Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3871-001

i4 Series Interface Module

COSMOD2W and COSMOD4W

*For use with COSMO-2W and COSMO-4W detectors

SPECIFICATIONS

Electrical Specifications

Power Supply Voltage: Resettable power; 2-Wire: Min. 8.5 Volts DC (Power limited); Max. 35 Volts DC (Power limited);

4-Wire: Min. 10 Volts DC (Power limited); Max. 35Volts DC (Power limited)

Device Power-up Time: 200 milliseconds

Max. Standby Current: 2-Wire: 62mA; 4-Wire: 52mA (Does not include current draw from attached detectors or EOL relay)

Max. Alarm Current: 2-Wire: 174mA; 4-Wire: 75mA (Does not include reverse polarity current draw from attached detectors)

Nom. Standby Current: 2-Wire: 45mA@12V, 27mA@24V; 4-Wire: 36mA@12V, 21mA@24V

(Does not include current draw from attached detectors or EOL relay)

Alarm Contact Rating: 100 mA @ 36 Volts DC, resistive, 25 ohms

Maintenance Contact Rating: 100 mA @ 36 Volts DC, resistive, 25 ohms

Max. IDC Loop Wiring Resistance: 2-Wire: 50 Ohms; 4-Wire: 300 Ohms

Trigger Inputs: Min. On Voltage: 1.5V; Max. On Voltage=Vin

Aux Power Out: Same Voltage as Input Power (Unregulated, limited to 250mA)

Min. Reset Time: 300 milliseconds

Initial Communication Cycle: 6 minutes

EZ Walk Test Availability: 6 minutes after power up or panel reset

Physical Specifications

Operating Temperature Range: 0 - 50° C (32 - 122° F)

Operating Humidity Range: 5 - 95% RH

Storage Temperature Range: -20 - 70° C (-4 - 158° F)

Height: 6.04 inches

Width: 6.04 inches

Depth: 1.16 inches

Shipping Weight: 0.6 lbs

Wire Gauge Acceptance: Min: 22 AWG; Max: 14 AWG

2-wire Compatibility Requirements

Min. Loop Voltage: 12.9 Volts DC

Max. Loop Voltage: 14.5 Volts DC

Max. Loop Resistance: 50 Ohms

Max. Loop Ripple: 240 mVpp

Max. Loading Capacitance: 0.01 mF

Max. Alarm Current: 46 mA

Max. Reset Voltage: 0.30 Volts DC

Alarm Delay: n/a

Min. Alarm Reset Time: 0.3 seconds

Max. Normal Load Current: 2.4 mA

Zone Type: Standard

EOL Device: 3.9k Ohms (+-5%)

Loop Style: B and D

Compatibility Zone Identifier: A

Detector Zone Identifier: A

Max. Detectors Per Zone: (12) 2-wire i4 series model #COSMO-2W and/or i3 series model #2WTA-B detectors

BEFORE INSTALLATION

This information is included as a quick reference installation guide. Refer to

the control panel installation manual for detailed system information. If the

module will be installed in an existing operational system, inform the operator

and local authority that the system will be temporarily out of service. Disconnect power to the control panel before installing the module.

Notice: This manual should be left with the owner/user of this equipment.

This product is intended for use in ordinary indoor locations.

GENERAL DESCRIPTION

The i4 series module is designed to interface between compatible i4 series

combination CO/smoke detectors (Model COSMO-2W and COSMO-4W) and

compatible security/fire panels. It can also be used to retrofit compatible i4

series detectors into an existing loop of i3 smoke detector models 2WTA-B or

4WTA-B, without adding wires. The module interprets signals and translates

them into a separate smoke zone and a separate CO zone, each with alarm

and trouble signals. When signaled by the panel, a module will synchronize

connected detector sounders in either Temporal 3 or Temporal 4 pattern. Local

status indication is provided by 4 LED’s and a 3 position DIP switch enables

user configuration.

