SYMEO L

OCAL POSITIONING RADAR

Product Family: LPR®-1DHP-200

Products:

LPR®-1DHP-220-R

LPR®-1DHP-260

LPR®-1DHP-281

LPR®-1DHP-290

Product Documentation

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Content

CONTENT .............................................................................................................................. 2

1 SAFETY NOTES ........................................................................................................ 6

2 THE LPR®-1DHP-200 PRODUCT FAMILY ................................................................. 8

3 RADAR BASICS ........................................................................................................ 8

3.1 Radar Distance Measurement Principle .................................................................. 8

3.2 Radar Beam and Opening Angle .............................................................................. 9

3.3 Fresnel Zone.............................................................................................................. 9

3.4 Radar Modes ........................................................................................................... 10

3.4.1 Primary Radar Mode ................................................................................................. 10

3.4.2 Secondary Radar Mode ............................................................................................ 11

3.4.3 Diversity Radar Mode................................................................................................ 12

3.5 Bandwidth Modes ................................................................................................... 13

3.6 Accuracy .................................................................................................................. 13

3.7 Range ....................................................................................................................... 14

4 COMPONENTS ........................................................................................................ 15

4.1 Device Overview ..................................................................................................... 15

4.2 LED Display ............................................................................................................. 18

4.3 Connectors .............................................................................................................. 19

4.3.1 Power Supply ............................................................................................................ 19

4.3.2 Ethernet M12 ............................................................................................................ 20

4.4 Mounting Brackets .................................................................................................. 21

4.4.1 Mounting Bracket – MTM102513 .............................................................................. 21

4.4.2 Diversity Mounting Bracket – MTM102512 ................................................................ 23

4.5 Corner Reflectors .................................................................................................... 23

4.5.1 Corner reflector 500mm – MTE000958 ..................................................................... 23

4.5.2 Corner reflector 250mm – MTE001011 ..................................................................... 24

4.5.3 Mount for corner reflector – MTM000169 .................................................................. 24

5 MOUNTING .............................................................................................................. 25

Content

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 2 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

5.1 General Mounting Instructions .............................................................................. 25

5.2 Mounting for Primary Radar Mode ......................................................................... 25

5.3 Mounting for Secondary Radar Mode .................................................................... 26

5.4 Mounting for Diversity Radar Mode ....................................................................... 27

6 QUICK SETUP ......................................................................................................... 27

6.1 Initial Setup ............................................................................................................. 27

6.2 Quick Setup for Primary Radar Mode .................................................................... 27

6.3 Quick Setup for Secondary Radar Mode ............................................................... 28

6.4 Quick Setup for Diversity Radar Mode .................................................................. 28

6.5 Review and Calibration of the Measurement Setup .............................................. 28

7 ESTABLISHING A TCP/IP CONNECTION ............................................................... 29

8 DEVICE SETUP VIA THE WEB USER INTERFACE................................................ 31

8.1 Open the Web User Interface ................................................................................. 31

8.2 Sign In ...................................................................................................................... 33

8.3 Initial Operation ....................................................................................................... 33

8.4 Change Settings, Review and Save Changes ....................................................... 36

8.5 Home Page .............................................................................................................. 38

8.1 Device ...................................................................................................................... 41

8.1.1 Device - Settings ....................................................................................................... 41

8.1.2 Device - Upload Configuration .................................................................................. 50

8.1.3 Device - Downloads .................................................................................................. 50

8.1.4 Device - Firmware Update......................................................................................... 50

8.1.5 Device - Factory Reset .............................................................................................. 51

8.1.6 Device - Reboot Device ............................................................................................ 51

8.2 Diagnostics ............................................................................................................. 52

8.2.1 Diagnostics – Operating System Status .................................................................... 52

8.2.2 Diagnostics – Hardware Status ................................................................................. 54

8.2.3 Diagnostics – Storage Devices ................................................................................. 55

8.2.4 Diagnostics – Range Measurement Statistics ........................................................... 55

8.2.5 Diagnostics – Record Measurement Data ................................................................. 59

8.2.6 Diagnostics – Packet Inspector ................................................................................. 59

Content

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 3 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8.2.7 Diagnostics – Station Scan ....................................................................................... 60

9 THE CUSTOMER PROTOCOL ................................................................................ 62

9.1 General Description ................................................................................................ 62

9.1.1 Structure of a Data Type ........................................................................................... 62

9.1.2 CRC .......................................................................................................................... 62

9.2 Data Types ............................................................................................................... 63

9.2.1 Type 0x16 – Distance Data ....................................................................................... 63

9.2.2 Type 0x03 – Relays Switching Commands ............................................................... 65

9.2.3 LPR®-1D24 Address ................................................................................................ 67

10 TECHNICAL DATA .................................................................................................. 68

10.1 General Technical Data .......................................................................................... 68

10.2 Product Name vs. Model Number .......................................................................... 68

10.3 Mode Dependent Technical Data ........................................................................... 69

10.3.1 Primary Radar Mode ................................................................................................. 69

10.3.2 Secondary Radar Mode ............................................................................................ 69

10.3.3 Diversity Radar Mode................................................................................................ 70

11 TROUBLESHOOTING .............................................................................................. 71

12 APPLICATIONS ....................................................................................................... 71

Content

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 4 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

The documentation for the LPR®-1DHP-200 Local Positioning Radar System is published by:

SYMEO GmbH

Prof.-Messerschmitt-Str. 3

D-85579 Neubiberg

www.symeo.com

If you have any questions or suggestions, please contact:

Email: info@symeo.com

phone: +49 89 660 7796 0

Copyright Symeo GmbH

HISTORY

Version Date Description

0001 28.05.2018 Initial Release

0002 09.08.2018 Comprehensive update

WORK

SYMBOLS USED

The following symbols are used throughout the documentation:

This symbol appears before instructions that must be followed at all times.

Failure to comply with these instructions will result in personal injury.

This symbol appears before instructions that must be followed at all times.

Failure to comply with these instructions will result in damage to

equipment.

This symbol appears before information of particular importance.

All rights reserved, particularly those relating to the translation, reprinting, and reproduction

by photocopying or similar processes of all or part of the documentation and for purposes of

the award of patents or submission of utility models.

Delivery options and technical changes reserved.

Wherever the term LPR®-1DHP-200 is used during this documentation, all products included

in the LPR®-1DHP-200 product family are addressed.

Application specific documentation can be obtained from the Partner Login under

www.symeo.com or from Symeo support.

Content

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 5 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

1 Safety Notes

General

The LPR®-1DHP-200 product family is a radar distance measurement sensor that may be

used to measure distances between a radar unit and a reflector or between two radar units.

LPR®-1DHP-200 radars are purely tracking and assistance systems.

They do not satisfy special requirements for personal or functional

safety or explosion protection.

All personnel that commission or operate an LPR®-1DHP-200 radar

have to be instructed that it does not satisfy norms and requirements for

functional safety (e.g. IEC 61058, EN ISO 13849, EN 62061).

Read the documentation before operation of the radar and follow the

included safety notes.

Take note of the safety and operating instructions of the system in

which you want to install the device.

Follow national safety norms and regulations.

Installation

Installation must be carried out by qualified and trained technicians.

When the system is mounted on fixed tubes, the necessary measures to

prevent slippage of the system must be taken.

Only screwed connections with safety against loosening may be used

for mounting the radar.

Adhere to the specified tightening torques for all screws and connectors.

Screwed connections must be examined at regular intervals, especially

if the radar is mounted exposed.

Repairs and Modifications

Repairs or modifications may only be performed by the manufacturer.

Opening of the device is prohibited.

Any change or modification not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

The warranty shall be voided if you cause defects to the device by

installing or exchanging system extensions.

Safety Notes

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 6 of 71

Transport and Storage

Do not drop the device and do not expose it to strong vibrations.

Power Supply

While installing or using it in open-air, transient overvoltage cannot be

excluded. Overvoltage protection is to be used for low voltage in

accordance to DIN EN 61643-21 and IEC 61643-21.

Be careful that the device can be damaged by reverse polarity despite

implementation of polarity reversal protection.

Setup and Operation

Protect the contacts of all of the device's sockets and plugs from static

electricity.

Proper operation (in accordance with IEC60950/EN60950) of the device

is only assured if the housing and integral covers for mounting slots are

fully installed (electric shock, cooling, fire protection, noise suppression).

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

In case of intense, direct solar radiation or other radiant heat, it may be

necessary to provide a sun or heat shield.

Be aware, that misuse, modification or damage of the sensor can lead

to erroneous distance measurements.

After mounting and commissioning, compare the actual distance to the

distance measured by the radar sensor with respect to your needed

accuracy. This step must be repeated after major changes to your

measurement setup.

System Extensions and Accessories

For LAN cabling, the requirements in accordance with EN 50173 and

EN 50174-1/2 apply. Use of either a Category 5 shielded cable for

10/100 Ethernet or Category 5e shielded cable for gigabit Ethernet is a

minimum requirement. The specifications of standard ISO/IEC 11801

must be complied with.

General Requirements for Compliance of Radio Apparatus

The operation of this device requires compliance with regional radio

regulations.

This device complies with Part 15 of the FCC Rules and with Industry

Canada license-exempt RSS standard(s).

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux

conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même

si le brouillage est susceptible d'en compromettre le fonctionnement.

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 7 of 71

Exposure Requirements

To satisfy FCC exposure requirements a separation distance of 20 cm

or more should be maintained between the antenna of this device

and persons during operation.

To ensure compliance, operations at closer distances than this are not

recommended.

To satisfy ISED exposure requirements a separation distance of 20 cm

or more should be maintained between the antenna of this device

and persons during operation.

To ensure compliance, operations at closer distances than this are not

recommended.

Pour satisfaire aux exigences d'exposition ISED, une distance de sépa

ration de 20 cm ou plus doit être maintenue entre l'antenne de cet

appareil et les personnes pendant le fonctionnement.

Pour assurer la conformité, les opérations à plus courte distance ne

sont pas recommandées.

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

-

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page

SYMEO Local Positioning Radar System

Primary Radar Mode

X

X

Secondary Ra

dar Mode

X

X

Diversity Radar Mode

X X X

Product Family LPR®-1DHP-200 – Product Documentation

2 The LPR®-1DHP-200 Product Family

The LPR®-1DHP-200 is a radar distance measurement sensor product family. The product

family consists of different product types, which are based on the same hardware platform.

Depending on your purchased product type, your radar provides one or more of three

different radar modes, namely a primary radar mode, a secondary radar mode and a

diversity radar mode. Table 2.1 shows the different product types and their supported radar

modes.

