Page 1

M211E-RF

-20°C

+=

317 g

I 56- 4267- 001

mm

mm

Load -VE Load +VE

RADIO SYSTEM INPUT / OUTPUT MODULE

INSTALLATION INSTRUCTIONS

E N G L I S H

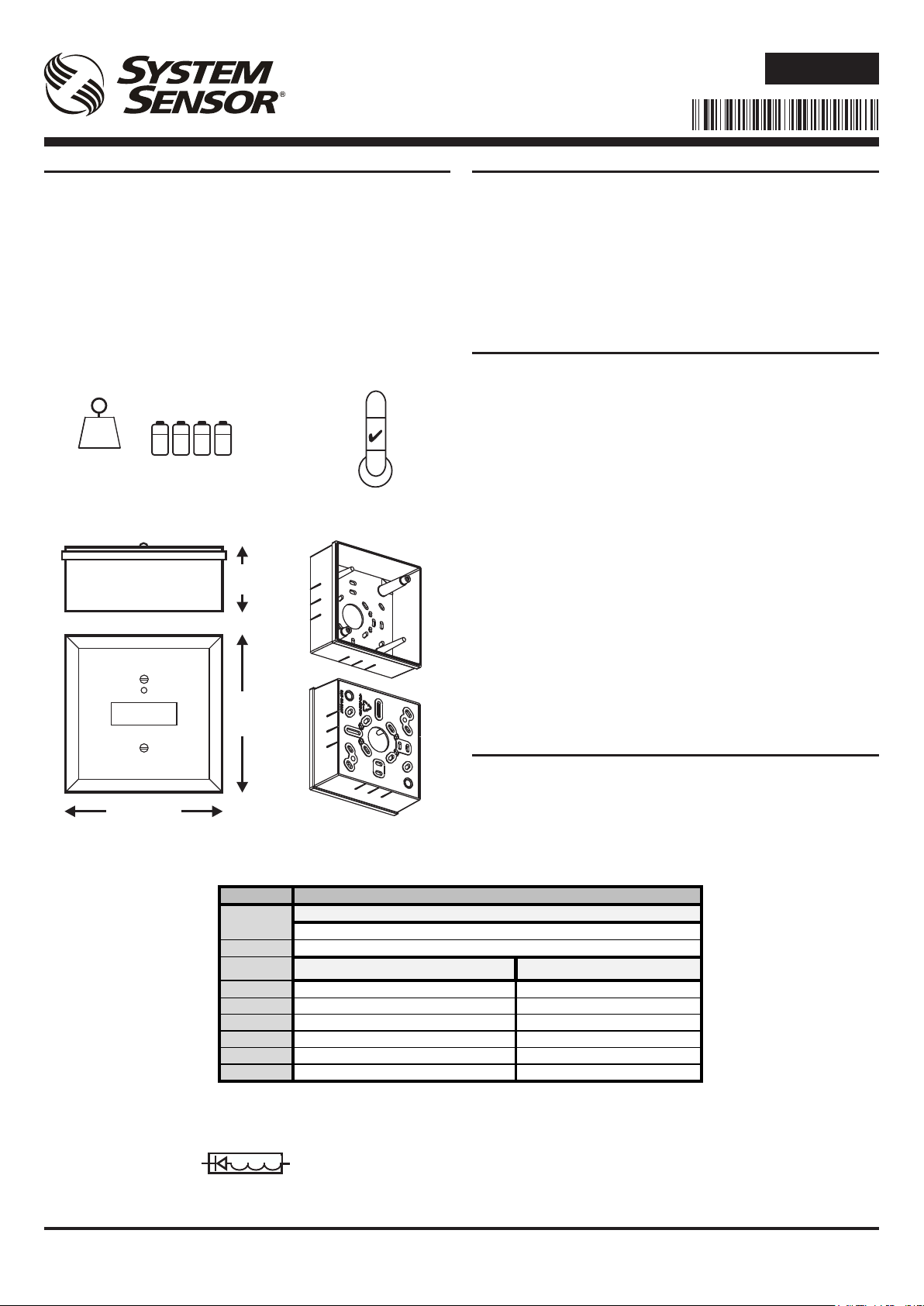

PARTS LIST

Module unit 1

SMB500 back box 1

Front cover 1

Batteries (Duracell Ultra 123 or Panasonic Industrial 123) 4

Back box xing screws and wall plugs 2

Module xing screws 2

3-pin terminal block 2

2-pin terminal block 1

47 k-ohm EOL resistor 2

18 k-ohm alarm resistor 1

Module installation instructions 1

SMB500 back box installation instructions 1

60°C

251 g

(66 g)

