Page 1

PDT 7500 Series

PRELIMINARY

Page 2

PDT 7500 Series

1999-2000 SYMBOL TECHNOLOGIES, INC. All rights reserved.

Symbol reserves the right to make changes to any product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under

any patent right or patent, covering or relating to any combination, system, apparatus,

machine, material, method, or process in which Symbol products might be used. An

implied l icen se on ly ex ists for e quip ment, circ uits, and subs ystems cont ained in S ymbo l

products.

Symbol is a registered trademark of Symbol Technologies, Inc. Other product names

mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Patents

This product is covered by one or more of the following U.S. and foreign Patents:

U.S. Patent No.4,387,297; 4,460,120; 4,496,831; 4,593,186; 4,603,262; 4,607,156;

4,652,750; 4,673,805; 4,736,095; 4,758,717; 4,816,660; 4,845,350; 4,896,026;

4,897,532; 4,923,281; 4,933,538; 4,992,717; 5,015,833; 5,017,765; 5,021,641;

5,029,183; 5,047,617; 5,103,461; 5,113,445; 5,130,520; 5,140,144; 5,142,550;

5,149,950; 5,157,687; 5,168,148; 5,168,149; 5,180,904; 5,216,232; 5,229,591;

5,230,088; 5,235,167; 5,243,655; 5,247,162; 5,250,791; 5,250,792; 5,260,553;

5,262,627; 5,262,628; 5,266,787; 5,278,398; 5,280,162; 5,280,163; 5,280,164;

5,280,498; 5,304,786; 5,304,788; 5,306,900; 5,321,246; 5,324,924; 5,337,361;

5,367,151; 5,373,148; 5,378,882; 5,396,053; 5,396,055; 5,399,846; 5,408,081;

5,410,139; 5,410,140; 5,412,198; 5,418,812; 5,420,411; 5,436,440; 5,444,231;

5,449,891; 5,449,893; 5,468,949; 5,471,042; 5,478,998; 5,479,000; 5,479,002;

5,479,441; 5,504,322; 5,519,577; 5,528,621; 5,532,469; 5,543,610; 5,545,889;

5,552,592; 5,557,093; 5,578,810; 5,581,070; 5,589,679; 5,589,680; 5,608,202;

5,612,531; 5,619,028; 5,627,359; 5,637,852;5,664,229; 5,668,803; 5,675,139;

5,693,929; 5,698,835; 5,705,800; 5,714,746; 5,723,851; 5,734,152; 5,734,153;

5,742,043; 5,745,794; 5,754,587; 5,762,516; 5,763,863; 5,767,500; 5,789,728;

5,789,731; 5,808,287; 5,811,785; 5,811,787; 5,815,811; 5,821,519; 5,821,520;

5,823,812; 5,828,050; 5,850,078; 5,861,615; 5,874,720; 5,875,415; 5,900,617;

5,902,989; 5,907,146; 5,912,450; 5,914,478; 5,917,173; 5,920,059; 5,923,025;

5,929,420; 5,945,658; 5,945,659; 5,946,194; 5,959,285; 6,002,918;D305,885;

PRELIMINARY

D341,584; D344,501; D359,483; D362,453; D363,700; D363,918; D370,478;

D383,124; D391,250; D405,077; D406,581; D414,171; D414,172, D419,548.

Invention No. 55,358; 62,539; 69,060; 69,187 (Taiwan); No. 1,601,796; 1,907,875;

1,955,269 (Japan).

European Patent 367,299; 414,281; 367,300; 367,298; UK 2,072,832; France 81/

03938; Italy 1,138,713.

rev. 03/00

Page 3

Quick Reference

Introduction

The PDT 7500 Series family of portable data terminals puts the

processing power of a 486 PC in the user’s hand. The terminal uses

a rechargeable Lithium-Ion 1400 mAh smart battery, and

incorporates pen technology and bar code scanning capability in a

key-based terminal.

The PDT 7500 ruggedized hand-held terminal combines:

• PC-standard architecture (32-bit 486 DX2)

• Microsoft

• Wireless communication capability using Symbol’s wireless

LAN technology

• An optional integrated Wireless Wide Area Network

(WWAN) cellular radio

• Integrated laser scanning capability (1- and 2-Dimensional)

• 35-key keypad for key input

• Touch screen

• IrDA-compliant interface for printi ng an d comm unica tion s .

®

MS-DOS 6.22 or Windows® CE OS

PRELIMINARY

1

Page 4

PDT 7500 Series

About This Guide

This guide provides informat ion on the o peratio n of th e PDT 7500

Series terminal. Specifically, the following topics are discussed:

• Parts of the PDT 7500 on page 3

• Installing New or Recharged Batteries on page 5

• Operating the PDT 7500 on page 8

• Using the PDT 7500 Keypad on page 11

• Using the Integrated Laser Scanner on page 12

• Host Communications on page 15

• Using the Touch Screen on page 16

• Troubleshooting on page 16.

