Page 1

(2)

(1)

Revision A January 2006

72-70762-01

Only RJ-45 data connectors should be connected to these sockets.

•The Power Injector Data In and Data & Power Out ports are shielded RJ-45 sockets.

the Power Injector to that particular outlet.

voltage indicated on the label is different from the power outlet voltage, do not connect

•A volatge mismatch can cause equipment damage and could pose a fire hazard. If the

1.5A international) is used on the phase conductor.

protection. Ensure a fuse or circuit breaker no larger than 120 VAC, 3A U.S. (240VAC,

power source.

power source.

connected to SELV interfaces on other equipment.

Extra-Low Voltage) circuits according to to IEC 60950. These interfaces can only be

rated current capcity of 5A [or a minimum wire gauge of 18AWG (0.75mm²)].

Injector connection) and on the other end by a plug containing a ground (earth) contact.

ground conductor) terminated on one end by an IEC 60320 appliance coupler (for Power

certified, as appropriate, for the country of operation.

•This product relies on on the building installation for short-circuit (over current)

•Follow basic electricity safety measures whenever connecting the Power Injector to its

• Read the installation instructions before connecting the Power Injector to a

Warnings

•This Power Injector Installation Guide (72-70762-01)

• The Power Injector Data and Data & Power interfaces are qualified as SELV (Safety

• The AC wall-socket outlet must be near the Power Injector and easily accessible.

• The power cord must be rated for a minimum of 250VAC RMS operation, with a minimum

• Power Injector (pt # AP-PSBIAS-1P2-AFR)

representative. The packages should contain the following:

Inspect the package contents and report any missing or damaged items to your sales

Outside Spain

Inside Spain

+44 118 945 7360

Contact local distributor or call

+1-954-255-2610 Outside US

1-800-347-0178 Inside US

Verifying Package Contents

• The power cord must be a three-conductor type (two current carrying conductors and one

•A power cord is not supplied with the device. Use only a correctly rated power cord that’s

•Only trained and qualified personnel should install and remove the Power Injector.

installation and use of the device. Also, review standard practices for preventing accidents.

Before operating any equipment, review this document for any hazards associated with

Safety Information

documentation derived from site survey and site network analysis.

procedures. For detailed site-specific installation procedures, refer to the site-specific

during the installation process. This guide does not provide site-specific installation

installation concepts. This guide provides specifications, procedures and guidelines to use

It assumes the technician is familiar with basic Ethernet LAN-based networking and device

This guide is intended for the technician responsible for installing the Symbol Power Injector.

Installation Guide

1-Port Power-over-Ethernet

Power Injector

Canada 905-629-7226

1-631-738-2400

To the Installer

For the latest version of this guide go to: http://www.symbol.com/manuals/

Distributor Operations

Europe/Mid-East

Sales Support

Latin America

Sweden/Sverige 84452900 +34 91 324 40 00

South Africa 11-8095311 Spain/España 91 324 40 00

Netherlands/Nederland 315-271700 Norway/Norge +47 2232 4375

Italy/Italia 2-484441 Mexico/México 5-520-1835

France 01-40-96-52-21 Germany/Deutschland 6074-49020

Denmark/Danmark 7020-1718 Finland/Suomi 9 5407 580

Australia 1-800-672-906 Austria/Österreich 1-505-5794-0

United Kingdom 0800 328 2424 Asia/Pacific +65-6796-9600

United States 1-800-653-5350

contact the Symbol Support Center:

facility’s Technical or Systems Support. If there is a problem with the equipment, they will

applications. If you have a problem running your unit or using your equipment, contact your

Before using the unit, it must be configured to operate in the facility’s network and run your

