Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-3387-006R

B200S

Intelligent Sounder Base

This model is compatible with Sytem Sensor Models MDL, MDL3R, MDLW, MDL3W and SYNC-1

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Specifications

Base Diameter: 6.875” (17.46 cm)

Base Height (less sensor): 2.0” (5.08 cm)

Weight: 0.50 lb. (227 gm)

Operating Temperature Range: Refer to applicable sensor Operating Temperature Range using the Base/Sensor Cross Reference Chart at systemsensor.com

Operating Humidity Range: 10% to 93% relative humidity (non-condensing)

External Supply Electrical Ratings

External Supply Voltage: 16 to 33 VDC (VFWR)

Standby Current: 500 μA maximum

Alarm Current: 35 mA maximum (at high volume setting); 15 mA maximum (at low volume setting)

SLC Electrical Ratings

SLC Operating Voltage: 15 to 32 VDC

SLC Standby Current: 300 μA maximum

Sound Output

High Volume: Greater than 85 dBA minimum measured in a UL reverberant room at 10 feet, 24 Volts (in continuous tone)

Low Volume: Greater than 75 dBA minimum measured in a UL reverberant room at 10 feet, 24 Volts (in continuous tone)

BEFORE INSTALLING

Please read the System Sensor Smoke Detector Application Guide, which provides detailed information on sensor spacing, placement, zoning, wiring, and

special applications. Copies of this manual are available from System Sensor.

NFPA 72 and NEMA guidelines should be observed.

NOTE: 200 Series sounder bases are not compatible with remote test capable

200 series detectors.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with this base must be tested and maintained

regularly following NFPA 72 requirements. The detector should be cleaned at

least once a year.

GENERAL DESCRIPTION

The B200S sounder base is used with System Sensor 200-Series sensor heads or

equivalent. For a list of compatible sensors, refer to the System Sensor website

at www.systemsensor.com. Refer to the appropriate manual for more information on sensors.

The B200S sounder base was designed specifically to meet the needs of dwelling unit applications. It offers maximum flexibility in configuration and operation to meet or exceed the requirements of UL268 and UL464.

The sounder base is capable of producing a variety of tone patterns, including

the distinctive three-pulse temporal pattern (ANSI Temporal 3) fire alarm signal now required by NFPA 72 for commercial and residential applications.

The B200S can be commanded by the Fire Alarm Control Panel to adopt the

address of the attached sensor head, but as a unique device type on the loop.

By using the address, the fire alarm control panel can command an individual

sounder base to activate, or a group of sounders in a suite or other multi-room

configuration. The command set from the panel can be tailored to the specific

event, allowing selection of volume, tone, and group. The device offers two

volume levels: 75 dBA and 85 dBA. The available tones are Continuous, ANSI

Temporal 3, ANSI Temporal 4, and March Time. In addition, some fire alarm

panels will offer the ability to command a custom tone pattern. Refer to the

appropriate fire alarm control panel manual for more information.

In addition, the B200S is equipped with the circuitry to recognize the System

Sensor synchronization protocol, enabling the sounder base to be used as a

component of the general evacuation signal – producing an NFPA 72 compliant

Temporal 3 pattern in synchronization with other System Sensor notification

devices. This requires connection to a power supply capable of generating

the System Sensor synchronization pulses, a FACP NAC output configured

to System Sensor synchronization protocol, or a separate synchronization

module.

The sounder base is intended for use with intelligent systems. In addition to

being connected to the SLC, the sounder base requires a connection to either

24 VDC constant power or a NAC circuit, depending on the FACP and intended

use. The connections for 24V constant/NAC power and the communication

loop are isolated to prevent electrical interaction between them.

When connected to a NAC, power is supervised via the NAC circuit supervision while in standby mode (EOL resistor required for Class B operation).

when activated, the B200S provides supervision of NAC power (see Figure 5).

When using a FACP equipped with a “sounder base standby power monitoring” mode (see table) and constant 24 V power, power supervision EOL

devices (supervision relays and resistors) should not be used (see Figure 4).

