Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3070-002

M500M-4-20

4-20mA Analog Input Module

SPECIFICATIONS

SLC

Normal Operating Voltage: 15 to 32 VDC

Maximum Current Draw: 9.3 mA (LED on)

Average Operating Current: 1 mA (LED flashing)

External Supply

Normal Operating Voltage: 24 VDC Nominal

Standby Current: 10 mA

Maximum Current: 510 mA

Initiating Device

Maximum Current: 500 mA

Temperature Range: –10˚C to 60˚C

Humidity: 10% to 95% Non-condensing

Dimensions: 41/2˝ H × 4˝ W × 11/4˝ D (Mounts to a 4˝ square by 21/8˝ deep box.)

Accessories: SMB500 Electrical Box

BEFORE INSTALLING

This information is included as a quick reference installation guide. Refer to

the control panel installation manual for detailed system information. If the

modules will be installed in an existing operational system, inform the operator and local authority that the system will be temporarily out of service. Disconnect power to the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

The M500M-4-20 4-20mA Analog Input Module is intended for use in intelligent, two-wire systems, where the individual address of each module is

selected using the built-in rotary switches. This module allows intelligent panels to interface and monitor two-wire or three-wire sensors, that produce a

4-20mA signal output. It transmits the status (normal, open, or alarm) of one

sensor back to the control panel. The M500M-4-20 has a panel controlled LED

indicator. Only one sensor can be connected to the M500M-4-20.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a listed compatible system control panel only.

