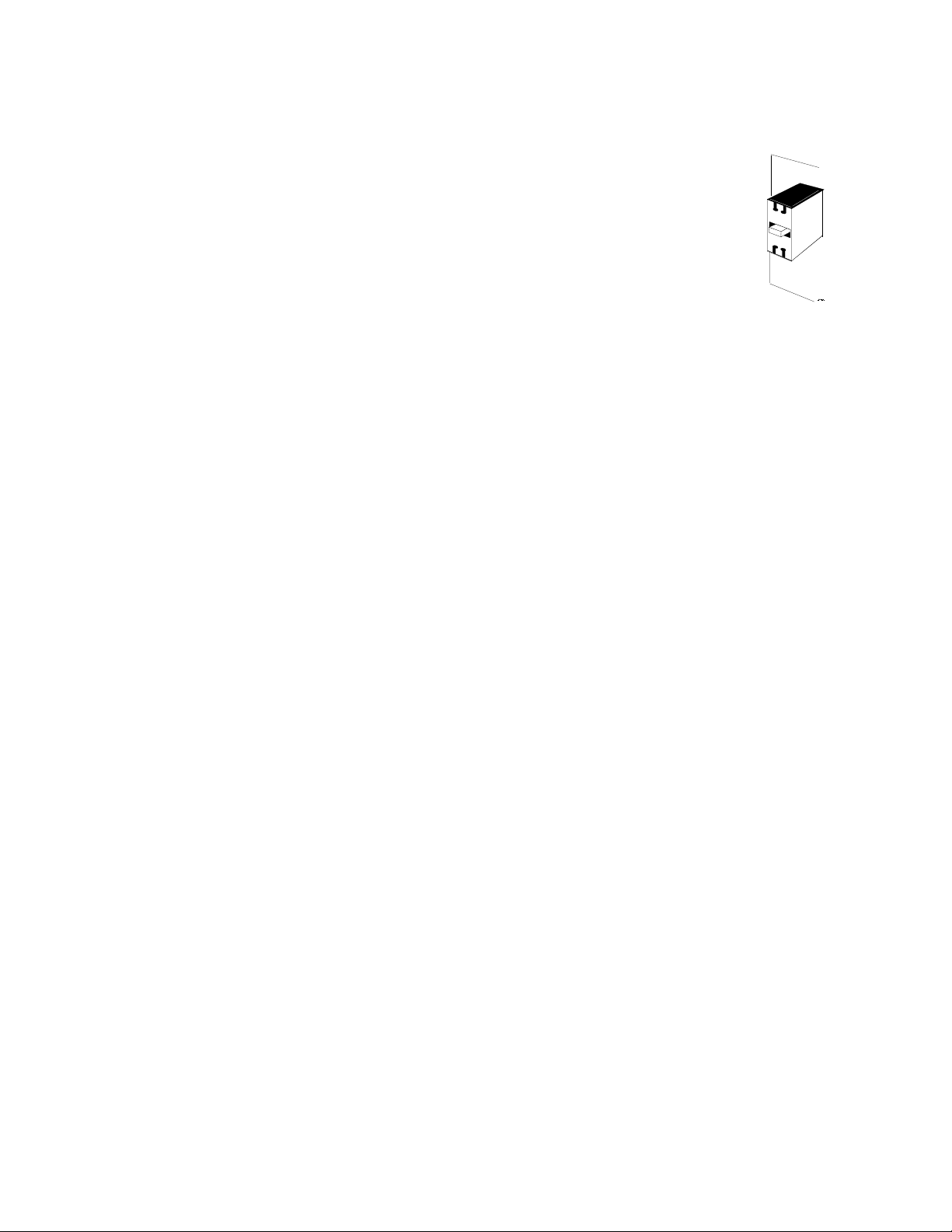

Voltage, Current Meters (4XMM - NOTIFIER)

The Meter Module provides a voltmeter to measure the

voltage across the batteries and an ammeter to measure

the charging current to the batteries. The meters are

provided as an assembly that mounts to the lower lefthand corner of the cabinet.

20

10

DC VOLTS

0

30

5

0

5

DC AMPERES

The PDRP-1002 PN 51135: A 03/11/99 9

Page 10

1 The PDRP-1002/PDRP-1002E

AC Circuit

Breaker

Acctbrkr.cdr

Specifications

AC Power

For the PDRP-1002: 120 VAC, 50/60 Hz, 1.2 amps

For the PDRP-1002E: 220/240 VAC, 50 Hz, 0.6 amps

Wire size: minimu m #14 AWG with 600V insulation

Battery (lead acid only)

Maximum Charging Circuit: 27.6V, 1.5 amps

Maximum Battery Capacity: 15 AH. (Batteries larger

than 12 AH require NOTIFIER #BB-17 or other UL

listed external battery cabinet.)

Initiating Device Circuits

Power-limited circuitry

Operation: Class A (Style D)/Class B (Style B)

Normal Operating Voltage: 24 VDC (ripple = 1.0V peak-to-peak)

Alarm current: 15 mA minimum

Short circuit current: 40 mA maximum

Maximum detector current in standby: 2 mA (max) per zone

Maximum loop resistance: 200 ohms

End-of-line resistor: 4.7K, 1/2-Watt (NOTIFIER part # 71252, UL listed)

Detector loop current is sufficient to ensure operation of one alarmed detector per zone.

Supervisory current: 5 mA (including end-of-line resistor)

AC Power

Notification Appliance and Releasing Circuits

Power-limited circuitry

Maximum allowable voltage drop due to wiring: 2 VDC

Normal Operating Voltage: 24 VDC

Total current available to all external devices: 2.25 amps

Maximum signaling current per circuit: 1.5 amps

End-of-line resistor: 4.7K, 1/2-Watt (NOTIFIER part # 71252, UL listed)

Alarm and Trouble Relays

Dry Form-C contacts rated: 2.0 amps @ 30 VDC (resistive), 0.5 amps @ 30 VAC

(resistive). All relays must be connected to a power limited power supply.

Four-wire Smoke Detector Power

Up to 200 mA is available for powering 4-wire smoke detectors.

Maximum ripple voltage: 1.0 V p/p

Non-resettable Power

Total DC current available from this output is up to 200 mA (subtracted from 4-wire

smoke power).

Maximum ripple voltage: 1.0 V p/p

RMS Regulated Power

Total DC current available for powering external devices is 0.5 amp (subtracted from

2.25 amps available to notification appliance circuits).

Maximum ripple voltage: 100 mV p/p

Note: For device compatibility, refer to Device Compatibility Chart.

10 The PDRP-1002 PN 51135:A 03/11 / 99

Page 11

RMS Regulated Power

Door = 16.125 in.

(409.58 mm)

Backbox = 16 in.

(406.4 mm)

Door = 14.625 in.

(371.48 mm)

Backbox = 14.5 in.

(368.3 mm)

1 The PDRP-1002/PDRP-1002E

Cabinet = 5.375 in.

(136.53 mm)

Backbox = 4.750 in.

(120.65 mm)

TR-4XR

RUBY RD

STEEL

16 GA.

14.594 in.

(370.69 mm)

Optional Trim Ring

TR-4XR

Figure 2 Cabinet Dimensions

1.5 in

(38.1 mm)

16.094 in.

(408.79 mm)

RPCABDIM.cdr

The PDRP-1002 PN 51135: A 03/11/99 11

Page 12

2 System Operation

2 System Operation

WARNING:When used for CO2 releasing applications, observe proper

precautions as stated in NFPA 12. Do not enter the protected space unless physical

!

lockout and other safety procedures are fully completed. Do not use software

disable functions in the panel as lockout.

System Status LEDs

Alarm, Trouble and Supe rvisory LEDs will flash on and off until the event(s) has been

acknowledged (TONE or ALARM SILENCE), at which point the LED will illuminate

steadily.

AC POWER

Green LED that illuminates steadily to

indicate presence of AC power.

SYSTEM ALARM

Red LED that flashes when an alarm

occurs.

RELEASE

Red LED that illuminates steadily when

release occurs.

RMS Regulated Power

SUPERVISOR Y

Yellow LED that flashes upon activation of

a supervisory device (such as tamper

switch) on Output 4 if selected (see

“Setting Mode of Operation” in Section 3

of this manual).

SYSTEM TROUBLE

BATT

EARTH

MICRO

FAIL

Yellow LED that flashes for any trouble

condition, including those associated with option boards.

CIRCUIT TROUBLE

Yellow LED that flashes for trouble conditions on output circuits (notification and

releasing circuits).

ALARM SILENCED

Yellow LED that illuminates steadily when the ALARM SILENCE switch has been

pushed after an alarm.

POW ER TROUBLE

Yellow LED that flashes for low or disconnected batteries and earth fault conditions.

BA TT

Yellow LED that illuminates steadily on mother boar d when battery is low or not

detected (not visible through door).