In this case, the B200S will provide supervision in both standby and alarm/

active mode. If your FACP is not listed in the table or you choose not to use

“sounder base standby power monitoring” mode, power supervision relays

and EOL resistors are required to provide supervision in standby mode.

NOTE: If the FACP’s “sounder base standby power monitoring” mode is

enabled, connecting B200S sounder bases to the NAC will result in power

supervision failure when in standby. Only connect B200S sounder bases to

constant 24 V power in this case. Refer to the panel manual for maximum allowable number of units per loop.

NOTE: For NFPA72 Installations, the Temporal 3 tone at high volume should

be used for public mode evacuation. The use of other tone styles and low

volume level will be at the discretion of the local Authority Having Jurisdiction (AHJ).

NOTE: When not used as a supplementary evacuation system, the external 24

VDC supply shall be treated as a component of the main power supply system

and shall fall under the requirements of the main power supply system per

NFPA 72.

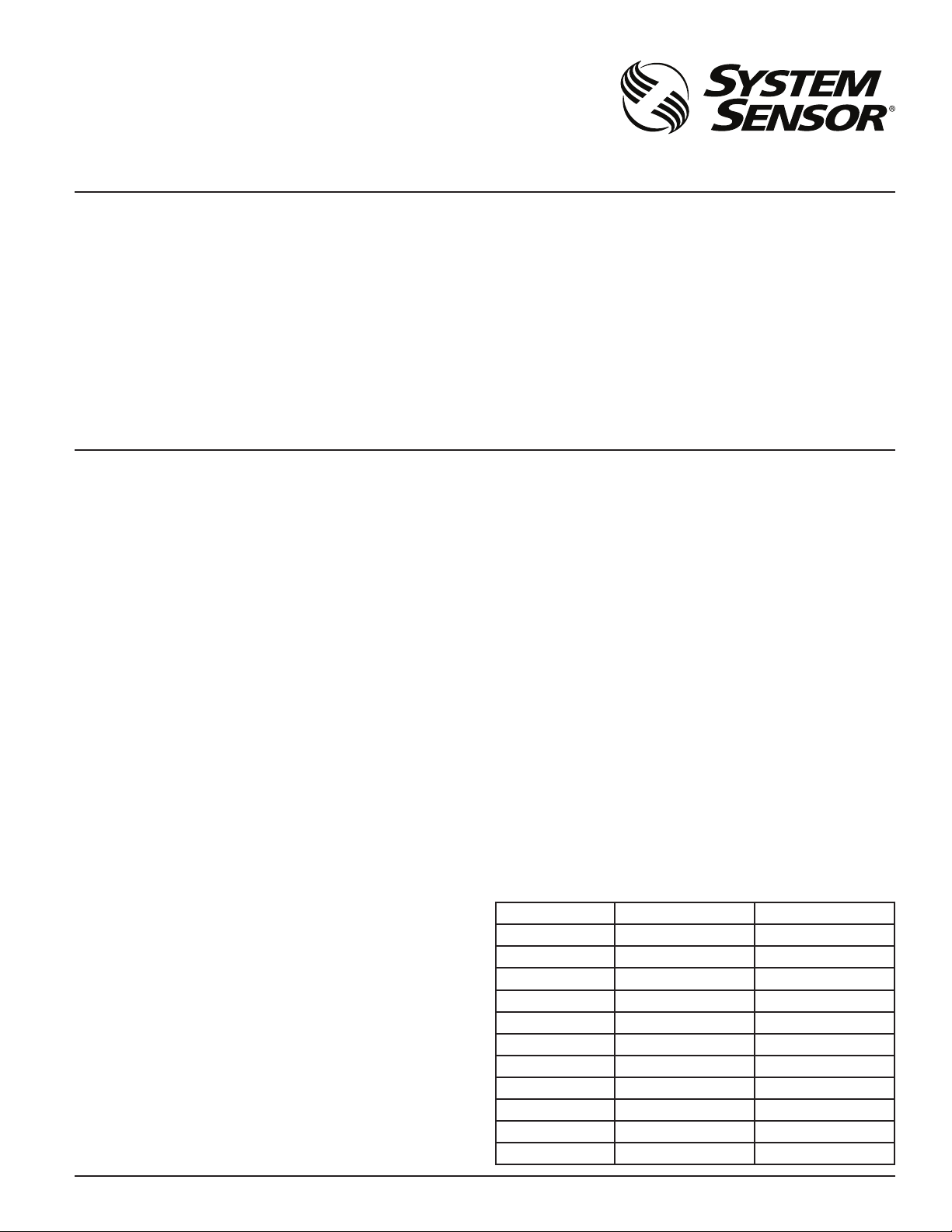

FACPS EQUIPPED WITH “SOUNDERBASE STANDBY POWER MONITORING” MODE

Manufacturer FACP Model Firmware Revision

Notifier NFS-320 Rev. 20 or Higher

Notifer NFS2-640 Rev. 20 or Higher

Notifier NFS2-3030 Rev. 20 or Higher

Gamewell-FCI E3 Series Rev. 2.4 or Higher

