Page 1

Specifications

Contact Ratings: 0.6 A @ 125VAC; 2 A @ 30VDC

Triggering Threshold Bandwidth

(Flow Rate): 3 gpm maximum

Static Pressure Rating: 450 PSI (Max)

Dimensions, Installed: 3.5″H x 3.0″W x 6.7″D

Operating Temperature Range: 32°F to 120°F (0°C to 49°C)

Compatible Pipe: See Low Flow models listed below

Shipping Weight: 4 to 7 lb., according to size.

Enclosure Rating: NEMA Type 4

Voltage Range: 8.4–35 V (DC–FWR); 108–132 VAC

Power Requirements: 300µA at 12 and 24 V (DC–FWR) or

400µA at 120 VAC

U. S. Patent Number: 3,845,259; 6,084,521; 6,275,160

Panel Compatibility:

The LFD waterflow indicators may receive power and operate on a twowire initiating zone of a fire alarm control panel. When determining compatibility of these devices, the standby operating voltage of the control

panel must be between 8.5 and 35 volts. In the standby mode, the LFD

draws a maximum current of 0.3mA. In alarm, the LFD acts as a short

across the initiating zone (similar to a manual fire box). For two wire

conventional fire alarm control panels, not more than 5 waterflow

indicators may be connected to a single initiating zone. The maximum

retard/reset time of the waterflow indicator plus the initiating zone shall

not exceed 90 seconds.

For two wire addressable control panels, the number of waterflow indicators connected to the panel’s signaling line circuit shall be limited

only by the circuit’s current capacity.

D770-30-00 1 I56-1620-002R

LFD Accuflow™Low Flow

Vane-type Waterflow Detector

with Solid State Time Retard

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Important

Please Read Carefully And Save

This instruction manual contains important information about the installation and operation of waterflow detectors. Purchasers who install waterflow detectors for use by others must leave this manual or a copy of it with

the user.

Read all instructions carefully before beginning. Follow only those instructions that apply to the model you are installing.

Use vane-type waterflow detectors in wet-pipe systems only. Do NOT use

them in dry pipe, deluge, or preaction systems. The sudden inrush of

water in such systems may break the vane or damage the mechanism.

Do not use in potentially explosive atmospheres. Do not allow unused

wires to remain exposed.

Principles Of Operation

Vane-type waterflow detectors mount to water-filled pipes in sprinkler systems. Waterflow in the pipe deflects a vane, which produces a switched

output–usually after a specified delay. All waterflow detectors have a controlled delay mechanism. Delays do NOT accumulate; they reset if the

flow of water stops before the entire delay has elapsed. All switches actuate when the water flow rate is 3 gallons per minute or greater. This

System Sensor installation manual covers the following waterflow detectors for sprinkler/fire alarm applications.

Low Flow Models Nominal Pipe O.D. Nominal Wall Thickness

LFD20 2″ (60.3mm) 3.9mm to 4.5mm

LFD25-73MM 21⁄2″ (73.0mm) 4.8mm to 5.2mm

LFD25-76MM 21⁄2″ (76.0mm) 4.3mm to 4.7mm

LFD30-2 3″ (88.9mm) 5.0mm to 5.6mm

LFD40 4″ (114.3mm) 5.4mm to 6.4mm

The LFD models are approved for use on stainless steel and brass pipe

only.

Do NOT use any of the LFD models on any other pipe materials.

Do NOT install steel or iron pipe sections in copper piping for mounting a

waterflow detector. Incompatibility between the dissimilar metals causes

bimetallic corrosion.

CAUTION

CAUTION

Installation Guidelines

Before installing any waterflow alarm device, be thoroughly familiar with:

NFPA 72: National Fire Alarm Code

NFPA 13: Installation of Sprinkler Systems

NFPA 25: Inspection, Testing and Maintenance of Sprinkler Systems

NFPA 750: Water Mist Fire Protection Systems

Other applicable NFPA standards, local codes, and the requirements of the

authority having jurisdiction

NOTE: Installation methods other than those listed in this installation

manual may prevent the device from reporting the flow of water

in the event the associated sprinkler system is activated by a

fire. System Sensor is not responsible for devices that have been

improperly installed, tested, or maintained.