EARTH

Yellow LED that illuminates steadily on mother boar d during a ground fault condition

(not visible through door)

4Xoper2.cdr

MICRO FAIL

Yellow LED that illuminates on motherboard when watchdog timer de tects

microprocessor failure (no t visi b le throu gh doo r)

12 The PDRP-1002 PN 51135:A 03/11 / 99

Page 13

RMS Regulated Power

Control Switches

2 System Operation

Tone Silence

Acknowledge alarms, troubles and

supervisories. The panel has alarm and

trouble resound with LED flash of new

conditions. The flashing trouble LED(s)

illuminate steadily on TONE SILENCE and

the piezo sounder silences. A second trouble

will resound the piezo. The piezo has three

sounds for alarm, trouble, and supervisory.

Trouble cond i tio ns are self- res to ring . Alar ms

latch and require RESET to clear.

Alarm Silence

Acknowledge for alarms and supervisories.

The ALARM SILENCE switch will silence

the local piezo, change any flashing alarm

LEDs to steady, and turn off the notification

circuits (not the releasing circuits). The

“ALARM SILENCED” LED will illuminate.

Alarm silence is a latching function and

requires a RESET to clear.

Alarm Activate

The ALARM A CTIVATE switch may be used

to activate Notification Appliance Circuits.

ALARM ACTIVATE also activates the

System Alarm relay. ALARM Activate is a

latching function. Pressing ALARM

SILENCE silences the notification circuits

and System Alarm Relay and lights the Alarm

Silenced LED. Pressing RESET returns the

system to normal.

System Reset

The RESET switch breaks power to all

initiating circuits, 4-wire smoke power and

option boards and will clear any activated

output circuits. If any alarms or troubles still

exist after reset, they will reacti vate th e panel.

Holding RESET down will perform a LAMP

TEST function and will activate the piezo sounder.

4XPTL.cdr

Zone Status LEDs

The alarm and/or trouble LED(s)

will flash until the event(s) has

been acknowledged (TONE or

ALARM SILENCE), at which

point the LED(s) will illuminate

steadily.

ABORT TROUBLE LED

MANUAL RELEASE TROUBLE LED

The PDRP-1002 PN 51135: A 03/11/99 13

ALARM LED

TROUBLE LE D

ALARM LED

TROUBLE LE D

ABORT LED

MANUAL RELEASE

Zone 1

Zone 2

Abort

Manual

Release

Page 14

2 System Operation

Supervisory

Zone Disable

RMS Regulated Power

Output circuit #4 is used as an input for monitoring supervisory devices such as valve

tamper switches (note that SW1 DIP switch #2 must be set “ON” -- see section “Setting

Mode of Operation”) By setting Switch short circuit on this input (activation of a N.O.

contact) will cause the supervisory LED to flash. The piezo sounder will generate a

unique sound. TONE SILENCE will silence the piezo and cause the LED to illuminate

steadily. Supervisory signals latch and require RESET to clear . An open circuit will be

reported as a circuit trouble.

If a zone has been disabled, an alarm

that occurs on that zone will flash the

red zone LED, but not the p iez o or any

output circuit.

If both power sources

are removed from the system, all zones

will be re-enabled upon restoration of

power. Disable status will be lost .

The Zone Disable routine m akes use of

the four panel switches as follows:

1. Press and hold in the TONE

SILENCE switch.

Last Event Recall

2. With the TONE SILENCE switch

held in, press (in sequence) the

ALARM SILENCE switch, the

ALARM ACTIVATE switch, and

then the RESET switch.

3. The Zone 1 Alarm LED will flash.

4. To disable Zone 1, press the RESET switch. The Zone 1 yellow LED will light to

show that the zone is disabled.

Note: The RESET switch toggles disable status for the selected zone.

5. To select the next zone, press the ALARM SILENCE switch.

6. To select the previous zone, press the ALARM ACTIVATE switch.

7. When disable selections are complete, release the TONE SILENCE switch.

If any zone has been disabled, the trouble relay will activate and System Trouble LED

will flash.

Last Event Recall allows the user to display the previous panel status. The last event

recall uses the four panel switches as follows:

1. Press and hold in the TONE SILENCE switch.

4XPTL.cdr

2. With the TONE SILENCE switch held in, press (in sequence) the RESET switch,

the ALARM ACTIVATE switch, and then the ALARM SILENCE switch.

3. Last Event is displayed.

4. Release the TONE SILENCE switch to return to normal operation.

Note: To clear the last event buffer, press RESET twice.

14 The PDRP-1002 PN 51135:A 03/11 / 99

Page 15

UL Power Limited Wiring Requirements

imited

3 Installation Procedur e

General

Carefully unpack the system and check for shipping damage. Mount the cabinet in a

clean dry, vibration-free area in which extreme temperatures are not encountered. The

location should be readily accessible with sufficient room for easy installation and

maintenance. Locate the top of the cabinet approximately f ive feet abov e the floo r with

the hinge mounting on the left. Determine the number of conductors required for the

devices to be employed. Pull required conductors into the box through the knockout

provided. All wiring should be in accordance with the National and/or Local codes for

fire alarm systems.

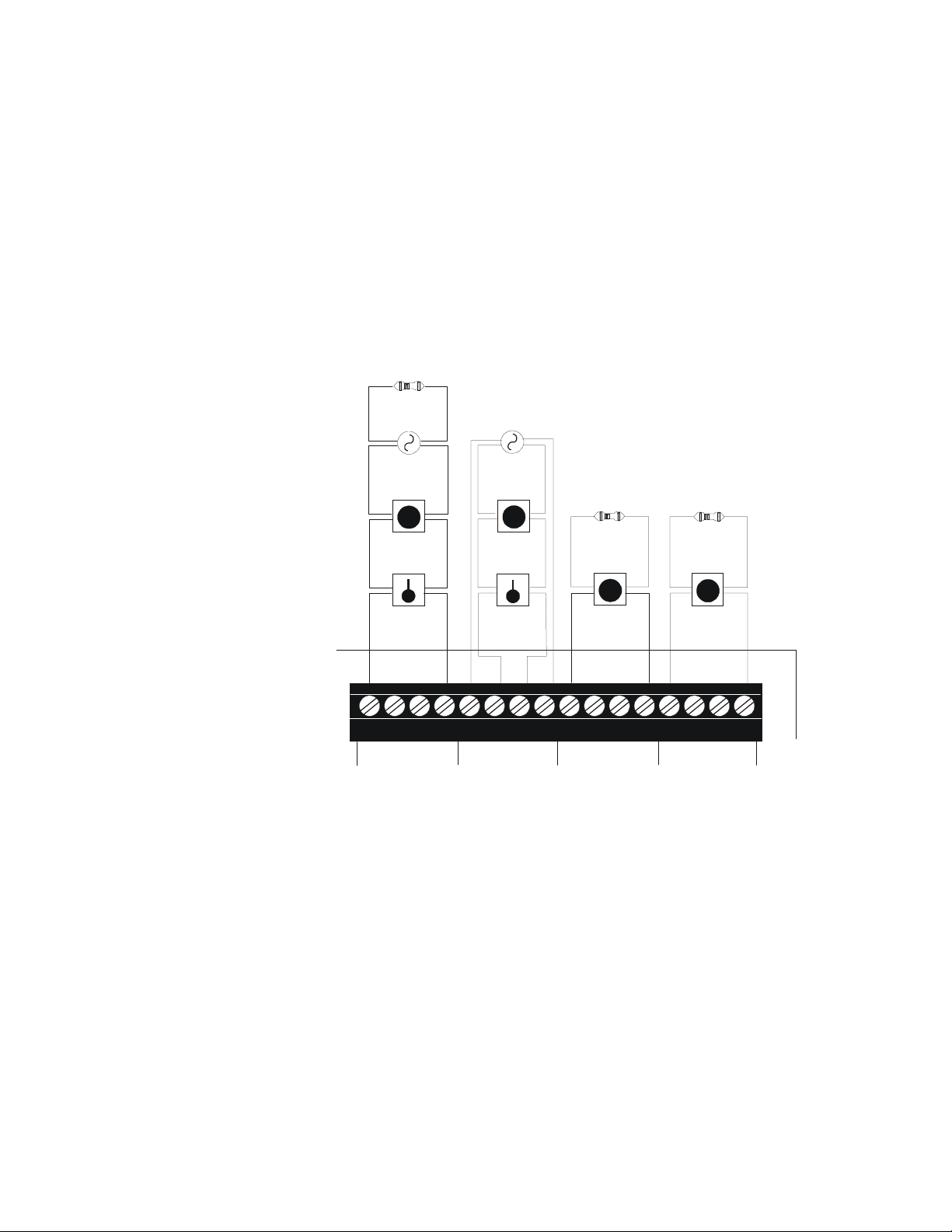

UL Power Limited Wiring Requirements

Power limited and non-power limited circuit wiring must remain separated in the

cabinet. All power limited circuit wiring must remain at least 0.25 in (6.35 mm) away

from any non-power limited circuit wiring. Furthermore, all power limited circuit

wiring and non-power limited circuit wiring must enter and exit the cabinet through

different knockouts and/or conduits. A typical wiring diagram for the PDRP-1002/

PDRP-1002E is shown below.