Service Information

Introduction

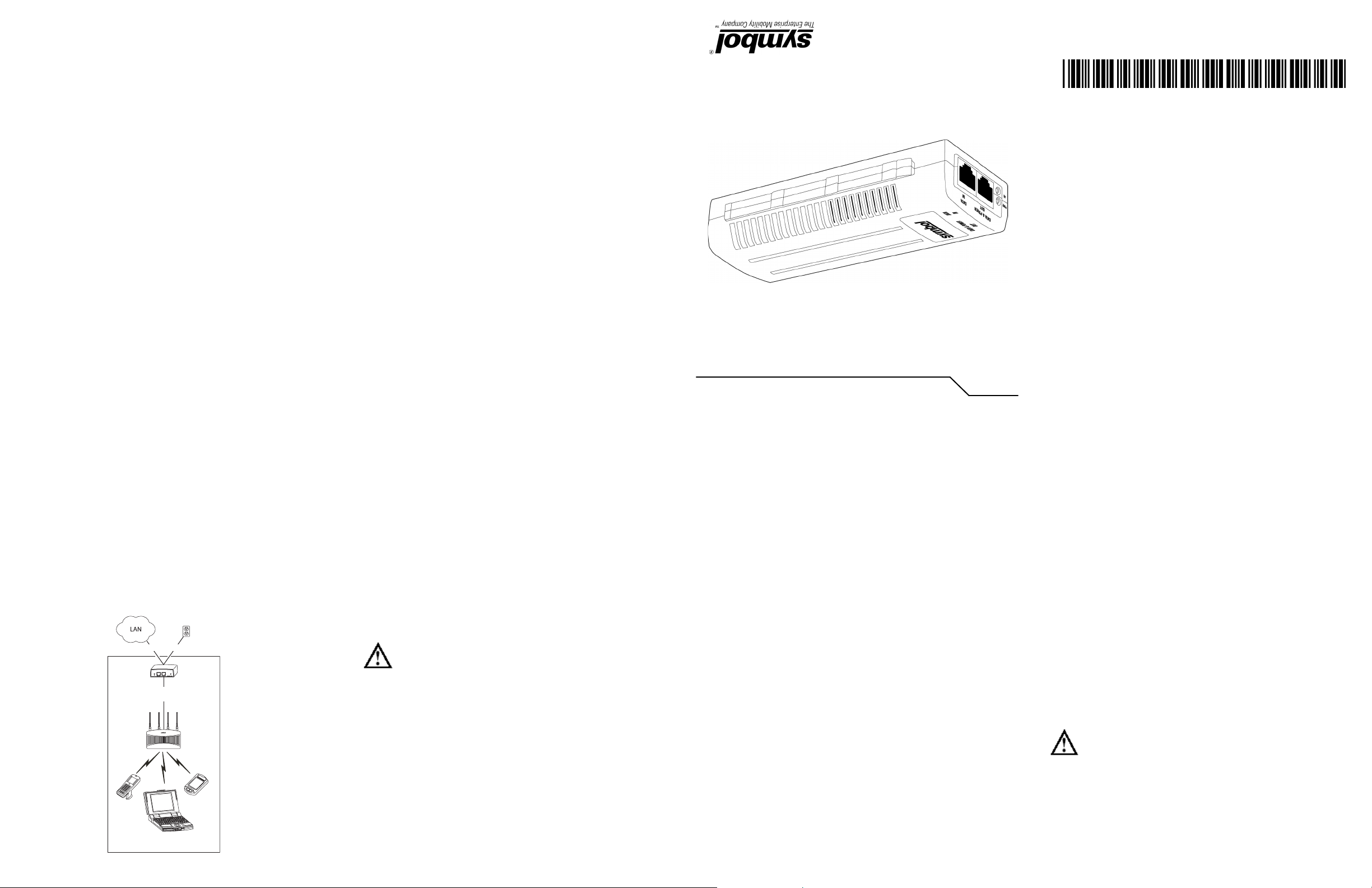

When users purchase a Symbol WLAN solution, they often need to place access points in

obscure locations. In the past, a dedicated 24-hour, 90-264 VAC power source was required for

each access point in addition to the Ethernet infrastructure. This often required an electrical

contractor to install power drops at each access point location. With the Symbol Power Injector

solution (pt # AP-PSBIAS-1P2-AFR), centralized power can be provided for devices without a

local power supply for each.

Product Description

The Symbol Power Injector (pt # AP-PSBIAS-1P2-AFR) is a single-port, 802.3af compliant Power

over Ethernet hub combining low-voltage DC with Ethernet data in a single cable connecting

to an AP. The Power Injector’s single DC and Ethernet data cable creates a modified Ethernet

cabling environment eliminating the need for separate Ethernet and power cables.

Data Power

Power

Injector

to AP-5131 LAN

Port

AP-5131

Wireless LAN

(3) (4) (5) (6)

The Power Injector is a small lightweight unit with a RJ-45 Ethernet cord input connector from

the hub on the front right-hand side of the unit and a RJ-45 data and power output connector

to the AP on the front left-hand side of the unit. On the back of the unit is a 110-220 VAC power

input.

A separate Power Injector is required for each device comprising the network.

The Symbol Power Injector supports the following Symbol device product families (all models

of the those listed):

•AP 100

•AP 200

•AP 300

•AP-5131

Caution - Using the Power Injector with an unsupported Symbol device could

render the device inoperable and void your warranty.