LPR®-1DHP- 220-R 260 281 290

Table 2.1: Supported radar modes for different LPR®-1DHP-200 product types.

Typical applications of the LPR®-1DHP-200 are:

Positioning of cranes, crane trolleys, hoists and other railbound transport systems

Process automation, monitoring and control

Collision avoidance

While reading this document keep in mind which radar modes are

supported by your device.

All LPR®-1DHP-200 product types can be configured with the help of a

Web User Interface (WebUI), which is described in chapter 8.

3 Radar Basics

3.1 Radar Distance Measurement Principle

The LPR®-1DHP-200 radar distance sensors use electromagnetic waves to measure the

distance and speed between two radars (secondary radar mode) or a single radar and a

reflector (primary radar mode).

The underlying measuring principle is based on the Round-Trip Time-Of-Flight (RTOF)

measurement between a transmitted radar signal and a received signal. The radar estimates

the time τ the radar signal needs to travel the unknown distance d from one radar to the other

(or to a reflector) and back. The distance is then calculated with the formula

where c is the speed of light.

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 8 of 71

= 0.5

Radar Basics

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

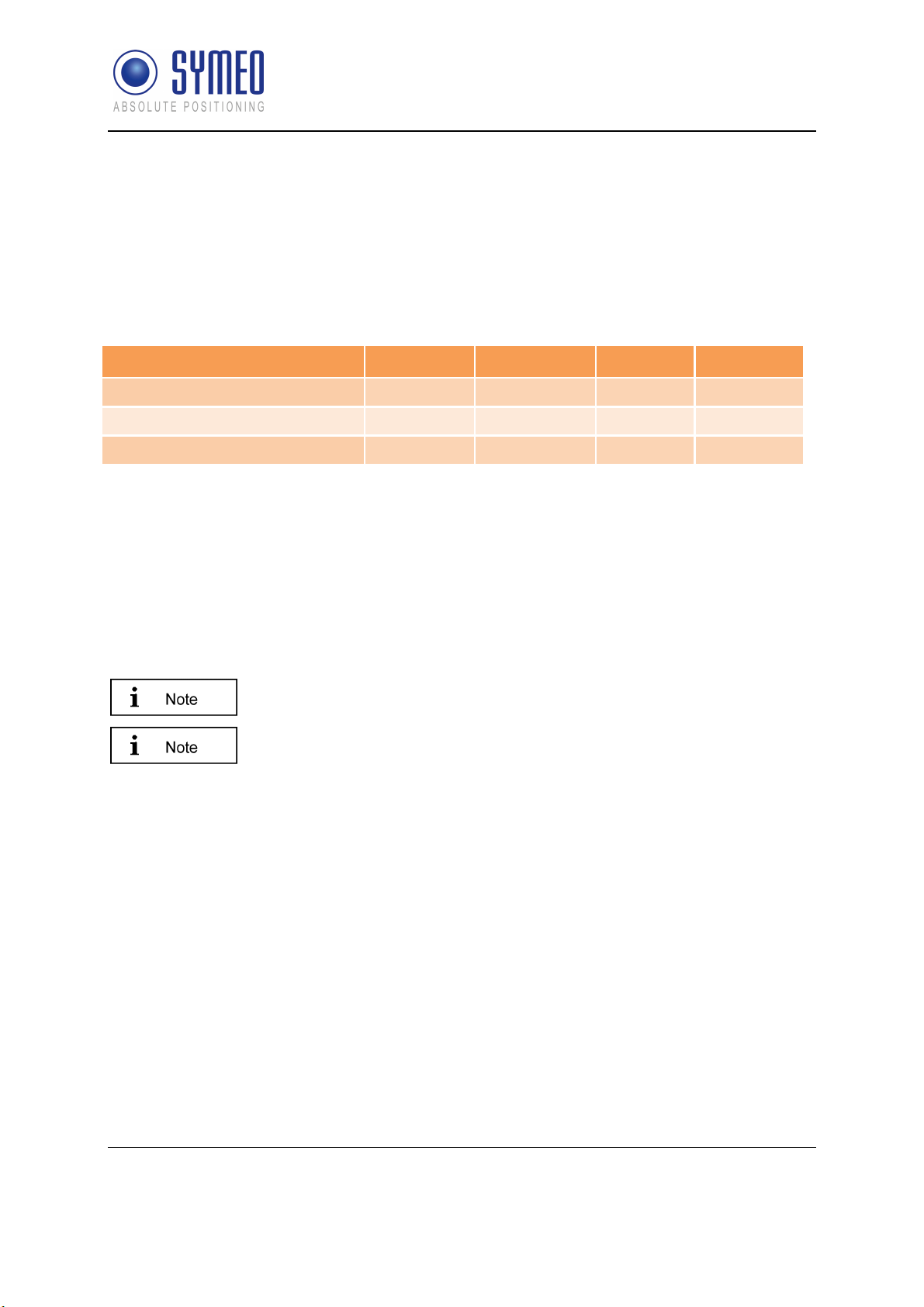

3.2 Radar Beam and Opening Angle

The LPR®-1DHP-200 emits a high frequency electromagnetic radio signal with its integrated

antenna. The EM-wave is focused by a dielectric lens and creates a radar beam with an

opening angle (half power beam width, HPBW) of +/-2,5°.

Distance d in m

Radar beam 3dB

diameter in m

1 3 10 30 50 70 100 200 300 400 600

0.1 0.3 0.9 2.6 4.4 6.1 8.7 17.5 26.2 34.9 52.4

Table 3.1: Radar beam 3dB diameter vs. distance

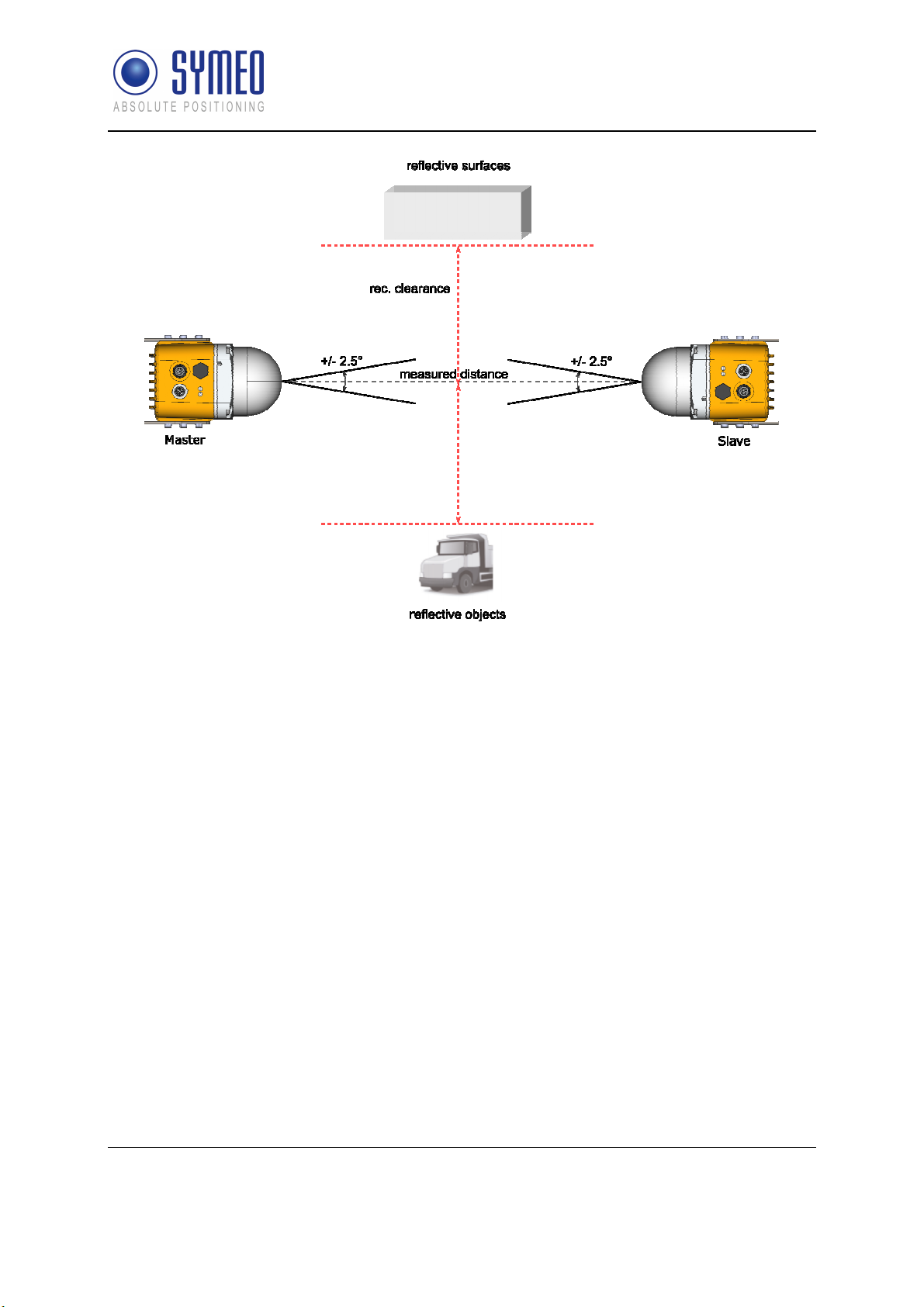

Figure 3.1: Radar beam and opening angle.

