Page 1

5071A Primary Frequency Standard

Assembly- Level Service

Manual

Rev. B, July 3, 2007

Part Number: 05071-90040

Page 2

Page 3

Assembly- Level Service Manual

This manual describes how to service the Symmetricom 5071A Primary

Frequency Standard. The information in this manual applies to instruments

having the number prefix listed below, unless accompanied by a "Manual

Updating Changes" package indicating otherwise.

SERIAL NUMBER PREFIX: US4538 AND ABOVE

Some sections of this manual refer to using the ‘5071A Profiling software’. This

revision of the manual no longer supplies a 3.5-inch floppy disk with this

software. To obtain a copy free of charge visit our web site at

http://www.symmttm.com/products_pfr_5071A.asp and follow the links to

“Software and Drivers”. The latest revision of the Profiling Software

(Symmetricom P/N 05071-13501) can then be saved to your computer hard disk.

This software is only available for use with a Windows®-based PC.

There are a limited number of 5071A replaceable parts available. The 5071A

Primary Frequency Standard is a very precise and complex product and

Symmetricom strongly recommends that they be sent in for repairs and postrepair performance testing. However, there are some assemblies, such as the

Cesium beam tube that we do sell should you wish to perform this in your own

facility. We require that you have a copy of the 5071A Assembly-Level Service

Manual (P/N 05071-90040) before doing any repairs or parts replacements.

Although Symmetricom Global Services (SGS) is always available to help when

you have questions, they cannot be expected to provide troubleshooting

assistance when you are repairing the 5071A - That is the purpose of the 5071A

Service Manual.

5071A Primary Frequency

Standard

Page 4

Safety Considerations and Warranty

©Copyright Symmetricom, Inc. 2006

All Rights Reserved. Reproduction, adaptation, or translations

without prior written permission is prohibited, except as

allowed under the copyright laws.

Manual part number

05071-90040

Safety Considerations

General

This product and related documentation must be reviewed for familiarization with this safety

markings and instructions before operation.

This product is a safety Class I instrument (provided with a protective earth terminal). If this

instrument is used in a manner not specified by Symmetricom, the protection provided by the

equipment may be impaired.

Before Applying Power

Verify that the product is set to match the available line voltage and the correct fuse is installed.

Refer to instructions in Chapter 1 of this Manual.

Before Cleaning

Disconnect the product from operating power before cleaning. Clean only with lightly damp cloth

and mild detergents. Do not get unit wet.

Safety Earth Ground

An uninterruptible safety earth ground is recommended from the mains power source to the product

input wiring terminals or supplied power cable. The terminal is located on the rear of the unit near

the AC input receptacle.

Warning Symbols That May Be Used In This Manual

Instruction manual symbol; the product will be marked with this symbol

when it is necessary for the user to refer to the instruction manual.

Indicates hazardous voltages.

Indicates earth (ground) terminal.

OR Indicates terminal is connected to chassis when

such connection is not apparent.

ii

Page 5

Safety Considerations and Warranty

Indicates Alternating current.

Indicates Direct current.

Rack Mounting

The Model 5071A Unit is designed for mounting in a standard 19-inch (48.26 cm) rack. Follow the

rack manufacturer's instructions for mounting the Model 5071A Unit while observing the following

guidelines:

Elevated Operating Temperature: If the Model 5071A Unit is installed in a closed or

multi-unit rack assembly, the ambient temperature of the rack environment may be greater

than the Model 5071A Unit's Maximum Operating Temperature of 50°C/122°F. Install

the Model 5071A Unit in an environment that is compatible with the Model 5071A Unit 's

operating temperature range, which is 0 °C to 50 °C, or 32 °F to 122 °F

Mechanical Loading: Mount the Model 5071A Unit so as to avoid uneven mechanical

loading that could cause hazardous conditions.

Circuit Overloading: Observe the power ratings on the Model 5071A Unit 's nameplate

and the additional load the Model 5071A Unit may place on the supply circuit.

Overloading the supply circuit may adversely affect the supply wiring and over-current

protection.

Reliable Earthing: Maintain reliable earthing (grounding) of rack mounted equipment.

Pay particular attention to supply connections other than direct connections to the branch

circuit (e.g., use of power strips).

CAUTION ________________

Damage to equipment, or incorrect measurement data, may result from failure to heed a caution.

Do not proceed beyond a CAUTION sign until the indicated conditions are fully understood and

met.

Whenever it is likely that the protection has been impaired, the instrument must be made

inoperative and be secured against any unintended operation.

If this instrument is to be energized via an autotransformer (for voltage reduction) make sure the

common terminal is connected to the earthed pole terminal (neutral) of the power source.

Instructions for adjustments while covers are removed and for servicing are for use by servicetrained personnel only. To avoid dangerous electric shock, do not perform such adjustments or

servicing unless qualified to do so.

-----------------------------------------------------------------------------------------------------------------------

iii

Page 6

Safety Considerations and Warranty

Safety Considerations (contd)

WARNING:

BODILY INJURY OR DEATH MAY RESULT FROM FAILURE TO HEED A

WARNING. DO NOT PROCEED BEYOND A WARNING SIGN UNTIL THE

INDICATED CONDITIONS ARE FULLY UNDERSTOOD AND MET.

AVERTISSEMENT:

LA BLESSURE PHYSIQUE OU RESULTAT DE MAI DE MORT DE L'ECHEC POUR

FAIRE ATTENTION A UN AVERTISSEMENT. Ne PAS PROCEDER AU DELA D'UN

SIGNE ANNONCIATEUR JUSQU'A CE QUE LES CONDITIONS INDIQUEES SONT

ENTIEREMENT COMPRISES ET SONT RENCONTREES.

-----------------------------------------------------------------------------------------------------

WARNING:

THE MODEL 5071A UNIT SHOULD ONLY BE PLUGGED INTO A GROUNDED

RECEPTACLE. SYMMETRICOM RECOMMENDS THAT THE CHASSIS

EXTERNAL GROUND BE CONNECTED TO A RELIABLE EARTH GROUND.

ANY INTERRUPTION OF THE PROTECTIVE GROUNDING CONDUCTOR (INSIDE

OR OUTSIDE THE INSTRUMENT) OR DISCONNECTING THE PROTECTIVE

EARTH TERMINAL WILL CAUSE A POTENTIAL SHOCK HAZARD THAT COULD

RESULT IN PERSONAL INJURY. (GROUNDING ONE CONDUCTOR OF A TWO

CONDUCTOR OUT-LET IS NOT SUFFICIENT PROTECTION.)

AVERTISSEMENT:

RELIER CET APPAREIL À UNE PRISE DE COURANT AVEC CONTACT

ADEQUATE DE MISE À LA TERRE. SYMMETRICOM RECOMMANDE QUE LE

CHÂSSIS SOIT RELIÉ À UNE TERRE FIABLE.

N'IMPORTE QUELLE INTERRUPTION DU CONDUCTEUR FONDANT

PROTECTIF (DANS OU HORS DE L'INSTRUMENT) OU DEBRANCHER LE

TERMINAL DE TERRE PROTECTIF CAUSERA UN DANGER DE CHOC

POTENTIEL QUI POURRAIT AVOIR POUR RESULTAT LA BLESSURE

PERSONNELLE. (FONDANT UN CONDUCTEUR D'UNE DEUX SORTIE DE

CONDUCTEUR EST LA PROTECTION PAS SUFFISANTE).

-----------------------------------------------------------------------------------------------------------

iv

Page 7

Safety Considerations and Warranty

Safety Considerations (contd)

WARNING:

FOR CONTINUED PROTECTION AGAINST FIRE, REPLACE THE LINE FUSE(S)

ONLY WITH 250V FUSE(S) OF THE SAME CURRENT RATING AND TYPE (FOR

EXAMPLE, NORMAL BLOW, TIME DELAY). DO NOT USE REPAIRED FUSES OR

SHORT CIRCUITED FUSEHOLDERS.

AVERTISSEMENT:

POUR LA PROTECTION CONTINUÉE CONTRE LE FEU, REMPLACER LE

FUSIBLE DE LIGNE (LES FUSIBLES) SEULEMENT AVEC 250V FUSIBLE (LES

FUSIBLES) DU MÊME COURANT ÉVALUANT ET TAPE (PAR EXEMPLE, LE

COUP NORMAL, LE DÉLAI). NE PAS UTILISER DE FUSIBLES RÉPARÉS OU

CIRCUITED FUSEHOLDERS COURT.

---------------------------------------------------------------------------------------------------------

DC Power Supply (VDC Operation Model) Installation

Use a 15 Amp DC circuit breaker in series with the DC power source.

Do not connect the unit directly to a DC power source without the breaker.

14 AWG (1.5mm

power source hookup.

The Unit Chassis must be grounded for proper safety.

---------------------------------------------------------------------------------------------------------

WARNING:

ENSURE THAT A DISCONNECT DEVICE, SUCH AS A SWITCH, WITH THE

APPROPRIATE VOLTAGE/CURRENT RATING IS PROVIDED WHEN CONNECTING A

DC POWER SOURCE TO THE VDC OPERATION MODEL.

AVERTISSEMENT:

S'ASSURER QU'UN DÉBRANCHER L'APPAREIL, TEL QU'UN COMMUTATEUR, AVEC

LE CLASSEMENT DE TENSION/COURANT APPROPRIÉ EST FOURNI EN

CONNECTANT UNE SOURCE DE POUVOIR DE DC AU MODÈLE DE

CONFIGURATION DE VDC.

