SYMEO LPR

®

Product: LPR®-2DB

Product Documentation

Symeo LPR®-System

LPR®-2DB

Product Documentation

CONTENT

1 GENERAL ........................................................................................................ 9

1.1 Safety Instructions ................................................................................................... 9

1.2 Installation ............................................................................................................... 9

1.3 Repairs.................................................................................................................... 9

1.4 Transport and Storage ............................................................................................ 9

1.5 Power Supply .........................................................................................................10

1.6 Setup and Operation ..............................................................................................10

1.7 System Extensions and Accessories ......................................................................10

1.8 Additional Instructions Regarding Compact Type and Integral Type Stations .........11

2 INTRODUCTION ............................................................................................ 12

2.1 Details ....................................................................................................................12

2.2 Overview of Files ....................................................................................................12

2.3 Project Planning .....................................................................................................15

3 SYSTEM DESCRIPTION ................................................................................ 18

3.1 Technical Data .......................................................................................................18

3.2 Operating Mode .....................................................................................................19

3.2.1 Operation Mode 1: Basic Cell ..........................................................................19

3.2.2 Operation Mode 2: Managed Cell ....................................................................20

3.2.3 Operation Mode 3: TDOA ................................................................................21

3.3 Vehicle Model.........................................................................................................22

3.3.1 Hover-Track ....................................................................................................23

3.3.2 Vehicle-Track ..................................................................................................23

3.4 System Design .......................................................................................................23

3.4.1 2D Positioning .................................................................................................24

4 HARDWARE ................................................................................................... 26

4.1 System components – Overview ............................................................................26

4.2 LPR-2DB Station (mobile station) ...........................................................................26

4.2.1 Overview compact station ...............................................................................26

4.2.2 Technical data compact station .......................................................................26

4.2.3 Station BSB000313, BSB000319 ....................................................................27

4.2.4 Station BSB000603, BSB000604, BSB000605, BSB000606 ...........................28

4.2.5 Lumberg Connector Type 0233 08 ..................................................................29

General

Copyright © Symeo 2012

Page 2 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

4.3 Cables for Compact Station ....................................................................................29

4.3.1 Cable for Power Supply ...................................................................................29

4.3.2 Recommended Cable Types HARTING Push Pull Connector .........................31

4.4 Connector box ........................................................................................................ 31

4.4.1 Example: Connector Box .................................................................................32

4.5 LPR-2DB Integral Station (fixed mounted unit) .......................................................33

4.5.1 Technical Data: LPR-2DB Integral Station .......................................................33

4.5.2 Components of LPR-2DB Integral Station .......................................................34

4.6 LPR Antennas for Compact Station (mobile unit) ...................................................34

4.6.1 Mounting devices of LPR Antennas .................................................................35

5 INSTALLATION .............................................................................................. 37

5.1 Installation of the LPR-2DB Station (mobile unit) ....................................................37

5.2 Installation of the LPR-2DB Integral Station ...........................................................38

5.2.1 Electrical Interface ...........................................................................................38

5.2.2 Installation .......................................................................................................39

5.2.3 Allocation of LPR-2DB Integral Stations and Installation Points .......................41

5.3 Installation of LPR antennas ...................................................................................41

5.3.1 Connection of antenna cables to the mobile units (LPR-2DB Station) .............41

5.3.2 Mounting of LPR antennas ..............................................................................42

5.3.3 Notes for mounting position of LPR antennas on the mobile unit .....................43

6 COORDINATE SYSTEM ................................................................................ 46

6.1 Survey Instructions for the LPR-2DB Integral Station .............................................46

6.1.1 Coordinate system of LPR-2DB Integral Station ..............................................46

6.1.2 Reference point of LPR-2DB Integral Station ..................................................47

6.1.3 Orientation of LPR-2DB Integral Station ..........................................................48

6.1.4 Formatting of coordinates ................................................................................49

6.2 Surveying of LPR-2DB Compact Station on mobile unit .........................................50

6.2.1 Reference system for vehicle type: forklift .......................................................50

6.2.2 Reference system for vehicle type: Van Carrier...............................................50

6.2.3 Reference system for vehicle type: passenger car ..........................................51

6.2.4 Reference system for vehicle type: crane/ trolley ............................................52

6.3 Surveying of LPR antennas ....................................................................................52

6.3.1 Formatting of coordinates ................................................................................53

7 COMMISSIONING .......................................................................................... 55

General

Copyright © Symeo 2012

Page 3 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

7.1 Check list installation and surveying .......................................................................55

7.1.1 Cells, Integral stations .....................................................................................55

7.1.2 LPR-2DB Station (Mobile units) .......................................................................56

7.1.3 Formatting of coordinates ................................................................................56

7.1.4 Folders structure .............................................................................................56

7.2 Editing of configuration files for the DSP ................................................................56

7.2.1 File basestation_config.txt ...............................................................................57

7.2.2 File stationXXM_config.txt ...............................................................................57

7.2.3 File stationXXY_config.txt ...............................................................................58

7.3 Upload of configuration files for the DSP ................................ ................................58

7.3.1 Connection with LPR mobile unit (type: compact) via TCP/IP ..........................59

7.3.2 Connection with LPR mobile unit (type: compact) via RS232 ..........................60

7.3.3 Upload DSP configuration file for LPR mobile unit (base station) ....................61

7.3.4 Upload DSP configuration file for master transponder unit ..............................62

7.3.5 Upload DSP configuration file for transponder unit ..........................................65

7.4 Editing of configuration files for Fusion Engine .......................................................67

7.4.1 fusion.ini ................................................................................................ ..........68

7.4.2 field.ini .............................................................................................................69

7.4.3 LPR_B.ini ........................................................................................................70

7.4.4 LoadPos.ini .....................................................................................................71

7.4.5 Customer.ini (or Symeo_2D.ini) ......................................................................71

7.5 Upload configuration files for FusionEngine ...........................................................73

7.5.1 Upload of files via WinSCP..............................................................................73

8 SYMEO MAP .................................................................................................. 78

8.1 Configuration and Connection with Symeo MAP ....................................................78

8.1.1 lpr.ini ...............................................................................................................78

8.1.2 Starting FusionEngine .....................................................................................79

8.1.3 Starting Symeo Map ........................................................................................80

8.1.4 Connection with mobile unit.............................................................................82

8.2 Display of Symeo MAP ...........................................................................................83

8.2.1 Level of Transponders .....................................................................................83

8.2.2 Radius/ Hyperboloids of Transponders ...........................................................83

8.3 Antenna Calibration ................................................................................................83

9 NETWORK SETTINGS ................................................................................... 85

9.1 TCP/IP connection between PC and LPR-2DB station ...........................................85

General

Copyright © Symeo 2012

Page 4 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

9.2 Open Web Server ..................................................................................................86

9.3 Settings ..................................................................................................................87

9.3.1 LAN .................................................................................................................88

9.3.2 Network ...........................................................................................................89

9.3.3 Serial-to-Ethernet ............................................................................................90

9.3.4 Remote Access ...............................................................................................92

9.3.5 Miscellaneous ................................................................ .................................93

9.3.6 Special functions .............................................................................................93

9.3.7 Accept settings/ System reboot .......................................................................94

9.4 System status.........................................................................................................94

9.5 Diagnostics ............................................................................................................96

9.6 Update Firmware ....................................................................................................97

9.6.1 Step 1 – File system ........................................................................................98

9.6.2 Step 2 – Linux Kernel .................................................................................... 100

9.6.3 Step 3 – User space (optional) ...................................................................... 103

9.6.4 Step 4 – Restart ............................................................................................ 103

9.7 System Log .......................................................................................................... 104

10 SYMEO 2D PROTOCOL .............................................................................. 106

10.1 Introduction / Basics ............................................................................................. 106

10.1.1 Configuration file Symeo_2D.ini .................................................................... 106

10.2 Binary format of the protocol ................................................................ ................ 108

10.2.1 Data types ..................................................................................................... 108

10.2.2 Byte Stuffing .................................................................................................. 108

10.2.3 General Structure .......................................................................................... 109

10.2.4 Data fields ..................................................................................................... 110

10.3 ASCII format of the Protocol ................................................................................. 116

10.3.1 Data Types .................................................................................................... 116

10.3.2 General Structure .......................................................................................... 116

10.3.3 Data fields ..................................................................................................... 117

10.4 Bit Mask SELECTED-FIELDS .............................................................................. 124

10.5 CRC Calculation ................................................................................................... 125

10.6 Error Codes .......................................................................................................... 126

10.6.1 Overview ....................................................................................................... 126

10.6.2 Error codes ................................................................................................... 126

10.6.3 LPR-B address .............................................................................................. 128

General

Copyright © Symeo 2012

Page 5 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

11 APPENDIX A: AGENCY CERTIFICATIONS ................................................ 129

United States (FCC) and Canada (Industry Canada) ...................................................... 129

United States (FCC)........................................................................................................ 129

Canada (Industry Canada) .............................................................................................. 131

General

Copyright © Symeo 2012

Page 6 of 132

Symeo LPR®-System

Version

Date

Description

3.17

2009-05-20

Initial release

3.18

2009-07-07

Added documents to one document

3.19

2010-02-01

Updated SYMEO Map and FusionEngine description

4.00

2010-06-30

Completely revised

4.01

2012-04-20

FCC Appendix added

This symbol appears before instructions that must be followed at all times.

Failure to comply with these instructions will result in personal injury.

This symbol appears before instructions that must be followed at all times.

Failure to comply with these instructions will result in damage to equipment.

This symbol appears before information of particular importance.

LPR®-2DB

Product Documentation

The documentation for the LPR Local Positioning Radar System is published by:

SYMEO GmbH

Prof.-Messerschmitt-Str. 3

85579 Neubiberg

www.symeo.com

If you have any questions or suggestions, please contact:

Email: info@symeo.com

phone: +49 89 660 7796 0

Copyright © Symeo GmbH 2009

All rights reserved

HISTORY

VERWENDETE SYMBOLE

The following symbols are used in the documentation:

All rights reserved, particularly those relating to the translation, reprinting, and reproduction

by photocopying or similar processes of all or part of the documentation.

All rights reserved, particularly for purposes of the award of patents or submission of utility

models.

Delivery options and technical changes reserved.

Published by SYMEO GmbH

General

Copyright © Symeo 2012

Page 7 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

General

Copyright © Symeo 2012

Page 8 of 132

Symeo LPR®-System

LPR®-2D systems are purely tracking and assistance systems. They

therefore do not satisfy special requirements for personal safety, e.g.

performance level c.

Follow the safety instructions in the operating instructions for the device

and the additional documentation!

All installation, repair and servicing work must be carried out by qualified

and trained technicians!

Repairs to the device must be carried out by authorized technicians.

Unauthorized opening and incorrect repairs could result in severe

danger to the user (danger of electric shock, radiated energy, fire

hazard).

Use the original packaging or other suitable packaging for returns and

whenever the system is to be transported. This ensures protection from

crushing, impacts, moisture and electrostatic discharge.

During setup and before operation, refer to the instructions for

environmental conditions included in the operating instructions for the

device.

Route the wires in such a way that they do not cause a hazard and are

not damaged. When connecting the wires, refer to the corresponding

instructions in the operating instructions for the device.

Do not drop the device and do not expose it to strong vibrations.

LPR®-2DB

Product Documentation

1 General

1.1 Safety Instructions

Keep these safety instructions and other documents together with the device.

1.2 Installation

1.3 Repairs

1.4 Transport and Storage

Copyright © Symeo 2012

Page 9 of 132

General

Symeo LPR®-System

A safety-inspected power cable that satisfies the regulations of the

country of use is required for the device. Devices with metal housings

must only be connected to a grounded, shock proof socket.

The device must not be operated unless the nominal voltage of the

device matches the local supply voltage. Check the supply voltage of

the device in stationary devices.

When connecting and disconnecting wires, refer to the instructions in

the operating instructions for the device.

Do not use any damaged wires (damaged insulation, exposed wires). A

faulty wire poses a risk of electric shock or fire hazard.

During installation, make sure that no objects or fluids get inside the

device (risk of electric shock, short circuit).

In emergencies (e. g. if there is damage to the housing, control

elements or the mains cable, if fluids or foreign bodies have infiltrated

the equipment), switch off the power supply to the device immediately

and notify your SYMEO Service.

Protect the contacts of all of the device's sockets and plugs from static

electricity. Do not touch the contacts. If it is ever necessary to touch the

contacts, take the following precautionary measures: Touch a grounded

object or carry a ground strap before touching the contacts. This will

divert static charges.

Proper operation (in accordance with IEC60950/EN60950) of the device

is only assured if the housing and integral covers for mounting slots are

fully installed (electric shock, cooling, fire protection, noise suppression).

If necessary, refer to the corresponding instructions in the operating

instructions for the device.

In the case of high outside temperatures and intense, direct solar

radiation or other radiant heat, it may be necessary to provide a sun or

heat shield.

Data links to peripheral devices must be provided with adequate

shielding.