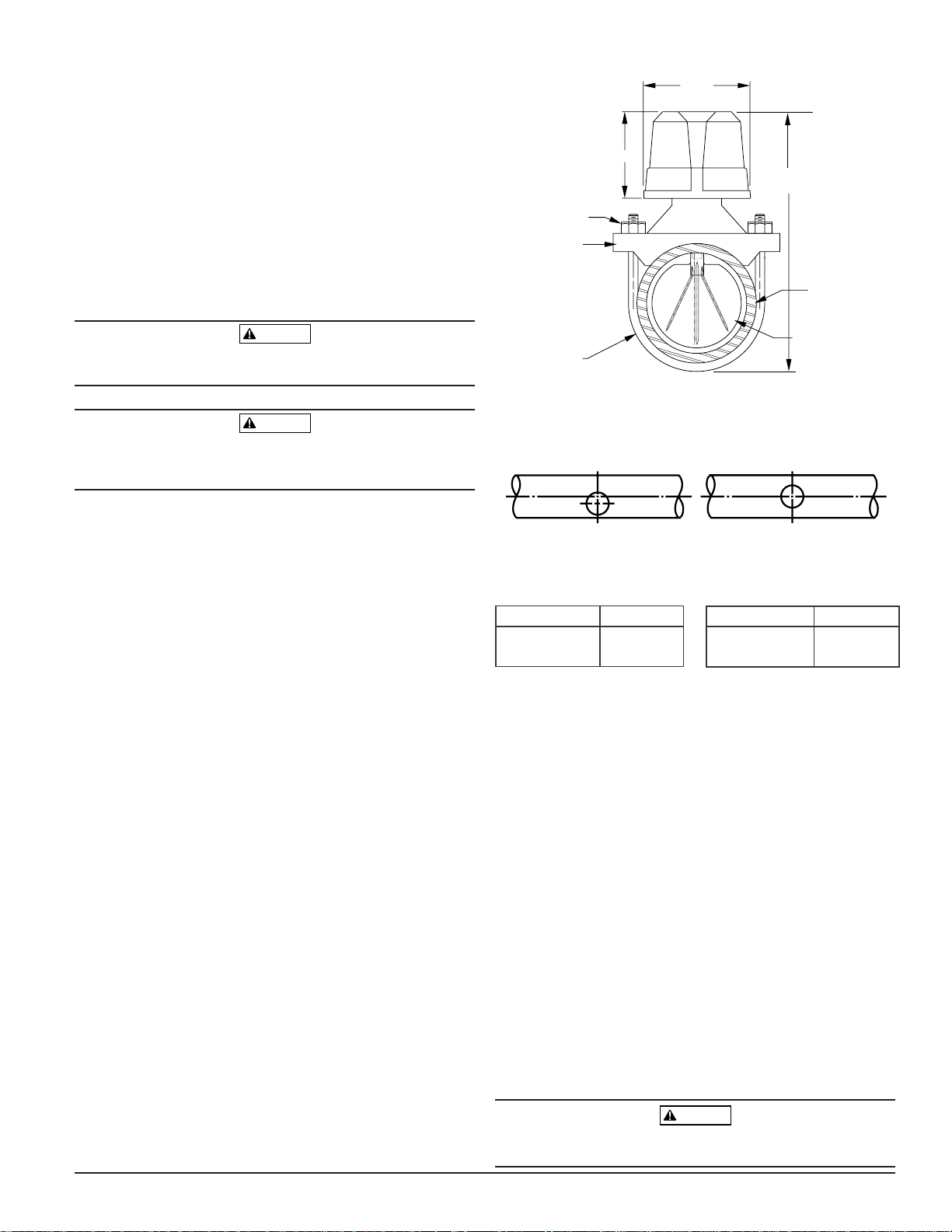

1. Mount the detector where there is adequate clearance for installation

and removal and a clear view of it for inspections. See Figure 1 for

mounting dimensions.

2.

Locate detector 6 to 7 ft. above the floor to protect from potential damage

.

