Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WARNING

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

D2 Duct Smoke Detector

SPECIFICATIONS

Operating Temperature: –4° to 158° F (–20° to 70° C)

Storage Temperature: –22° to 158° F (–30° to 70° C)

Humidity: 0% to 93% Relative Humidity Non-condensing

Air Velocity: 100 to 4000 ft./min. (0.5 to 20.3 m/sec.)

Rectangular Footprint Dimensions: 14.38 in L x 5 in W x 2.5 in D (37 cm L x 12.7 cm W x 6.36 cm D)

Square Footprint Dimensions: 7.75 in L x 9 in W x 2.5 in D (19.7 cm L x 22.9 cm W x 6.35 cm D)

Weight: 1.8 pounds; 0.82 kg

Electrical

Power supply voltage: 8.5-35 VDC

Input capacitance: 0.1 µF max.

Reset Voltage: 2.5 VDC min.

Reset Time (with RTS451/RTS151): .03 to 0.3 sec.

Reset Time (by power down): 0.3 sec. max.

Power Up Time: 35 sec. max.

Alarm response time: 15 sec.

Sensitivity Test: See detector label

Current Requirements (Using No Accessories)

Peak standby current 120µA

Average standby current 60µA

Max. alarm current 130 mA

Table of Contents Page

[1] Limitations of Duct Smoke Detectors .........................1

[2] General Description .....................................1

[3] Contents of the Duct Smoke Detector Kit ......................1

[4] Exploded View of Duct Smoke Detector Components .............2

[5] Detector Installation .....................................2

[6] Sampling Tube Installation ................................3

[7] Measurement Tests ......................................3-4

[8] Field Wiring ...........................................4

[9] Detector Status Indicator ..................................4

[10] Verification of Operator ..................................5

[11] Dectector Cleaning Procedures .............................5

[12] Sensor Replacement ....................................6

[13] Optional Accessories ....................................6

Wiring Diagrams ..........................................4,6

Warranty .............................................6

The D2 model is a photoelectric detector approved for an extended air speed

range of 100 to 4000 feet per minute (0.5 m/s to 20.3 m/s) and an operational

temperature range of −4°F to 158°F (−20°C to 70°C).

BEFORE INSTALLING

Read the System Sensor Guide for Proper Use of Smoke Detectors in Duct Applications (A05-1004), which provides detailed information on detector spacing,

placement, zoning, wiring, and special applications. Copies of this manual

are available online at www.systemsensor.com. NFPA Standards 72 and 90A

should also be referenced for detailed information.

NOTICE: This manual shall be left with the owner/user of this equipment.

IMPORTANT: This detector must be tested and maintained regularly following

NFPA 72 requirements. The detector should be cleaned at least once a year.

[1] LIMITATIONS OF DUCT SMOKE DETECTORS

The National Fire Protection Association has established that DUCT DETECTORS MUST NOT BE USED AS A SUBSTITUTE FOR OPEN AREA DETECTOR

PROTECTION as a means of providing life safety. Nor are they a substitute for

early warning in a building’s regular fire detection system.

System Sensor supports this position and strongly recommends that the user

read NFPA Standards 90A, 72, and 101. The D2 Air Duct Smoke Detectors are

listed per UL 268A.

SS-300-014 1 I56-3050-004R

DEVICE STANDBY ALARM

RA400Z/RA100Z 0mA 12mA Max.

RTS451/RTS151 0mA 12mA Max.

RTS451KEY/RTS151KEY 0mA 12mA Max.

This device will not operate without electrical power. Fire situations may

cause an interruption of power. The system safeguards should be discussed

with your local fire protection specialist.

This device will not sense smoke unless the ventilation system is operating

and the cover is installed.

For this detector to function properly, it MUST be installed according to the instructions in this manual. Furthermore, the detector MUST be operated within

ALL electrical and environmental specifications listed in this manual. Failure

to comply with these requirements may prevent the detector from activating

when smoke is present in the air duct.

[2] GENERAL DESCRIPTION

Smoke introduced into the air duct system will be distributed throughout the

entire building. Smoke detectors designed for use in air duct systems are used

to sense the presence of smoke in the duct.

Model D2 Duct Smoke Detector utilizes photoelectric technology for the detection of smoke. This detection method, when combined with an efficient

housing design, samples air passing through the duct allowing detection of a

developing hazardous condition. When sufficient smoke is sensed, an alarm

signal is initiated and appropriate action can be taken to shut off fans,

blowers, change over air handling systems, etc. These actions can facilitate

the management of toxic smoke and fire gases throughout the areas served

by the duct system.

