Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

WARNING

CAUTION

CAUTION

I56-3140-003R

2D51 Photoelectric Smoke Detector

FOR USE WITH INNOVAIRFLEX 4-WIRE DUCT SMOKE

DETECTOR HOUSINGS OR PENDANT MOUNT APPLICATIONS

SPECIFICATIONS

Height: 2.0 in

Diameter: 4.1 in; 6.1 in

Weight: 3.1 oz. (88 g)

Operating Temperature Range: –20°C to 70°C (–4°F to 158°F)

Operating Humidity Range: 0% to 95% Relative Humidity Non-condensing

BEFORE INSTALLING

Please thoroughly read the System Sensor manual A05-1003, Applications

Guide for System Smoke Detectors, which provides detailed information on

detector spacing, placement, zoning, wiring, and special applications. Copies

of this manual are available from System Sensor.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector must be tested and maintained regularly following

NFPA 72 requirements. The detector should be cleaned at least once a year.

GENERAL DESCRIPTION

The 2D51 photoelectronic detector uses a state-of-the-art optical sensing

chamber. This detector is designed to provide protection in duct applications

when installed with an Innovair Flex 4-wire duct smoke detector housing and

to be used with compatible UL listed control panels only.

The 2D51 can also be used in pendant mount applications when installed with

a B210LP or B501 base and D4P120 power board components.

Two LEDs on each detector provide local visible alarm indication. They flash

every five seconds indicating that power is applied and the detector is working

properly. The LEDs latch on in alarm. LEDs will be off when a trouble condition exists indicating that the detector sensitivity is outside the listed limit.

See applicable Innovair Flex duct smoke detector installation manual for more

information.. The alarm can be reset by a momentary power interruption,

test/reset button, or remote test accessory with reset function. This detector

may be tested by activating the internal reed switch with a magnet, test/reset

button, or remote test accessory.

INSTALLATION

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations.

Remove power from initiating-device circuits before installing detectors.

1. Install detectors:

a. Place the detector into the detector base.

b. Turn the detector clockwise until the detector drops into place.

c. Continue turning detector clockwise to lock it in place.

2. After all detectors have been installed, apply power to the control unit.

3. Test the detector using the test/reset button or magnet as described

under TESTING

4. Reset the detector at the system control panel or on power board.

5. Notify the proper authorities that the system is back on line.

Dust covers are an effective way to limit the entry of dust into smoke detector sensing chambers. However, they may not completely prevent airborne dust particles

from entering the detector. Therefore, System Sensor recommends the removal

of detectors before beginning construction or other dust producing activity.

Be sure to remove the dust covers from any sensors that were left in place during construction as part of returning the system to service.

TESTING

Before testing, notify the proper authorities that the smoke detector system

is undergoing maintenance and will temporarily be out of service. Detectors

must be tested after installation and as part of periodic maintenance. Test the

2D51 as follows:

SS-300-017 1 I56-3140-003R

NOTE: Before testing the detector, check to ensure the the power board LEDs

blink. If they do not, the detector may not have power or may not be installed

properly (check the wiring), if it is defective, or the detector sensitivity is outside the listed limits return it for repair.

ALARM TESTS

1a. Test/Reset Button - Press and hold the test button located on the power

board cover for at least 2 seconds.

OR

1b. M02-04-00 Magnet Test - Place the painted surface of the magnet onto

the MAGNET TEST location on the sensor cover or the duct smoke

detector (Figure 1).

2. The red alarm LED on the sensor and the power board should latch on,

as should any accessories (i.e. RA100Z, RTS151). Verify system control

panel alarm status and control panel execution of all intended auxiliary

functions (i.e fan shutdown, damper control, etc.).

3. The detector must be reset by the system control panel, front cover Test/

Reset button, or remote accessory.

4. To reset using the Test/Reset button on the power board cover simply

press and release.