--------------------------------------------------------------------------------------------------------

Acoustic Noise Emissions

LpA<47 dB at operator position, at normal operation, tested per EN 27779. All data are the results

from type test.

Geräuschemission

LpA<47 dB am Arbeits platz, normaler Betrieb, geprüft nach EN 27779. Die Angagen beruhen auf

Ergebnissen von Typenprüfungen.

Electrostatic Discharge Immunity Testing

When the product is tested with 8kV AD, 4kV CD and 4kV ID according to IEC801-2, a system

error

may occur that may affect measurement data made during these disturbances. After these

occurrences, the system self-recovers without user intervention.

2

) gage wire is the minimum gage permitted by the NEC for DC

v

Page 8

Safety Considerations and Warranty

Certification and Warranty

Certification

Symmetricom certifies that this product met its published specification at the time of shipment

from the factory. Symmetricom further certifies that its calibration measurements are traceable to

the United States National Institute of Standards and Technology (NIST), to the extent allowed by

the Institute’s calibration facility, and to the calibration facilities of other International Standards

Organization members.

Warranty

Symmetricom warrants Symmetricom hardware, accessories and supplies against defects in

materials and workmanship for a period of two years from date of shipment. If Symmetricom

receives notice of such defects during the warranty period, Symmetricom will, at its option, either

repair or replace products which prove to be defective. Replacement products may be either new

or like-new.

Symmetricom warrants that Symmetricom software will not fail to execute its programming

instructions, for the period specified above, due to defects in material and workmanship when

properly installed and used. If Symmetricom receives notice of such defects during the warranty

period, Symmetricom will replace software media which does not execute its programming

instructions due to such defects.

Symmetricom does not warrant that the operation of Symmetricom products will be uninterrupted

or error free. If Symmetricom is unable, within a reasonable time, to repair or replace any product

to a condition as warranted, the customer will be entitled to a refund of the purchase price upon

prompt return of the product.

Symmetricom products may contain remanufactured parts equivalent to new in performance or

may have been subjected to incidental use.

The warranty period begins on the date of delivery or on the date of installation if installed by

Symmetricom. If customer schedules or delays Symmetricom installation more than 30 days after

delivery, warranty begins on the 31st day from delivery.

Warranty does not apply to defects resulting from

(a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts or supplies

not supplied by Symmetricom, (c) unauthorized modification or misuse, (d) operation outside of

the published environmental specifications for the product, or (e) improper site preparation or

maintenance.

TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE

EXCLUSIVE AND NO OTHER WARRANTY OR CONDITION, WHETHER WRITTEN OR

ORAL, IS EXPRESSED OR IMPLIED AND SYMMETRICOM SPECIFICALLY DISCLAIMS

ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY,

SATISFACTORY QUALITY, AND FITNESS FOR A PARTICULAR PURPOSE.

vi

Page 9

Safety Considerations and Warranty

Warranty (contd)

Symmetricom will be liable for damage to tangible property per incident up to the greater of

$300,000 or the actual amount paid for the product that is the subject of the claim, and for

damages for bodily injury or death, to the extent that all such damages are determined by a court

of competent jurisdiction to have been directly caused by a defective Symmetricom product.

TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY

STATEMENT ARE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. EXCEPT AS

INDICATED ABOVE, IN NO EVENT WILL SYMMETRICOM OR ITS SUPPLIERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR OTHER DAMAGE,

WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

For consumer transactions in Australia and New Zealand: the warranty terms contained in this

statement, except to the extent lawfully permitted, do not exclude, restrict or modify and are in

addition to the mandatory statutory rights applicable to the sale of this product to you.

Assistance

Product maintenance agreements and other customer assistance agreements are available for

Symmetricom products.

For any assistance, contact your nearest Symmetricom Sales and Service Office.

vii

Page 10

DECLARATION OF CONFORMITY

In accordance with ISO/IEC GUIDE 22 and EN 45014

Symmetricom, Inc.

2300 Orchard Parkway

San Jose, CA 95131

Declares under our sole legal responsibility that the

PRIMARY FREQUENCY STANDARD

MODEL NO. 5071A

CONFORMS TO THE FOLLOWING EUROPEAN UNION DIRECTIVES:

Safety

73/23/EEC Low Voltage Safety as amended by 93/68/EEC

IEC 61010-1

EN 61010-1

Electromagnetic Compatibility

89/336/EEC Electromagnetic Compatibility

EN61326 EMC Requirements for Measurement, Control and Laboratory Equipment.

EN61000-3-2 Harmonic Current Emissions

EN61000-3-3 Voltage Fluctuation and Flicker Emissions

WEEE

Waste Electrical and Electronic Equipment Directive (WEEE) 2002/95/EC

For more information about Symmetricom’s WEEE compliance and recycle

program, please visit the Symmetricom’s WEEE/RoHS website at

http://www.symmetricom.com/About_Us/WEEE_RoHS_Initiatives.htm

RoHS

Restriction of the Use of Certain Hazardous Substances Directive 2002/95/EC

This product falls under the category of Monitoring and Control Instruments

Equipment (Category 9 as defined in Annex 1A of the WEEE 2002/96/EC

Directive) which is excluded from the RoHS Directive 2002/95/EC (reference

Article 2, paragraph 1) requirements.

Note: The Model 5071A is compliant when supplied with or without the High Performance

Option. CE Marking first affixed 2007

We declare that the equipment specified above conforms to the above Directives and Standards.

28 March 2007 Robert Mengelberg Compliance Program Manage

Date Name Title Signature

viii

Page 11

Contents

Assembly- Level Service Manual ............................................................................................i

Declares under our sole legal responsibility that the .......................................................viii

Contents...................................................................................................................................ix

Preface...................................................................................................................................xiii

Repair Strategy...................................................................................................................xiii

Text Conventions used in this manual................................................................................xiii

Instrument Identification ....................................................................................................xiii

Instruments Covered by This manual................................................................................. xiv

Manual Organization..........................................................................................................xiv

How to Order Manuals ....................................................................................................... xiv

1. Performance Tests – Verifying Specifications...................................................................1

Introduction ...........................................................................................................................1

Operational Verification .....................................................................................................1

Complete Performance Tests..............................................................................................1

RS-232 Verification............................................................................................................1

Test Record............................................................................................................................2

Equipment Required.............................................................................................................. 2

5071A Operational Verification............................................................................................ 5

Power-On Self-Tests and Servo Lock.................................................................................5

Rear-Panel Output Signal Checks.......................................................................................7

RS-232 Serial Port Verification..........................................................................................8

5071A Complete Performance Tests...................................................................................10

Test 1 — Output Signals: Harmonic Distortion and Spurious Signals Check..................10

Test 2 — Frequency Accuracy .........................................................................................18

Test 3 — Stability.............................................................................................................21

Performance Test Record..................................................................................................22

2. Service................................................................................................................................. 25

Introduction .........................................................................................................................25

Returning the Instrument to Symmetricom for Service....................................................... 26

To Provide Repair Information.........................................................................................26

To Pack in the Original Packaging Materials ...................................................................26

Pre-Troubleshooting Information........................................................................................27

Safety Considerations .......................................................................................................27

Recommended Test Equipment........................................................................................28

Repair Considerations.......................................................................................................28

After Service Considerations............................................................................................28

Service Accessories ..........................................................................................................29

Assembly Identification and Location..............................................................................31

Diagnostic Trees and Procedures.........................................................................................33

5071A Diagnostic Tree Organization...............................................................................34

Navigating the Diagnostic Trouble-Tree Sections............................................................34

Top-Level Diagnostic Tree Organization.........................................................................35

Top-Level Diagnostic Tree (Diagnostic Section 1)...................................................37

1.0.0 First Power On.........................................................................................................37

ix

Page 12

Contents

1.0.1.1.0 DC Input 1 and 2 Power Steering Circuit Check...............................................38

1.0.1.1 Digital Supply Voltage Check..............................................................................38

1.0.1.2 A3 Microprocessor Fault ......................................................................................38

1.0.2 DC-Supply Test/Log-Record Examination..............................................................39

1.0.3 Power On Fatal Error Check .................................................................................... 40

1.0.4 Instrument Self Tests...............................................................................................40

1.0.5 CBT Warm Up.........................................................................................................40

1.0.6 Servo-Lock Warning State.......................................................................................41

1.0.7 User-Input/Output Checks.......................................................................................41

1.0.8 5071A Profiling .......................................................................................................42

1.0.9 Delayed Failures, Warnings, and Messages.............................................................44

Power-on Fatal-Error Diagnostic Tree (Subsection 1) .....................................................45

Self Test Diagnostic Tree (Subsection 2) .........................................................................47

Warm-up And Fatal Error Diagnostic Tree (Subsection 3)..............................................49

Warning Message Diagnostic Tree (Subsection 4)...........................................................57

I/O Diagnostic Tree (Subsection 5) ..................................................................................60

CBT Performance Evaluation (Subsection 6)...................................................................61

Advisory Messages (Subsection 7)...................................................................................65

Functional-Group-Diagnostic Trees (Diagnostic Section 2) ............................................... 66

Power-Supply Diagnostic Tree (Functional Group Subsection 1)....................................67

Analog-Signal Chain Diagnostic Tree (Functional-Group Subsection 2) ........................74

RF-Chain Diagnostic Tree (Functional-Group Subsection 3) ..........................................77