The Power Injector has the following features:

•Independent power controller (SPEAR™), CPU controller and input (Data) and output

(Data + Power) shielded RJ-45 connectors

•Supports standard 10/100BaseT Ethernet networks over a standard TIA/EIA-568

Category 5 (or higher) cabling

•Meets the IEEE 802.3af standard

•Universal AC Input: 110/220 V, 60/50 Hz.

•Minimum port output continuous allowable power of 15.4W at 48V

(minimum 12.95W at the PDTE)

•Underload, overload, short-circuit & under/over voltage port protection.

•Port Status and Main power LED indicators

•Standalone or wall mount installation support

• Interconnection option with other Power Injector units.

Technical Specifications

Physical Specifications

Width 58.5mm

Height 31mm

Depth 145mm

Weight 450gr

Environmental Specifications

Operating Temperature 0°C to 40°C (32°F to 104°F)

Storage Temperature -20°C to 70°C (-4°F to 158°F)

Operating Humidity 10% to 93% Non-condensing

Storage Humidity 10% to 93% Non-condensing

Electrical Specifications

Input Voltage 90VAC to 264VAC (47Hz - 63Hz)

Maximum Output Power .15.4 W

Nominal Output Voltage 48VDC

Ethernet Interface

Input (Data In) Ethernet 10/100Base-T

(RJ-45 female socket)

Output (Data & Power Out) Ethernet 10/100Base-T, plus 48VDC

RJ-45 female socket, with DC voltage

on pairs 7-8 and 4-5

Installation

Preparing for Site Installation

The Power Injector can be installed free standing, on an even horizontal surface or wall

mounted using the power injector’s wall mounting key holes.

The following guidelines should be adhered to be fore cabling the Power Injector to the Ethernet

source and Symbol device:

•Verify the device receiving converged power and Ethernet from the Power Injector is a

product approved by Symbol (AP100, AP200, AP300 and AP-5131).

•Do not block or cover airflow to the Power Injector.

•Keep the Power Injector away from excessive heat, humidity, vibration and dust.

•The Power Injector is not a repeater, and does not amplify the Ethernet data signal. For

optimal performance, ensure the Power Injector is placed as close as possible to the

network data port. Do not configure the cable length between the Ethernet network

source, the Power Injector and the Symbol AP beyond 100 meters (333ft).

