Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-1367-004R

B501BHT

Temporal Tone Sounder Base

Specifications

Base Diameter: 6.0 inches (15.2 cm)

Base Height (less sensor): 2.3 inches (5.9 cm)

Weight: 0.4 lb. (181 gm)

Operating Temperature Range: 32° to 120°F (0° to 49°C)

Operating Humidity Range: 10% to 93% Relative Humidity

Electrical Ratings

External Supply Voltage: 17 to 32 VDC

Standby Current: 1.0 mA maximum

Alarm Current: 15 mA maximum

Maximum Ripple Voltage: 10% of supply voltage

Start-up Capacitance: 200 µF

Communication/Initiating Loop Supply

Current Draw from Remote Output

of Sensor to turn on Horn: 700 µA maximum

Sound Output: Greater than 90 dBA measured in anechoic room at 10 feet, 24 volts. 85 dBA minimum

measured in UL reverberant room.

Before Installing

Please read the System Smoke Detector Application Guide,

which provides detailed information on sensor spacing. placement, zoning, wiring, and special applications. Copies of this

manual are available from System Sensor. NFPA 72 and NEMA

guidelines should be observed.

NOTICE: This manual should be left with the owner/user of

this equipment.

IMPORTANT: The detector used with this base must be tested

and maintained regularly following NFPA 72 requirements.

The detector should be cleaned at least once a year.

General Description

The B501BHT sounder base is used with System Sensor 200

and 500 Series sensor heads. Refer to the appropriate manual

for more information on sensors.

The B501BHT incorporates the distinctive three-pulse temporal pattern fire alarm evacuation signal now required by NFPA

72 for commercial and residential applications.

The sounder base is intended for use with intelligent systems.

Refer to the panel manual for the maximum allowable number of units per loop. The sounder base requires an external

24VDC supply with reverse polarity capability or a relay module configured to reverse the power as in Figure 5. The connections for the external supply (terminals 1 and 2) and the

communication loop (terminals 3 and 4) are isolated to prevent electrical interaction between them.

When the sensor’s visible LEDs are latched on for approximately 10 seconds, the associated horn sounds. A loop of

horns can be made to sound by reversing the polarity of the

external supply when configured as in Figure 4 and 5. When

configured as in Figure 5, a loop of horns can also be made to

sound by turning on the Intelligent Relay Module.

NOTE: When not used as a supplementary evacuation system

the external 24 VDC supply shall be treated as a component of

the main power supply system and shall fall under the requirements of the main power supply system per NFPA 72.