[2.1] DETECTOR FEATURE SET

- Utilizes 2151 plug-in head

- Sampling tubes installed from front or rear

- Compatible with existing accessories

[3] CONTENTS OF THE DUCT SMOKE DETECTOR KIT

1. Sensor/power board assembly and covers

2. Three #10 sheet metal screws for mounting

3. Drilling template

4. One sampling tube end cap

5. One plastic exhaust tube

NOTE: A sampling tube must be ordered to complete the installation. It must

be the correct length for the width of the duct where it will be installed. See Table 1 on page 3 to determine the inlet tube required for different duct widths.

ACCESSORY CURRENT LOADS AT 24 VDC

www.systemsensor.com

I56-3050-004R

Page 2

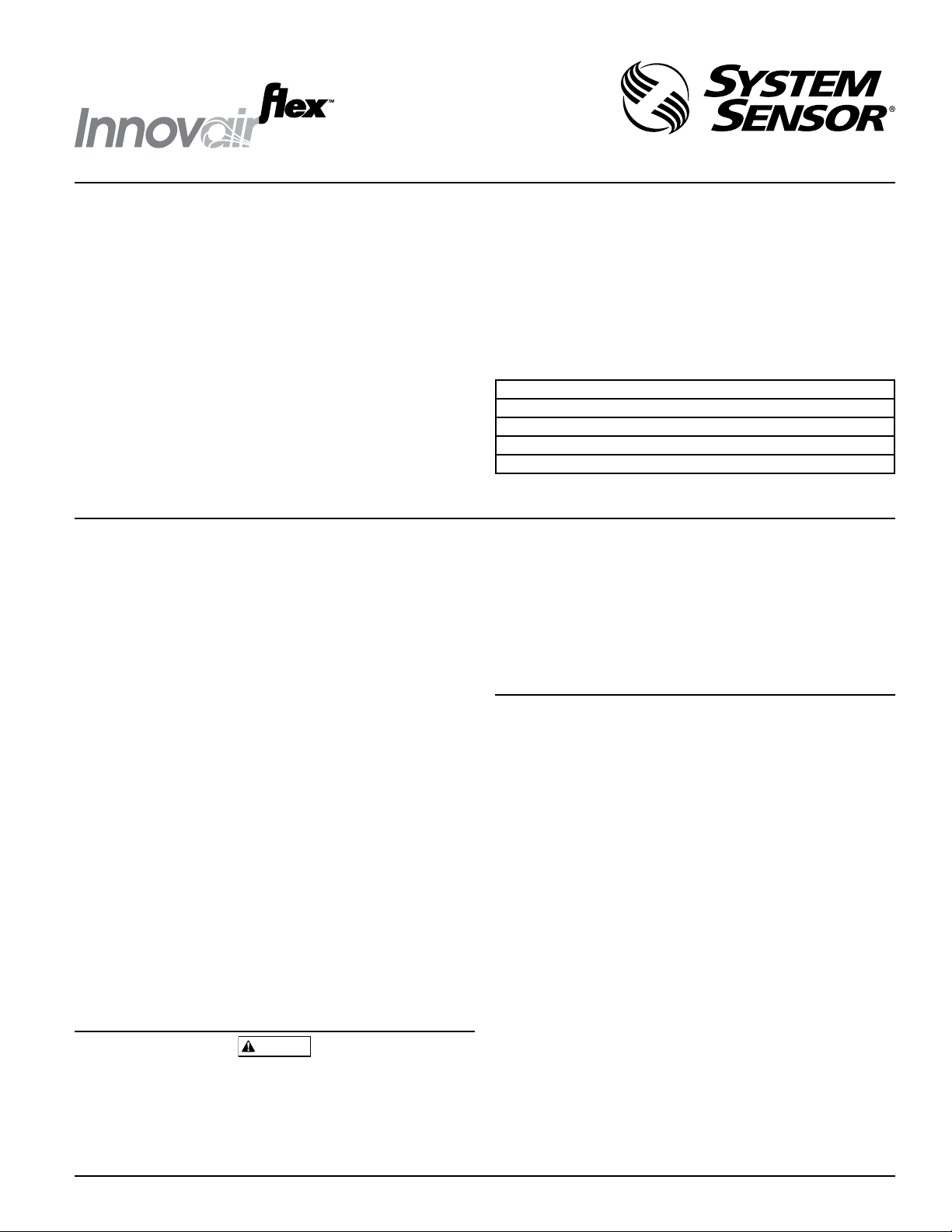

[4] FIGURE 1. EXPLODED VIEW OF DUCT SMOKE DETECTOR COMPONENTS:

SAMPLING TUBE

(sold seperately)

EXHAUST TUBE

SENSOR HEAD

SENSOR MODULE COVER

MAGNET TEST LOCATION

WIRING TERMINALS

[5] DETECTOR INSTALLATION

[5.1] VERIFY DUCT AIR FLOW DIRECTION AND VELOCITY

Model D2 detectors are designed to be used in air handling systems having air

velocities of 100 to 4000 feet per minute. Duct widths from 6 inches to 12 feet

can be accommodated. Be sure to check engineering specifications to ensure

that the air velocity in the duct falls within these parameters. If necessary, use

a velocity meter (anemometer) to check the air velocity in the duct.

[5.2] DETERMINE MOUNTING LOCATION

AND CONFIGURATION

On ducts wider than 18 inches it is recommended that the detector be

mounted downstream of a bend, obstruction in the duct, or the supply or

return air inlet.

Exception: Installation of duct detectors can be on or within a commercial

packaged rooftop heating and air-conditioning system, fire/smoke dampers

and economizers. They may be mounted in either the supply and/or return air

section as determined by local code.

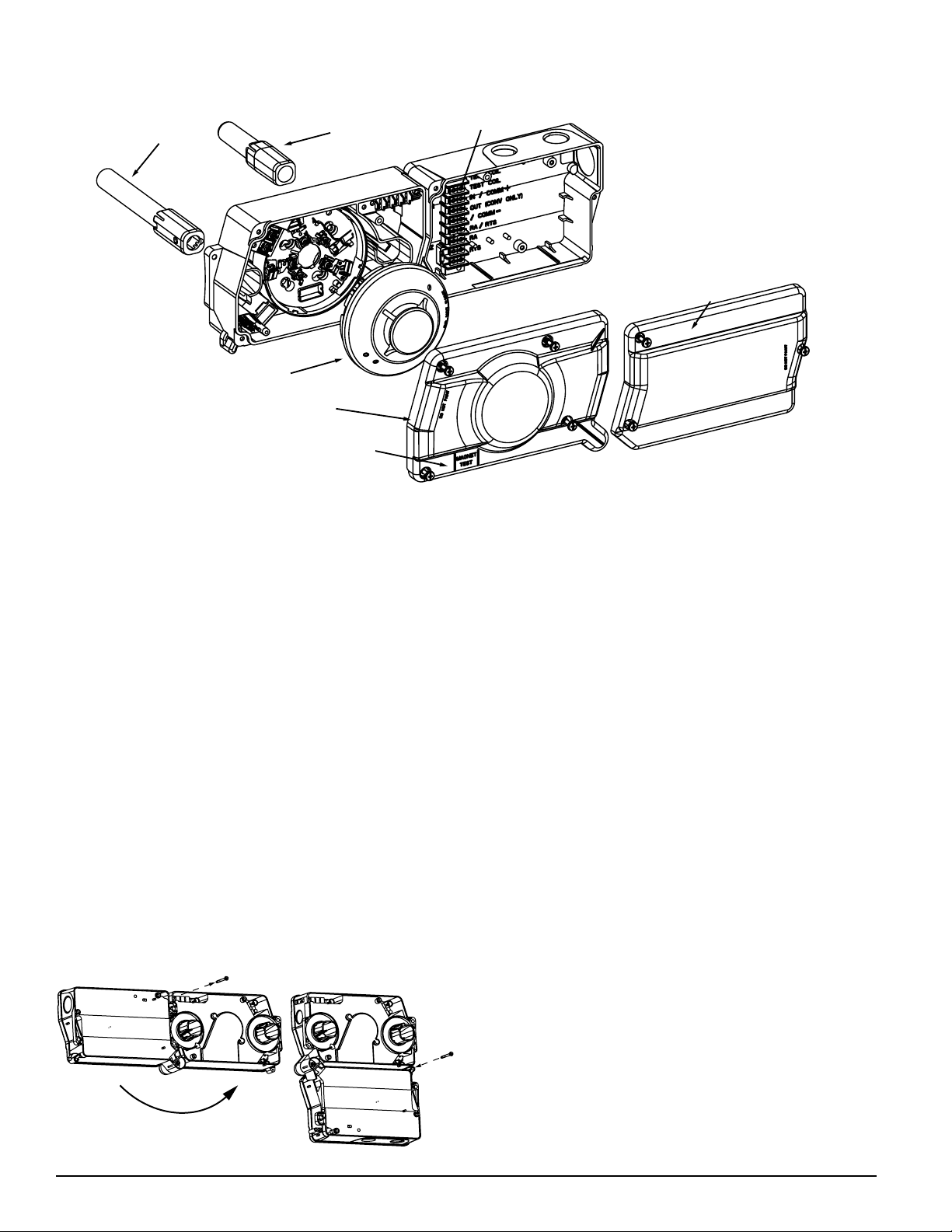

Once a suitable location is selected, determine if the detector is to be mounted

in a side-by-side “rectangular” configuration or a top-over-bottom “square”

