Page 1

PDT 6800 Series

Product Reference Guide

Page 2

PDT 6800 Series

Product Reference Guide

70-32645-02

Revision A

August 2001

Page 3

1998-2001 by Symbol Technologies, Inc. All rights reserved.

No part of this publication may be reproduced or used in any form, or by any electrical or

mechanical means, without permission in writing from Symbol. This includes electronic or

mechanical means, such as photocopying, recording, or information storage and retrieval

systems. The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware,

furnished to the user is on a licensed basis. Symbol grants to the user a non-transferable and

non-exclusive license to use each software or firmware program delivered hereunder (licensed

program). Except as noted below, such license may not be assigned, sublicensed, or otherwise

transferred by the user without prior written consent of Symbol. No right to copy a licensed

program in whole or in part is granted, except as permitted under copyright law. The user

shall not modify, merge, or incorporate any form or portion of a licensed program with other

program material, create a derivative work from a licensed program, or use a licensed

program in a network without written permission from Symbol. The user agrees to maintain

Symbol’s copyright notice on the licensed programs delivered hereunder, and to include the

same on any authorized copies it makes, in whole or in part. The user agrees not to

decompile, disassemble, decode, or reverse engineer any licensed program delivered to the

user or any portion thereof.

Symbol reserves the right to make changes to any software or product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any

Symbol Technologies, Inc., intellectual property rights. An implied license only exists for

equipment, circuits, and subsystems contained in Symbol products.

Symbol, Spectrum One, and Spectrum24 are registered trademarks of Symbol Technologies,

Inc. Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

http://www.symbol.com

ii

Page 4

Contents

About This Guide

Chapter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Notational Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Symbol Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Warranty Coverage and Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Chapter 1. Getting Started

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parts of the PDT 6800 Series Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Battery Chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Printer Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Radio and Network Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Before You Use the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Install and Charge Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Load the Appropriate Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2. Accessories Setup

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Required Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

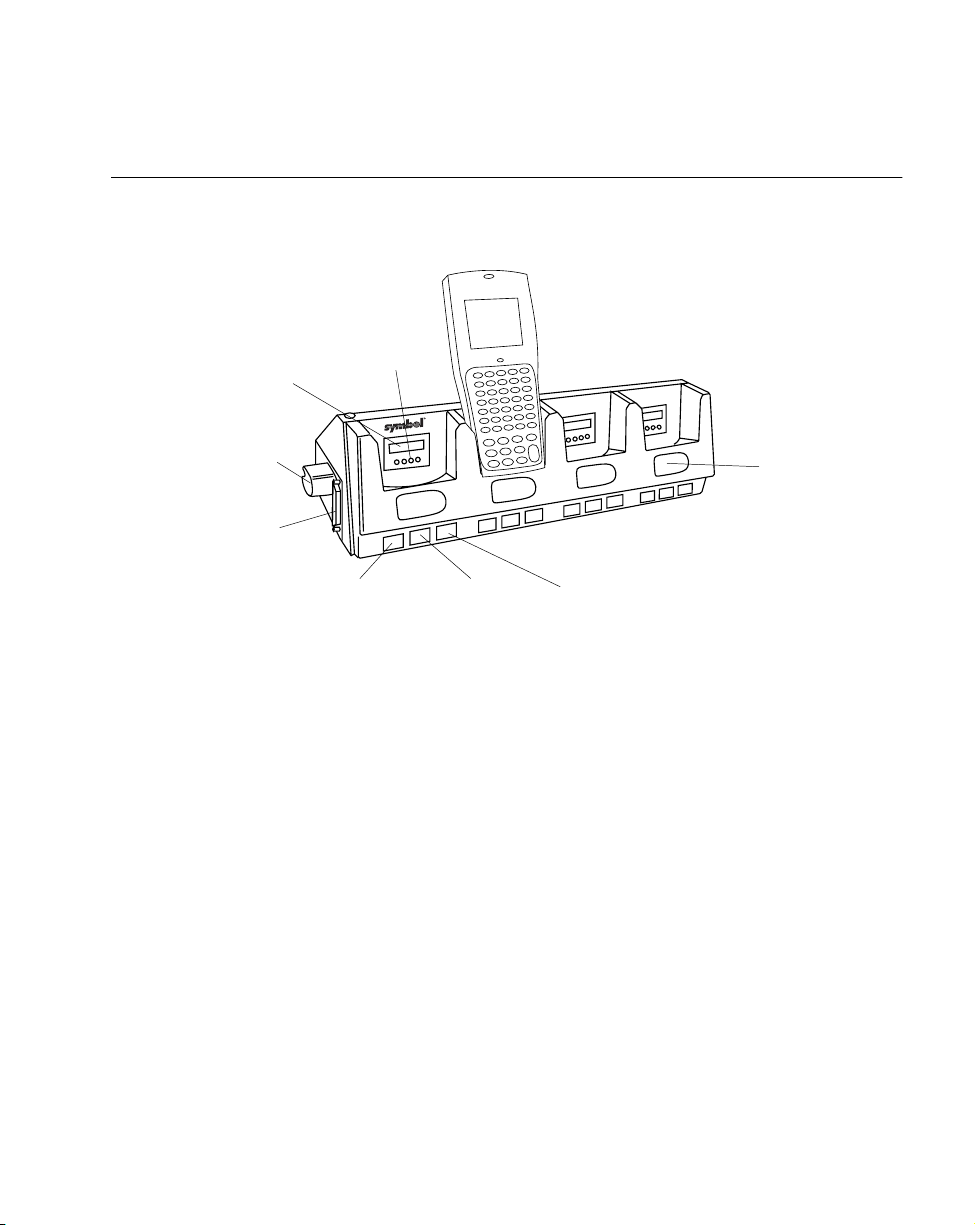

Parts of the CRD 38/6865 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Parts of the CRD 38/6866 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wall Mounting the CRD 38/6865 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Wall Mounting the CRD 38/6866 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

iii

Page 5

PDT 6800 Series Product Reference Guide

Table Mounting the CRD 38/6866 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Connecting for Data Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Connecting the CRD 38/6865 Internal Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Connecting to the Telephone Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Connecting the CRD 38/6866 to Other Cradles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

CCM 38/6860 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Parts of the CCM 38/6860 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Wall Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Coupling CCMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Connecting the CCM for Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Daisy-Chaining Two or More CCMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

PC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Parts of the PC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Connecting the PC Adapter to the Terminal and Serial Device. . . . . . . . . . . . . . . . . . . . . . . . 2-17

Chapter 3. Batch and Spectrum One Terminal Setup

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Downloading the Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Initiate Host Communications Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4. Spectrum24 RF Terminal Setup

Spectrum24 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Accessing the Flash Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Standard Spectrum24 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Chapter 5. Operating the PDT 6800 Series

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Powering the Terminal On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Removing Terminal From a Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Real-Time Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Laser Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Restoring Power After Automatic Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Powering the Terminal Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Forcing Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Restarting After a Forced Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Booting the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

iv

Page 6

Contents

Warm Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cold Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Boot to Command Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Adjusting the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Backlighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

PDT 6800 Series Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Using the Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Scanning 1D Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Scanning 2D Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Scanning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Running Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Communicating With a Host. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Communicating With a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Radio Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Chapter 6. Maintaining the Terminal