3. On horizontal runs, position the detector on the top or side of the pipe.

Do not mount it upside down because condensation may collect in the

housing and impair the operation of the detector. For vertical flow

applications, mount the detector on pipe through which water flows

upward. Otherwise, the unit may not operate properly.

4. Mount the detector at least 6 inches from a fitting that changes the

direction of water flow and no less than 24 inches from a valve

or drain.

5. Be sure the direction-of-flow arrow matches the direction of flow in

the pipe.

Mounting Instructions

1. Drain the pipe.

2. Cut a hole at the desired location. Center the hole in the pipe, as

shown in Figure 2, and be sure the hole is perpendicular to the center

of the pipe. Before drilling, use a punch or scribe to mark the drill site

to prevent the bit from slipping. If the hole is off center, the vane will

bind against the inside wall of the pipe. Use a drill or hole saw to cut

a hole of the proper diameter. See Table 1 for hole size.

When drilling the hole with a hole saw, make certain that the center of the

cut does not remain in the pipe.

3. Remove burrs and sharp edges from the hole. Clean and remove all

scale and foreign matter from the inside of the pipe for one diameter

on each side of the hole to ensure free movement of the vane. Clean

the outside of the pipe to remove dirt, metal chips, and cutting lubricant.

CAUTION

Page 2

4. Seat the gasket against the saddle and mount the detector directly to

the pipe. Carefully roll the vane opposite the direction of flow and

insert it through the hole. Seat the saddle firmly against the pipe so

that the locating boss goes into the hole.

5. Install the U-bolt, tightening the nuts alternately to ensure a uniform

seal. See Table 2 for torque values.

6. Remove the metal cover with the tamper-proof wrench provided. Move

the actuator lever back and forth to check for binding. If the vane

binds, remove the detector and correct the cause before proceeding.

Pre-operation

Fill the sprinkler system and check for leaks around the waterflow detector. If it leaks, first check for the proper torque on the U-bolt nuts. If the

leak persists, drain the system and remove the detector (refer to

Maintenance). Check for dirt or foreign objects under the gasket, and

make sure that the pipe surface is not dented. Reinstall the detector and

check again for leaks. Do not proceed until all leaks have been stopped.

Be sure the direction-of-flow arrow points in the right direction or else

water flow will go unreported. See Figure 9.

Wiring

High Voltage. Electrocution Hazard. Do not handle live AC wiring or work

on a device to which AC power is applied. Doing so may result in injury or

death.

1. All models have two wires and two sets of terminals.

Relay Wires (W1 & W2 designated on PCB): These wires are connected to a latching normally open (as in No Flow) relay contact. They

are isolated from all electronics. They will close and cause a short when

water flows and the retard time elapses. They will remain shorted until

waterflow stops. Once waterflow stops, these contacts will re-open.

Power Terminals (T2 designated on PCB): This is a two screw terminal block. The Accuflow gets its power from these terminals. These terminals must have voltage present from the FACP or other suitable

source of power before anything will work. If no power is present, the

Accuflow will not provide proper alarm signals. These terminals will

accept power in any polarity as well as AC-line power.

Aux Relay Terminals (T1 designated on PCB): This is a THREE screw

terminal block. These terminals are connected to a latching Form C

relay. In no flow conditions, COM is connected to A. When flow is

detected COM will disconnect from A and connect to B. This relay will

latch in that state and reset after water stops flowing.

2. Adjust Dip Switch to desired time delay. See Figure 11. For Dip Switch

location, see Figure 9.

3. When connected to a listed sprinkler/fire alarm control panel, the initiating circuit must be nonsilenceable.

4. A ground screw is provided with all waterflow detectors. When

grounding is required, clamp wire with screw in hole located between

conduit entrance holes. See Figure 10A, page 4.

5. If a second conduit entry is required, remove the knockout plug using

a flat blade screwdriver as shown on Figure 10B, page 4. Strike sharply

with a hammer to pierce the wall of the knockout plug. Move to an

adjacent wall section and repeat until the plug falls out. Make sure that

the waterflow detector is supported adequately during this operation

to avoid injury.