configuration as shown in Figure 2. If mounting in the square configuration,

remove the rear attachment screw, rotate the unit at hinge, and replace the

screw into the new attachment hole as shown in Figure 2. Do NOT remove

the hinge screw during this process. Final installation approval shall be based

upon passing section 10.4.2 and 10.4.4 tests.

FIGURE 2:

REMOVE SCREW AND PIVOT

DETECTOR AS SHOWN BELOW.

REPLACE SCREW

TO SECURE DETECTOR

IN PLACE.

TERMINAL HOUSING

MODULE COVER

H0574-05

[5.3] DRILL THE MOUNTING HOLES

Remove the paper backing from the mounting template supplied. Affix the template to the duct at the desired mounting location. Make sure the template lies

flat and smooth on the duct.

[5.3.1] FOR RECTANGULAR SIDE-BY-SIDE MOUNTING CONFIGURATION:

Center punch at (4) target centers: (2) “A” for sampling tubes and (2) “B” for

the rectangular configuration mounting tabs as shown on mounting template.

Drill pilot holes at target “A” centers and cut two 1.375 inch diameter holes using a 13/8 inch hole saw or punch. Drill .156 inch diameter holes using a 5/32”

inch drill at target “B” centers.

[5.3.2] FOR SQUARE TOP-OVER-BOTTOM MOUNTING CONFIGURATION:

Center punch at (4) target centers: (2) “A” for sampling tubes and (2) “C” for

the square configuration mounting tabs as shown on mounting template. Drill

pilot holes at target “A” centers and cut two 1.375 inch diameter holes using a

13/8” inch hole saw or punch. Drill .156 inch diameter holes using a 5/32 inch

drill at target “C” centers. If desired, drill an additional .156 inch hole at the

location of one of the mounting tabs on the lower housing.

[5.4] SECURE THE DUCT DETECTOR TO THE DUCT

Use two (rectangular configuration) or three (square configuration) of the provided sheet metal screws to screw the duct detector to the duct.

CAUTION: Do not overtighten the screws.

H0550-00

SS-300-014 2 I56-3050-004R

Page 3

[6] SAMPLING TUBE INSTALLATION

SAMPLING TUBE ENDCAP

[6.1] SAMPLING TUBE SELECTION

The sampling tube must be purchased separately. Order the correct length,

as specified in Table 1, for width of the duct where it will be installed. It is

recommended that the sampling tube length extend at least 2/3 across the duct

width for optimal performance.

TABLE 1. SAMPLING TUBES RECOMMENDED FOR

DIFFERENT DUCT WIDTHS:

width of the duct. If there are more than 2 holes in the section of the

tube extending out of the duct, select a shorter tube using Table 1. Oth-

erwise, trim the tube to leave approximately 1-2 inches extending outside the duct. Plug the end with the end cap and tape closed any holes

in the protruding section of the tube. Be sure to seal the duct where the

tube protrudes.

FIGURE 4:

Outside Duct Width

Sampling Tube

Recommended*

1

/4˝

12˝

Up to 1 ft. DST1

1 to 2 ft. DST1.5

2 to 4 ft. DST3

2˝

4 to 8 ft. DST5

8 to 12 ft. DST10 (2-piece)

*Must extend a minimum of 2/3 the duct width

The sampling tube is always installed with the air inlet holes facing into the

air flow. To assist proper installation, the tube’s connector is marked with an

arrow. Make sure the sampling tube is mounted so that the arrow points into

the airflow as shown in Figure 3. Mounting the detector housing in a vertical

orientation is acceptable provided that the air flows directly into the sampling

tube holes as indicated in Figure 3. The sampling tube and exhaust tube

can be mounted in either housing connection as long as the exhaust tube is

mounted downstream from the sampling tube.

FIGURE 3. AIR DUCT DETECTOR SAMPLING TUBE:

ARROW MUST FACE

INTO AIR FLOW

CAUTION: The sampling tube end cap, included with the detector, is critical to proper operation of the duct smoke detector. The end cap is needed to

create the proper air flow to the sensor of the duct smoke detector. Once any

sampling tube length adjustments are made, plug the end of the sampling tube

with the provided end cap.