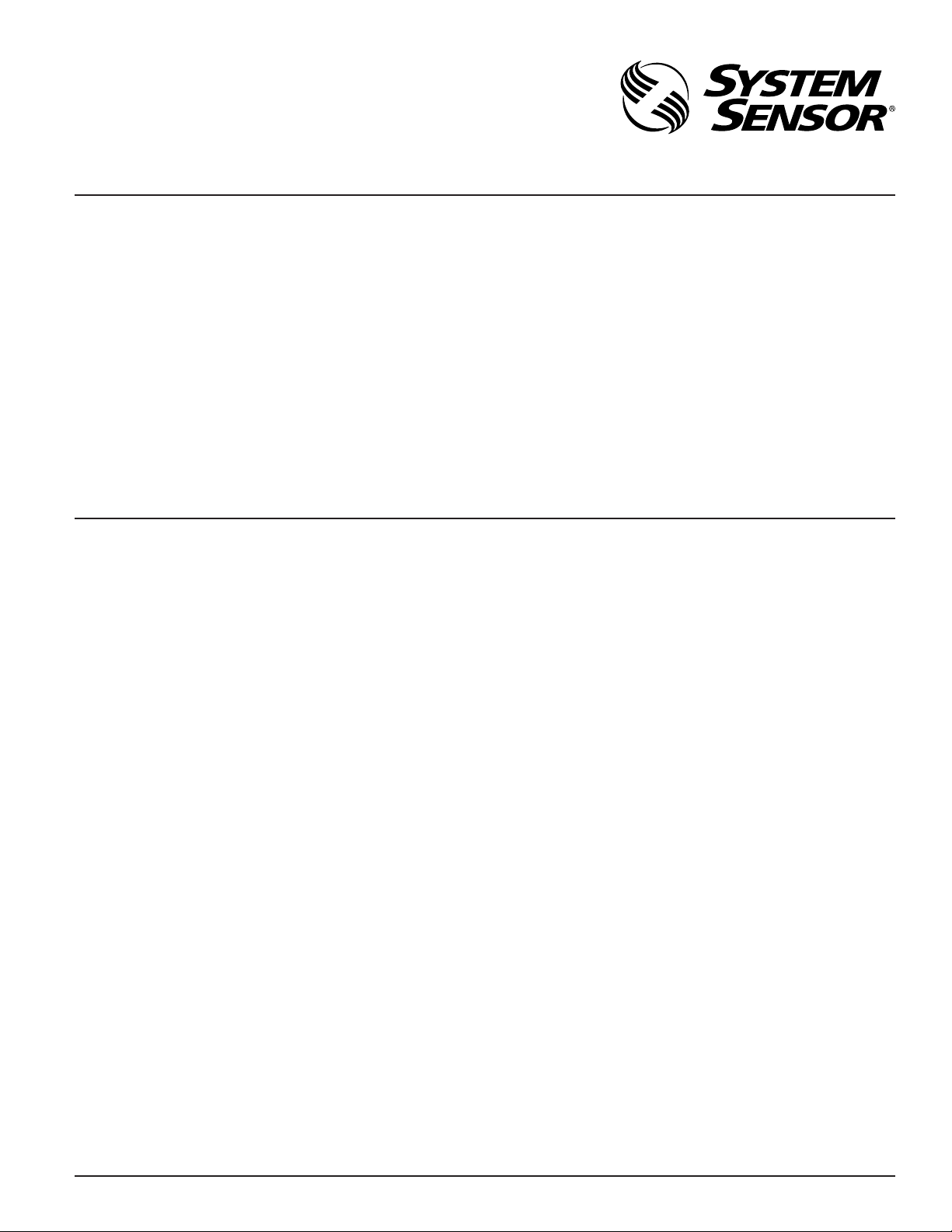

B501BHT Terminals

No. Function

1 External Supply Positive (+)

2 External Supply Negative (–)

3 Negative (–) Comm. Line In and Out

4 Positive (+) Comm. Line In and Out

5 Sounder Base Interconnect

Terminals 3 and 4 are used for the communication circuit.

