Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3247-006

CO1224A

Carbon Monoxide Alarm

Specications

Electrical Specifications

System Voltage

Nominal: 12/24 VDC

Min: 10 VDC

Max: 33 VDC

Avg. Standby Current: 20 mA

Max Alarm Current: 40 mA (75 mA test)

Alarm Contact Ratings: 30 VDC @ 0.5 A

Trouble Contact Ratings: 30 VDC @ 0.5 A

Audible Signal (temp 4 tone): 85 dBA min. in alarm (at 10ft)

Max. Start-up Capacitance: 20 uF

NOTICE: This manual shall be left with the owner/user of this

equipment.

WARNING: This product is intended for use in ordinary indoor

locations of dwelling units, including homes, residential

buildings, hotels, schools, dormitories, and day care centers. It is

not intended for use in industrial factories or commercial parking

garages.

General Description

• Listed to CSA 6.19-01

• Six-wire, system monitored or stand-alone operation

• Local sounder

• Low current draw

• Alarm relay, Form C

• Trouble relay, Form A

• Dual LED’s

• Test/Hush button

• SEMS wiring terminals

• Mount to single gang electrical box or surface mount to wall

or ceiling

• Optional drywall anchors included

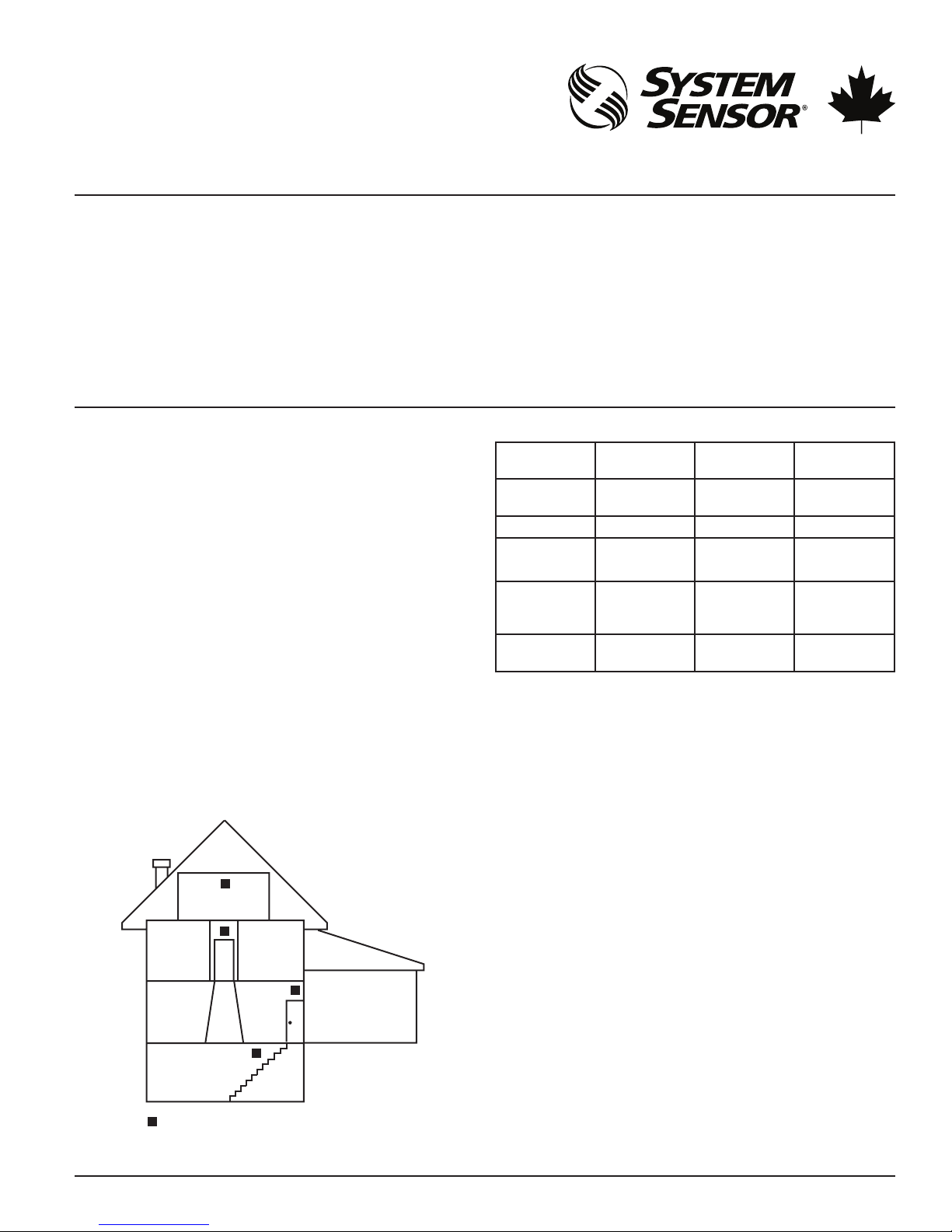

Figure 1. Alarm Location Diagram:

BEDROOM

TO

BEDROOM BEDROOM

LIVING

ROOM

BASEMENT

BR

KITCHEN

CLOSED

DOOR

GARAGE

6581 Kitimat Rd., Unit #6, Mississauga, Ontario, L5N 3T5

1-800-SENSOR2, FAX: 905-812-0771

www.systemsensor.ca

Physical Specifications

Operating Temperature Range: 0° to 40°C (32° to 104°F)

Operating Humidity Range: 22 – 90% %RH

Length: 5.1˝

Width: 3.3˝

Height: 1.3˝

Weight: 7 oz

Wire Gauge Acceptance: 14-22 AWG

Table 1. Operation Modes:

OPERATION

MODE

Normal

(standby)

Alarm OFF Temp 4* pattern Temp 4* pattern

Alarm Test OFF Temp 4 pattern Temp 4 pattern

RealTest Mode

CO End of Life OFF OFF

*Temp 4 pattern is repeated pattern of four short indications

