System Sensor PS24LO, PS24LOA, PS24LOW, PS24LOWA, PS24M Installation And Maintenance Instructions Manual

...Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

F

I

R

E

60% 60%

100%100%

100%

(REF)

7%

60% 60%

7%

PA400*, PS12LO(W), PS12M(W),

PS24LO(W)*, and PS24M(W)*

Electronic Mini-Sounders and

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

A Division of Pittway

Optional Strobes

*ULC models add suffix “A”; available in 24VDC only

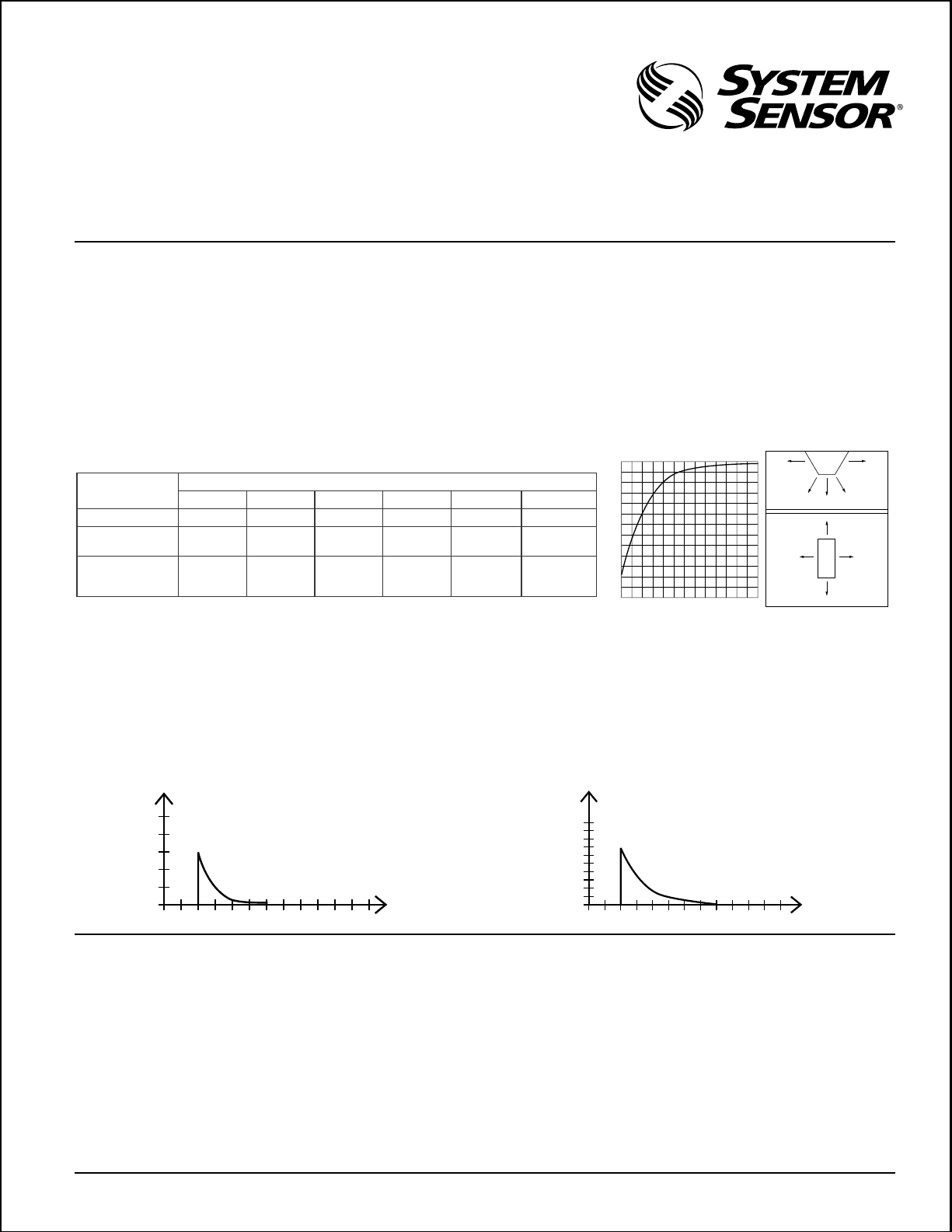

Specifications

PA400 Sounder

Operating Voltage: 9.6VDC (absolute min.) to 33VDC (absolute max.)