SMOKE RESPONSE TESTS

To determine if smoke is capable of entering the sensing chamber, visually

identify any obstructions. Plug the exhaust and sampling tube holes to prevent ducted air from carrying smoke away from the detector head, then blow

smoke such as cigarette, cotton wick, or punk directly at the head to cause

an alarm. REMEMBER TO REMOVE THE PLUGS AFTER THIS TEST, OR THE

DETECTOR WILL NOT FUNCTION PROPERLY.

SMOKE ENTRY USING AEROSOL SMOKE

This test is intended for low-flow systems (100-500 FPM). If the air speed is

greater than 500 FPM, use a conventional manometer to measure differential

pressure between the sampling tubes, as described per the installation manual

provided with the duct smoke detector.

Drill a 1⁄4 inch hole 3 feet upstream from the duct smoke detector. With the air

handler on, measure the air velocity with an anemometer. Air speed must be

at least 100 FPM. Spray aerosol smoke* into the duct through the 1⁄4 inch hole

for five seconds. Wait two minutes for the duct smoke detector to alarm. If the

duct smoke detector alarms, air is flowing through the detector. Remove the

duct smoke detector cover and blow out the residual aerosol smoke from the

chamber and reset the duct smoke detector. Use duct tape to seal the aerosol

smoke entry hole.

*Aerosol smoke can be purchased from Home Safeguard Industries at homesafeguard.com, model 25S Smoke Detector Tester, and Chekkit Smoke Detector

Tester model CHEK02 and CHEK06 available from SDi. When used properly,

the canned smoke agent will cause the smoke detector to go into alarm. Refer to the manufacturer’s published instructions for proper use of the canned

smoke agent.

Canned aerosol simulated smoke (canned smoke agent) formulas will vary by

manufacturer. Misuse or overuse to these products may have long term adverse

effects on the smoke detector. Consult the canned smoke agent manufacturer’s

published instructions for any further warnings or caution statements.