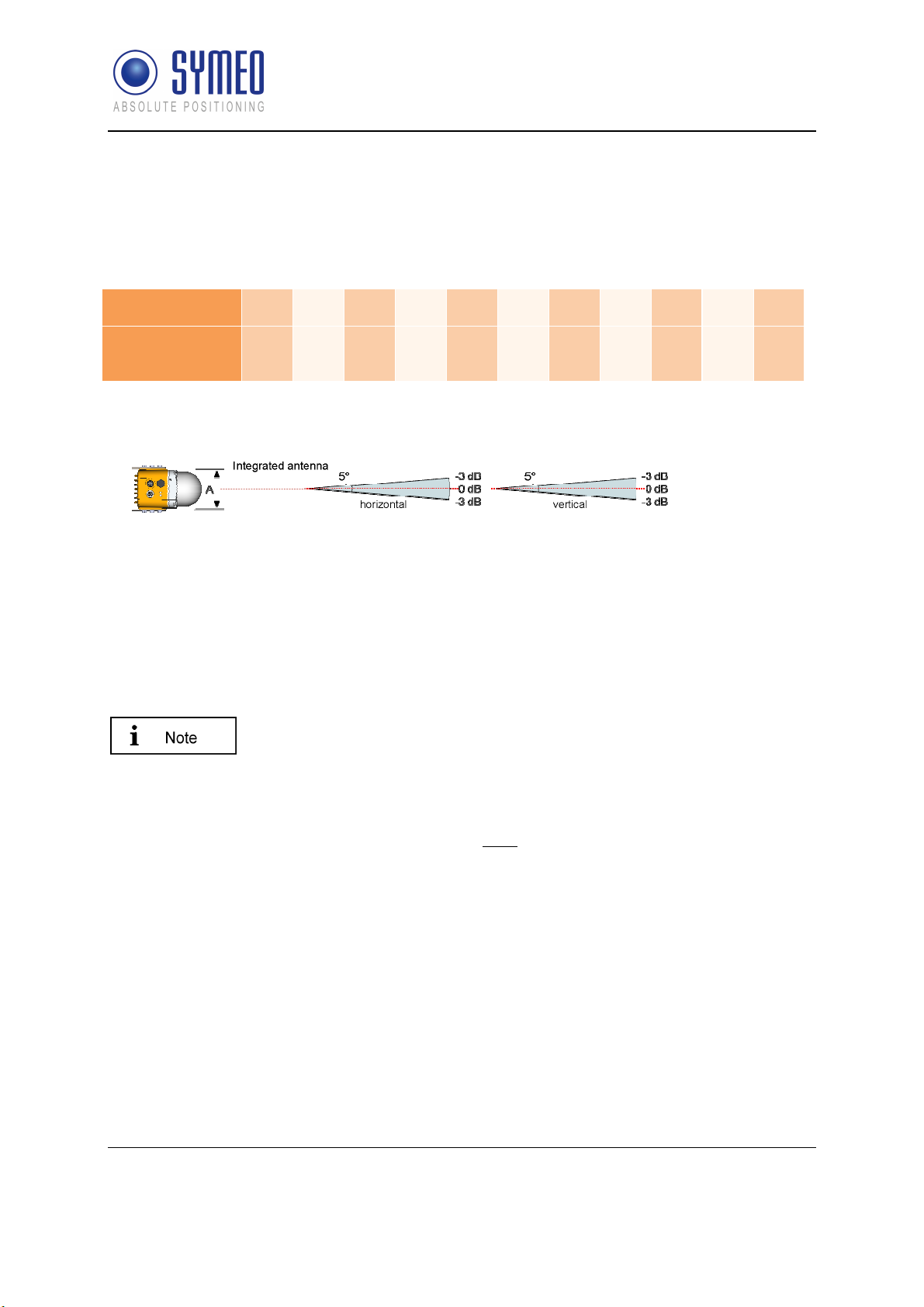

3.3 Fresnel Zone

The area for radio transmission between two antennas is called Fresnel zone. The main part

of energy is concentrated in the first Fresnel zone.

The Fresnel zone has to be free of any obstacles to ensure that the

signal is not attenuated or interrupted.

The maximum radius of the first Fresnel zone (in the middle between two antennas) can be

calculated as follows:

= 0.5 ∙√ ∙

is the wave length and the distance between the two radar devices or a radar device and

a reflective target For a frequency of 61 GHz a wave length of approx. 0.005 m is

calculated. The maximum radius of the first Fresnel Zone is indicated by . The maximum

radius for different distances is given in Table 3.2.

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 9 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 3.2: Fresnel zone

Distance d in m

Fresnel Zone

Radius r in m

10 20 30 40 50 70 100 200 300 400 600

0.11 0.16 0.19 0.22 0.25 0.30 0.36 0.50 0.62 0.71 0.86

Table 3.2: Fresnel zone radius vs. distance

3.4 Radar Modes

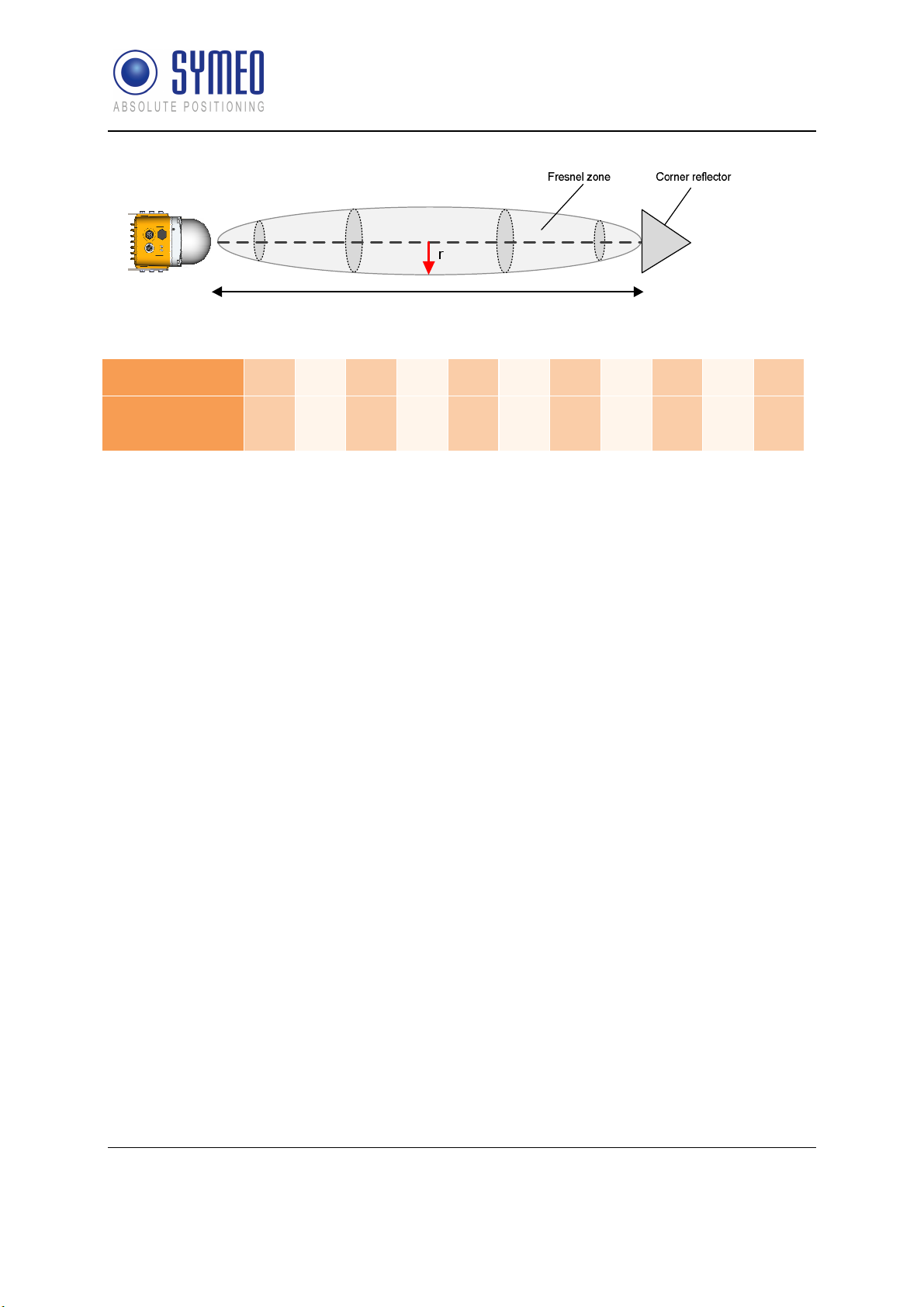

3.4.1 Primary Radar Mode

In primary radar mode, a single radar measures the distance and speed to a reflective object

/ target, typically a metal corner reflector. The following features differentiate the primary

radar mode from the other radar modes:

Suitable for ranges up to 50 m

Range depends on target radar cross section (RCS)

Very high update rate (up to 350 Hz)

Cost effective installation with a single radar

Distance measurements to passive objects enable additional applications for primary radar

mode,:

Presence / absence check (e.g. in a radar barrier)

Profile / measurement (e.g. of bulk material)

Detection of arbitrary objects (e.g. of personell or vehicles)

Figure 3.3 shows the typical setup of a LPR®-1DHP-220-R radar and a corner reflector for a

primary radar distance measurement.

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 10 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 3.3: Primary radar mode measurement setup

3.4.2 Secondary Radar Mode

In secondary radar mode two radars measure the distance and speed between each other.

The following features differentiate the secondary radar mode from the other radar modes:

Suitable for ranges up to 300 m

Distance is always measured to the partner unit and not to passive objects

Figure 3.4 shows the typical setup of two LPR®-1DHP-260 radars for a secondary radar

range measurement.

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 11 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 3.4: Secondary radar mode measurement setup