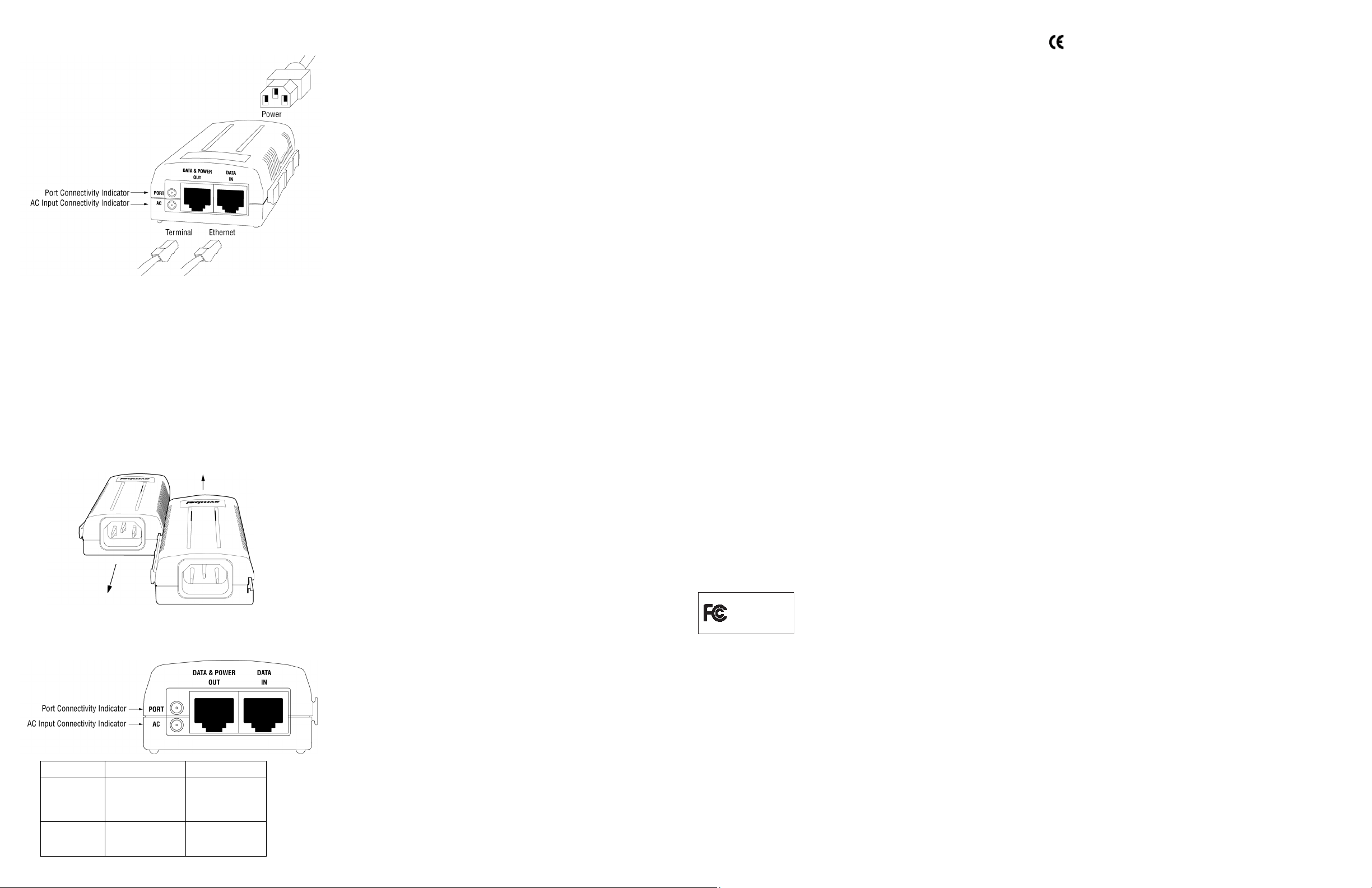

Cabling the Power Injector

To install the Power Injector to an Ethernet data source and Symbol device:

Caution - Ensure AC power is supplied to the Power Injector using an AC cable

with an appropriate ground connection approved for the country of operation.

1. Connect the Power Injector to an AC outlet (110VAC to 220VAC).

2. Connect RJ-45 Ethernet cable between the network data supply (host) and the Power

Injector Data In connector.

3. Connect a RJ-45 Ethernet cable between the Power Injector Data & Power Out connector

and the Symbol device receiving converged power and Ethernet.

Page 2

Ensure the cable length from the Ethernet source (host) to the Power Injector and Symbol

device receiving converged power and Ethernet does not exceed 100 meters (333 ft).

The Power Injector has no On/Off power switch. The Power Injector receives power and is

ready for Symbol device connection and operation as soon as AC power is applied.

Multiple Power Injector Installations

Each Power Injector has a coupling rail designed to connect Power Injectors together to support

multiple device installations. Align the power injectors and slide the units together using the

coupling rail to connect the units. Cable each device as described in the Cabling the Power

Injector section of this document. Only one Symbol device (AP 100, AP 200, AP 300 or

AP-5131) can be powered from a single Power Injector.

Troubleshooting

The following potential Power Injector problem scenarios should be addressed as follows:

Power Injector does not power up properly

1. Verify the power cord power cord is operational for the intended country of operation

2. Verify the voltage at the power inlet is between 100 and 240 VAC.

3. Remove and reapply power to the Power Injector and verify the LED behavior during the

powering sequence.

A Power Injector port indicator is not illuminated and the Symbol AP does

not operate

1. The Power Injector did not detect the AP and thus the port is not enabled.

2. Ensure you are using a standard 5/5e/6, straight-wired cable with four pairs.

3. Verify the input Ethernet cable is connected to the Power Injector Data In port.

4. Verify the Symbol AP is connected to the Power Injector Data & Power port.

5. Reconnect the Symbol AP to a different Power Injector. If the AP receives power, there

is probably a faulty port or RJ-45 connection on the Power Injector.

6. Verify there is not a short over any of the twisted pair cables or over the RJ-45

connectors.

Symbol AP receives power but no Ethernet

1. Verify the Ethernet cable is connected to an active hub or switch port on the network.

2. Verify the port indicator on the front panel is continuously illuminated.

3. Verify you are using a standard UTP/FTP Category 5 straight (non-crossover) cabling

with all four pairs.

4. Ensure the Ethernet cable length is less than 100 meters from the Ethernet data source

to the Power Injector.

5. Reconnect the Symbol AP to a different Power Injector. If the AP receives power, there

is probably a faulty port or RJ-45 connection on the Power Injector.