Gamewell-FCI S3 Series All Revisions

Honeywell XLS120 Rev. 21 or Higher

Honeywell XLS140-2 Rev. 21 or Higher

Honeywell XLS3000 Rev. 21 or Higher

Silent Knight 5820XL, 5820XL-EVS Rev. 13 or Higher

Silent Knight 5808 Rev. 13 or Higher

Silent Knight 5700 Rev. 13 or Higher

SS-450-000 1 I56-3387-006R

Page 2

Silent Knight IFP-2000, IFP-2000ECS Rev. 4 or Higher

1

3

4

Silent Knight IFP-1000, IFP-1000ECS Rev. 13 or Higher

Silent Knight IFP-100, IFP-100ECS Rev. 13 or Higher

Silent Knight IFP-50 Rev. 13 or Higher

Johnson Controls IFS-320 Rev. 21 or Higher

Johnson Controls IFC2-640 Rev. 21 or Higher

Johnson Controls IFC2-3030 Rev. 21 or Higher

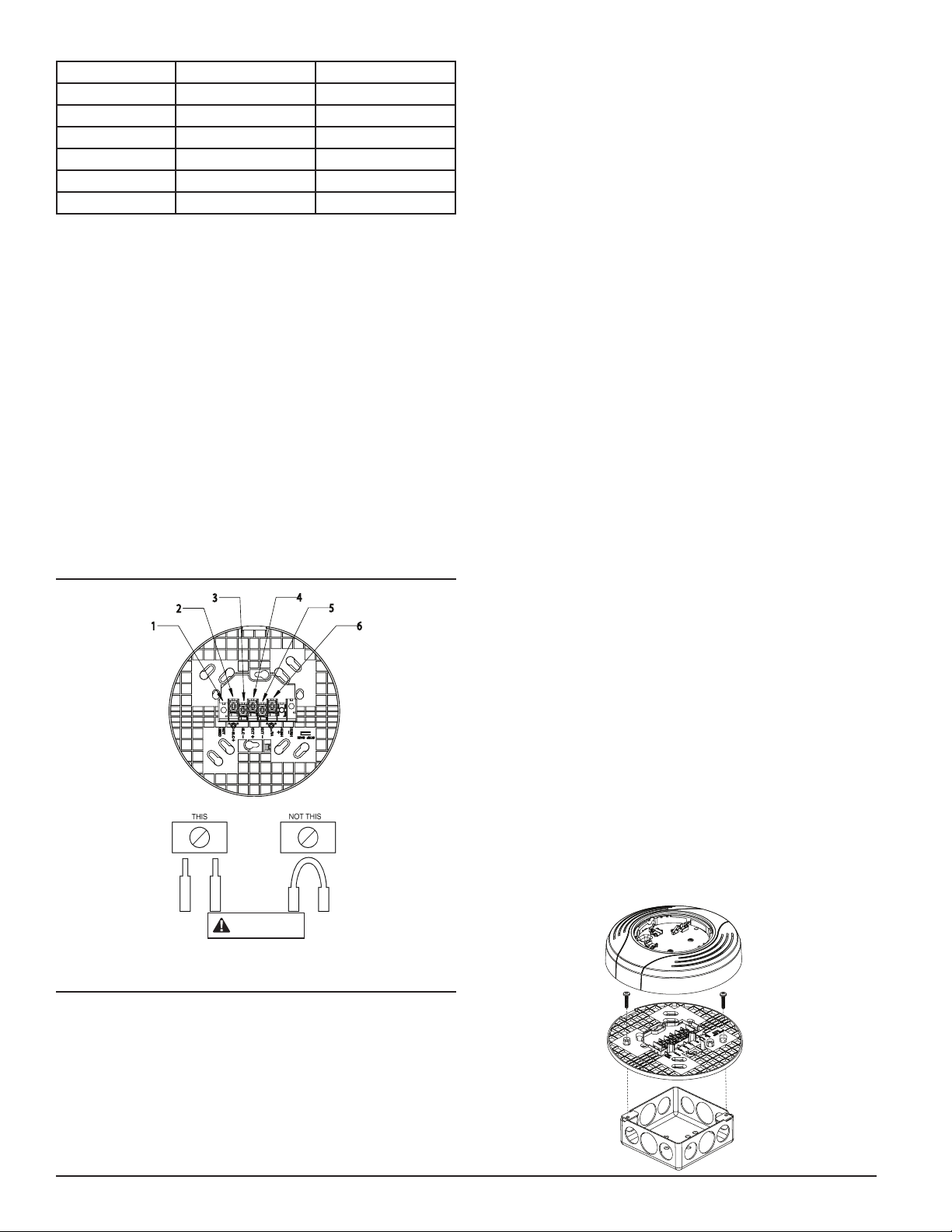

WIRING GUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and the local codes having jurisdiction and must not be of such length or wire

size which would cause the base to operate outside of its published specifications. The conductors used to connect smoke sensors to control panels and

accessory devices should be color coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from responding properly

in the event of a fire.

Wire sizes up to 12 AWG (2.5 mm2) may be used with the base. The sounder

base will be shipped with the screw terminals set for 14 AWG wiring. If 12

AWG wire is to be used, back out the screws to allow the wire to fit beneath

the clamping plates.For best system performance, the power (+ and -) wires

and the communication circuit wires should be twisted pair or shielded cable

installed in a separate grounded conduit to protect the communication loop

from electrical interference.

Make wire connections by stripping about 3/8” of insulation from the end of

the wire. Then, slide the bare end of the wire under the appropriate clamping

plate (See Figure 1), and tighten the clamping plate screw. Do NOT loop the

wire under the clamping plate (See Figure 2) The wiring diagram for a typical

2-wire intelligent system is shown in Figure 4.

FIGURE 1:

2

5

6

mount directly to 4˝ square (with and without plaster ring), 4˝ octagon, 3 1/2˝

octagon, single gang or double gang junction boxes.

1. Connect field wiring to terminals, as shown in Figure 1 and 2.

2. Attach the mounting plate to the junction box as shown in Figure 3.

3. To mount the sounder base, hook the tab on the sounder base to the groove

on the mounting plate.

4. Then, swing the sounder base into position to engage the pins on the

product with the terminals on the mounting plate.

5. Secure the sounder base by tightening the mounting screws.

6. Install a compatible smoke sensor as described in the installation manual

for the sensor.

TAMPER RESISTANT FEATURE

NOTE: Do not use the tamper-resist feature if the removal tool is to be used.