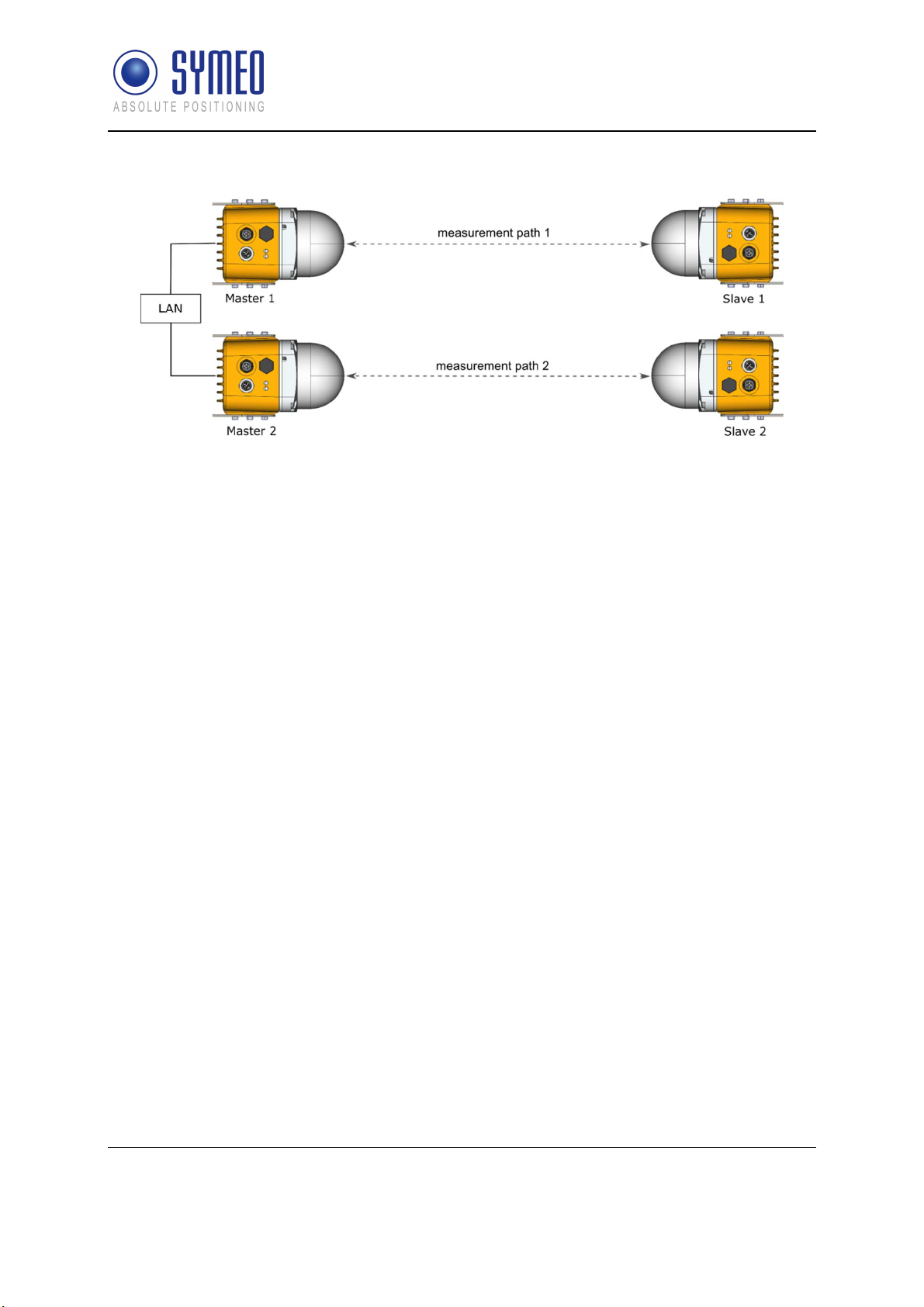

3.4.3 Diversity Radar Mode

In diversity radar mode four radar units are grouped into two pairs, which are mounted in a

way that two secondary range measurements are performed side by side separated by a

defined distance. The following features differentiate the diversity radar mode from the other

radar modes:

Suitable for ranges up to 500 m

Distance is always measured to the partner unit and not to passive objects

No clearance to reflective surfaces / objects required (see chapter 5.1; Fresnel zone still

needs to be free of obstacles)

If one of the two measurement paths fails, the system falls back to operation in

secondary radar mode and is therefore still available (error is indicated in diversity status

byte)

Figure 3.5 shows the typical setup of four LPR®-1DHP-281 radars for a diversity radar range

measurement.

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 12 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 3.5: Diversity radar mode measurement setup

3.5 Bandwidth Modes

The LPR®-1DHP-200 is able to operate in the 57 - 64 GHz band. Depending on your used

region and regulatory authority setting, a limited number of bandwidth modes are available

for selection in the WebUI.

The selected bandwidth modes have impact on the accuracy, resolution and range of the

radar. The dependency of performance and bandwidth mode with respect to regional

restrictions is depicted in chapter 10. It is recommended to use the 0.5 GHz or 2 GHz

bandwidth mode for standard applications.

Within a single bandwidth mode, multiple sync channels are available. For each channel

block, the effective bandwidth of a sync channel reduces with increasing sync channel

number.

3.6 Accuracy

To maximize the accuracy of a LPR®-1DHP-200 measurement setup, different error sources

which influence the accuracy need to be taken into account:

Mounting position

o

Adhere to the mounting instructions (see chapter 5) to minimize systematic errors

(e.g. horizontal or vertical offset and alignment).

Reflective surfaces and objects

o

Reflections of the radar signal, e.g. from walls, can cause distance errors in primary

and secondary radar mode which vary with the measured distance. Ensure the

recommended clearance to surfaces and objects described in chapter 5.1 or use

diversity radar mode to minimize errors caused by reflections.

Measurement noise

o

Measurement noise caused by the radar itself is the lower limit to the overall

accuracy. The noise will decrease with increasing bandwidth. For primary radar

mode, noise will increase with range and decrease with target radar cross section

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 13 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

(dependent on target size, shape and material). In secondary radar mode noise is

constant within the specified range and will increase for ranges above.

Temperature drift

o

Changes in device and air temperature can lead to measurement offsets of approx.

+/-10mm. These errors vary slowly with time and can be countered by ensuring

constant environmental conditions, running a warm up phase of 30 minutes before

operation or by using a calibration reference.

3.7 Range

To maximize the range of a LPR®-1DHP-200 measurement setup the following aspects have

to be taken into account:

Mounting position

o

Adhere to the mounting instructions (see chapter 5). Ensure minimum alignment error

and vertical / horizontal offset and equal orientation (for secondary and diversity radar

mode)

Fresnel zone

o

Ensure the Fresnel zone is free of absorbing or reflecting objects

Reflective surfaces and objects

o

Reflections of the radar signal, e.g. from walls, can lead to a reduction of the received

signal strength and hence maximum range. Ensure the recommended clearance to

surfaces and objects described in chapter 5.1 or use diversity radar mode to counter

the effects caused by reflections

Target RCS (only primary radar mode)

o

In primary radar mode the maximum range depends on the target RCS (radar cross

section) which is a function of target size, material and shape. If the maximum range

is required use targets with a high RCS (e.g. the corner reflector MTE000958)

VGA value

o

For maximum range set the “VGA value” to the highest possible value that is allowed

in you regulatory domain. The WebUI will use your region settings to limit the “VGA

value” and hence range is reduced in certain regions (see chapter 10).

The minimum range of the sensors can be reduced to values below the specified minimum

distance by adapting the “VGA value”, the “RX attenuator” and the threshold settings (for

primary radar). This however affects the maximum range and the accuracy of the radar and

shall therefore only be applied by trained personell.

Radar Basics

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 14 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