International Contacts

Outside North America, contact Symbol at:

Symbol Technologies, Inc.

Symbol Place

Winnersh Triangle, Berkshire, RG41 5TP

United Kingdom

Telephone: 0800-328-2424 (Inside UK), +44 118 945 7529 (Outside UK)

For other sales offices, use the Symbol Services Web site for contact information

http://www.symbol.com/services/howto/howto_contact_us.html

Web Support sites

Comprehensive On-line support is available at the MySymbolCare Web-site. Registration is free

and a variety of services can be linked through this Web-portal.

MySymbolCare - RMA repair requests

http://www.symbol.com/services/msc/msc.html

Symbol Services Homepage

http://www.symbol.com/services/

Symbol Software Updates

http://www.symbol.com/services/downloads/

Symbol Developer Program Web Site

http://devzone.symbol.com/

Additional Information

Obtain additional information by contacting Symbol at:

• 1-800-722-6234, inside North America

• +1-631-738-5200, in/outside North America

• http://www.symbol.com/

Marking and European Economic Area (EEA)

Statement of Compliance

Symbol Technologies, Inc., hereby declares that this device is in compliance with all the

applicable Directives, 89/336/EEC, 73/23/EEC. A Declaration of Conformity may be obtained

from http://www2.symbol.com/doc/

Copyright

Copyright © 2006 by Symbol Technologies, Inc. All rights reserved.

No part of this publication may be modified or adapted in any way, for any purposes without

permission in writing from Symbol Technologies (Symbol). The material in this guide is subject

to change without notice. Symbol reserves the right to make changes to any product to improve

reliability, function or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of this product, circuit, or application described herein.

No license is granted either expressly or by implication, estoppel, or otherwise under any

Symbol Technologies, Inc., intellectual property rights. No license is granted, either expressly

or by implication estoppel, or otherwise under any patent right or patent, covering or relating

to any combination, system, apparatus, machine, material, method or process in which Symbol

products might be used. An implied license exists only for equipment, circuits and subsystems

contained in Symbol products.

Symbol and the Symbol logo are registered trademarks of Symbol Technologies, Inc. Other

product names mentioned in this guide may be trademarks or registered trademarks of their

respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Patents

This product is covered by one or more of the patents listed on the Web site:

www.symbol.com/patents

(7) (9) (11) (13)

Power Injector LED Indicators

The Power Injector demonstrates the following LED behavior under normal and/or problematic

operating conditions:

LED AC (Main) Port

Green (Steady) Power Injector is receiving

Green (Blinking) Output voltage source is

power from AC outlet

out of range

Indicates a device is

connected to the

Power Injector’s outgoing

Data & Power cable

The Power Injector is

overloaded or has a

short circuit

(8) (10) (12) (14)

Customer Support

Symbol Technologies provides its customers with prompt and accurate customer support. Use the

Symbol Support Center as the primary contact for any technical problem, question or support issue

involving Symbol products. If the Symbol Customer Support specialists cannot solve a problem,

access to all technical disciplines within Symbol becomes available for further assistance and

support. Symbol Customer Support responds to calls by email, telephone or fax within the time

limits set forth in individual contractual agreements.

When contacting Symbol Customer Support, please provide the following information:

• Serial number of unit

• Model number or product name

• Software type and version number

North American Contacts

Inside North America, contact Symbol at:

For sales and product information:

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

Telephone: 1-631-738-2400/1-800-SCAN 234

Fax: 1-631-738-5990

For product support and service:

Symbol Global Support Center:

Telephone: 1-800-653-5350, +1-631-738-6213 (Outside North America)

Fax: 631-563-5410

Email: support@symbol.com

Or see the Symbol Web for additional local contact numbers http://www.symbol.com/services/

contactsupport

Regulatory Information

All Symbol devices are designed to comply with rules and regulations in locations they are sold

and will be labeled as required. Any changes or modifications to Symbol Technologies equipment,

not expressly approved by Symbol Technologies, could void the user’s authority to operate the

equipment.

Local language translations are available at the following website:

http://www.symbol.com/services/manuals/.

EMI Compliance: Category 5 foiled twisted-pair cables must be used to ensure compliance with

Class B emission limits.

Radio Frequency Interference Requirements

Symbol Technologies Inc.

Tested to Comply

With FCC Standards

For Home or Office Use

radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected

• Consult the dealer or an experienced radio/TV technician for assistance

Radio Frequency Interference Requirements – Canada

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Note: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate

Loading...

Loading...