Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-2816-003R

B401BH-2

Sounder Bases

SpECIfICATIONS

Base Diameter: 6 inches (152 mm)

Base Height (less base and sensor): 0.75 inches (19mm)

Weight: 0.32 lb. (145 g)

Operating Temperature Range: 14° to 140°F (–10° to +60°C)

Operating Humidity Range: 10% to 95%, non-condensing

Electrical Ratings

Voltage: 17 to 32 VDC

Standby Current: 1.0 mA maximum

Alarm Current: 15 mA maximum

Maximum Ripple Voltage: 10% of supply voltage

Start-up Capacitance: 200 µF

Horn Input Current Requirement: 600 µA maximum

Sound Output: Greater than 90 dBa measured in anechoic room at 10 feet (3 meters),

24 volts. 85 dBa minimum measured in UL reverberant room.

Sounder Delay Time: 0.75 to 5.7 sec

BEfORE INSTALLINg

Please thoroughly read the, System Smoke Detector Application Guide, which

provides detailed information on detector spacing, placement, zoning, wiring,

and special applications. Copies of this manual are available from System Sensor. NFPA 72 and NEMA guidelines should be observed.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with these bases must be tested and maintained regularly following NFPA 72 requirements. The detector used with

these bases should be cleaned at least once a year.

gENERAL DESCRIpTION

Model B401BH-2 sounder bases is intended for use with System Sensor 400

Series plug-in sensor heads in conventional 2-wire plug-in systems. Refer to

systems manuals for the maximum allowable number of units per loop. The

B401BH-2 requires an external 24VDC (nominal) supply with reverse polarity

capability. The connections of the external supply (terminals 1 and 2) and the

initiating loop (terminals 3, 4, and 5) are isolated in the B401BH-2 to prevent

electrical interaction between them.

A loop of horns can be made to sound by reversing the polarity of the external

supply.

NOTE: When the associated system is NOT used as a supplementary evacuation system, the external 24VDC supply must be treated as a component of the

main power supply system with the result that it falls under the requirements

of NFPA 72.