A plastic exhaust tube is included with the unit to be installed if needed. Install into the housing connection that is downstream from the sampling tube

connection. The exhaust tube can be installed from the front of the detector

or the back. A longer 1 foot exhaust tube, model ETX is available as an accessory in cases where the molded exhaust tube does not extend at least 2 inches

into the duct.

[6.2] SAMPLING TUBE INSTALLATION

1. For tubes shorter than the width of the duct, slide the sampling tube,

with installed end cap, into the housing connection that meets the airflow first. Position the tube so that the arrow points into the airflow as

shown in Figure 3. Per NFPA sampling tubes over 3 feet long should be

supported at the end opposite of the duct detector. In ducts wider than 8

feet, work must be performed inside the duct to couple the other section

of the sampling tube to the section already installed using the 1/2 inch

conduit fitting supplied. Make sure that the holes on both sections of the

air inlet sampling tube are lined up and facing into the airflow.

2. For tubes longer than the width of the air duct, the tube should extend

out of the opposite side of the duct. Drill a 3/4 inch hole in the duct opposite the hole already cut for the sampling tube. Ensure that the sampling tube is angled downward from the duct smoke detector to allow for

moisture drainage away from the detector. The sampling tube should be

angled at least 1/4” downward for every 12” of duct width per Figure 4.

There should be 10 to 12 holes spaced as evenly as possible across the

SS-300-014 3 I56-3050-004R

AIR FLOW

DIRECTION

H0551-00

3

/4˝

HOLE

NOTE: Air currents inside the duct may cause excessive vibration, especially

when the longer sampling tubes are used. In these cases, a 3 inch floor flange

(available at most plumbing supply stores) may be used to fasten the sampling

tube to the other side of the duct. When using the flange/connector mounting

technique, drill a 1 to 11⁄4 inch hole where the flange will be used.

[6.3] MODIFICATIONS OF SAMPLING TUBES

There may be applications where duct widths are not what is specified for the

installation. In such cases, it is permissible to modify a sampling tube that is

longer than necessary to span the duct width.

Use a 0.193 inch diameter (#10) drill and add the appropriate number of holes

so that the total number of holes exposed to the air flow in the duct is 10 to 12.

Space the additional holes as evenly as possible over the length of the tube.

NOTE: This procedure should only be used as a temporary fix. It is not intended as a permanent substitute for ordering the correct length tubes.

[6.4] REMOTE SAMPLING TUBE INSTALLATION

The detector arrangement can also incorporate the remote mounting of the

sampling tube and/or exhaust tube. In this case both the detector, sampling

tube and exhaust tube (if included) should be rigidly mounted to withstand

the pressure and vibrations caused by the air velocity. The location of the

detector’s sampling tube should be such that there is uniform airflow in the

cross section area.

The pressure differential across the sampling and exhaust ports in the detector housing shall be verified to be between .01 and 1.11 inches of water. Do

so by measuring the pressure difference between the inlet and outlet ports

on the detector housing using a manometer as described in Section 10.4.4 of

this manual.

[7] MEASUREMENT TESTS

[7.1] AIR FLOW

The D2 is designed to operate over an extended air speed range of 100 to

4000 FPM. To verify sufficient sampling of ducted air, turn the air handler on

and use a manometer to measure the differential pressure between the two

sampling tubes. The differential pressure should measure at least 0.01 inches

of water and no more than 1.11 inches of water. Because most commercially

available manometers cannot accurately measure very low pressure differentials, applications with less than 500 FPM of duct air speed may require one

of the following: 1) the use of a current-sourcing pressure transmitter (Dwyer

Series 607) per Section 7.2; or 2) the use of aerosol smoke per section 10.4.4.

[7.2] LOW FLOW AIR FLOW TEST USING DWYER SERIES 607 DIFFERENTIAL PRESSURE TRANSMITTER

Verify the air speed of the duct using an anemometer. Air speed must be at

least 100 FPM. Wire the Dwyer transmitter as shown in Figure 5. Connect the

leads of the meter to either side of the 1000Ω resistor. Allow unit to warm up

for 15 seconds. With both HIGH and LOW pressure ports open to ambient air,

measure and record the voltage drop across the 1000Ω resistor (measurement

1), 4.00 volts is typical. Using flexible tubing and rubber stoppers, connect the

HIGH side of the transmitter to the sampling tube of the duct smoke detec-

DETECTOR

H0215-00

Page 4

tor housing, and the LOW side of the transmitter to the exhaust tube of the

TO SAMPLING TUBE

UL/FM LISTED

CAUTION

duct smoke detector housing. Measure and record the voltage drop across the

1000Ω resistor (measurement 2). Subtract the voltage recorded in measurement 1 from the voltage recorded in measurement 2. If the difference is greater

than 0.15 volts, there is enough air flow through the duct smoke detector for

proper operation.