Figure 1: IO module + back box outside dimensions

58

125

125 mm

Table 1: Terminal Connections

DESCRIPTION

The M211E-RF radio input-output module is a battery operated RF

device designed for use with the M200G-RF radio gateway, running

on an addressable re system (using a compatible proprietary

communication protocol).

It is a dual module having separate input and output capability,

combined with a wireless RF transceiver and is supplied with a

wireless back box.

This device conforms to EN54-18 and EN54-25. It complies with the

requirements of 2014/53/EU for conformance with the RED directive.

SPECIFICATIONS

Supply Voltage: 3.3 V Direct Current max.

Standby Current: 122 µA@ 3V (typical in normal operating mode)

Red LED Current Max: 2 mA

Green LED Cur. Max: 5.5 mA

Re-Sync Time: 35s (max time to normal RF communication from

Batteries: 4 X Duracell Ultra123 or Panasonic Industrial 123

Battery Life: 4 years @ 25oC

Radio Frequency: 865-870 MHz. Channel width: 250kHz

RF Output Power: 14dBm (max)

Range: 500m (typ. in free air)

Relative Humidity: 5% to 95% (non-condensing)

Terminal Wire Size: 0.5 - 2.5 mm

IP Rating: IP20

Input Module

End-of-Line Resistor: 47K

Supervision Current: 34 µA typical

Output Module

End-of-Line Resistor: 47K

Supervision Current: 60 µA typical

Relay Contacts: 2 A @ 30 VDC (resistive load)

External Power Supply Unit

7.53

Voltage: 30V DC max. 8V DC min.

Supervision Fault Voltage: 7V DC typical

device power on)

2

INSTALLATION

This equipment and any associated work must be installed in

accordance with all relevant codes and regulations.

Figure 1 details the dimensions of the back box and cover.