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Page 2

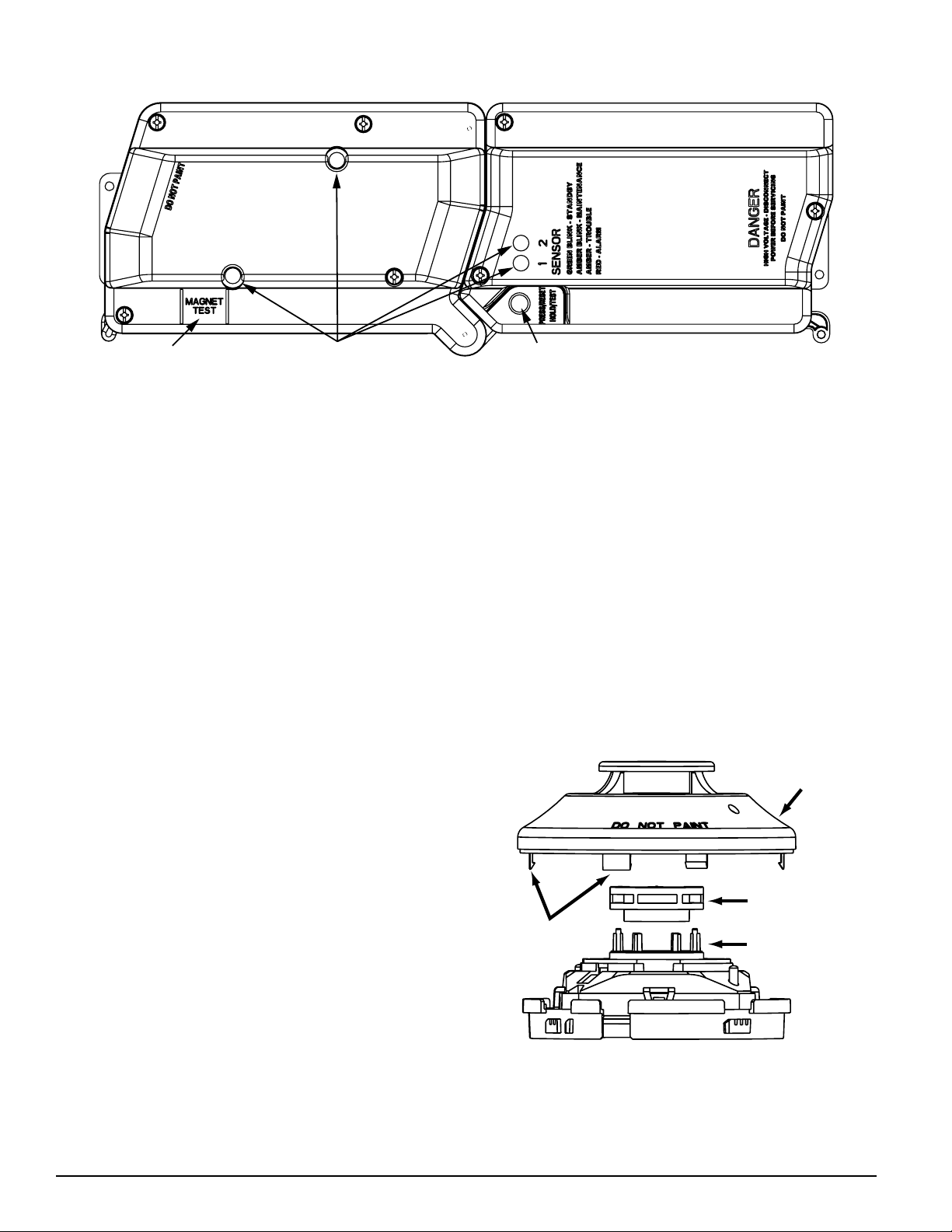

FIGURE 1. CO-LOCATED INNOVAIR FLEX DUCT SMOKE DETECTOR:

SENSOR UNIT

POWER BOARD UNIT

TEST MAGNET

POSITION

LED STATUS INDICATORS

SENSITIVITY VERIFICATION

The sensitivity of the sensor is confirmed to be operating within its allowable

range each time the sensor and power board LEDs blink green every 5 seconds. Note in a maintenance condition the sensor LEDs will blink red every 5

seconds and power board will blink amber. The maintenance condition indicates that the sensor is operating outside its original factory preset sensitivity

and shall be cleaned or replaced. This is a valid UL test.

Notify the proper authorities that the system is back on line.

Detectors that fail these tests should be cleaned as described below and retested. If the detectors still fail these tests, they should be returned for repair.

MAINTENANCE OF DUCT SMOKE DETECTORS

Duct smoke detector should be tested and inspected in accordance with NFPA

72 recommendations. Detectors should be tested annually and visually inspected semiannually. It may be necessary to clean or maintain duct smoke

detectors more frequently based on indoor air quality conditions.

If any unitary packaged air conditioning units are run during the drywall in-

TEST/RESET BUTTON

H0614-00

6. Reinstall the chamber cover/screen assembly by sliding the edge over the

sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently

pushing it until it locks into place.

8. Reinstall the detector.

REINSTALLATION

1. Reinstall the detector in its housing.

2. Restore system power.

3. Perform Detector Check.

4. Notify the proper authorities testing has been completed and the smoke

detector system is back in operation.

NOTE: Verify sensor cover gasket is properly seated on cover prior to cover

installation. Refer to applicable Innovair Flex duct smoke detector installation

manual for more information.

NOTE: If excessive dust is found in the detector housing and/or sampling

tubes they should also be cleaned with a vacuum cleaner or compressed air.