Accessories

Each PDT 7500 requires one 1400 mAh Li-Ion battery (p/n 2138602-06). The following optional accessories are available from

Symbol Technologies:

• Additional Li-Ion battery

• Stylus for performing pen functions

• Single-slot cradle

• Four-slot cradle

• Vehicle cradle

• IrDA compliant printer

• UBC 2000 charging adapter

• Null modem c able

•Holster.

PRELIMINARY

2

Page 5

Quick Reference

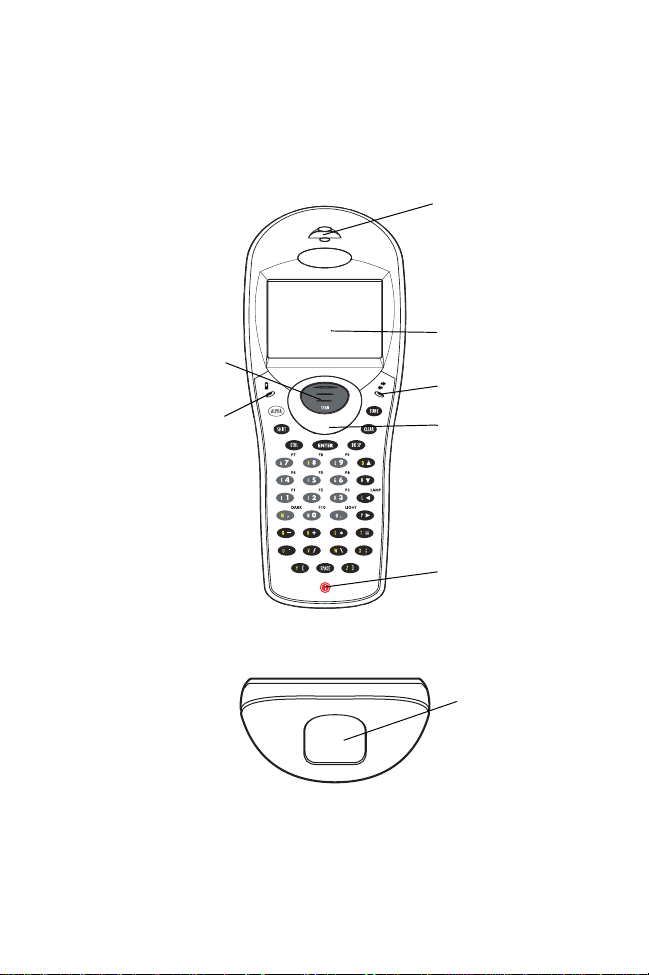

Parts of the PDT 7500

Front View

Scan Button

Battery Charge

LED

Top V i ew

Scan LED

LCD

Communication LED

Thumb Rest

Power Key

Scan Window

PRELIMINARY

3

Page 6

PDT 7500 Series

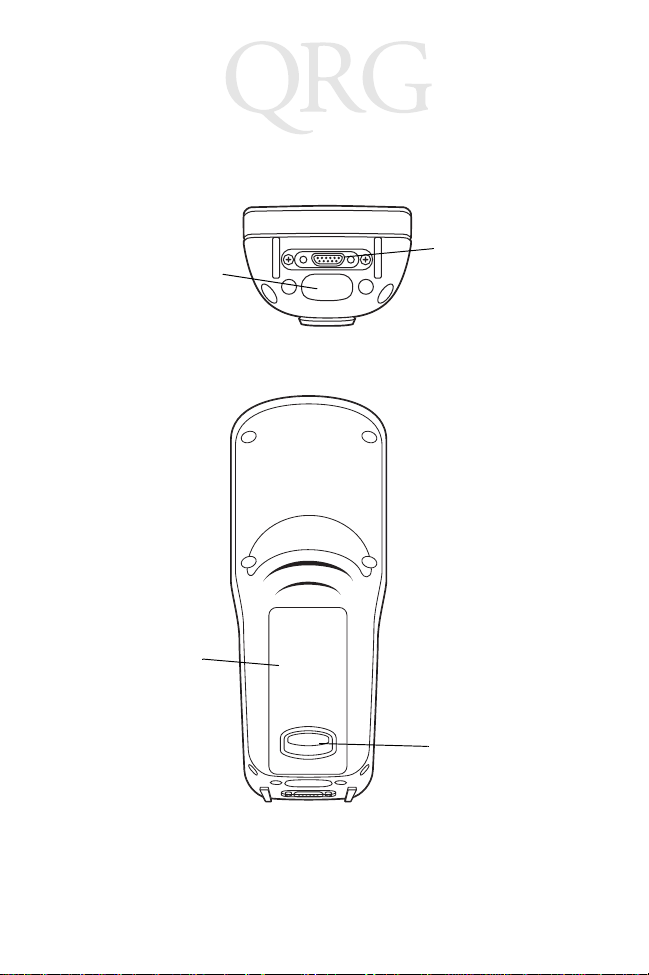

Parts of the PDT 7500 (continued)