C-Field Diagnostic Tree (Functional-Group Subsection 4)..............................................81

Assembly/Module Diagnostic Trees (Diagnostic Section 3)............................................... 82

A2 CBT Controller Diagnostic Tree (A/M Subsection 1)................................................83

A2 Hot-Wire Ionizer Diagnostic Tree ..............................................................................84

A2 Thermistor Diagnostic Tree........................................................................................86

A2-Mass-Spectrometer Diagnostic Tree...........................................................................88

A2 Cesium-Oven Diagnostic Tree....................................................................................90

A5 Diagnostic Tree (A/M Subsection 2) ..........................................................................92

A8 Diagnostic Tree (A/M Subsection 3) ..........................................................................95

A9 Diagnostic Tree (A/M Subsection 4) ..........................................................................99

A10 Diagnostic Tree (A/M Subsection 5) ......................................................................101

A15 Diagnostic Tree (A/M Subsection 6) ......................................................................107

A16 Diagnostic Tree (A/M Section 7)............................................................................111

A18 Diagnostic Tree (A/M Subsection 8) ......................................................................116

A19 Diagnostic Tree (A/M Subsection 9) ......................................................................120

3. Theory of Operation........................................................................................................125

Introduction .......................................................................................................................125

Basic Operating Principles..............................................................................................125

Simplified Functional Description..................................................................................126

Functional Block Descriptions........................................................................................126

A1 Motherboard Circuit Description..............................................................................126

Simplified Functional Description..................................................................................... 127

Instrument Control Block ...............................................................................................128

Reference Oscillator/RF chain Block .............................................................................128

Cesium Beam Tube Block..............................................................................................128

Analog Signal Chain Block ............................................................................................129

Input/Output Block.........................................................................................................129

Power Supply Block .......................................................................................................129

x

Page 13

Contents

Functional Block Descriptions ..........................................................................................130

Instrument Control Block ...............................................................................................133

Reference Oscillator/RF chain Block .............................................................................137

Cesium Beam Tube Block..............................................................................................139

Analog Signal Chain Block ............................................................................................141

Input/Output Block.........................................................................................................143

Power Supply Block .......................................................................................................144

A1 Motherboard Circuit Description..............................................................................146

A11 Power Steering Logic Assembly.............................................................................147

Figure 3-8. Opt. 048, Power Supply Block Diagram......................................................156

A12 Dc-Dc Power Converter Module ............................................................................158

LF1 AC-Line Filter/Cable Assembly..............................................................................158

T1 Toroidal Power Transformer.....................................................................................158

B1 Internal-Standby Battery...........................................................................................158

4. Replacing Assemblies - Disassembly and Reassembly .................................................160

Introduction .......................................................................................................................160

Tools Required ..................................................................................................................160

Do This First...................................................................................................................... 161

To Remove the Covers ...................................................................................................... 161

To remove the A2 CBT Control Assembly....................................................................... 162

To Remove Any Other PC Boards ....................................................................................162

To Remove A1 Motherboard Assembly............................................................................162

To Remove A10 Output Frequency Distribution Amplifier Module................................ 163

To Remove A12 Dc-Dc Power Converter Module ...........................................................164

To Remove A13 Front Panel Module................................................................................ 165

To Remove A14 Signal Amplifier Module....................................................................... 166

To Remove A15 9.2 GHz Microwave Generator Module................................................. 167

To Remove A16 High Voltage Supply Module................................................................ 167

To Remove A17 CBT Assembly....................................................................................... 168

Preparation......................................................................................................................168

10890A or 10891A CBT Removal.................................................................................168

CBT Installation..............................................................................................................169

Operation Verification....................................................................................................171

Disposal Procedure for Symmetricom Cesium Beam Tubes..........................................172

To Remove A19 Reference Oscillator Module ................................................................. 173

xi

Page 14

Contents

5. Replaceable Parts ............................................................................................................174

Introduction .......................................................................................................................174

Replaceable Parts Table..................................................................................................... 174

How To Order A Part ........................................................................................................174

Parts Identification..........................................................................................................174

Contacting Symmetricom ...............................................................................................175

6. Specifications....................................................................................................................179

Introduction .......................................................................................................................179

7. Service and Support........................................................................................................ 180

Index ..................................................................................................................................... 182

xii

Page 15

Preface

This manual provides assembly-level service information for the

Symmetricom 5071A Primary Frequency Standard.

Repair Strategy

The Symmetricom 5071A Primary Frequency Standard can be returned to

Symmetricom for all service work, including troubleshooting, and verifying

specifications. Contact Symmetricom for more details.

If you decide to service the instrument yourself, use the operational

verification procedure in Chapter 1, “Performance Tests,” in this manual to

define the type of problem. For more complete tests, use the full performance

tests in Chapter 1. After a repair, re-check the Standard's operation with the

verification or full-performance test procedures.

This service manual is designed to isolate failures to the assembly or module

level only. If a failure occurs, you can isolate the faulty assembly or module

by using the procedures in Chapter 2 “Service.” The procedures in Chapter 4

“Replacing Assemblies” enable you to remove and replace defective

assemblies or modules.

Text Conventions used in this manual

Throughout this manual there are symbols used to denote special meanings.

These are explained below:

< > These separators mark where information may be any value or text (otherwise

known as “wild cards”). The actual value in these cases is not critical to the process.

Instrument Identification

Instrument identification is made from the serial number located on the rear

panel of the 5071A. Symmetricom uses a two-part serial number with the first

part (prefix) identifying a series of instruments and the second part (suffix)

identifying a particular instrument within a non-repeating series. A

Symmetricom assigned alpha character within the serial number identifies the

country in which the instrument was manufactured. The letters “A” or “US”

denote manufacture in the United States of America.

xiii

Page 16

Preface

Instruments Covered by This manual

This manual applies directly to Symmetricom 5071A Primary Frequency

Standards that have the same serial number prefix(es) shown on the title

page. If the serial number prefix of your Standard differs from that listed on

the title page of this manual, then there may be differences between this

manual and your instrument. Instruments having a higher serial prefix are

covered when required by one or more manual-change sheets included with

this manual. If a required change sheet is missing, contact Symmetricom by

phone or email using the information provided at the back of this manual.

Manual Organization

This assembly-level service manual consists of a table of contents,

preface, Six chapters and an index. The page running headers identify the

chapters and sections of this manual. The chapter contents are

summarized as follows:

Chapter 1, Performance Tests, provides test procedures to ensure

that the Standard meets all warranted specifications.

Chapter 2, Service, is divided into five sections. Section 1 contains

instructions for returning the Standard to Symmetricom for

service. Section 2 contains pre-troubleshooting information

and Sections 3, 4, and 5 provide the diagnostic

troubleshooting-tree procedures (diagnostic trees) to isolate

faulty assemblies and/or modules.

Chapter 3, Theory of Operation, provides two levels of hardware

functional description based on a signal-flow block-diagram

perspective.

Chapter 4, Replacing Assemblies, contains procedures for replacing

defective assemblies and/or modules in the instrument.

Chapter 5, Replaceable Parts, lists the replaceable parts inside the

Standard and explains how to order them from Symmetricom.

Chapter 6, Specifications, This information is duplicated in the 5071A

Operating and Programming manual P/N 05071-90041, and is

therefore not printed in this manual.

How to Order Manuals

A copy of this manual (part number 05071-90040) can be downloaded from

the following website:

http://www.symmttm.com/products_pfr_5071A.asp

The Symmetricom 5071A Operating and Programming manual (part number

05071-90041) can be obtained from the same site as well.

xiv

Page 17

1. Performance Tests – Verifying

Specifications

Introduction

NOTE

In the interest of PRESERVING its usability the information in

this chapter has been retained in its original form without

changes. No attempt has been made to update the equipment,

accessories, or parts to current availability. It is therefore

necessary for the user of this manual to consider the

recommendations of test equipment and accessories as

suggestions. Some or all of these items may no longer be

available from Symmetricom or any other vendors. An updated

list of available replacement parts from Symmetricom is provided

in Chapter 5.

This chapter provides procedures to test the electrical performance of the

5071A Primary Frequency Standard, using the specifications listed in

Chapter 6, “Specifications.” Three types of tests are provided:

Operational Verification

Complete Performance Tests

RS-232 Verification

Operational Verification

The Operational Verification test is an abbreviated series of checks that may

be performed to give a high degree of confidence that the instrument is

operating properly without performing the complete Performance Tests. An

operational verification is useful for incoming inspection, routine

maintenance, and after instrument repair.

Complete Performance Tests

The complete Performance Tests verify the specifications listed in Chapter 6

of this manual. All tests can be performed without access to the inside of the

instrument.

RS-232 Verification

The RS-232 Serial Port verification checks the serial port for successful data

communication with a terminal or PC.

1

Page 18

1. Performance Tests – Verifying Specifications

Test Record

Test Record

The results of the Operational Verification, complete Performance Tests, and

RS-232 Verification can be recorded on a copy of the Performance Test

Record, located at the end of this chapter.

Equipment Required

Equipment required for the performance tests in this chapter is listed in the

following table. Any equipment that satisfies the critical specification listed in

the table may be substituted for the recommended model(s). (The

performance test and diagnostic procedures assume the use of the listed

equipment.)

If operational verification or full-performance tests are being performed, use

the test equipment called out on this page and the appropriate test

cables/adapters listed on page 6.

If diagnostic troubleshooting is required, use the test equipment called out on

this page, page 5, and the appropriate test cables/adapters listed on page 6.