followed by a five second pause.

When the unit has been in alarm for 30 minutes the alarm signal

will be given once every minute.

If ambient conditions return to normal, the unit will self-restore

out of alarm and into Normal (standby) mode.

Hush feature: If required, the audible alarm can be silenced for

5 minutes by pushing the button marked “Test/Hush”. The red

alarm light will continue to flash in temp-4 pattern. If carbon

monoxide is still present after the 5 minute hush period, the

audible alarm will sound. The hush facility will not operate at

levels above 350 ppm (parts per million) carbon monoxide.

Trouble feature: When the sensor supervision is in a trouble

condition (such as a sensor that has been tampered with), the

alarm will sound a trouble signal every 30-60 seconds and the

trouble contact will open . The alarm must then be replaced.

End of Life Timer feature: When the alarm has reached the end of

its life, the trouble signal will sound every 30-60 seconds and the

trouble contact will open. This indicates that the CO sensor inside

the alarm has passed the end of its life and must be replaced.

This alarm’s lifespan is approximately ten years from the date of

manufacture. Refer to Alarm Replacement on page 3.

Refer to Figure 4 for wiring of the alarm and trouble relays.

GREEN

LED

Blink 1 per

minute

Blink 1 per

second (waiting

for gas entry)

RED

LED

OFF OFF

OFF (Red after

CO is sprayed)

SOUNDER

Temp 4 pattern

(after CO is

sprayed)

Chirp every

30-60 seconds

–

CARBON MONOXIDE ALARM

LOCATION FOR MULTI-LEVEL RESIDENCE

1 I56-3247-006

10-28

S0295-00

Page 2

Installation Guidelines

In a wall location, the alarm should be at least as high as a

light switch, and at least six inches from the ceiling. In a ceiling

location, the alarm should be at least 12 inches from any wall.

