Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3870-001

M500FP Firephone Control Module

SPECIFICATIONS

Normal Operating Voltage: 15 to 32 VDC

Maximum Current Draw: 7.5mA (LED on)

Average Operating Current: 2.4mA (LED flashing)

SLC Wiring Resistance: 40 Ohms

Supervisory Wiring Resistance: 50 Ohms

Handset Offhook Resistance: 400 to 1,500 Ohms

External Supply Voltage (between Terminals T10 and T11)

Regulated 24VDC

Temperature Range: 32˚F to 120˚F (0˚C to 49˚C)

Humidity: 10% to 93% Non-condensing

Dimensions: 4.5” H x 4.275” W x 1.4”D (Mounts to a 4” square by 21/8” deep box.)

Accessories: SMB500 Electrical Box; CB500 Barrier

BEFORE INSTALLING

This information is included as a quick reference installation guide. If the

modules will be installed in an existing operational system, inform the operator and local authority that the system will be temporarily out of service.

Disconnect power to the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

M500FP Firephone Control Modules are intended for use in intelligent, twowire systems, where the individual address of each module is selected using

the built-in rotary switches. This module is used to connect a remote firefighter telephone to a centralized telephone console. A ringing sound is provided at each off-hook handset until it is connected to the console. Wiring to

individual telephone jacks and handsets is supervised, and status is reported

to the panel as NORMAL, TROUBLE, or TELEPHONE. The M500FP has two

pairs of output termination points available for fault-tolerant wiring, and includes a panel-controlled LED indicator.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to Listed compatible system control panels only.