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

When to Replace or Recharge the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Replacing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Removing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Installing the Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Battery Charging Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Charging the NiCd Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Charging the Lithium Ion Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Chapter 7. Error Recovery and Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Startup Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Boot Failure Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Spectrum24 Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Self Test Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Running Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Self Test Summaries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Keyboard Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Memory Transfer Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

v

Page 7

PDT 6800 Series Product Reference Guide

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Set Communications Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Internal Modem Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Scanning Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

What If... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Appendix A. Null Modem Pin-outs

Null Modem Pin-Outs for Full Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Null Modem Pin-outs for Half-Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B. Keyboard Layouts

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

35-Key Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

46-Key Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Appendix C. Communications Status Codes

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Appendix D. Specifications

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

RF Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Scanning Decode Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Appendix E. Boot-Up Quick Reference

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

vi

Page 8

Contents

Appendix F. 2D Scanner Drivers and Applications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Using Scn2dssi.exe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Output Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Application Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

New APIs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Using Bldscan.exe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Screen Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Index

Feedback

vii

Page 9

PDT 6800 Series Product Reference Guide

viii

Page 10

About This Guide

The PDT 6800 Series Product Reference Guide provides general instructions for setup,

initializing, operating, troubleshooting, and maintaining the PDT 6800 Series terminal.

Chapter Descriptions

Following are brief descriptions of each chapter in this guide.

Chapter 1, Getting Started provides a product overview and information on terminal

!

parts, operation, accessories, batteries, and loading software.

Chapter 2, Accessories Setup general information on the CCM 38/6860, CRD 38/

!

6865, CRD 38/6866, and PC adapter.

Chapter 3, Batch and Spectrum One Terminal Setup provides information on batch

!

and Spectrum One hardware requirements and loading programs.

Chapter 4, Spectrum24 RF Terminal Setup provides general information on

!

Spectrum24 software, initialization, and options.

Chapter 5, Operating the PDT 6800 Series describes how to use the terminal.

!

Chapter 6, Maintaining the Terminal includes tips on properly maintaining your

!

terminal and batteries.

Chapter 7, Error Recovery and Troubleshooting basic information on terminal and

!

software troubleshooting.

Appendix A, Null Modem Pin-outs provides the pin-outs for null modem

!

communication.

Appendix B, Keyboard Layouts describes the 35-key and 46-key keyboards and the

!

associated key functions.

Appendix C, Communications Status Codes provides communication status codes

!

and their meaning.

ix

Page 11

PDT 6800 Series Product Reference Guide

Appendix D, Specifications provides the technical specifications for the terminal.

!

Appendix E, Boot-Up Quick Reference provides the key sequence necessary to

!

initiate a warm boot, cold boot, or command mode start.

Appendix F, 2D Scanner Drivers and Applications describes the installation of the

!

2D scan engine drivers and applications.

Notational Conventions

The following conventions are used in this document:

• Italics are used to highlight specific items in the general text, and to identify

chapters and sections in this and related documents.

• Bullets ( •) indicate:

• action items

• lists of alternatives

• lists of required steps that are not necessarily sequential

Sequential lists (e.g., those that describe step-by-step procedures) appear as

!

numbered lists.

Related Publications

The following is a list of documents and publications that you may find useful if you want to

know more about the PDT 6800 Series terminals or about the tools and utilities that are

available for writing applications for the terminals.

PDT 6800 Series Quick Reference Guide

!

p/n 70-32644-XX

CCM 38/6860 Quick Reference Guide

!

p/n 70-33400-XX

CRD 38/6865 Quick Reference Guide

!

p/n 70-33401-XX

CRD 38/6866 Quick Reference Guide

!

p/n 70-33402-XX

Printer Interface Module Quick Reference Guide

!

p/n 59164-00-82

Series 3000 Application Programmer's Guide

!

p/n 70-16308-XX

x

Page 12

About This Guide

Series 3000 Application Programmer’s Reference Manual

!

p/n 70-16309-XX

Series 3000 System Software Manual

!

p/n 70-16310-XX

Series 3000 Application Developer’s Library

!

p/n 70-16311-XX

Spectrum24 Access Point User’s Guide

!

p/n 70-12057-XX

Spectrum24 Network Terminal Technical Reference Guide

!

p/n 70-20193-XX

Novell LAN Workplace Reference Manual

!

p/n 70-20288-XX

Spectrum24 TNClient System Administrator’s Guide

!

p/n 70-20244-XX

Spectrum24 STEP Installation and Configuration Guide for Series 3000 Flash Disk

!

Terminals

p/n 70-20343-XX

Spectrum24 NDK Series 3000

!

p/n 70-20481-XX

Service Information

If you have a problem with your equipment, contact the Symbol Support Center for your

region. See page xii for contact information. Before calling, have the model number, serial

number, and several of your bar code symbols at hand.

Call the Support Center from a phone near the scanning equipment so that the service person

can try to talk you through your problem. If the equipment is found to be working properly

and the problem is symbol readability, the Support Center will request samples of your bar

codes for analysis at our plant.

If your problem cannot be solved over the phone, you may need to return your equipment for

servicing. If that is necessary, you will be given specific directions.

Note: Symbol Technologies is not responsible for any damages incurred

during shipment if the approved shipping container is not used.

Shipping the units improperly can possibly void the warranty. If the

xi

Page 13

PDT 6800 Series Product Reference Guide

original shipping container was not kept, contact Symbol to have

another sent to you.

Symbol Support Center

For service information, warranty information or technical assistance contact or call the

Symbol Support Center in:

United States

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

1-800-653-5350

United Kingdom

Symbol Technologies

Symbol Place

Winnersh Triangle, Berkshire RG41 5TP

United Kingdom

0800 328 2424 (Inside UK)

+44 208 945 7529 (Outside UK)

Australia

Symbol Technologies Pty. Ltd.

432 St. Kilda Road

Melbourne, Victoria 3004

1-800-672-906 (Inside Australia)

+61-3-9866-6044 (Outside Australia)

Denmark

Symbol Technologies AS

Gydevang 2,

DK-3450 Allerod, Denmark

7020-1718 (Inside Denmark)

+45-7020-1718 (Outside Denmark)

Canada

Symbol Technologies Canada, Inc.

2540 Matheson Boulevard East

Mississauga, Ontario, Canada L4W 4Z2

905-629-7226

Asia/Pacific

Symbol Technologies Asia, Inc.

230 Victoria Street #04-05

Bugis Junction Office Tower

Singapore 188024

337-6588 (Inside Singapore)

+65-337-6588 (Outside Singapore)

Austria

Symbol Technologies Austria GmbH

Prinz-Eugen Strasse 70

Suite 3

2.Haus, 5.Stock

1040 Vienna, Austria

1-505-5794 (Inside Austria)

+43-1-505-5794 (Outside Austria)

Europe/Mid-East Distributor Operations

Contact your local distributor or call

+44 118 945 7360

xii

Page 14

About This Guide

Finland

Oy Symbol Technologies

Kaupintie 8 A 6

FIN-00440 Helsinki, Finland

9 5407 580 (Inside Finland)

+358 9 5407 580 (Outside Finland)

Germany

Symbol Technologies GmbH

Waldstrasse 68

D-63128 Dietzenbach, Germany

6074-49020 (Inside Germany)

+49-6074-49020 (Outside Germany)

Latin America Sales Support

7900 Glades Road

Suite 340

Boca Raton, Florida 33434 USA

1-800-347-0178 (Inside United States)

+1-561-483-1275 (Outside United States)

Netherlands

Symbol Technologies

Kerkplein 2, 7051 CX

Postbus 24 7050 AA

Varsseveld, Netherlands

315-271700 (Inside Netherlands)

+31-315-271700 (Outside Netherlands)

France

Symbol Technologies France

Centre d'Affaire d'Antony

3 Rue de la Renaissance

92184 Antony Cedex, France

01-40-96-52-21 (Inside France)

+33-1-40-96-52-50 (Outside France)

Italy

Symbol Technologies Italia S.R.L.