Bottom View

IrDA Port

Back View

Li-Ion Battery

Serial

Communications

Port

Battery Latch

PRELIMINARY

4

Page 7

Quick Reference

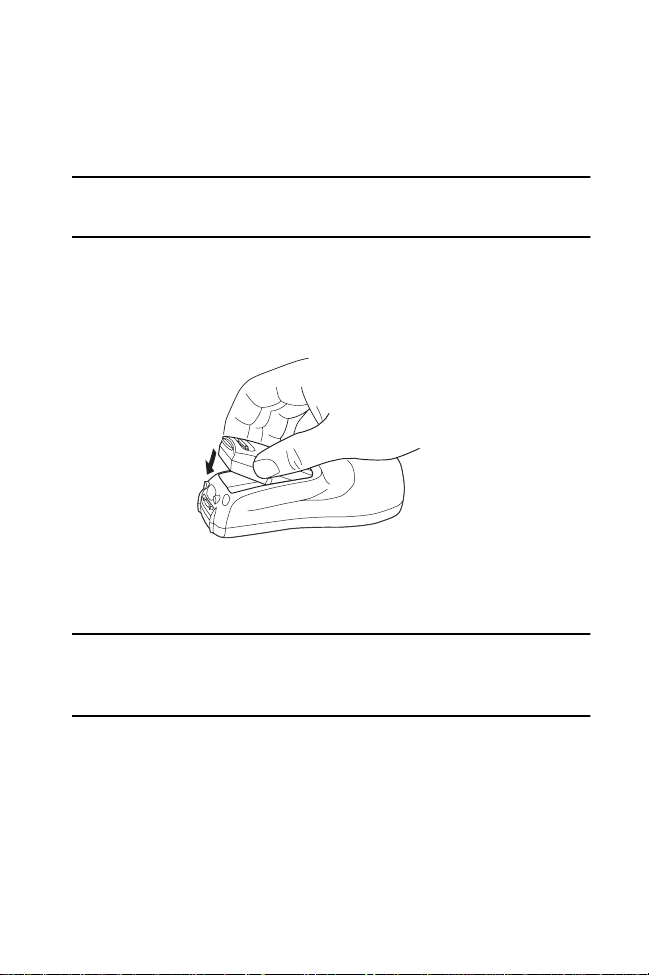

Installing New or Recharged Batteries

Caution: To ensure proper terminal operation, use ONLY the

Symbol Li-Ion battery in the PDT 7500.

To install a new or recharged Li-Ion battery:

1. Hook the base of the new battery in the top of the battery

compartment, then press the into place.

2. Slide the battery latch to secure the battery.

If the battery latch is not closed, do not operate the terminal,

otherwise data may be lost.

Caution: Do not expose the battery to temperatures in excess of

140°F (60°C). Do not disassemble, incinerate, or short

circuit the battery .

PRELIMINARY

5

Page 8

PDT 7500 Series

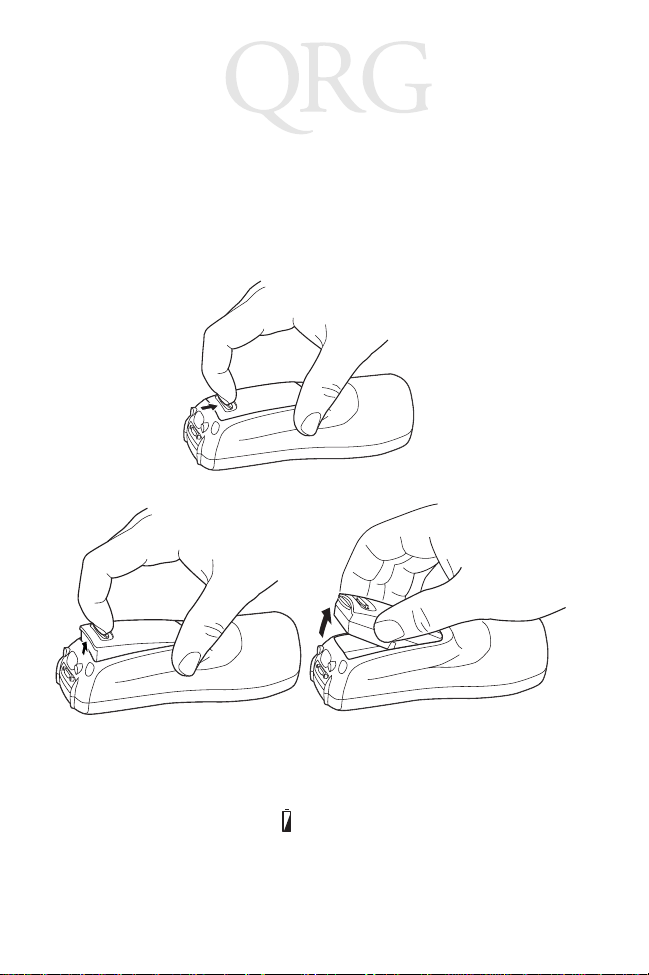

Removing the Battery from the Terminal

To remove the Li-Ion battery from the terminal:

1. Suspend the terminal’s power.

2. Slide the battery release switch towards the top of the terminal

until the lock releases.