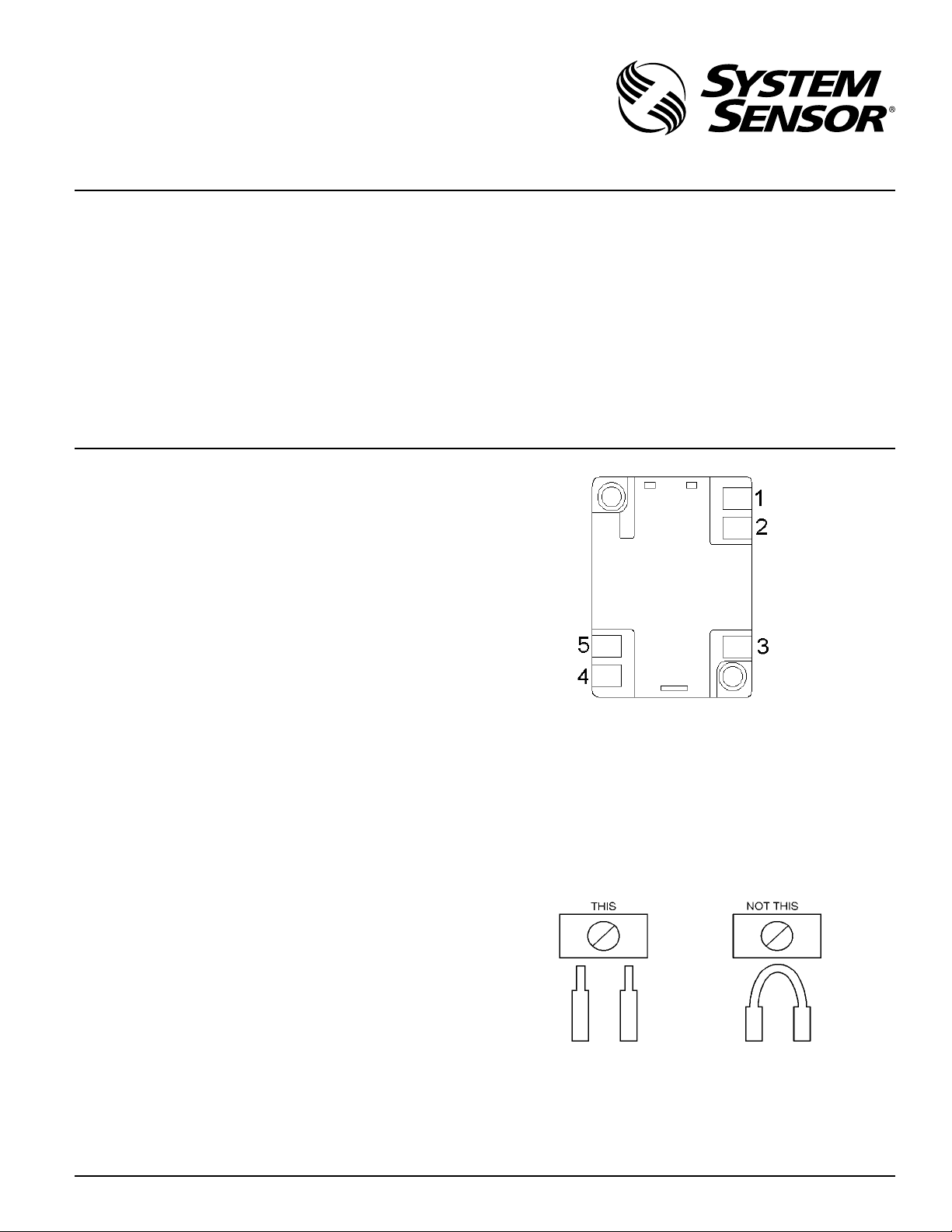

B401BH-2 TERMINALS

No. Function

1 External Supply Positive (+)

2 External Supply Negative (–)

3 Negative (–) V

4 Positive (+) V In

5 Positive (+) V Out

Terminals 3, 4, and 5 are used for the communication/initiating circuit.

INSTALLATION WIRINg gUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and all applicable local codes and any special requirements of the authority

having jurisdiction, using the proper wire size. The conductors used to connect smoke detectors to control panels and accessory devices should be colorcoded to reduce the likelihood of wiring errors. Improper connections can

prevent a system from responding properly in the event of a fire.

fIgURE 1. TERMINAL LAyOUT :

For signal wiring (the wiring between interconnected detectors), it is recommended that the wire be no smaller than AWG 18. However, the screws and

clamping plate in the base can accommodate wire sizes up to AWG 12. The

use of twisted pair wiring or shielded cable for the power (+ and –) loop is

recommended to minimize the effects of electrical interference on the initiating loop.

Begin electrical connections by stripping about 3/8” insulation from the end

of the wire. Then, slide the bare end of the wire under the clamping plate and

tighten the clamping plate screw. Break the wire at each terminal to ensure

that the connections are supervised, as shown in Figure 2.

fIgURE 2.

DO NOT loop the wire under the clamping plate.

Check the zone wiring of the detector base before the detector heads are

installed. Perform continuity, base polarity, and dielectric tests on the wiring.

Smoke detectors and alarm system control panels have specifications for allowable supervision current. Consult the control panel manufacturer’s specifications for the total loop current supervision allowed for the control panel

being used before wiring the detector loops.