Via Cristoforo Columbo, 49

20090 Trezzano S/N Navigilo

Milano, Italy

2-484441 (Inside Italy)

+39-02-484441 (Outside Italy)

Mexico

Symbol Technologies Mexico Ltd.

Torre Picasso

Boulevard Manuel Avila Camacho No 88

Lomas de Chapultepec CP 11000

Mexico City, DF, Mexico

5-520-1835 (Inside Mexico)

+52-5-520-1835 (Outside Mexico)

Norway

Symbol Technologies

Trollasveien 36

Postboks 72

1414 Trollasen, Norway

66810600 (Inside Norway)

+47-66810600 (Outside Norway)

xiii

Page 15

PDT 6800 Series Product Reference Guide

South Africa

Symbol Technologies Africa Inc.

Block B2

Rutherford Estate

1 Scott Street

Waverly 2090 Johannesburg

Republic of South Africa

11-4405668 (Inside South Africa)

+27-11-4405668 (Outside South Africa)

Sweden

Symbol Technologies AB

Albygatan 109D

Solna

Sweden

84452900 (Inside Sweden)

+46 84452900 (Outside Sweden)

Symbol Technologies S.A.

Edificioi la Piovera Azul

C. Peonias, No. 2 - Sexta Planta

28042 Madrid, Spain

+913244000 (Inside Spain)

+34-9-1-320-39-09 (Outside Spain)

Spain

If you purchased your Symbol product from a Symbol Business Partner, contact that Business

Partner for service.

Warranty

Symbol Technologies, Inc. (“Symbol”) manufactures its hardware products in accordance with

industry-standard practices. Symbol warrants that for a period of twelve (12) months from date of

shipment, products will be free from defects in materials and workmanship.

This warranty is provided to the original owner only and is not transferable to any third party. It shall

not apply to any product (i) which has been repaired or altered unless done or approved by Symbol, (ii)

which has not been maintained in accordance with any operating or handling instructions supplied by

Symbol, (iii) which has been subjected to unusual physical or electrical stress, misuse, abuse, power

shortage, negligence or accident or (iv) which has been used other than in accordance with the product

operating and handling instructions. Preventive maintenance is the responsibility of customer and is not

covered under this warranty.

Wear items and accessories having a Symbol serial number, will carry a 90-day limited warranty. Nonserialized items will carry a 30-day limited warranty.

xiv

Page 16

About This Guide

Warranty Coverage and Procedure

During the warranty period, Symbol will repair or replace defective products returned to Symbol’s

manufacturing plant in the US. For warranty service in North America, call the Symbol Support Center

at 1-800-653-5350. International customers should contact the local Symbol office or support center.

If warranty service is required, Symbol will issue a Return Material Authorization Number. Products

must be shipped in the original or comparable packaging, shipping and insurance charges prepaid.

Symbol will ship the repaired or replacement product freight and insurance prepaid in North America.

Shipments from the US or other locations will be made F.O.B. Symbol’s manufacturing plant.

Symbol will use new or refurbished parts at its discretion and will own all parts removed from repaired

products. Customer will pay for the replacement product in case it does not return the replaced product

to Symbol within 3 days of receipt of the replacement product. The process for return and customer’s

charges will be in accordance with Symbol’s Exchange Policy in effect at the time of the exchange.

Customer accepts full responsibility for its software and data including the appropriate backup thereof.

Repair or replacement of a product during warranty will not extend the original warranty term.

Symbol’s Customer Service organization offers an array of service plans, such as on-site, depot, or phone

support, that can be implemented to meet customer’s special operational requirements and are available

at a substantial discount during warranty period.

General

Except for the warranties stated above, Symbol disclaims all warranties, express or implied, on products

furnished hereunder, including without limitation implied warranties of merchantability and fitness for

a particular purpose. The stated express warranties are in lieu of all obligations or liabilities on part of

Symbol for damages, including without limitation, special, indirect, or consequential damages arising

out of or in connection with the use or performance of the product.

Seller’s liability for damages to buyer or others resulting from the use of any product, shall in no way

exceed the purchase price of said product, except in instances of injury to persons or property.

Some states (or jurisdictions) do not allow the exclusion or limitation of incidental or consequential

damages, so the proceeding exclusion or limitation may not apply to you.

xv

Page 17

PDT 6800 Series Product Reference Guide

xvi

Page 18

Chapter 1

Getting Started

Introduction

The PDT 6800 Series terminal is a hand-held, battery-powered, portable data collection

device. Data is entered from the terminal’s keyboard or through the integrated laser scanner.

As a remote terminal, it collects and stores data that is later uploaded to a host computer. The

PDT 6800 Series terminals include:

PDT 6800 - batch terminal (no radio)

!

PDT 6810 - Spectrum One® network

!

PDT 6842 - 2 Mb Spectrum24® radio network

!

PDT 6845 - 2 Mb Spectrum24® radio (short range) network

!

PDT 6846 - 11 Mb Spectrum24® radio network

!

Since the procedures and descriptions in this guide are similar for all terminals listed above,

PDT 6800 Series terminals is used as a general term describing all terminals, unless otherwise

specified.

PDT 6800 Series terminals use Caldera’s DR DOS™ operating system that is compatible with

and extends Microsoft

they are not one hundred percent MS-DOS compatible. DR DOS provides access to a number

of commercially available programming tools. Additional programming tools are available

from Symbol for easier programming and access to special features.

®

MS-DOS®. Although the terminals are MS-DOS feature compatible,

1-1

Page 19

PDT 6800 Series Product Reference Guide

Power saving features of the PDT 6800 Series terminals include auto-off and power save

modes, which reduce power consumption until an operator provides input. These features

conserve battery power, lengthening the time between charges or replacement.

Parts of the PDT 6800 Series Terminal

Scan LED

Recharge

Contact s

Battery

Display

Optical

Connectors

Status LED

Status

-

-

+

Keyb oa rd

=

Battery Compartment

Wrist Strap

Battery

Release

Button

Battery

Lock

Scan Window

Trigger

1-2

Handle

(Battery

Compartment)

Figure 1-1. Parts of the PDT 6800 Series Terminal

Battery Pack

Page 20

Getting Started

Accessories

The following accessories are available for the PDT 6800 Series terminal.

Battery Chargers

The terminal uses a six-cell 600 mAh (intrinsically safe) Nickel Cadmium (NiCd) battery, or

a Lithium Ion battery.

The NiCd battery is charged using one of the following charging accessories:

CCM 38/6860 — Four-slot Charging and Communications Module (CCM) for

!

charging NiCd battery packs in the terminal and spare battery packs; also performs

communications between terminals and a host, modem, or printer.