stallation phase of any building under construction to accelerate the drying of

joint compound, the subsequent sanding of those drywall joints and resulting

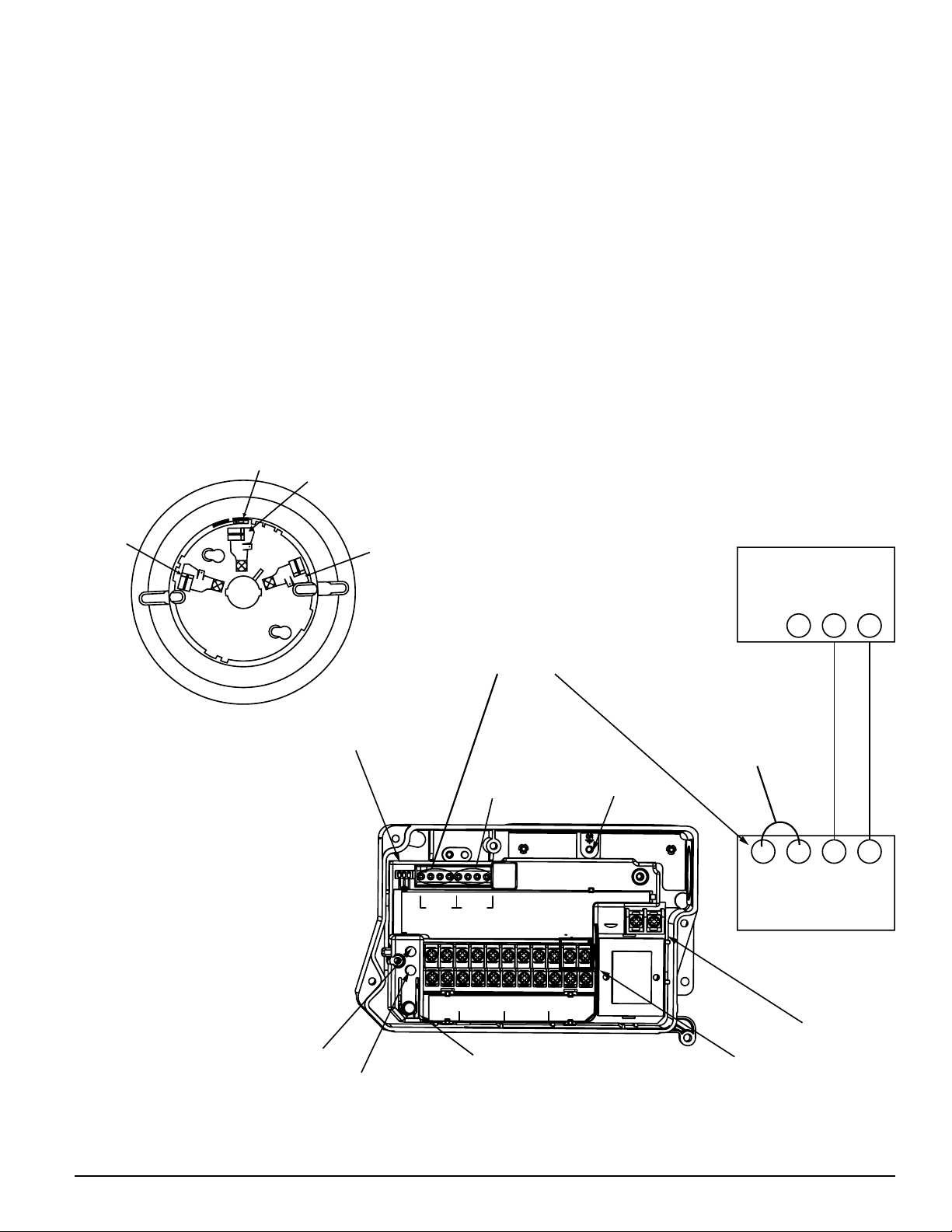

FIGURE 2:

dust may compromise the sensor heads in duct smoke detectors.

The 2D51 sensor head in 4-wire InnovairFlex duct smoke detectors may exhibit

a “maintenance” condition that will require cleaning of the sensing chambers

on the sensor head or replacement of the sensor head. The “maintenance”

condition is indicated at the fire alarm panel if present or on the sensor or

SENSOR

COVER

power board of the duct smoke detector (the sensor LED will blink “red” every

five seconds and the power board LED will blink “amber every five seconds).

To avoid this condition, it is recommended that the sensor heads be removed

during the construction phase and replaced once construction is completed

and the Certificate of Occupancy is issued. The sensor heads twist out for

removal and twist in for insertion.