Where to install, ideally:

• Within 10 feet of all sleeping areas

• Inside the bedroom if it contains a fuel burning appliance

• On every floor of the building

• Ideally, install in any room that contains a fuel burning

appliance

• If the appliance in the room is not normally used, such as the

boiler room, the alarm should be placed just outside the room

so the alarm can be heard more easily

Where NOT to install, ideally:

• Alarms operate best if not installed within 10 feet of any

cooking appliance

• Directly above a sink, cooker, stove or oven

• Next to a door or window that would be affected by drafts i.e.

extractor fan or air vent

• Outside

• Do not install in any environment that does not comply with

the alarm’s environmental specifications

• In or below a cupboard

• Where air flow would be obstructed by curtains or furniture

• Where dirt or dust could collect and block the sensor

• Where it could be knocked, damaged, or inadvertently

removed

Mounting

The CO1224A can be wall- or ceiling-mounted:

1. To a single gang box, or

2. Direct mount to wall or to ceiling using drywall fasteners.

in place. Do not put wires more than 2 gauge apart under the

same clamping plate.

WARNING: Gas detectors on a zone that is bypassed may not

signal a trouble condition. Do not bypass zones used for gas

detectors.

Wiring diagrams locatsed on page 4, Figure 4.

Installation

WARNING

Remove power from alarm control unit or initiating device circuits

before installing detectors.

1. Using a small, flat head screw driver, push in the small tab

located on the underside of the alarm. Once the snap is

loosened, lift the bottom end of the cover up and unhinge the

top to remove the cover.

2. Wire the alarm base screw terminals per Figure 4.

3. Screw the base of the alarm onto a single gang electrical box,

or to the surface of the wall or ceiling. Use the hardware

included in the packaging.

4. Hinge the top portion of the cover onto the base; with the

cover at a 45 degree angle, fit the hinges into the slots of the

base.

5. Push the unhinged bottom portion of the cover down until it

snaps into place.

6. After all alarms have been installed, apply power to the alarm

control unit.

7. Test each alarm as described in Testing.

8. Notify the proper authorities that the system is in operation.

CAUTION

Airborne dust particles can enter the alarm. System Sensor

recommends the removal of alarms before beginning construction

or any other dust producing activity.

Figure 2. Mounting of Alarm:

S0296-00

S0301-00

Wiring Installation Guidelines

All wiring must be installed in compliance with the Canadian

Electrical Code, applicable local codes, and any special

requirements of the local Authority Having Jurisdiction (AHJ).

Proper wire gauges should be used. The conductors used to

connect carbon monoxide alarms to the alarm control panel and

accessory devices should be color-coded to reduce the likelihood

of wiring errors. Improper connections can prevent a system from

responding properly in the event of a CO.

The screw terminals in the mounting base will accept 14-22 gauge

wire. Wire connections are made by stripping approximately

of insulation from the end of the feed wire, inserting it into the

proper base terminal, and tightening the screw to secure the wire

1

/4˝

Carbon monoxide alarms are not to be used with detector guards

unless the combination has been evaluated and found suitable for

that purpose.

Testing

Alarm must be tested after installation.

NOTE: Before testing, notify the proper authorities that

maintenance is being performed and the system will be

temporarily out of service. Disable the zone or system undergoing

maintenance to prevent any unwanted alarms.

Ensure proper wiring and power is applied. After power up, allow

80 seconds for the alarm to stabilize before testing.

Test the CO1224A alarm as follows:

1. A test button is located on the detector housing (See Figure

3).

2. Use the tip of your finger to press and hold the test button for

1-4 seconds.

3. If the sounder beeps twice in the Temporal 4 pattern and the

LEDs light up, the detector is operational.

4. The detector now enters Realtest speed up test mode indicated

by a quickly blinking green LED. See Functional Gas Test

section for instructions on testing with canned CO.

Note: The alarm contact has a time delay of approximately

10 second before operation. To test for the alarm contact

operation, the test button must be held down for at least 10

seconds.

2 I56-3247-006

10-28

Page 3

Figure 3. Test Button Location and Operation:

T

GAS

ENTRY

PORTS

EST/HUSH

BUTTON

If an alarm fails the above test method, its wiring should be

checked. If the alarm still fails after rewiring, it should be replaced.