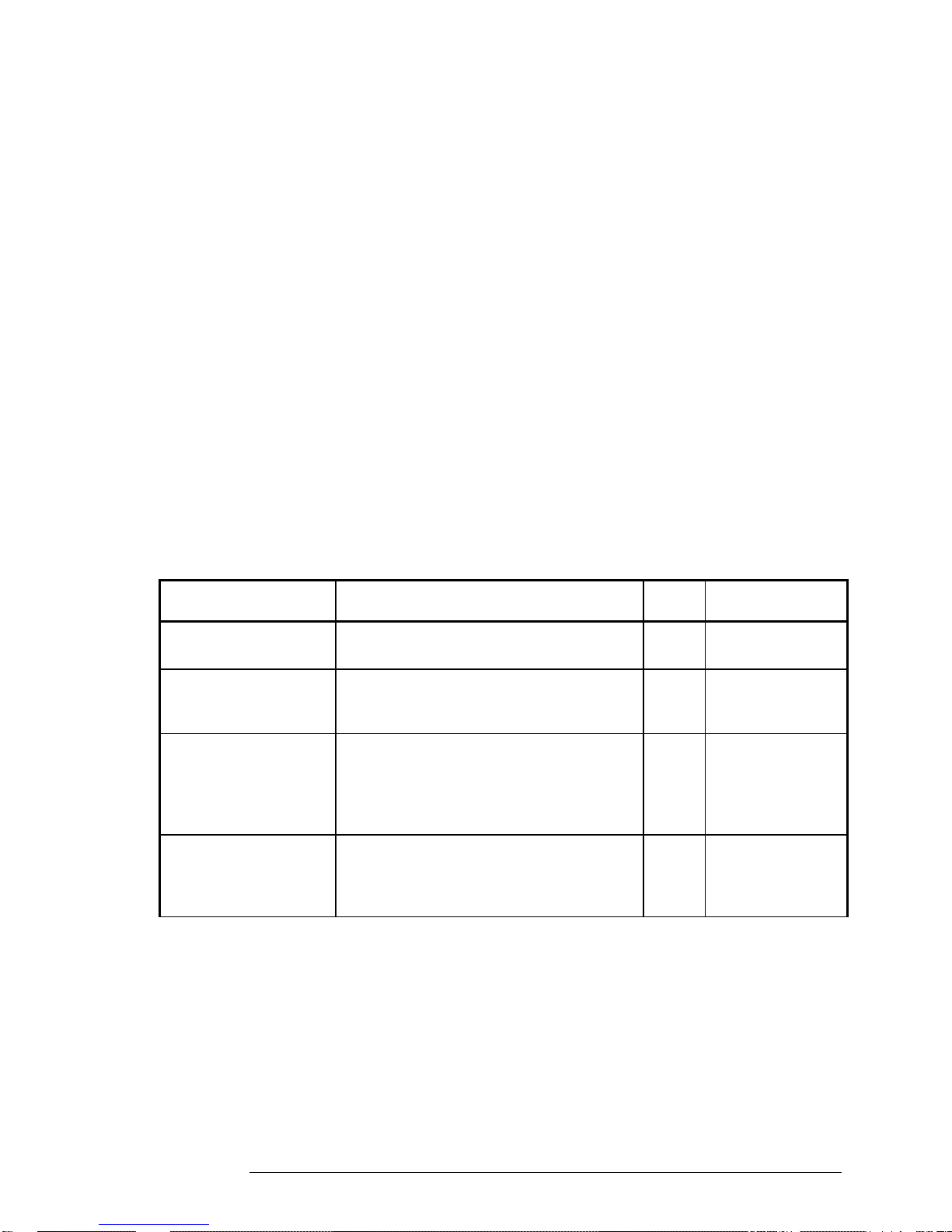

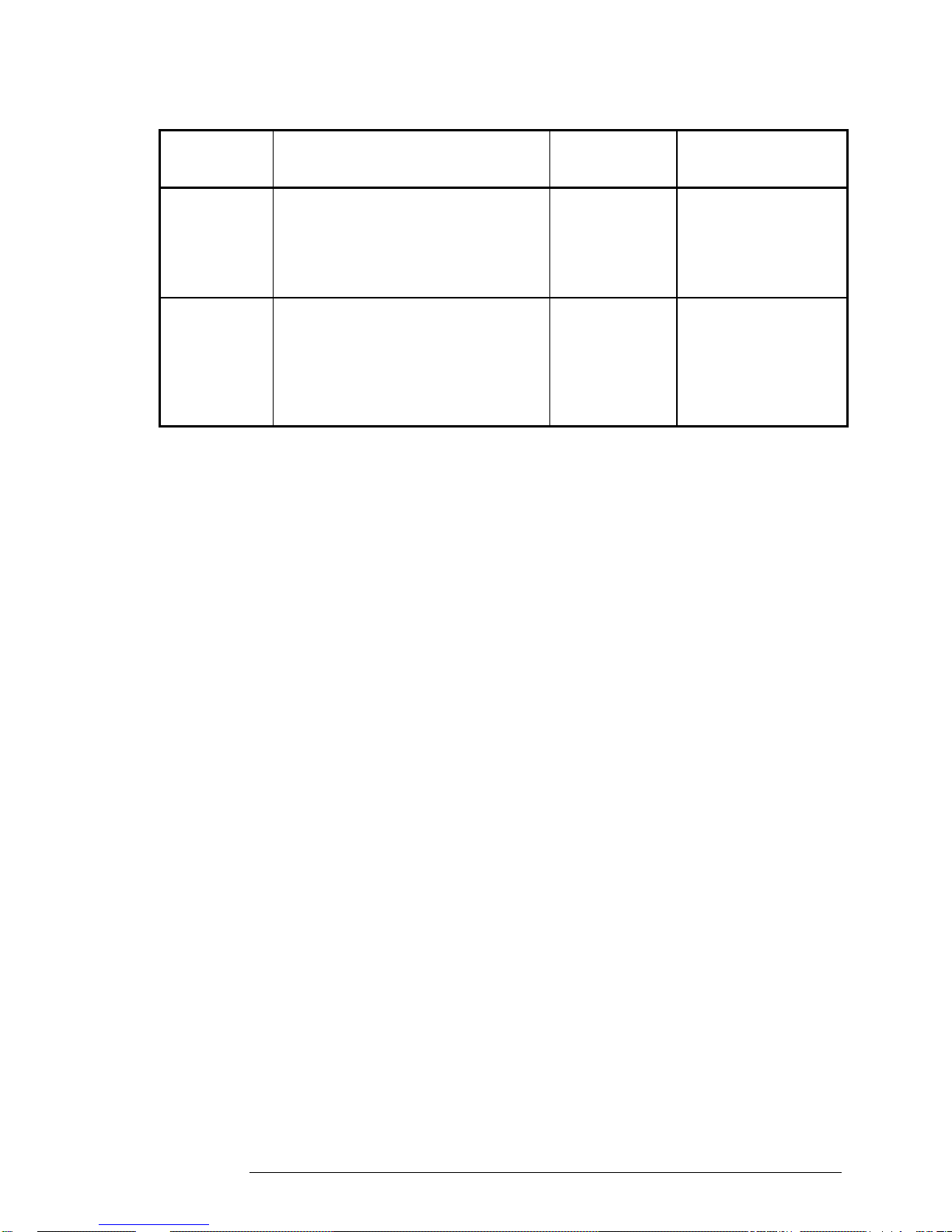

Table 1-1. Recommended Test Equipment

Instrument Required Characteristics Use Model

General-Purpose

Oscilloscope

Spectrum Analyzer Frequency Range Span: 0 to 40 MHz

Linear Phase

Comparator

Strip Chart Recorder Paper Movement: 1 inch/hour

At least 100 MHz bandwidth

Input: 1 M

Measurement Resolution 1 kHz/Div.

Center Frequency Accuracy: 1 PPM

Input Frequency Range: 5 to 10 MHz

Input Level (50): 1 Vrms

Output: 0 to +1 Vdc

Output Linearity: Proportional from

0 to 360 degrees phase

Input Range: 0 to +1 Vdc

Full Scale Range: +1 Vdc

Full Scale Resolution: 50 minor divisions

OV, T HP/Agilent

54600A

P, T HP/Agilent

3585A/B

P HP/Agilent

K34-59991A

P No

Recommendation

2

Page 19

1. Performance Tests – Verifying Specifications

Equipment Required

Table 1-1. Recommended Test Equipment (Continued)

Digital Multimeter

40kV ac/dc High

Voltage Probe

Clip-on Current Probe Range: >= 1 Amp dc

Universal Counter Range: >= 500 MHz

CW Microwave

Counter

Spectrum Analyzer Frequency Range: >= 9.5 GHz

Input Probe 10:1 Divider (included with

Input Probe

RF Signal Generator Frequency Range: > 80 MHz

Input Resistance: 10 M

Accuracy: 0.04% at 1 Vdc

Range: >= 5KV dc, input Z= 1 G,

Accuracy: 2%, 10 M load

Output: 1 Vdc at 10 Amp dc

Accuracy: 0.1 PPM

Range: >= 10 GHz

Accuracy: >= 0.1 ppm

Resolution: 100 kHz / Division

Center Frequency Accuracy: 1 PPM

Input: Up to 1 watt input capability

Dynamic Range: 100 dB

54600A oscilloscope)