SS-500-004 1 I56-3871-001

4

The i

COSMOD2W, 2-wire interface module, offers additional functionality

including:

• Ability to query for a “need for maintenance” condition from 2-wire i4

series model COSMO-2W and i3 series model 2WTA-B smoke detectors

• One relay is available to indicate a multitude of maintenance conditions

at the control panel

• All conditions are displayed at the module and at the detector

• EZ Walk test mode allows the installer to easily verify that all detectors

on a loop are operational

• Allows 2-wire smoke detectors to be used on any compatible 4-wire

control panel and provides Style D wiring on the detector loop

FEATURES

• Compatible with System Sensor i4 series combination CO/smoke detectors

and System Sensor i3 Series smoke detectors models 2WTA-B or 4WTA-B.

• Allows up to 12 compatible devices including the i4 series combination

CO/smoke detector to be integrated with a panel

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6583

www.systemsensor.com

Page 2

• Allows sounder activation of all detectors on loop in either Temporal 3

HOLE FOR MOUNTING

or Temporal 4 pattern

VISIBLE ANNUNCIATON

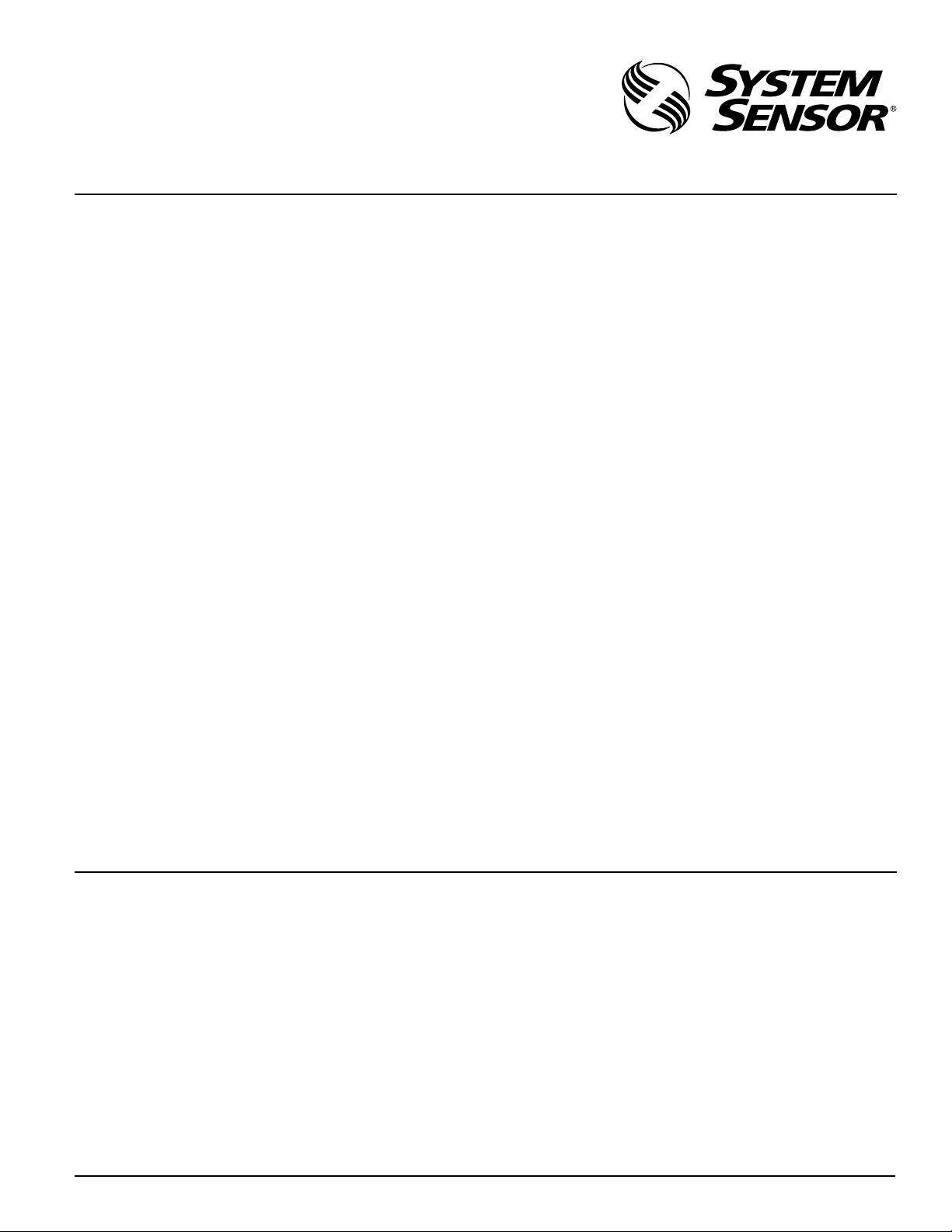

The i4 series interface module has four visible LED’s: The green LED is a supervisory LED; it blinks during power on, reset, and during normal operation.