3. Lift the battery up and out of the battery compartment.

Charging the Battery in the Terminal

To charge the terminal’s battery, place the PDT 7500 in the cradle

or connect the synchronization/charging cable.

PRELIMINARY

The terminal’s charging LED turns yellow while charging, then

turns green when the battery is fully charged, which takes 2-3

hours. A flashing yellow LED indicate s there may be a pr oblem with

the battery.

6

Page 9

Quick Reference

For instructions on setting up the cradle, refer to the Quick

Reference Guide that shipped with your cradle or to the PDT 7500

Series Product Reference Guide (72-39225-xx for DOS terminals,

or 72-41235-xx for Windows CE Terminals).

Charging the Spare Battery

The cradle also has a sp are battery charging slot. To charge the

spare Li-Ion battery in the CRD 7500 cradle, place the battery in to

the charging slot in the cradle. Charging begins automatically and

the charge LED on the cradle turns yellow. The charge LED turns

green upon successful completion of the charge cycle, which takes

approximately 4 hours. If the LED does not light, no battery is

present. If the LED blinks yellow, the battery is faulty.

You may also charge the battery in the UBC 2000 Battery Charger.

See the Quick Reference Guide which came with the UBC 2000 for

more information.

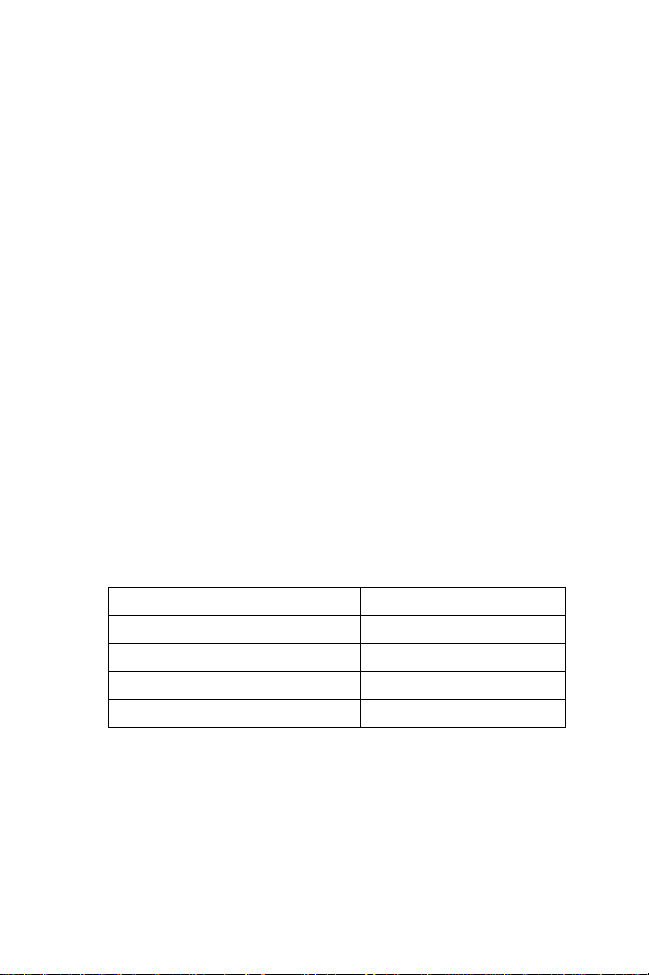

LED Indication

For all charging methods, the terminal’s battery charging LED

indicates the battery charging status, as follows:

Battery Charge State Charge LED Indication

Battery absent/no charge power Off

Battery charging Yellow

Battery fully charged Green

Abnormal battery Flashing Yellow

PRELIMINARY

7

Page 10

PDT 7500 Series

Operating the PDT 7500

Powering the Terminal On/Off

Note: Before the terminal can be powered on, it must be ini-

tialized and the battery must be fully charged. Refer to

the PD T 7500 Series Product Refer ence Guide for your

terminal for information on initializing the terminal.

To power on the terminal:

1. Make sure the terminal’s battery is fully charged.

2. Press the PWR key.

To suspend the terminal’s operation, press the PWR key.

Turning the Backlight On/Off

To turn the backlight on or off, press the blue FUNC key, then the

LAMP key.

Controlling the Screen Contrast

To lighten the screen contrast, press the blue FUNC key, then the

LIGHT key. To darke n the screen contrast, press the FUNC key,

then the DARK Key.

Resetting the PDT 7500

If your PDT 7500 Series terminal stops responding to input from

buttons on the screen, you must reset it.

Performing a Warm Boot (DOS and Windows CE Terminals)

A warm boot restarts the terminal and saves all stored records and

entries.

Note: Files that remain open during a warm boot may not be

PRELIMINARY

retained.

To perform a warm boot, pre s s and ho ld dow n the PWR ke y for 6

seconds, then release.