1:1 1 M (for 50 measurements)

Power: >= +7 dBm

T HP/Agilent 34401A

T HP/Agilent 34300A

T HP/Agilent 34302A

T HP/Agilent 53131A,

Opt 010, 030

T HP/Agilent 5350B,

Option 010

T HP/Agilent 8566A/B

T HP/Agilent 10071A

T HP/Agilent 10070A

T HP/Agilent 8656B

Pulse Generator Repetition Rate: 10 Hz

Pulse Width: <= 10 usec

Output Voltage: >= +3V

General-purpose DC

Power Supply,

Adjustable

IBM-Compatible PC

Service Accessories

Kit

Profiling Software For Online CBT Performance Testing

0 - 10V,

>= 25 ma

MS-DOS 3.3 or later, 640 kB RAM,

1 serial (COM: ) Port

Special Test Tools, Devices, and

Fixtures

(See Title Page for download

instructions)

T HP/Agilent 8111A

T HP/Agilent E3610A

T Any Vendor

T 05071-67003

T 05071-13501

3

Page 20

1. Performance Tests – Verifying Specifications

Equipment Required

Table 1-1. Recommended Test Equipment (Continued)

BNC, and Datacommunication cables

Adapters

Microwave Test Cable SMA (male) at both ends, <10dB loss

Special Tools Narrow bladed non-conducting

BNC Cables, 50 , 1 M long, quantity 4

RS-232 Cable, 9-pin (jack) to 9-pin

(jack)

50 BNC In-line Feed through

2-Way 3dB Power Splitter

BNC (jack) to BNC (jack), quantity 4

BNC (jack) to SMC (plug), quantity 2

BNC (plug) to SMC (jack)

BNC (jack) to SMB (plug)

BNC (plug) to SMB (jack)

N (plug) to BNC (jack)

N (plug) to SMA (jack)

SMA (jack) to SMA (plug) Right-Angle

SMA (plug) to SMA (plug)

SMA (jack) to SMA (jack)

SMB (jack) to SMB (jack)

SMB (plug) to SMB (plug)

SMC (jack) to SMC (jack)

SMC (plug) to SMC (plug)

at

10 GHz

screwdriver

TORX T-8 Driver

TORX T-10 Driver

TORX T-15 Driver

TORX T-25 Driver

T HP/Agilent 10503A

24542U

T HP/Agilent 10100C

0960-0496

1250-0080

1250-0832

1250-0831

1250-1236

1250-1857

1250-0780

1250-1250

1250-1249

1250-1159

1250-1158

1250-0672

1250-0669

1250-0827

1250-1113

T GoreTex

32R01R01048.0

T Jacobsen #8777

8710-1614

8710-1623

8710-1622

8710-1617

OV = Operational Verification

P = Complete Performance Tests

T = Troubleshooting

4

Page 21

1. Performance Tests – Verifying Specifications

5071A Operational Verification

5071A Operational Verification

Power-On Self-Tests and Servo Lock

1 Inspect the 5071A for any damage (see the section titled “Initial

Inspection” in Chapter 7 of the 5071A Operating and

Programming Manual for detailed inspection information).

2 Ensure that the ac-power setting, ac-line fuse (rear panel), and

supplied power cord are appropriate for your ac-power source.

(Refer to Chapter 7, “Installation,” for detailed information.)

3 Now, apply power to the instrument by connecting ac-power

source to the instrument via the ac power cord. The amber

Attention light is lit indicating normal power-up sequence and the

following messages are displayed on the LCD in sequence:

a. The message “waiting for ion pump start” may appear. If so it could

stay on for up to 20 minutes before the following messages appear.

b. Warming up (this indicates self-test passed successfully)

c. Lowering E_mult voltage

d. Setting Osc. Control

e. Setting RF amplitude

f. Setting E_mult voltage

g. Logging signal levels

h. Setting C-field

i. Locking servo loops

j. Operating normally

4 After about 15 minutes (typically), the Attention (amber) light

goes out and the Continuous Operation (green) light flashes.

This indicates that all servo loops have locked and the instrument

is operating normally.

5 Press Shift, then 5 (Utilities).

LCD display shows RESET.

6 Press Enter.

This resets the continuous operation circuit, causing the light to be

on steadily. Any subsequent fault will cause the Continuous

Operation light to go out or flash.

7 Mark Pass or Fail on the Performance Test Record, line 1.

5

Page 22

NOTE

1. Performance Tests – Verifying Specifications

5071A Operational Verification

The 5071A powers up at shipment receipt with the following

configuration:

Output Ports:

Port 1 5 MHz output

Port 2 10 MHz output

RS-232C:

Baud rate 2400

Data bits 8

Parity none

Stop bits 1

System Logs:

Printer log disabled

Error log lock

completed

These first-time power-up configurations can be changed by

using the front panel controls. See the section titled “Setting the

Output Port Frequency” in the 5071A Operating and

Programming Manual for instructions on how to do this.

6

Page 23

1. Performance Tests – Verifying Specifications

5071A Operational Verification

Rear-Panel Output Signal Checks

Check the rear-panel outputs for appropriate signal waveform,

frequency and voltage.

Required Equipment

BNC-to-BNC 1-meter cable (male connectors),

model number HP/Agilent 10503A

Type N (male)-to-BNC (female) adapter,

HP/Agilent part number 1250-0780

50- feedthrough BNC (male) and (female) adapter,

model number HP/Agilent 10100C

HP/Agilent 54600A General-Purpose 100 MHz Oscilloscope

(or equivalent)

To check the rear-panel output connectors quickly for the presence

of valid output signals, perform the following steps:

NOTE

The LCD display backplane light will turn off after approximately

4 minutes to conserve energy if no front-panel key is pressed.

Press any key to turn the backplane light back on.

1 Connect one of the 5071A outputs to an input channel of the

HP/Agilent 54600A with a 50- feed through termination and BNC

cable as shown in Figure 1-1.

Figure 1-1. Rear-Panel Outputs Verification Setup

7

Page 24

1. Performance Tests – Verifying Specifications

5071A Operational Verification

2 On the HP/Agilent 54600A Oscilloscope, press “Autoscale.”

(Use manual settings if needed to check the 1pps Outputs.)

3 Verify that the output signal waveform, frequency, and nominal

voltage correspond to the values listed in Chapter 6,

“Specifications,” for the signal under test.

4 Repeat steps 1 through 4 for all outputs.

5 Mark Pass or Fail on the Performance Test Record, line 2.

RS-232 Serial Port Verification

1 Ensure that the correct hardware connections exist between the

5071A and your terminal, personal computer, or workstation for

your remote operation needs as shown in Figure 1-2.

2 Ensure that the 5071A and your data communications equipment

(terminal) are powered-up and have passed their own self-tests.

3 On your terminal, press the “Enter” or “Return” key several times.

4 Observe the returned scpi> or E-xxx> prompt on the terminal

screen.

if the above prompt appears, the RS-232 Verification check passed.

If the prompt does not appear:

Check and verify all serial port parameters: baud rate, data bits,

stop bits, and parity.

Check and verify the hardware connections and cabling for correct

DTE-DCE signal paths. (Serial-port pin assignments are shown on

page 4-2 of the Operating and Programming manual.)

Check and verify all cables and connections for open or shorted

lines.

5 Mark Pass or Fail on the Performance Test Record, line 3.

8

Page 25

1. Performance Tests – Verifying Specifications

5071A Operational Verification

Figure 1-2. RS-232C Cabling Setups

9

Page 26

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

5071A Complete Performance Tests

Before performing the following tests, the 5071A under test must have

been in operation for at least 30 minutes. If you are initially starting the

5071A, follow the instructions in the “Power-On Self Tests” procedure under

the Operational Verification Test on page 7.

Test 1 — Output Signals: Harmonic Distortion

and Spurious Signals Check

A. Harmonic Distortion Check for the 5 and 10 MHz Outputs

Harmonics on the 10 MHz and 5 MHz output signals must be more than 40

dBc below the fundamental. To perform this check, a spectrum analyzer is

tuned to the fundamental frequency and an amplitude reference is

established. The output frequency spectrum is then examined to determine

fundamental-to-sideband amplitude relationship at harmonic points of the

fundamental.

Equipment

HP/Agilent 3585B Spectrum Analyzer

Setup

Figure 1-3. Harmonic Distortion Test Setup

Specifications

Verify all harmonics are < 40 dBc with respect to the fundamental

frequency.

10

Page 27

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Procedure

If you are using the HP/Agilent 3585B Spectrum Analyzer, follow the steps

below to test for harmonic signals on the 5 and 10 MHz outputs. If you are

using a different spectrum analyzer, use these steps as a guide for operation

of that analyzer.

1 Connect the 5071A Port 1 to the HP/Agilent 3585B analyzer as shown in

2 On the 5071A, set output ports 1 and 2 to 10 MHz using the front panel

3 On the HP/Agilent 3585B, perform the following steps:

Figure 1-3. Set the 3585B for 50 input impedance.

controls. See the section titled “Setting the Output Port Frequency” in the

5071A Operating and Programming Manual for instructions on how to do

this.

a) Press the green “INSTR PRESET” button and allow the analyzer

to go through its auto range algorithm (this takes about 5

seconds).

b) Press the “DISP LINE” (display line) button in the marker menu

and adjust the line to 40.0 dBc.