Current Drain: 12 mA at 12 volts

15 mA at 24 volts

Temperature Range: -10

Sound Output: Greater than 90 dBA measured in anechoic room at 10 feet, 24 volts.

PS12/24 Strobe

PS12LO(W) PS12M PS24LO(W) PS24M(W) PS24LOA(W) PS24MA(W)

Panel Voltage 12–17 VDC 12–17 VDC 22.5 - 30 VDC 22.5 - 30 VDC 22.5 - 30 VDC 22.5 - 30 VDC

Max. Current Drain @

Listed Panel Voltage

Min. Light Output @

100% Viewing Angle

(See Fig 2)

50 mA 180 mA 25 mA 75 mA 50 mA 180 mA

1.5 candela 15 candela 1.5 candela 15 candela 1.5 candela 15 candela

Temperature Range: 0°C to 49°C (32°F to 120°F)

Under no circumstances can the PS24 voltage exceed 33VDC or be less than 18VDC.

Under no circumstances can the PS12 voltage exceed 18.7VDC or be less than 9.6VDC.

To calculate battery requirements, use current values shown above. However, note that there is an in-rush current associated with

strobe power-up. The information in Figures 3 and 4 is useful when selecting fuse values.

As Figure 3 shows, 12V strobe in-rush current typically peaks at 3A and drops to nominal in 600

current typically peaks at 7.0A and drops to nominal in 800

Figure 3. 12 volt strobe in-rush current:

1A/div

o

C to +60oC (14oF to 140oF)

0°C to 49°C (32°F to 120°F) with strobe added

See Figure 1 for other voltages. 82 dBA minimum measured in UL reverbarant room

(75 dBA minimum with strobe)

Figure 1: Figure 2:

MODEL

µ

S.

92

91

90

89

dBA output

88

87

86

10 12 14 16 18 20 22

Voltage

µ

S. In a 24V strobe (Figure 4), in-rush

Figure 4. 24 volt strobe in-rush current:

1A/div

200

µ

S/div

General Information

The National Fire Protection Association has published codes,

standards, and recommended practices for the installation and

use of the above appliances. Therefore, the installer must be familiar with these requirements, with local codes, and any special

requirements of the authority having jurisdiction.

Model PA400

The PA400W (white) and PA400R (red) Piezo Alert electronic

sounder and optional supplementary signal strobes are intended

to be connected to the alarm indicating circuit of a UL-listed 12 or

24 VDC fire alarm control panel. The models PS12 and PS24 optional strobe additions to the PA400 require a 12 VDC or 24 VDC

Technical Manuals Online! - http://www.tech-man.com

200

µ

S/div

panel, respectively and are able to operate from a full-wave rectified, unfiltered supply.

Installation Notes

The wiring must be in compliance with all codes and must not be

of such length or wire size that would cause the appliance to operate outside of its published specifications. The appliances must

also be tested after installation in accordance with the control

panel manufacturer’s test procedure.

NOTE: Do not loop wires under terminal screws. Wires

connecting the device to the panel must be broken at the

device screw terminal in order to maintain electrical

supervision.