For LAN cabling, the requirements in accordance with EN 50173 and

EN 50174-1/2 apply. Use of either a Category 5 shielded cable for

10/100 Ethernet or Category 5e shielded cable for gigabit Ethernet is a

minimum requirement. The specifications of standard ISO/IEC 11801

LPR®-2DB

Product Documentation

1.5 Power Supply

1.6 Setup and Operation

1.7 System Extensions and Accessories

General

Copyright © Symeo 2012

Page 10 of 132

Symeo LPR®-System

must be complied with.

The warranty shall be voided if you cause defects to the device by

installing or exchanging system extensions.

The Compact type LPR station must not be opened except for

installation. The Compact station contains no serviceable components.

When opening, ensure that no fluid gets into the housing. When sealing

the station, ensure that the seal is included in the cover and that the

Compact station is completely closed. Otherwise, moisture can

penetrate the station and damage it.

In order to install the Integral type LPR station, the hood must be

detached from the serviceable components. Refer also to the

instructions on installing the transponder.

Please take note of the safety and operating instructions in the

operating instructions for the system in which you want to install the

component.

LPR®-2DB

Product Documentation

1.8 Additional Instructions Regarding Compact Type and Integral Type Stations

Copyright © Symeo 2012

Page 11 of 132

General

Symeo LPR®-System

This symbol appears before information of particular importance.

This symbol appears before instructions that must be followed at all

times. Failure to comply with these instructions will result in damage to

equipment.

This symbol appears before instructions that must be followed at all

times. Failure to comply with these instructions will result in personal

injury.

This symbol appears if the following sub-chapter describes difference in

the operating mode. An overview about the operating modes is given in

chapter 3.2.

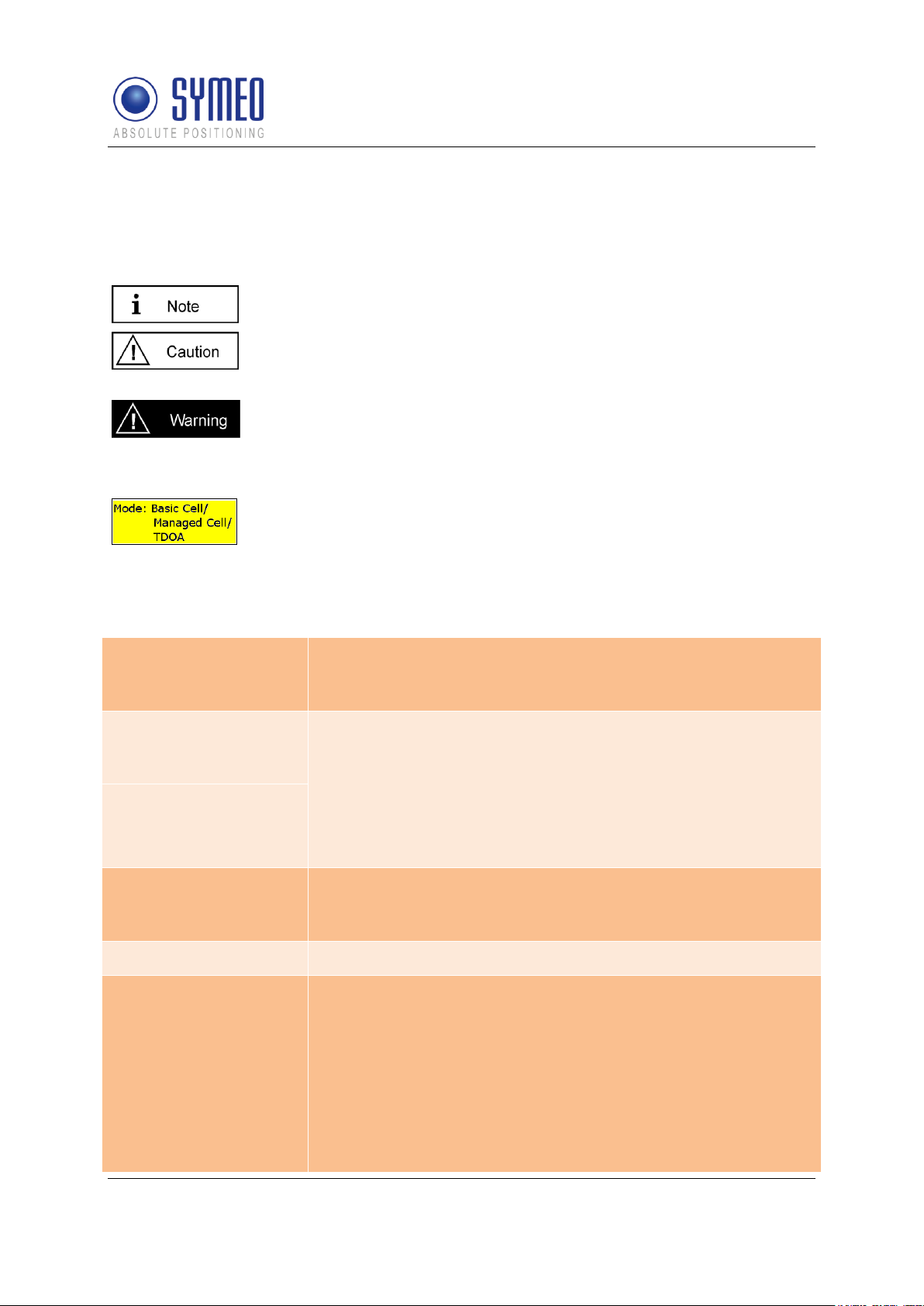

LPR-2DB Station

(Mobile unit / base

station):

- master_basestation_config.txt or Basestation_config.txt

(depending on the selected operating mode)

LPR-2DB Integral

Stations

(transponders):

- STATION010_CONFIG.TXT

- STATION011_CONFIG.TXT

- STATION012_CONFIG.TXT

- STATION013_CONFIG.TXT

- STATION014_CONFIG.TXT

- STATION015_CONFIG.TXT

Master LPR-2DB

Integral Station

(optional):

- station01M_config.txt (depending on the selected operating

mode)

Symeo MAP (optional)

- SYMEO Map XP Installer

FusionEngine:

- FusionEngine.exe

- const_pos.ini

- field.ini

- fusion.ini

- LPR_B.ini

- movingcell.ini

- multi_cell.ini (TDOA)

- HoverTrack.ini / VehicleTrack.ini or TDOA.ini (depending on

LPR®-2DB

Product Documentation

2 Introduction

2.1 Details

2.2 Overview of Files

Copyright © Symeo 2012

Page 12 of 132

Introduction

Symeo LPR®-System

the selected model, application and operation mode)

- symeo_map.ini

- symeo_2D.ini

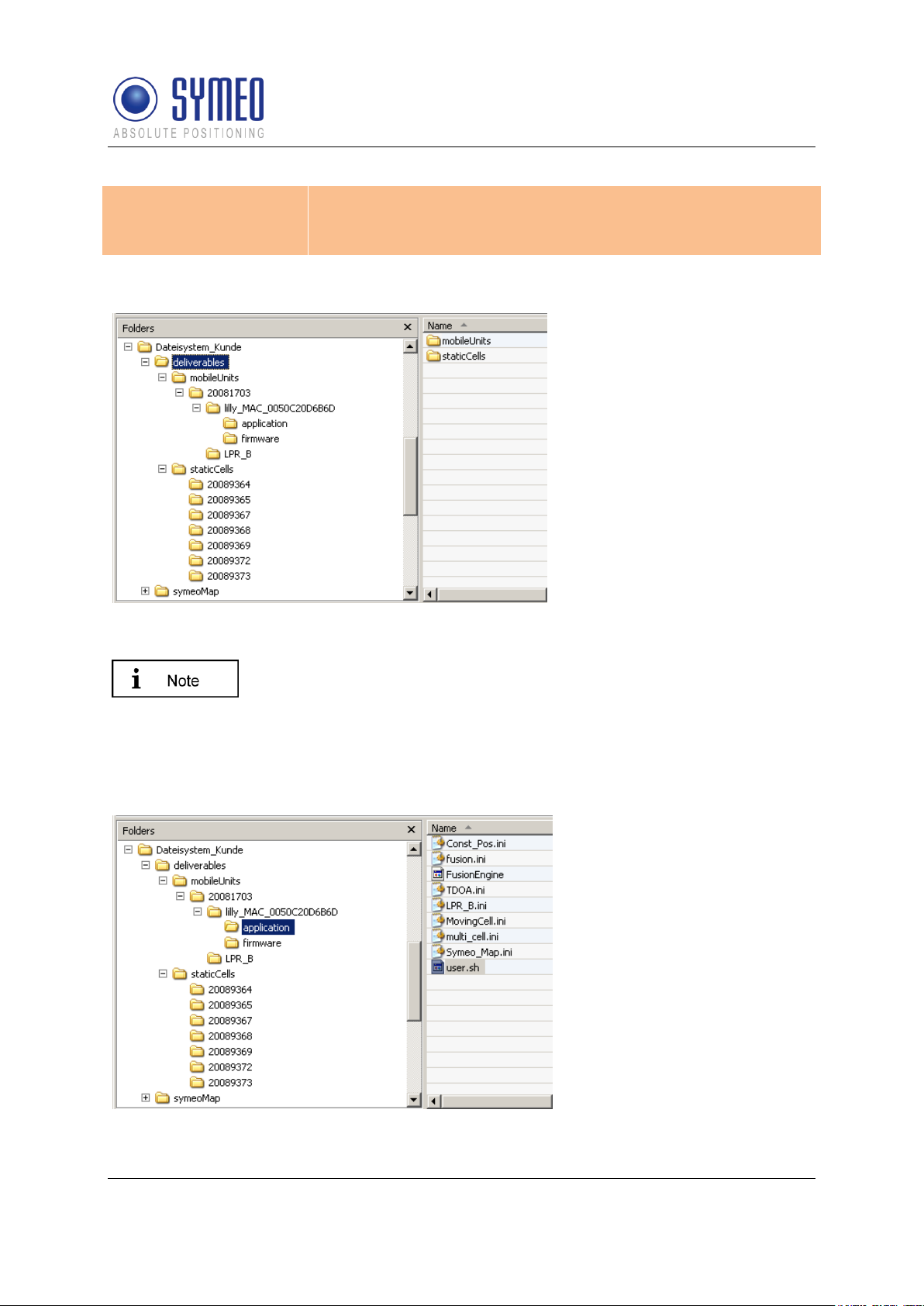

Figure 1- folder structure

The folder “mobileUnits”

contains all files for the

vehicles. The folder

“staticCells” contains all files

for the LPR-2DB Integral

Station including the master

LPR-2DB Integral Station. The

folder name for all LPR stations

is named with the serial

number.

To allocate the stations for the customer, it makes sense to create a

text-file that describes the function of that LPR station, i.e.

“forklift_123_customer.txt”.

If it is later necessary to replace a LPR unit (e.g. due to a defect) you

can find easily the necessary configuration files for the appropriate

station.

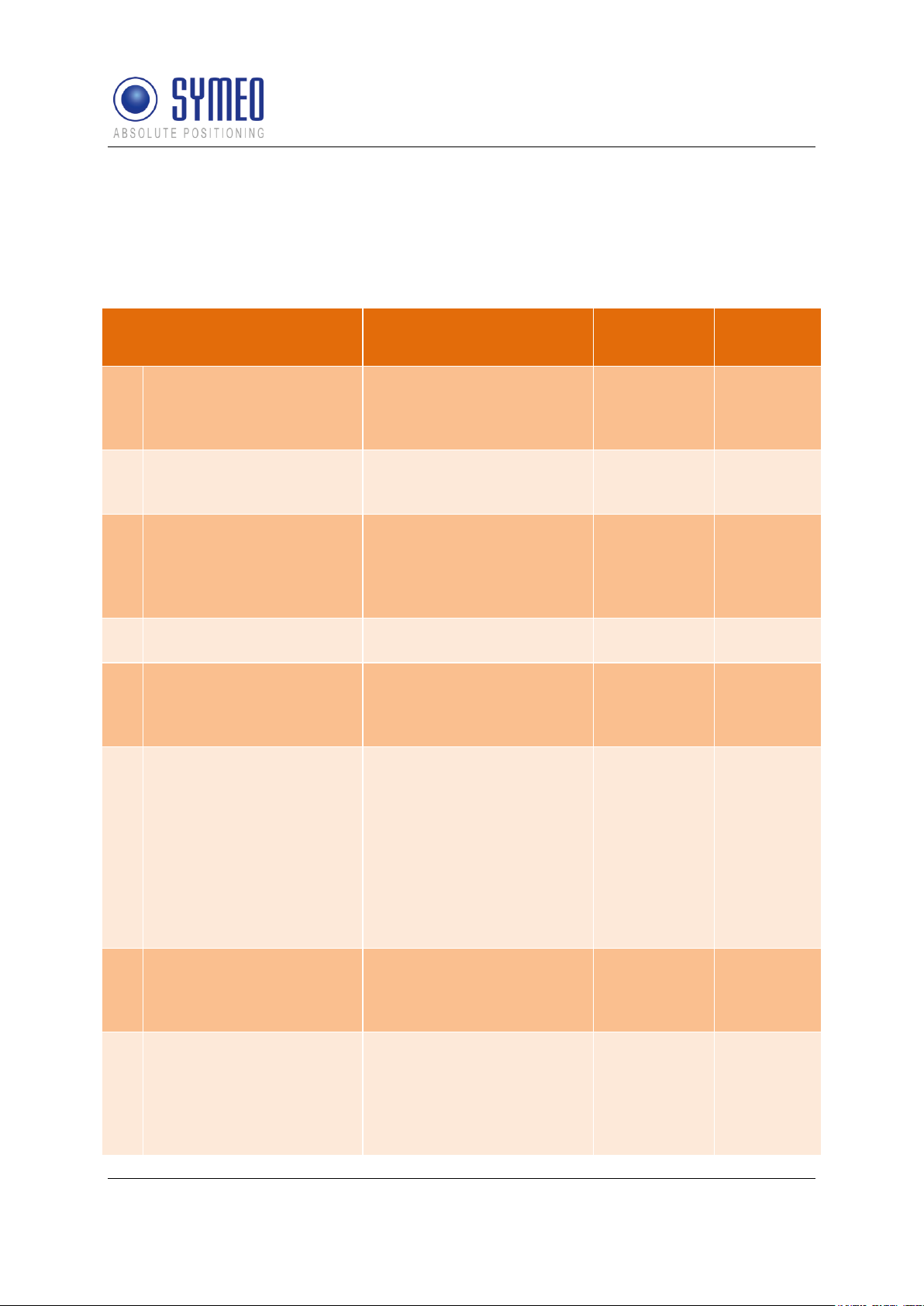

Folder for the files of the

FusionEngine

LPR®-2DB

Product Documentation

All files are delivered in the structure shown in Figure 1 (“deliverables” and “symeoMap”).