CRD 38/6865 — Single-slot cradle for charging NiCd battery packs; also performs

!

communications between terminals and a host, a modem, or a printer.

CRD 38/6866 — Four-slot cradle for charging NiCd battery packs in the terminal

!

and for communicating between terminals and a host, a modem, or a printer.

UBC Charger — UBC 1000 or 2000 battery charger.

!

PC Adapter — Works with the Printer Interface Module (PIM) to communicate with

!

the host PC without a cradle or to charge a NiCd battery pack in the terminal

without a cradle.

The Lithium Ion battery is charged using the UBC 2000 charging adapter p/n 21-32665-24.

Printer Interface Module

The Printer Interface Module works with the PC Adapter to perform communications

between the terminal and a host PC or a printer without a cradle.

Radio and Network Options

Spectrum One Network

The PDT 6810 includes an internal radio frequency transmitter/receiver for use in a Symbol

Spectrum One network.

Spectrum24 Network

The PDT 6842, PDT 6845, and PDT 6846 include an internal radio frequency transmitter/

receiver for use in a Symbol Spectrum24 network. Refer to Spectrum24 Network Terminal

Technical Reference Guide, p/n 70-20193-XX, for more information.

1-3

Page 21

PDT 6800 Series Product Reference Guide

Unpacking

Remove the clear protective tape from the display and the optical connector.

Save the shipping container for later storage or shipping. Inspect all equipment for damage

and make sure you have received everything listed on the packing slip.

If you find anything unsatisfactory or missing, contact your authorized customer support

representative immediately.

Before You Use the Terminal

Install and Charge Battery

Prior to using the PDT 6800 Series terminal for the first time, install the battery pack. Be sure

to charge the battery pack before use. Refer to Chapter 6, Maintaining the Terminal.

If you hear a repeated tone or see a message on the display, recharge or replace the battery

pack. Refer to Chapter 6, Maintaining the Terminal.

Load the Appropriate Software

What software you load and how you load it depends on the environment in which you use it:

If the terminal is intended for use in batch applications (PDT 6800) or in a Spectrum

!

One network environment (PDT 6810), refer to Chapter 3, Batch and Spectrum One

Terminal Setup for information on loading the software.

If the terminal is intended for use in a Spectrum24 network environment (PDT 6842,

!

PDT 6845, or PDT 6846), refer to Chapter 4, Spectrum24 RF Terminal Setup for

information on loading the software.

If you are using the 2D scan engine, install the appropriate drivers and applications.

!

Refer to Appendix F, 2D Scanner Drivers and Applications .

1-4

Page 22

Chapter 2

Accessories Setup

Introduction

This chapter provides instructions for setting up the cradle, module, and PC adapter for

charging the NiCd battery and communicating with a host, printer, or modem.

Note: The Lithium Ion battery is charged in the UBC 2000 battery adapter

p/n 21-32665-24. Refer to Chapter 6, Maintaining the Terminal for

more information.

The CRD 38/6865 cradle, CRD 38/6866 cradle, and CCM 38/6860 Charging and

Communications Module provide RS-232 communication, charging, and storage for the

PDT 6800 Series terminal.

The PC adapter provides charging for the NiCd battery and communications for the terminal.

Save the shipping container for storing or shipping the cradle, module, or PC adapter. Inspect

all equipment for damage. If anything is damaged or missing, call your authorized customer

support representative immediately.

2-1

Page 23

PDT 6800 Series Product Reference Guide

Required Parts

Before attempting to mount or connect the cradles, verify that you have the following parts:

CRD 38/6865 CRD 38/6866

Single-Slot Cradle with Charging Slot:

US Kit: 3865-110

!

International Kit: 3865-111

!

AC Power Supply:

US:59915-00-00

!

International: 60507-00-00

!

Null Modem Cable, DB 25 Male to DB 25

Female (p/n 25-19297-01)

Null Modem Cable, DB25 Male to DB 9

Female (p/n 25-19299-01)

Four-Slot Cradle

US Kit: 3866-100

!

International Kit: 3866-101

!

AC Power Supply

US:60153-00-00

!

International: 60174-00-00

!

Null Modem Cable, DB 25 Male to DB 25 Female

(p/n 25-19297-01)

Null Modem Cable DB25 Male to DB 9 Female

(p/n 25-19299-01)

Chaining Interconnect Cable (p/n 60427-00-00)

Wall Mounting Kit (p/n 3866-000) Two Wall Mounting Kits (p/n 3866-000)

per 38/6866

Before attempting to mount or connect the Charging and Communications Module (CCM)

38/6860, verify that you have the following parts:

Four-slot CCM Kit (includes power supply, mounting brackets, and hardware:

US: 3860-100

!

International: 3860-101

!

AC Power Supply:

US: 58690-00-00

!

International: 58690-01-00

!

Null Modem Cable

DB-25 Female to DB-25 Female (p/n 59846-00-00)

!

DB-25 Female to DB-9 Female (p/n 25-19298-01)

!

CCM Four-Slot Add-on Kit (includes CCM, coupling kit, and mounting brackets):

p/n 3861-101

!

2-2

Page 24

Parts of the CRD 38/6865

Screw Hole

Covers

Optical

Connectors

Battery

Contacts

Spare Battery

Charging Slot

Chargin g LED COMM LED

Figure 2-1. Parts of the CRD 38/6865

Accessories Setup

Power Po rt

Serial Por t

Parts of the CRD 38/6866

Power Port

Serial Port

COMM LEDChargin g LED

Figure 2-2. Parts of the CRD 38/6866

Optical

Connectors

Screw Hole

Covers

Battery

Contac ts

2-3

Page 25

PDT 6800 Series Product Reference Guide

Wall Mounting the CRD 38/6865

The CRD 38/6865 can be wall-mounted on a wall bracket for convenience. To wall-mount

the 38/6865:

1. Mark where you want the cradle positioned on the wall.

2. Using a fastener appropriate to the wall construction, insert and secure the fastener

(Figure 2-3). Let the head protrude slightly.

Figure 2-3. Wall Mounting the 38/6865

3. Slide the bracket down over the head of the fastener.

4. Remove the black tape covers from the cradle screw holes ( Figure 2-4).

2-4

Figure 2-4. Removing the Tape Covers

Page 26

Accessories Setup

5. Position the cradle on the bracket.

Figure 2-5. Secure Cradle to Bracket

6. Secure the cradle to the bracket using two #10 metal screws (Figure 2-5).

Wall Mounting the CRD 38/6866

The CRD 38/6866 can be wall-mounted on two mounting brackets. Follow the directions for

Wall Mounting the CRD 38/6865 on page 2-4, using two brackets.

Table Mounting the CRD 38/6866

Note: Installing the suction cup feet is not mandatory but helps keep the

cradle in place.

1. On the bottom of the cradle, thread each of the four suction cup feet into the screw

holes.

2-5

Page 27

PDT 6800 Series Product Reference Guide

2. Wet the base of each suction cup and secure the cradle to a smooth tabletop by

pushing firmly down on the cradle (Figure 2-6).

Figure 2-6. Installing Suction Cups on the CRD 38/6866

Connecting Power

Note: Connecting power to both CRD 38/6865 and CRD 38/6866 is the

same.