1 I56-305-07

Page 2

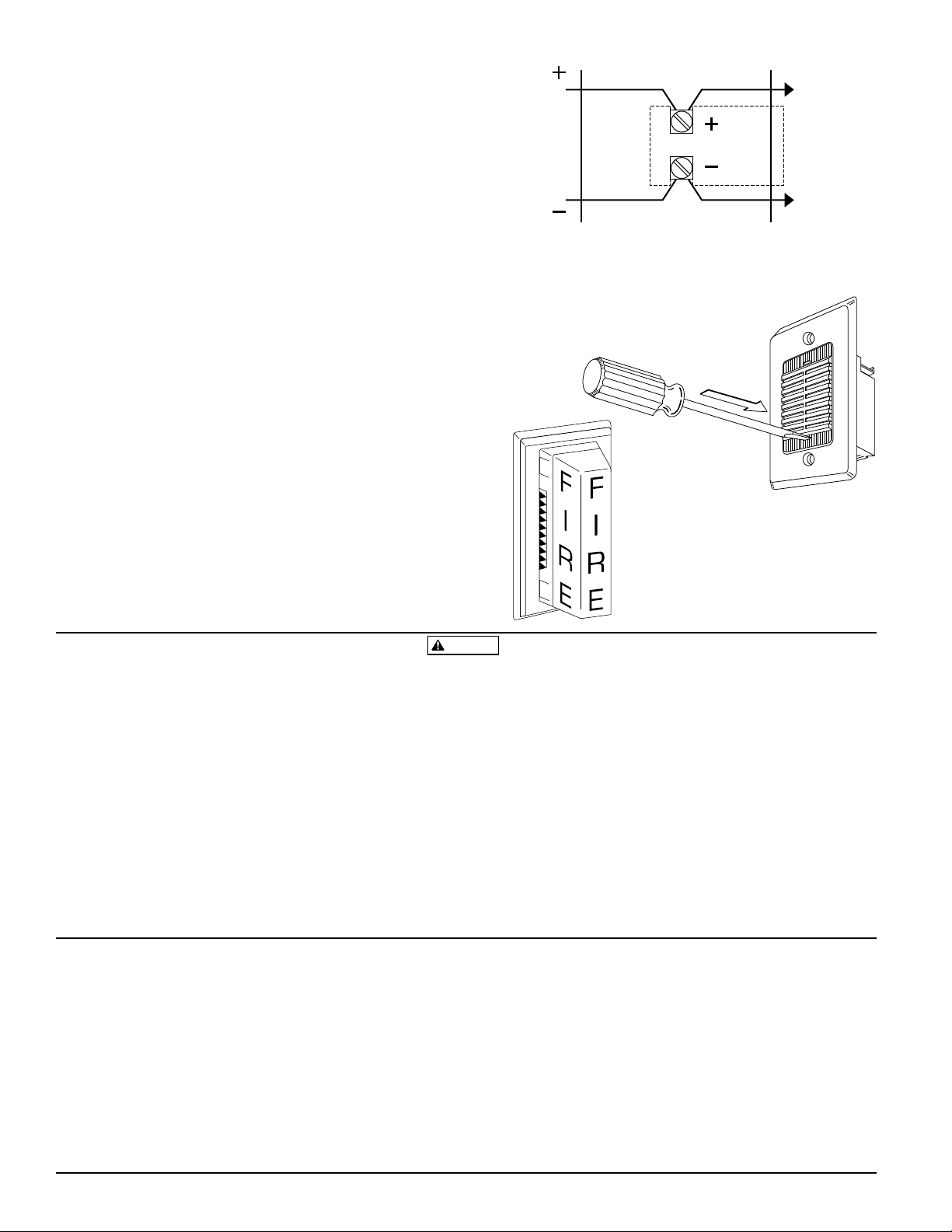

Mounting

PA400 Sounders

1. The PA400 is intended for mounting to a standard 2-1/2" deep

single-gang box which allows sufficient clearance for conduit

entrance.

2. The PA400 is compatible with DC line supervision. The Piezo

Alert is polarized and has terminals marked with polarity. Apply positive supply voltage to the (+) terminal and negative

supply voltage to the (–) terminal. (See Figure 5.)

3. Mount the appliance to the electrical outlet box using the two

mounting screws supplied.

4. Field repair of the PA400 should not be attempted. Return to

factory for repair or replacement.

PS12 or PS24 Strobes

These optional strobes are interconnected to the PA400 by first removing the two mounting screws from the sounder. Use a small

screwdriver to punch out the skinned-over areas as indicated in

Figure 6. Install the adapter plate on top of the sounder and screw

the combined sounder and adapter plate to the electrical outlet

box. Make sure field wiring terminals are oriented in the upward

position when mounted in the outlet box. Next, slide the strobe

directly into the slots in the plates. The positive solder lug may be

colored red or marked with a plus sign (+). This lug must be in

the slot closest to the field wiring terminals. Grasp the catch area

on each end of the strobe and squeeze while applying inward

force. Make sure the strobe catches fully engage the slots in the

adapter plate and that no gap appears at the interface between the

strobe and adapter plate.