NOTE: Power terminals must be connected to FACP or other non-

silenceable initiating circuit.

Operation Testing

Always notify a central station monitoring waterflow alarms before repairing, maintaining, or testing waterflow alarm devices.

1. Replace the cover and tighten the tamper proof screws with the tamper

proof wrench. Store the wrench in a secure place.

2. Open the inspector’s test valve and time how long it takes for the detector to indicate a flow condition. The detector should remain activated

until the inspector’s test valve is closed. Air pockets in the sprinkler

system may increase the apparent delay.

WARNING

CAUTION

A78-1609-00

Figure 1. Mounting dimensions:

3″

3-3/4″

Pipe saddle

U-bolt nut

Plastic vane

Pipe

U-bolt

Overall width = pipe diameter + 3″

Pipe diameter

plus 5-1/4″

Figure 2. Mounting hole location:

D770-30-00 2 I56-1620-002R

Maintenance

To prevent accidental water damage, control valves should be shut tight

and the system completely drained before waterflow detectors are

removed or replaced.

Inspect detectors monthly for leaks and replace if a leak occurs. Test detectors at least monthly, as described under Operational Testing, to ensure

proper operation. Test more often if required by the authority having jurisdiction.

Under normal conditions, System Sensor waterflow detectors should provide years of trouble-free service.

Do not repair or replace any other waterflow detector components. If any

other part of the detector does not perform properly, replace the entire

detector.

To remove a detector:

1. Drain the pipe.

2. Turn off electrical power to the detector and disconnect the wiring.

3. Loosen the nuts and remove the U-bolts.

4. Gently lift the saddle far enough to get your fingers under it. Then, roll

the vane so it will fit through the hole while continuing to lift the

waterflow detector saddle.

5. Lift the detector clear of the pipe.

If a vane breaks in a pipe, find and remove it. If it is not removed, the vane

may restrict the flow of water to all or part of the sprinkler system.

CAUTION

Table 1:

LFD MODEL Hole Size

20, 25-73MM, 25-76MM 1-1/4

"

30-2, 40 2

"

Table 2:

LFD MODEL Torque

20, 25-73MM, 25-76MM 30 - 35 ft-lb

30-2, 40 55 - 60 ft-lb

A78-1496-07

Wrong

Right

Remove burrs from edge of hole. Clean out scale and foreign

matter for one pipe diameter on each side of hole.

Page 3

Break wire as shown for

supervision of connection.

DO NOT allow stripped wire

leads to extend beyond

switch housing. Do NOT

loop wires.

D770-30-00 3 I56-1620-002R

Figure 3. Wiring LFD to bell:

BELLBELL

POWER SOURCE

A

B

C

O

M

POWER

TERMINALS

AUX RELAY

TERMINALS

Figure 7. Wiring the LFD to a panel and other device:

Leave the Relay Wires installed under the Power Terminals and connect

the panel initiating loop wires as shown below. The LFD requires power

to operate, therefore connect the FACP initiating loop wires to the Power

Terminals and Relay Wires as shown. If power should be interrupted

before the panel, the batteries in the panel will maintain power to the

LFD.

EOL

OR NEXT

DEVICE

FACP

POWER SOURCE

BELLBELL

A B COM

POWER

TERMINALS

AUX RELAY

TERMINALS

RELAY

WIRES

Figure 6. Wiring the LFD to a panel:

Leave the Relay wires installed under the Power Terminals and connect

the panel initiating loop wires as shown below.

OR NEXT

DEVICE

POWER

TERMINALS

AUX RELAY

TERMINALS

A B

C

O

M

EOL

FACP

RELAY

WIRES

TO NEXT MODULE

OR EOL

INTELLIGENT

MODULE

FACP

A B COM

POWER

TERMINALS

AUX RELAY

TERMINALS

RELAY

WIRES

Figure 8. (2 Wire Addressable) Wiring the LFD to an addressable

panel using the SLC loop wires for power:

Remove the Relay Wires from under the Power Terminals. Connect these

wires to the Addressable Module.

NOTE: Consult FACP Manufacturers’ Compatibility Guide prior to

installation.

