Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SSK451 Multi-Signaling Accessory

Specications

Dimensions: 4.8″ W x 4.7″ H x 1.5″ D

(12.2 cm W x 11.9 cm H x 3.8 cm D)

Weight: 0.35 lb. (160 g)

Operating Voltage: 24 VDC

Power Requirements:

Standby 8 mA

Trouble 16 mA

Alarm w/o strobe 40 mA

Alarm with strobe 65 mA

Connections: Strip terminal, 14 AWG to 22 AWG wire

Sounder: 87 dBA at ten feet

Temperature: 14°F to 140°F (-10°C to 60°C)

Humidity: 95% relative humidity; non-condensing

Listing: UL 268A

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

H0482-00

Notice:

This manual should be left with the owner/user of this

equipment.

General Information

The National Fire Protection Association (NFPA) has published codes, standards, and recommended practices for

the installation and use of this product. It is recommended

that the installer be familiar with these requirements, with

local codes, and any special requirements of the local authority having jurisdiction. For further information, consult NFPA 72 and 90A requirements.

The System Sensor SSK451 multi-signaling accessory is

designed for use with System Sensor DH100ACDC and

DH400ACDC duct smoke detector models and combines a

horn feature with the key-activated test and reset functions.

Green, yellow and red LEDs provide a visual indication of

power, trouble and alarm conditions, respectively.

To meet special code requirements of certain jurisdictions,

an optional PS24LO strobe can be easily added to the

SSK451 to provide visual alarm signaling. A “SMOKE” lens

can be added to the strobe.

The SSK451 can be wired such that its horn produces either

a continuous or a temporal tone. The SSK451 conveniently

installs to a double-gang electrical box.

Contents

1 SSK451 Multi-Signaling Accessory

1 Mounting Hardware Kit (contains 4 mounting

screws, and 2 spacers for optional PS24LO strobe)

1 Installation and Maintenance Instructions

D200-94-00 1 I56-1222-03

Page 2

Installation

COMMON 3

TEMPORAL SELECT

2

ALARM SIGNAL

1

SUPERVISORY SIGNAL

4

RESET

7

TEST 8

POWER (-)

6

POWER (+) 5

SSK451

FIELD INSTALLED

JUMPER FOR

TEMPORAL PATTERN

15 ALARM SIGNAL

3

SUPER

VISORY

14

CONTAC

T

2 RESET

11 TEST

20 AUX. POWER (-)

19 AUX. POWER (+)

DH100 ACDC

NO

FIELD INSTALLED

JUMPER

COMMON 3

TEMPORAL SELECT 2

ALARM SIGNAL 1

SUPERVISORY SIGNAL 4

RESET 7

TEST 8

POWER (-) 6

POWER (+) 5

SSK451

FIELD INSTALLED

JUMPER FOR

TEMPORAL PATTERN

5 ALARM SIGNAL

10

SUPERVISOR

Y

11

CONTAC

T

3 RESET

4 TEST

6

AUX. POWER (-)