Spacing between radio system devices must be a minimum of 1m

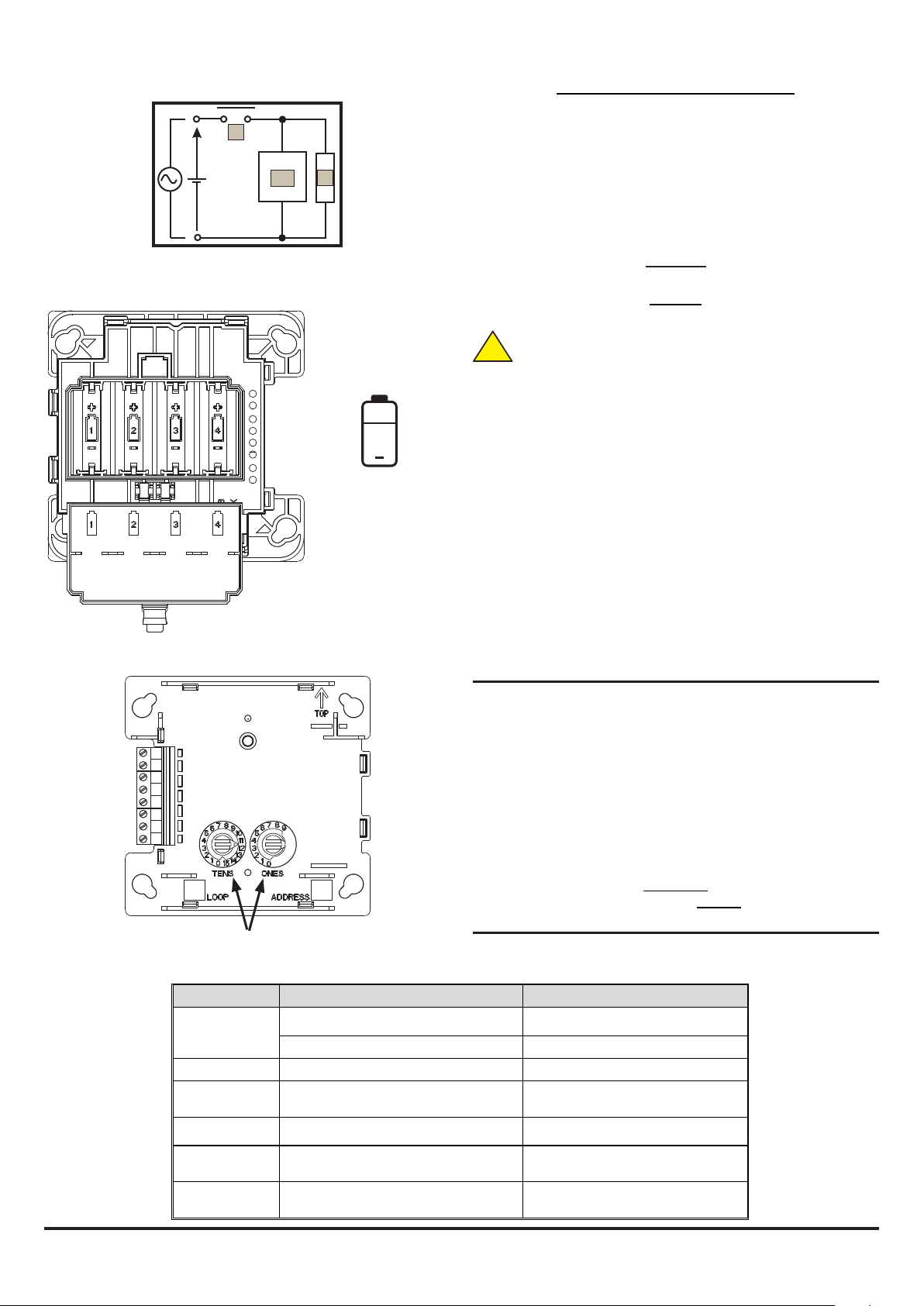

Table 1 shows the wiring conguration of the module.

TERMINAL

Figure 2: Diode Polarity

CONNECTION / FUNCTION

Input Module

Input -ve

1

Input +ve

2

Output module (Supervised mode) Output module (Relay mode)

3 Connect to T8 Relay NO (normally open)

4 To load +ve Relay C (common)

5 Connect to T7 Relay NC (normally closed)

6 Supervision: connect to load -ve Not used

7 To ext PSU –ve Not used

8 To ext PSU +ve Not used

Input Module requires 47K EOL for normal operation.

Output Module requires 47K EOL at the load for normal

operation in supervised mode.

If the load is a low impedance (compared to the EOL) a

series diode should be added for correct load supervision

(see Figure 2 for diode polarity).

D200-309-00 I56-4267-001Pittway Tecnologica S.r.l. Via Caboto 19/3, 34147 TRIESTE, Italy

Page 2

Figure 3: Switching Inductive Loads

(i)

+

(iii)

(ii)

Figure 4: Rear of Module with

Battery Compartment and Cover

+

NOTE POLARITY

Figure 5: Front of Module with Address Switches

1

2

3

4

5

6

7

8

ROTARY ADDRESS SWITCHES

Table 2: Module Status LEDs

WARNING: Switching Inductive Loads

See Figure 3. Inductive loads can cause switching surges, which may

damage the module relay contacts (i).

To protect the relay contacts, connect a suitable Transient Voltage

Suppressor (iii) - for example 1N6284CA - across the load (ii) as

shown in Figure 3.

Alternatively, for unsupervised DC applications, t a diode with a

reverse breakdown voltage greater than 10 times the circuit voltage.

Figure 4 details the battery installation and Figure 5 the location of the

address switches.

Important

Batteries should only be installed at the time of commissioning

Warning

Observe the battery manufacturer’s precautions for use

and requirements for disposal.

Possible explosion risk if incorrect type is used

!

Do not mix batteries from dierent manufacturers.

When changing the batteries, all 4 will need to be replaced

Using these battery products for long periods at temperatures

below -20°C can reduce the battery life considerably

(by up to 30% or more)

Fixing the module: Remove the 2 screws from the front cover to

reveal the RF module. Remove the RF module from the back box (see

below). Screw the back box to the desired position on the wall using

the xings provided. Ret the module in the box (see below). Wire

the plug-in terminals as required by the system design. Ret the front

cover to protect the module.