1. Connect the power supply cord’s round plug to the power port on the left side of the

cradle.

2. Connect the power supply’s AC plug to a standard electrical outlet.

2-6

Page 28

Accessories Setup

The green and red indicators light for 3 seconds, blink for 3 seconds, then go out.

CRD 38/6865

CRD 38/6866

Figure 2-7. Connecting Power to the CRD 38/6865 and CRD 38/6866

Connecting for Data Communications

To connect the CRD 38/6865 or CRD 38/6866:

1. Be sure to unplug the cradle’s power supply before connecting the serial cables.

2. Turn off the PC.

3. Plug the RS-232 serial cable’s DB-25 connector in the cradle’s communication port

(Figure 2-8).

4. Connect the cable’s other connector to the host computer’s serial (COMM) port.

2-7

Page 29

PDT 6800 Series Product Reference Guide

5. Reconnect the cradle’s power supply

CRD 38/6865

2-8

CRD 38/6866

Figure 2-8. Connecting the CRD 38/6865 and CRD 38/6866 for

Communications with Computer, Printer, or Modem

Page 30

Accessories Setup

Connecting the CRD 38/6865 Internal Modem

RJ-11

Port

Figure 2-9. RJ-11 Internal Modem Connection

Some cradles use an optional internal modem that communicates at rates of up to 14,400 bps

(with v.32 bit data compression). It can be connected directly to a telephone line through the

RJ-11 port shown in Figure 2-9.

The four-slot cradle does not have an internal modem.

Note:

To connect the internal modem:

1. Connect the phone cord into the RJ-11 port on the back of the cradle.

2. Connect the other end of the phone cord into the wall phone jack.

Caution

When connecting the internal modem to the phone line, always connect the

phone line to the cradle first, then to the wall phone jack. When removing

the connection, always remove the telephone line from the wall phone jack,

then remove from the cradle.

There are specific firmware settings which are used to configure the modem’s hardware and

software for proper operation and regulatory compliance. The terminal’s application can

control these settings and enable you to view and amend the settings for country/region,

pulse/tone dialing, or repeat dial timing. Incorrectly defining these settings can lead to illegal

use of the modem and can create unreliable operation. The application developer should

consult the Series 3000 Application Programmer’s Reference Manual for correct settings.

2-9

Page 31

PDT 6800 Series Product Reference Guide

Connecting to the Telephone Network

A compliant telephone cord is required with an RJ-11 plug connection to the modem,

terminated with an appropriate and correctly wired local telecom connector compatible with

the telephone network. Such a cable may be obtained from your local supplier. Alternately,

compliant RJ-11 plugs to RJ-11 plug cables may be used with a range of adapters for

locations such as Europe.

Connecting the CRD 38/6866 to Other Cradles

Up to twenty-four CRD 38/6866 cradles can be connected in a series using an RS-232 intercradle cable (p/n 60427-00-00) between each cradle.

Caution

Each cradle must have its own power supply; any other power hook-up

method is unsafe.

1. Plug one end of the inter-cradle cable into the communication port located on the

right end of the first cradle.

2. Plug the other end of the inter-cradle cable into the communication port located

below the power connector on the left end of the second cradle.

3. Connect the power supply to the second cradle as described in Connecting Power on

page 2-6.

4. Repeat the above steps for any additional cradles being added to the chain.

2-10

Chaining Interconnect Cable

(p/n 60427-00-00)

Figure 2-10. Connecting the CRD 38/6866 to Other Cradles

Page 32

CCM 38/6860

Parts of the CCM 38/6860

Battery

Optical

Connectors

Charging

Contacts

Accessories Setup

Power Po rt

Communications

Port

Terminal In

COMM LED

Te r m i n a l

Charge LED

Battery

Charge LED

Figure 2-11. Parts of the CCM 38/6860

Spare Battery

Charging Slot

2-11

Page 33

PDT 6800 Series Product Reference Guide

Wall Mounting

The CCM 38/6860 can be table or wall mounted.

To wall mount the CCM:

1. Attach the wall-mounting brackets to the bottom of the CCM using the screws

provided (Figure 2-12)

Step 1

Step 2

Figure 2-12. Wall Mounting the CCM

2. Position the CCM with attached brackets on the wall.

3. Insert the appropriate wall-mounting hardware into the bracket holes as shown in

Figure 2-12 and secure.

Appropriate wall-mounting hardware is provided by customer.

Note:

Coupling CCMs

Up to four CCM 38/6860s can be coupled together for table or wall mounting, with power

provided by a single power supply attached to the left-most CCM. To couple two or more

CCMs for table or wall mounting:

1. Verify that add-on kit p/n 3861-101 contains the following parts:

" 1 CCM

" 1 coupling bracket

" 6 cross-head screws

" 2 flat-head screws

2-12

Page 34

Accessories Setup

2. On the add-on (or right-hand) CCM, use a 3/16-inch driver and remove the jack

screws, securing the communications port, and replace them with the flat-head

screws ONE AT A TIME.

Note: Be sure to remove the jack screws one at a time; otherwise, the

connector will fall into the housing.

3. Mate the power port on the right side of the first cradle with the power port on the

left hand side of the second cradle.

4. Place the coupling bracket between the CCMs, aligning the holes in the coupling

bracket with the holes in the CCM’s base (Figure 2-13).

5. Install 6 cross-head screws through the coupling bracket into the CCMs and tighten.

6. To wall mount the coupled CCMs, refer to Wall Mounting above.

Screws

Coupling

Bracket

Screws

Figure 2-13. Coupling Two CCMs

Connecting Power

Only the power connection is required for charging batteries in the CCM.

1. Install the power supply.

a. Attach the power supply to the left side of the CCM as shown in Figure 2-14

using two cross-head screws.

b. Connect the power supply plug to an AC wall outlet.

2-13

Page 35

PDT 6800 Series Product Reference Guide

2. When the CCM is connected to power, all the LEDs flash at the same time for 3

seconds, flash once from left to right, and then turn on for 3 seconds before going

out.

Insert Screw

Power Supply

Insert Screw

Null Modem Cable

+-

LEDs

-

+

Figure 2-14. Connecting the CCM 38/6860 for

Charging and Communications

Connecting the CCM for Serial Communications

CCM

Note: Both the communications cables and the power supply connection are

required for performing communications through the CCM.

1. Turn off the PC.

2. Plug the RS-232 null modem cable’s DB-25 connector in the cradle’s communication

port.

2-14

Page 36

Accessories Setup

3. Connect the cable’s other connector to the host computer’s serial (COMM) port.

Daisy-Chaining Two or More CCMs

Up to twenty-four CCMs can be daisy-chained together for charging and communications.

To daisy chain two or more groups of four CCMs requires:

one 25-pin, male-to-female, straight-through RS-232 cable per group of coupled

!

CCMs

one power supply per group of coupled CCMs.

!

Depending on how close together you place the CCMs, the cables can be from 1-foot to 10feet long.