3 Installation Procedure

AC Power

Power L

Circuits

Notification Appliance

Circuits

Non-Power

Limited Circuits

R

e

la

PC Board

Power Limited

Circuits

y

s

I

n

it

ia

ti

n

g

C

i

r

c

u

it

s

4XTM

Power Limited

Circuit

4XZM

Non-Power

Limited Circuit

RP1002PL.cdr

Figure 3 Typical Wiring Diagram for UL Power Limited Requir emen t s

The PDRP-1002 PN 51135: A 03/11/99 15

Page 16

3 Installation Procedure

Initiating Device Circuits

Zones

Wire all alarm initiating devices sequentially for proper supervision. Initiating devices

include: heat, photoelectric, and ionization type detectors; and waterflow alarm

devices. Refer to the Compatibility Chart in Appendix B.

Note:

• Observe polarity when connecting polarized devices.

• All circuits are supervised and power limi te d.

• Leave Dummy Load (provided) on al l unused circuits.

4.7K, 1/2-Watt (part # 71252 UL listed)

Two-wire

Smoke

Detector

Heat

Detector

Class B (Style B)

Initiating Device Circuit

Class A (Style D)

Initiating Device

+

+

_

_

+

+

Circuit

_

_

Abort Switch

4.7K, 1/2-Watt

(part # 71252

UL listed)

Manual Release

4.7K, 1/2-Watt

(part # 71252

UL listed)

Zones

Manual

Pull Station

TB4

+

B+ A+ A-

1234

_

+

B+ A+ A-

B-

5678910

_

B-

B+ A+ A-

11 12

B+ A+ A-

B-

13

IN #1 IN #2 IN #3 IN #4

Figure 4 Example of an A larm Initiating Device

14

B-

15 16

AIDEX.cdr

16 The PDRP-1002 PN 51135:A 03/11 / 99

Page 17

Zones

4-Wire Smoke Detector Connections

Refer to the Device Compatibility Document for suitable 4-wire smoke detectors.

3 Installation Procedure

24 VDC (+)

+ +

Common (-)

-

-

IDC (+)

+ +

-

-

IDC (-)

Four-wire Smoke Detectors

TB1

+

-

1234

+24VR

A maximum of 200mA is available from the +24VDC

4-wire smoke detector power circuit on TB1 terminals 3

and 4. Any power that is drawn from the +24VDC Nonresettable Power on TB2 terminals 1 an d 2 mu st be

subtracted from available 4-wire detector power. (See

“Specifications” and “Power” sections.)

UL listed 24 VDC

Class B Initiating Device Circuit

24 VDC (+)

+ +

Common (-)

-

-

IDC (+)

+ +

-

-

IDC (-)

Red

Black

UL listed

4.7K, 1/2-Watt

ELR

TB4

B+ A+ A- B-

1234

IN #1

Initiating Device Circuits 1,2, 3, or 4

can be used. Class A (Style D) wiring

can also be employed.

Listed

Power

Supervision

Relay

RP4WR.cdr

Figure 5 Diagram of Connections for a 4-Wire Smoke Detector

Notes on Class A (Style D) and Class B (Style B) field wiring:

1) The Power Supervision Relay coil leads must be connected to the last detector

base 24V screw terminals.

2) Calculation of the maximum allowable resistance in the 24VDC detector power

wiring:

R

Where:

R

is the maximum resistance of the 24V wires.

MAX

V

is the minimum operating voltage of the detector or end-of-line relay, whiche ver is

OM

greater, in volts.

N

is the total number of detectors on the 24V supply loop.

I

is the detector current standby.

S

N

is the number of detectors on the 24V power loop which must function at the same

A

time in alarm.

I

is the detector current in alarm.

A

I

is the end-of-line relay current.

R

= (20.6 - VOM)

MAX

_________________________________________________________________________________________

(N x I

) + (NA x IA) + (IR)

S

The PDRP-1002 PN 51135: A 03/11/99 17

Page 18

3 Installation Procedure

a

,

Output Circuits

Notification Appliance Circuits

Notification Appliance Circuits

This control panel can provide two Class A (Style Z)/Class B (Style Y) Notification

Appliance Circuits and two Class B (Style Y) Releasing Circuits (see section “Setting

Mode of Operation” for DIP switch configuration). Each circuit is capab le of 1 .5 am ps

of current. Total current drawn from all four circuits cannot exceed 2.25 amps. Refer

to the Compatibility Chart. Circuits are supervised and power-limited.

Note: Wirin g mu st be configured to maintain a minimum volta ge o f 20.4V on release circuits. Calcu lat ion of

maximum allowable resistance:

= 20.6V-20.4V

________________________________________________________________________

R

MAX

Where:

Class A

(Style Z)

Notification

Applianc e Circuit

R

= maximum allowable resistance of wiring

MAX

I

= solenoid current

S

Class B (Style Y) Notification

Applianc e Circuit

4.7K, 1/2-Watt

(part #71252 UL listed)

I

S

Polarized Bell

Polarized Strobe

Polarized Horn

TB2

+

-

+ -

B+ A+ A-

345678910111213141516

OUT #1

4.7K, 1/4-Watt

B+ A+ A-

B-

+

+ -

OUT #2

-

Releasing Circuits

UL listed & FM approved

Releasing Devices

No Connection

NCNCB+ B-

B-

OUT #3

4.7K, 1/4-Watt

No Connection

B+

B-

OUT #4

See note

below

Dummy Load all

unused Notification

Appliance Circuits

Note: Output #4 can be configured for relea sing or supervisory circuit (see Section “Se tt in g M ode of O pe r

configured as a releasing circuit, the circuit will be non-power limited. If configured as a supervisory circuit

will be power limited. All wiring must follow the power limited “General” Section.

B+ A + A-

B-

B+

Dummy Load all

B-

unused Releasing

Circuits

Figure 6 Notification Appliance Circuits

18 The PDRP-1002 PN 51135:A 03/11 / 99

RPNAC.cdr

Page 19

Alarm Relay

3 Installation Procedure

Alarm Relay

One Form-C dry alarm contact is provided in the basic panel for controlling

supplementary devices. It is rated 2 amps at 30 VDC and 0.5 amps at 30 VAC

(resistive), and is non-silenceable when an alarm occurs. See below for terminal

location.

Trouble Relay

One Form-C dry trouble contact is provided in the basic panel for controlling

supplementary devices. It is rated 2 amps at 30 VDC and 0.5 amps at 30 VAC

(resistive), and will silence when trouble condition is cleared. See below for terminal

location.

Note: The alarm and tr ouble Form-C dry contact relay s must be power limited relays. They must be wired

from one of the 24V power limited ter mi nals as shown in the figure below or a comparable UL liste d power

limited power supply.

Alarm

NO NC C

Trouble

NO NC C

Power

or

TB1

1234 12

+24VU +24VR

or

+24VNR

TB2

TB3

1234

Alarm

Schematic representa tion of

Alarm/Trouble coil s and c ont acts.

56

Trouble

Figure 7 Alarm/Trouble Coils and Contacts

CAUTION: Several different sources of power can be connected to this panel.

!

Disconnect all sources of power before servicing. The pane l and associated equipmen t

may be damaged by removing and/or inserting cards, modules, or interconnecting

cables while this unit is energized.

This output is not suitable

for powering devices

requiring fil tered DC power.

RMS-Regulated Power

24 VDC power for inductivetype devices such as door

holders can be connected to TB1

terminals 1 (+) and 2(-).

The combined current draws from the Resettable

and Non-resettable outputs cannot exceed 200 mA.

4-Wire Smoke Detector Power

24 VDC filtered, resettable power

for 4-wire smoke detectors can be

obtained from TB1 Terminals 3(+)

and 4(-).

Non-resettable Power

24 VDC filtered, nonresettable

power can be drawn from TB2

Terminals 1 (+) and 2(-).

RPALMTBL.CDR

+24VU

+ - + -

TB1

+24VR +24VNR

+ -

TB2

1234 12

Figure 8 Diagram of Power Termi nals

The PDRP-1002 PN 51135: A 03/11/99 19

RPPWRTRM.cdr

Page 20

3 Installation Procedure

AC Power

Primary power required for the PDRP-1002 panel is 120 VAC, 50/60 Hz, 1.2 amps and

primary power for the PDRP-1002E is 220/240 VAC, 50 Hz, 0.6 amps. Overcurrent

protection for this circuit must comply with Article 760 of the National Electrical Code

(NEC) and/or local codes. Use #14 AWG (2.00 mm

2

)or larger wire with 600 volt rating.

Battery Power

Observe polarity when connecting battery. Connect battery cable to J9 on the main

board using the plug-in connector provided. See Appen dix A for calcul ation of correct

battery rating.

CA UTION: Batteries contain s ulfuric acid which can cause se ver e b urns to the skin and

!

eyes, and can destroy fabrics. If contact is made with sulfuric acid, immediately flush

skin or eyes with water for 15 minutes and seek immediate medical attention.

