Page 1

Page 2

Congratulations on your purchase of the Synergy E6/7 radio controlled helicopter kit. The Synergy E6/7 was

designed and developed by Botos Design & Distribution Inc.. The design of the Synergy E6/7 emerged from

many years of experience in the hobby including design, research & development, and last but not least

as a world class pilot who truly enjoys this wonderful hobby.

This radio controlled helicopter is NOT A TOY. It is a sophisticated piece of equipment, it was designed

and intended for hobby use only. If not properly assembled, maintained, and operated, it is capable of

causing property damage and bodily harm to both the operator and/or spectators. Botos Design &

Distribution Inc., its affiliates, and its authorized distributors assume no liability for damage that could occur

from the assembly or use/misuse of this product. If you are new to the hobby we strongly recommend

seeking the help and advice from an experienced modeler.

Operating a model helicopter requires a high degree of diligence and skill. If you are new to the hobby, it

is best to seek help and guidance from experienced radio controlled helicopter pilots. This will both greatly

speed up the learning process and make it much safer for you.

For those pilots who will be operating their Synergy E6/7 in the United States, we strongly recommend

joining the AMA. The AMA is a non-profit organization that provides services to the model aircraft pilots. As

an AMA member, you will receive a monthly magazine entitled Model Aviation and most importantly a

liability insurance plan to cover against a possible accident or injury. All AMA charter aircraft clubs require

individuals to hold a current AMA sporting license prior to operation of their models