NOTE

c) Press the “PEAK SEARCH” button and then the “MKR->REF LVL”

button (both are in the marker menu area).

d) Set both the resolution bandwidth (RES BW) and the video

bandwidth (VIDEO BW) to 1 kHz. Enter the 1 kHz values using the

numeric and unit keys. The RES BW and VIDEO BW values are

displayed at the bottom of the screen.

The sweep time is 125 seconds. DO NOT adjust the sweep

time manually.

e) Press the “CONT” button in the sweep menu area to begin a new

sweep.

f) When the new sweep has passed through the fundamental

frequency, press the “PEAK SEARCH” button again. Then press

the “OFFSET” and the “ENTER OFFSET” buttons in the marker

menu area. Verify that both the offset frequency (Hz) and the

offset level (dB) go to zero (0 Hz and 0 dB should be displayed at

the top of the screen). If necessary, press and hold the “ENTER

OFFSET” button to zero-out the marker offsets.

g) When at least one sweep has completed, verify that there are no

harmonic signals on or above the 40dBc display line. Use the knob

in the marker area to move the offset marker to any harmonic signal

that you want to measure or record. The marker shows the offset

frequency and level in dBc from the output signal at 5 or 10 MHz.

Verify that there are no harmonically related signals on or above

40dBc within 5 harmonics of the fundamental.

11

Page 28

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

4 On the 5071A, set output ports 1 and 2 to 5 MHz using the front

panel controls.

5 Repeat step 3.

6 Connect 5071A Port 2 to the HP/Agilent 3585B Spectrum

Analyzer and repeat steps 2 through 5 to test Port 2.

7 Record the actual reading in the appropriate place in the

Performance Test Record.

B. Non-Harmonic (Spurious) Signal Check for the 5 and 10 MHz Outputs

Non-harmonically related (spurious) signals on the 5 and 10 MHz outputs

must be more than 80 dBc below the output signal levels. To perform this

test, a spectrum analyzer is tuned to the 5 or 10 MHz signal and an amplitude

reference is established. The output frequency spectrum is then examined at

1 MHz on either side of the center frequency to determine the fundamentalto-sideband amplitude relationship for any signals occurring within this range.

Equipment

Setup

HP/Agilent 3585B Spectrum Analyzer

Figure 1-4. Non-Harmonic Distortion Test Setup

12

Page 29

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Specifications

All spurious nonharmonic signals must be < 80 dBc with respect to the

fundamental frequency.

Procedure

If you are using the HP/Agilent 3585B Spectrum Analyzer, follow the steps

below to test for spurious signals on the 5 and 10 MHz outputs. If you are

using a different spectrum analyzer, use these steps as a guide for operation

of that analyzer.

1 Connect the 5071A Port 1 to the 3585B analyzer as shown in

Figure 1-4. Set the 3585B for 50 input impedance.

2 On the 5071A, set output ports 1 and 2 to 10 MHz using the front

panel controls. See the section titled “Setting the Output Port

Frequency” in the 5071A Operating and Programming Manual for

instructions on how to do this.

3 On the 3585B, perform the following steps:

a) Press the green “INSTR PRESET” button and allow the analyzer

to go through its auto range algorithm (this will take about 5

seconds).

NOTE

b) Press the “DISP LINE” (display line) button in the marker menu

and adjust the line to 80.0 dBc.

c) Press the “PEAK SEARCH” button and then the “MKR->REF LVL”

button (both are in the marker menu area).

d) Set both the resolution bandwidth (RES BW) and the video

bandwidth (VIDEO BW) to 1 kHz. Enter the 1 kHz values using the

numeric and unit keys. The RES BW and VIDEO BW values are

displayed at the bottom of the screen.

The sweep time is 125 seconds. DO NOT adjust the sweep time

manually.

e) Press the “CONT” button in the sweep menu area to begin a new

sweep.

f) When the new sweep has passed through the fundamental

frequency, press the “PEAK SEARCH” button again. Then press

the “OFFSET” and the “ENTER OFFSET” buttons in the marker

menu area. Verify that both the offset frequency (Hz) and the

offset level (dB) go to zero (0 Hz and 0 dB should be displayed at

the top of the screen). If necessary, press and hold the “ENTER

OFFSET” button to zero-out the marker offsets.

13

Page 30

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

g) When at least one sweep has completed, verify that there are no

spurious signals on or above the 80 dBc display line. Use the

knob in the marker area to move the offset marker to any spurious

signal that you want to measure or record. The marker shows the

offset frequency and level in dBc from the output signal at 5 or 10

MHz.

h) Verify that one of the following conditions is true:

No spurious signals are on or above the 80 dBc display line

between 4 MHz and 6 MHz for the 5 MHz output, or

No spurious signals are on or above the 80 dBc display line

between 9 MHz and 11 MHz for the 10 MHz output.

4 On the 5071A, set output ports 1 and 2 to 5 MHz using the front

panel controls.

5 Repeat step 3.

6 Connect 5071A Port 2 to the 3585B Spectrum Analyzer and

repeat steps 2 through 5 to test Port 2.

7 Record the actual reading in the appropriate place in the

Performance Test Record.

C. Harmonic Distortion Check for the 1 MHz Output

Harmonics on the 1 MHz output signal must be more than 40 dBc below the

fundamental. To perform this check, a spectrum analyzer is tuned to the

fundamental frequency and an amplitude reference is established. The output

frequency spectrum is then examined to determine the fundamental-tosideband amplitude relationship at harmonic points of the fundamental.

Equipment

HP/Agilent 3585B Spectrum Analyzer

Setup

Figure 1-5. 1MHz Output Harmonic Distortion Test Setup

14

Page 31

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Specifications

All harmonics must be < 40 dBc with respect to the fundamental frequency.

Procedure

If you are using the HP/Agilent 3585B Spectrum Analyzer, follow the steps

below to test for harmonic signals on the 1 MHz output. If you are using a

different spectrum analyzer, use these steps as a guide for operation of that

analyzer.

1. Connect the 5071A 1 MHz output to the 3585B Spectrum Analyzer as shown

in Figure 1-5. Set the 3585B for 50 input impedance.

2. On the 3585B, perform the following steps:

a. Press the green “INSTR PRESET” button and allow the analyzerto go

through its auto range algorithm (this will take about 5 seconds).

b. Press the “STOP FREQ” button. Then set the stop frequency to 20 MHz

using the numeric and unit keys in the entry menu.

c. Press the “DSP LINE” button and move the display line to40.0 dBc.

d. Press the “PEAK SEARCH” button, then the “MKR->REF LVL” button.

e. When the new sweep has passed through the fundamental frequency,

press the “OFFSET” and the “ENTER OFFSET” buttons in the marker

menu area. Verify that both the offsetfrequency (Hz) and the offset level

(dB) go to zero (0 Hz and 0 dBshould be displayed at the top of the

screen). If necessary, pressand hold the “ENTER OFFSET” button to

zero-out the markeroffsets.

f. When at least one sweep has completed, verify that there are no

signals on or above the 40 dBc display line at multiples of 1 MHz up to

4 MHz. Use the knob in the marker area to move the offsetmarker to

any signals within this range if you want to measure or record these

signals. The marker shows the offset frequency and level in dBc from

the 1 MHz signal.

3. Record the actual reading in the appropriate place in the Performance Test

Record.