4 Components

4.1 Device Overview

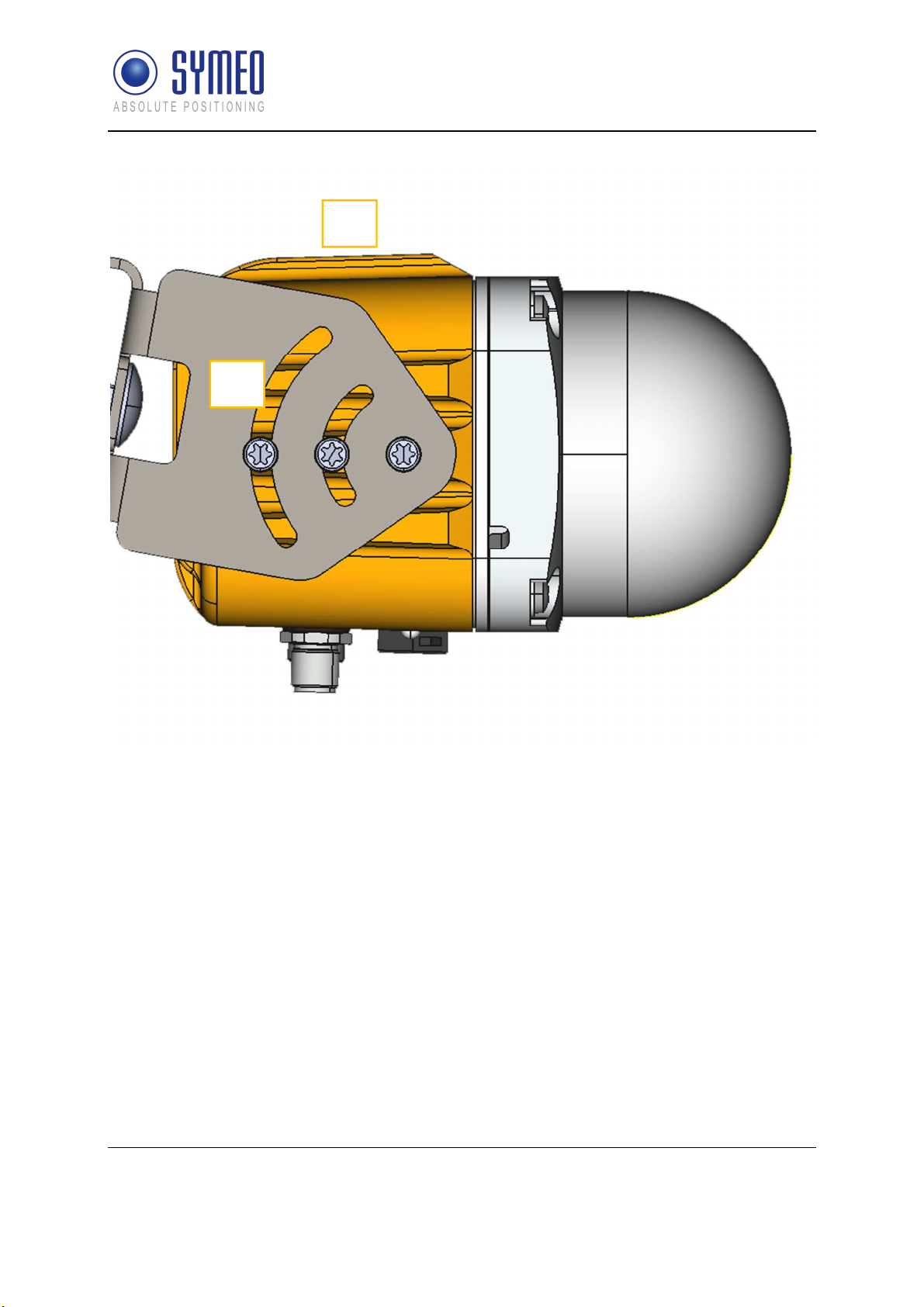

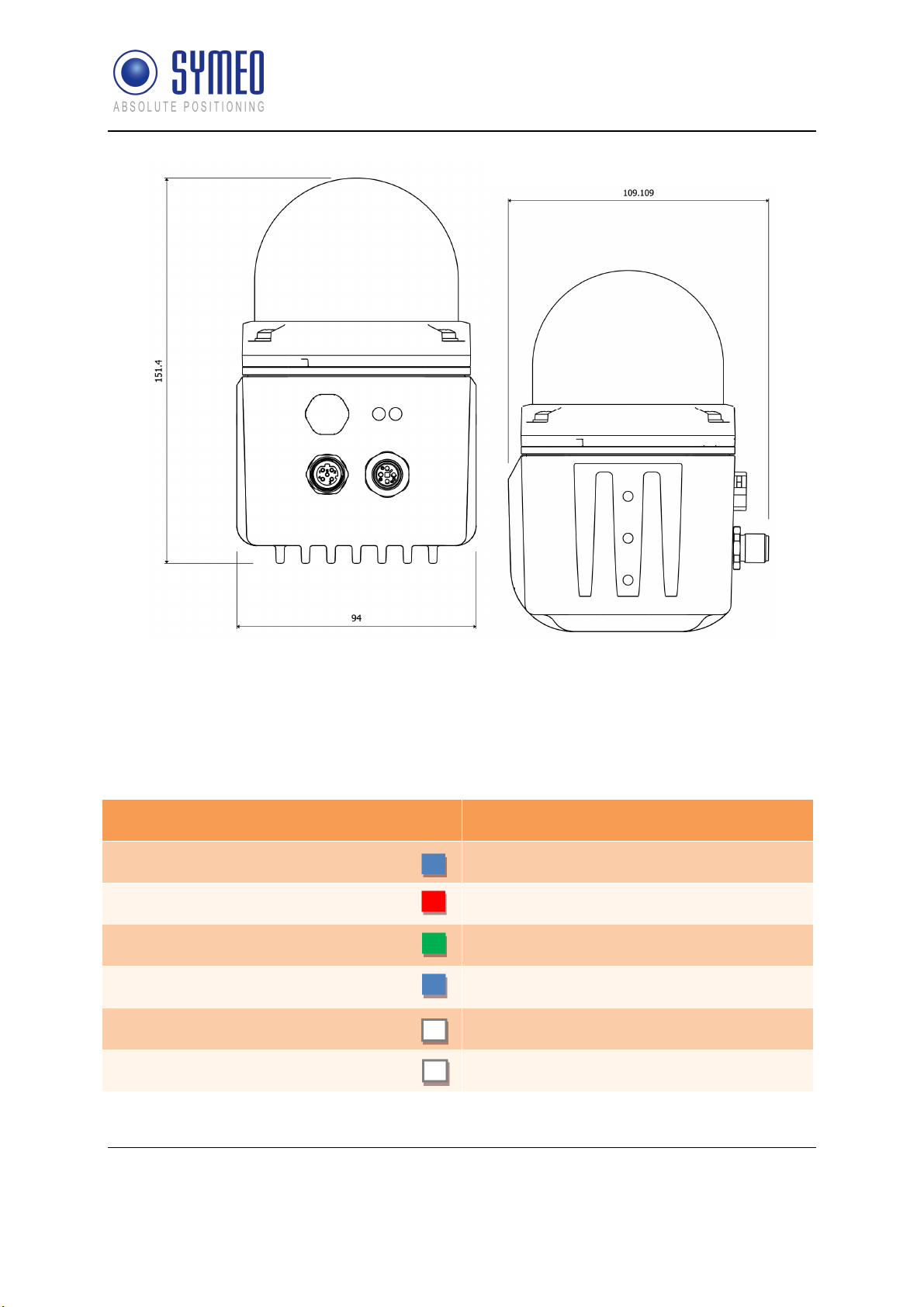

The LPR®-1DHP-200 consists of the following parts (see Figure 4.1 and Figure 4.2):

Dielectric Lens (A1)

o

focuses the radar beam

Metal gland (A2)

o

fixes the lens to the housing with four screws

o

seals the device against water and dirt

o

holds the inner parts of the device in place

Housing (A3)

o

provides LEDs (B1) and a pressure equalization membrane (B2)

o

provides the M12 power supply connector (C1) and the M12 Ethernet connector (C2)

o

provides 2 x 3 M6 screwing holes (B3) for mounting in the mounting bracket

o

provides an adjustment guide for usage with a laser level for exact radar beam

alignment (B4)

o

ensures IP65 protection class and heat dissipation

The housing must not be opened.

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 15 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

A1

A2

B3

B2

A3

Figure 4.1: Front view of the LPR®-1DHP-200

C2

C1

B1

B3

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 16 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

B4

B3

Figure 4.2: Side view of the LPR®-1DHP-200

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 17 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 4.3: LPR®-1DHP-200 housing dimensions

4.2 LED Display

The LEDs (Status LED on the left and Ethernet LED on the right) indicate the different states

of the device (see Table 4.1).

LED Indication Status of the Device

Status LED lights up BLUE Device is booting up

Status LED lights up RED Invalid measurement

Status LED lights up GREEN Valid measurement

Status LED flashes BLUE Firmware update in progress

Ethernet LED lights up WHITE Ethernet interface established

Ethernet LED flashes WHITE Ethernet interface transmits data

Table 4.1: LED Display

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 18 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

4.3 Connectors

The housing of the LPR®-1DHP-200 provides the following M12 connectors (see Figure 4.1

and Figure 4.2):

Power supply input (C1)

Ethernet connector (C2) for network connection

The necessary connectors for manufacturing cables that fit your installation and cable length

are available from symeo and are described in the following chapters.

4.3.1 Power Supply

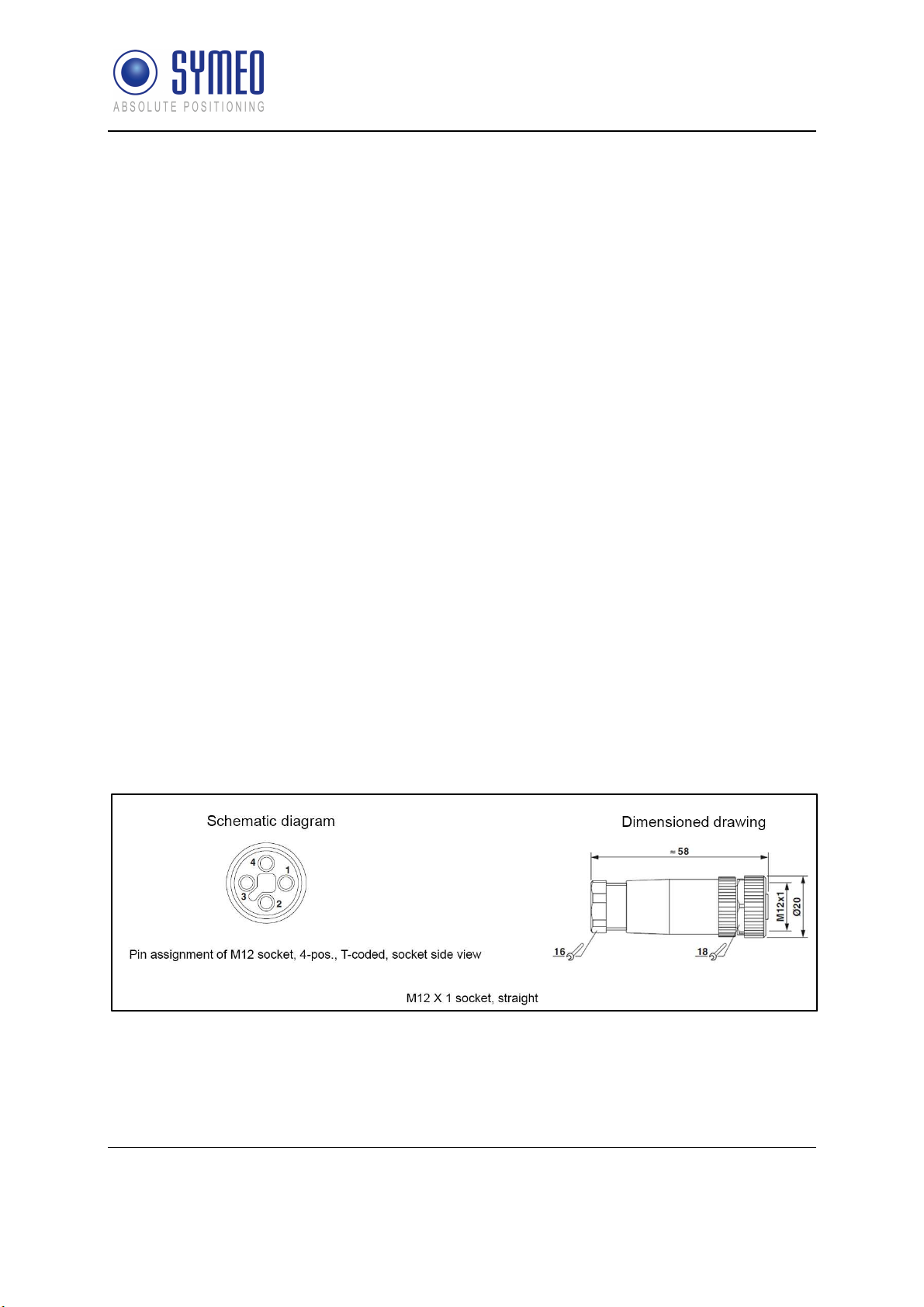

The LPR®-1DHP-200 is powered by a 4-pin M12-Connector.

Plugs

Recommended connector:

SACC-M12FST-4PECON-PG 9-M – 1418052 (obsolete)

SACC-M12FST-4CON-PG 9-M - 1418052

o Cable diameter: 6 - 8 mm

Tightening torque: 0.4 Nm

o Symeo order number: MTE101761

The connector is also part of the following M12 connector set:

M12 connector set (Ethernet + Power supply)

o Symeo order number: MTE102366

Figure 4.4: M12 power supply connector

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 19 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Pin Assignment

Power Supply 11 V DC – 36 V DC M12 Connector

VDC+ Pin 1

VDC+ Pin 2 (bridged to Pin 1)

VDC- Pin 3

VDC- Pin 4 (bridged to Pin 3)