First

One Power Supply

and RS-232 Cable

per Group of

Coupled CCMs

(a “Group” Can

Number from

1 to 4 CCMs)

Coupled

Group

RS-232

Cable

Second

Coupled

Group

Figure 2-15. Daisy-Chaining Multiple CCMs

To chain the CCMs:

1. Couple the CCMs as directed in the section Coupling CCMs.

2. In the first coupled section, connect the serial cable to the left-most CCM.

3. Connect the RS-232 cable’s (male or female) DB-25 connector in the serial port of

the right-most CCM in the first coupling.

4. Connect the (male or female) DB-25 in the serial port of the left-most CCM in the

second coupling.

2-15

Page 37

PDT 6800 Series Product Reference Guide

5. Connect the power supplies for each coupled section as directed in Connecting

Power.

PC Adapter

The PC Adapter works with the Printer Interface Module (PIM) so you can:

Communicate to and from the PC without a CCM 38/6860, CRD 38/6865, or CRD

!

38/6866 cradle

Charge the NiCd battery pack in the terminal without a cradle.

!

Note: The Lithium Ion battery DOES NOT charge when the PC Adapter

and PIM are connected. Use the UBC 2000 battery adapter p/n 2132665-24 to charge the Lithium Ion battery.

Parts of the PC Adapter

PIM

PC Adapter

DB-9 Connector

RS-232

Pin Port

Power S upply Port

Batter y Charge

Indicator LED

Figure 2-16. Parts of the PC Adapter

The Battery Charge Indicator LED flashes when the terminal power is turned on and

!

while the NiCd battery pack is being charged.

Note: When power to the PC Adapter is turned on, NiCd battery charging

begins automatically and continues for 7 hours.

2-16

Page 38

Accessories Setup

The LED flashes once when the terminal is turned on. It remains steady while the

terminal is powered and blinks slowly during downloading.

The RS-232 25-pin port attaches the null modem cable connected to a PC or other

!

RS-232 device. See Appendix A, Null Modem Pin-outs for null modem pin-outs.

The DB-9 connector attaches the PIM’s DB-9 connector.

!

The power supply port attaches the 15-Volt power supply.

!

Connecting the PC Adapter to the Terminal and Serial Device

PIM’s Optical

Connector

PIM

Power Supply

DB-25RS-232 Cable

Connector

PC

Adapter

Power

Supply

Port

Figure 2-17. Setting Up the PC Adapter

1. Turn the PC and terminal OFF.

2. Plug the PIM’s DB-9 connector in the PC Adapter’s DB-9 port.

DB-9 Port

2-17

Page 39

PDT 6800 Series Product Reference Guide

3. Attach the PIM’s optical connector to the terminal by inserting the clips on the

connector in the slots on either side of the port (Figure 2-18).

PIM Optical

Connector

Optical

Port

Clips

Slots

PIM Cable

Figure 2-18. Attaching the PIM’s Optical Connector

1. Connect the RS-232 cable’s DB-25 connector in the PC Adapter’s RS-232 port.

2. Plug the other end of the RS-232 cable in the RS-232 device (e.g., host PC).

3. Plug the jack end of the 16-Volt power supply into the power supply port.

4. Plug the 15-Volt power supply’s cube into an electrical outlet. The Battery Charge

Indicator LED flashes when the terminal is powered on.

2-18

Page 40

Chapter 3

Batch and Spectrum One Terminal Setup

Introduction

Before using the PDT 6800 Series terminal, perform the following:

Install the battery (refer to Chapter 6, Maintaining the Terminal)

!

Charge the battery (refer to Chapter 6, Maintaining the Terminal)

!

Load the system files and application(s) (refer to Series 3000 Application

!

Programmer’s Guide p/n 70-16308-XX).

Hardware Requirements

Following is the equipment required to initialize a batch or Spectrum One radio terminal:

PDT 6800 (batch) or PDT 6810 (Spectrum One) terminal

!

One or more CCM 38/6860 or CRD 38/6866, or a CRD 38/6865

!

OR

!

PC adapter with Printer Interface Module (PIM)

!

RS-232 null modem cable

!

Power Supply

!

Host Computer.

!

Refer to Chapter 2, Accessories Setup for setting up the cradles or PC Adapter for

communications.

3-1

Page 41

PDT 6800 Series Product Reference Guide

Communications

For terminals being used in a direct communications (batch) environment or a Spectrum One

network environment, applications are transferred from a host computer to the terminal:

over a communications line using a null modem connected to the cradle

!

OR

through the PC Adapter.

!

The procedure uses the SENDHEX program on the host computer and the Program Loader

function (from Command Mode) on the terminal.

Programs are stored in the terminal’s nonvolatile memory (NVM), also called the application

EEPROM.

Note: For details on the SENDHEX program, refer to the Series 3000

Application Programmer's Manual.

Other software may be used in place of the SENDHEX program.

Downloading the Program

To download the program, initiate the communications software on the host computer and

terminal as described in the following sections.

Note: To cancel communications at any time during the session, press

CLEAR on the terminal. The session stops immediately.

Communications parameters specified on the host and the terminal

must match. These parameters typically are:

38400 bps

7-bit parity

Odd parity

Xon/Xoff flow control

To program the EEPROM, the terminal must be connected to the

host through a cradle, CCM 38/6860, or PC Adapter with PIM.

3-2

Page 42

Batch and Spectrum One Terminal Setup

Initiate Host Communications Software

If using a cradle (CCM 38/6860, CRD 38/6866, CRD 38/6865), do steps 1-3. Otherwise

continue with step 4.

1. Connect the cradle to the host computer. Refer to Chapter 2, Accessories Setup.

2. Power on the cradle.

3. Place the terminal in the cradle.

4. Connect the PC adapter.

5. Power on the host computer.

6. Start the communications program.

7. At the DOS prompt, enter the SENDHEX command:

sendhex pgmname 38400 com2

where:

SENDHEX is the command

pgmname is the application being loaded (.hex extension is optional)

parameters are the communications parameters following the program

name. Parameters include baud rate, communications port,

data bits, parity, and flow control. To accept the default

parameters, do not enter a value.

In the example, the baud rate is set to 38400 bps and the communications port to

COM2. The default values are accepted for the remaining parameters.

Note: Versions of SENDHEX earlier than 3.0 do not support flow control.

If you use an earlier version and encounter communication errors, use

a lower baud rate.

8. SENDHEX displays the prompt:

Press <Enter> to begin communications.

9. Do NOT press <ENTER> yet. Before starting communications (refer to Starting

Communications on page 3-6), set up the terminal as described in Initiate Terminal

Communications.

3-3

Page 43

PDT 6800 Series Product Reference Guide

Initiate Terminal Communications

1. Boot the terminal to command mode.

For the 35-Key terminal:

" Press and hold <BKSP> and <SHIFT>.

" Press and release PWR.

" Release <BKSP> and <SHIFT>.

For the 46-Key terminal:

" Press and hold <F> and <I>.

" Press and release <PWR>.

" Release <F> and <I>.

The terminal displays:

COMMAN D M ODE

Select func tion

Self test

2. Scroll through Command Mode options using UpArrow or DownArrow until

"Program loader" is displayed. Press <ENTER>.

3. The terminal displays:

Progra m l oader

WARNIN G: EEPROM

WILL BE ERASED

CONTINUE? <ENT>

Before loading the new application, erase the NVM’s original contents.

To cancel this operation, press CLEAR.