Copyright © Symeo 2012

Page 13 of 132

Introduction

Symeo LPR®-System

Folder for the files of the

firmware for the mobile unit

Folder for the configuration

files of the DSP for the mobile

unit

Folder for the configuration

files of the DSP for the

transponder unit

LPR®-2DB

Product Documentation

Copyright © Symeo 2012

Page 14 of 132

Introduction

Symeo LPR®-System

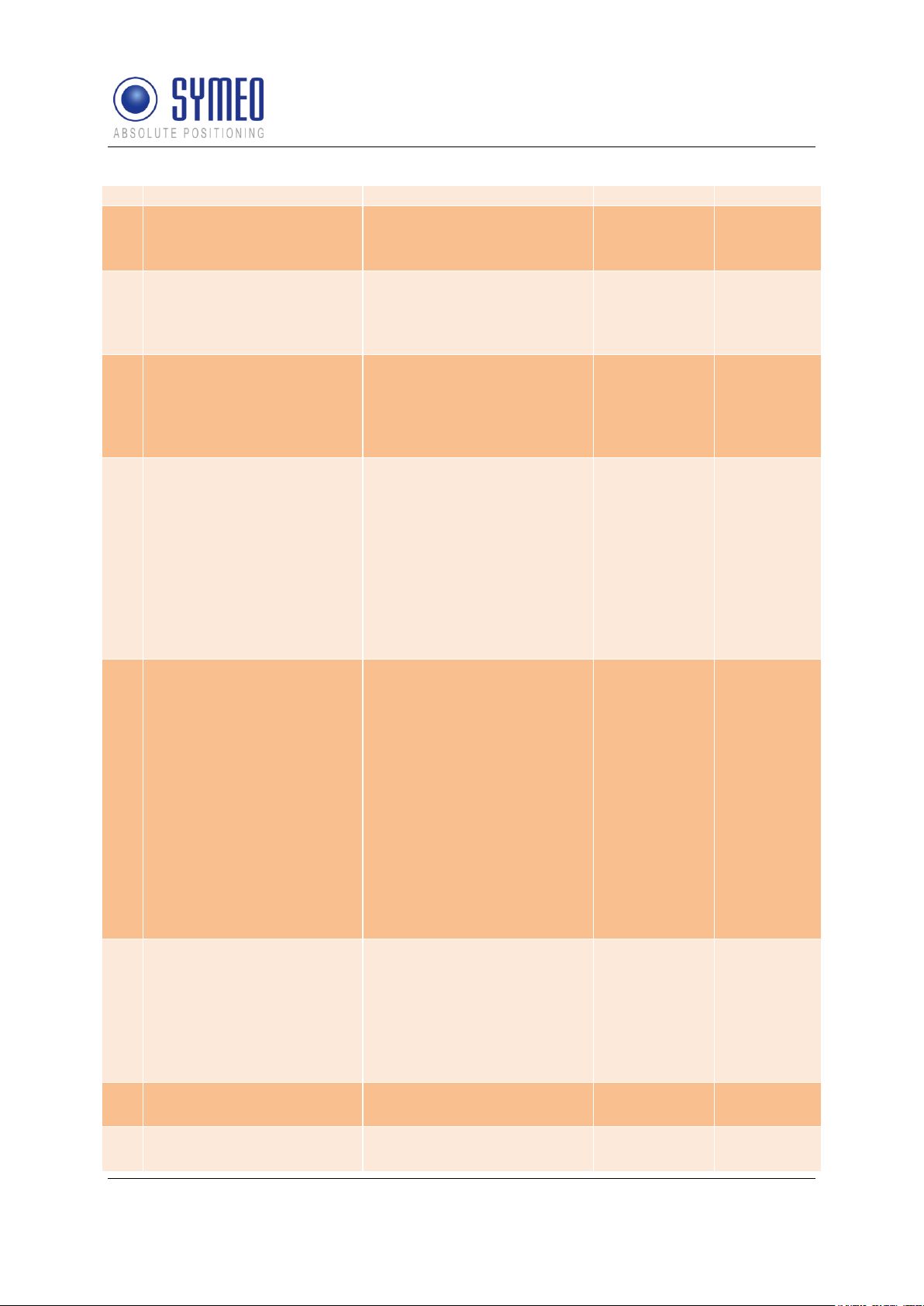

ToDo

Description

Responsible

Relevant

chapter

1

Definition of measurement

area/cell

Analyzing of layout,

pictures, definition of

mounting positions

Customer

provides

information to

Symeo

--2

Definition of local

coordinate system, point

of origin

Local Coordinates

available? Coordinates of

light towers available?

Customer

---

3

Definition of operating

mode

3 operating modes are

available. Operating mode

depends on the number of

vehicles and the number of

cells

Symeo

Chapter 3.2

4

Definition of vehicle model

HoverTrack-model or

VehicleTrack-model

Symeo

Chapter 3.3

5

Definition of antenna

positions and position of

mobile unit on the vehicle

for mounting

Defining mounting position

of 1, 2, 3 or 4 antennas on

the vehicle

Customer/

Symeo

Chapter 5.3

6

Definition of the height of

the antenna above ground

level

The height of the top of the

antennas above ground

has to be calculated to set

the appropriate height for

the mounting of the

transponders, height of

transponders ideally

0.5meters over antennas

level, up to 2.5meters is

possible

Customer

Chapter 6.3

7

Definition of protocol for

interface

Structure of the protocol

can be configured.

Customer/

Symeo (if

information is

provided)

Chapter 0

8

Mounting of the LPR-2DB

Integral Station on the LTs

Mounting of the LPR-2DB

Integral Station (labeled

XX0, XX1, XX2, XX3, XX4,

XX5 and Master XXM)

according to the files VisioLPR_CellPlanning.pdf and

Customer

Chapter 5.2

LPR®-2DB

Product Documentation

2.3 Project Planning

The planning from identifying the position for the transponders to the commissioning with

Symeo MAP is separate into intermediate steps. In the following all possible steps are listed

with refer to the relevant chapter in this document.

Copyright © Symeo 2012

Page 15 of 132

Introduction

Symeo LPR®-System

CellPlanning.xlsx

9

Mounting of the antennas

Mounting on defined

positions on vehicle with

installation brackets

Customer

Chapter 5.3

10

Mounting of the mobile

station on the vehicle

Mounting of the mobile

station, connection to the 1,

2, 3 or 4 antennas, power

10-36VDC and TCP/IP

Customer

Chapter 5.1

11

Surveying of LPR-2DB

Integral Station

Surveying of the mounted

LPR-2DB Integral Stations

needs to be done to local

coordinates with best

possible accuracy (+- 2cm)

Customer

Chapter 6.1

12

Surveying of vehicle

Surveying of the antenna

positions on to the vehicle.

Depending on the steering

of the vehicle (front and/or

back) the definition of point

of origin on vehicle has to

be set. Offset from point of

origin to container center

has to be determined.

Customer

Chapter

6.2/ chapter

6.3

13

Implementation of

Surveying coordinates in

configuration files

The surveying coordinates

have to be provided in a

data format provided from

Symeo. Transponder

coordinates have to be

implemented into

configuration files for the

master transponder or the

mobile unit. Vehicle

coordinates have to be

implemented into the

configuration files of the

mobile station on the

vehicle.

Customer

Chapter

6.1.4 and

6.3.1

Chapter

7.2.2 or

7.4.2

14

Upload of configuration

files

Configuration files to be

uploaded to the MasterTransponder (operating

mode 2b and 3b) or mobile

unit (operating mode 1, 2a,

2b) and mobile station on

vehicle

Customer/

Symeo

Chapter 7.3

15

Modifying of ini-files for

software FusionEngine

Modification of ini-files

Customer

Chapter 7.4

16

Upload of files for software

fusion engine

Upload of ini-files via

WinSCP

Customer

Chapter 7.5

LPR®-2DB

Product Documentation

Copyright © Symeo 2012

Page 16 of 132

Introduction

Symeo LPR®-System

17

Testing of correct

positions

Testing cell with analyzing

Software Symeo MAP

Customer/

Symeo

Chapter 0

LPR®-2DB

Product Documentation

Copyright © Symeo 2012

Page 17 of 132

Introduction

Symeo LPR®-System

Frequency range

5.725-5.875 GHz

5.725-5.875 GHz

Transmitting power*1

Max. 0.010 W / 10 dBm output on the antenna port

Output power is adjustable

For overall output power antenna gain and cable attenuation

must be added

Range*2

Max. 300 m

Measurement accuracy*2

up to ± 10 cm

Measurement frequency

Max. 20 Hz

Power supply

10-36 V DC

Ambient temperature *2

-40°C bis +70°C

LPR®-2DB

Product Documentation

3 System Description

SYMEO Industrial Local Positioning Radar (LPR) is a system for contactless, real-time

determination of distances and positions.

LPR B 2D is a distance measurement system which is particularly well suited for use in very

harsh, industrial environments, in which other systems such as mechanical rotary encoders

or lasers cannot function for long periods.

The system composes of mobile units and fixed, wall-mounted units at known positions. The

mobile units compute its position using the delay time of the radio-signals between wall

mounted units and the mobile unit.

LPR-2DB has an in-build communication channel to handle all background communication

necessary for operation of the positioning system. LPR-2DB units use the same frequency

band and the same hardware for communicating as for measuring distance. This means that

no external WLAN or cable networks are needed for transmitting measurement values and

other reference data.

The system is organized in a cellular fashion. 4 to 6 wall-mounted units are arranged to form

a group with a unique group-ID and an individual measurement ID ranging from 0-5 for each

wall-mounted unit. For the communication between the mobile unit and the 6 transponders 6

different measurement channels separated in frequency (FDMA) are used, allowing instant

position computation.

For arrangements with more than 6 transponders neighboring cells with different group IDs

can be set up. To separate the communication of neighboring cells different communication

frequency channels can be assigned for different cells. For some system topologies an

additional cell-master is required to handle measurement timing and communication.