Removing the module from the back box: Slacken o the 2 xing

screws, twist the module clockwise slightly and lift out. Reverse this

process to ret the module.

Device Removal Warning: In a working system, an alert message will

be sent to the CIE via the Gateway when the front cover is removed

from the back box.

SETTING THE ADDRESS

Set the loop address by turning the two rotary decade switches on

the front of the module using a screwdriver to rotate the wheels to the

desired address.

Except when Advanced Protocol (AP) is being used (see below) the

dual I/O module will take two module addresses on the loop; the input

module address will be the number shown on the switches (N), the

output module address will be incremented by one (N+1). So for a

panel with 99 addresses, select a number between 01 and 98.

In Advanced Protocol (AP) addresses in the range 01-159 are available,

depending on panel capability (check the panel documentation for

information on this).

Important

Set the loop address on the module Before inserting the batteries

LED INDICATORS

The radio module has a tri-colour LED indicator that shows the status

of the device (see Table 2):

Module Status LED State Meaning

Power-on

initialisation

(no fault)

Fault Blink Amber every 1s.

Un-commissioned

Sync

Normal Controlled by panel; can be set to Red ON,

Idle

(low power mode)

Long Green pulse Device is un-commissioned

3 Green blinks Device is commissioned

Red/Green double-blink every 14s

(or just Green when communicating).

Green/Amber double-blink every 14s

(or just Green when communicating).

Green ON, periodic blink Green or OFF.

Amber/Green double-blink every 14s Commissioned RF network is in standby;

(factory default)

Device has an internal trouble

Device is powered and is waiting to be

programmed.

Device is powered, programmed and

trying to find/join the RF network.

RF communications is established;

device is working properly.

used when the gateway is powered off.

D200-309-00 I56-4267-001 Pittway Tecnologica S.r.l. Via Caboto 19/3, 34147 TRIESTE, Italy

Page 3

PROGRAMMING AND COMMISSIONING

Conguring the Output Module Mode

The output module is supplied congured as a Supervised Output

Module (factory default setting). To change the output to relay

mode (Form C - volt-free changeover contacts) requires a separate

programming operation using the Device Direct Command in AgileIQ

(See Radio Programming and Commissioning Manual - ref. D200-

306-00 for details.)

Starting with an un-commissioned module:

1) Remove it from the back box.

2) Ensure that the address is set to 00 (default setting).

3) Insert the batteries.

4) Select the Device Direct Command tab in AgileIQ.

5) Double click on the screen to reveal the list of options and follow

the instructions to congure the output module mode.

Note: Remove the batteries from the device afterwards if the system

commissioning operation is not about to be done.

It is recommended that the output module conguration is noted for

future reference on the module label after commissioning:

OUTPUT MODULE: Supervised ¨ Relay ¨

Commissioning

1) Remove the module from the back box.

2) Ensure that the correct address has been set.

3) Insert the batteries.

4) Ret the module and replace the back box front cover.

To load network parameters into the RF module, it is necessary to link

the RF gateway and the RF module in a conguration operation using

the AgileIQ software tool. At commissioning time, with the RF network

devices powered on, the RF gateway will connect and program them

with network information as necessary.

The RF module then synchronises with its other associated devices

as the RF mesh network is created by the Gateway. (For further

information, see the Radio Programming and Commissioning

Manual - ref. D200-306-00.)

NOTE: Do not run more than one USB interface at a time to

commission devices in an area.