Figure 5:

From

control

panel

or

previous

To

EOL

or

Next

Device

device*

*NOTE: Shown with control panel in alarm. Panel polarity

reversed in supervisory condition.

A78-1315-00.

Figure 6:

A78-1314-01

The Limitations of Sounders and Strobes

System Sensor’s sounder and signal strobe is designed to provide fire and

security hazard warning.

The strobe is for supplementary signaling use only.

The sounder or sounder/strobe combination will not work without

power. The sounder or sounder/strobe gets its power from the fire or se-

curity panel monitoring the alarm system. If power is cut off for any reason, the sounder or sounder/strobe combination will not provide the

desired audible or visual warning.

The sounder may not be heard. The loudness of the sounder meets or

exceeds current Underwriters Laboratories’ standards. however, the

sounder may not alert a sound sleeper or one who has recently used drugs

or has been drinking alcoholic beverages. The sounder may not be heard if

it is placed in an area which is isolated by a closed door, or if it is located

on a different floor from the person in hazard or if placed too far away to

be heard over the ambient noise such as traffic, air conditioners, machin-

Three-Year Limited Warranty

System Sensor warrants its enclosed sounder/strobe to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this sounder/strobe. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of

the sounder/strobe which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll

free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

A78-1778-00

WARNING

ery, or music appliances that may prevent alert persons from hearing the

alarm. The sounder may not be heard by persons who are hearing im-

paired.

The signal strobe may not be seen. The electronic visual warning signal

meets or exceeds current Underwriters Laboratories’ standard 1638. The

visual warning signal is suitable for direct viewing and must be installed

within an area where it can be seen by building occupants. The strobe

must not be installed in direct sunlight or areas of high light intensity

where the visual flash might be disregarded or not seen. The strobe may

not be seen by the visually impaired.

The signal strobe may cause seizures. Individuals who have a positive

photic response to visual stimuli with seizures, such as epileptics, should

avoid prolonged exposure to environments in which strobe signals, including this strobe, are activated.

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Technical Manuals Online! - http://www.tech-man.com

2 I56-305-07

© System Sensor 1996

Page 3

INSTALLATION AND MAINTENANCE INSTRUCTIONS

PS12/24ADA Series Strobes with

Mini-sounder for Fire Protective

Signaling Systems

Table 1. PS12/24ADA Series Electrical Ratings

Model

PS24110ADA

PS24110ADAW

PS2475ADA

PS2475ADAW

PS2415ADA

PS2415ADAW

PS1215ADA

PS1215ADAW

PS241575ADA

PS241575ADAW

PS121575ADA

PS121575ADAW

Supply

Voltage

Range

20-30V 225

20-30V 185

20-30V 90

12-17V 182

20-30V 108

12-17V 240

* Horn current is 12mA@12VDC, 15mA@24VDC

Operating Current from Regulated Supply Operating Current from

Average

Operating

Current

Horn/

Strobe*

Average

Operating

Current

Strobe

Only

210

170

75

170

93

225

Current

Peak

Peak

Inrush

Current

(mA)

10.5V/17V

Current

(mA in

access of

Peak)

(mA)

20/30V

470/500 – 0

385/400 – 0

160/180 – 0

– 360/380 0

210/220 – 0

– 510/560 0

Average

Operating

Current

(mArms)

Horn/Strobe*

260

215

105

212

135

285

3825 Ohio Avenue, St. Charles, Illinois 60174

Full-Wave Rectified Unfiltered Supply

Average

Operating

Current

(mArms)

Strobe Only

245

200

90

220

120

270

Peak Current

Peak Current

(mA)

20Vrms/

30Vrms

400/500 –

320/370 –

275/290 –

275/290 –

10.5Vrms/

17Vrms

– 330/380

– 500/530

(mA)

Inrush Current

(Amps in

excess

of Peak)

0.08

0.04

0.02

0.02

1

0.02

A Division of Pittway

1-800-SENSOR2, FAX: 630-377-6495

NOTE: In-rush current du-

ration is less than

20 microseconds

(0.00002 seconds).