The yellow LED is used to indicate a loop wiring fault and will blink when it

is in EZ Walk test mode. The red LED signals smoke events; it blinks during

smoke maintenance events and lights constantly during smoke alarm events.

The blue LED signals CO events; it blinks during CO trouble or CO end-of-life,

and lights constantly during CO alarm.

FIGURE 1: MODULE FRONT VIEW

Green LED

Yellow LED

Red LED

Blue LED

EZ Walk Test Switch

(2-wire only)

S0331-00

TABLE 1: OPERATION MODES

OPERATION

MODE

Normal (standby) Blink 5 Sec. OFF OFF OFF

No power/

Non-operational

Loop wiring fault Blink 5 Sec. ON OFF OFF

EZ Walk Test Mode

(2-wire only)

Alarm Smoke Blink 5 Sec. OFF ON OFF

Alarm CO Blink 5 Sec. OFF OFF ON

Alarm Smoke & CO Blink 5 Sec. OFF ON ON

Maintenance

(2-wire only)

Freeze Trouble (2wire only)

CO Trouble Blink 5 Sec. OFF OFF Blink 5 Sec.

GREEN

LED

OFF OFF OFF OFF

Blink 5 Sec. Blink 5 Sec. OFF OFF

Blink 5 Sec. OFF Blink 5 Sec. OFF

Blink 5 Sec. OFF Blink 10 Sec. OFF

YELLOW

LED

RED LED BLUE LED

NORMAL (STANDBY)

The module is powered and detectors on the loop are operating normally.

NO POWER/NON-OPERATIONAL

Power is not applied to the module or communication between the module

and the detectors on the loop is unsuccessful.

LOOP WIRING FAULT

If an open circuit occurs on the loop, the module will indicate the condition

by illuminating the yellow LED. 2-wire units will then power the style-D terminals. When the wiring issue on the loop has been resolved, the module will

turn the yellow LED off.

EZ WALK TEST MODE

This indicates the module and detectors are in EZ Walk Test Mode. See “EZ Walk

Test” section for instructions on how to initiate and perform the EZ Walk test.

ALARM SMOKE/ALARM CO/ALARM SMOKE & CO

A smoke alarm will be indicated by the red LED. A CO alarm will be indicated

by the blue LED.

A smoke alarm is not self-restoring. Once a smoke alarm has been signaled,

the red LED will illuminate until the module is reset by removal of power.

Note: On some panels, resetting a smoke alarm may require additional steps

at the keypad to clear the trouble conditions on CO and smoke maintenance zones due to power loss to the module.

A CO alarm is self-clearing. Once a CO alarm has been signaled, the blue LED

will illuminate. Once the initiating device ceases to signal the CO event, the

blue LED will turn off. If a CO alarm is signaled, and not cleared, prior to a

smoke alarm condition, the module will keep both the blue and red LED’s

illuminated. If a smoke alarm is signaled first, the module will not be able to

receive notification of a CO alarm condition and will not be able to report it

to the panel.

MAINTENANCE

This condition means one or more detectors on the loop have a smoke maintenance issue. See “Smoke Maintenance Inquiry” section for further details.

FREEZE TROUBLE

This condition means one or more detectors on the loop are measuring the

ambient temperature is near the freezing point. See “Freeze Trouble Inquiry”

section for further details.

CO TROUBLE

The module can be notified of a detector with a CO trouble condition. All CO

trouble conditions will be reported on the CO zone and displayed with a blinking blue LED. The module is not able to determine the number of detectors

that have a CO trouble condition or which trouble condition exists.