CLEANING

Before removing the detector, notify the proper authorities that the smoke

detector system is undergoing maintenance and will be temporarily out of

service. Disable the zone or system undergoing maintenance to prevent un-

COVER

REMOVAL

TABS

SENSING

CHAMBER

COVER AND

SCREEN

SENSOR

CHAMBER

wanted alarms. If the sensor heads are not removed during the construction

phase and the senor chamber becomes dirty causing a maintenance condition

(it will not always be visible on the exterior black screen on the sensor head),

the sensor head must be cleaned with compressed air. To clean the sensor

head chamber, follow the following step-by-step instructions:

C1009-00

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal

tabs that hold the cover in place.

3. Vacuum the screen carefully without removing it.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing chamber.

SS-300-017 2 I56-3140-003R

Page 3

PENDANT MOUNT APPLICATION

B501/B210LP

The 2D51 can also be used as a pendant mount detector for use in no-flow/

low-flow air-handling systems (0-4000 fpm). The pendant mounted 2D51 is to

be installed into a B210LP or B501 base and wired to a D4P120 power board

only control unit. The D4P120 power board is capable of controlling up to (2)

2D51 sensors.

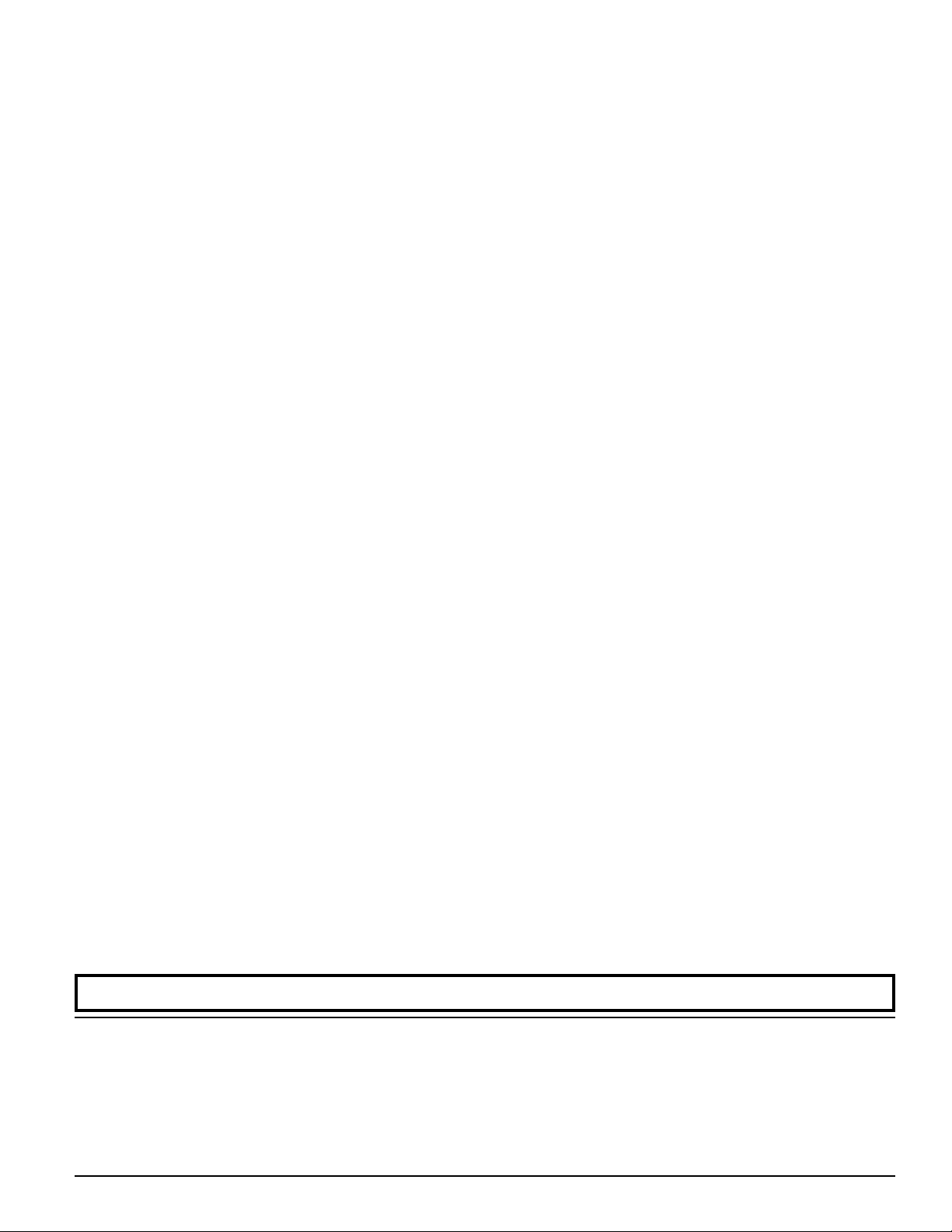

INSTALLATION/WIRING

The B210LP or B501 base(s) can be wired to the D4P120 power board per the

following:

1. Install a jumper wire across the sensor #1 (Y,Y) Tamper terminals as

shown in Figure 3 of the power board.

2. Connect wires to Terminals 1 and 2 of the base. Route wires through the

conduit openings in the D4P120 power board housing. NOTE: Terminal 3

on base is unused.

3. Connect the opposing end of the wires to the terminal connections

marked “SENSOR 1” on the power board. See Figure 3 for Reference.

Ensure that wires are connected to the appropriate terminal locations. A

No. 0 or 1 phillips screwdriver should be used for terminal connection.

If a second sensor is to be installed repeat steps 1-3 while substituting SENSOR 2 in all references. In addition, adjust the middle Dip switch on the powerboard to indicate (2) sensors as shown in Figure 3.