FIGURE 5. PROCEDURE FOR VERIFYING AIR FLOW:

[8] FIELD WIRING; INSTALLATION GUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and the local codes having jurisdiction. Proper wire gauges should be used.

The conductors used to connect smoke detectors to control panels and accessory devices should be color-coded to prevent wiring mistakes. Improper connections can prevent a system from responding properly in the event of a fire.

For signal wiring, (the wiring between interconnected detectors or from detectors to auxiliary devices), it is recommended that single conductor wire be no

TO EXHAUST TUBE

smaller than 18 gauge. The duct smoke detector terminals accommodate wire

sizes up to 12 gauge.

HIGH

DIFFERENTIAL

PRESSURE

TRANSMITTER

MODEL #607-01

LOW

1000 OHM 5%

1 WATT RESISTOR

15 TO 36

VDC SUPPLY

9 VOLT

BATTERY

9 VOLT

BATTERY

9 VOLT

BATTERY

Smoke detectors and alarm system control panels have specifications for allowable loop resistance. Consult the control panel manufacturer’s specifications for the total loop resistance allowed for the particular model control

panel being used before wiring the detector loop.

[8.1] WIRING INSTRUCTIONS

The D2 detectors are designed for easy wiring. The housing provides a terminal strip with clamping plates. Wiring connections are made by sliding the

bare end of the wire under the plate, and tightening the clamping plate screw.

See Figure 6 below for system wiring.

[9] DETECTOR STATUS INDICATION

VOLT METER FLUKE

MODEL 87 OR

EQUIVALENT

+–

H0163-01

Detector status is indicated by the LED’s on the sensor. Refer to table below

for more details.

FIGURE 6. SYSTEM WIRING DIAGRAM FOR D2 2-WIRE DUCT SMOKE DETECTORS

(DETECTORS POWERED FROM INITIATING CIRCUIT):

COMPATIBLE 2-WIRE

CONTROL PANEL

ALARM

INITIATION

LOOP

Do not loop wire under terminals when wiring detectors. Break wire runs to provide system supervision of connections.

TABLE 2. DETECTOR STATUS INDICATIONS

Status Sensor LEDs Designation Description/Trouble Shooting

Sensor

Initialization

Standby

Maintenance Not illuminated

Alarm Solid Red The unit is in alarm.

1ST DETECTOR

IN LOOP D2

2ND DETECTOR

IN LOOP D2

LAST DETECTOR

IN LOOP D2

EOL RESISTOR

SPECIFIED

BY PANEL

(+)

(–)

(+) IN (+) OUT

RA

(+)

(–)

RA

(–)

~

~

(+)

RA400Z (OPTIONAL)

REMOTE ALARM LED

(–)

4.4 VDC NOM.

IN ALARM

~

~

(+) IN (+) OUT

RA

(+)

(–)

RA

(–)

~

~

(+)

RA400Z (OPTIONAL)

REMOTE ALARM LED

(–)

4.4 VDC NOM.

IN ALARM

~

~

(+) IN (+) OUT

RA

(+)

(–)

RA

(–)

(+)

(–)

MANUFACTURER

RA400Z (OPTIONAL)

REMOTE ALARM LED

4.4 VDC NOM.

IN ALARM

E

O

L

R

STYLE D OPTIONAL WIRING

H0564-01

Alternating red blink every

5 seconds

Simultaneous red blink every

5 seconds

At power up the sensor will take approximately 30 seconds to inialize. Also occurs when

sensor is removed during a seven minute delay.

The LED on the sensor should flash approximately every 5 seconds. If the sensor LEDs

are not illuminated, then the detector lacks power (check wiring, panel or power supply).

The sensor is outside of its sensitivity limits and shall be cleaned or replaced.

See Section 10.3 for details.

SS-300-014 4 I56-3050-004R

Page 5

[10] VERIFICATION OF OPERATION

CAUTION

[10.1] POWER THE UNIT

Apply 12VDC or 24 VDC to terminals marked as + in and -, see Figure 1, and

electrical specs for details.