MOUNTING

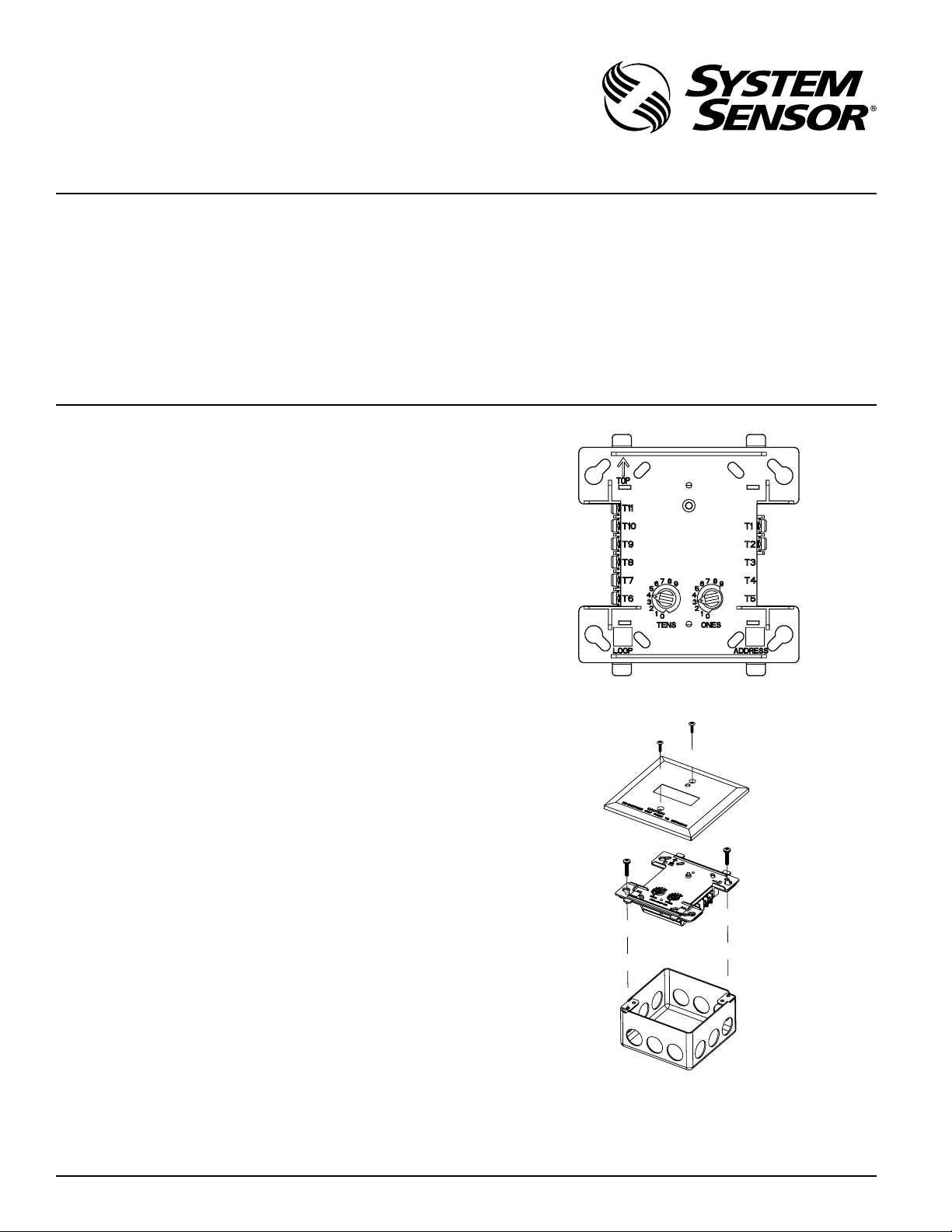

This module mounts directly to 4″ square electrical boxes (see Figure 2A).

The box must have a minimum depth of 21/8″. Flush mounted electrical boxes

(SMB500) are available.

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances and

regulations.

1. Install module wiring in accordance with the job drawings and appropriate wiring diagrams (Figures 3-4).

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as shown in

Figure 2.

FIGURE 1. CONTROLS AND INDICATORS

FIGURE 2. MODULE MOUNTING:

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

C1059-02

C1070-03

SS-460-010 I56-3870-001

Page 2

SHOWN IN ALARM

TELEPHONE CONSOLE MUST

ALL WIRING SHOWN IS SUPERVISED

(+)

ALL WIRING SHOWN IS SUPERVISED AND POWER LIMITED

SIGNAL LINE CIRCUIT (SLC)

(+)