INSTALLATION

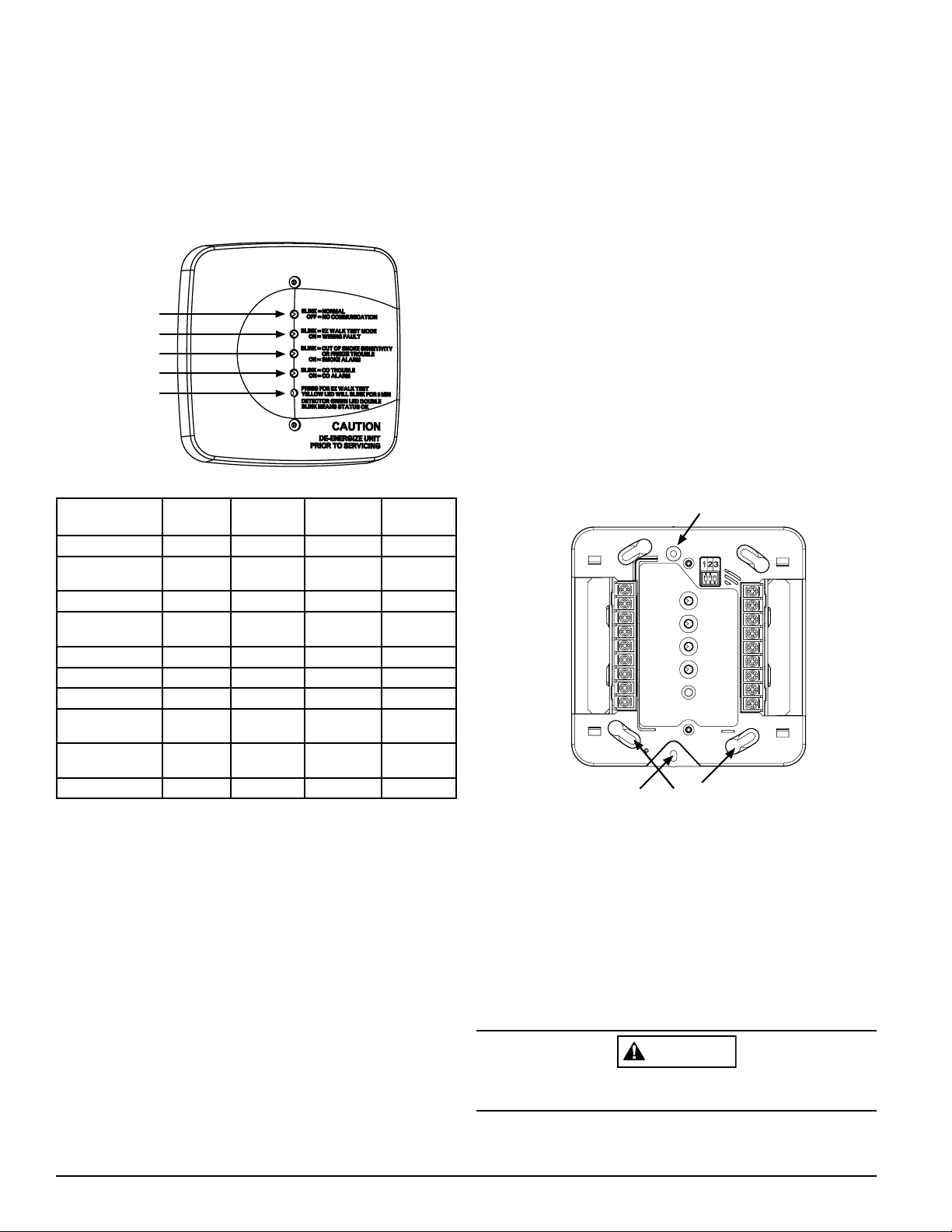

MOUNTING

The module can be mounted to a 4-11/16 inch back box or inside a listed, dedi-

cated enclosure. When mounting inside an enclosure with pre-stamped holes,

it may be easier to align the bottom screw hole first. It is not necessary to use

the module cover when mounting inside an enclosure.