[10.2] PERFORM DETECTOR CHECK

VERIFY STANDBY per Table 2 on page 4. The use of a remote accessory is

recommended.

[10.3] SENSITIVITY VERIFICATION

The sensitivity of the sensor is confirmed to be operating within its allowable

range each time the sensor LEDs blink red every 5 seconds. Note in a maintenance condition the sensor LEDs will not be illuminated as depicted in Table

2. The maintenance condition indicates that the sensor is operating outside its

original factory preset sensitivity and shall be cleaned or replaced. See Section

9 for reference. This is a valid UL test.

The SENS-RDR sensitivity reader can also be used to measure the sensitivity

of the sensor. Sensitivity testing shall not be used as a substitute for alarm

testing.

[10.4] DUCT SMOKE DETECTOR TEST AND

MAINTENANCE PROCEDURES

Test and maintain duct smoke detectors as recommended in NFPA 72. The

tests contained in this manual were devised to assist maintenance personnel

in verification of proper detector operation.

Before conducting these tests, notify the proper authorities that the smoke

detection system will be temporarily out of service. Disable the zone or system

under test to prevent unwanted alarms.

[10.4.1] ALARM TESTS

1a. M02-04-00 Magnet Test (Sold Separately) – Place the painted surface of

the magnet onto the MAGNET TEST location on the sensor cover of unit

(Figure 1).

OR

1b. Remote Test Accessory - See list on page 1.

The red LEDs on the sensor should latch on, as should any accesso-

ries (i.e. RA400Z/RA100Z, RTS451/RTS151). Verify system control panel

alarm status and control panel execution of all intended auxiliary functions (i.e. fan shutdown, damper control, etc.)

2. The detector must be reset by the system control panel, or remote test

accessory

[10.4.2] VERIFY AIRFLOW TEST PER SECTION 7 HAS BEEN PERFORMED.

[10.4.3] SMOKE RESPONSE TESTS

To determine if smoke is capable of entering the sensing chamber, visually

identify any obstructions. Close cover tamper terminals on sensor side of

housing to ensure communication to panel. Plug the exhaust and sampling

tube holes to prevent ducted air from carrying smoke away from the detector

head, then blow smoke such as cigarette, cotton wick, or punk directly at the

head to cause an alarm. REMEMBER TO REMOVE THE PLUGS AFTER THIS

TEST, OR THE DETECTOR WILL NOT FUNCTION PROPERLY.

[10.4.4] SMOKE ENTRY USING AEROSOL SMOKE

This test is intended for low-flow systems (100-500 FPM). If the air speed is

greater than 500 FPM, use a conventional manometer to measure differential

pressure between the sampling tubes, as described in 7.1.

Drill a 1⁄4 inch hole 3 feet upstream from the duct smoke detector. With the air

handler on, measure the air velocity with an anemometer. Air speed must be

at least 100 FPM. Spray aerosol smoke* into the duct through the 1⁄4 inch hole

for five seconds. Wait two minutes for the duct smoke detector to alarm. If the

duct smoke detector alarms, air is flowing through the detector. Remove the

duct smoke detector cover and blow out the residual aerosol smoke from the

chamber and reset the duct smoke detector. Use duct tape to seal the aerosol

smoke entry hole.

*Aerosol smoke can be purchased from Home Safeguard Industries at homesafeguard.com, model 25S Smoke Detector Tester, and Chekkit Smoke Detector

Tester model CHEK02 and CHEK06 available from SDi. When used properly,

the canned smoke agent will cause the smoke detector to go into alarm. Refer to the manufacturer’s published instructions for proper use of the canned

smoke agent.

Canned aerosol simulated smoke (canned smoke agent) formulas will vary

by manufacturer. Misuse or overuse to these products may have long term

adverse effects on the smoke detector. Consult the canned smoke agent manufacturer’s published instructions for any further warnings or caution statements.

[10.5] INSTALL THE COVER

Install the covers making sure that the cover fits into the base groove. Tighten

the seven screws that are captured in the covers.

[11] DETECTOR CLEANING PROCEDURES

Notify the proper authorities that the smoke detector system is undergoing

maintenance, and that the system will temporarily be out of service. Disable

the zone or system undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

FIGURE 7. DETECTOR SENSOR EXPLODED VIEW:

SENSOR

COVER

SENSING

CHAMBER

COVER AND

COVER

REMOVAL

TABS

SCREEN

SENSOR

CHAMBER

C1009-00

[11.1] DETECTOR SENSOR

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal

tabs that hold the cover in place. See Figure 7.

3. Vacuum the screen carefully without removing it. If further cleaning is

required continue with Step 4, otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing chamber.