CONNECT MODULES TO LISTED COMPATIBLE

WARNING

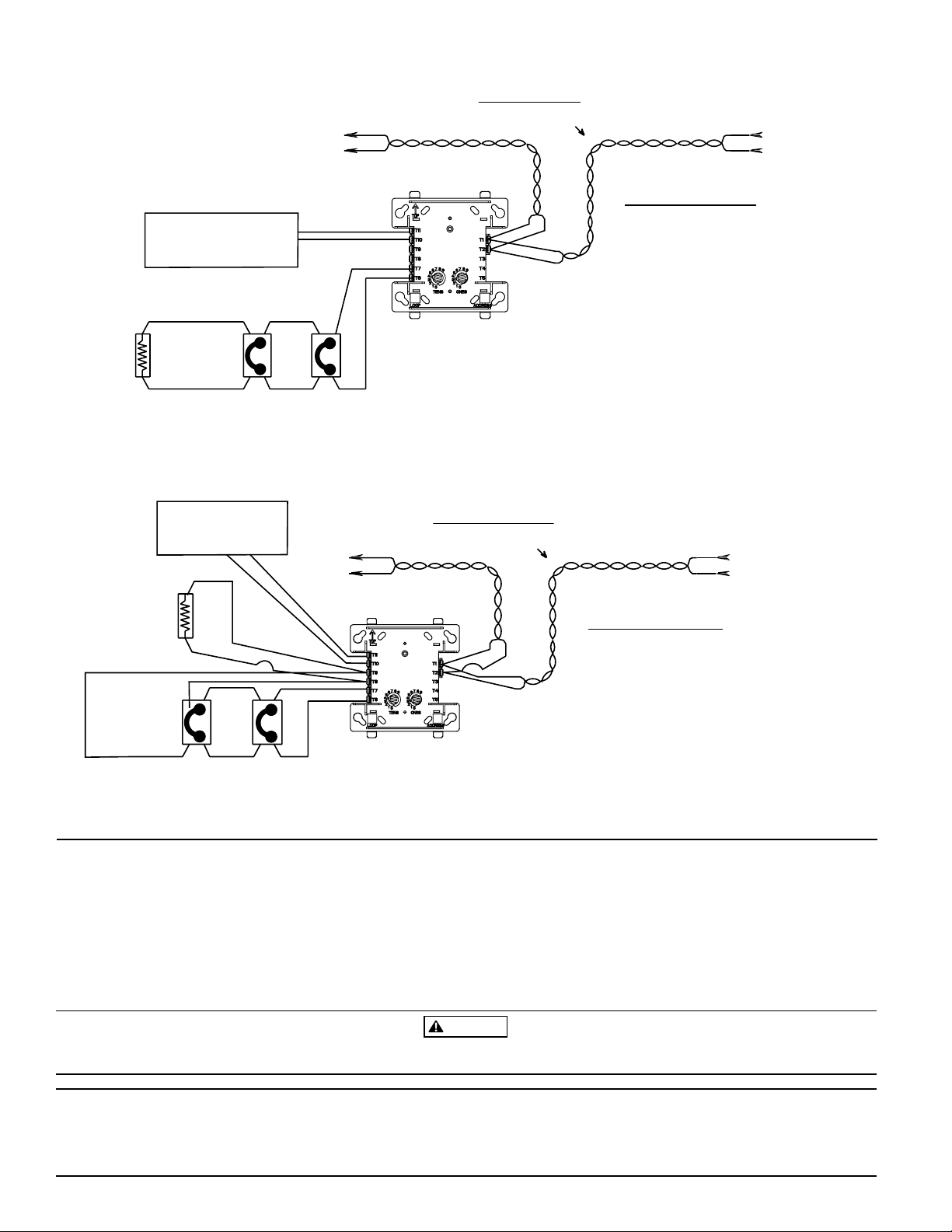

FIGURE 3. TYPICAL CIRCUIT CONFIGURATION, NFPA STYLE Y, CLASS B STYLE WIRING:

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

(-)

(+)

DO NOT LOOP WIRE AROUND TERMINALS.

BREAK ALL WIRE TO ENSURE

SUPERVISION OF CONNECTIONS.

3.9K EOL

RESISTOR

CONTROL PANELS ONLY

TELEPHONE CONSOLE

24 VOLTS DC POWER LIMITED

Relay Contact Rating:

24 VDC, 3 Amperes Maximum

TELEPHONE CONSOLE MUST

PROVIDE ITS OWN

WIRING SUPERVISION

(-)

TO NEXT

DEVICE

(-)

(-)

(+)

(-)

(+)

FIGURE 4. TYPICAL FAULT TOLERANT CIRCUIT CONFIGURATION, NFPA STYLE Z, CLASS A STYLE WIRING:

PROVIDE ITS OWN

WIRING SUPERVISION

TELEPHONE CONSOLE

24 VOLTS DC POWER LIMITED

Relay Contact Rating:

24 VDC, 3 Amperes Maximum

TO NEXT

DEVICE

AND POWER LIMITED

SIGNAL LINE CIRCUIT (SLC)

32 VDC MAX.

(-)

TWISTED PAIR

IS RECOMMENDED

(+)

(-)

FROM PANEL OR

(+)

PREVIOUS DEVICE

BRANCH CIRCUITS

MODULE POLARITIES ARE

SHOWN IN ALARM

CONNECT MODULES TO LISTED COMPATIBLE

CONTROL PANELS ONLY

(-)

FROM PANEL OR

(+)

PREVIOUS DEVICE

C1076-08

3.9K EOL

RESISTOR

(-)

(+)

(-)

(-)

(+)

(-)

(+)

(+)

BRANCH CIRCUITS

DO NOT LOOP WIRE AROUND TERMINALS.

BREAK ALL WIRE TO ENSURE

SUPERVISION OF CONNECTIONS.

MODULE POLARITIES ARE

C1077-07

THREE-YEAR LIMITED WARRANTY

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for the enclosed product.

No agent, representative, dealer, or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the product which

is found to be defective in materials or workmanship under normal use and service

during the three year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns Department, RA

#__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing

the malfunction and suspected cause of failure. The Company shall not be obligated to

replace units which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

All relay switch contacts are shipped in the standby state (open) state, but may have transferred to the activated (closed) state during shipping. To ensure that

the switch contacts are in their correct state, modules must be made to communicate with the panel before connecting circuits controlled by the module.

FCC STATEMENT

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation

is subject to the following two conditions: (1) This device may not cause harmful radiation, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

SS-460-010 2 I56-3870-001

© System Sensor 2009

Loading...

Loading...