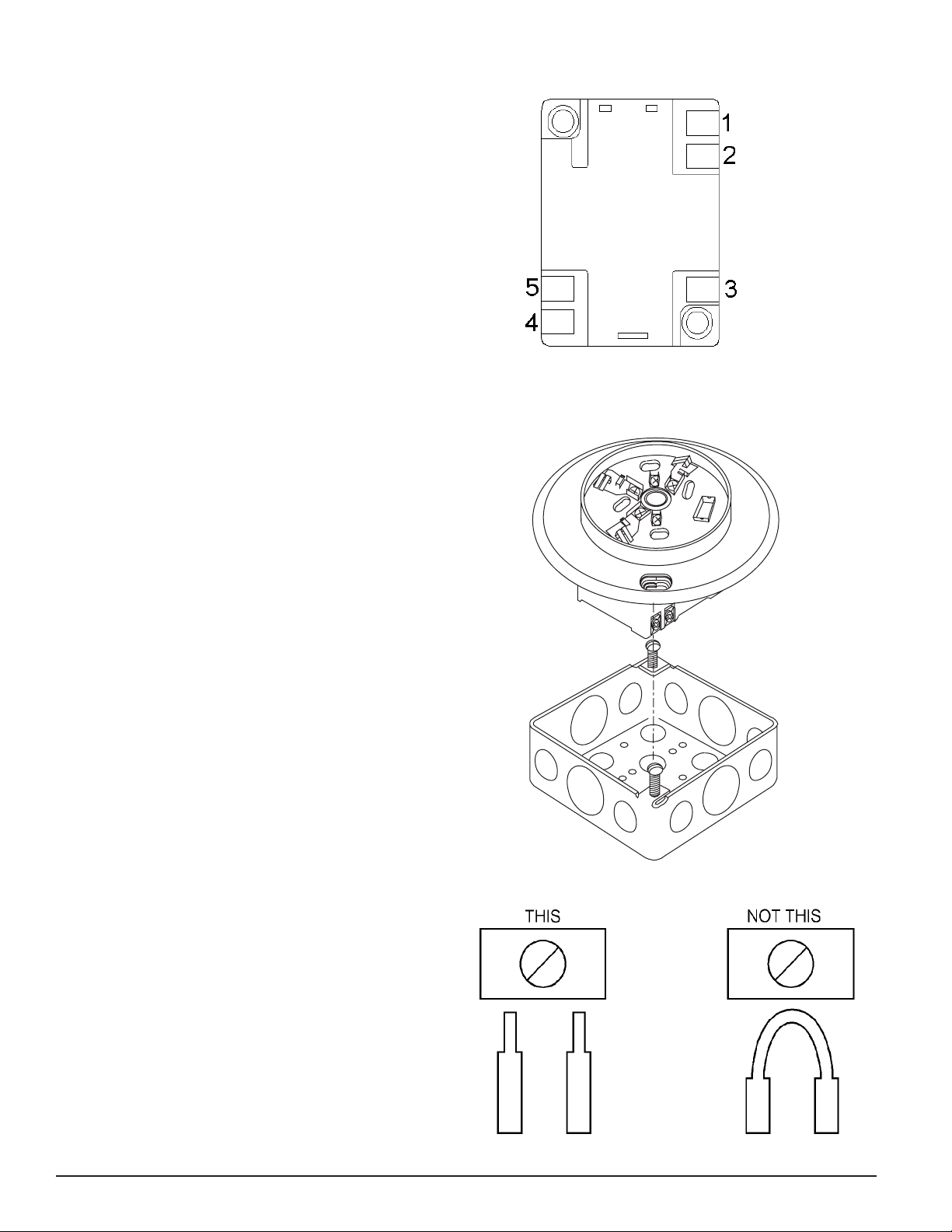

Mounting

Mount the B501BHT directly to an electrical box, using the

mounting kit, supplied (see Figure 2).

The sounder base is 1.1-inches deep. Electrical boxes must

be 4-inches square by at least 11⁄2 inches deep - 21⁄8 inches is

recommended.

NOTE: A maximum space of 1⁄8 inch from the outside edge of

the electrical box to the inside edge of the drywall or ceiling

tile is allowable.

Wiring Guidelines

All wiring must be installed in compliance with the National

Electrical Code and the local codes having jurisdiction and

must not be of such length or wire size which would cause

the base to operate outside of its published specifications. The

conductors used to connect smoke sensors to control panels

and accessory devices should be color coded to reduce the

likelihood of wiring errors. Improper connections can prevent

a system from responding properly in the event of a fire.

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

D550-06-00 1 I56-1367-004R

Page 2

For signal wiring (the wiring between interconnected sensors

MOUNT B501BHT

TO ELECTRICAL BOX

4 INCH SQUARE BOX

or modules), it is recommended that the wire be no smaller

than 18 gauge (1.0 square mm). Wire sizes up to 12 gauge (2.5

square mm) may be used with the base. For best system performance, the power (+ and –) wires and the communication

circuit wires should be twisted pair or shielded cable installed

in separate grounded conduit to protect the communication

loop from electrical interference.

Make wire connections by stripping about 3⁄8” of insulation

from the end of the wire. Then, slide the bare end of the

wire under the clamping plate, and tighten the clamping

plate screw. Do NOT loop the wire under the clamping plate

(See Figure 3).

The zone wiring of the sensor base should be checked before

the sensor heads are installed. Check the wiring for continuity

and polarity in the base.

See the individual sensor manual for the maximum sensor installation temperature.

Wiring Instructions

NOTE: External supply shown in normal standby configuration in Figure 4 and 5.

The wiring diagram for a typical 2-wire intelligent system is

shown in Figure 4 and 5 (the monitor module is supervising

the external supply).

Testing

Sensors and bases must be tested after installation and as an integral part of periodic maintenance. Test the B501BHT as follows:

NOTE: Before testing, notify the proper authorities that the

smoke sensor system is undergoing maintenance and, therefore, will be temporarily out of service. Disable the system undergoing maintenance to prevent unwanted alarms.

1. If configured as in Figure 4 or 5, reverse the polarity of the

external 24VDC supply. If configured as in Figure 5, turn

on the Intelligent Relay Module. All B501BHT bases on the

loop should sound in approximately 10 seconds.