FIGURE 3: WIRING OF BASE TO D4P120

BASE

TERMINAL 3

3

TAMPER PROOF

TAB

2

1

BASE

TERMINAL 2

BASE

TERMINAL 1

FIELD SELECTABLE

DIP SWITCHES

1/2 SENSORS

7/0 MIN TMPR DELAY

OFF/ON TRBL SHUTDN

Y

R+Y

TAMPER

SENSOR 1SENSOR 2

ACC -

SENSOR #1

TERMINALS

SENSOR #2

TERMINALS

R

B

B

YY

+

-

-

TAMPER

ALARM, 15

R TEST, 11

R RESET, 2

ACC +

B501/B210LP

+ –

3 2 1

FIELD INSTALLED

JUMPER WIRE

GROUND

SCREW

Y Y R B

AUX OUT +, 19

AUX OUT -, 20

24V AC/DC, 9

INT/AUX-, 1

INT+, 12

120 VAC

24V AC/DC, 10

TAMPER

SENSOR 1

+ –

D4P120

16, NC

3, C

14, N0

13, NC

5, NO

4, C

AUX A

SUPALARM

18, C

8, NC

17, NO

6, C

7, NO

AUX B

120

POWER

BOARD LED 2

POWER

TEST/RESET

BUTTON

24 VAC/

DC INPUT

VAC INPUT

BOARD LED 1

H0577-11

SS-300-017 3 I56-3140-003R

Page 4

Please refer to insert for the Limitations of Fire Alarm Systems

System Sensor warrants its enclosed smoke detector to be free from defects in materials

and workmanship under normal use and service for a period of three years from date

of manufacture. System Sensor makes no other express warranty for this smoke detector. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector which is found to be defective in materials or workmanship under normal use

and service during the three year period commencing with the date of manufacture.

After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System Sensor, Repair

THREE-YEAR LIMITED WARRANTY

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please include a

note describing the malfunction and suspected cause of failure. The Company shall not

be obligated to repair or replace units which are found to be defective because of damage,

unreasonable use, modifications, or alterations occurring after the date of manufacture.

In no case shall the Company be liable for any consequential or incidental damages for

breach of this or any other Warranty, expressed or implied whatsoever, even if the loss

or damage is caused by the Company’s negligence or fault. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

SS-300-017 4 I56-3140-003R

©2011 System Sensor

Loading...

Loading...