Table 4.2: Pin assignment power supply

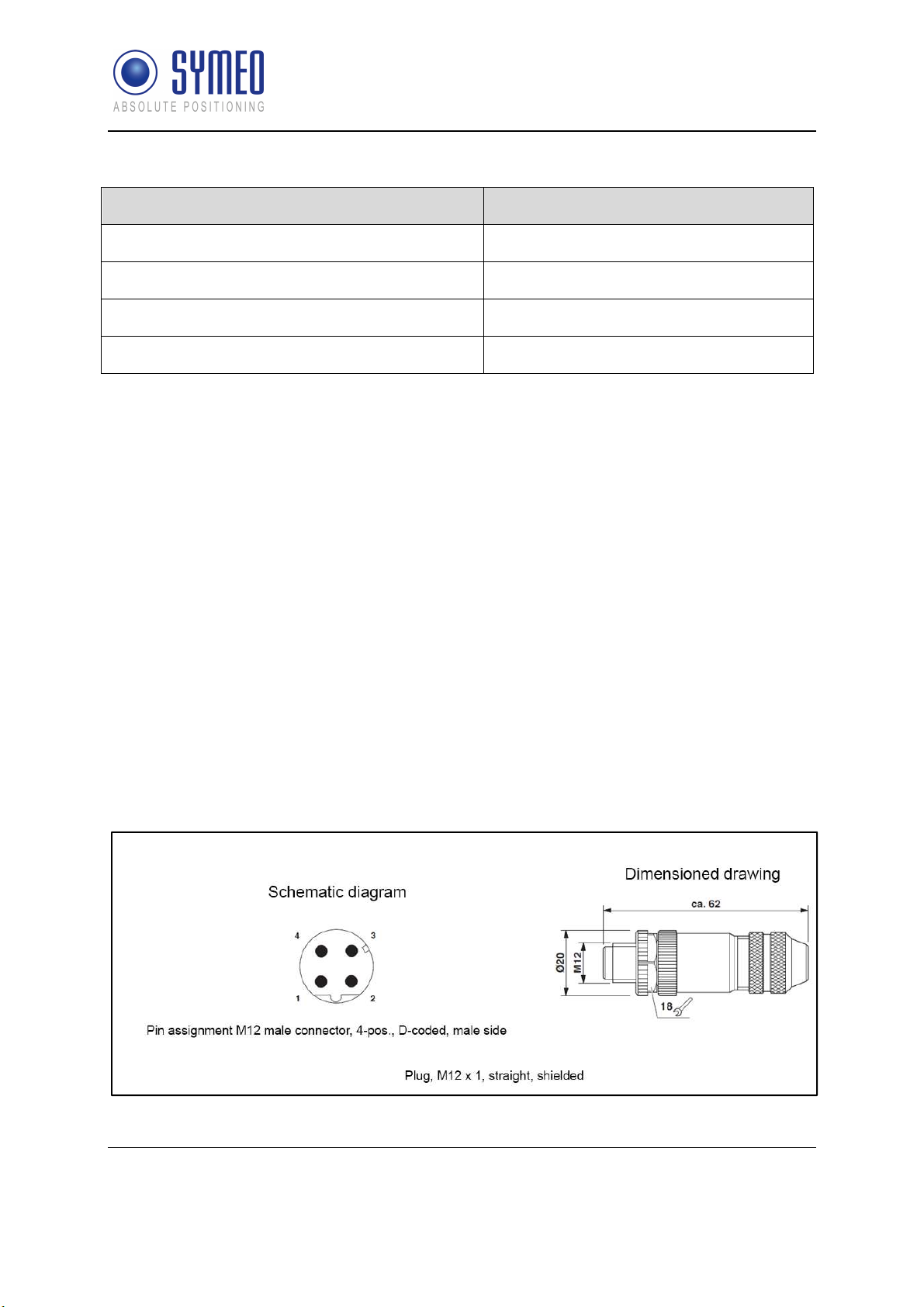

4.3.2 Ethernet M12

The LPR®-1DHP-200 can be connected to a LAN or a Profinet bus system (Production Code

"n" required) via an M12 Ethernet Connector.

Plugs

Recommended connector:

SACC-M12MSD-4CON-PG 7-SH – 1521258

o Cable diameter: 4 – 6 mm (PG7)

Tightening torque: 0.4 Nm

o Symeo order number: MTE101768

o

The connector is also part of the following M12 connector set:

M12 connector set (Ethernet + Power supply)

o Symeo order number: MTE102366

Figure 4.5: M12 Ethernet connector

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 20 of 71

Pin Assignment

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Signal Color of Wire

PROFInet®

TD+ Yellow White/Orange 1

TD- Orange Orange 3

RD+ White White/Green 2

RD- Blue Green 4

Table 4.3: Pin assignment for Ethernet M12

Color of Wire

EIA/TIA 568B

Pin Assignment

If the Ethernet connecter is left unused, install the protective cap of the

connector.

Connector Cable M12 – RJ45

A connector cable M12 – RJ45 (2m) for connecting the radar to a PC for initial

commissioning and configuration is available from Symeo:

Symeo order number: MTE102007

4.4 Mounting Brackets

4.4.1 Mounting Bracket – MTM102513

For mounting the LPR®-1DHP-200 to a pipe, a mounting bracket is available from Symeo.

The pipe diameter should measure between 40 and 75 mm.

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 21 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 4.6: LPR®-1DHP-200 mounted to a pipe with the mounting bracket.

Figure 4.7: MTM102513 dimensions.

Adhere to the following tightening torques for mounting:

LPR®-1DHP-200 to mounting bracket (6x M5 screws): 4Nm

Tube clamp (2x M8 screws): 8Nm

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 22 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

4.4.2 Diversity Mounting Bracket – MTM102512

For mounting two LPR®-1DHP-200 for operation in the diversity radar mode a diversity

mounting bracket is available from Symeo.

Figure 4.8: Two LPR®-1DHP-200 mounted in the diversity mounting bracket.

Adhere to the following tightening torques for mounting:

LPR®-1DHP-200 to mounting bracket (2x 6x M5 screws): 4Nm

Tube clamp (2x M8 screws): 8Nm

4.5 Corner Reflectors

For operation in the primary radar mode different types of corner reflectors used as targets

for the distance measurement are available from Symeo.

4.5.1 Corner reflector 500mm – MTE000958

Corner reflector with edge length 500mm for maximum range.

Figure 4.9: Corner reflector 500mm.

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 23 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

4.5.2 Corner reflector 250mm – MTE001011

Corner reflector with edge length 250mm. Range is reduced to approx. 70% compared to

MTE000958.

Figure 4.10: Corner reflector 250mm.

4.5.3 Mount for corner reflector – MTM000169

For mounting the corner reflector, a pipe mounting bracket is available from Symeo. The pipe

diameter should be between 40 and 75 mm.

Components

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 24 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

5 Mounting

5.1 General Mounting Instructions

Site-specific mounting instructions must be followed if available.

The more accurately the radar units and reflectors are aligned to each other, the better

the performance of the measurement setup will be in terms of accuracy and range.

The radar units and/or corner reflectors must move parallel to the radar beam in the

installation.

Ensure that the Fresnel Zone is free of obstacles.

Ensure that your measured distances lie in the specified measuring range (see chapter

10)

For primary and secondary radar mode (not for diversity radar mode) ensure that

reflective surfaces (e.g. walls, the roof, the floor, crane tracks) and other reflective objects

(e.g. poles, tubes, bridges, vehicles) have the recommended clearance to the center of

the radar beam that is in accordance with

Figure 3.3 and Figure 3.4).

Measuring

distance d in m

Recommended

clearance in m

Table 5.1: Recommended clearance to reflective surfaces and objects.

10 20 30 50 70 100 150 200 250 300

0.2 0.5 0.7 1.1 1.6 2.2 3.3 4.4 5.5 6.6

Table 5.1 (see also

5.2 Mounting for Primary Radar Mode

The Primary Radar Mode is available for Product Types LPR®-1DHP220-R and LPR®-1DHP-290.

Mounting

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 25 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

For a primary radar distance measurement, typically a single radar unit and a recommended

corner reflector are mounted facing each other.

For operation in the primary radar mode the following issues must be considered:

The radar and the corner reflector must be installed in a way that the center of the corner

reflector is aligned with the center of the radar beam.

The reflector has to be either the nearest (first) target or the strongest target to be

detected properly.

Radar and radar reflector must be aligned to each other with maximum accuracy (at least

+/- 2,5°).

Minimum horizontal and vertical offset between radar and reflector must be ensured.

Follow the subsequent steps for proper installation of radar unit and reflector:

Mount a standard mounting bracket on one side of your measurement setup.

Mount the radar into the mounting bracket.

Mount a corner reflector to the other side of your measurement setup.

Mount the corner reflector in a way, that the opening faces the radar. The 3 corners of the

corner reflector opening must have equal distance to the radar.

Carefully align the radar to the corner cube reflector. To do so, it is recommended to use

a laser level fitted into the alignment aid, which should point at the reflector.

Fix the system by tightening the screws of the mounting bracket and the pipe clamp with

the correct tightening torques.

Connect the power supply and Ethernet cable with M12 connectors as specified in

chapter 4.3.1 and 4.3.2.

5.3 Mounting for Secondary Radar Mode

The Secondary Radar Mode is available for Product Types LPR®1DHP-260 and LPR®-1DHP-290.

For a secondary radar distance measurement, two radar units, one configured as a “master”

and one as a “slave” are mounted facing each other in a way, that the center of the emitted

radar beam of each unit hits the other unit. The master unit initiates the measurement while

the slave unit replies.

For operation in the secondary radar mode the following issues must be considered:

The two radar units must be installed in a way, that the center of the emitted radar beam

of each unit hits the other unit.

The two radar units must be oriented exactly equally or turned by 180° along the radar

beam axis (e.g. connectors of both devices facing downwards).

Minimum horizontal and vertical offset between both radar units must be ensured.

Both radar units must be aligned to each other with maximum accuracy (at least +/- 2,5°).

Mounting

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 26 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Follow the subsequent steps for proper installation of the radar units:

Mount a standard mounting bracket to one side of the measurement setup.

Mount the radar unit into the mounting bracket.

Repeat the first two steps on the other side of the measurement setup.

Carefully align both radar units to each other. To do so, it is recommended to use a laser

level fitted into the alignment aids. The laser dot should point to the other sensor for both

directions (Master -> Slave, Slave -> Master).

Fix the systems by tightening the screws of the mounting brackets and the pipe clamps

with the correct tightening torques.

Connect the power supply and Ethernet cable with the M12 connectors as specified in

chapter 4.3.1 and 4.3.2 to both stations. The Ethernet connection at the Slave unit is only

required for configuration and can be removed during operation. If removed install the

protective cap of the connector.

6 Quick Setup

This chapter gives a short introduction for the setup of the radar sensors with the help of the

WebUI. For detailed information on all possible settings, please refer to chapter 8.

6.1 Initial Setup

The following steps must be followed for the initial setup of all radar units:

Mount and align the radar units as outlined in chapter 5.

Connect the radar units to a power source (11 – 36V) and wait until booting is finished

(blue LED switches to red or green).

Connect the radar unit to a PC via Ethernet and open the Webinterface (WebUI) in a

Webbrowser (http://192.168.1.99). See chapter 7 for a detailed description.

Sign in to the WebUI (see chapter 8.2).

Choose country and regulatory authority.