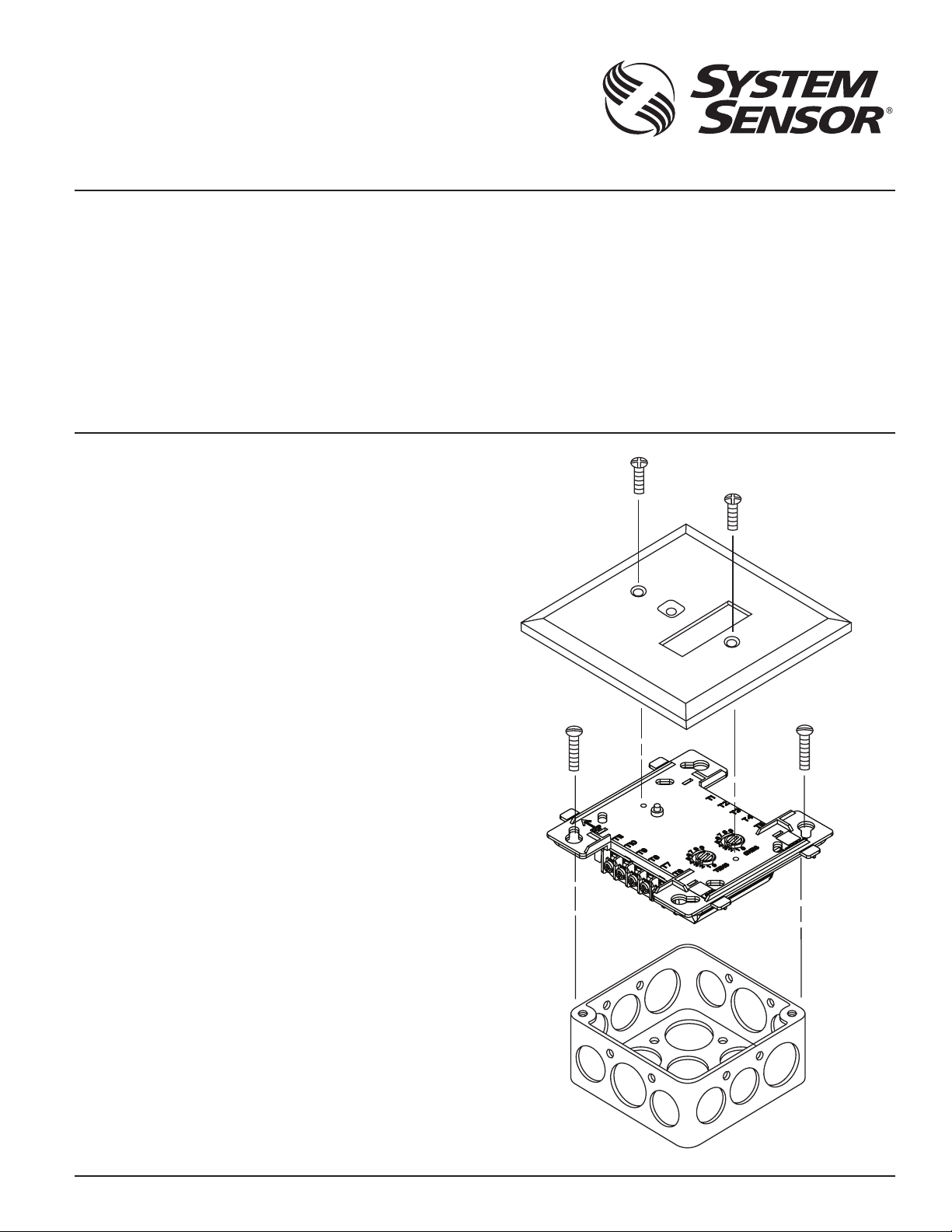

MOUNTING

The M500M-4-20 mounts directly to 4-inch square electrical boxes (see Figure

1). The box must have a minimum depth of 21/8 inches. Surface mounted

electrical boxes (SMB500) are available from System Sensor.

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations. This module is intended for powerlimited wiring only.

1. Install module wiring in accordance with the job drawings and appropriate wiring diagrams.

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as shown in

Figure 1.

FIGURE 1. MODULE MOUNTING:

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

C0959-00

SS-460-000 1 I56-3070-002

Page 2

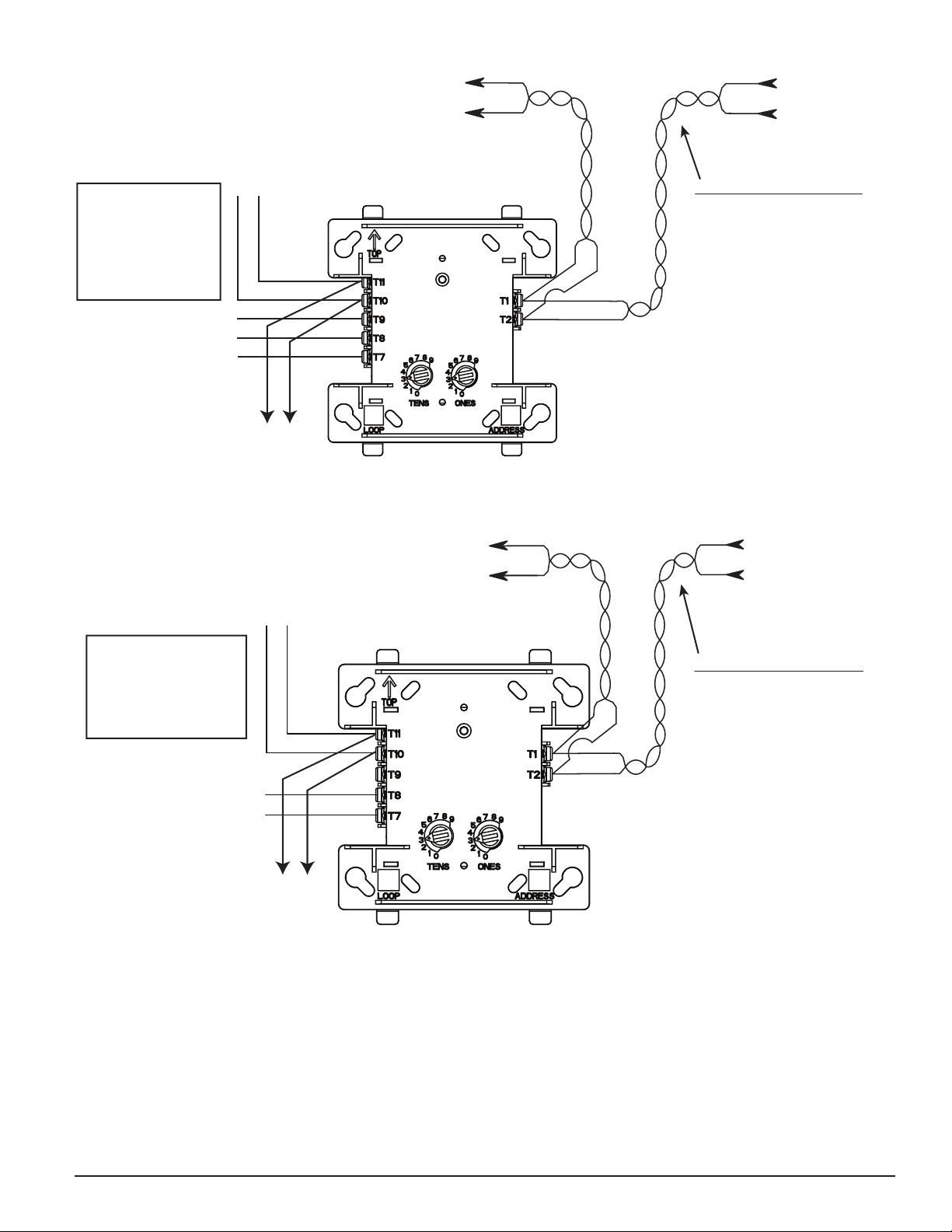

(+)

(–)

(+)

(–)

(+)

(–)

TERMINAL WIRING MUST

BE POWER LIMITED.

DO NOT LOOP WIRE UNDER TERMINALS.

BREAK ALL WIRE RUNS TO PROVIDE

SUPERVISION OF CONNECTIONS.

M500M-4-20

MODULE

TO NEXT

DEVICE

SIGNAL LINE CIRCUIT (SLC) 32

VDC MAX.

TWISTED PAIR

IS RECOMMENDED

FROM PANEL OR

PREVIOUS DEVICE

SLC WIRING

24 VDC POWER

LIMITED

( + ) ( - )

(–) SENSE

(+)

{

TO 4-20mA

2-WIRE DEVICE

24 VDC POWER SUPPLY

ISOLATED, REGULATED,

POWER LIMITED PER

NFPA 70, UL 864 LISTED

FOR FIRE PROTECTION

SIGNALING USE WITH

BATTERY BACKUP.

TO NEXT

MODULE

(+)

(–)

(+)

(–)

(+)

(–)

TERMINAL WIRING MUST

BE POWER LIMITED

TO NEXT

DEVICE

M500M-4-20

MODULE

SIGNAL LINE CIRCUIT (SLC)

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

FROM PANEL OR

PREVIOUS DEVICE

SLC

WIRING

( - )

SENSE

( + )

{

TO 4-20mA

3-WIRE

DEVICE

DO NOT LOOP WIRE UNDER TERMINALS.

BREAK ALL WIRE RUNS TO PROVIDE

SUPERVISION OF CONNECTIONS.

24 VDC POWER

LIMITED

( + ) ( - )

24 VDC POWER

SUPPLY ISOLATED,

REGULATED, POWER

LIMITED PER NFPA 70,

UL 864 LISTED FOR

FIRE PROTECTION

SIGNALING USE WITH

BATTERY BACKUP.

TO NEXT

MODULE

FIGURE 2. 4-20 A MODULE 3-WIRE CONFIGURATION:

m

C1034-01

FIGURE 3. 4-20 A MODULE 2-WIRE CONFIGURATION:

m

C1035-01

SS-460-000 2 I56-3070-002

©2008 System Sensor

Loading...

Loading...