This detector base includes a tamper-resist feature that prevents its removal

from the base without the use of a tool. To activate this feature, break the tab

from the detector base as shown in Figure 7A. Then, install the detector. To

remove the detector from the base once the tamper-resist feature has been

activated, insert a small-bladed screwdriver into the slot from the top and

press down on the lever (see Figure 7B). This allows the detector to be rotated

counterclockwise for removal. The tamper-resist feature can be defeated by

breaking and removing the plastic lever from the base. However, this prevents

the feature from being used again.

TESTING AND MAINTENANCE

Sensors and bases must be tested after installation and as an integral part of a

periodic maintenance program. Test the B200S as follows:

NOTE: Before testing, notify the proper authorities that the smoke sensor

system is undergoing maintenance and, therefore, will be temporarily out of

service. Disable the system undergoing maintenance to prevent unwanted

alarms.

1. Via the fire alarm control panel, command the individual B200S to activate

using the associated sensor address. That sounder base should sound in

approximately five seconds.

2. Via the fire alarm control panel, command all B200S sounder bases to activate using group communication to all associated addresses. All devices on

the loop should sound, and if a temporal tone is commanded, the tones can

be synchronized to each other.

NOTE: Synchronization requires a power supply capable of producing the System Sensor synchronization pulses or a synchronization module.

When performing maintenance on connected smoke sensors, carefully note

the location and address of each removed sensor. When re-installed, the

B200S will confirm that address of the sensor matches the address stored in

C0471-07

the sounder base memory. If there is a mismatch, this will be communicated

to the fire alarm control panel and the sounder base can be commanded to

chirp at regular intervals until the correct head is installed.

FIGURE 2:

If a replacement head is installed or address changes are required, the mismatch may be resolved at the panel by commanding the B200S sounder base to

re-enter its address learning mode and adopting the address of the new sensor.

C0473-00

FIGURE 3: MOUNTING

CAUTION

For system monitoring - for terminals 2, 3, 4, and 5, do not use looped wire

under terminals. Break wire run as shown in Figure 2 to provide monitoring

of connections.

B200S TERMINALS

No. Function

1. Not Used

2. Positive (+) Comm. Line In and Out

3. Negative (-) Comm. Line In and Out

4. External Supply Positive (+)

5. External Supply Negative (-)

6. Remote Annunciator

MOUNTING

Mount the B200S mounting plate directly to an electrical box. The plate will

SS-450-000 2 I56-3387-006R

C0891-07

Page 3

FIGURE 4: WIRING DIAGRAM

THE SYNCHRONIZATION PULSES (SEE FIGURE 6)

USED TO PROVIDE THE SYNCHRONIZATION PULSES

(CONNECTED TO 24V POWER USING COMPATIBLE FACP WITH “SOUNDER BASE STANDBY POWER MONITORING” ENABLED)

NOTE: Only use this wiring diagram when connecting to 24VDC power using a FACP listed in the table on page 1. Please consult your FACP manufacturer for

panel-specific wiring configurations and special cases.

Additional Audible Visible devices may be connected to the same power supply or the the NAC output of the Fire Alarm Control Panel (FACP) to provide a synchronized communication of the alarm signal.

CLASS A OPTIONAL WIRING

OPTIONAL REMOTE

ANNUNCIATOR MODEL

(–) SLC

(+) SLC

RA400Z/100Z

EXT +

RA

SLC –

EXT –

C0474-12

(+) CONSTANT POWER

CONTROL PANEL

(–) CONSTANT POWER

U.L. LISTED COMPATIBLE

(+) NAC

(–) NAC

USED

NOT

FIRST

SOUNDER

BASE

SLC +

EXT +

SLC –

(+) (+)

(–)

HORN HORNHORN/STROBE

EXT +

RA

EXT –

SLC +

USED

NOT

SECOND

SOUNDER

BASE

SLC –

RA

EXT –

SLC +

USED

NOT

NTH

SOUNDER

BASE

/

/

(+)

E

O

L

(–)

(–)

A SEPERATE SYNCHRONIZATION MODULE MAY BE USED TO PROVIDE

FIGURE 5: WIRING DIAGRAM (CONNECTED TO NAC OR 24V POWER; OPTIONAL EOL DEVICES FOR CONSTANT SUPERVISION)

NOTE: Only use this wiring diagram when connecting to a NAC or a 24V power supply that does not support “sounder base standby power monitoring”

(see page 1).