8

Page 11

Quick Reference

Performing a Cold Boot (DOS and Windows CE Terminals)

A cold boot restarts the terminal. In the Windows CE environment,

the registry and objects stored are reset to original settings.

T o perform a cold boot, press and hold the PWR key for 15 seconds,

then release. On the DOS terminal, this value can be reconfigured

in Setup (see the Product Reference Guide for more information).

Performing a Hard Reset (Windows CE Terminals Only)

A hard reset also restarts the PDT 7500 Series terminal, but erases

all stored records and entries. Therefore, never perform a hard reset

unless a warm/cold boot does not solve your problem.

Note: On the Windows CE termi nal, you ca n restore any data

previously synchroni zed with your computer dur ing the

next ActiveSync operation. See the Quick Reference

Guide which came with your cradle, or the PDT 7500

Product Reference Guide for Windows CE for more information.

To perform a hard reset:

1. Remove the battery for 20 minutes or longer.

2. Replace the battery in the terminal.

3. The calibration screen displays.

Note: With a hard reset, formats preferences and other settings

are restored to their original factory defaults.

Calibrating the Screen (Windows CE Terminals Only)

The first time you start your PDT 7500 terminal (and whenever the

terminal is cold-booted), the calibration screen displays. This

PRELIMINARY

section describes how to calibrate your terminal so the cursor on the

touch screen aligns with the tip of your stylus.

Note: If your terminal came loaded with another software ap-

plication, the calibration screen may not display.

9

Page 12

PDT 7500 Series

To calibrate your PDT 7500 terminal:

1. If necessary , adjust the contrast on the PDT 7500 so the screen

is clear and readable. See “Controlling the Screen Contrast”

on page 8 for instructions.

2. As the screen instructs, carefully press and briefly hold the stylus on the center of each target. Repeat as the target moves

around the screen.

3. Tap the screen when prompted to accept new calibration.

PRELIMINARY

10

Page 13

Quick Reference

Using the PDT 7500 Keypad

The PDT 7500 uses an alphanume ric keypa d that produ ces the 26character alphabet (A-Z), numbers (0-9), and assorted characters.

The keypad is color-coded to indicate which modifier key (ALPHA,

CTRL, FUNC, and SHIFT) to press to produce a particular

character or action.

Alpha key

Shift key

Control key

Enter key

Power key

• The default numeric keypad produces the numbers 0-9.

• Press ALPHA and the appropriate key to produce the alpha

characters A-Z.

• Press FUNC (blue) and the correspond ing numeric ke y to produce the function keys F1-F10.

• Press the cursor keys ( , , , ) to move the cursor left,

right, up and down on the screen.

• Press BKSP to erase information entered on the display, one

PRELIMINARY

character at a time.

• Press SPACE to enter a blank space.

• Press CLEAR to partially or completely escape from an application level or screen. CLEAR also erases all entered data

from the screen.

11

Function key

Clear key

Bac kspace key

Space key

Page 14

PDT 7500 Series

•Press ENTER after entering data or a command.

•Press CTRL to perform the control function. This key is un-

der application control.

•Press SHIFT and a key to produce various character keys; refer

to the PDT 7500 Series Product Reference Guide for your terminal or your application guide for the keypad mapping.

Note: Key function can be changed by an application. Your

keypad may not function exactly as described above.

Using the Integrated Laser Scanner

To use the laser scanner:

1. Verify the system is on. The LED lights yellow if scanning is

enabled and the laser is on.

2. Aim the PDT 7500 scan w indow at the ba r code and pr ess the

scan button.

Do not hold the PDT 7500 at a right angle to the bar code.

You can tilt the 7500 up to 65° forward or backward and

achieve a successful decode.

3. Ensure that the scan beam crosses all bars and spaces on the

symbol, as shown below.

Right

Wrong

Hold the scanner farther away for larger symbols, and closer

PRELIMINARY

for symbols with bars that are close together.

4. The LED turns from yellow to green for successful decodes.

The PDT 7500 may also beep on successful decode.

12

Page 15

Quick Reference

Scanning PDF417 Bar Codes

The PDF417 bar code symbol has multiple rows, but the raster

pattern also has multiple scanning rows. Two basic steps are

required as you scan:

1. Point the scanner at the bar code and press the scan button.

Slab Raster

2. As the raster pattern spreads, keep the pattern in the same horizontal plane as the bar code.

3/4”

3. The terminal indicates a successful scan by changing the LED

from yellow to green, beeping one or more times, and/or displaying the decoded bar code on the screen.

“Tall” PDF Bar Codes

If the PDF417 symbol is “tall, ” the vertical sc an pattern may n ot be

high enough to cover it.

PRELIMINARY

In this case, try a slow “up and down” scanning motion. With the

raster pattern open, try to move the scanner slowly down toward

the bottom of the sy mbol, keeping th e beam hori zontal to the rows,

and then slowly back upwar d toward the top.