For further information, you can contact the AMA at

Academy if Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256

Page 3

Page 4

Page 5

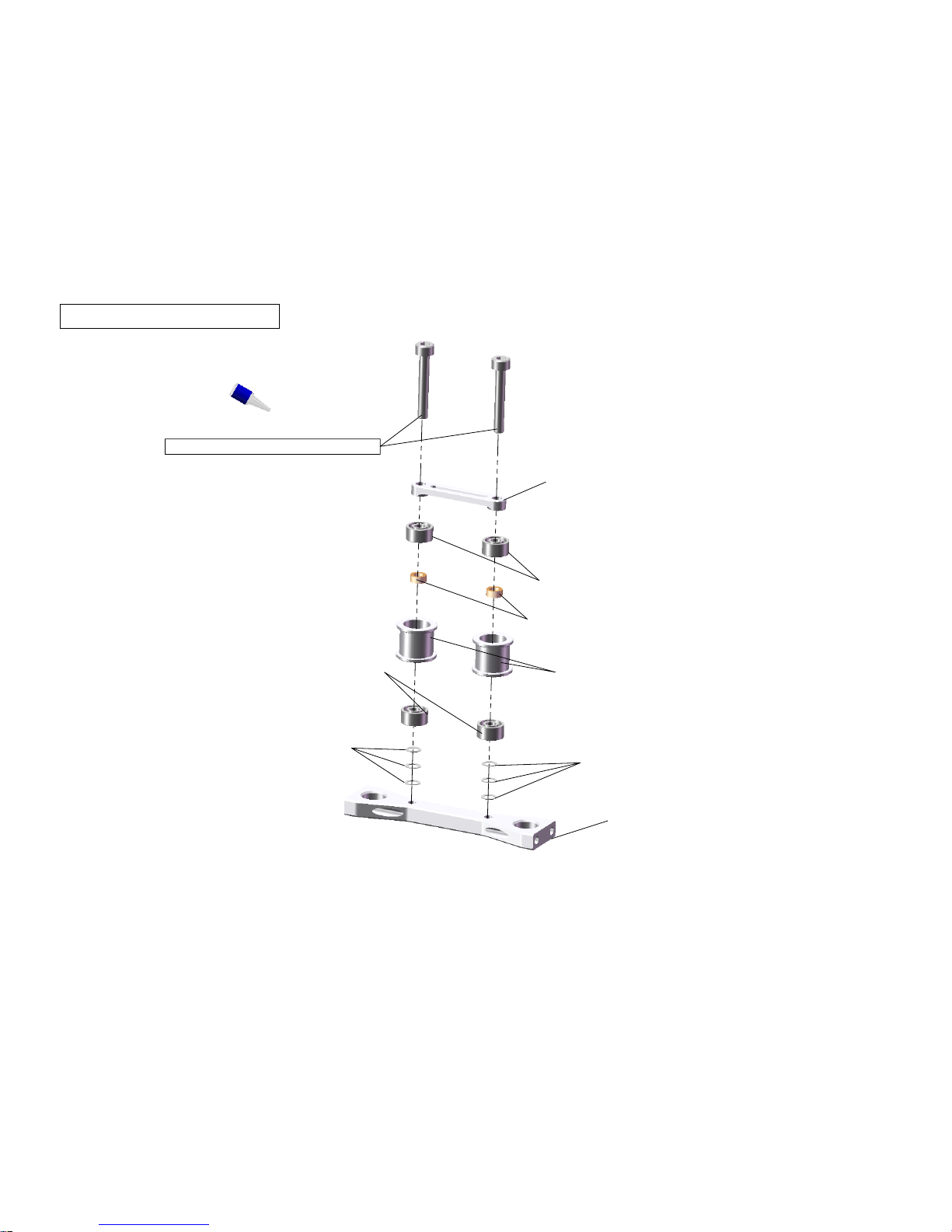

Belt Idler Assembly

100-320 M3x20 Socket Head

610-319 Idler Brace

108-384 3x8x4 Radial Bearing

109-352 3x5x2 Brass Spacer

610-318 Belt Tension Idler

108-384 3x8x4 Radial Bearing

106-301 3x.15mm Shim

310-101 Idler Mount Bracket

A1

106-301 3x.15mm Shim

Page 6

Main Shaft Bearing Blocks

A2

108-105 10x19x5 Radial Bearing

108-105 10x19x5 Radial Bearing

310-150 Main Shaft Bearing Block E6/7

310-151 Third Main Shaft Bearing Block

Important -

Keep this orientation

in mind for future reference. Make

sure bearing block and bearing

orientation is correct. Top bearing

is facing up, middle beaing is facing

down, lower bearing is facing up.