3.1 Technical Data

*1

Transmitting power can be adjusted to assure that emission limits at the antenna are within

legal limits, e.g. 25 mW EIRP in the EU and 10 mW EIRP in the US

*2

Depending on the antenna type, mounting position and environment

System Description

Copyright © Symeo 2012

Page 18 of 132

Symeo LPR®-System

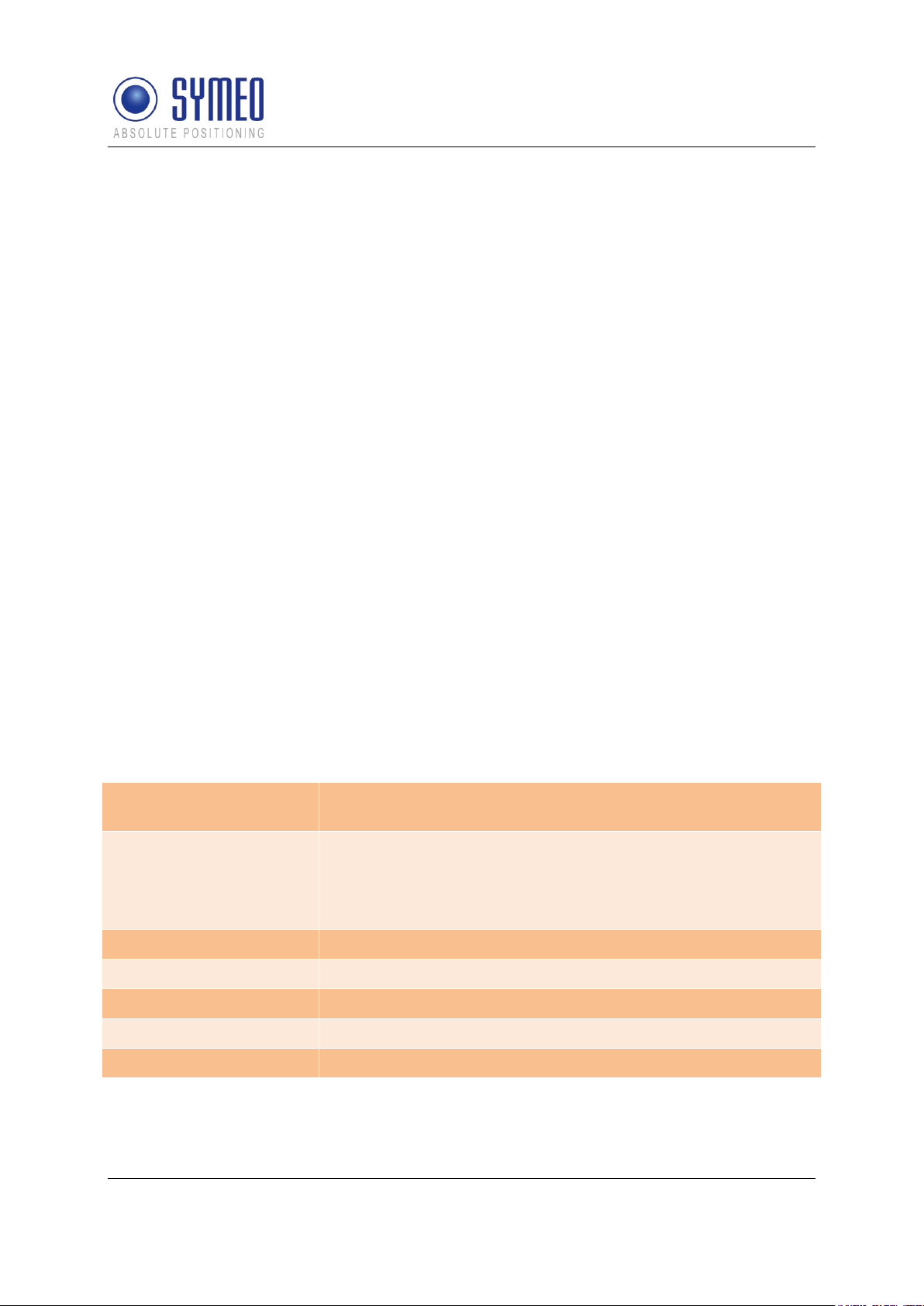

Operating Mode

Properties

Mode 1: Basic Cell

6 fixed wall-mounted units [LPR-2DB Integral Station], 1 mobile

unit [LPR-2DB Station]; measurement principle: RTOF (round

trip of flight)

Mode 2a: Managed Cell

6 fixed wall-mounted units [LPR-2DB Integral Station], 1Master,

up to 5 mobile units [LPR-2DB Station] ; measurement principle:

RTOF (round trip of flight); cell coordinates are stored on the

mobile unit(s)

Mode 2b: Managed Cell

6 fixed wall-mounted units [LPR-2DB Integral Station], 1 Master,

up to 10 mobile units [LPR-2DB Station] ; measurement

principle: RTOF (round trip of flight); cell coordinates are stored

at the master

Mode 3a: TDOA

6 fixed wall mounted units [LPR-2DB Integral Station], 1 Master,

no limitation of mobile units [LPR-2DB Station] ; measurement

principle: TDOA (time difference of arrival); cell coordinates are

stored on the mobile unit(s)

Mode 3b. TDOA

6 fixed wall mounted units [LPR-2DB Integral Station], 1 Master,

no limitation of mobile units [LPR-2DB Station] ; measurement

principle: TDOA (time difference of arrival); cell coordinates are

stored at the master

The operating mode is normally set by Symeo after consulting the

customer.

LPR®-2DB

Product Documentation

*3

Temperature inside the housing can range from -40°C to 85°C.

3.2 Operating Mode

There are different system topologies to determine a 2D position with a Symeo LPR® system.

Which operating is best suited depends on the application and the environment. It depends

on the number of mobile units you want to track and on the number of cells which are

necessary to cover the environment.

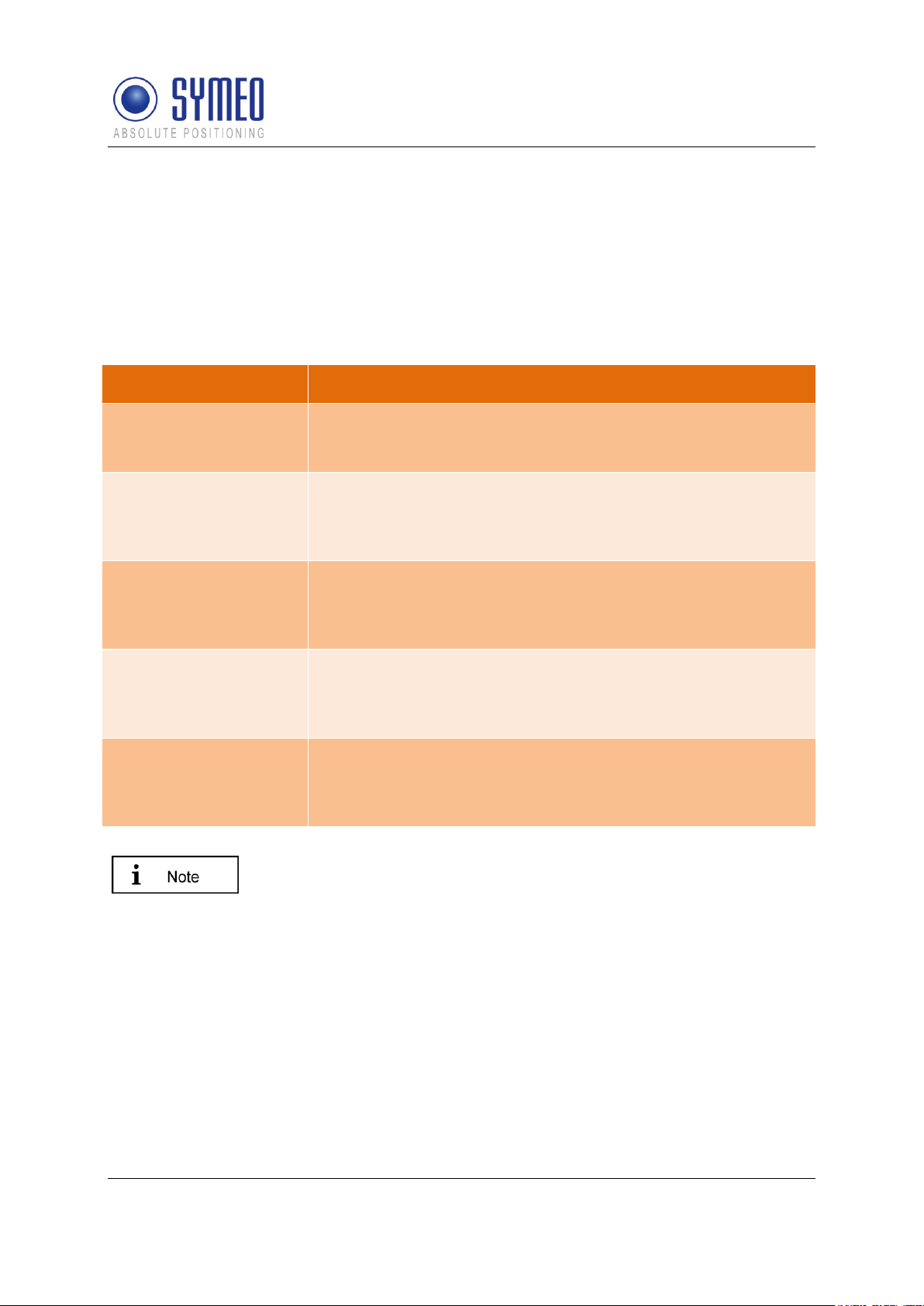

3.2.1 Operation Mode 1: Basic Cell

4-6 fixed mounted units (i.e. at a wall or on light poles) at known positions as basic cell and

one single mobile unit form the setup for mode 1. The fixed mounted units are configured as

reply units or “slave transponders”. Each fixed mounted unit has the same group ID and a

different measurement ID ranging from 0...5. Additionally, the units within the same group

must be set to the same communication channel. The positions of the fixed mounted units

are known to the mobile unit. The measurement of mode 1 is based on the measurement

principle RTOF (Round Trip Of Flight). It is organized as follows:

The mobile unit acts as “master base-station” and sends a measurement command to the

fixed mounted units. The fixed mounted units synchronize to this signal and transmit a return

System Description

Copyright © Symeo 2012

Page 19 of 132

Symeo LPR®-System

2

2

2

2

2

2

1

3

4

4

4

4 4

4

3 3

3

3

3

LPR®-2DB

Product Documentation

signal with precisely known delay and an individual frequency offset corresponding to the

fixed mounted unit measurement ID. The mobile unit computes the round-trip time-of-flight

and therefore the 1D distance to each transponder. Finally, the mobile unit calculates of all

single 1D distances a 2D position.

Figure 2 - System setup for mode 1

1: Mobile unit

2: Wall-mounted unit

3: Communication channel (commands)

4: Broadband measurement signals

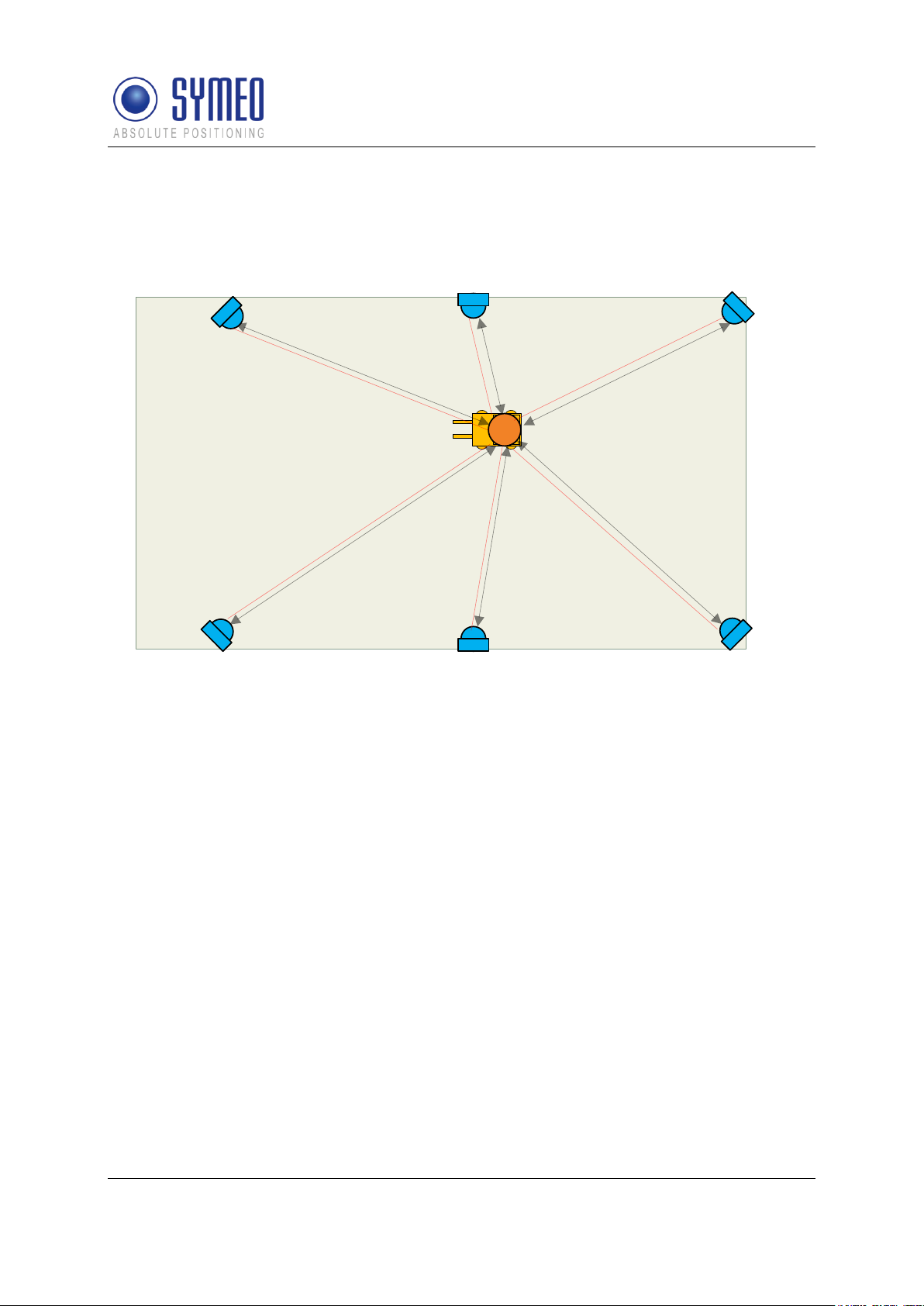

3.2.2 Operation Mode 2: Managed Cell

Mode 2 is used when several mobile units are present at the same time within the cell. In this

case the measurement intervals between the mobile units are synchronized. This is done by

using the setup of mode 1 and an additional master transponder for coordination. The master

transponder assigns the measurement slots for different mobile units. The mobile unit no

longer initializes the measurement and simply acts as base-station. The measurement of

mode 2 is based on the measurement principle RTOF (Round Trip Of Flight). The detailed

measurement procedure is as follows:

The master transponder repeatedly broadcasts his group-ID. Base-stations in range reply to

this broadcast with their ID. The master transponder keeps a list of active base-stations in

range, assigns measurement slots to the stations and broadcasts them to the individual

stations in range. The base-station then transmits the broadband measurement signal and

computes its position as described in mode 1.