Figure 4. (4 Wire Addressable) Wiring the LFD to an addressable

panel using an auxiliary power supply for power:

Remove the Relay Wires from under the Power Terminals. Connect these

wires to the Addressable Module.

Figure 5. Wiring the LFD using 4 wires. (Aux. Power from Panel):

Remove the Relay Wires from the Power Terminals. Cut off the spade lugs

from the ends of the Relay Wires. Put wire nuts over ends of Relay Wires

as shown. Use Aux. Relay Terminals to make connection to panel and next

device as shown.

AUX. POWER

OUTPUT

INITIATING

LOOP

A B COM

POWER

TERMINALS

AUX RELAY

TERMINALS

RELAY

WIRES

FACP

EOL POWER

SUPERVISION

RELAY (SHOWN

ENERGIZED)

A77-716 12/24V

EOL

NOTE: To comply with NFPA code, never put more than two wires in

a wire nut.

Relay wires and power terminal wiring must be contained within either a

common enclosure or enclosures within 20 feet of each other with wiring

inside conduit.

CAUTION

AUX.

POWER

OUTPUT

MODULE

SLC

LOOP

A B COM

POWER

TERMINALS

AUX RELAY

TERMINALS

RELAY

WIRES

FACP

MODULE

A B COM

POWER

TERMINALS

AUX RELAY

TERMINALS

RELAY

WIRES

NOTE: PLACE MODULE EOL

RESISTOR ACROSS RELAY

WIRES INSIDE AFD COVER.

NOTE: PLACE MODULE EOL

RESISTOR ACROSS RELAY

WIRES INSIDE AFD COVER.

AFD

ENCLOSURE

AFD

ENCLOSURE

EOL POWER

SUPERVISION

RELAY (SHOWN

ENERGIZED)

A77-716 12/24V

Page 4

D770-30-00 4 I56-1620-002R

©

2001 System Sensor

Three-Year Limited Warranty

System Sensor warrants its enclosed waterflow detector to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this waterflow detector. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the waterflow detector which is found to be defective in materials

or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System

Sensor, Repair Department, RA #__________, 3825 Ohio Avenue,

St. Charles, IL 60174. Please include a note describing the malfunction and

suspected cause of failure. The Company shall not be obligated to repair or

replace units which are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case shall the Company be liable for any consequential or

incidental damages for breach of this or any other Warranty, expressed or

implied whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This Warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

1. Waterflow detectors may not work or operate properly if sprinkler piping being monitored is plugged with pipe scale, mud, stones or other

foreign material. Sprinkler systems should be checked regularly for

such blocking material, following the instructions of NFPA Standard 13

and NFPA 750.

2. Alarms generated by the activation of waterflow detectors may not be

received by a central station if telephone or other communication lines

to the detector are out of service, disabled, or open.

3. Vane-type waterflow detectors have a normal service life of 10-15

years. Hard water systems, however, may substantially reduce water-

The Limitations of Waterflow Alarm Devices

WARNING

flow detector service life.

4. Waterflow detectors are not a substitute for insurance. Building owners should always insure property and lives being protected by sprinkler systems.

5. If valves controlling the water supply to a sprinkler system are closed,

vane-type waterflow detectors will not work. All valves controlling a

sprinkler water supply should be sealed or locked in the normally open

position. The normally open position should be monitored by a sprinkler supervisory switch.

Figure 11. Solid State Retard Timing Char t:

Figure 10A. Ground screw location:

Figure 10B. Knockout plug removal:

CAUTION: Only use the above timer settings.

Timing must not exceed 90 seconds.

GROUND

SCREW

(GREEN)

MOUNTING

PLATE

Switch 1 Switch 2 Switch 3

Time (sec) (60 sec) (30 sec) (15 sec)

0OFFOFFOFF

15 OFF OFF ON

30 OFF ON OFF

45 OFF ON ON

60 ON OFF OFF

75 ON OFF ON

90 ON ON OFF

ON 1 2 3

A78-1914-05

A78-1914-04

Figure 9. Assembly diagram:

Please refer to insert for the Limitations of Fire Alarm Systems

Loading...

Loading...