Page 7

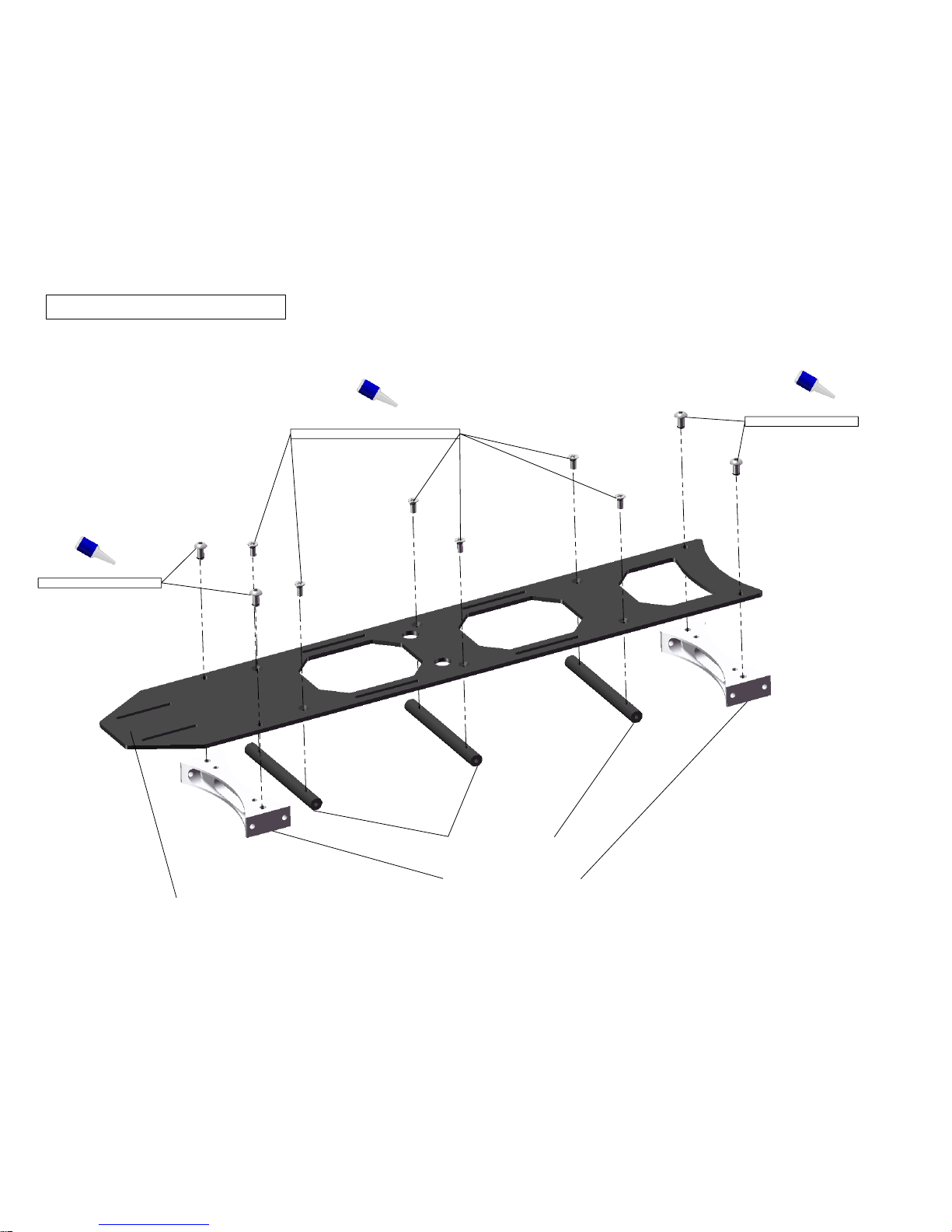

101-306 M3x6 Button Head

101-306 M3 Button Head

103-256 M2.5 Flat Head Cross Recess

310-112 Landing Gear Mount

310-110 Frame Spacer

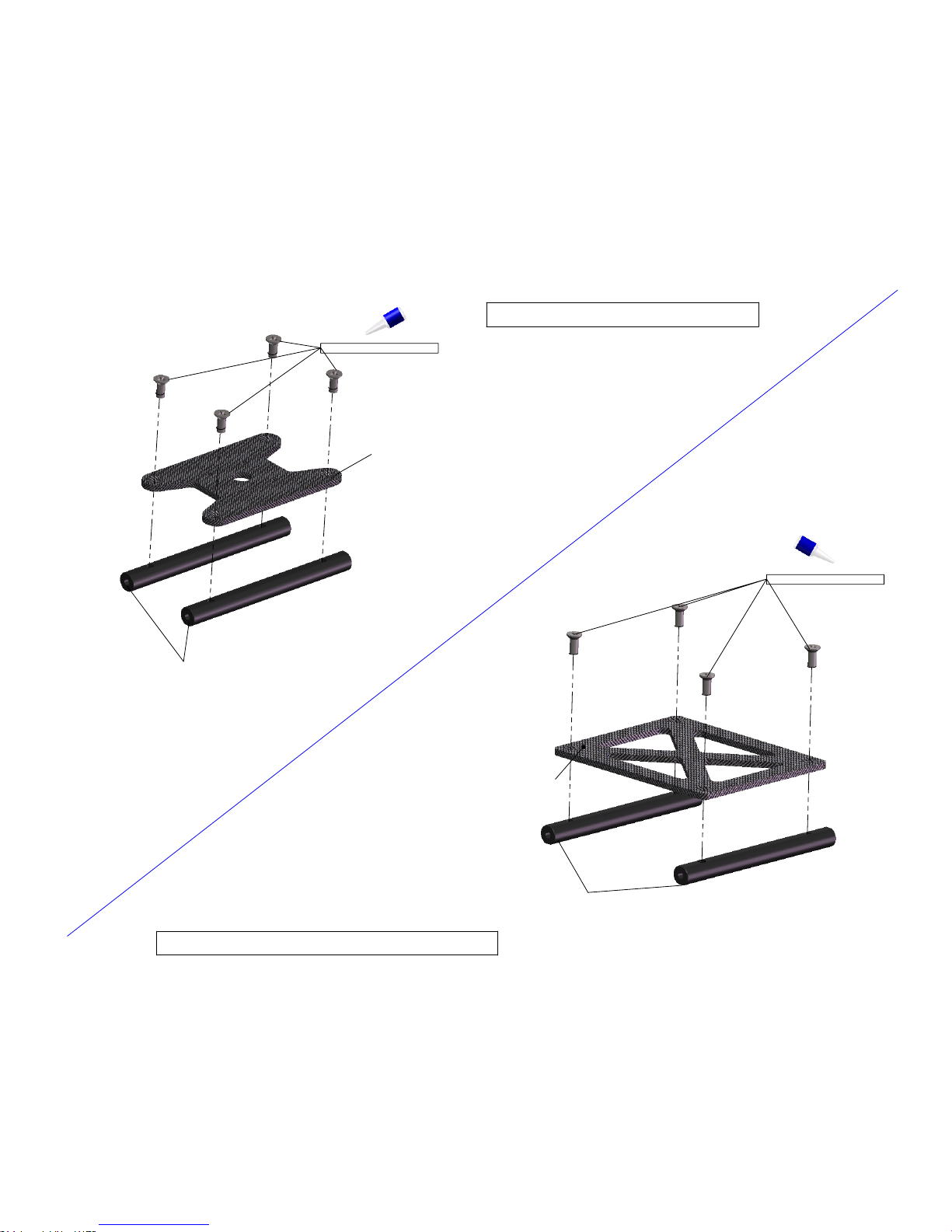

Base Plate Assembly

A3

310-103 CF Base Plate

Page 8

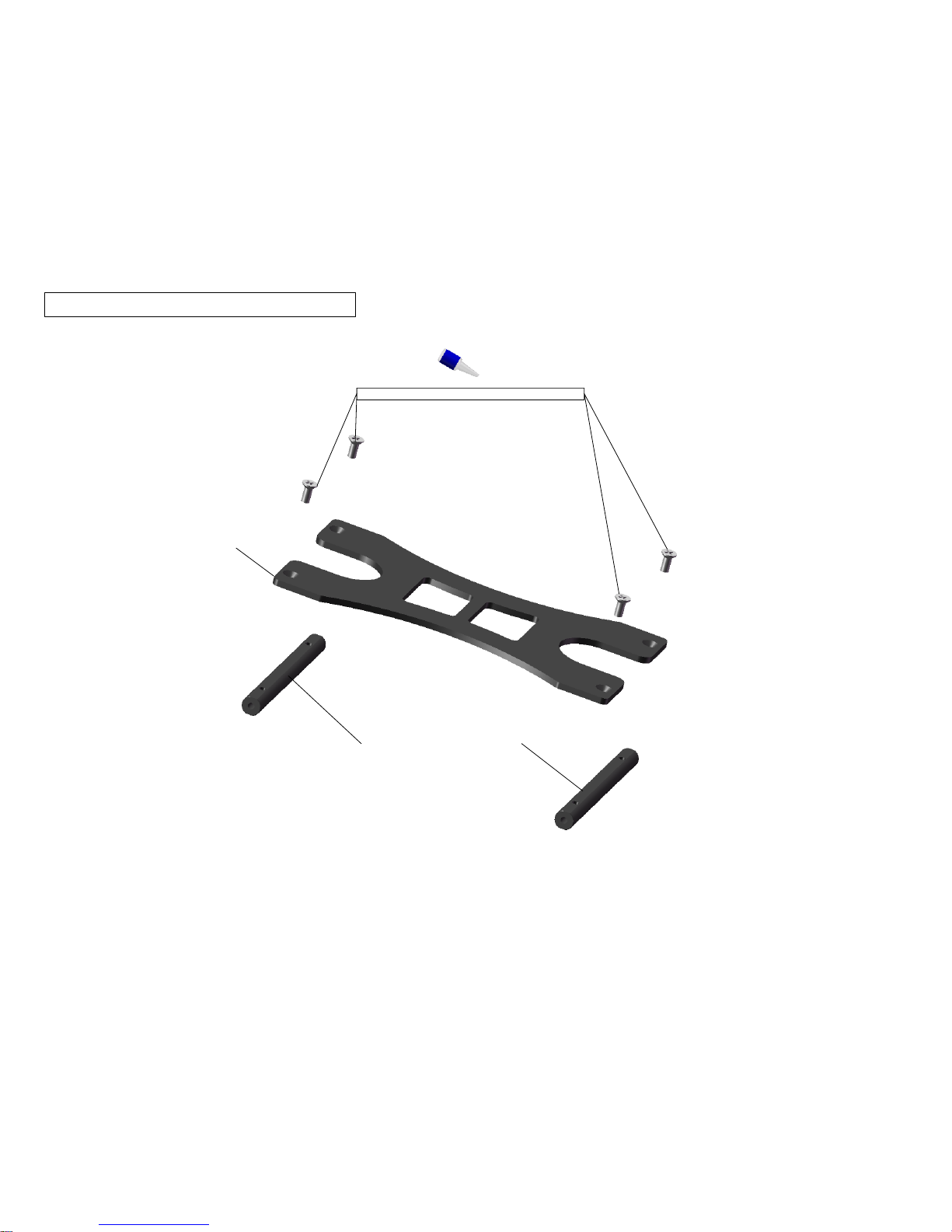