Measurement rate for the stations present can be set to equal distribution for all mobile units

or to a preferred channel with maximum measurement rate for one base-station and slower

measurement rate for the remaining stations.

Copyright © Symeo 2012

Page 20 of 132

System Description

Symeo LPR®-System

3

2

2

2

2

2

2

1

4

5

5 5

5 5

5

4

4

LPR®-2DB

Product Documentation

If desired the master transponder can store the coordinates of the cell (mode 2b). The

master transponder then repeatedly broadcasts his coordinates and all base-stations in

range receive the data. Alternatively the coordinates can be kept on the mobile unit

permanently as in mode 1 (mode 2a).

Finally, depending on the master-transponder type, the position data of the mobile units can

also be transmitted to the master transponder and can be retrieved by the user.

Figure 3 - System setup for mode 2

1: Mobile unit

2: fixed mounted units

3: Master unit

4: Communication channel (commands)

5: Broadband measurement signals

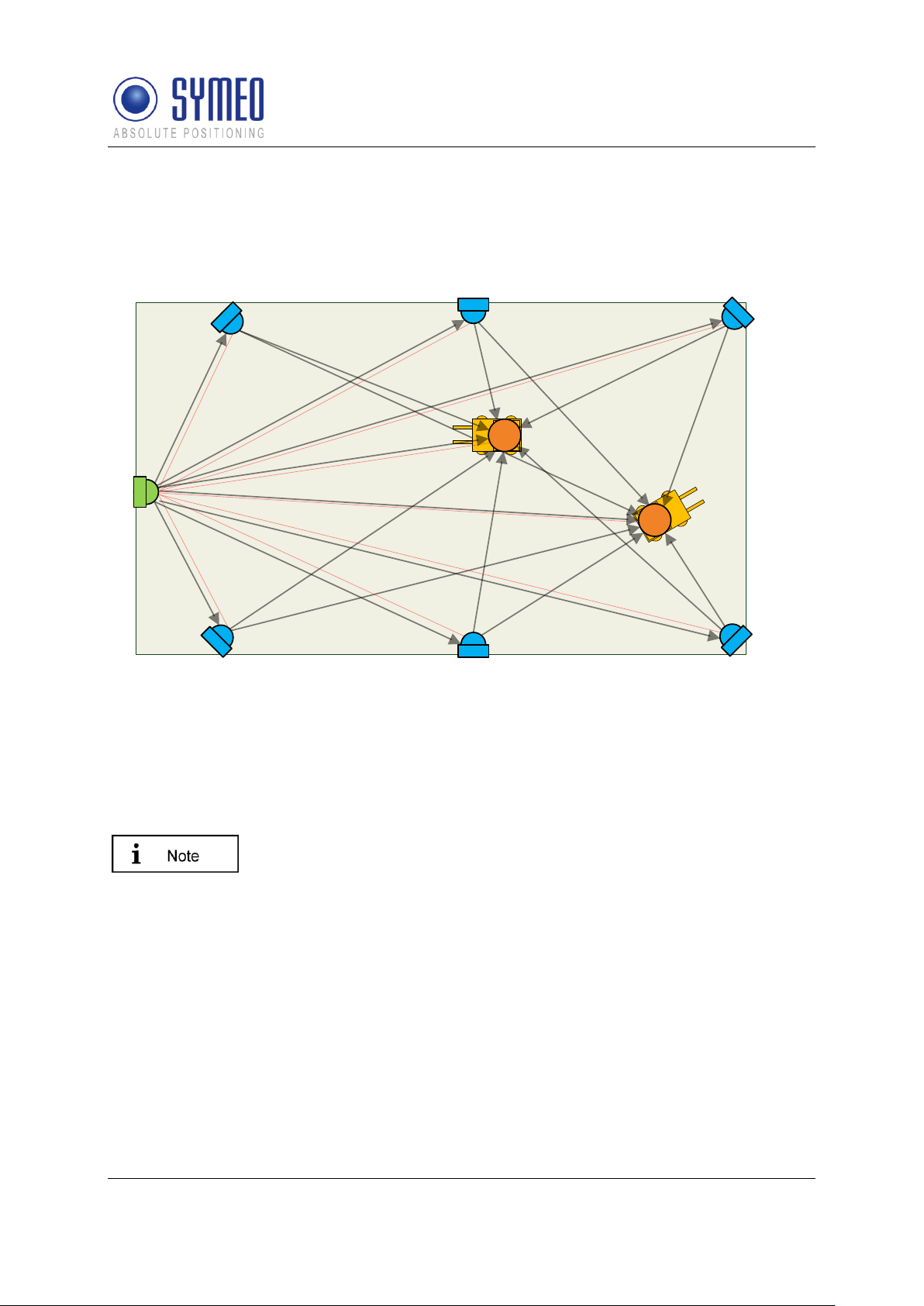

3.2.3 Operation Mode 3: TDOA

Sometimes many mobile units are present in a cell, or measurement of the position of mobile

units at exactly the same time is desired. Using mode 3, only the fixed mounted units

transmit broadband measurement signals. The mobile unit receives these signals and

computes its position from the time-differences of the signals.

Mode 3 has the same basic hardware as mode 2, but the organization of the measurement is

completely different:

The master transponder sends a broadband synchronization signal preceded by the group ID

of the cell. The slave transponders precisely synchronize to this signal and in turn each

transponder transmits the broadband measurement signal. All base-stations within the cell

receive the signal and compute the time-difference between the received signals. The timedifference is used to obtain the position.

System Description

Copyright © Symeo 2012

Page 21 of 132

Symeo LPR®-System

3

2

2

2

2

2

2

1

1

4

5

5 5

5 5

5

4

4

5

5

5

Additionally to the described solution of a fixed master, there is the

possibility to use a moving master. In this case each fixed mounted unit

can be the master. The sequence is set by the user.

LPR®-2DB

Product Documentation

If desired the master transponder can store the coordinates of the cell (mode 3b). The

master transponder then repeatedly broadcasts his coordinates and all base-stations in

range receive the data. Alternatively the coordinates can be kept on the mobile unit

permanently as in mode 1 (mode 3a).

Figure 4 - System setup for mode 3

1: Mobile units

2: fixed mounted units

3: Master unit

4: Communication channel (commands)

5: Broadband measurement signals

3.3 Vehicle Model

To determine a 2D-position with an LPR-2DB system a Kalmar filter is used. Therefore a

system model is necessary which represents the system. Depending on the vehicle type in

your application different models can be used:

Hover-Track-Model

Vehicle-Track-Model

Depending on the chosen model for the Kalman filter different numbers of states are

estimated (position, velocity, acceleration, angle, etc).

Copyright © Symeo 2012

Page 22 of 132

System Description

Symeo LPR®-System

The model is set by Symeo by delivery.

Reference system crane

y

x

(0,0)

center of antenna

reference system forklift

y

x

center of antenna

center of antenna

(0,0)

rear axle front axle

reference system automobile

y

x

center of antenna

center of antenna

(0,0)

front axle

rear axle

LPR®-2DB

Product Documentation

3.3.1 Hover-Track

The HoverTrack model is used for vehicles that can move in x- and y-direction but cannot

turn over its center. A typical example is the trolley of a crane. The name based on a

hovercraft which can move forward and backward as well as sideward.

To make a 2D-positioning the mobile unit needs at least one antenna. The usage of a

second, third or fourth antenna results in more robust and more reliable position.

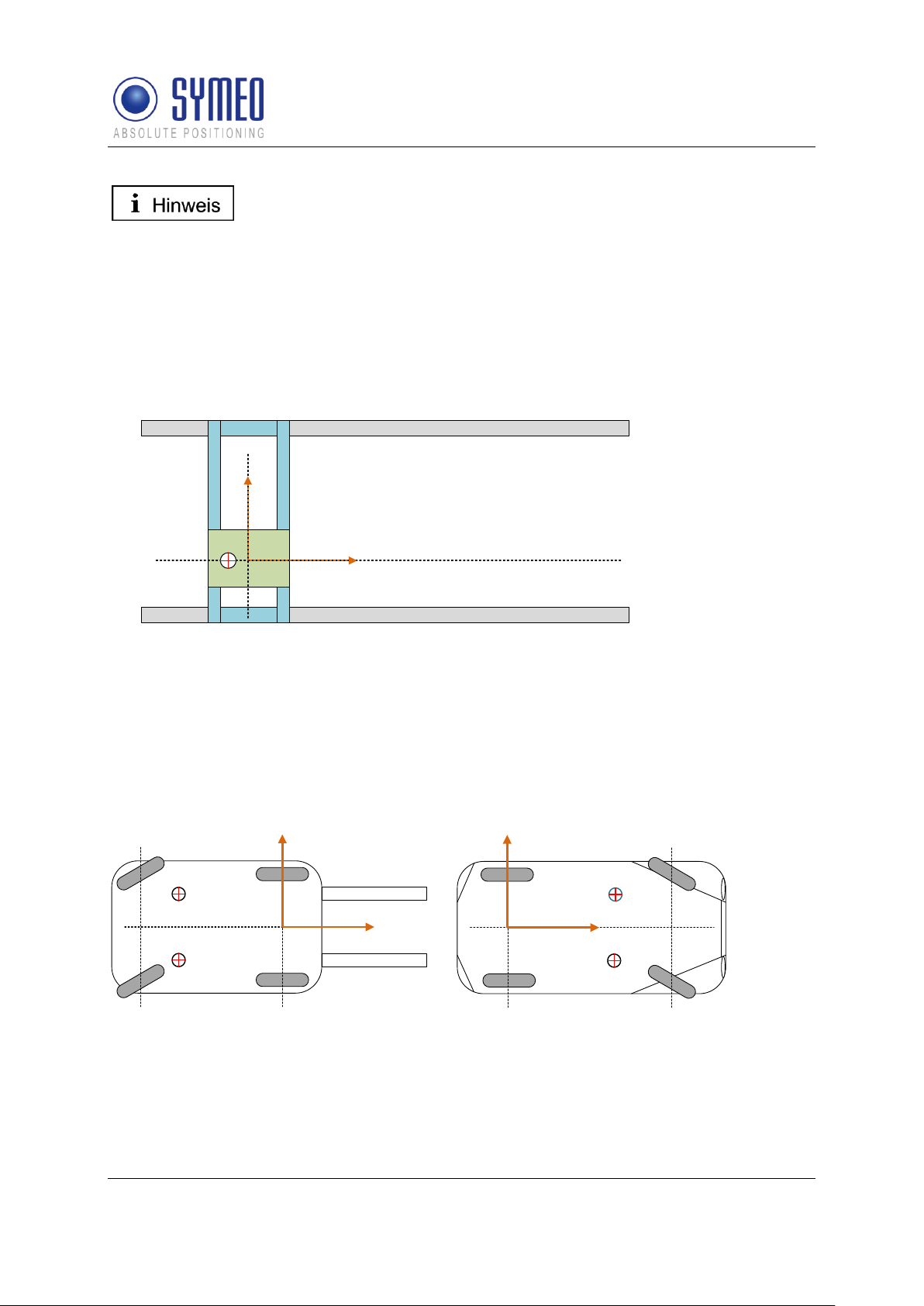

Figure 5 – HoverCraft model for a trolley

3.3.2 Vehicle-Track

If the object can also turn around its center the vehicle-track model is used. Examples for the

vehicle model are each kind of steerable vehicles (fork lift, van carrier, automobile, etc.). It is

possible to determine besides the 2D position also the orientation of the vehicle. For this it is

at least a second antenna necessary.

Figure 6 – Vehicle Model for a forklift and a trolley

3.4 System Design

Each LPR unit (base station, integral station) contains a DSP. For each LPR unit a

configuration file is provided by SYMEO.

Copyright © Symeo 2012

Page 23 of 132

System Description

Symeo LPR®-System

LPR-2DB Station (Mobile

unit):

basestation_config.txt

LPR-2DB Integral Station

(Fixed-mounted unit /

transponder):

stationXX0_config.txt

stationXX1_config.txt

stationXX2_config.txt

stationXX3_config.txt

stationXX4_config.txt

stationXX5_config.txt (XX: Cell-ID)

Master LPR-2DB Integral

Station (Fixed-mounted

master unit /master

transponder):

stationxxM_config.txt (XX: Cell-ID)

DSP

LPR-2DB

Integral Station/

Transponder

DSP

Master LPR2DB Integral

Station/ Master

Mobile unit/ base station

ARM9

DSP

RS232

User

RS232 Service

TCP/IP

User & Service

RS232

User & Service

access via radio

channel (FSK channel)

access via

TCP/IP or

serial interface

access via radio

channel (FSK channel)

LPR®-2DB

Product Documentation

The configuration files are:

The settings for the files are described in chapter 7.2.