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

C0471-00

C0473-00

D450-00-00 1 I56-2816-003R

Page 2

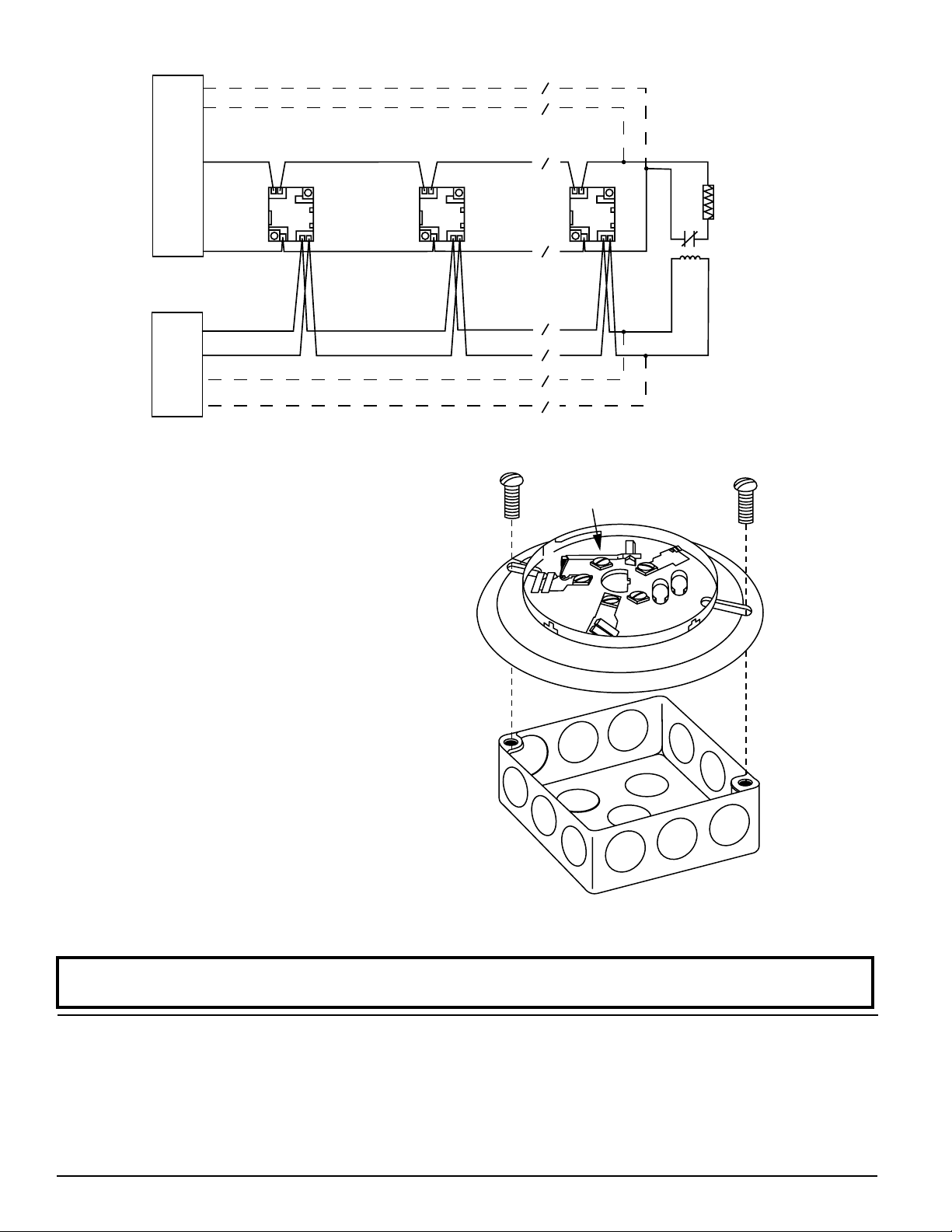

fIgURE 3. TypICAL WIRINg LAyOUT :

SCREWS

(NOT SUPPLIED)

DETECTOR

BASE

BOX

(NOT SUPPLIED)

SHORTING

SPRING

CLASS A OPTIONAL WIRING

(+) INIT.

4

5

3

UL LISTED COMPATIBLE

CONVENTIONAL CONTROL PANEL

SUPPLY

EXTERNAL 24V

(−) INIT.

(−)POWER

(+)POWER

4

5

3

1

2

CLASS A OPTIONAL WIRING

WIRINg INSTRUCTIONS

The shorting spring in the base will disengage automatically when the detector head is removed from the base.

DO NOT remove the shorting spring since it reengages as the detector head is

turned into the base, completing the circuit.

A typical wiring for a two-wire conventional system is shown in Figure 3. Refer to this diagram as needed while wiring the base into the system.

NOTE: Figure 3 shows external 24V supply polarity when

the loop system is in standby (NOT alarming).

MOUNTINg

NOTE: It is recommended that the base be completely wired before mounting.

See Figure 4. Attach the base directly to an electrical box using the screws

supplied with the box. Then, use the plastic screw covers, supplied with the

base, to cover the screws.

The sounder base is 1.1 inches (28 mm) deep. Electrical boxes must be 4 inches

(102 mm) square by at least 1-1/2 inches (38 mm) deep; 2-1/8 inches (54 mm)

is recommended.

TESTINg

Before testing, notify the proper authorities that the smoke detector system is undergoing maintenance and that the system will be temporarily out of service. Disable the zone or system undergoing maintenance to prevent unwanted alarms.

Detectors and bases must be tested after installation and following periodic

maintenance.

Test the B401BH-2 as follows:

1. Test the conventional detector head following the procedure in its manual. The B401BH-2 should sound approximately 0.75 to 5.7 seconds after

the detector alarms.

2. Reverse the polarity of the external 24 VDC supply. This should cause

every base in the loop to sound after approximately 0.75 to 5.7 seconds.

Please refer to insert for the Limitations of Fire Alarm Systems

4

5

1

2

3

1

2

UL

LISTED

EOL

RELAY

24V

fIgURE 4. MOUNTINg TO AN ELECTRICAL BOx:

UL

LISTED EOL

RESISTOR

C0956-01

C0503-01

THREE-yEAR LIMITED WARRANTy

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for this air duct smoke

detector. No agent, representative, dealer, or employee of the Company has the authority

to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the replacement of any part of the product which

is found to be defective in materials or workmanship under normal use and service

during the three year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns Department, RA

#__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a note describing

the malfunction and suspected cause of failure. The Company shall not be obligated to

replace units which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

D450-00-00 2 I56-2816-003R

©2010 System Sensor

Loading...

Loading...