Note:

4. Press <ENTER> to erase the EEPROM.

Wait while the EEPROM is erased. When complete, the program prompts for the

communications parameters.

3-4

Page 44

Batch and Spectrum One Terminal Setup

5. Baud Rate - the terminal displays:

Comm Parameters

Baud

4 960 0

Scroll through the list using UpArrow or DownArrow. When the correct rate is

displayed (38400 is recommended), press <ENTER>.

6. Data Bits - the terminal displays:

Comm Parameters

Data Bits

7

Press <7> (recommended) or <8> to specify data bits, or scroll through the list using

UpArrow and DownArrow. Press <ENTER> when the correct value is displayed.

Note: If 8 data bits is selected, the program selects "No parity" and skips

the next step.

7. Parity - if 7 data bits is selected, the terminal displays:

Comm Parameters

Parity

Odd

Press the first letter of a parity option (Even, Odd, None, Space, or Mark), or scroll

using UpArrow and DownArrow and press <ENTER> when the correct value is

displayed.

8. Flow Control - the terminal displays:

Comm Parameters

Flow Control

None

Press the first letter of a flow control option (None, Xon/Xoff, or RTS/CTS), or scroll

using UpArrow or DownArrow and press <ENTER> when the correct value is

displayed.

3-5

Page 45

PDT 6800 Series Product Reference Guide

Starting Communications

1. The terminal is ready to receive the program from the host PC and displays:

Comm Parameters

Start? <ENT >

2. Press <ENTER> on the terminal.

3. Press <ENTER> on the host computer. The SENDHEX program begins transmitting

the program image. When communications are established, the terminal displays:

Progra m l oader

Receiv ing : XX XX

where XXXX is the program segment address being transferred.

4. When the transmission is complete, the terminal displays:

Progra m l oader

Status 0000

A status of 0000 (all zeros) indicates a successful transfer. Other status values

indicate an error. These values are provided in Appendix C, Communications Status

Codes.

If you received an error, press CLEAR on the terminal to return to the Command

Mode main menu.

Ending Communications

To return to the Command Mode main menu:

1. Press CLEAR on the terminal.

2. Power down the terminal.

3. Detach any cables connected to the terminal.

4. Reboot the terminal using the appropriate cold boot sequence. Refer to Booting the

Ter min al on page 5-4.

3-6

Page 46

Chapter 4

Spectrum24 RF Terminal Setup

Spectrum24 Terminals

In Spectrum24 terminals, wireless connectivity is accomplished using standard

communications protocols. Because they are standard, the protocols are generalized and take

up considerably more space on the terminal’s NVM than is required for Spectrum One

terminals. Because there is less space available in NVM for application files, the terminal

operates with an additional megabyte of non-volatile memory or flash disk. This extra

memory is used to reduce not only the boot times but also the time and resources required to

load applications into the terminal. The flash disk also offers the possibility of running

multiple applications from the same terminal (refer to the Spectrum24 Setup and Utilities

Reference Guide p/n 72-50795-01 for more information). With version 3.03 or later of the

system software (LWP.HEX), the terminal can also run diagnostic tools.

Accessing the Flash Disk

The flash disk is accessed through a driver, FLASHDSK.SYS, which makes the flash disk

appear to a program as another disk drive (E:). The drive has characteristics of fast reading

but slow writing (for example, even for the smallest files, the write process takes 3-4 seconds).

These characteristics make it ideal for files that are written once, accessed often, and seldom

updated.

®

We recommend that you use the flash disk (E:) mainly for application and configuration file

storage. It is important to note that because of the slow writing time (3-4 seconds), writing

files during a power interruption (low battery, dead battery, suspend, power off, or power

failure) could corrupt the disk. Be sure to only write data to the disk with the terminal

connected to external power or with the battery fully charged to avoid problems. To avoid

overwriting the flash disk by mistake, the flash disk is set to read-only mode for normal

4-1

Page 47

Series 6800 Product Reference Guide

operation. The software installation or application software takes care of write/read mode

switching for you.

Standard Spectrum24 Software

The terminal comes with the system software installed, including:

Spectrum24 radio drivers

!

TCP/IP software

!

configuration files

!

various utilities.

!

A BIOS of version 3.08 or later is required.

The default files cover most expected installations/initializations with minor changes as

detailed in this chapter.

If your requirements are more advanced, refer to the Spectrum24 Network Terminal

Technical Reference Guide (p/n 70-20193-XX) for more information on the Spectrum24 RF

network, SLAODI.COM, the Symbol-provided ODI driver, and the configuration file setups

required for various platforms.

Refer to the Spectrum24 Setup and Utilities Reference Guide (p/n 72-50795-XX) for more

information on Spectrum24 boot options, addressing, initializing the terminal, and Access

Point (AP) associations.

4-2

Page 48

Chapter 5

Operating the PDT 6800 Series

Introduction

This chapter describes how to operate a PDT 6800 Series terminal, including:

Powering the terminal on and off

!

Booting the terminal

!

PDT 6842 - Switching 802.11 to Spring RF protocol

!

Adjusting the display contrast

!

Entering data using the keyboard

!

Entering data using the scanner

!

Communicating with a PC or printer

!

Communicating on an RF network.

!

5-1

Page 49

PDT 6800 Series Product Reference Guide

Powering the Terminal On

There are several ways to power on a terminal. Each way lets you resume at the same location

in the application where you left off.

Note: The PDT 6800 Series terminal always checks for enough battery

power for safe operation before it powers on.

Removing Terminal From a Cradle

The terminal automatically powers on when it is removed from a cradle. While the terminal

is in the cradle, the NiCd battery is constantly being charged. If you remove the terminal from

the cradle but do not use it right away, press the PWR key to turn it off, or let it power off

automatically. Refer to the section Restoring Power After Automatic Shutdown on page 53.

Note: The Lithium Ion battery is charged in the UBC 2000 battery adapter

p/n 21-32665-24, not in the cradle.

Keyboard

Your terminal can be programmed to power on from the keyboard by:

Pressing the PWR key only

!

Pressing any key.

!

If you press the PWR key while the terminal is in the cradle, the terminal powers on. If you

leave the terminal in the cradle and press PWR to turn the terminal off, it appears to turn off,

but is on very low power.

See the Series 3000 Application Programmer's Guide for more information on programming

your keyboard.

Real-Time Clock

If the application program allows it, the terminal can be powered on by the real-time clock.

This lets the terminal perform unattended operations such as an overnight communication

session.

5-2

Page 50

Operating the PDT 6800 Series

Laser Trigger

If the application program allows, you can power on the terminal by pulling the trigger.

Restoring Power After Automatic Shutdown

The terminal shuts off if you do not use it for an amount of time set by your application. Press

the PWR key or press the trigger to restore power and return to your application.

Powering the Terminal Off

To perform a normal power off, press the PWR key or let the terminal shut down

automatically as programmed. See your application guide or the section Restoring Power

After Automatic Shutdown for more information. Consult your system administrator if you

are unable to power off the terminal.

Forcing Power Off

If pressing the PWR key does not turn off the terminal, force the power off to reduce battery

drain and preserve your data.

To force power off, press and hold the PWR key for 15 seconds, until the terminal powers

down.

Restarting After a Forced Power Off

When a terminal is powered off because of software or hardware failure, use the following

methods to restart:

Use the warm-boot procedure for a software failure.