The access to the LPR-2DB Station can either be done via TCP/IP or via RS232 interface.

The LPR-2DB Integral Station and the master LPR-2DB Integral Station can only be

accessed via the frequency channel of the mobile station.

Figure 7 – LPR units including DSP: Access to the DSP via TCP/IP, RS232 or frequency

channel

In chapter 7.3 all different connections to the LPR stations are described. To configure the

connection via TCP/IP web interface exists (chapter 0).

3.4.1 2D Positioning

Each mobile unit calculates the distance of its antennas to each LPR-2DB Integral Station/

transponder. A positioning does not happen in this moment, only the calculation of 6 single

1D distance measurements.

Copyright © Symeo 2012

Page 24 of 132

System Description

Symeo LPR®-System

DSP

ARM9 (SW

FusionEngine)

PC (SW

FusionEngine)

RS232

RS

232

(optional: Netcat)

PC (SW

Symeo Map)

PC (SW

Symeo Map)

Mobile Einheit

TCP/IP

RS

232

TCP/IP

In mode 1 (Basic Cell) and in mode 2a (Managed Cell) the cell

coordinates of the transponders are stored in the Fusion Engine. In

mode 2b (Managed Cell) and mode 3 (TDOA) the coordinates of the

transponders are stored in the cell master.

LPR®-2DB

Product Documentation

These 1D distances are forwarded to the software FusionEngine. The FusionEngine can

either be on the ARM9 board of the mobile unit or on a separate PC of the customer. In the

software FusionEngine all 1D distance measurement are merged to a 2D positioning.

Figure 8 – cycle of a 2D positioning measurement and possible interfaces

Furthermore in the files for the FusionEngine are set the parameters of the model (see

chapter 3.3) as well as the settings for the antennas (coordinates, calibration).

The position calculated in the FusionEngine can be graphical shown with the software

Symeo MAP (see chapter 0).

Copyright © Symeo 2012

Page 25 of 132

System Description

Symeo LPR®-System

All corresponding installation, repair and servicing work must be carried

out by qualified and trained technicians.

Technical Data

Power draw

RS232 port, 4 W

TCP/IP port, 6 W

Voltage range

10-36VDC

Dimensions (LxWxH)

260 x 160 x 91 mm

Type of protection

IP 65 with appropriate cable connectors

Connections

Power-Supply and Communication: Plugged connection

Antenna: Screwed cable gland

LPR®-2DB

Product Documentation

4 Hardware

4.1 System components – Overview

The system can exist of multiple cells and mobile units for the vehicles. Each cell exists of 4

to 6 LPR transponder stations (type integral). Depending on the chosen operating mode a

master is added to each cell. The 4 to 6 LPR-2DB Integral Stations/ Transponders as well as

the master LPR-2DB Integral Station/ maser transponder is mounted at a fixed place, e.g. a

wall or light poles. On the mobile units LPR stations (type: compact, BSB000313,

BSB000319, BSB000603, BSB000604, BSB000605, BSB000606) are installed.

Additional hardware for the mobile units are connector boxes, connector cables and

antennas.

For the determination of the position of the LPR-2DB Integral Station at the light poles or at

the wall the system range of max. 300 meters and the position of the antennas on the

vehicles are important.

4.2 LPR-2DB Station (mobile station)

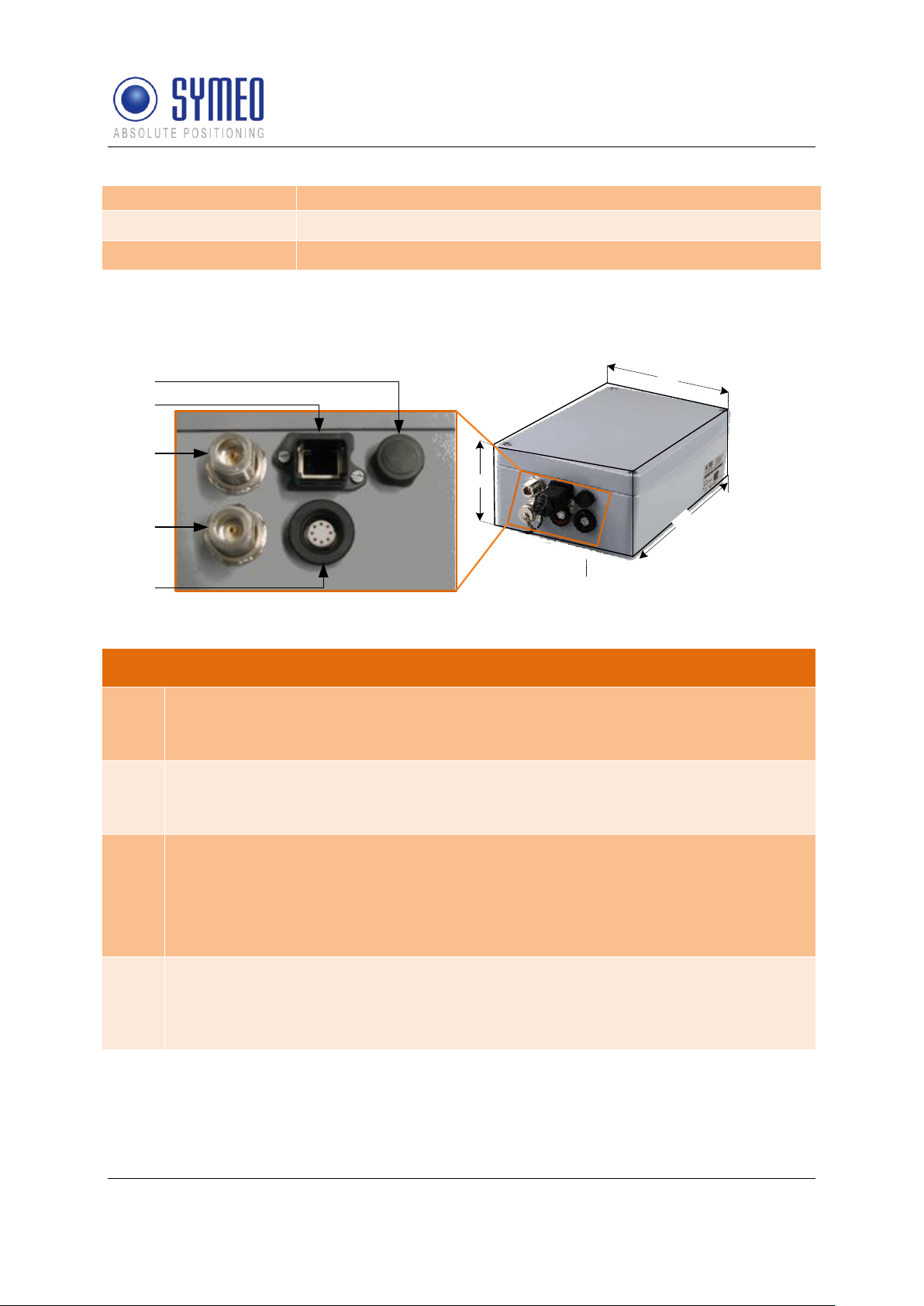

4.2.1 Overview compact station

Following hardware exists for an LPR station on the mobile unit:

BSB000313 (single receiver, TCP/IP interface, 2 antenna ports)

BSB000319 (single receiver, RS232 interface, 2 antenna ports)

BSB000603 (double receiver, TCP/IP interface, 4 antenna ports)

BSB000604 (double receiver, RS232 interface, 4 antenna ports)

BSB000605 (double receiver, TCP/IP interface, 2 antenna ports)

BSB000606 (double receiver, RS232 interface, 2 antenna ports)

4.2.2 Technical data compact station

Hardware

Copyright © Symeo 2012

Page 26 of 132

Symeo LPR®-System

Ethernet: Plugged connection

Antennas

Connection of up to 4 independent antennas

Compliance

CE mark

1

91

260

160

2

3

4

5

Description of Interfaces

1

Pressure equalization membrane.

The membrane prevents forming of condensation water inside the Compact Station.

The pressure equalization membrane must not be changed or covered!

2

Network (optional).

The standard industrial Ethernet port of the station is designed as a Harting type

push pull connector.

3, 4

Antenna connections.

The antennas are connected to the Compact Station via a specially converted low-

loss HF cable with N-plug.

3: Antenna port no. 1,

4: Antenna port no. 2.

5

Power supply with integrated communication ports.

Power is supplied via a Lumberg Type 0233 08 push pull connector. There is no

power switch because of the intended area of application. A 3 Ampere (slow blow)

fuse is mounted inside the Compact Station.

LPR®-2DB

Product Documentation

4.2.3 Station BSB000313, BSB000319

Figure 9- interfaces of LPR station on vehicle as a single receiver

Copyright © Symeo 2012

Page 27 of 132

Hardware

Symeo LPR®-System

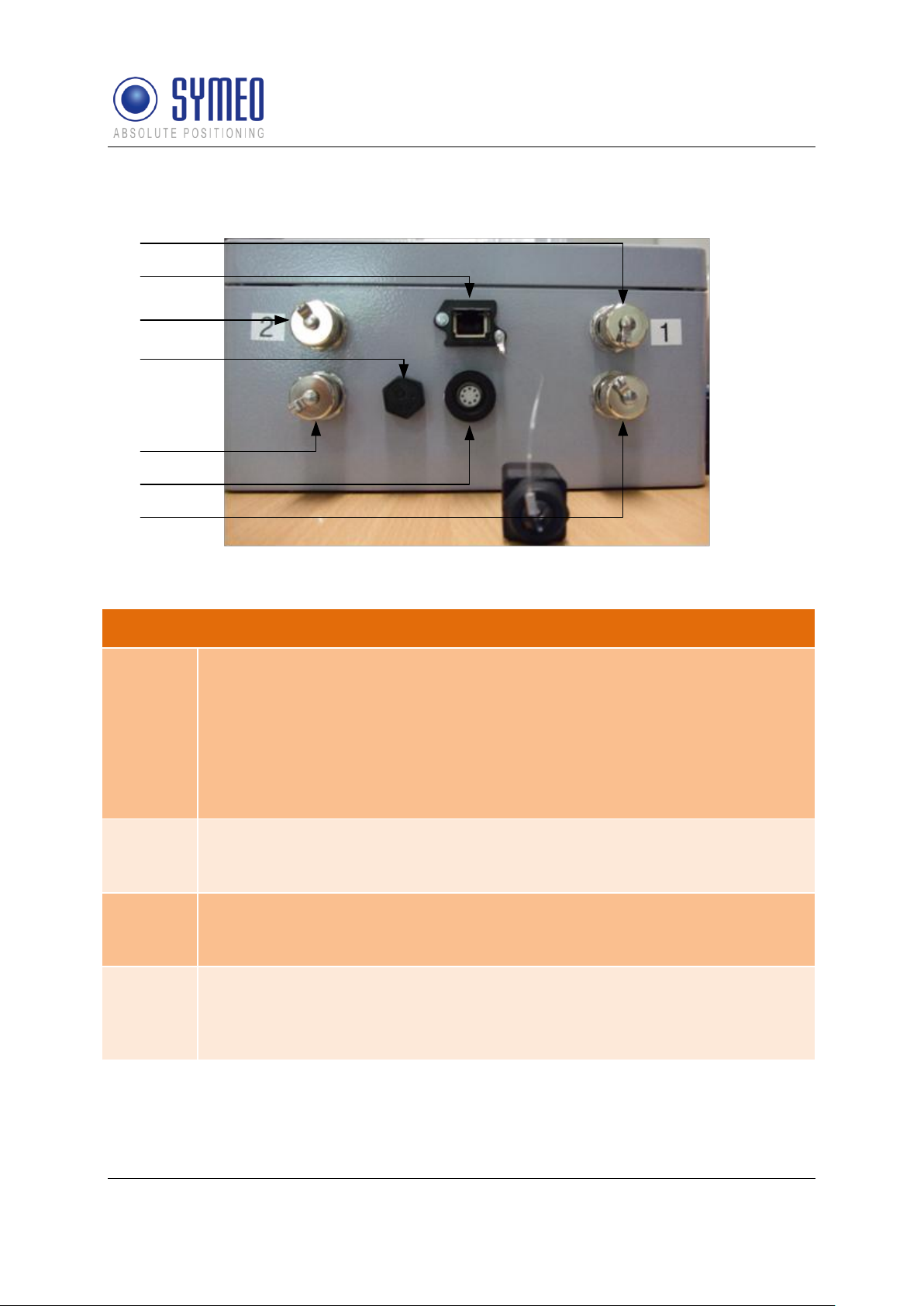

1

2

3

4

5

6

7

Technical Data and Description of Interfaces

1, 3, 5, 7

Antenna connections.

The antennas are connected to the Compact Station via a specially converted

low-loss HF cable with N-plug.

1: Antenna port no. 1,

3: Antenna port no. 2,

5: Antenna port no. 4,

7: Antenna port no. 3,

2

Network (optional).