13

3/4”

Page 16

PDT 7500 Series

The scan beam does not have to be perfectly parallel with the top

and bottom of the symbol (up to a 4

o

tilt will work).

PRELIMINARY

14

Page 17

Quick Reference

Host Communications

The PDT 7500 Series terminal can communicate with a host PC

either directly through its communications port using an RS-232

serial cable or the cradle, or wirelessly via the Spectrum24® wireless

LANs. For more information on setting up an d performing wireles s

communications with your PDT 7540 terminal, refer to the PDT

7500 Series Product Reference Guide.

Using the RS-232 Serial Cable

To connect the RS-232 serial cable for host communication:

1. Connect the RS-232 serial communication cable’s connector

to the adapter cable’s connector.

2. Plug the adapter cable’s subminiature connector into the serial

communication port on the bottom of the terminal.

3. Plug the other end of the RS-232 serial communication cable

into the host PC.

4. Begin host communication as specified by your application.

Using the Cradle

To communicate through the cradle:

1. Make sure all connections between the cradle and the host

computer are secure. See the Quick Reference Guide that

shipped with your cra dle for instructions on setting up the cradle.

2. Power on the host computer, the cradle, and the terminal.

3. Insert the terminal into the cradle.

4. Begin host communications as specified by your application.

PRELIMINARY

15

Page 18

PDT 7500 Series

Communicating with Printers

The PDT 7500 communicates with IrDA-compliant peripherals

through the IrDA interface in the base of the terminal. To print,

point the PDT 7500’s IrDA port at the IrDA port on the IrDAcompliant printer from a maximum distance of 39 inches (1 meter)

and run the application ’ s print function. Print er communication can

also be established through an RS-232 cable connected directly to

the printer.

Using the Touch Screen

Some PDT 7500 termina ls are equipped with a Touch Screen, which

has software that allows the stylus to function as a mouse. An

optional stylus is available from Symbol for use with the terminal.

Further use of the stylus function is application-dependent. Refer to

application documentation for more information.

Troubleshooting

Problem Cause Solution

PDT 7500 does

not power on.

Rechargeable

Li-Ion battery

did not charge.

PRELIMINARY

Li-Ion battery

not charged.

System crash. Hold PWR key for 15 seconds.

Battery failed. Replace battery.

PDT 7500 removed from cradle while battery

was charging.

Charge or replace the Li-Ion

battery in the PDT 7500.

DOS terminal users may change

this value in Setup.

Insert PDT 7500 in cradle and

begin charging. The Li-Ion battery requires 2-3 hours to recharge fully.

16

Page 19

Quick Reference

Problem Cause Solution

Cannot see

characters on

display.

Scanner does

not power on

when the scan

button is

pressed.

Scanner does

not decode a

bar code.

PDT 7500 not

powered on.

Contrast not adjusted properly.

Scanner is not

enabled.

Bar code is unreadable.

Scan window is

dirty .

Scan code not

enabled.

Press the PWR key.

Press the blue FUNC key and

then the Dark or Light keys to

adjust contrast.

See your System Administra t or.

Verify that the bar code is not

defective, i.e., smudged or broken.

Clean scan window with a lens

tissue. Tissues for eyeglasses

work well. Do not use tissues

coated with lotio n.

See your System Administra t or.

PRELIMINARY

17

Page 20

PDT 7500 Series

Problem Cause Solution

Fail to communicate with

IrDA printer.

Distance from

printer is more

than 1 meter

(3.28 feet).

Obstruction interfered with

communication.

Application is

not enabled to

run IrDA printing.

Bring the terminal closer to the

printer and attempt communications again.

Check the path to ensure no objects were in t h e way.

Printer support must be included with the application to run

IrDA printing on the terminal.

See your System Administrator.

PRELIMINARY

18

Page 21

Quick Reference

Pin-Outs

Pin Description

1GND

2DSR

3RXD

4CTS

5DCD

6GND

7 PWROUT (+5V)

8 PWRIN(+15V)

9DTR

10 Ring

11 TXD

12 RTS

13 Reserved

14 GND

15 PWRIN(+15V)

Regulatory Information

Radio Frequency Interference Requirements

This device has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the Federal Communications Commissions Rules and

Regulation. These limits are designed to provide reasonable protection against harmful

PRELIMINARY

interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause ha rmful interference to

radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

19

Page 22

PDT 7500 Series

However, there is no guarantee that interference will not occur in a particular

installation. If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with FCC Part 15. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference an d (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Important Note: To comply with FCC and Industry Canada RF exposure requirements,

this hand-held device is approved for operation in a user's hand when there is 20 cm or

more between the antenna and the user's body.

Radio Frequency Interference Requirements - Canada

This device complies with RSS 210 of Industry & Science Canada. Operation is subject

to the following two conditions: (1) this device may not cause harmful interfer ence and

(2) this device must accept any interference received, including interference that may

cause unde sired operation.

This Class B digital apparatus complies with Industry Canada Standard ICES-003.