Functional Gas Test

NOTE: Check with local codes and the AHJ to determine whether

or not a functional gas test is necessary for an installation.

Solo C6 brand canned CO testing agent may be used to verify the

alarm’s ability to sense CO by utilizing the functional speed-up

test feature of the CO1224A as follows:

1. Press the test button as described in Testing above.

2. Once the alarm has entered the speed-up test mode, indicated

by a quickly flashing green LED, spray a small mount of CO

agent within 1/4" of the alarm’s gas entry ports (see Figure 3).

The unit will go into alarm if gas entry is successful.

3. The alarm will automatically exit the speed-up test mode 20

seconds after entering speed-up test mode.

Testing the alarm will activate the alarm relay and send a signal

to the panel.

CAUTION: This carbon monoxide alarm is designed for indoor use

only. Do not expose to rain or moisture. Do not knock or drop the

alarm. Do not open or tamper with the alarm as this could cause

malfunction. The alarm will not protect against the risk of carbon

monoxide poisoning if not properly wired. The alarm will only

indicate the presence of carbon monoxide gas at the sensor. Carbon

monoxide gas may be present in other areas.

This carbon monoxide alarm is NOT:

• Designed to detect smoke, fire or any gas other than carbon

monoxide

• To be seen as a substitute for the proper servicing of fuel-

burning appliances or the sweeping of chimneys.

• To be used on an intermittent basis, or as a portable alarm

for the spillage of combustion products from fuel-burning

appliances or chimneys.

Carbon monoxide gas is a highly poisonous gas which is

released when fuels are burnt. It is invisible, has no smell and

is therefore impossible to detect with the human senses. Under

normal conditions in a room where fuel burning appliances are

well maintained and correctly ventilated, the amount of carbon

monoxide released into the room by appliances should not be

dangerous.

Symptoms of carbon monoxide poisoning: Carbon monoxide

bonds to the hemoglobin in the blood and reduces the amount of

oxygen being circulated in the body. The following symptoms are

related to carbon monoxide poisoning and should be discussed

with all members of the household:

• Mild exposure: Slight headache, nausea, vomiting, fatigue

(often described as “flu-like” symptoms).

3 I56-3247-006

10-28

S0298-01E

• Medium exposure: Sever throbbing headache, drowsiness,

confusion, fast heart rate.

• Extreme exposure: Unconsciousness, convulsions, cardio

respiratory failure, death.

Concentration (ppm CO) Symptoms

200 Mild headache after 2-3 hours

of exposure

400 Headache and nausea after

1-2 hours of exposure

800 headache, nausea, and diz-

ziness after 45 minutes of

exposure;

collapse and unconsciousness

after 2 hours of exposure

Many causes of reported carbon monoxide poisoning indicate

that while victims are aware that they are not well, they become

so disoriented that they are unable to save themselves by either

exiting the building or calling for assistance. Also young children

and pets may be the first to be affected.

Per CSA 6.19-01 the CO1224A has been tested to the following

sensitivity limits.

Parts Per Million Detector response time, min.

30 ±3ppm No alarm within 30 days

70 ±5ppm 60-240

150 ±5ppm 10-50

400 ±10ppm 4-15

What to do if the carbon monoxide alarm goes into alarm:

Immediately move to a spot where fresh air is available, preferably

outdoors. Find a phone in an area where the air is safe and call

your security service provider. Tell your provider the alarm status,

and that you require professional assistance in ridding your home

of the carbon monoxide.

IMPORTANT: This alarm should be tested and maintained

regularly following National Fire Protection Association (NFPA) 720

requirements.

Maintenance

Occasionally clean the outside casing with a cloth. Ensure that the

holes on the front of the alarm are not blocked with dirt and dust.

Do not paint, and do not use cleaning agents, bleach, or polish

on the alarm.

Alarm Replacement

This alarm is manufactured with a long-life carbon monoxide

sensor. Over time the sensor will lose sensitivity, and will need

to be replaced with a new System Sensor carbon monoxide alarm.

This alarm’s lifespan is approximately ten years from the date of

manufacture.