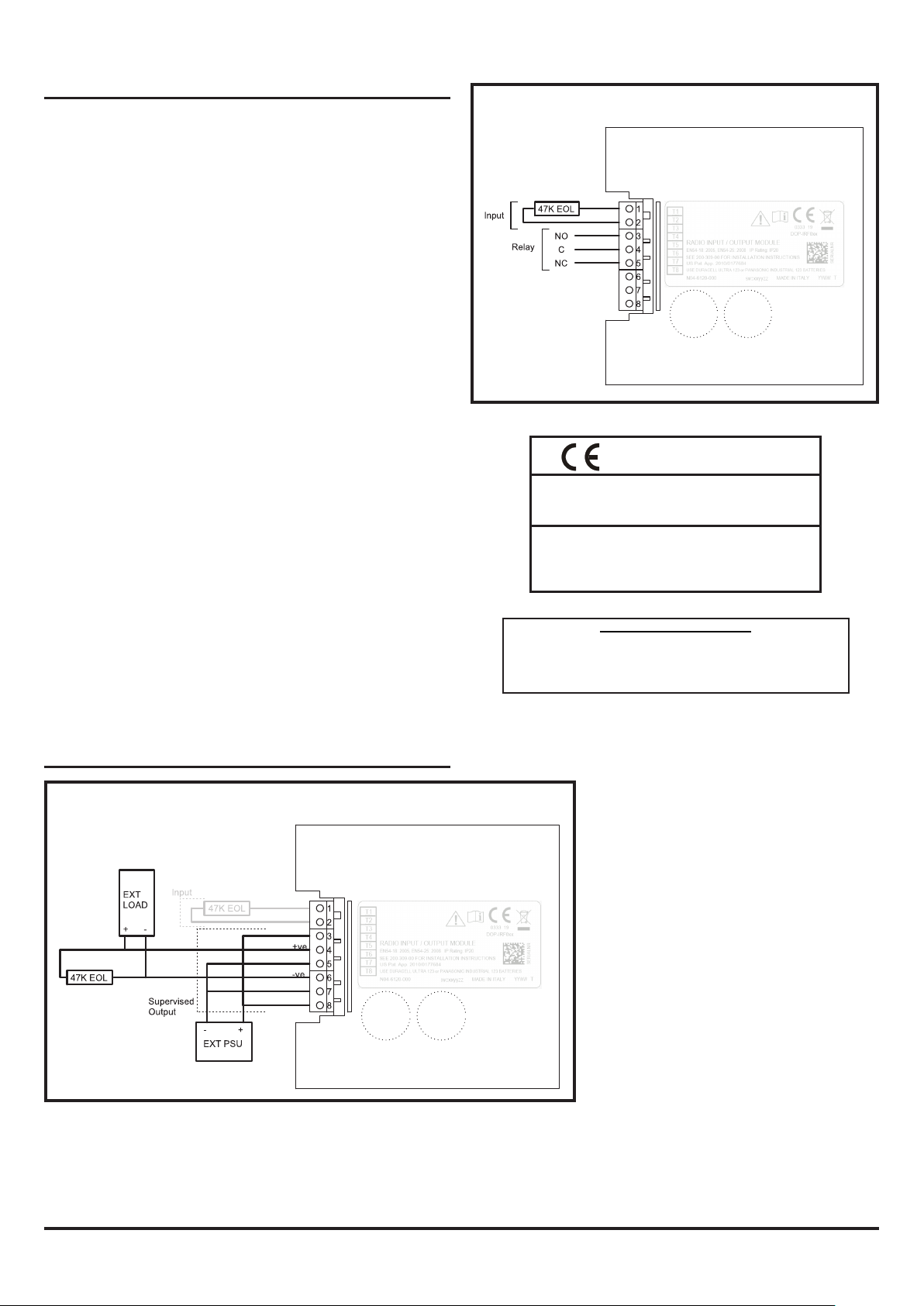

WIRING DIAGRAMS

Figure 7: Input / Output Module Relay Mode

0333 19

Honeywell Products and Solutions Sàrl

(Trading as System Sensor Europe)

Zone d’activités La Pièce 16

CH-1180 ROLLE, Switzerland

EN54-25: 2008 / AC: 2010 / AC: 2012

Components Using Radio Links

EN54-18: 2005 / AC: 2007 Input/Output Devices

for use in re detection and re alarm systems for buildings

Hereby, Honeywell Products and Solutions Sàrl declares that the radio

equipment type M211E-RF is in compliance with directive 2014/53/EU

EU Declaration of Conformity

The full text of the EU DoC can be requested from:

HSFREDDoC@honeywell.com

DOP-IRF024

Patents Pending

Figure 6: Output Module Supervised

D200-309-00 I56-4267-001Pittway Tecnologica S.r.l. Via Caboto 19/3, 34147 TRIESTE, Italy

Loading...

Loading...