2. Latch the sensor LED on from the control panel. That unit’s

B501BHT should sound in approximately 10 seconds.

NOTES:

1. There is approximately a 10 second delay built into the

B501BHT before sounding. This delay is present whether

the control signal comes from the sensor or from the external power supply polarity being reversed.

2. During automatic testing cycles, the horn may sound if

the associated sensor is left in the test mode with LEDs

latched on for more than 4 seconds. Therefore, it is necessary to complete testing of each sensor within this 4-second limit to prevent the horn from sounding.

Figure 1. Terminal layout:

C0471-00

Figure 2. Mounting:

C0472-00

Figure 3:

C0473-00

D550-06-00 2 I56-1367-004R

Page 3

Figure 4. Wiring diagram:

INTELLIGENT

MONITOR

MODULE

(+) 2

(–)

1

67

U.L.

LISTED

EOL

RESISTOR

47K

U.L.

LISTED

EOL

RELAY

24V

5

4

123

5

4

123

5

4

123

(+) COMM.

(–) COMM.

(–) POWER

(+) POWER

U.L. LISTED COMPATIBLE

CONTROL PANEL

EXTERNAL

24V SUPPLY

CLASS A OPTIONAL WIRING

CLASS A OPTIONAL WIRING

*

GROUPING OF UP TO 6 MODEL B501BHT TEMPORAL TONE SOUNDER BASES.

OPTIONAL SOUNDER INTERCONNECT

*

UL LISTED

COMPATIBLE

CONTROL

PA NEL

INTELLIGENT

MONITOR

MODULE

INTELLIGENT

RELAY

MODULE

FIRST

SOUNDER

BASE

(+) POWER

(–) POWER

LAST

SOUNDER

BASE

(–) COMM.

(+) COMM.

UL

LISTED

EOL

RELAY

24V

UL LISTED

EOL

RESISTOR

47k

UL LISTED

24V SUPPLY

SLC

(+)

(–)

THIS IS A STANDARD RELAY

MODULE CONFIGURED TO

REVERSE THE POWER

OPTIONAL SOUNDER INTERCONNECT

*

*

GROUPING OF UP TO 6 MODEL B501BHT TEMPORAL TONE SOUNDER BASES.

†

†

Detector Activates Sounder Base(s) - (Complies with UL268)

UL has approved grouping for up to six B501BHT base with

horn units. When wired as a group, any detector in the group

that has its LED’s latched on by the panel will cause other

B501BHT units in the group to sound. This type of “local”

grouping is accomplished by wiring the grouped devices to-

gether using terminal 5, Sounder Base Interconnect, as shown

in the diagram.

NOTE: Since a local grouping of horns is not supervised, the

groups can only be used as a supplementary evacuation system.

It is not acceptable to group horns for primary alarm signaling.

Figure 5. Wiring diagram:

Detector Activates Sounder Base(s); Intelligent Relay Module Activates All Sounder Bases - (Complies with UL 268 and UL 464)

UL has approved grouping of up to six B501BHT bases with

horn units. When wired as a group, any detector in the group

that has its LED’s latched on by the panel will cause other

B501BHT units in the group to sound. This type of “local”

C0474-00

grouping is accomplished by wiring the grouped devices together using terminal 5, Sounder Base Interconnect, as shown

in the diagram.

NOTE: Since a local grouping of horns is not supervised, the

groups can only be used as a supplementary evacuation system. It is not acceptable to group horns for primary alarm

signaling.

C0968-00

D550-06-00 3 I56-1367-004R

Page 4

Please refer to insert for the Limitations of Fire Alarm Systems

THREE-YEAR LIMITED WARRANTY

System Sensor warrants its enclosed smoke detector base to be free from defects in materials and workmanship under normal use and service for a period of three years from date

of manufacture. System Sensor makes no other express warranty for this smoke detector

base. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector base which is found to be defective in materials or workmanship under normal

use and service during the three year period commencing with the date of manufacture.

After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System Sensor, Returns

D550-06-00 4 I56-1367-004R

©2007 System Sensor

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a

note describing the malfunction and suspected cause of failure. The Company shall not

be obligated to repair or replace units which are found to be defective because of damage,

unreasonable use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental damages for

breach of this or any other Warranty, expressed or implied whatsoever, even if the loss

or damage is caused by the Company’s negligence or fault. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Loading...

Loading...