Cet appareil numérique de la classe B est conform à la norme NMB-003 d’Industrie

Canada.

CE Marking and European Union Compliance

Products intended for sale within the European Union are marked with the

CE Mark which indicates compliance to applicable Directives and

European Normes (EN), as follows. Amendments to these Directives or

ENs are included:

Applicable Directives

PRELIMINARY

• Electromagnetic Compatibility Directive 89/336/EEC

• Low Voltage Directive 73/23/EEC

20

Page 23

Quick Reference

Applicable Standards

• EN 55 022 - Limits and Methods of Measurement of Radio Interference Characteristics of Information technology Equipment

• EN 55024:1998; Information technology equipment-Immunity characteristicsLimits and methods of measurement.

• EN 50 082-1:1997 - Electromagnetic Compatibility - Generic Immunity Standard, Part 1: Residential, commercial, Light Industry

• IEC 1000-4-2(1995-01) - Electromagnetic compatibility (EMC) - Part 4:Testing

and measurement techniques - Section 2: Electrostatic dischar ge immunity test.

• IEC 1000-4-3(1995-03) - Electromagnetic compatibility (EMC) - Part 4:Testing

and measurement techniques - Section 3: Radiated, radio-frequency, electromagnetic field immunity test.

• IEC 1000-4-4(1995-01) - Electromagnetic compatibility (EMC) - Part 4:Testing and

measurement techniques - Section 4: Electrical fast transient/burst immunity test.

• EN 60 950 + Amd 1 + Amd 2 - Safety of Information Technology Equipment

Including Electrical Business Equipment

• EN 60 825-1 (EN 60 825) - Safety of Devices Containing Lasers.

Laser Devices

Symbol products using lasers comply with US 21CFR1040.10, Subchapter J and

IEC825/EN 60 825 (or IEC825-1/EN 60 825-1, depending on the date of

manufacture). The laser classification is marked on one of the labels on the product.

Class 1 Laser devices are not considered t o be hazardou s when used for th eir int ended

purpose. The following statement is required to comply with US and international

regulations:

Caution: Use of controls, adjustments or performance of procedures other than those

specified herein may result in hazardous laser light exposure.

Class 2 laser scanners use a low power, visible light diode. As with any very bright light

source, such as the sun, the user should avoid staring directly into the light beam.

Momentary exposure to a Class 2 laser is not known to be harmful.

RF Devices

Symbol’s RF products are designed to be compliant with the rules and regulations in

the locations into which they are sold and will be labeled as required. The majority of

Symbol’s RF devices are type appro ve d and do not requ ire t he u ser t o obt ain l ice nse or

authorization before using the equipment. Any changes or modifications to Symbol

Technologies equipment not expressly approved by Symbol Technologies could void

the user’s authority to operate the equipment.

PRELIMINARY

21

Page 24

PDT 7500 Series

Scanner Labeling

AVOID EXPOSURE - LASER LIGHT IS

EMITTED FROM THIS APERTURE

ÉVITER TOUTE EXPOSITION -

LUMIÈRE LASER ÉMIS PAR CETTE OUVERTURE

This label is located inside the battery compartment .

PRELIMINARY

22

Page 25

Quick Reference

In accordance with Clause 5, IEC 0825 and EN60825, the following information is

provided to the user:

ENGLISH HEBREW

CLASS 1 CLASS 1 LASER PRODUCT

CLASS 2 LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

DANISH

KLASSE 1 KLASSE 1 LASERPRODUKT ITALIAN

KLASSE 2 LASERLYF CLASSE 1 PRODOTTO AL LASER DI CLASSE 1

SE IKKE IND I STRÅLEN CLASSE 2 LUCE LASER

KLASSE 2 LASERPRODUKT NON FISSARE IL RAGGIOPRODOTTO

AL LASER DI CLASSE 2

DUTCH

KLASSE 1 KLASSE-1 LASERPRODUKT NORWEGIAN

KLASSE 2 LASERLICHT KLASSE 1 LASERPRODUKT, KLASSE 1

NIET IN STRAAL STAREN KLASSE 2 LASERLYS IKKE STIRR INN I LYSSTRÅLEN

KLASSE-2 LASERPRODUKT LASERPRODUKT, KLASSE 2

FINNISH PORTUGUESE

LUOKKA 1 LUOKKA 1 LASERTUOTE CLASSE 1 PRODUTO LASER DA CLASSE 1

LUOKKA 2 LASERVALO

ÄLÄ TUIJOTA SÄDETTÄ CLASSE 2 LUZ DE LASER NÃO FIXAR O RAIO LUMINOSO

LUOKKA 2 LASERTUOTE PRODUTO LASER DA CLASSE 2

FRENCH SPANISH

CLASSE 1 PRODUIT LASER DE CLASSE 1 CLASE 1 PRODUCTO LASER DE LA CLASE 1

CLASSE 2 LUMIERE LASER CLASE 2 LUZ LASER

NE PAS REGARDER LE RAYON FIXEMENT NO MIRE FIJAMENTE EL HAZ

PRODUIT LASER DE CLASSE 2 PRODUCTO LASER DE LA CLASE 2

GERMAN SWEDISH

KLASSE 1 LASERPRODUKT DER KLASSE 1 KLASS 1 LASERPRODUKT KLASS 1

KLASSE 2 LASERSTRAHLEN KLASS 2 LASERLJUS STIRRA INTE MOT STRÅLEN

NICHT DIREKT IN DEN LASERSTRAHL SCHAUEN LASERPRODUKT KLASS 2

LASERPRODUKT DER KLASSE 2

PRELIMINARY

23

Page 26

PDT 7500 Series

Service Information

Before you use the unit, it must be configured to operate in your facility’s network and

run your applications.