NOTICE: This manual should be left with the owner/user

of this equipment.

General Description

The National Fire Protection Association has published

standards and recommended practices for the installation

and use of the above appliances. It is recommended that

the installer be familiar with these requirements, with local

codes, and any special requirements of the local fire

authority having jurisdiction.

The Piezo electronic sounder and signaling strobe are

intended to be connected to the alarm indicating circuit of a

UL-listed fire alarm control panel. Both are compatible with

DC line supervision. The electronic sounder can be

connected to either 12 or 24 VDC panels. Models

PS2415ADA, PS2475ADA, PS24110ADA, and PS241575ADA

require 24 volt panels. Models PS1215ADA and

PS121575ADA require 12 volt panels. Panels may have full-

Figure 1. Vertical and horizontal light distsribution:

wave rectified, unfiltered power supplies. The strobes

produce one flash per second (nominal) with continuous

nominal voltage applied.

The sounder/strobe strobe is rated for 0° to 49° C and is

NOT suitable for outdoor use.

The rated light output of the PS2415ADA, PS1215ADA,

PS241575ADA, and PS121575ADA is 15 cd (See Figure 1).

The rated light output of the PS2475ADA is 75 cd (See

Figure 1).

The rated light output of the PS24110ADA is 110 cd (See

Figure 1).

NOTE: The 15/75 cd strobe has been measured to be 75 cd

@ 0° viewing angle.

Percent of

0˚

45˚

90˚ –90˚

–45˚

LIGHT

Degrees Rating

0 100

5 - 25 90

30 - 45 75

50 55

55 45

60 40

65 35

70 35

75 30

80 30

85 25

90 25

D900-08-00 1 I56-732-04

Technical Manuals Online! - http://www.tech-man.com

Page 4

Greater than 90 dBA measured in anechoic room at 10 feet,

24 volts (see Figure 2 for other voltages); 79 dBA minimum

measured in UL reverberant room @ 12V and 82 dBA @

24V.

Figure 2:

90

89

NOTE: All models can be powered using full wave recti-

fied unfiltered supplies. Under no circumstances

can PS24ADA series devices input voltage exceed

33 VDC or be less than 16 VDC (16-33Vrms for fullwave rectified, unfiltered supplies). Under no circumstances can a PS12ADA series device input

voltage exceed 18.7 VDC or be less than 9.6 VDC

(9.6 - 18.7Vrms for full-wave rectified, unfiltered

supplies).

Installation

A. General:

Phillips head screws are used to attach PS12/24ADA to

semi-flush plate or the electrical outlet box. Slotted head

screws are used to attach semi-flush plate to outlet box.

See Figures 3 and 4 for wiring methods.

NOTE: Do not loop wires under the terminal screw. Wires

connecting the device to the panel must be broken

at the device terminal connection in order to

maintain electrical supervision.

The PS12/24ADA is designed for wall mounting ONLY.

It is intended for mounting to a standard 2-1/2" deep

single gang box which allows sufficient clearance for

conduit entrance.

88

87

dBA output

86

85

84

10 12 14 16 18 2 0 22

Voltage

All strobes must be mounted so that the top of the lens is

24 inches (61cm) below ceilings or as required by the

authority having jurisdiction.

B. Sounder/Strobe combination mounting:

1. Surface Mount: (See Figure 5)

2. Semi-Flush Mount: (See Figures 6 and 7)

3. Semi-Flush Mount with Plaster Ring or Double Gang

Box: (See Figure 8)

Installation procedures must conform to all applicable codes

and the requirements of the authority having jurisdiction.

NOTE: The rated output of the sounder is specified at 10

feet. It cannot be assumed that the output will

meet the NFPA standard of 15 dB over ambient

noise at all locations within a room. Additional

sounders may be needed to ensure sound output

level complies with NFPA requirements.

Figure 3. Operating horn and strobe in tandem:

From

Control

Panel

or

Next

Device

Previous

Device

Polarity shown in alarm condition. Polarity is reversed in

supervisory condition.