Voltmeter/Ammeter

To monitor battery voltage and battery charging current, a 4XMM (NOTIFIER) is

required. To install the power meter module, remove the jumper labeled “AMP” and

connect cable assembly P2 to pin connector J2 and cable assembly P3 to pin connector

J3 on the main board. Secure the 4XMM to the backbox with the two screws provided.

On some models, it will be necessary to install the meter b racket with the nuts and bolts

provided.

AC Power

5

0

10

DC VOLT S

0

DC AMPERES

P2

20

J2

J9

P3

J3

30

5

RPMBVM.cdr

Figure 9 Diagram of the 4XMM Voltmeter Connected to the Main Board

20 The PDRP-1002 PN 51135:A 03/11 / 99

Page 21

Voltmeter/Ammeter

Optional Modules

Transformer

Ground

Neutral

Hot

Optional Ammeter

Connection

3 Installation Procedure

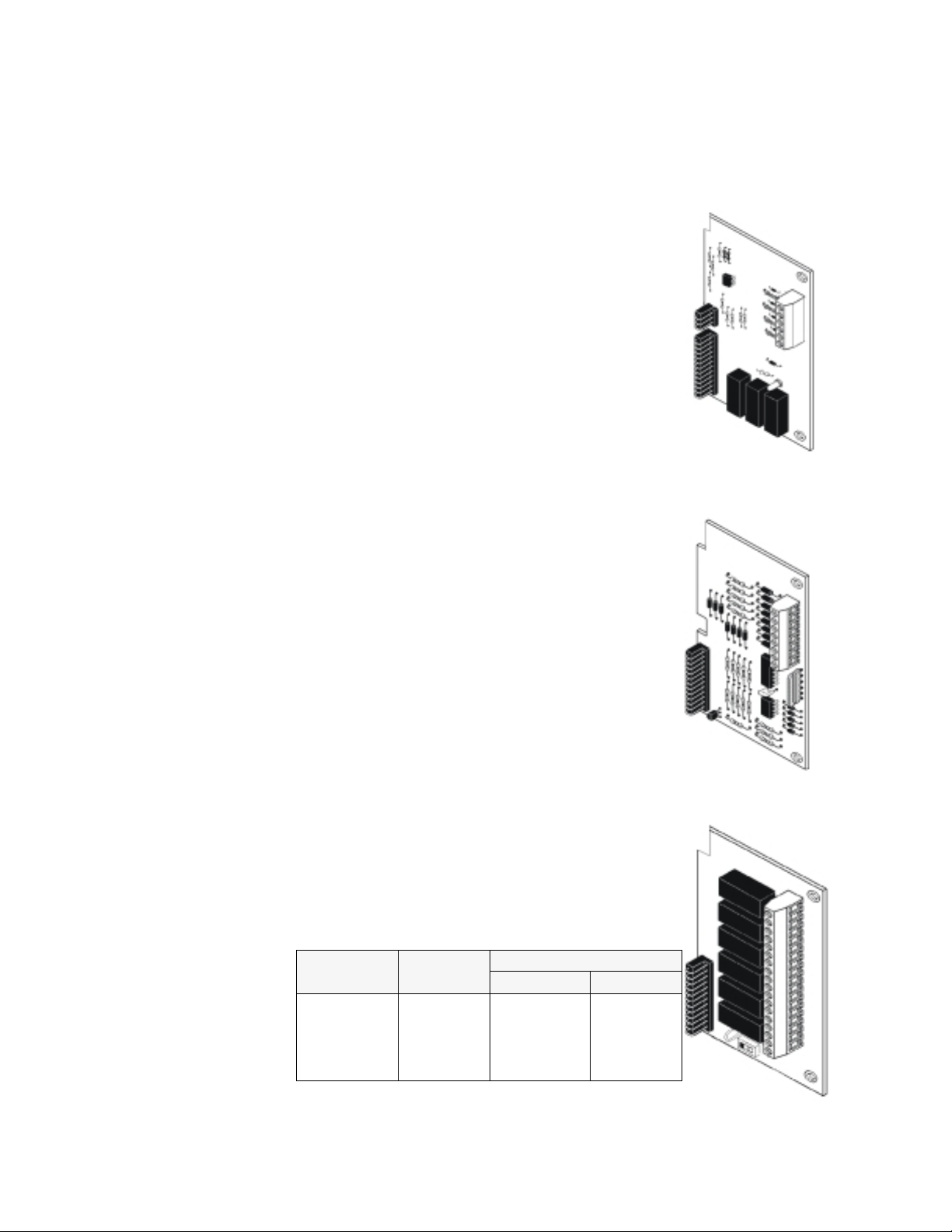

The fire control panel has two module connectors - J5 and J8. Three modules are

available for the panel and they can be used in any combination, including duplicate

modules. The corresponding option jumper must be cut before installation of an

optional module.

J4

*Jumper “OPT 1”

J5

must be cut if a

module is

installed in this

position

Batteries

Optional

VoltmeterConnection

J7

J8

Cross Zone

Supervisory

Ground Fault LEDBattery Fail LED

Note:

• Optional 4XLM module for an RZA-4X Annunciator mu st be inst al le d on J7 and J8

• 4XTM and 4XZM module s can be in sta ll ed in ei th er location.

Delay Timer

Figure 10 Optional Panel Modules

Abort Option

Abort Option

Delay Timer

Micro Fail LED

*Jumper “OPT 2”

must be cut if a

module is

installed in this

position

only

.

4XRP102a.cdr

The PDRP-1002 PN 51135: A 03/11/99 21

Page 22

3 Installation Procedure

Installing Option Modules

Installing Option Modules

Insert the two stand-offs (provided) into the holes located on the right-side edge of the

main board. Carefully align the pins on the main board with J1 and/or J2 on the option

board. Insert screw through the option board until it is secured on the stand-offs. Affix

the terminal identification labels provided with the option modules as shown below.

(Part # 42050)

Stand-offs)

Option Board

(4XZM shown)

Main

Board

4XSTNOFF.cdr

4XOPTNBD.cdr

Figure 11 Installing Option Modules.

22 The PDRP-1002 PN 51135:A 03/11 / 99

Page 23

Transmitter Module - 4XTM (NOTIFIER)

Transmitter Module - 4XTM (NOTIFIER)

Polarities shown in activated positions. The wiring of this module must follow the

requirements as specified in the “General” section, “

Requirements.

3 Installation Procedure

UL Power Limited Wiring

”

1

2

3

4

5

6

7

TBL Jumper

Disconnect LED

4XTBa.cdr

Disconnect Switch

+

Remote Alarm

}

-

+

Remote Trouble

}

-

No Connection

+

Municipal Box*

}

-

Power Limited Circuit

Non-Power Limited Circui

* Dummy load terminals

6 and 7 (4.7K, 1/4 W

resistor) if Municipal

Box is not connected.

Push the disconnect switch down to prevent unwanted activation of the Municipal Box

and Remote Station Outputs during testing of the control panel. The Disconnect LED

will remain illuminated while the Municipal Box is disconnected. The System Trouble

LED will indicate disconnected and/or Open Circuit conditions on the Municipal box.

Cutting the TBL jumper will allow the alarm reverse polarity circuit to open on tr ouble,

if no alarm exists

Note: Remote Alarm, Remote Trouble, and Municipal Box wiring can leave the building.

.

The PDRP-1002 PN 51135: A 03/11/99 23

Page 24

3 Installation Procedure

Zone Relay Module - 4XZM (NOTIFIER)

Zone Relay Module - 4XZM (NOTIFIER)

Non-power li mited and po w er limited wiring mu st h ave a minimum distance of 0.25 i n.

(6.35 mm) wire to wire. If this module is used to drive non-power limited and power

limited circuits, please follow the instructions below.

Relay #1 through #4 will activa te w it h Output #1 through #4

and remain latched unless jumper “LATCH” is cut.

1 NO

2 NC

3 C

4 NO

5 NC

6 C

7 NO

8 NC

9 C

10 NO

11 NC

12 C

13 NO

14 NC

15 C

16 NO

17 NC

18 C

4XZMA.cdr

Use Disable switch to disconnect the relays.

Cut jumper fo r no n -latching (s ilenceable) r elay operati o n.

Relay #1

Relay #2

Relay #3

Relay #4

Alarm

Trouble

1) Skip a set of dry contacts to maintain the 0.25 in (6.35 mm) required space

between power limited and non-power limited circuits. The wiring of this module must

follow the requirements as specified in the “

Wiring Requirements

.”

General

” section, “

UL P ower Limited

OR

2) If this module is needed to drive power limited and non-power limited relays that

are next to each other, refer to the figure below showing a typical connection.

Relay #1

Relay #2

Relay #3

Relay #4

Note: Refer to the Protected Premises Unit label, located on the door of the control panel, to

indicate if any dry contacts are t o be use d as non-power limited dry contacts.