The standard industrial Ethernet port of the station is designed as a Harting

type push pull connector.

4

Pressure equalization membrane.

The membrane prevents forming of condensation water inside the Compact

Station. The pressure equalization membrane must not be changed or covered!

6

Power supply with integrated communication ports.

Power is supplied via a Lumberg Type 0233 08 push pull connector. There is

no power switch because of the intended area of application. A 3 Ampere (slow

blow) fuse is mounted inside the Compact Station.

LPR®-2DB

Product Documentation

4.2.4 Station BSB000603, BSB000604, BSB000605, BSB000606

Figure 10 - interfaces of LPR station on a vehicle as double receiver

Copyright © Symeo 2012

Page 28 of 132

Hardware

Symeo LPR®-System

For configuration of the connector with cables, you have to identify the

matching pin assignment on the solder side.

The connectors have an anti twist device.

Option 1: It is possible to order cables (length: 5 m) by Symeo with

integrated Lumberg connector and cut cable head (see chapter 4.3).

Option 2: It is possible to order a connector box to wire all cables (see

chapter 4.3.2).

When plugging the push pull connectors into their sockets check that

the plug doesn’t slip out of the socket when pulling slightly at the cable.

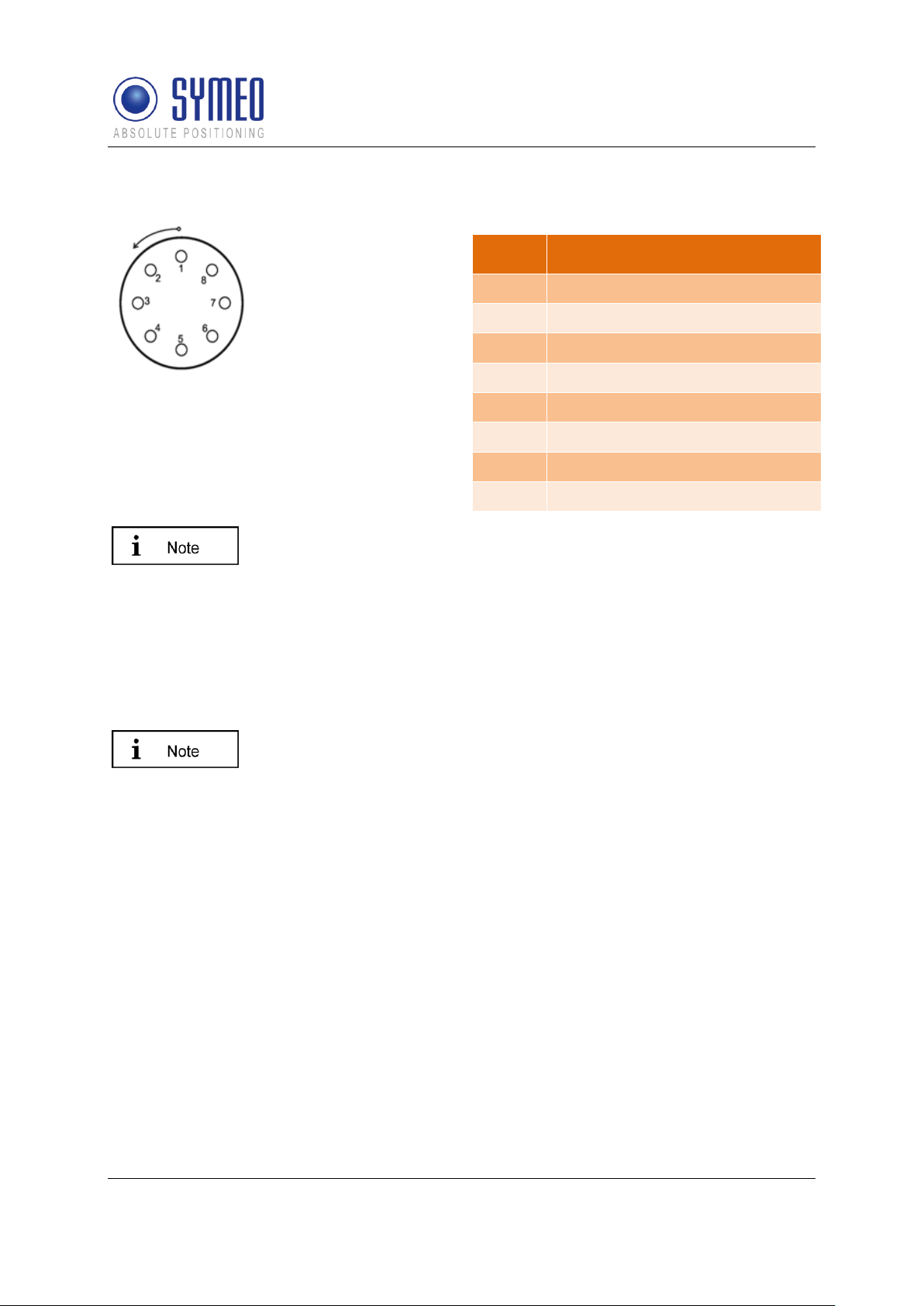

Pin

Function

1

UBB (+)

2

UBB (-)

3

LPR data port RXD

4

LPR data port TXD

5

Network diagnostic port RXD

6

Network diagnostic port TXD

7

GND-RS232

8

GND RS232

LPR®-2DB

Product Documentation

4.2.5 Lumberg Connector Type 0233 08

Figure 11 - Solder side view of the pin

assignment of the Lumberg power connector

plug (power supply with integrated service

port)

4.3 Cables for Compact Station

4.3.1 Cable for Power Supply

Cables are delivered with a cable length of 5m and can be cut to the required length.

Copyright © Symeo 2012

Page 29 of 132

Hardware

Symeo LPR®-System

PIN-Assignment of Cable Lumberg Connector 0223 08

Plug

Lumberg 0223 08

Cable

8-wire AWG24 UL/CSA; cladding diameter = 6.4mm

Color according to DIN

47100)

Pin / color

Function

1 – white

UBB (+)

2 – brown

UBB (-)

3 – green

LPR Dataport RXD

4 – yellow

LPR Dataport TXD

5 – grey

Network diagnostics port RXD

6 – pink

Network diagnostics port TXD

7 – blue

GND-RS232

8 – red

GND-RS232 and shielding

Consider the dependency of the maximum baud rate according to the

cable length:

15m: 19.200baud

5m: 57.600baud

<2m: 115.200baud

If this cable is only used for power supply, the TXD-wires of the cable

must be terminated. Otherwise signals from other systems can disturb

the system via the TXD-wire. Then measurements can fail. You have to

LPR®-2DB

Product Documentation

Figure 12 – Cable for power supply with integrated RS232 interface

According to the cable length the baud rate at the stations has to be adjusted.

Copyright © Symeo 2012

Page 30 of 132

Hardware

Symeo LPR®-System

ground the TXD-wires (PIN 4 and PIN 6) with PIN 7 and 8.

Technical Data: HARTING Push Pull Connector

Wire gauge data

AWG 22 – 24 stranded

AWG 22 – 23 solid

Wire isolation

Max. 1.6 mm Ø

Cable diameter

6.5 mm – 7.2 mm

Figure 13 – Connector box

Connection Box

Size (LxWxH)

125mm x 80mm x 57mm (without cable bushing)

Position mounting holes

4 x diameter 4.3mm; 52 x 113mm

Clamps

Wago 870-911 for cable diameter 0.08 till 2,5mm² ( till 4mm² if

flexible cables)

LPR®-2DB

Product Documentation

4.3.2 Recommended Cable Types HARTING Push Pull Connector

If the station is delivered with a HARTING Push Pull connector following type of cable should

be considered for assembling:

HARTING RJ Industrial® Ethernet Shielded Twisted Pair Standard Cable, AWG 22 solid,

according Category 5 cabling standard (ISO/IEC 11801:2002)

HARTING RJ Industrial® Ethernet Shielded Twisted Pair Trailing Cable, AWG 22/7

stranded, according Category 5 cabling standard (ISO/IEC 11801:2002)

Transmission characteristics according Category 5 ISO/IEC 801:2002 and EN 50173-1:

The assembly instruction of the HARTING Push Pull Connector is delivered with the product.

4.4 Connector box

The connection box is configured with 14 clamps. Therefore the connector box can be used

either for power supply or for relays.

Hardware

Copyright © Symeo 2012

Page 31 of 132

Symeo LPR®-System

Cable bushing

3 x PG Connection for cladding diameter 5 – 10 mm

1 x sealing cap

Protection category

IP65

If usage of appropriate cables (diameter 5 till 8mm) and correct

connection of cap and cable bushing is assured

If the cable bushing are not used the sealing cap (including the sealing

ring) has to be mounted to keep the protection category IP65.

Figure 14

1: Power consumption (by

customer)

2: Serial Interface (by customer)

3: From LPR

The shielding has to be allocated.

3 2 1

LPR®-2DB

Product Documentation

4.4.1 Example: Connector Box

Connection of an 8-pin cable

In this example the power supply is at pin1 and 2. The serial interface is at pin 5 to 10 and

the shielding at pin 14.

For safety of clamping use appropriate wires end sleeves according to AWG24.

If this cable is only used for power supply, the TXD-wires of the cable must be terminated.

Otherwise signals from other systems can disturb the system via the TXD-wire. Then

measurements can fail. You have to ground the TXD-wires (PIN 4 and PIN 6) with PIN 7 and

8.

Hardware

Copyright © Symeo 2012

Page 32 of 132

Symeo LPR®-System

The electronics inside LPR-2DB Integral Station hood itself do not

include any components that can be serviced by the user. They must

not be detached from the hood because they contain parts that are

electrically charged inside when connected to the LPR-2DB Integral

Station base.

All corresponding installation, repair and servicing work must be carried

out by qualified and trained technicians.

If the LPR-2DB Integral Station is installed on a pole, it must be secured

to ensure that it does not slip.

If the direct current is incorrectly connected, the LPR-2DB Integral

Station will be damaged and must be returned to the SYMEO service for

further inspection.

The plugged connection between the LPR-2DB Integral Station hood

and base provides protection against direct contact, i.e. it can be

connected and disconnected while it is under load.

Refer to the general design notes regarding your LPR system.

Technical Data

Power draw

4W, 10-36VDC

Dimensions (LxWxH)

212 (incl. mounting bracket) x 126 x 281 mm

Type of protection

IP 65 with feasible cables according to the cable gland

Antenna

Integrated inside the housing

Compliance

CE mark

LPR®-2DB

Product Documentation

4.5 LPR-2DB Integral Station (fixed mounted unit)

Following hardware exists for an LPR-2DB Integral Station on the light poles:

TPB000250 (LPR-2DB Integral)

TPB000251 (LPR-2DB Integral)

TPB000530 (LPR-2DB Integral, cell coordinator)

4.5.1 Technical Data: LPR-2DB Integral Station

Copyright © Symeo 2012

Page 33 of 132

Hardware

Symeo LPR®-System

7

5 6 4

3 2 1

Figure 15 – Hood, Base and Bracket (from left to right)

1

LED

2

Cable feedthrough

3

Terminal pin

4

Terminal block

5

Plug

6

Transponder locating

slot

7

Installation points

LPR®-2DB

Product Documentation

4.5.2 Components of LPR-2DB Integral Station

The base is where the terminal block for the electrical connection and the plug for connecting

the hood is located.

Strain relief clamps are applied to the base to avoid mechanical stress on the power supply

cables.

The LPR-2DB Integral Station can be fixed onto the mounting bracket with the two screws

provided with the base.

Depending on the requirements and application, the LPR-2DB Integral Station can be

adjusted vertical with an angle from 0° to 25°.

4.6 LPR Antennas for Compact Station (mobile unit)

There are different antennas that can be installed depending on the required directional

characteristic.

Copyright © Symeo 2012

Page 34 of 132

Hardware

Symeo LPR®-System

6 dBi Omnidirectional Antenna

10 dBi Omnidirectional Antenna

8,5°

vertical

-3 dB

0 dB

-3 dB

30°

vertical

-3 dB

0 dB

-3 dB

A

A

A = 190mm

d = 20mm

A = 440mm

d = 20mm

Antenna Connector Type N

Antenna Connector Type N

10 dBi Sector Antenna

vertical

60°

30°

(optional)

-3 dB

0 dB

-3 dB

horizontal

160°

-3 dB

0 dB

-3 dB

A

d

B

A = 280mm

B = 125mm

d = 150mm

Antenna Connector Type N

The LPR-2DB integral station contains an integrated 10 dBi antenna.

Only this integrated antenna is approved to be in compliance with part

15 of FCC rules and with RSS-210 of Industry Canada.