!

When a warm boot fails, use the cold-boot procedure.

!

If a system software problem in the nonvolatile memory (NVM) occurs, see

!

Chapter 3, Batch and Spectrum One Terminal Setup.

Note: Do not use the PWR key to restart a terminal when it was forced off

due to defective system or application software in the NVM. Pressing

the PWR key causes the program to resume where it stopped, trying

to perform the same unsuccessful operation.

5-3

Page 51

PDT 6800 Series Product Reference Guide

Booting the Terminal

Powering the terminal on does not boot the system or initialize the program or data. To

initialize the terminal, perform either a warm boot or cold boot.

Warm Boot

A warm boot resets the operating system while preserving the program and data on the RAM

disk. This process is similar to pressing the <Ctrl+Alt+Del> keys on a PC, except that it does

not clear the system’s memory. To perform a warm boot:

For the 35-Key terminal:

" Power the terminal off

" Press and hold <F> and <J>

" Press and release <PWR>

" Release <F> and <J>.

For the 46-Key terminal:

" Power the terminal off

" Press and hold <4> and <5>

" Press and release <PWR>

" Release <4> and <5>.

The terminal displays configuration information, copyright, RAM size, and expanded

memory RAM size. Other information displayed depends on the operating system, installed

device drivers, and AUTOEXEC.BAT commands. If this warm boot procedure fails to restart

the terminal, use the Cold Boot procedure.

Cold Boot

A cold boot fully resets the system and clears memory, including the RAM disk. Any

programs and data stored in memory or on the RAM disk are deleted. Nonvolatile memory

(NVM - the Application EEPROM) is not affected. If the cold-boot procedure fails to restart

the terminal, see Chapter 7, Error Recovery and Troubleshooting.

Caution

This procedure permanently erases all data and software in the terminal unless they reside in NVM. Contents of RAM are lost.

5-4

Page 52

Operating the PDT 6800 Series

To perform a cold boot:

For the 35-Key terminal:

" Power the terminal off

" Press and hold <SPACE>, <FUNC>, and Up Arrow

" Press and release <PWR>

" Release <SPACE>, <FUNC>, and Up Arrow.

For the 46-Key terminal:

" Power the terminal off

" Press and hold <A>, <B>, and <D>

" Press and release <PWR>

" Release <A>, <B>, and <D>.

The terminal displays version information, copyright, RAM size, and installed expanded

memory RAM size. Other information displayed depends on the operating system, installed

device drivers, and AUTOEXEC.BAT commands.

Cold-Boot Failure

During a cold boot, the system briefly displays a status line for each driver as it loads in the

format:

0: Driver #.##

The line shows a status value, usually 0, followed by the name and version number of the

driver. If the system halts at one of these lines and displays a status value other than 0, the

displayed device driver failed to load properly.

If such a failure occurs, try cold booting the terminal again. If this does not solve the problem,

call the Symbol Support Center.

More troubleshooting information is provided in the publications listed in Related

Publications on page x.

5-5

Page 53

PDT 6800 Series Product Reference Guide

PDT 6842 - Switching 802.11 to Spring RF Protocol

After a cold boot, the PDT 6842 boots up with the 802.11 RF protocol. If you are using the

Spring RF protocol, do the following to switch from 802.11 to Spring:

1. Cold boot the terminal. The following prompt displays:

SOFTWA RE UPDATE

Update ?[y /n]:

2. Within four seconds, type the letter “y”. If you do not type the letter “y” within four

seconds, the terminal boots up with the 802.11 RF protocol.

The next prompt displays:

RF PRO TOC OL UP DA TE

OPPORT UNI TY

Update RF protocol

[y/n]:

3. Within ten seconds, type the letter “y”. If you do not type the letter “y” within ten

seconds, the terminal boots up with the 802.11 RF protocol.

The next prompt displays:

RF Pro toc ol

Currently 802.11

1. Abo rt update

2. Make pre-802.11

3. Make 802.11

Select [1, 2,3]:

4. Select 2 to boot up with the Spring RF protocol.

The next prompt displays:

Enter password

→

5. Enter the password RFPROT, then press ENTER. The terminal continues to boot up.

The procedure to switch to the Spring RF protocol is complete. If a compatibility problem

exists, the terminal pauses with an error message. Contact your System Administrator.

5-6

Page 54

Boot to Command Mode

Command Mode provides functions for:

Running the Self-Test program to verify that the hardware is operating properly

!

(refer to Chapter 7, Error Recovery and Troubleshooting).

Performing a Memory Transfer to upload data from a terminal to a host system (refer

!

to Chapter 7, Error Recovery and Troubleshooting ).

Performing a Program Download to transfer an application from the host to a

!

terminal (refer to Chapter 3, Batch and Spectrum One Terminal Setup).

To boot to Command Mode:

For the 35-Key terminal:

" Power the terminal off

" Press and hold <BKSP> and <SHIFT>

" Press and release <PWR>

" Release <BKSP> and <SHIFT>.

For the 46-Key terminal:

" Power the terminal off

" Press and hold <F> and <I>

" Press and release <PWR>

" Release <F> and <I>.

Operating the PDT 6800 Series

Adjusting the Display

Display Contrast

The screen’s contrast is adjustable to eight levels, making the display more readable in

different lighting conditions, at various temperatures, and at different viewing angles.

To reduce (lighten) display contrast, press FUNC Y.

!

To increase (darken) display contrast, press FUNC X.

!

Backlighting

The backlight illuminates the display in dimly lit areas.

5-7

Page 55

PDT 6800 Series Product Reference Guide

Use of backlighting can significantly reduce battery life.

Note:

To turn the backlight on or off, press FUNC then L, or use the key sequence listed in your

application guide. The backlight turns off automatically when the terminal is powered off or

when the terminal has not been used for an amount of time set by the application. See the

Series 3000 Application Programmer's Guide for more information.

PDT 6800 Series Keyboard

The keyboard is used for entering data and issuing commands to the terminal. Figure 5-1 and

Figure 5-2 illustrate the standard 35-key and 46-key keyboards respectively. The keys on the

keyboard are distinguished as modifier keys and character keys. Because terminal keyboards

have fewer keys than PC keyboards, each character key can produce more than the usual one

or two characters. The modifier keys, SHF (Shift), CTL, and FUNC, used individually or in

combination, determine which character or special function the character keys produce.

Because the keyboard is programmable, your terminal may not work as described here. For

more information and illustrations of other keyboard states, see the Series 3000 Application

Programmer's Guide and your application guide.

5-8

FUNC ALPHA CLEAR SHIFT PWR

BKSP SPACE CTRL [ A ] B

' C = D * E / F - G

+ H . I , J \ K ; L

MNO P

Q

7

T

4

W

F1 F2 F3

1

Z

F10

0

Figure 5-1. 35-Key Keyboard

R

8

U

5

X

23

ENTER

S

F9F8F7

9

V

F6F5F4

6

Y

Page 56

Operating the PDT 6800 Series

ABC

FGH

L

K

P

U

Z

7

45

1

MN

Q

R

VWX

.

BKSP

8

90

6

23

E

D

I

J

O

S

T

Y

=

Figure 5-2. 46-Key Keyboard

Using the Keyboard