D900-08-00 2 I56-732-04

EOL

A78-2663-00

Figure 4. Operating horn and strobe independently:

To

or

From

Control

Panel

or

Previous

Device

Blk

Red

Cut and

Remove for

Independent

Operation

Note: Remove paper

shield; cut and

remove red and

black wires between

the horn and strobe.

When finished wiring,

place paper shield

back on unit.

Polarity shown in alarm condition. Polarity is reversed in

supervisory condition.

Device

Technical Manuals Online! - http://www.tech-man.com

To

Next

A78-2664-00

Page 5

C

C

D

D

C

C

Screw types used in Figures 5 – 8 below:

A=#6-32x1-1/2" Phillips Oval Head

B=#8-32x5/8" Slotted Pan Head

C=#6-32x5/8" Slotted Pan Head

D=#8 Phillips Oval Head Sheet Metal

Figure 5. Surface mount to single gang box:

A

A

1) Complete Field Wiring (see Figure 3)

2) Screw PS12/24ADA to Outlet Box with A Screws

A78-2602-00

Figure 6. Semi-flush mount to single gang box:

A

A

A78-2604-00

1. Complete Field Wiring (See Figure 3)

2. Screw PS12/24ADA to Outlet Box with A Screws

Figure 7. Semi-flush mount to 4" box:

B

B

D

D

A78-2603-00

1. Screw Semi-Flush Plate to 4" Box with B Screws

2. Complete Field Wiring (See Figure 3)

3. Screw PS12/24ADA to Semi-Flush Plate with D Screws

D900-08-00 3 I56-732-04

Technical Manuals Online! - http://www.tech-man.com

Figure 8. Semi-flush mount with plaster ring or double

gang box:

1. Screw Semi-Flush Plate to Box with C Screws

A78-2605-00

2. Complete Field Wiring (See Figure 3)

3. Screw PS12/24ADA to Semi-Flush Plate with D Screws

Page 6

The Limitations of Sounder/Strobes

The Sounder and/or Strobe will not work without power. The sounder/

strobe gets its power from the fire/security panel monitoring the alarm

system. If power is cut off for any reason, the sounder/strobe will not provide the desired audio or visual warning.

The Sounder may not be heard. The loudness of the sounder meets (or

exceeds) current Underwriters Laboratories’ standards. However, the

sounder may not alert a sound sleeper or one who has recently used drugs

or has been drinking alcoholic beverages. The Sounder may not be heard

if it is placed on a different floor from the person in hazard or if placed too

far away to be heard over the ambient noise such as traffic, air conditioners, machinery or music appliances that may prevent alert persons from

hearing the alarm. The Sounder may not be heard by persons who are

hearing impaired.

WARNING

must be installed within an area where it can be seen by building occupants. The strobe must not be installed in direct sunlight or areas of high

light intensity (over 60 foot candles) where the visual flash might be disregarded or not seen. The strobe may not be seen by the visually im-

paired.

The signal strobe may cause seizures. Individuals who have a positive

photic response to visual stimuli with seizures, such as epileptics, should

avoid prolonged exposure to environments in which strobe signals, including this strobe, are activated.

System Sensor recommends that the Multi-Alert Sounder and Signal

Strobe always be used in combination so that the risks from any of the

above limitations are minimized.

The Signal Strobe may not be seen. The electronic visual warning signal

that flashes at least once every three seconds meets or exceeds current Underwriters Laboratories’ standard 1971 and uses an extremely reliable xenon flash tube. The visual warning signal is suitable for direct viewing and

Three-Year Limited Warranty

System Sensor warrants its sounder/strobe to be free from defects in materials and workmanship under normal use and service for a period of three

years from date of manufacture. System Sensor makes no other express

warranty for this sounder/strobe. No agent, representative, dealer, or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this

Warranty shall be limited to the repair or replacement of any part of the

sounder/strobe which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll free

number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

D900-08-00 4 I56-732-04

Technical Manuals Online! - http://www.tech-man.com

The signal strobe cannot operate from coded power supplies. Coded

power supplies produce interrupted power. The strobe must have an uninterrupted source of DC power in order to operate correctly.

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

© System Sensor 1996

Loading...

Loading...