LPR®-2DB

Product Documentation

Figure 16- Typical LPR antennas for 2D applications

4.6.1 Mounting devices of LPR Antennas

Depending on the required antenna, different adapters are available

Hardware

Copyright © Symeo 2012

Page 35 of 132

Symeo LPR®-System

6 dBi and 10 dBi Omnidirectional Antenna

A

A = 228mm

B = 38mm

d = 50mm

B

d

applicable for wall and pole mounting

10 dBi Sector Antenna

A

d

B

A = 150mm

B = 128mm

d = 100mm

applicable for wall and pole mounting

LPR®-2DB

Product Documentation

Figure 17 - Available Adapters for different Antenna Types

Copyright © Symeo 2012

Hardware

Page 36 of 132

Symeo LPR®-System

During Installation, the LPR-2DB Station has to be opened. Therefore it

is important to avoid ingress of moisture, dust or any particles into the

housing during the installation process. Make sure that there is enough

room for the connectors, and particularly that the antenna cable is

accessible; pay attention to the permitted bending radius (center of

radius to cable core) for standard cables of 10,5cm (for multiple bending

under mechanical load) and 4cm (unloaded and static bending).

The LPR-2DB Station should preferably be installed so that the

connecting sockets point downwards. In this way, the connections are

protected from rain and dust.

To install the LPR-2DB Station, you require 4 round head M6 x 30

screws (at least).

LPR®-2DB

Product Documentation

5 Installation

5.1 Installation of the LPR-2DB Station (mobile unit)

BSB000313 (single receiver, TCP/IP interface, 2 antenna ports)

BSB000319 (single receiver, RS232 interface, 2 antenna ports)

BSB000603 (double receiver, TCP/IP interface, 4 antenna ports)

BSB000604 (double receiver, RS232 interface, 4 antenna ports)

BSB000605 (double receiver, TCP/IP interface, 2 antenna ports)

BSB000606 (double receiver, RS232 interface, 2 antenna ports)

Check the position of the station on the device on which the LPR-2DB Station is to be

installed (e.g. a crane bridge). Bear in mind the installation instructions listed above.

Drill holes in the device on which the LPR-2DB Station/ Rubber pads are to be installed.

Drill-hole distances: 11 cm wide, 24 cm high.

Rubber pads are provided by Symeo (see Figure 18). The rubber pads reduce vibration

to the LPR station. Place 4 rubber pad into the drill holes ad fasten the screws.

Open the LPR-2DB Station: With a Phillips screwdriver (Size 0), loosen the top four

screws of the LPR-2DB Station lid.

Screw the LPR-2DB Station tightly to the device. The installation holes of the rubber pads

are provided for this purpose. Check that the station is mounted securely.

Close the station: Place the cover of the LPR-2DB Station on top and fasten the cover

with the four screws. Make sure that the cover is securely attached to the housing.

Copyright © Symeo 2012

Page 37 of 132

Installation

Symeo LPR®-System

All installation, repair and servicing work must be carried out by qualified

and trained electrical technicians!

Polarity reversal or incorrect connection will damage the Integral

Station. If this happens, the LPR-2DB Integral Station must be returned

to the SYMEO service for inspection.

LPR®-2DB

Product Documentation

Figure 18 – Rubber pad for Compact station

5.2 Installation of the LPR-2DB Integral Station

TPB000250 (LPR-2DB Integral)

TPB000251 (LPR-2DB Integral)

TPB000530 (LPR-2DB Integral, cell coordinator)

5.2.1 Electrical Interface

The bases can be connected via the terminal block.

Installation

Copyright © Symeo 2012

Page 38 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

Figure 19 – Connecting the power supply

5.2.2 Installation

The LPR-2DB Integral Stations are supplied already preassembled (hood + base) and with

the bracket separate. Figure 20 shows various views of the assembled LPR-2DB Integral

Station including the mounting bracket.

Installation

Copyright © Symeo 2012

Page 39 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

Figure 20 – Complete LPR-2DB Integral Station including mounting bracket

The bracket can be bolted directly to the wall. The LPR-2DB Integral Station can also be

secured to posts/poles with two pipe clips (not included).

Mount the bracket on the wall or a pole.

Detach the hood from the base with the Torx-head screwdriver T25.

Insert the cable through the feedthrough.

Fit the LPR-2DB Integral Station base onto the bracket and tighten it with an SW13 fork

wrench.

Pass the cable through the terminal pins to the terminal block and clamp it according to

the instructions on the terminal block.

Tighten the screwed cable gland on the feedthroughs with an SW 19 fork wrench.

Fit the LPR-2DB Integral Station hood (note the assignment of 90°/160° in the installation

plan).

Screw the LPR-2DB Integral Station hood tightly onto the base.

You can use the slots in the LPR-2DB Integral Station bracket to adjust the vertical

orientation of the LPR-2DB Integral Station between 0° and 25° (mandatory if so

indicated in the installation plan). Tilt the LPR-2DB Integral Station to the required angle

("View" on the antenna of the base station) and tighten the screws with an SW 13 fork

wrench.

Installation

Copyright © Symeo 2012

Page 40 of 132

Symeo LPR®-System

(0,0,0)

x

y

Short-ID: 101

Short-ID: 10M

Short-ID: 102

Short-ID: 103

Short-ID: 104

Short-ID: 100

Short-ID: 105

Figure 21 – Example Cell plan for one cell

LPR-2DB Integral Station

Installation

Cell

ID

Angle

Pole

10 0 -143

LT-11

10 1 -90

LT-08

10 2 -41

LT-05

10 3 0

LT-06

10 4 180

LT-09

10 5 -180

LT-12

10 M -40

LT-05

Table 1 – Example of light pole

allocation table

If several antennas are used, ensure that they are connected to the

correct ports.

When installing the cable, ensure that electrostatic charging does not

occur.

Make sure that the cable is not kinked or trapped during installation. The

minimum bending radius must always be maintained. With the standard

antenna cables delivered, the minimum bending radius (center of radius

to cable core) for standard cables is 10,5cm (for multiple bending under

mechanical load) and 4cm (unloaded and static bending). The cable

must not be attached in a way that alters its cross-section. On demand,

cables with different flexibility characteristics are available.

The antenna plug must not be removed (e.g. for installation purposes)

or repaired because the specified electrical properties can only be

achieved with mechanical installation assistance.

When installing the antenna cable, ensure that the screw connection is

seated properly. The antenna cable plugs should be finger-tightened

before tightening with an appropriate tool to no more than 1.3 Nm

LPR®-2DB

Product Documentation

5.2.3 Allocation of LPR-2DB Integral Stations and Installation Points

If a cell plan and/or a light pole allocation table is drawn by Symeo or together with Symeo,

the position and orientation of the LPR-2DB Integral Station must be installed referred to this

master document. The cell plan contains the LPR-2DB Integral Stations with a definite

identifier installed at the wall or on the light poles (compare chapter 7.1.1).

5.3 Installation of LPR antennas

5.3.1 Connection of antenna cables to the mobile units (LPR-2DB Station)

Installation

Copyright © Symeo 2012

Page 41 of 132

Symeo LPR®-System

tightening torque.

The line of sight between the antennas on each unit must not be

obstructed. Therefore, when installing the antenna fixture, ensure that

no components are blocking the line of sight between the antennas. If

necessary, contact the SYMEO technical department.

If you change the position of one antenna, this will affect the

measurement data that is output.

LPR®-2DB

Product Documentation

5.3.2 Mounting of LPR antennas

Install the antenna fixture according to the accompanying operating instructions.

Secure the antenna in the fixture.

Connect the antenna to the antenna cable.

Copyright © Symeo 2012

Page 42 of 132

Installation

Symeo LPR®-System

4 slots for

clamping

Assembly bracket

of antenna

Fixing nut for

antenna

LPR®-2DB

Product Documentation

Figure 22 – Antenna with assembly bracket and antenna cable

5.3.3 Notes for mounting position of LPR antennas on the mobile unit

Considering the correct mounting position of the antennas you have to take care to

guarantee a free line of sight between the antenna(s) on the vehicle and all LPR-2DB

Integral Stations.

If construction on the vehicle partly interfere the free line of sight (e.g. driver cabin), the

distance between the antennas and this construction barrier should be chosen big to make

the “blind” sector small.

Copyright © Symeo 2012

Page 43 of 132

Installation

Symeo LPR®-System

1

3

2

Antenna

Antenna

1

Free visual range of antennas

2

Construction (e.g. driver cabin)

3

„blind“ sector

Antenna

Antenna

Center of rotation of

vehicle

Center of rotation of

vehicle

LPR®-2DB

Product Documentation

Figure 23– Mounting position of antenna

On the other hand the antenna should be close to the center of rotation of the vehicle type to

make the positioning error due to the rotation of the vehicle as small as possible (see Figure

24).

The position of the antenna(s) is in some cases a trade-off between minimizing the error due

to construction barrier on the vehicle and the minimizing the rotation error. Contact Symeo if

there are questions regarding the installation position of the antenna.

If a second antenna is used on the vehicle the distance to the first antenna should be at least

1 meter to calculate an orientation of the vehicle. The orientation is necessary to determine a

load position if the antenna is not mounted above the load position.

Figure 24 – Mounting position of antenna

Depending on the position of the LPR-2DB Integral Stations different minimum system

ranges result. The system range depends on the selection of the antennas and the antenna

cable length as well as of the antenna cable length. In general the antenna cable length on

the vehicle should be as short as possible to minimize the signal loss in the cable.

Copyright © Symeo 2012

Page 44 of 132

Installation

Symeo LPR®-System

LPR®-2DB

Product Documentation

Installation

Copyright © Symeo 2012

Page 45 of 132

Symeo LPR®-System

LPR®-2DB

Product Documentation

6 Coordinate System

The LPR-2DB Integral Station and the antennas of the mobile stations must be surveyed.

6.1 Survey Instructions for the LPR-2DB Integral Station

The Integral Stations are supplied already preassembled (hood + base) and with the bracket

separate. Figure 25 shows various views of the assembled LPR-2DB Integral Station

including the mounting bracket

Figure 25 – Complete LPR-2DB Integral Station including mounting bracket

6.1.1 Coordinate system of LPR-2DB Integral Station

The accuracy of the position output depends in large part on the exact recording of the

positions of the LPR-2DB Integral Station. Accordingly, the positions of the installed stations

must be calibrated to a tolerance of +/- 2 cm (in each direction). At the same time, the

orientation of each Integral Station in the x-y direction is also recorded. The inclination of the

stations is not recorded.

LPR works with a Cartesian coordinate system, which is spanned by the x-y plane (see

Figure 9). The positions of the Integral Stations are identified in this coordinate system. By

default, the coordinate system has a positive effective direction.

Coordinate System

Copyright © Symeo 2012

Page 46 of 132

Symeo LPR®-System

z

y

x

[0,0,0]

Measurement point

LPR®-2DB

Product Documentation

Figure 26 – transponder coordinate system

Positions in all four quadrants can be measured in the transponder coordinate system: LPR

calculates the 2D position in the plane spanned by x and y.

Since it is not always possible to mount all the LPR components (LPR-2DB Integral Station,

LPR-2DB Station antennas) in this plane, the deviation of the installation position in "z"

relative to this plane must be specified for all LPR components.

In plane areas the z-position can be estimated directly towards the ground level.

The LPR-2DB Integral Stations must be measured in x-/y- and z-direction.

6.1.2 Reference point of LPR-2DB Integral Station

The position of the measuring point is critical for measuring the LPR-2DB Integral Station.

The measuring point is marked by matting on the stations housing.

In a top view, the measuring point is located at the same level as the antenna patches

(horizontal structures, roughly in the middle of the board portion above the copper reflector).

In the front view, the zero point is located midway between the copper reflectors.

Figure 27 – Position of the measuring point on the LPR-2DB Integral Station

Copyright © Symeo 2012

Page 47 of 132

Coordinate System

Symeo LPR®-System

LPR®-2DB

Product Documentation

Figure 28 – Position of the measuring point on the Integral Station

6.1.3 Orientation of LPR-2DB Integral Station

The alignment of the stations is recorded as a vector in the coordinate system that is defined

for the application, and is entered as an ex/ey value. Integer values are possible for ex/ey.

The following diagram illustrates this principle (corresponding negative values for an opposite

alignment).

Figure 29 – Examples of LPR-2DB Integral Station alignment with ex/ey value

Coordinate System

Copyright © Symeo 2012

Page 48 of 132

Symeo LPR®-System

a

y

x

Description

Meaning

Cell

Cell number

ID

LPR-2DB Integral Station ID

TID

Fixed allocated

x

x-position of the transponder in own coordinates in mm

Short ID

LPR-2DB Integral Station formatting

Cell

ID

TID

x , y , height

,

direction

x (ex)

,

direction

y (ey)

,

beam

width

12 0 T0=(

, , , , , 200

)

12 1 T1=(

, , , , , 200

)

12 2 T2=(

, , , , , 200

)

12 3 T3=(

, , , , , 200

)

12 4 T4=(

, , , , , 200

)

12 5 T5=(

, , , , , 200

)

12 M T30=(

, , , , , 200

)

LPR®-2DB

Product Documentation

It is also possible to compute the orientation vectors from the angle of the integral station in

the plane:

Figure 30 – Computation of ex/yx from angle a

Hereby is ex = cos(a) and ey = sin(a).

So just compute the values and multiplicate with 10 and truncate the decimal place:

Example: a = 12°, 10*cos(a)=9,78; 10*sin(a)=2,08 ex = 9; y = 2

6.1.4 Formatting of coordinates

The coordinates of the integral stations must be provided as EXCEL-file in following format:

Coordinate System

Copyright © Symeo 2012