15

Page 32

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

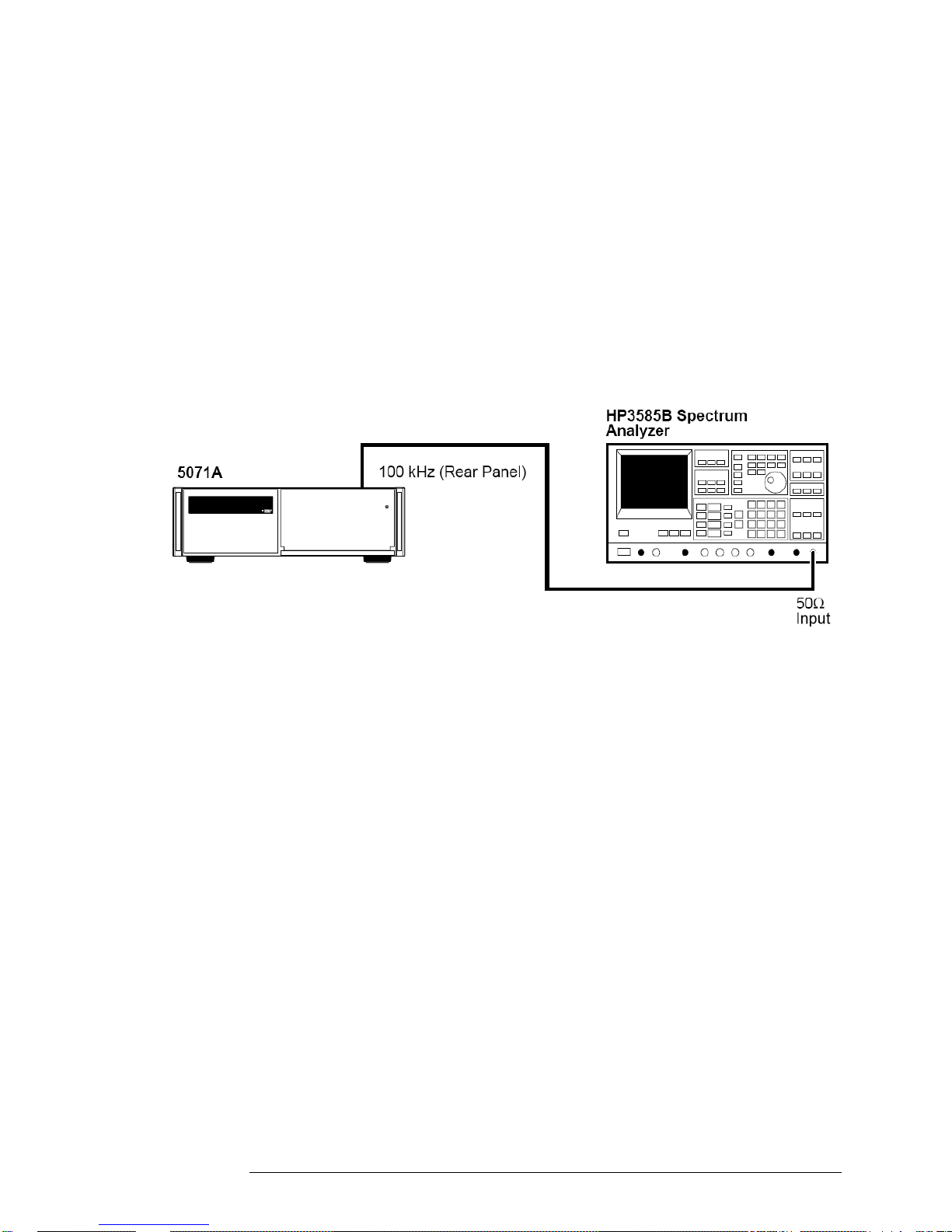

D. Harmonic Distortion Check for the 100 kHz Output

Harmonics on the 100 kHz output signal must be more than 40 dBc below the

fundamental. To perform this check, a spectrum analyzer is tuned to the

fundamental frequency and an amplitude reference is established. The output

frequency spectrum is then examined to determine fundamental-to-sideband

amplitude relationship at harmonic points of the fundamental.

Equipment

HP/Agilent 3585B Spectrum Analyzer

Setup

Figure 1-6. 100 kHz Harmonic Distortion Test Setup

Specifications

All harmonics must be < 40 dBc with respect to the fundamental frequency.

Procedure

If you are using the HP/Agilent 3585B Spectrum Analyzer, follow the steps

below to test for harmonic signals on the 100 kHz output. If you are using a

different spectrum analyzer, use these steps as a guide for operation of that

analyzer.

1 Connect the 5071A 100 kHz output to the 3585B Spectrum Analyzer as

shown in Figure 1-6. Set the 3585B for 50 input impedance.

2 On the 3585B, perform the following steps:

a. Press the green “INSTR PRESET” button and allow the analyzer to go

through its auto range algorithm (this will take about 5 seconds).

b. Press the “STOP FREQ” button. Then set the stop frequency to 3 MHz

using the numeric and unit keys in the entry menu.

c. Press the “DSP LINE” button and move the display line to 40.0 dBc.

16

Page 33

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

d. Press the “PEAK SEARCH” button, then the “MKR->REF LVL” button.

e. Set the resolution bandwidth (RES BW) to 300 Hz and the video

bandwidth (VIDEO BW) to 1 kHz.

NOTE The sweep time is 66.8 seconds. DO NOT adjust the sweep

time manually.

f. Press the “CONT” button in the sweep menu area to begin a new

sweep.

g. When the new sweep has passed through the fundamental frequency,

press the “OFFSET” and the “ENTER OFFSET” buttons in the marker

menu area. Verify that both the offset frequency (Hz) and the offset

level (dB) go to zero (0 Hz and 0 dB should be displayed at the top of

the screen). If necessary, press and hold the “ENTER OFFSET” button

to zero-out the marker offsets.

h. When at least one sweep has completed, look for any signals that

appear on or above the 40 dBc display line at multiples of 100 kHz up

to 500 kHz. Use the knob in the marker area to move the offset marker

to any signals within this range if you want to measure or record these

signals. The marker shows the offset frequency and level in dBc from

the 100 kHz signal.

3 Record the actual reading in the appropriate place in the Performance Test

Record.

17

Page 34

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Test 2 — Frequency Accuracy

The following accuracy check measures the changing phase relationship

between the 5071A 10 MHz output and another primary frequency standard

(5071A Primary Frequency Standard or better). An HP/Agilent K34-59991A

Linear Phase Comparator is used to measure the phase between the 5071A

under test and the reference standard.

NOTE

In this test, the reference standard must be of known accuracy. The

measurement time must be of sufficient length so the accuracy of

the measurement is not impaired by the stability of either the

reference standard or the unit under test. If the reference standard is

a 5071A with the High-Performance CBT, the accuracy

measurement must be made for 24 hours if the unit under test is a

Long-Life (Standard) CBT. The test can be made in 2 1/2 hours if

the unit under test has the High-Performance CBT.

Equipment

HP/Agilent K34-59991A Linear Phase Comparator

Strip Chart Recorder

Setup

Figure 1-7. Frequency Accuracy Test Setup

18

Page 35

1. Performance Tests – Verifying Specifications

o

5071A Complete Performance Tests

Specifications

NOTE

Long-Life (Standard): 1x10

High-Performance: 2x10

The accuracy of the 5071A is better than 2x10

1x10

known with sufficient precision to make this measurement accurately.

Procedure

1 The 5071A must be on for at least 30 minutes and the green

2 Connect the HP/Agilent K34-59991A Phase Comparator OUTPUT

3 Turn on the K34-59991A power.

4 Connect the 10 MHz reference to INPUT A and the 5071A (unit

5 Set K34-59991A “ZERO-OPER-FULL” front panel mounted toggle

12

13

-13

-12

(Long-Life). Be sure the accuracy of the reference standard is

(High-Performance)

continuous operation LED must be on.

terminals to the strip chart recorder as shown in Figure 1-7. Set

the recorder for 1V full scale and 1 inch/hour. Turn on the

recorder.

under test) 10 MHz to INPUT B as shown in Figure 1-7.

switch to “ZERO.” Adjust the “ZERO SCALE” control for a zero

reading on the meter. Then adjust the recorder for a zero

indication.

6 Set K34-59991A switch to “FULL” and adjust “FULL SCALE”

control for a full scale reading on the recorder.

7 Check both “ZERO” and “FULL SCALE” settings on the recorder

and readjust if necessary.

8 Set K34-59991A switch to “OPER” for normal operation.

9 The recorder now provides a continuous record of the phase

difference between the reference standard and the 5071A unit

under test. When its output reaches full scale (360 degrees), the

K34-59991A will automatically reset to 0 (0 degrees).

10 With the recorder set as described, the phase record is 100 ns full

scale (with 10 MHz inputs). The figure below shows an example of

a frequency difference measurement under these conditions.

11 The frequency difference between the unit under test and the

reference is given by the following equation:

f/F = t/T

Where: f/F is the desired frequency difference, and t is the

phase change (in seconds) over the measurement time, T.

The Figure 1-8 shows a typical plot using the strip chart recorder.

19

Page 36

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

NOTE

Figure 1-8. Error Measurement

In the example, the frequency difference, f/F, is computed as follows:

f/F = t/T

t

= (7 minor divisions × 2x10

= 14x10

T

= 8 hours or 2.88 × 10

f/F

= t/T = 14 × 10

= 4.9 × 10

-13

9

seconds

-9

/2.88 × 10

or 4.9 parts in 1013

-9

seconds/minor divisions)

4

seconds

4

This shows that frequency difference between the unit under test and the

reference is 4.9 parts in ten to the 13th. This is only an example. The

measured frequency accuracy of a 5071A should be 1 x 10

13

Long-Life (Standard), or 2 x 10

or better for a high performance unit

12

or better for a

The final computation should include the accuracy of the reference

source.

12 Record the actual reading in the appropriate place in the

Performance Test Record.

20

Page 37

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Test 3 — Stability

NOTE

High accuracy precision measurements of time stability are

available through the National Institute of Standards and

Technology (NIST) in the USA. NIST can completely characterize

and verify all major specifications of the 5071A. For information

regarding the various tests available, contact:

M.C. 847.4

National Institute of Standards and Technology

325 Broadway

Boulder CO 80303-3328

USA

Telephone: (303) 497-3753

A. Time Domain

This is an engineering-level measurement requiring a special test setup. The

test setup must be carefully designed to eliminate all sources of noise. For

more information on how to make this measurement, see NIST Technical

Note 1337 (available from US Government Printing Office, Washington DC.,

USA). This is an excellent theoretical as well as technical reference for this

measurement.

Record the actual reading in the appropriate place in the Performance Test

Record. This completes the performance test.

B. Frequency Domain

This measurement requires the HP/Agilent 3048A or equivalent Phase Noise

Measurement System, a highly specialized test system. In order to perform

properly, this system must contain a reference oscillator with phase noise

characteristics that are equal to or better than the 5071A. Instructions for

performing frequency domain stability tests can be found in the HP/Agilent

3048A system documentation.

Record the actual reading in the appropriate place in the Performance Test

Record.