7 AUX. POWER (+)

DH400 A

CDC

NO

FIELD INSTALLED

JUMPER

DETECTOR

HEAD

TEST COIL

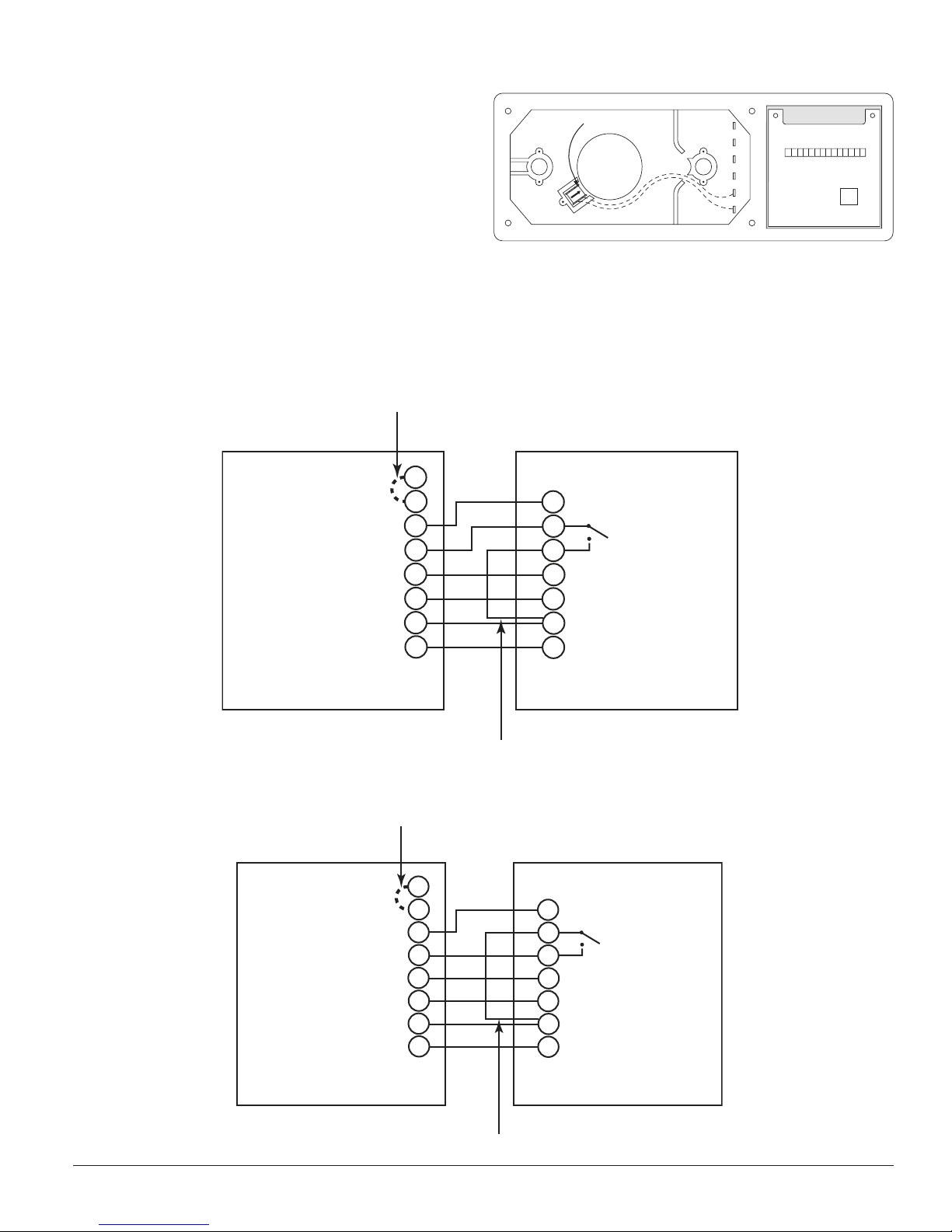

Figure 3: Test Coil Installation

Wire the SSK451 as shown in Figure 1, for DH100ACDC

duct smoke detectors, or Figure 2, for DH400ACDC duct

smoke detectors. Limit wire runs to 25 ohms or less per

interconnecting wire.

Test Coil Installation

NOTE: When the SSK451 is used with a DH400ACDC

duct smoke detector, a test coil, part number COIL,

must be ordered separately. When the SSK451 is

used with a DH100ACDC duct smoke detector, a

test coil is not required.

The COIL is installed in the DH400ACDC duct smoke detector housing as shown in Figure 3. Please follow the instructions enclosed with the COIL for proper installation of

the COIL to the DH400ACDC duct smoke detector.

Figure 1: SSK451 with DH100ACDC Duct Smoke Detector

H0277-00

Figure 2: SSK451 with DH400ACDC Duct Smoke Detector

D200-94-00 2 I56-1222-03

NOTE: Wiring

diagram shown is for

DH100ACDC 4-wire

duct smoke detector

system equipped

without a control panel.

H0483-00

NOTE: Wiring

diagram shown is for

DH400ACDC 4-wire

duct smoke detector

system equipped

without a control panel.

H0484-00

Page 3

Temporal Sounder

RED TERMINAL

ON TO

P

The SSK451 accessory provides the option of sounding a

continuous or temporal pattern. The SSK451 will default

to sound in a continuous pattern. For a temporal pattern,

wire a eld-installed jumper between terminals 2 and 3 on

the SSK451.

Optional SMOKE Strobe Lens

NOTE: To meet the code requirements of certain juris-

dictions, an optional SMOKE lens can be purchased separately.

SMOKE lens, wall mount PS12/24SLENSW

SMOKE lens, ceiling mount PS12/24SLENSC

Mounting

Secure the SSK451 to a double-gang electrical box with the

four mounting screws provided.

Installation of the Optional Add-On PS24LO Strobe

This optional strobe can be purchased separately and is

easily added to the SSK451 accessory.

H0485-00

The PS24LO strobe will be mounted on top of the sounder,

on the left-hand side of the SSK451. Place one mounting

spacer between the SSK451 and the strobe adapter plate

at each screw attachment location. Attach the adapter

plate, spacer and SSK451 to the left-hand side of the double-gang electrical outlet box with two mounting screws.

Please follow the instructions enclosed with the lens for

proper installation of the lens to the strobe.

Operation

The green “POWER” LED is illuminated whenever the duct

smoke detector is receiving power. With a DH100ACDC

duct smoke detector, the yellow “TROUBLE” LED is lit

when the sensor board is missing or the cover is removed

for more than twenty minutes. With a DH400 ACDC duct

smoke detector, the yellow “TROUBLE” LED is lit when the

detector head is missing. The red “ALARM” LED is displayed and the horn will sound whenever the duct smoke

detector is in alarm.

No LEDs will be illuminated if the duct smoke detector is

not receiving power.

Test Function

Insert the key and turn clockwise to the “TEST” position.