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

Power Limited Circuit

Power Limited Circuit

No Connection

Non-power Limited Circuit

Non-power Limited Circuit

4XZMptl.cdr

24 The PDRP-1002 PN 51135:A 03/11 / 99

Page 25

LED Interface Module - 4XLM (NOTIFIER)

LED Interface Module - 4XLM (NOTIFIER)

The wiring of this module must follow the requirements as specified in section”

Requirements

.”

3 Installation Procedure

UL Power Limited Wiring

1 +24V

2 Out#1

3 Out#2

4 Out#3

5 Out#4

6 System Trouble

7 Sound

8 Resound

4XLMa.cdr

Front View

Connect to corresponding terminals

of RZA-4X Remote Annunciator.

RZA4XBX.cdr

RZA4Xfr.cdr

Side View

Single-gang Box

Note: Make wiring connections with system

power off. Maximum wire impedance is 50

ohms per wiring connection .

Figure 12 LED Interface Module - 4XLM

The PDRP-1002 PN 51135: A 03/11/99 25

Page 26

3 Installation Procedure

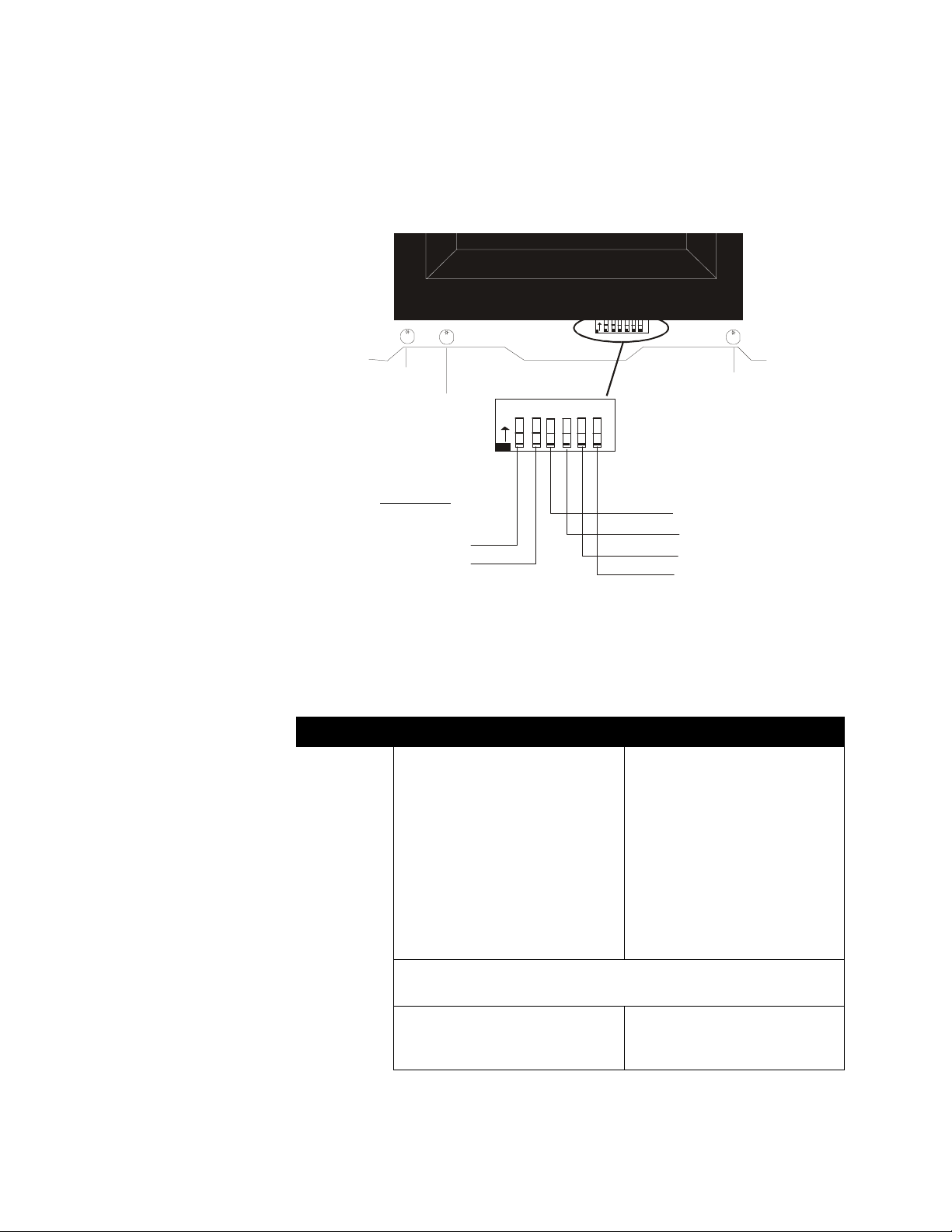

Setting Mode of Operation

DIP Switch

The DIP switch is located at the bottom of the PDRP-1002/PDRP-1002E main board.

To set a switch to the “ON” position, slide the switch up until it stops. The flushsurface switches are designed to pre v ent accidentally changing a switch setting and may

therefore require use of a pen or screwdriver to set them.

O

123456

N

DIP Switch

4XRPDIPS.cdr

Battery Fail

LED

Ground Fault LED

DIP Switches

Switch 1: CROSS ZONE

Switch 2: SUPERVISORY

Note: The Reset key must be depressed af te r any switch configuration has been made.

O

123456

N

Micro Fail LED

Switch 3: DELAY TIMER

Switch 4: DELAY TIMER

Switch 5: ABORT OPTION

Switch 6: ABORT OPTION

Cross Zone

Select the desired mode of operation and set SW1 DIP switch 1.

Switch 1 OFF ON

Output 1

Zone 1

either

is activated by an alarm on

Zone 2

or

.

Output 1

(Pre-discharge alarm) is

activated by the first alarmed zone

in the system. Initiation of an alarm

on the other zone will shut this

output off.

Output 2

either

is activated by an alarm on

Zone 1

or

Zone 2

. Output 2

will pulse at 60 ppm while timer is

running or frozen by abor t. Output 2

will sound steadily upon release (time

out).

Outputs 3 and 4

will be activated when the timer expires (provided that

Output 2

occur on both

is activated when alarm s

Zone 1

and

Zone 2

Output 2 will pulse at 60 ppm while

timer is running or frozen by abort.

Output 2 will sound st eadily upon

release (time out).

.

Output 4 is functioning as a releasing circuit - set via DIP Switch 2).

Timer

The

alarm occurs on either

Zone 2

Note: Outputs 1 and 2 refer to Notification Appliance Circuits. Output 3 refers to a releasing circuit. Output

4 is determined by setting switch 2. Zones 1 and 2 re fe r to In it ia ting D evice Cir cuits.

26 The PDRP-1002 PN 51135:A 03/11 / 99

will start whenever an

Zone 1

.

or

Timer will start

The

occur on both

Zone 1

when alarms

Zone 2

and

.

Page 27

Output 4 Supervisory/Releasing Service

Output 4 Supervisory/Releasing Service

Set the function of Output 4 via SW1 DIP switch 2.

Switch 2 OFF ON

3 Installation Procedure

Output 4

solenoid releasing circuit. This

circuit will be a non-power

limited circuit in this mode.

will function as a

Output 4 will function as a supervisory input

circuit. A short condition on this circ uit will

illuminate the Supervisory LED and sound

the supervisory ton e on the piezo. An open

condition generates a circuit trouble

condition. This circuit will function as a

power limited circuit in this mode.

Timer

Select the desired Timer setting and set SW1 DIP switches 3 and 4 per the appropriate

column.

No Delay* 10 Seconds 20 Seconds 30 Seconds

Switch 3 OFF OFF ON ON

Switch 4 OFF ON OFF ON

*Abort switch is inoperative when no delay is selected.

Abort Function

Select the desired abort funct ions and set SW 1 DIP switc hes 5 and 6 per the appr opriate

column.

Switch 1 OFF OFF ON ON

Switch 2 OFF ON OFF ON

Standard UL-type

delay

timer which

continues to count down

upon ABORT , and stops

and holds at 10 seconds

until release of the

ABORT switch. Upon

release of the ABORT

switch, the timer

resumes the countdown

at 10 seconds.

These modes are the onl y on es t hat

comply with UL Standard 864

Note: ABORT timer will not operate when timer is set for “NO DELAY”.

IRI-type delay

timer

which

functions the same as

the UL-type timer

with the except ion

that the ABORT will

function only if

pressed and held

before 2nd zone goes

into alarm.

NYC-type delay

timer.

Pressing

ABORT, once an

alarm exists, changes

timer value to the

time selected via DIP

Switches 3 and 4

plus 90 seconds.

The timer will not

start as long as the

ABORT switch is

held. SYSTEM

RESET restores

timer to original

times selected via

DIP Switches 3 and

4. Successive

ABORTS will add

90 seconds to

selected timer value.