6.2 Quick Setup for Primary Radar Mode

The following settings must be set in the WebUI for operation in primary radar mode:

Device -> Settings -> Measurement basics

o

Station mode = Primary

o

Bandwidth mode = Choose a bandwidth that fits your required range and accuracy

o

Channel block = Use recommended selection

o

Sync channel = different than any other LPR®-1DHP-200 sensor in range; for

neighboring measurement paths use only every fourth sync channel.

Quick Setup

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 27 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Device -> Settings -> Measurement details

o

Target search mode = “First” if the reflector is the first target in range, “Strongest” if

the reflector is the strongest target in range.

The setting “Target search mode” highly impacts the behavior of the radar,

especially in multi target environments (see Figure 8.16). “First target” may

lead to distance measurements to unintended targets in the vicinity of the

radar (e.g. a person passing the radar beam). “Strongest target” may lead

to distance measurements to unintended targets present in the

background of your intended target (e.g. a wall behind a corner reflector).

Perform therefore always a test as described in chapter 6.4 to verify this

setting.

Review and Calibrate your measurement as stated in chapter 6.4.

6.3 Quick Setup for Secondary Radar Mode

The following settings must be set in the WebUI of the master and slave sensor for operation

in secondary radar mode.

Only the Master unit outputs range data.

Master

Device -> Settings -> Measurement basics

o

Station mode = Master

o

Bandwidth mode = Choose a bandwidth that fits your required range and accuracy

o

Channel block = Use recommended selection

o

Sync channel = different than any other LPR®-1DHP-200 sensor in range (except the

related Slave); for neighboring measurement paths use only every fourth sync

channel.

Slave

Device -> Settings -> Measurement basics

o

Station mode = Slave

o

Bandwidth mode = same as Master

o

Channel block = same as Master

o

Sync channel = same as Master

Review and Calibrate your measurement as stated in chapter 6.4.

6.4 Review and Calibration of the Measurement Setup

Diagnostics -> Range measurement statistics -> Live range measurement

Quick Setup

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 28 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

o

Run a warm up phase of 30 minutes before calibration.

o

Compare the “current distance” to the actual distance in your measurement setup for

all ranges.

o

The mean value of the difference between the actual distance and the measured

distance is the reference-offset value, which needs to be added to the current

distance to match the radar’s and installation’s coordinate systems. The radar

therefore offers the setting “Measurements Details -> Customer specific offset”.

o

Make sure that the maximum and standard deviation of the difference between the

offset corrected measured and actual distance meets your accuracy requirements for

all possible distances in your measurement setup.

The LPR®-1DHP-200 are delivered with the fixed TCP/IP IP-Address

192.168.1.99.

7 Establishing a TCP/IP Connection

For configuration of the radar units, a TCP/IP connection has to be set up. Make sure that:

The unit is running.

The radar unit is connected with an appropriate Ethernet cable to a PC or a similar

device, which has a web browser installed.

The radar and the PC are located in the same subnet of the TCP/IP network. That means

that the first three numbers of the radar’s and PC’s IP-addresses must be equal.

No firewall is blocking the communication between PC and radar.

If PC and radar are not located in the same subnet open the TCP/IP network settings of your

network adapter in your operating system. Enter a fixed IP-Address e.g. 192.168.1.1 and the

subnet mask 255.255.255.0.

Establishing a TCP/IP Connection

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 29 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 7.1: Network Settings under Microsoft Windows

The LPR®-unit should be available via your PC now. You can check the connection with a

ping to the LPR®-1DHP-200 unit:

1. Push the Windows Start Button

2. Choose Run (Skip under Windows 10)

3. Enter cmd and confirm

4. Enter: ping 192.168.1.99 or the IP-address of the LPR®-1DHP-200 unit in the cmd.exe

window and confirm

The LPR®-1DHP-200 should answer with a Reply.

Figure 7.2: Ping LPR®-1DHP-200 Unit

For detection of all Symeo devices located in your network (useful if the IP-Address of a

radar unit is unknown), you can download the tool Symeo IP Discover in the Partner Login

under www.symeo.com.

Establishing a TCP/IP Connection

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 30 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8 Device Setup via the Web User Interface

The Web User Interface allows you to change all settings, perform firmware updates, view

system status and diagnostic information and much more.

8.1 Open the Web User Interface

A TCP/IP Connection is required.

Open your web browser. In the address bar of the web browser, enter the IP address of

the LPR®-1DHP-200: e.g. http://192.168.1.99.

The welcome page for the LPR®-1DHP-200 WebUI should appear.

A language selection can be made using the flags in the top right corner of the interface.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 31 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.1: Open Web User Interface

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 32 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8.2 Sign In

In order to be able to change settings a sign in to the WebUI is necessary. Press therefore

“Sign In” in the upper right corner of the WebUI. You will be prompted to enter your

information for authentication. The dialog box with the username and password field will

appear (see Figure 8.2).

Figure 8.2: WebUI Login

Enter the user name "symeo" and the password "54all2u" and press "Login". Now your

status is displayed as "Logged in".

8.3 Initial Operation

When the WebUI is opened for the first time or after a software reset, the note “Environment

uninitialized” will appear (see Figure 8.1).

During the initial operation, you need to configure the operating country, in

which you want to use this unit. This is necessary to abide to the radio

signal restrictions enforced by the local authorities. Your selection will

have impact on the selectable Bandwidth Modes as well as on the

maximum transmit power and hence range of the radar unit.

Since this is a mandatory setting, all functionality of this device will remain

disabled, until the country setting has been successfully configured.

Click the “Configure environment” button to configure the working environment.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 33 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.3: Initial setup of environment of the LPR®-1DHP-200

Select your country to determine the operating environment and confirm it with the “Save”

button (see

Figure 8.3

).

The setting has to be the same on all Symeo devices used in a specific country.

Now activate the settings by clicking the "Activate changes" button (see Figure 8.4).

Figure 8.4: Initial setup of environment - Activate changes

The following window appears:

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 34 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.5: Initial setup of environment - Amend invalid settings

In the top left corner, a red frame appears which indicates that for a functioning measuring

distance, the measurement values, which have not yet been set or which are invalid, are still

to be processed.

Click the “Amend invalid settings” button.

Figure 8.6: Settings window for mandatory values

You will be automatically guided to the settings menu sub-item “Measurement basics”, where

strictly necessary parameters must be set. For further information about these mandatory

settings please refer to the chapter “Device - Settings – Measurement Basics

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 35 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

If you have entered all these settings, click the “Submit Changes” button.

Figure 8.7: Change of mandatory values

8.4 Change Settings, Review and Save Changes

Upon pressing the “Submit Changes” button in any settings sub item, the WebUI is updated

and the choice of valid settings is adapted to your made changes. The settings will however

not be applied to the radar until you “Save all changes” in the the “Review changes” page or

in the top left corner of this page.

You can review your changes by clicking the “Review changes” button in the top left

corner of the homepage or at the bottom of the screen (see Figure 8.8).

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 36 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.8: Save or discard all changes

Confirm the changes by clicking the “Save all changes” button. The dialog box “Changes

have been applied” will appear (see

Figure 8.9

).

If you would like to discard all changes made after the last save, press “Discard all changes”.

After saving, it takes several seconds until the measurement is restartet with the new

settings. Some settings additionally require a reboot of the radar.

Figure 8.9: Changes have been saved

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 37 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8.5 Home Page

On the home page (see Figure 8.10), important information about the LPR®-1DHP-200 is

displayed.

You can always return to the start page if you press on the Symeo symbol in the top

left hand corner of this page.

Figure 8.10: The home page of the LPR®-1DHP-200

On top of every page, the device status is shown (see

Figure 8.11

):

Figure 8.11: WebUI - Device Status

The “Device Status” window shows the status of the Services, of the Interfaces and the

Remote Access status.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 38 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

The service status “Distance measurement” is green, if the measurement is setup

correctly.

This also applies to the Remote Access Option if it is available, configured and

connected.

The interface status “Binary protocol” button turns green if a client is successfully

connected to the customer port.

The “Information overview” window (see Figure 8.12) shows:

Hostname of the LPR®-1DHP-200 unit

IP-address

Application version

Mode: Primary, Master or Slave

System time

Figure 8.12: WebUI Information overview

The “Product properties” window displays:

Model number

Product name

Serial number

Unit production code

o

States the available and active performance features of the purchased product (see

Figure 8.13).

Figure 8.13: WebUI - Product properties

Click the “Unit production code” button under the menu item “Product properties” (see

Figure 8.13). The table with the product features will be displayed.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 39 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

The table below shows a complete list of all features available for this unit (see Figure 8.14).

Figure 8.14: WebUI - Product features

Not all product features can be combined with each other.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 40 of 71

8.1 Device

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

In this menu (see

Figure 8.15

Settings

Upload configuration

Downloads

Firmware update

Factory reset

Reboot device

), the following subpages are available:

Figure 8.15: Device Menu

8.1.1 Device - Settings

In this menu, the following settings are available:

Customer protocol

Forwarding

LAN

Logging

Measurement basics

Measurement details

Modem

Network routes

Relay

Remote access

Timezone

VPN remote access

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 41 of 71

Product Family LPR®-1DHP-200 – Product Documentation

Device - Settings – Customer Protocol

In this menu, the following settings are available:

Mode of customer protocol

o

Interface to customer - either TCP or UDP

Port

o

Port of customer protocol binary XP (Integer number in range 1100..65535)

Protocol frame length

o

Frame length of customer protocol binary XP (Default value 47 bytes). Each data

packet is zero-padded to the selected protocol frame length before the data packet is

sent. (Integer number in range 47..100 byte)

Enable custom output interval

o

Enable a custom output interval of own distance. If disabled, the own measured

distance is output with the internal measurement rate.

Output interval of own distance

o

Output interval of own measured distance in milliseconds (Integer number in range

10..60000 ms)

SYMEO Local Positioning Radar System

Device - Settings – Forwarding

In this menu, the following settings are available:

LAN forwarder (must be first activated by the user)

o

Forward packages via LAN to connected LPR®-1D24 unit

The following extra options will be available after enabling LAN forwarding:

Destination IP address

o

Destination IP address of connected LPR®-1D24 unit

Enable custom forward interval

o

Enable a custom forward interval of own distance. If disabled, the own measured

distance is forwarded with measurement rate

Device - Settings – LAN

In this menu, the following settings are available:

Link type

Address Mode

IP-Address

Netmask

Gateway

Hostname

o

Local hostname, this name will also be offered to the DHCP server in DHCP mode

DNS

o

IP of name server (domain name system)

Syslog

o

IP of server for syslog messages

NTP Server

o

IP or hostname of time server (network time protocol)

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 42 of 71

Product Family LPR®-1DHP-200 – Product Documentation

Device - Settings – Logging

In this menu, the following settings are available:

Logging mode

o

Defines whether unit logs system events and measurements to a storage device.