The red LED will illuminate and the horn will sound. If

an optional strobe is installed, it will pulse.

Alarm Indication

With the key in the “TEST” position, some time will

elapse (40 seconds maximum), depending on the duct

smoke detector type, before the red alarm LED will illuminate and the horn will sound.

Reset Function

Turn the key counterclockwise to the “RESET” position

and hold. The red alarm LED should turn off and the

horn will cease sounding. Then, turn the key back to the

“ON” position and remove.

Slide the strobe terminals directly into the two slots in the

adapter plate and SSK451. The positive lug, which will be

colored red, must be installed into the top slot.

Grasp the catch area on the top of the strobe and squeeze

while applying inward force. Repeat for the catch area on

the bottom of the strobe.

Make sure the strobe catches fully engage into the slots in

the adapter plate and that no gap appears at the interface

between the strobe and adapter plate.

D200-94-00 3 I56-1222-03

Page 4

WARNING

Ordering Information

ON

RESET TEST

ALARM

ALARM POWER

ALARM

RESE

T

T

E

S

T

943B-0505

SSK451 Multi-Signaling Accessory

PA400B Mini-Alert™ Sounder, beige

PA400W Mini-Alert™ Sounder, white

PS24LOB Mini-Alert™ Add-On Strobe, beige

PS24LOW Mini-Alert™ Add-On Strobe, white

PS12/24SLENSW Smoke Lens Wall Mount

Innovair Duct Smoke Detectors

DH100ACDCP 4-Wire Photoelectric Duct Smoke Detector

DH100ACDCI 4-Wire Ionization Duct Smoke Detector

Other Accessories

RTS451 Remote Test/Reset Station

RTS451KEY Key-Activated Remote Test/Reset Station

APA451 Piezo Annunciator

RA400Z Remote Annunciator Alarm

The sounder or sounder/strobe combination will not operate if the

power is cut off for any reason.

If power is cut off for any reason, the sounder or strobe/sounder combina-

tion will not provide the desired audible or visual warning.

The sounder may not be heard. The loudness of the sounder meets

or exceeds the current Underwriters Laboratories’ standards. However,

the sounder may not alert a sound sleeper or one who has recently used

drugs or has been drinking alcoholic beverages. This sounder may not be

heard if it is placed in an area that is separated by a closed door, or if it is

located on a different oor from the person in a hazardous situation, or

if it is placed too far to be heard over ambient noise, such as, trafc, air

conditioners, machinery or musical appliances that may prevent alert per-

sons from hearing the alarm. For these reasons, Pittway recommends that

sounders (85dBA minimum at 10 feet) used in a residence shall be placed

on every level and in every bedroom that does not have a smoke detector

with a built-in sounder.)

In this case, a visual indicator shall also be used.

The Sounder and add-on strobe are for supplemental signaling only.

The signal strobe may not be seen. The electronic visual warning sig-

nal meets or exceeds current Underwriters Laboratories’ standards. The

visual warning signal is suitable for direct viewing and must be installed

within an area where it can be seen by building occupants. The strobe

must not be installed in direct sunlight or areas of high light intensity

where the visual ash might be disregarded or not seen.

The strobe may not be seen by the visually impaired.

The signal strobe may cause seizures. Individuals who have a positive

photic response to visual stimuli with seizure, such as epileptics, should

avoid prolonged exposure to environments in which strobe signals, in-

cluding this strobe, are activated.

H0489-00

H0490-00

H0486-00

H0488-00

H0487-00

The sounder may not be heard by persons who are hearing-impaired.

System Sensor warrants its enclosed multi-signaling accessory to be free

from defects in materials and workmanship under normal use and ser-

vice for a period of three years from date of manufacture. System Sensor

makes no other express warranty for this multi-signaling accessory. No

agent, representative, dealer, or employee of the Company has the au-

thority to increase or alter the obligations or limitations of this Warranty.

The Company’s obligation of this Warranty shall be limited to the repair

or replacement of any part of the multi-signaling accessory which is

found to be defective in materials or workmanship under normal use and

service during the three year period commencing with the date of man-

ufacture. After phoning System Sensor’s toll free number 800-SENSOR2

(736-7672) for a Return Authorization number, send defective units post-

D200-94-00 4 I56-1222-03

© System Sensor 1999

Three-Year Limited Warranty

age prepaid to: System Sensor, Repair Department, RA #__________, 3825

Ohio Avenue, St. Charles, IL 60174. Please include a note describing the

malfunction and suspected cause of failure. The Company shall not be ob-

ligated to repair or replace units which are found to be defective because of

damage, unreasonable use, modications, or alterations occurring after the

date of manufacture. In no case shall the Company be liable for any conse-

quential or incidental damages for breach of this or any other Warranty, ex-

pressed or implied whatsoever, even if the loss or damage is caused by the

Company’s negligence or fault. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This Warranty gives you specic legal

rights, and you may also have other rights which vary from state to state.

Loading...

Loading...