Local Jurisdiction

delay timer.

the timer has started,

pressing ABORT

restores timer to its

full time as s e t o n

DIP Switches 3 and

4. The timer will

not start as long as

ABORT is held.

Release of the

ABORT switch

continues the

countdo wn, where as

pressing ABORT

again will restore

the timer to its full

value.

Once

The PDRP-1002 PN 51135: A 03/11/99 27

Page 28

Appendix A: Power Calculations

Appendix A: Power Calculations

Standby Battery Requirements

The Standby Battery Current figure obtained in the following table (Table 1) represents

the amount of current that must be supplied by the secondary power source (batteries)

to sustain control panel operation for one hour.

Standby Battery Requirements

Basic Contro l Panel

Control panel with AC power off, System Trouble LED and audible trouble sounder on.

If using a 4XZM Zone Relay Module1 [ ] X 8 mA =

f using a 4XTM Transmitter Module, add 11 mA

If using the Reverse Polarity Alarm output, add 5 mA

If using the Reverse Polarity Trouble output, add 5 mA

If using a 4XLM/RZA-4X Driver/Annunciator combination:

1

[ ] X 19 mA =

If using a 4XMM Meter Module, add 1 mA

If using the Noti•Fire 911AC DACT, add 30 mA

Number

in use

(see Appendix B for data)

a. Two-wire detector he ads

Device

Current

X =

Total

Current

88 mA

b. Four-wire detector heads

c. End of Line Relays

d. Add lines a, b, & c for

X =

X 25.0 mA =

Place subtotal here

Add last column for Standby Battery Current :

and continue to next table (Table 2)

Table 1 Standby Battery Requirements

Note: The control panel will support the installation of one or two optional modules, inc lu ding two of the

same type of module.

28 The PDRP-1002 PN 51135:A 03/11 / 99

Page 29

Ampere-Hour Calculations

Appendix A: Power Calculations

Ampere-Hour Calculations

Standby Battery Current

Convert the total from

Table 1 to amps and enter

here

amps X

Enter 0.25 for 5 minutes in alarm

or 0.5 for 10 minutes in alarm

Add Standby and A larm amp/h ours

Select a battery with an equal or greater amp/hour rating than the f igur e obtained

in

Table 2. Batteries must be lead-acid type.

PS-1270 12 volt, 7 amp/hour (two required)

PS-12120 12-volt, 12 amp/hour (two required)

StandbyTime

24, 60, or 90

hours

hours =

+

=

Table 2 Ampere-Hour Calcula t ions

Standby

amp/hours

Alarm

amp/hours

Total amp/

hours needed

Notes:

1. Alarm amp-hours assumes a maximum system draw of 3 amps in alarm for 5

minutes (0 .25 amp/hour) or for 10 minutes (0.5 amp/hour)

2. NFPA 72 Central Station and Local and Propri etary Fire A larm S ystems requir e 24

hours of standby.

3. NFPA 72 Auxiliary and Remote Station Fire Alarm Systems require 60 hours of

standby.

4. Factory Mutual Systems require 90 hours of standby.

5. The battery charger in this panel will charge a maximum of 15 amp/hours of

batteries within 48 hours (7 amp/ hour mini mum). Batteries larger than 12 amp/

hour will require a UL listed battery cabinet (e.g. NOTIFIER BB-17).

The PDRP-1002 PN 51135: A 03/11/99 29

Page 30

Appendix B: Device Compatibility

Appendix B: Device Compatibility

FM-Approved Releasing Devices

Smoke Detector/Base Detector Type

System Sensor 2424 Photoelectric 0.10 41

System Sensor 2424TH Photoelectric 0.10 41

System Sensor 2451 Photoelectric 0.10 39

System Sensor 2451TH (with/B402B Base) Photoelectric 0.10 39

System Sensor 1424 Ionization 0.10 41

System Sensor 1451 (w/B402B Base) Ionization 0.10 39

System Sensor 2412 Photoelectric 0.12 77

System Sensor 2412AT Photoelectric 0.12 58

System Sensor 2412TH Photoelectric 0.12 77

System Sensor 2312/24TB Photoelectric 0.12 50

System Sensor B112LP Base

System Sensor B114LP Base

System Senso r B404B Base

System Sensor 6424 Projected Beam 10 28.4

System Sensor DH400ACDCI Ionization Duct 25 95

Max Standby

Current (mA)

see note

see note

see note see note

Max Alarm

Current (mA)

39

75

System Sensor DH 40 0ACDCP Photoelectric Duct 25 95

System Sensor 1112/24 Ionization 0.05 50

System Sensor 2112/24 Photoelectric 0.05 50

System Sensor 2112/24B Photoelectric 0.05 65

System Sensor 21 12 /2 4T Photoelectric w/13 5°

Thermal

System Sensor 2112/24TSRB Photoelec tr ic w/135°

Thermal Supervisory Relay

Note: Contact manufacturer for currents.

0.05 50

15 45

Table 3 UL Listed Four-Wire Smoke Detectors

FM-Approved Releasing Devices

(System Sensor’s PDRP-1002/PDRP-1002E)

Solenoid Group [A]

Skinner solenoid valve Model LV2LBX25, 24 VDC, 11 Watts, 458 mA, 1/2 in. NPS, 5/

8 in. orifice.

Solenoid Group [B] These valves are interchangeable

ASCO solenoid valve Model T8210A107, 24 VDC, 16.8 Watts, 700 mA, 1/2 in. NPS,

5/8 in. orifice.

.

ASCO solenoid valve Model R8210A107, 24 VDC, 16.8 Watts, 700 mA, 1/2 in. NPS,

5/8 in. orifice.

ASCO solenoid valve Model 8210A107, 24 VDC, 16.8 Watts, 700 mA, 1/2 in. NPS, 5/

30 The PDRP-1002 PN 51135:A 03/11 / 99

Page 31

FM-Approved Releasing Devices

8 in. orifice.

Solenoid Group [C]

Star Sprinkler Corp. Solenoid P/N 5550, 24 VDC, part of Model D deluge valve.

Kidde-Fenwal Electric Control Head P/N 890181; 24V, 2.0 Amps

Kidde-Fenwal Electric Control Head P/N 899175; 24V, 2.0 Amps

Kidde-Fenwal Electric Control Head Stackable (XP) P/N 48650001; 24V, 0.2 Amps

Kidde-Fenwal Electric and Cable Op Control Head (XP) P/N 897494; 24V, 1.5 Amps,

33 Watts

Refer to the FM approval guide for automatic water control valves which are

compatible with solenoids listed above.

Appendix B: Device Compatibility

Model Type Current (mA)

FM980-24 Floor Mount, single 68

FM996-24 Wall Mount Surface Wiring 68

FM998-24 Wall Mount Concealed Wiring 68

Table 4 24 VDC Door Holders

Vendor Model Current(mA)

System Sensor A77-716B 20

Air Products & Controls, LTD MR-101/C

MR-201/C

15

35

Table 5 UL Listed 24 VDC Relays

The PDRP-1002 PN 51135: A 03/11/99 31

Page 32

Appendix B: Device Compatibility

FM-Approved Releasing Devices

SYSTEM SENSOR

System Sensor MA-12/24D Electronic Sounder 24VDC 73 46

System Sensor SS24 Strobe 24VDC

System Sensor SS24LO Strobe 24VDC 45 25

System Sensor SS24LOC Ceiling Strobe (SS24LOBC - beige) 24VDC 45 25

System Sensor SS24M Strobe 24VDC 125 75

System Sensor SS24MC Ceiling Strobe 24VDC 125 75

System Sensor MASS24D Electronic Sounder/Strobe 24VDC 118 71

System Sensor MASS24LO Electronic Sounder/Strobe 24VDC 118 71

System Sensor MASS24LOC Electronic Ceiling Sounder/Strobe 24VDC 118 71

System Sensor MASS24LOLA Electronic Sounder/Strobe with Fuego lens 24VDC 118 71

System Sensor MASS24M Electronic Sounder/Stro be 24VDC 198 121

System Sensor MASS24MC Electronic Ceiling Sounder/Strobe 24VDC 198 121

System Sensor PA400R Sounder 24VDC

System Sensor PS24LO Add-on Strobe 24VDC 45 25

Rated

Voltage²

FWR DCFiltered

DC

note 5

note 5

30

15

System Sensor SS24 15ADA Signaling Strobe 24VDC 90 75

System Sensor SS2475ADA Signaling Strobe 24VDC 200 170

System Sensor SS24110ADA Signaling Strobe 24VDC 245 210

System Sensor SS241575ADA Signaling Strobe 24 VDC 120 93

System Sensor SS24 15ADAS Signaling Strobe with Synch. Circuit 24 VDC 125 10 6

System Sensor SS241575ADAS Signaling Strobe with Synch. Circuit 24 VDC 180 115

System Sensor MASS2415ADA Sounder/Signaling Strobe 24VDC 163 121

System Sensor MASS2475ADA Sounder/Signaling Strobe 24VDC 273 216

System Sensor MASS 24110ADA Sounder/Signaling Strobe 24VDC 318 256

System Sensor MASS 241575ADA Sounder/Signali ng Strobe 24 VDC 193 139

System Sensor MASS 2415ADAS Sounder/Signaling Strobe w/ Synch. Ckt. 24 VDC 163 121