Stock units do not have a storage device installed and are therefore not

ready for logging.

The following settings are available:

Disabled

Log to SD card if available

Log to USB stick if available (recommended)

Log to USB stick if available, use SD card as fallback

SYMEO Local Positioning Radar System

Device - Settings – Measurement Basics

In this menu, the following settings are available:

Station mode

o

Depending on the configuration the unit can either be run in secondary radar mode

(master measures the distance to slave) or in primary radar mode (radar measures

the distance to a reflective target)

Bandwidth mode

o

The LPR®-1DHP-200 supports different bandwidth modes, which impact the sensors

performance. For best accuracy, choose a large bandwidth. For maximum range and

update rate, choose a small bandwidth.

Channel block

o

The RF frequency range is grouped into several blocks. Each channel block defines a

set of available sync channels. It is recommended to keep the default value for

optimum performance

Sync channel

o

The sync channel determines the actual center frequency and bandwidth of the radar

signals and differentiates the LPR®-1DHP-200 links. The sync channel has to be the

same for a pair of master and slave but different than that of any other LPR®-1DHP200 device in range. The sync channel with the lowest number provides the highest

bandwidth in each channel block.

Changing bandwidth mode, channel block or sync channel influences the

sensors performance and reference plane. A recalibration and test of the

installation (see chapter 6.4), is therefore necessary after changing these

settings.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 43 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Device - Settings – Measurement Details

The available measurement details settings depend on your selected radar mode:

Measurement Details for Primary Radar Mode

In this menu, the following settings are available:

Customer specific offset

o

The offset can be used to calibrate the reference plane for the distance

measurements according to the customer’s setup. The value is added to the

measured distance.

Average spectra

o

Spectra can be averaged before applying the peak search algorithm. Averaging more

spectra will reduce the noise but it will also reduce the measurement rate.

Peak search mode

o

The radar will either detect the first or the strongest target above the thresholds

defined below.

Start target range

o

This parameter defines the start of the target search area. Targets below this distance

will be ignored.

Minimum level short range

o

This parameter defines the required minimum level for valid targets in the short range

area. Targets with a lower signal level will be ignored.

End short range

o

This parameter defines the end of the short range area where the respective

minimum level is required for valid targets.

Minimum level mid range

o

This parameter defines the required minimum level for valid targets in the long range

area. Targets with a lower signal level will be ignored.

End mid range

o

This parameter defines the end of the mid range area where the respective minimum

level is required for valid targets.

Minimum level long range

o

This parameter defines the required minimum level for valid targets in the long range

area. Targets with a lower signal level will be ignored.

End long range

o

This parameter defines the end of the long range area where the respective minimum

level is required for valid targets.

FFT size

o

The maximum range and update rate of the sensor is limited internally by the FFT

size. For maximum range, choose the large FFT. For maximum update rate, choose

the small FFT.

Maximum occurring speed

o

The maximum occurring speed is used internally to validate the measurement results.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 44 of 71

Kalman filter

o

The Kalman filter reduces the noise of the distance measurement output for standard

measurement setups with linear motion. For non-standard applications in primary

radar mode it may be advantageous to disable the filter.

Raw data output

o

Raw data can be provided by the unit for further analysis.

Raw data mode

o

Depending on the configuration the unit can provide raw ADC data, FFT spectra

and/or the configured threshold values.

Raw data rate

o

The raw data rate can be used the scale the amount of data which has to be

recorded. Data is sent every n measurements.

RX attenuator mode

o

The RX attenuator can be enabled when the received signal is too strong.

VGA value

o

The VGA value determines the power of the transmitted signal.

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

The LPR®-1DHP-200 in primary radar mode can either output the distance to the first or the

strongest valid target. A target is valid, if its signal level is higher than a set signal level

threshold level profile, which is segmented into 3 range zones (short range, mid range, long

range). The start and end positions of the 3 range zones and their corresponding signal

threshold levels can be configured individually with the settings described above. An

example of the radar target spectrum (target signal strength vs. distance) recorded in a multi

target environment is shown in where the window for valid targets defined by the range

zones and their threshold levels is marked green. Targets outside of this window will be

ignored.

A change of the range zones and their threshold level settings is only necessary in a multi

target environment and should only be conducted by trained personal.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 45 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.16: Radar target spectrum in a multiple target environment

Measurement Details for Secondary Radar Mode

In this menu, the following settings are available:

Customer specific offset (only Master mode)

o

This offset can be used to calibrate individual LPR® links to account for tolerances. It

is added to the measured distance

Minimum level

o

This parameter defines the required minimum level for valid measurements in

secondary radar mode. Measurements with a lower signal level will be discarded

Maximum occurring speed (only Master mode)

o

The maximum occurring speed is used internally to validate the measurement results

Diversity mode (only Master mode)

o

In diversity mode the measurement results of two LPR®-1DHP-200 units are

combined for optimum performance

Raw data output

o

Raw data can be provided by the unit for further analysis

RX attenuator mode

o

The RX attenuator can be enabled when the received signal is too strong.

VGA value

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 46 of 71

o

The VGA value determines the power of the transmitted signal.

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 47 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Measurement Details for Diversity Radar Mode

For diversity radar mode, you must enable the “Diversity mode” setting under the Settings ->

Measurement details. The following settings will additionally appear:

Diversity partner IP address

o

In diversity mode the unit will connect to the diversity partner at the specified IP

address.

Diversity partner sync channel

o

The sync channel of the diversity partner unit must also be specified. It is used

internally to verify data from the correct partner unit is received.

Device - Settings – Modem

In this menu, the following settings are available:

PPP Point to Point protocol connection

APN address

APN username

APN password

Device - Settings – Network Routes

In this menu, you can adapt the network routes.

Click the “+ add route” button.

The dialog box “add route” will appear.

Press the „add route” button.

Device - Settings – Relay

In this menu, the following setting are available:

Relay data output

o

Relay switch commands can be used to control relays at other LPR® units, e.g. at

LPR®-1D24 devices

If the “Relay data output” is enabled, the following settings will additionally appear:

Relay destination address

o

LPR®-B address of destination device where the relays are switched (hex value)

Zone 1 distance

o

Relays assigned to zone 1 will open when measured distance is below this value

Zone 2 distance

o

Relays assigned to zone 2 will open when measured distance is below this value

The virtual relays 1-4 can be assigned to switch according to system health, Zone 1 state or

Zone 2 state.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 48 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Device - Settings – Remote Access

This function allows to configure a VPN-access if required.

In this menu, the following setting are available:

HTTP

OpenVPN Client

If you disable http, the access to the WebUI of this unit will be disabled.

An access to the WebUI is then only possible via HTTPS.

Device - Settings – Timezone

In this menu, the following settings are available:

NTP Server

o

IP or hostname of time server (network time protocol)

Timezone

o

Must be set to custom timezone if needed timezone is not in the dropdown menu

Custom timezone

o

Needs to be filled if customer specific timezone is used.

Device - Settings – VPN Remote Access

In this menu, the following settings are available:

Settings:

o

OpenVPN Client - enabled / disabled

o

PPP - enabled / disabled

o

APN address

o

APN username

o

APN password

Current VPN certificate

o

Certificate name

Change VPN certificate

o

Choose new certificate

The certificate must be an All-In-One certificate. All keys and certificates must be

contained in the same file.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 49 of 71

Product Family LPR®-1DHP-200 – Product Documentation

8.1.2 Device - Upload Configuration

SYMEO Local Positioning Radar System

In this menu (see

Figure 8.17

), you can upload a local configuration file:

Figure 8.17: Device - Application Settings

Click the “Browse” button to choose a local configuration file for upload.

Click the “Upload configuration” button to upload your configuration.

8.1.3 Device - Downloads

In this menu, you can download several files from the unit:

Settings - downloads settings of this unit (all configuration parameters)

Profinet GSDML file - downloads Profinet GSDML file (if Profinet available)

8.1.4 Device - Firmware Update

In this menu (see

Use the „Browse“ button to find the firmware file provided by Symeo and press “Upload

firmware“.

Press “Flash Firmware” (see

Wait until firmware update and automatic reboot are finished.

Figure 8.18

), you can update the firmware:

Figure 8.19

Figure 8.18: Device - Firmware update

)

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 50 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.19: Device - Device configuration - Firmware update success message

All stations that measure or forward together should have the same

firmware version.

8.1.5 Device - Factory Reset

In this menu, (see Figure 8.20), you can restore factory settings.

Figure 8.20: Device - Factory Reset

All settings are reset by restoring factory settings.

8.1.6 Device - Reboot Device

In this menu (see Figure 8.21), you can reboot the device:

Reboot the device

Figure 8.21: Device - Reboot Device

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 51 of 71

8.2 Diagnostics

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

In this menu (see

Figure 8.22

), the following subpages are available:

Operating System Status

Hardware Status

Storage device

Range measurement statistics

Record measurement data

Packet inspector

Station scan

Figure 8.22: Diagnostics Menu

8.2.1 Diagnostics – Operating System Status

Under this menu (see Figure 8.23), following information is available:

Device information

Uptime, Memory

Networking information

Filesystem

Software version

In case of problems, this information may be requested by Symeo support.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 52 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Figure 8.23: Diagnostics - Operating System Status

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 53 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8.2.2 Diagnostics – Hardware Status

In this menu (see Figure 8.24), system values and system voltages are displayed.

In case of problems, this information may be requested by Symeo support.

Figure 8.24: Diagnostics - Hardware Status

This display is automatically refreshed every 5 seconds.

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 54 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

8.2.3 Diagnostics – Storage Devices

Here (see Figure 8.25) you can see available storage devices and format them if necessary.

Figure 8.25: Diagnostics - Storage Devices

8.2.4 Diagnostics – Range Measurement Statistics

This section (see Figure 8.26) allows you to view raw measurements and range statistics.

Please select a topic from the menu on the left (see Figure 8.26) to view the

corresponding information:

Live range measurement

Signal strength statistics

Measurement rate statistics

Figure 8.26: Diagnostics - Range Measurement Statistics

Device Setup via the Web User Interface

Copyright © Symeo GmbH 2018

DOC.EDO.000341.WORK.EN_LPR-1DHP-200_Product-Documentation.docx

Page 55 of 71

SYMEO Local Positioning Radar System

Product Family LPR®-1DHP-200 – Product Documentation

Live Range Measurement

In this menu (see Figure 8.27), the current distance and the current RSSI value (Signal

strength) will be displayed, furthermore, the distance over time graph.