6. Reinstall the chamber cover/screen assembly by sliding the edge over the

sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently

pushing it until it locks into place.

8. Reinstall the detector.

[11.2] REINSTALLATION

1. Reinstall the detector in its housing.

2. Restore system power.

3. Perform Detector Check, Section [10.2].

4. Notify the proper authorities testing has been completed and the smoke

detector system is back in operation.

[12] SENSOR REPLACEMENT (PART NO. 2151)

1. Remove the sensor head by rotating counterclockwise.

2. Pull gently to remove it.

3. To replace the sensor head, align the mounting features and rotate clockwise into place.

SS-300-014 5 I56-3050-004R

Page 6

SEPARATELY. SEE FIGURE 9 ABOVE FOR REFERENCE.

[13] OPTIONAL ACCESSORIES

The D2 duct smoke detector can be used with the RA400Z/RA100Z, RTS451/

RTS151, or RTS451KEY/RTS151KEY remote test station.

FIGURE 8. WIRING DIAGRAMS FOR OPTIONAL ACCESSORIES:

(+)

ALARM +

FIGURE 9. D2 WITH OPTIONAL TEST COIL:

AUX OUT –

D2

DUCT DETECTOR

(–)

RA400Z/RA100Z

(OPTIONAL)

REMOTE (LED)

ANNUNCIATOR

[13.1] RTS451/RTS151/RTS451KEY/RTS151KEY REMOTE TEST

STATION

The RTS451/RTS151/RTS451KEY/RTS151KEY Remote Test Station facilitates

RED

H0611-05

TEST COIL

TEST COIL SCREW

TEST COIL TERMINALS

test of the alarm capability of the duct smoke detector as indicated in the

RTS451/RTS151/RTS451KEY/RTS151KEY manual. The D2 duct smoke detector

must be reset by the system control panel. If a system control panel is used,

the panel itself may also require testing.

To install the RTS451/RTS151/RTS451KEY/RTS151KEY, connect the device as

shown in Figure 10 on page 6; wire runs must be limited to 25 ohms or less

per interconnecting wire.

NOTE: The use of a remote test station requires the installation of an accessory coil, part number DCOIL, sold separately. See Figure for reference.

1) Install DCOIL in housing pocket insuring that arrow is pointing toward detector

2) Install DCOIL mounting screw

3) Connect each DCOIL lead to a Test Coil Terminal

FIGURE 10. WIRING DIAGRAM FOR RTS451/RTS151/RTS451KEY/RTS151KEY REMOTE TEST STATION TO

2-WIRE D2 DUCT DETECTOR:

MAGNET

TEST

SWITCH

ALARM

LED (RED)

4

5

2

(–)

(+)

1

RTS451/RTS451KEY

(OPTIONAL) REMOTE

TEST STATION

METHOD #1 - AUX POWER LOCATED

AT DUCT DETECTOR

+ TEST COIL

– TEST COIL

+ IN

+ OUT

–

– RA

+ RA

+ RTS

D2

24 VDC

AUX POWER

(–)

SUPPLIED

BY USER

(+)

(100mA

SUPPLY)

24 VAC (+10%, –15%)

FULL WAVE RECTIFIED,

UNFILTERED POWER

MAY BE USED

24 VDC

AUX POWER

SUPPLIED

BY USER

(100mA

SUPPLY)

24 VAC (+10%, –15%)

FULL WAVE RECTIFIED,

UNFILTERED POWER

MAY BE USED

MAGNET

TEST

SWITCH

ALARM

LED (RED)

4

5

2

(–)

(+)

1

RTS451/RTS451KEY

(OPTIONAL) REMOTE

TEST STATION

METHOD #2 - AUX POWER LOCATED

AT TEST STATION

+ TEST COIL

– TEST COIL

+ IN

+ OUT

–

– RA

+ RA

+ RTS

H0561-00

D2

NOTE: THE USE OF EITHER THE RTS451 OR RTS451KEY REQUIRES THE INSTALLATION OF AN ACCESSORY COIL, DCOIL, SOLD

H0612-02

Please refer to insert for the Limitations of Fire Alarm Systems

THREE-YEAR LIMITED WARRANTY

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for the enclosed product.

No agent, representative, dealer, or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the product which

is found to be defective in materials or workmanship under normal use and service

during the three year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns Department, RA

SS-300-014 6 I56-3050-004R

©2012 System Sensor

#__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing

the malfunction and suspected cause of failure. The Company shall not be obligated to

replace units which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Loading...

Loading...