System Sensor MASS241575ADAS Sounder/Signaling Strobe w/ Synch. Ckt. 24 VDC 193 139

System Sensor PS24 15ADA Mini-Sounder/Strobe 24VDC 110 90

System Sensor PS24 75ADA Mini-Sounder/Strobe 24VDC 135 108

System Sensor PS241575ADA Mini-Sounder/Strobe 24VDC 135 108

System Sensor PS24110ADA Mini-Sounder/Strobe 24VDC 240 225¥

System Sensor SP1R2415ADA Speaker/Signaling Strobe 24VDC 90 75

System Sensor SP1R2475ADA Speaker/Signaling Strobe 24VDC 200 170

System Sensor SP1R24110ADA Speaker/Signaling Strobe 24VDC 245 210

32 The PDRP-1002 PN 51135:A 03/11 / 99

Page 33

FM-Approved Releasing Devices

System Sensor SP1R 241575ADA Speaker/Signaling Strobe 24 VDC 120 93

System Sensor V4R2415ADA Speaker/Signaling Stro be 24VDC 90 75

System Sensor V4R2475ADA Speaker/Signaling Strobe 24VDC 200 170

System Sensor V4R24110ADA Speaker/Signaling Strobe 24VDC 245 210

System Sensor V4R241575ADA Speaker/Signaling Strobe 24 VDC 120 93

System Sensor SP100W24LOC Ceiling Speaker/Stro be, 8" round grille 24VDC 45 25

System Sensor SP101R24LO Speaker/Strobe, 5" square grille 24VDC 45 25

System Sensor SP101R24M Speaker/Strobe, 5" square grille 24VDC 125 75

System Sensor SP100W24MC Ceiling Speaker/Strobe, 8" round grille 24VDC 125 75

Appendix B: Device Compatibility

System Sensor MA12/24EH Multi Alert Horn with Mechanical Tone 12VDC/

24VDC

System Sensor MAEH24LO Multi Alert Horn with Mechanical Tone/Strobe 24VDC 109 68

System Sensor MAEH24LOC Multi Alert Horn with Mechanical Tone/Strobe 24VDC 109 68

System Sensor MAEH24LOLA Multi Alert Horn with Mechanical Tone/Strobe 24VDC 153 96

System Sensor MAEH24M Multi Alert Horn with Mechanical Tone/Strobe 24VDC 189 118

System Sensor MAEH24MC Multi Alert Horn with Mechanical Tone/Strobe 24VDC 189 118

System Sensor MAEH1215ADA Multi Alert Horn with Mechanical Tone/Strobe 12VDC 240 191

System Sensor MAEH121575ADA Multi Alert Horn with Mechanical Tone/Strobe 12VDC 310 246

System Sensor MAEH2415ADA Multi Alert Horn with Mechanical Tone/Strobe 24VDC 278 216

System Sensor MAEH2475ADA Multi Alert Horn with Mechanical Tone/Strobe 24VDC 273 216

System Sensor MAEH241575ADA Multi Alert Horn with Mechanical Tone/Strobe 24VDC 343 271

System Sensor MAEH24110ADA Multi Alert Horn with Mechanical Tone/Strobe 24VDC 318 256

System Sensor MAEH2415ADAS Multi Alert Horn with Mechanical Tone/Strobe 24VDC 198 152

System Sensor MAEH241575ADAS Multi Alert Horn with Mechanical T one/Strobe 24VDC 253 241

System Sensor H12 Spect rAlert Horn 12VDC 25 14

20/64 38/43

System Sensor H42 SpectrAlert Horn3 24VDC 42 37

System Sensor S1215 SpectrAlert Strobe 12VDC 159 133

System Sensor S121575 SpectrAlert Strobe 12VDC 182 168

System Sensor S2415 SpectrAlert Strobe3 24VDC 142 83

System Sensor S241575 SpectrAlert Strobe3 24VDC 132 76

System Sensor S2475 SpectrAlert Strobe3 24VDC 170 145

System Sensor S24110 SpectrAlert Strobe3 24VDC 220 169

System Sensor P1215 SpectrAlert Horn/Strobe 12VDC 173 144

System Sensor P121575 SpectrAlert Horn/Strobe 12VDC 196 179

System Sensor P2415 SpectrAlert Horn/Strobe3 24VDC 165 94

System Sensor P241575 SpectrAlert Horn/Strobe3 24VDC 177 111

The PDRP-1002 PN 51135: A 03/11/99 33

Page 34

Appendix B: Device Compatibility

FM-Approved Releasing Devices

System Sensor P2475 SpectrAlert Horn/Strobe3 24VDC 215 180

System Sensor P24110 SpectrAlert Strobe3 24VDC 265 214

System Sensor RP1215ADAARetrofit Strobe Plate 12VDC 200 170

System Sensor RP121575ADAARetrofit Strobe Plate 12VDC 240 255

System Sensor RP241 5ADAARetrofit Strobe Plate 24VDC 90 75

System Sensor RP241575ADAARetrofit Strobe Plate 24VDC 120 93

System Sensor RP2475ADAARetrofit Strobe Plate 24VDC 200 170

System Sensor RP24110ADAARetrofit Strobe Plate 24VDC 245 210

System Sensor H24 Spect rAlert 24VDC 42 37

System Sensor S2415 SpectrAlertStrobe3 24VDC 142 83

System Sensor S241575 SpectrAlert Strobe3 24VDC 132 76

System Sensor S2475 SpectrAlert Strobe3 24VDC 170 145

System Sensor S24110 SpectrAlert Strobe3 24VDC 220 169

System Sensor S2415 SpectrAlert Horn/Strobe3 24VDC 165 94

System Sensor S241575 SpectrAlert Horn/Strobe3 24VDC 177 111

System Sensor S2475 SpectrAlert Horn/Strobe3 24VDC 215 180

System Sensor P24110 SpectrAlert Horn/Strobe3 24VDC 265 214

System Sensor S2415 SpectrAlertStrobe3 24VDC 142 83

System Sensor S241575 SpectrAlert Strobe3 24VDC 132 76

Note:

1) Control panels suppling Special Application (FWR, Filtered) power must use the notification appliances,

relays or door holders listed in this table.

2) All currents are in Millamperes and worst case average.

3) Nominal Oper ating voltage.

4) Refer to Installation Instruct io ns for m o re inf ormation.

5) Contact manufacturer for current s.

Table 6 UL Listed Notification Appliances

34 The PDRP-1002 PN 51135:A 03/11 / 99

Page 35

FM-Approved Releasing Devices

Appendix B: Device Compatibility

Number of

Detectors Per Zone

Model Det. IDDetector Type Base Model Base

ID

System Sensor 1400 A Ionization n/a n/a 10 0 20

System Sensor 1451 A Ionization B401B / B406B A 120 15 / 1

System Sensor 1851DH A Ionization DH1851DC A 120 15

System Sensor 2400 A Photoelectric n/a n/a 120 15

System Sensor 2400AIT A Photo / Isolated

Thermal / Horn

System Sensor 2400AT A Photo / Thermal / Horn n/a n/a 120 1

System Sensor 2400TH A Phot o / Thermal n/a n/a 120 15

System Sensor 2451 A Phot oelectric B401B / B406B A 120 15 / 1

System Sensor 2451TH A Phot o / Thermal B401B / B406B A 120 15 / 1

System Sensor 2851DH A Photoelectric DH2851DC A 120 15

System Sensor 1451DH A I onization DH-400 A 120 15

System Sensor 2451 A Photoelectric DH-400 A 120 15

System Sensor 2300T A Photo / Thermal n/a n/a 120 15

n/a n/a 120 1

Standby

Current

(uA)

PDRP-1002/

PDRP-1002E

System Sensor 1800 A Ionization n/a n/a 100 n/a

System Sensor 1851B A Ionization B101B A 120 n/a

System Sensor 1851B A Ionization B107B A 120 n/a

System Sensor 2800 A Photoelectric n/a n/a 120 n/a

System Sensor 2800TH A Phot o / Thermal n/a n/a 120 n/a

System Sensor 2851B A Photoelectric B101B A 120 n/a

System Sensor 2851B A Photoelectric B107B A 120 n/a

System Sensor 2851B TH A Photo / Thermal B101B A 120 n/a

System Sensor 2851B TH A Photo / Thermal B107B A 120 n/a

System Sensor 1151 A Ionnization B401 / B110LP /

B116LP

System Sensor 2151 A Photoelectric B401 / B110LP /

B116LP

A 120 15 / 15 / 1

A 120 15 / 15 / 1

Table 7 UL Listed, Compatible Two-Wire Smoke Detectors for Notifier Control Panels

The PDRP-1002 PN 51135: A 03/11/99 35

Page 36

Appendix C: NFPA Standard-Specific Requirements

FM-Approved Releasing Devices

Appendix C: NFPA Standard-Specific Requirements

The PDRP-1002/PDRP-1002E has been desig ned for use in commercial, indus trial, and

institutional applications and meets the requirements for service under the National Fire

Protection Association (NFPA) Standards outlined in this appendix. The minimum

system components required for compliance with the appropriate NFPA standards are

listed below.