ESC Mount Plate Assembly

A4

103-256 M2.5x6 Flat Head Cross Recess

310-102 ESC Mount Plate

310-110 Frame Spacer E6/7

Page 9

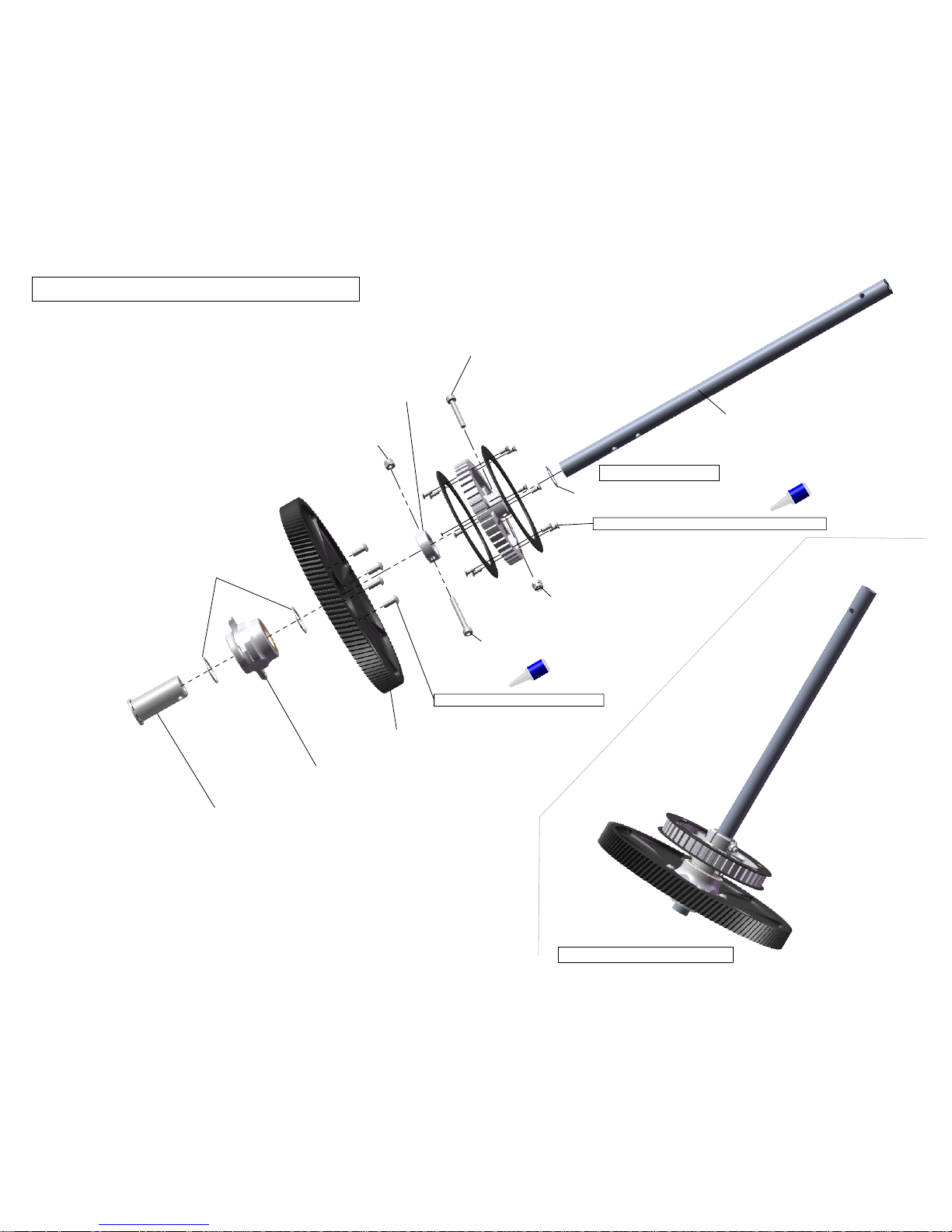

Main Transmission Assembly

A5

310-140 E Main Shaft

109-110 10mm Main Shaft Shim

100-320A M3x20 Socket Head

100-325A M3x25 Socket Head

100-351 M3 Nylock Nut

100-351 M3 Nylock Nut

101-308 M3x8 Button Head x4

610-146 Auto Hub Lock Collar

103-204 M2x4 Type I Cross Recessed x12

310-116 Helical Main Gear 116T

200-407 Auto Hub Assembly

610-147 Auto Hub Sleeve

610-151 Auto Hub Delrin Shim

Complete Transmission

Important Shim!