FIGURE 2: MOUNTING

TO VISTA ENCLOSURE

(No. 6x3/4 Type AB)

SLOT FOR MOUNTING

TO VISTA ENCLOSURE

(No. 6x5/16Type AB or Type F)

SLOTS FOR MOUNTING

TO 4-11/16 JUNCTION BOX

0331-00

WIRING GUIDELINES

All wiring must be installed in compliance with the NFPA 70 standards, National Electrical Code, applicable state and local codes, and any special requirements at the local Authority Having Jurisdiction (AHJ).

The screw terminals in the mounting base will accept 14-22 gauge wire. Wire

connections are made by stripping approximately ¼” of insulation from the

end of the feed wire, inserting it into the proper base terminal, and tightening

the screw to secure the wire in place. Do not put wires more than 2 gauge

apart under the same clamping plate.

Note: The module must be installed in the same room and within 20 feet of

the panel and enclosed within conduit or equivalently protected against mechanical injury.

WARNING

Remove power from alarm control unit or initiating device circuits before installing detectors.

SS-500-004 2 I56-3871-001

Page 3

WER +)

WER –)

FIGURE 3: COSMOD2W WIRING DIAGRAM

SMOKE

AUXPOWER

(resettable)

SMOKE

ZONE

CO

ZONE

ALL CIRCUITS ARE SUPERVISED

(EXCEPT TRIGGERS) AND MUST

BE POWER LIMITED

Note: See Table 3 for dip

switch configurations

Panel

EOL

Resistors

3.9k

RESISTOR

(supplied

with module)

MAINT.

ZONE

BELL

OR

SMOKE

TRIGGER OUT

CO

TRIGGER

OUT

FIGURE 4: COSMOD4W WIRING DIAGRAM

Panel

EOL

Resistor

SMOKE

POWER

(resettable)

SMOKE

ZONE

CO

ZONE

COSMOD2W

ALL CIRCUITS ARE SUPERVISED

(EXCEPT TRIGGERS) AND MUST

BE POWER LIMITED

COSMOD4W

Panel

EOL

Resistors

LOOP STYLE D WIRING

COSMO-2W

COSMO-4W

EOL

RELAY

#EOLR-1

3.9k

RESISTOR

(supplied

with module)

S0329-00

BELL

OR

SMOKE

TRIGGER OUT

CO

TRIGGER

OUT

FIGURE 5: MODULE TERMINALS

POWER IN +

POWER IN –

SMOKE ALARM CONTACT

MAINTENANCE TROUBLE RELAY CONTACT

(COSMOD2W ONLY)

CO ALARM CONTACT

CO TRIGGER

SMOKE ZONE EOL RESISTOR

(VALUE DEFINED BY PANEL)

CO ZONE EOL RESISTOR

(VALUE DEFINED BY PANEL)

IDC +

IDC –

STYLE D + (4-WIRE DETECTOR PO

STYLE D – (4-WIRE DETECTOR PO

SMOKE TRIGGER / BELL IN

SS-500-004 3 I56-3871-001

S0330-00

S0334-00

Page 4

WIRING DIAGRAMS

Install module wiring in accordance with appropriate wiring diagrams.

(Figure 3 and Figure 4)

The module relays have a maximum ON resistance of 25 ohms. This resistance plus the wiring resistance to the panel must be less than the maximum

zone wiring resistance stated in the panel manual.

INPUT TRIGGERS/SOUNDER ACTIVATION

Many panels can be programmed with triggers which are auxiliary relays that

activate upon an alarm condition. Two inputs are used to signal the module

to activate device sounders. The first is configurable by DIP switch to one of

two modes; bell in or smoke trigger. When in the bell mode, the module will

follow a valid coded signal from a Bell Out/NAC circuit consisting of high to

low, then low to high for less than 1.9 seconds each. In smoke trigger mode,

while the input is held high, the module will synchronize the detectors in a

Temporal 3 pattern.

The second input is for a CO trigger ; the CO trigger input allows a single module to have CO silence/hush capability and allows multiple module installations to have all sounders activated in Temporal 4 in the event of a CO alarm.

While the CO trigger is held high, the module will synchronize the detectors

in a Temporal 4 pattern. After 30 minutes in Temporal 4 alarm, the time period

between the Temporal 4 pulse will change from 5 seconds to 60 seconds.