21

Page 38

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

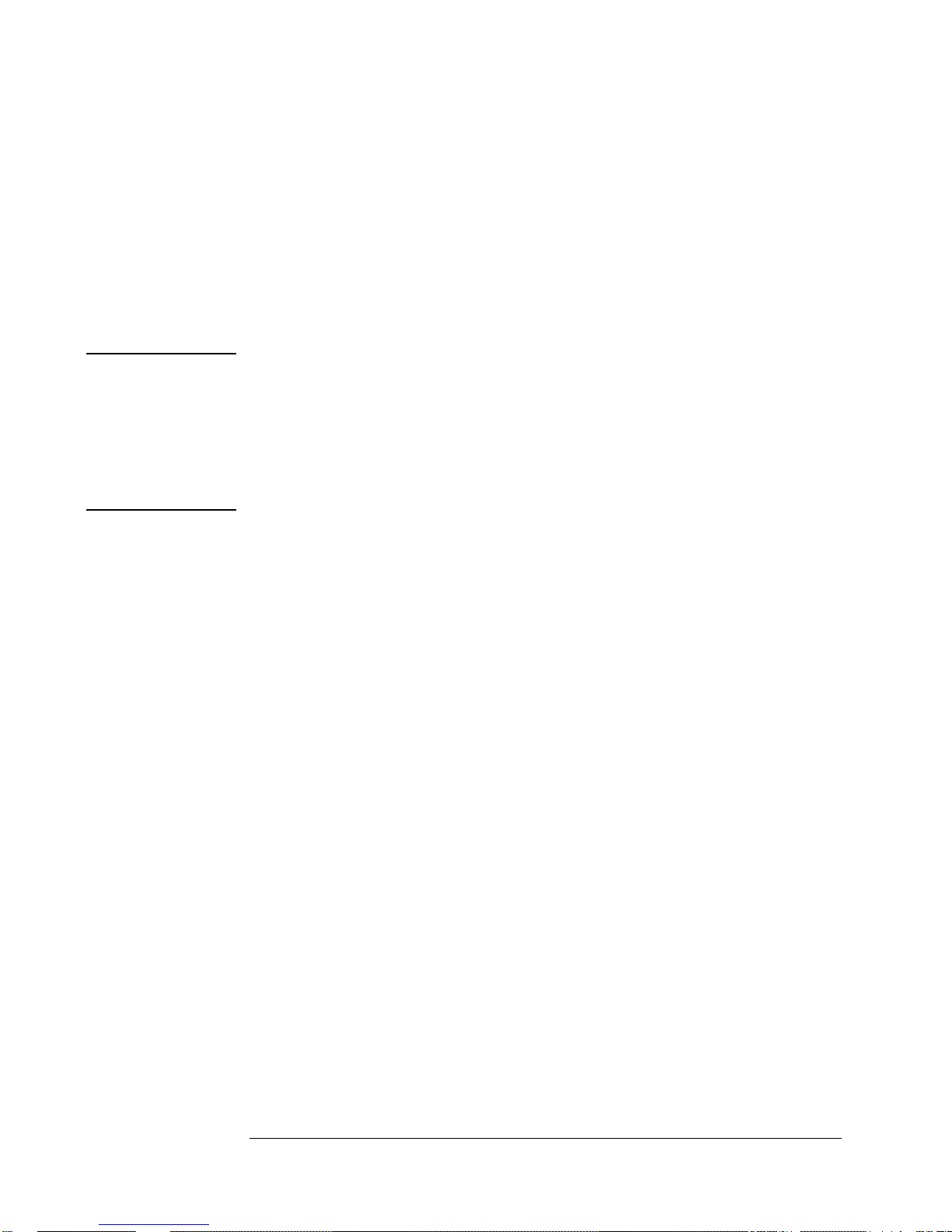

Performance Test Record

Model 5071A Primary Frequency Standard

Serial Number:

Test Performed By: Temperature:

Date: Relative Humidity:

Notes:

Repair/Work Order No.

Test

Number Operational Verification

1

2

3

Test

Number Description

1

Power-On Self-Tests/Servo Lock

Rear-Panel Output Signal Checks

RS-232 Serial Port Verification

Complete Performance Tests

Output Signals: Harmonic Distortion

and Spurious Signals Check

A. Harmonic Distortion Check for

the 5 and 10 MHz Outputs

B. Non-harmonic (Spurious)

Signal Check for the 5 and

10 MHz Outputs

C. Harmonic Distortion Check for

the 1 MHz Output

D. Harmonic Distortion Check for

the 100 kHz Output

Pass Fail

_______ ______

_______ _______

_______ _______

Actual

Reading

____________

____________

____________

____________

Test Results

Limits

Greater than 40 dBc

Greater than 80 dBc

Greater than 40 dBc

Greater than 40 dBc

22

Page 39

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

Number

Test

2

3

Description

Frequency Accuracy

Stability

A. Time Domain

B. Frequency Domain

Actual

Reading

____________

____________

____________

Limits

Long-Life:

12

-

1x10

High-Performance:

13

-

2x10

See Specifications

table in Chapter 6 of

this manual.

23

Page 40

1. Performance Tests – Verifying Specifications

5071A Complete Performance Tests

24

Page 41

2. Service

Introduction

NOTE

In the interest of PRESERVING its usability most of the

information in this chapter has been retained in its original form.

No attempt has been made to update the equipment, accessories,

or parts to reflect current availability. It is therefore necessary for

the user of this manual to consider the recommendations of test

equipment and accessories as suggestions. Some or all of these

items may no longer be available from Symmetricom or any other

vendors. An updated list of available replacement parts from

Symmetricom is provided in Chapter 5.

This chapter provides service information for your 5071A and is divided into

three major sections:

Returning the Instrument to Symmetricom for Service. This section

provides you with step-by-step instructions on how to return the

instrument for service.

Pre-Troubleshooting Information. This section provides you with pertinent

information such as safety considerations, recommended test equipment,

repair and after service considerations, service accessories, and

assembly identification and location.

Diagnostic Trees and Procedures. This section provides you with

diagnostic trees and procedures to isolate faulty assemblies or modules.

(Once you find a faulty assembly or module, use Chapter 4, “Replacing

Assemblies,” to remove the defective assembly and replace it with a

functioning unit.)

If the instrument is under warranty, return the instrument to Symmetricom for

service. Refer to the first section of this chapter titled “Returning the

Instrument to Symmetricom.” If you decide to troubleshoot the instrument

yourself, refer to the section titled “Diagnostic Trees and Procedures.”

25

Page 42

2. Service

Returning the Instrument to Symmetricom for Service

Returning the Instrument to

Symmetricom for Service

To Provide Repair Information

If you are shipping the instrument to Symmetricom for service or repair, call

your nearest Symmetricom sales representative or distributor to make

arrangements. Alternatively you can visit our web site at

http://www.symmetricom.com/support/warrantyandrepair and fill out the form

to receive an RMA and return address information.

IMPORTANT

NOTE

If you do not have the original shipping container for the 5071A it is

STRONGLY recommended that you first order the packaging kit part

number 59991-91105 from Symmetricom before returning for repair.

This kit provides all the necessary packaging material to give the

greatest amount of protection against shipping damage. Any 5071A

received for repair in any other packaging and found damaged will

not be covered under any Symmetricom warranty program. Such

damage will be evaluated and you will be provided with a quotation to

repair such damage before regular repair or calibration can be

performed.

It is also advised that all hazardous materials regulations for labeling be

followed for your local and country laws. The following web site will provide

you with up-to-date instructions: http://www.symmttm.com/5071A/Shipping/

Be sure to include the RMA with the shipment.

To Pack in the Original Packaging Materials

To protect your 5071A against shipping damage repack the instrument in its

original packaging for shipment. Shipping kit Part Number 59991-91105 is

available through Symmetricom. In any correspondence, refer to the instrument

by the model number and complete serial number.

1 Disconnect the power cord, probes, cables, or other accessories

attached to the instrument.

2 Make sure the folded corrugated spacer (which normally contains

the manuals) is in the box to ensure proper fitting.

3 Make sure the four polystyrene corner blocks are in their proper

positions in the box.

4 Place the instrument on the four polystyrene corner blocks with

the 3-ply pad at the rear panel end of the instrument.

26

Page 43

2. Service

Pre-Troubleshooting Information

5 Place four more polystyrene corner blocks on top of the

instrument to secure it.

6 Do not return the manuals with the instrument. Return an

accessory only when it is a part of the failure symptoms.

7 Seal the shipping container securely.

8 Apply the appropriate shipping labels.

Pre-Troubleshooting Information

This section contains the following pertinent troubleshooting information:

Safety Considerations

Recommended Test Equipment

Repair Considerations

After Service Considerations

Service Accessories

Assembly Identification and Location

WARNING

Safety Considerations

Although this instrument has been designed in accordance with international

safety standards, this manual contains information, cautions, and warnings

which must be followed to ensure safe operation and to retain the instrument

in a safe condition. Service instructions, and adjustment procedures requiring

removal of the instrument cover, are for use by service-trained personnel

only. To avoid dangerous electric shock, do not perform any servicing or

make any adjustments with the cover removed, unless qualified to do so.

BEFORE APPLYING AC POWER, THE INSTRUMENT AND ALL

PROTECTIVE EARTH TERMINALS, EXTENSION CORDS, AUTO

TRANSFORMERS, AND DEVICES CONNECTED TO THE

INSTRUMENT SHOULD BE CONNECTED TO A PROTECTIVE

EARTH GROUNDED SOCKET.

ANY INTERRUPTION OF THE PROTECTIVE GROUNDING

CONDUCTOR INSIDE OR OUTSIDE THE INSTRUMENT OR

DISCONNECTION OF THE PROTECTIVE EARTH TERMINAL

WILL CAUSE A POTENTIAL SHOCK HAZARD THAT COULD

RESULT IN PERSONAL INJURY. INTENTIONAL