Page 10

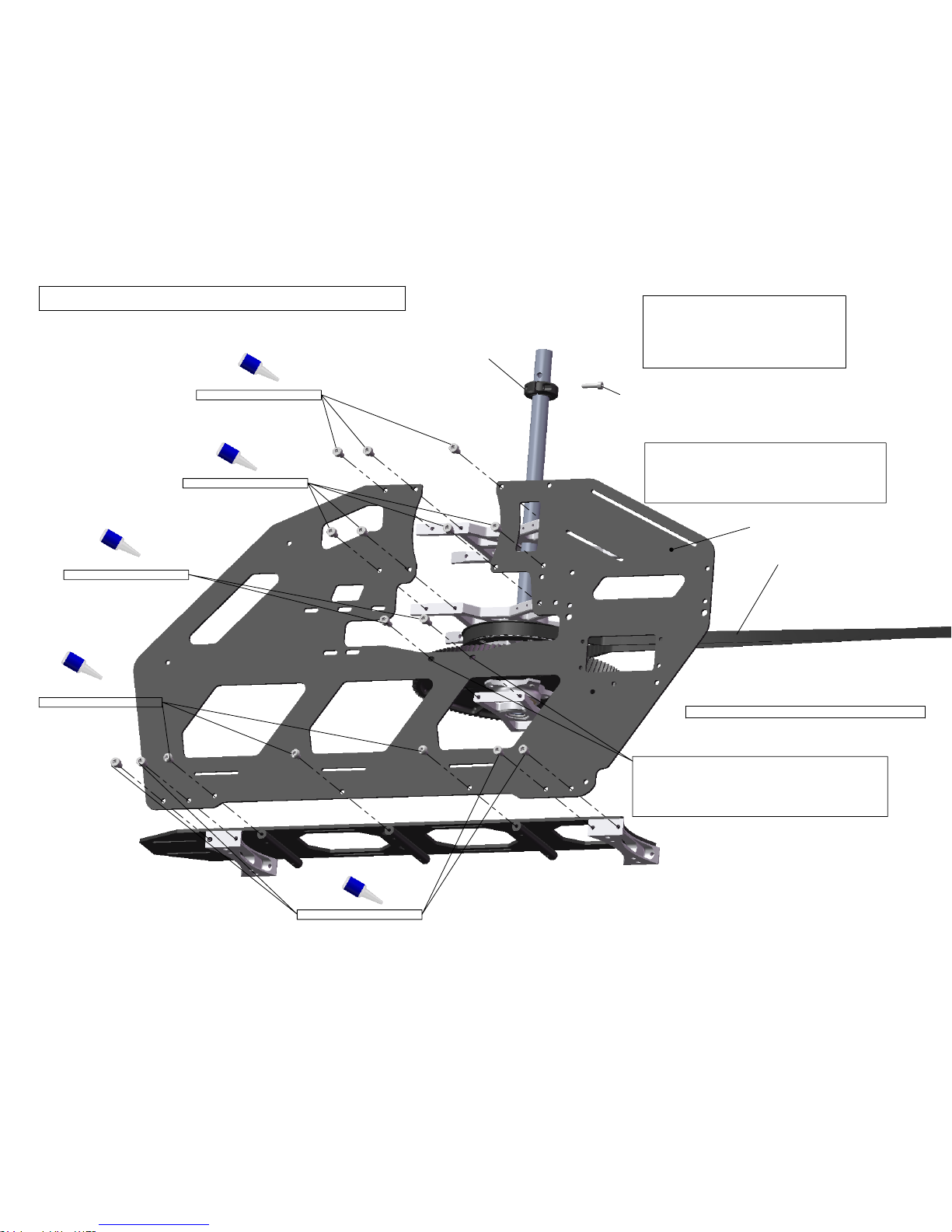

100-306 M3x6 Socket Head

100-306 M3x6 Socket Head

101-306 M3x6 Button Head

100-306 M3x6 Socket Head

100-308 M3x8 Socket Head

Transmission & Base Plate Install

A6

Important

Remember to place 10mm shim

between Main Belt Pulley and Mid Main

Shaft Bearing Block. Inner race of bearing

rides on this shim.

Important -

Lower Bearing Block holes are adjustable

for correct third bearing block alignment.

Transmission should spin freely when aligned

correctly.

610-150 Main Shaft Collar

100-261 M2.5x10 Socket Head

Note-

Do not fully tighten frame bolts yet!

615-320 E6 - 736XL

315-320 E7 - 770XL

310-311 - Main Frame E6/7

Important -

Make sure bearing

block and bearing orientation

is correct. Top bearing is facing

up, middle beaing is facing down,

lower bearing is facing up. Refer to

page A2 for correct orientation.

Page 11

Tail Servo Install

100-266 M2.5x6 Socket Head

100-261 M2.5x10 Socket Head

107-104 2mm Pivot Ball

106-115 Servo Hold Down

106-115 Servo Hold Down

100-252 2mm Nylock Nut

310-100 Tail Servo Mount

A7

Page 12

103-256 M2.5x6 Flat Head

310-104 Sensor Mount Plate

310-110 Frame Spacer E6/7

Sensor Mount Assembly

Lower Frame Brace Assembly

103-256 M2.5x6 Flat Head

310-110 Frame Spacer E6/7

310-105 CF Lower Frame Brace

A8

Page 13

Sensor Mount & Lower Frame Brace Install

101-306 M3x6 Button Head

Note

- Do not fully tighten frame bolts yet!

Reserved for Boom Support

A9

Note - Mounting sensor at this

time is an option.

Page 14

Belt Idler Assembly Installation

100-308 M3x8 Socket Head

A10

Page 15

Right Frame Side Assembly

100-306 M3x6 Socket Head

101-306 M3x6 Button Head

100-306 M3x6 Socket Head

101-306 M3x6 Button Head

100-306 M3x6 Socket Head

100-308 M3x8 Socket Head

100-308 M3x8 Socket Head

A11

310-311 CF Main Frame E6/7

Page 16

310-420 Canopy Mount E6/7

100-376 M3x16 Set Screw

100-376 M3x16 Set Screw

310-420 Canopy Mount E6/7

101-306 M3x6 Button Head

310-106 Anti-Rotation Brace E6/7

A12

Anti-Rotation Brace & Rear Canopy Mount

Page 17

90°

Main Frame Alignment

A13

Note - Ensure main shaft spins

freely within bearings. If main

shaft does not spin freely loosen

all bolts and ensure frames are

square with bearing block. Secure

all main frame bolts at this time.

Page 18

Servo Horn Assembly

100-352 M3 Nut

107-106 Pivot Ball

310-107 CF Servo Arm

Plastic Servo Arm

(Not Included)

100-252 M2 Nylock Nut

Servo Arm Screw

(Not Included)

100-206 M2x6mm Socket Head

Cyclic Servo Install

100-261 M2.5x10 Socket Head

106-115 Servo Hold Down

Note

- All three cyclic servos should

be installed at this point in time. At a

minimum the elevator servo should be

installed as it may be difficult to install

later in the assembly.

106-115 Servo Hold Down

A13

Note -

Some plastic servo arms may require

modification in order to be able to use CF Servo arms.

You may use other plastic servo arms as long as pivot

ball position is 20mm from center.