Note: CO trigger may not be used with UL 864 panels. All detectors will sound

with no triggers connected, however, hush capability is not enabled.

TABLE 2: DIP SWITCH CONFIGURATIONS

DIP SWITCH # 1 DIP SWITCH # 2 DIP SWITCH # 3

ON

(DEFAULT)

OFF

Bell In

Smoke Trigger

Smoke Maint on

Smoke Trouble and

Form-B Maint Relay

(COSMOD2W only)

Smoke Maint on

Form-B Smoke main

tenance Relay only

(COSMOD2W only)

Unused

Unused

POWER UP AND COMMUNICATIONS

COMMUNICATIONS CHECK (2-WIRE ONLY)

Upon power up, the module will send a request for communication check. All

compatible detectors on the loop that understand the communication protocol

will respond. If all detectors respond correctly, the green LED will blink once

every 5 seconds. If the module does not get a response, it will turn off the

green LED and continue to try every 2 minutes until a response is received.

SMOKE MAINTENANCE INQUIRY

The module sends a smoke maintenance inquiry to the detectors every 24

hours. (Compatible 2-wire detectors only) If a response indicating a maintenance problem is received, the red LED on the module will blink once every 5

FREEZE TROUBLE INQUIRY

The module sends a freeze trouble inquiry to the detectors every four hours.

(Compatible i3 Series 2-wire smoke detectors only) If a response indicating a

freeze problem is received, the red LED on the module will blink once every

10 seconds and a smoke maintenance condition will be indicated to the panel.

TESTING

Modules must be tested after installation and following periodic maintenance.

Testing should be performed at least once per year.

NOTE: Before testing, notify the proper authorities that the system will be temporarily out of service. Disable the zone or system to prevent any unwanted

alarms.

EZ WALK TEST

The communication loop between the 2-wire modules and detectors can be

manually tested by putting the module and detectors into EZ Walk test mode.

This feature is for use with System Sensor detectors (i4 series model COSMO-2W

and i3 series model 2WTA-B) installed with the model COSMOD2W module.

The EZ Walk loop test verifies the initiating loop wiring and provides visual

status indication at each detector:

1. Ensure proper wiring and power is applied. Wait approximately 5 minutes from power-up before performing the EZ Walk test. The green LED

on the module must be blinking indicating the module is in ready/

standby mode to start the EZ Walk mode.

2. Locate the EZ Walk recessed test switch located behind the module cover

(See Figure 1). Depress the test switch with a small screwdriver. The yellow LED will blink showing that the module and detectors are in EZ Walk

mode for 5 minutes.

3. Observe the LEDs at each detector to make sure the green LED is double

blinking every 5 seconds as listed in Table 3.

4. At the end of the five minute period, the module will terminate EZ Walk

and the yellow LED will stop blinking. The EZ Walk test period can be

extended by pressing the test switch multiple times. Each press will add

5 minutes of additional time.

If a module or detector fails the test, its wiring should be checked. If the

module still fails, it should be replaced. Notify the proper authorities when all

testing has been completed.

NOTE: The EZ Walk loop test should not be used in lieu of functional testing

(alarm, trouble and other functional tests) of the system.

TABLE 3: EZ WALK TEST DETECTOR MODES

PROPER OPERATION

OUT OF SENSITIVIY

DETECTOR

GREEN LED

Double Blink 5 Seconds OFF

OFF Double Blink 5 Seconds

DETECTOR

RED LED

seconds and a smoke maintenance condition will be indicated to the panel. It

is likely that the detector needs to be cleaned or replaced, refer to the detector

FREEZE CONDITION

OFF Double Blink 10 Seconds

instruction manual for maintenance instructions.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installa

tion. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for the enclosed product.

No agent, representative, dealer, or employee of the Company has the authority to in

crease or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the product which

is found to be defective in materials or workmanship under normal use and service

during the three year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns Department, RA

FCC STATEMENT

THREE-YEAR LIMITED WARRANTY

#__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing

the malfunction and suspected cause of failure. The Company shall not be obligated to

replace units which are found to be defective because of damage, unreasonable use,

-

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

-

SS-500-004 4 I56-3871-001

©2012 System Sensor

Loading...

Loading...