If you have a problem running your unit or using your equipment, contact your

facility’s Technical or Systems Support. If there is a problem with the equipment, they

will contact the Symbol Support Center.

United States 1-800-653-5350 Canada 905-629-7226

United Kingdom 0800 328 2424 Asia/Pacific 337-6588

Australia 1-800-672-906 Austria 1-505-5794

Denmark 7020-1718 Finland 9 5407 580

France 01-40-96-52-21 Germany 6074-49020

Italy 2-484441 Mexico 5-520-1835

Netherlands 315-271700 Norway 66810600

South Africa 11-4405668 Spain 9-1-320-39-09

Sweden 84452900

Latin America Sales Support 1-800-347-0178 Inside US

Europe/Mid-East Distributor Operations Contact local distributor or call

+1-561-483-1275 Outside US

+44 208 945 7360

Warranty

Symbol Technologies, Inc. (“Symbol”) manufactures its hardware products in

accordance with industry-standard practices. Symbol warrants that for a period of

twelve (12) months from date of shipment, products will be free from defects in

materials and workmanship.

This warranty is provided to the original owner only and is not transferable to any third

party. It shall not apply to any product (i) which has been repaired or altered unless

done or approved by Symbol, (ii) which has not been maintained in accordance with

any operating or handling instructions supplied by Symbol, (iii) which has been

subjected to unusual physical or electrical stress, misuse, abuse, power shortage,

negligence or accident or (iv) which has been used other than in accordance with the

product operating and handling instructions. Preventive maintenance is the

responsibility of customer and is not covered under this warranty.

PRELIMINARY

Wear items and accessories having a Symbol serial number, will carry a 90-day limited

warranty. Non-serialized items will carry a 30-day limited warranty.

24

Page 27

Quick Reference

Warranty Coverage and Procedure

During the warranty period, Symbol will repair or replace defective products returned

to Symbol’s manufacturing plant in the US. For warranty service in North America, call

the Symbol Support Center at 1-800-653-5350. International customers should contact

the local Symbol office or support center. If warranty service is required, Symbol will

issue a Return Material Authorization Number. Products must be shipped in the

original or comparable packaging, shipping and insurance charges prepaid. Symbol

will ship the repaired or replacement product freight and insurance prepaid in North

America. Shipments from the US or other locations will be made F.O.B. Symbol’s

manufacturing plant.

Symbol will use new or refurbished parts at its discretion and will own all parts

removed from repaired products. Customer will pay for the replacement product in

case it does not return the replaced product to Symbol within 3 days of receipt of the

replacement product. The process for retur n and cu stomer’s charges will be in

accordance with Symbol’s Exchange Policy in effect at the time of the exchange.

Customer accepts full responsibility for its software and data including the appropriate

backup thereof.

Repair or replacement of a product during warranty will not extend the original

warranty term.

Symbol’s Customer Service organization offers an array of service plans, such as on-site,

depot, or phone support, that can be implemented to meet customer’s special

operational requirements and are available at a substantial discount during warranty

period.

General

Except for the warranties stated above, Symbol disclaims all warranties, express or

implied, on products furnished hereunder, including without limitation implied

warranties of merchantability and fitness for a particular purpose. The stated express

warranties are in lieu of all obligations or liabilities on part of Symbol for damages,

including without limitation, special, indirect, or consequential damages arising out of

or in connection with the use or performance of the product.

Seller’s liability for damages to buyer or others resulting from the use of any product,

shall in no way exceed the purchase price of said product, except in instances of injury

to persons or property.

Some states (or jurisdictions) do not allow the exclusion or limitation of incidental or

consequential damages, so the proceeding exclusion or limitation may not apply to you.

This product is marked with in accordance with the Class II

PRELIMINARY

product requirements specified in the R&TTE Directive, 1999/5/EC.

The equipment is intended for use throughout the European Community, but it's

authorization for use in France is restricted as follows:

• PAN European Frequency Range: 2.402 - 2.480 GHz

• Restricted Frequency Range for use in France: 2.448 - 2.480 GHz

0168

25

Page 28

PRELIMINARY

72-38888-02

Revision A — April 2000

Symbol Technologies, Inc. One Symbol Plaza Holtsville, NY 11742-1300

Loading...

Loading...