CLASS A OPTIONAL WIRING

OPTIONAL REMOTE

ANNUNCIATOR MODEL

(–) SLC

(+) SLC

CONTROL PANEL

U.L. LISTED COMPATIBLE

RA400Z/100Z

SLC +

USED

NOT

FIRST

SOUNDER

BASE

(+) NAC OR CONSTANT POWER*

(–) NAC OR CONSTANT POWER*

EXT +

SLC –

RA

EXT –

SLC +

USED

NOT

SECOND

SOUNDER

BASE

EXT +

SLC –

RA

EXT –

SLC +

USED

NOT

NTH

SOUNDER

BASE

/

/

EXT +

RA

SLC –

EXT –

E

O

L

/

(+) NAC

UL LISTED 24V

POWER SUPPLY

(–) NAC

(+) (+)

(–)

(–)

HORN HORNHORN/STROBE

A SEPERATE SYNCHRONIZATION MODULE MAY BE

(+)

E

*WHEN USING 24V CONSTANT POWER

O

L

(–)

(AUX POWER), ADDITIONAL POWER

SUPERVISION RELAYS AND MODULES WILL

BE REQUIRED FOR PROVIDING SUPERVISION

WHEN THE SOUNDER BASES ARE INACTIVE.

(SEE FIGURE 6)

SS-450-000 3 I56-3387-006R

/

C0474-11

Page 4

BREAK TAB AT

USE SMALL-BLADED

SLOT

FIGURE 6: SYNCHRONIZATION DIAGRAM (FOR MDL SERIES SYNC MODULES ONLY)

FACP #1

TEMP JUMP OFF

+

B+

NAC 1

}

B–

B+

NAC 2

}

B–

B+

NAC 3

}

B–

NOTE: Wiring shown for System Sensor MDL Series Sync Module. For additional wiring configurations, see your sync module manual.

FIGURE 7A:

PLASTIC LEVER

EOL

(1)

–

+

–

+

–

+

}

–

+

}

–

+

}

–

+

}

–

HORN

CONTROL

ZONE 1

IN

MASTER

ZONE 2

IN

SLAVE

IN

ZONE 1

OUT

ZONE 2

OUT

NAC

SLAVE IN

SLAVE

OUT

DOTTED LINE BY

TWISTING TOWARD

CENTER OF BASE.

}

}

}

}

+

–

+

–

+

–

+

–

SOUNDER

BASE

SOUNDER

BASE

TO NEXT DEVICE

OR EOL (1)

OPTIONAL

2 STYLE Y ZONES

(CLASS B)

TO NEXT DEVICE

OR EOL (1)

SCREWDRIVER TO

PUSH PLASTIC LEVER

IN DIRECTION OF

ARROW.

C1090-00

C0144-00

FIGURE 7B:

C1082-00

Please refer to insert for the Limitations of Fire Alarm Systems

THREE-YEAR LIMITED WARRANTY

System Sensor warrants its enclosed smoke detector base to be free from defects in materials and workmanship under normal use and service for a period of three years from date

of manufacture. System Sensor makes no other express warranty for this smoke detector

base. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector base which is found to be defective in materials or workmanship under normal

use and service during the three year period commencing with the date of manufacture.

After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System Sensor, Returns

SS-450-000 4 I56-3387-006R

©2013 System Sensor

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a

note describing the malfunction and suspected cause of failure. The Company shall not

be obligated to repair or replace units which are found to be defective because of damage,

unreasonable use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental damages for

breach of this or any other Warranty, expressed or implied whatsoever, even if the loss

or damage is caused by the Company’s negligence or fault. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Loading...

Loading...