Page 19

A15

Landing Gear Assembly

Complete Landing Gear

101-308 M3x8 Button Head

610-324 Landing Gear Strut

610-322 Skid Tube Lock x4

610-321 Skid Tube

106-966 Skid Tube Plug x4

Page 20

100-312 M3x12 Socket Head

A16

Landing Gear Install

Page 21

101-306 M3x6 Button Head

310-108 CF Radio Plate

310-111 Main Boom Clamp E6/7

100-310 M3x10 Socket Head

310-111 Main Boom Clamp E6/7

Main Boom Clamp Assembly

A17

Page 22

100-308 M3x8 Socket Head x8

Main Boom Clamp Install

A18

Page 23

100-412 M4x12 Socket Head

310-130 Motor Mount 30mm

100-466 M4x6 Set Screw

Helical Pinion (14T & 15T included in kit)

Recommended Motor 12s - Hacker Turnado 470kv

10s - Hacker Turnado 580kv

Available Pinions

303-012 - 12T Helical Pinion

303-013 - 13T Helical Pinion

303-014 - 14T Helical Pinion

303-015 - 15T Helical Pinion

Brushless Motor Mounting

A19

Important!

Motor mount is designed to accept motor

with 4mm bolts and 30mm bolt pattern option.

25x3mm motor mounting was left out due to weakness

of the M3 bolts and increasing power of todays motors.

Motor shaft should be minimum of 32mm in length

outside of the motor in order to properly engage

motor shaft bearing block.

Inportant!

Pinion should rest on inner race

of lower pinion support. Failure

to configure properly will result

in premature motor bearing wear.

Note

- Synthetic grease may be used

on main gear / pinion in order to reduce

heat and improve gear interation.

Page 24

100-310 M3x10 Socket Head

310-128 Motor Mount CF Washer

310-129 Motor Shaft Support CF Washer

310-152 Motor Shaft Support Bearing Block

108-615 6x15x5 Radial Bearing(factory installed)

100-310 M3x10 Socket Head

310-129 Motor Shaft Support CF Washer

310-128 Motor Mount CF Washer

Brushless Motor Install

A20

Page 25

ESC / Front Canopy Mount

100-306 M3x6 Socket Head

100-376 M3x16 Set Screw

Electronic Speed Control(not included)

310-420 Canopy Mount E6/7

Note -

ESC of 120 amp or higher

recommended for 10S and 12S

operation.

A21

Page 26

115-114 Push Rod Guide

610-128 Boom Support Clamp, Lite

Tail Boom 615-140 - Tail Boom 775mm E6

315-140 - Tail Boom 810mm E7

Tail Push Rod

615-111 - Carbon Tail Control Rod 695mm E6

315-111 - Carbon Tail Control Rod 728mm E7

106-965 Push Rod Sleeve (Teflon Heat Shrink Tubing)

107-043 43mm Rod

107-043 43mm Rod

107-100 Ball Link

107-100 Ball Link

Boom & Push Rod Assembly

A22

Approx. 5mm

Insert 43mm threaded rod approximately 27mm into

carbon tube. Use Medium CA to glue threaded rod

into carbon rod.

Note - Space Tail Control Guides evenly.

Place the rear Tail Control Guide behind

Boom Support Clamp. CA can be used to

secure Tail Control Guides but generally

this is not needed.

Page 27

100-310 M3x10 Socket Head

101-412 M4x12 Button Head

109-345 3x4x5 Brass Spacer

100-354 M3 Washer

100-316 M3x16 Socket Head

Boom Support Assembly

Boom Installation

Feed belt through boom

1.

Slide boom forward until flush with front boom clamp

2.

Secure boom clamp bolts now, belt tension adjusted in rear

3.

Note - Use Medium CA to secure Boom Support

End to Carbon Boom Support Rod

A23

Boom Support Ends

115-119 Boom Support End

615-117 Carbon Boom Support Rod 520mm E6

315-117 Carbon Boom Support Rod 585mm E7

Page 28

100-251 M2 Nut

107-104 2mm Pivot Ball

100-320 M3x20 Socket Head

108-373 3x7x3 Radial

109-355 3x5x5 Spacer

115-316 Tail Bell Crank

108-373 3x7x3 Radial

100-351 M3 Nylock Nut

615-317 Tail Lever Mount

106-301 M3 Shim

Step #2 Tail Box Assembly

Step #1 - Tail Bell Crank Assembly

100-335 M3x35 Socket Head x5

101-306 M3x6 Button Head x4

108-616 6x13x5 Flange Bearing

610-224 3x6x26 Spacer

115-112 Main Boom Clamp, Lite

615-311 Tail Box Plate

Belt Drive Tail Box Assembly

A24

Tail Bell Crank Assembly

100-306 M3x6 Socket Head

Page 29

Belt Drive Tail Box Assembly

A25

100-306 M3x6 Socket Head

101-306 M3x6 Button Head

615-136 CF Vertical Fin

108-616 6x13x5 Flange Bearing

109-357 3x5x7 Brass Spacer

108-384 3x8x4 Radial Bearing

109-357 3x5x7 Brass Spacer

615-316 Belt Tension Idler

IMPORTANT!

Do not over tighten belt idler bolt!

Over tightening will cause bearings

inside idler to bind.