Periodically check the alarm’s replacement date. Remove the alarm

cover and refer to the sticker placed on the inside of the alarm. The

sticker will indicate the date that the alarm should be replaced.

This alarm is also equipped with a feature that will sound a trouble

signal every 30-60 seconds and open the trouble relay once it has

reached the end of its useful life. If this occurs, it is time to replace

the alarm.

NOTE: Before replacing the alarm, notify the proper authorities that

maintenance is being performed and the system will be temporarily

out of service. Disable the zone or system undergoing maintenance

to prevent any unwanted alarms. Dispose of alarm in accordance

with any local regulations.

Page 4

Figure 4. Wiring Diagram:

SINGLE UNIT, SINGLE ZONE, 4 CONDUCTOR CABLE

MULTIPLE UNIT, SINGLE ZONE, 6 CONDUCTOR CABLE

NON-RESETTABLE PWR

CO ZONE

UL LISTED

PANEL

+

−

CLOSED WITH

POWER APPLIED

AND NO FAULT

+ −

TT

C

ALARM

INITIATION

CONTACTS

NO

DETECTED

EOL RESISTOR

SPECIFIED BY PANEL

MANUFACTURER

S0313-00

CAUTION

It should be noted the installation, operation, testing and maintenance of the CO1224A is different than System Sensor conventional 4-wire smoke detectors, such as the i3 Series. Below are

specific installation requirements for the CO1224A:

* Connect to a non-resettable power supply

* Connect to a non-fire zone: Per NFPA 720 section 5.3.7.2 the CO1224A

shall not be connected to a zone that signals a fire condition

* Per NFPA 720 section 5.3.7, do not connect the CO1224A on a zone

with other fire or intrusion initiating devices - i.e. do not connect on

the same zone as smoke detectors

* Wiring of the trouble relay will send a trouble signal to the control

panel upon an open circuit, a ground fault, sensor removal or sensor

end of life

* If wiring one CO1224A per zone: Use 4 conductors

* If wiring multiple CO1224A alarms per zone: Use 4 conductors from

panel to first CO1224A, then use 6 conductors from the second

CO1224A to other alarms on the zone

NON-RESETTABLE PWR

CO ZONE

UL LISTED

PANEL

+

−

+ −

TT TT

C

ALARM

INITIATION

CONTACTS

NO

FIRST CO1224

DETECTOR

IN LOOP

Input powered (12 or 24 VDC) from ULC Listed Fire/Burg Control Panel (Class 2).

Please refer to insert for the limitations of Carbon Monoxide Alarms

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

System Sensor warrants its enclosed product to be free from defects in

materials and workmanship under normal use and service for a period

of three years from date of manufacture. System Sensor makes no other

express warranty for the enclosed product. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the

product which is found to be defective in materials or workmanship under

normal use and service during the three year period commencing with

the date of manufacture. After phoning System Sensor’s toll free number

800-SENSOR2 (736-7672) for a Return Authorization number, send defective units postage prepaid to: System Sensor, Returns Department, RA

System Sensor® is a registered trademark of Honeywell International, Inc.

4 I56-3247-006

©2016 System Sensor. 10-28

SUPERVISORY TROUBLE CONTACTS

+ −

C

NO

LAST CO1224

DETECTOR

FCC Statement

Three-Year Limited Warranty

IN LOOP

ALARM

INITIATION

CONTACTS

CLOSED WITH

POWER APPLIED

AND NO FAULT

DETECTED

EOL RESISTOR

SPECIFIED BY PANEL

MANUFACTURER

POSITIVE

NEGATIVE

TROUBLE

TROUBLE

NORMALLY

CLOSED

COMMON

NORMALLY

OPEN

S0314-00

#__________, 6581 Kitimat Road, Unit 6, Mississauga, Ontario L5N-3T5.

Please include a note describing the malfunction and suspected cause

of failure. The Company shall not be obligated to replace units which

are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no

case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

POWER

}

TROUBLE

RELAY

}

ALARM

RELAY

S0300-01

Loading...

Loading...