PDRP-1002/PDRP-1002E Control Panel

(backbox and door), main supply transformer and power supply.

Batteries

Initiating Devices

Notification Appliances

Appliance Circuits .

Releasing Devices

The following additional equipment is needed for compliance with the NFPA standards

listed below.

NFPA 72 Signaling Systems for Central Station Service (Protected Premises Unit)

NOTI•FIRE 911AC DACT* - for connection to a compatible listed Central Station

DA CR or Protected Premises Receiving Unit. This unit must be installed as outlined in

Figure 13.

NFPA 72 Auxiliary Fire Alarm System

4XTM Transmitter Module for connection to a compatible listed Local Energy

Municipal Box. This unit must be installed as outlined in Figure 15.

NFPA 72 Remote Station Fire Alarm System

4XTM Transmitter Module for connection to Fire•Lite RS82-9 Remote Station

Receiver. See Figure 16 for installation instructions.

(refer to Appendix A for Standby Power Requirements).

- connected to one of the control panel’s Initiating Device Circuits.

- connected to one of the control panel’s Notification

- connected on one of the control panel’s Releasing Circuits.

containing the main control board, cabinet

OR

NOTI•FIRE 911AC DACT* - For connection to a compatible listed remote station

DACR. This unit must be installed as outlined in Figure 13.

*Applications which require the NOTI•FIRE 911AC are not FM approved

.

36 The PDRP-1002 PN 51135:A 03/11 / 99

Page 37

NFPA 72 Signaling Systems for Central Station Service

NFPA 72 Signaling Systems for Central Station Service

(Protecte d Premises Unit) and Remote Station Fire Ala rm Sys te m ( Protected Pr em is es Unit)

NOTI•FIRE 911 AC D ACT* - for connection to a Central Station Receiver or Protected

Premises Receiving Unit. This unit must be installed as illustrated below. For

additional information on the 911AC, refer to document 74-06200-005.

All connections between the FACP and 911AC must be in conduit, less than 20 ft

(609.6cm) in length in the same room. If the NOTI•FIRE 911AC is not mounted in the

PDRP-1002/PDRP-1002E backbox all connections must be in conduit, less than 20 ft.

(609.6 cm) in length in the same room.

*This application using the NOTI•FIRE 91 1AC is not FM approved.

Note: For 911AC

• The Maximum standby load shall be 125 mA.

• The Standby by Battery Requirement: 24VDC, 7Amp-Hour-Max.

• The PDRP-1002/PDRP-1002E is not suitabl e fo r transm ission of a supe rvi sory sig na l to the DACT.

Note: The PDRP-1002/

PDRP-1002E is not

suitable for transmission

of a supervisory signal to

th e DACT

To AC

Power

Alarm

Appendix C: NFPA Standard-Specific Requirements

NOTE on STD DACT:

Place jumper over pins 2 and 3,

marked DACT, when employing a

DACT. This di rect s the c o ntr ol pane l

1

2

3

4

5

6

7

8

9

10

11

12

1

12VAC, 20VA, 60Hz or +24VDC

2

12VAC, 20VA, 60Hz or -24VDC

3

(Refer to manual)

BATTERY -

4

BATTERY +

5

INITIATING A1 -

6

INITIATING A2 -

7

INITIATING B1 +

8

INITIATING B2 +

9

SUPE R V IS O R Y H I

10

SUPE R V IS O R Y LO

11

TROUBLE RELAY NC

12

TROUBLE RELAY COM

13

TROUBLE RELAY NO

14

ALARM RELAY NC

15

ALARM RELAY COM

16

ALARM RELAY NO

17

Digital Alarm Co mmunicator Transmitter Listed for Central Station or Remote Station Service.

Slide Cover Back to Access Programming Jack and Relays

- 12 VDC Sealed

R echa rge able

+ Battery

+

-

PS1270

12Volt

7AH Battery

Alternate RJ31X

Primary RJ31X

Telco J a c k

Telco J a c k

to transmit all trouble conditions

except AC LOSS.

To Central Station

JP-1

Motherboard 911AC

Alarm

normally open

contacts

Trouble

normally open

RP911AC.CD

contacts

Figure 13 NFPA 72 Signaling Systems for Central Station Service

TB3-1 6 and 7

TB3-3 8 and 9

TB3-4 10

TB3-6 11

STDDACT

The PDRP-1002 PN 51135: A 03/11/99 37

Page 38

Appendix C: NFPA Standard-Specific Requirements

Using the MS-5012 as a DACT

1) Reference the MS-5012 manual for additional information.

2) Program the MS-5012 for slave applications.

3) The PDRP-1002/PDRP-1002E is not suitable for transmission of a supervisory

signal to the DACT.

Secondary

Modular Cable

P/N MCBL-6

Phone Line

Primary

Phone Line

NFPA 72 Signaling Systems for Central Station Service

120 VAC

HOT

Neutral

Ground

Yellow

Yellow

Black

White

Green

AC Wiring for DACT/FACP must be

connected to the s a me circuit.

Red

Black

MS-5012

J2

AC POWER

ALARM

1

23

5

4

7

8

A

OB

TROUBLE

SUPERVISORY

6

9

12VDC

Battery

2-7AH

Alarm

TB2

J3

Trouble

F

E

1st

D

EVENT

ENTER

C

STORE

TB3

Motherboard MS-5012

TB3-1 TB2-2

Alarm

TB3-3 TB2-1

1 2 3 4 5 6

TB3

MS5012X2.CDR

PDRP-1002/PDRP-1002E

Trouble

38 The PDRP-1002 PN 51135:A 03/11 / 99

TB3-4 TB2-4

TB3-6 TB2-3

Figure 14 Using the MS-5012 as a DACT

Page 39

NFPA 72 Auxiliary Fire Alarm System

NFPA 72 Auxiliary Fire Alarm System

All connections are power limited and supervised. This application is not suitable for

separate transmission of sprinkler supervisory or trouble conditions.

Note: Maximum loop resistan ce allowed for wiri ng from control panel to Municipa l Bo x is 3 ohm s.

Appendix C: NFPA Standard-Specific Requirements

4XTB

4XTM (NOTIFIER)

Transmitter Module

(activated polarities

shown)

+

Municipal Box Circuit

-

-

+

6

7

Figure 15 NFPA 72 Auxiliary Fire Alarm System

FIRE

AUXPROSS.CDR

Gamewell

Model M34-56

Local Energy

Municipal Box

The PDRP-1002 PN 51135: A 03/11/99 39

Page 40

Appendix C: NFPA Standard-Specific Requirements

NFPA 72 Remote Station Fire Alarm System

Intended for connection to a polarity reversal circuit of a remote station receiving unit

having compatible ratings. All connections are power limited and supervised with the

exception of the reverse polarity loop. Supervision of the loop is the responsibility of

the receiver.

NFPA 72 Remote Station Fire Alarm System

DRY

SUPPLEMENTARY

CONTACTS,

RATED

3A, 120 VAC

RESISTIVE

3A, 30 VDC

RESISTIVE

REMOTE STATION

MASTER BOARD

(RSM-9)

N.C.2

N.O.2

POLE 2

N.C.1

N.O.1

POLE 1

A.C. CKT BREAKER

120 VAC

1.2 AMPS

9

10

SIGNALING

11

RELAY FOR

BELLS AND

12

1

DRY

13

CONTACTS

14

CONTROL CARD

(RSC)

CIRCUIT SIDE

ZONE CARD(RSZ)

CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

OPTIONAL ZONE CARD

(RSZ) CIRCUIT SIDE

K | | | | | | | | | | K

PRESS TO

RESET

BATTERY

CKT FUSE

8 AG

5 A

125 V

FILTER

CAP

--

-K

--

--

--

K

2

8

7

6

5

BATT

CONN

4

3

2

2

1

1

2

1

2

2

1

1

2

1

2

2

1

1

2

1

2

1

2

2

1

1

1

GROUNDING

TERMINAL

N/C

BELL

or

HORN

}

}

}

}

}

}

}

120 VAC 1.2 A

}

50-60 Hz

INPUT

+

-

H

10 K

ELR

ALARM

SIGNAL

INPUT 3

ALARM

SIGNAL

INPUT 4

ALARM

SIGNAL

INPUT 5

ALARM

SIGNAL

INPUT 6

ALARM

SIGNAL

INPUT 7

ALARM

SIGNAL

INPUT 8

ALARM

SIGNAL

INPUT 9

Fire•Lite

RS82-9

Remote Station

Receiver

UL listed

-

+

-

+

Recommended Types:

ELPOWER EP 1250C

+

POWER SONIC PS 1245