100-351 M3 Nylock Nut

Page 30

Tail Output Shaft Install

615-124 6mm Tail Output Shaft

615-314 9T Tail Pulley (for 6mm Shaft)

100-364 M3x4 Set Screw

A26

Page 31

Tail Hub Assembly

A27

100-308 M3x8 Socket Head

100-354 M3 Washer

108-503 5x10x3 Radial Bearing

106-501 5mm Shim

108-511 5x10x4 Thrust Bearing

515-525 HD Tail Blade Grip

108-503 5x10x3 Radial Bearing

107-106 Pivot Ball

615-324 HD Tail Rotor Hub

Tail Thrust Bearing Note -

- Large OD / Large ID - Inside

- Small OD/ Small ID - Outside

- Shim goes between Thrust

and Radial

GREASE THRUST BEARING INNER RACE!

DO NOT OVER TIGHTEN!

Page 32

Pitch Slider Assembly

615-319 Tail Pitch Slider Bushing (for 6mm shaft)

108-812 8x12x2.5 Radial Bearing

107-103 2mm Pivot Ball Short

115-319 Tail Bearing Ring

108-812 8x12x2.5 Radial Bearing

115-322 Tail Pitch Link

106-813 Tail Slider Lock Ring

606-921 Tail Pitch Link Pin

506-920 E-Ring

115-321 Pitch Plate

Use Medium CA to secure 2mm pivot ball

1. After installing lock ring be sure that the

radial bearings do not have lateral load

on them. Adjust lock ring as needed to

ensure smooth operation.

2. Secure lock ring with CA or Epoxy

Red Loctite Tail Pitch Slider to Tail

Pitch Plate for extra security.

A28

Page 33

100-464 M4x4 Set Screw

Tail Pitch Slider & Tail Rotor Hub Installation

A29

Size Links for free tail slider operation

100-316 M3x16 Socket Head

100-351 M3 Nylock Nut

100-351 M3 Nylock Nut

Page 34

Swash Plate Assembly

107-108 Pivot Ball Long x3

107-106 Pivot Ball x4

108-373 3x7x3 Radial Bearing

100-316 M3x16 Socket Head

109-352 3x5x2 Brass Spacer

100-312 M3x12 Socket Head

100-364 M3x4 Set Screw

200-401 Swash Plate Assembly

A30

Page 35

21.25

Servo to Swash Link

Servo to Swash Linkage

Note - Link legth is approximate,

adjust as needed.

107-100 Ball Link

107-100 Ball Link x6

107-043 43mm Rod

A31

Page 36

100-512 M5x12 Socket Head

100-554 M5 Washer

106-801 8x1mm Washer

108-816 8x16x5 Radial Bearing

108-817 8x16x5 Thrust Bearing*

Apply Grease

*Note Thrust Bearing Order

Large ID Large OD - Inside Position

Small ID Small OD - Outside Position

106-803 8x.5mm Washer

606-803 Solid Head Damper

120-114 Head Axle

107-106 Pivot Ball

100-312 M3x12 Socket Head

100-308 M3x8 Socket Head

100-306 M3x6 Socket Head

520-513 FBL Blade Grip Arm

100-312 M3x12 Socket Head

Apply Grease

Flybarless Head Assembly

Inner Swash Driver Assembly

620-111 FBL Head Block

520-514 FBL Main Blade Grip

620-211 FBL Washout Hub

106-301M3 Shim

108-383 3x8x3 Radial Bearing

620-214 FBL Washout Arm

108-383 3x8x3 Radial Bearing

100-312 M3x12 Socket Head

606-923 Washout Pin

120-214 Washout Link

108-262 2x6x2.5 Radial Bearing

506-920 E-Ring

100-308 M3x8 Socket Head

109-352 3x5x2 Brass Spacer

A32

Note - Plastic links are directional.

Pay close attention to orientation.

Page 37

Use middle hole on head block

when using stock 78mm pitch links

Upper Hole can be used with linkage

adjustment.

Align Swash Driver paralell with head

block. Adjust height of swash driver so

washout link is 90 degrees to Washout

Arm at zero degrees collective pitch.

See illustration below.

Do not make washout arm parallel

with washout base at zero degrees

pitch!

x2

107-100 Ball Link x4

Rotor Head Installation

100-320A M3x20 Socket Head

100-312 M3x12 Socket Head x2

100-351 M3 Nylock Nut

A33

107-078 78mm Rod

Approx. 61mm

107-078 78mm Rods

Correct Angle at 0 Pitch

Page 38

100-435A M4x35 Shouldered Bolt (E6)

100-535A M5x35 Shouldered Bolt (E7)

310-144 - Blade Bolt Adapter 4mm (E6)

310-145 - Blade Bolt Adapter 5mm (E7)

100-451 M4 Nylock Nut (E6)

100-551 M5 Nylock Nut (E7)

Main Blade Grip - Blade Bolts

A34

Note E6 uses 4mm blade bolts

E7 uses 5mm blade bolts

Page 39

110-418 Canopy Grommets x4

310-400 E6/7 Canopy Stock

Canopy Mounting

A35

Page 40

Loading...

Loading...