Page 1

7875 Scanner/Scale

Page 2

7875 Scanner / Scale

1999 SYMBOL TECHNOLOGIES, INC. All rights reserved.

Symbol reserves the right to make changes to any product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under

any patent right or patent, covering or relating to any combination, system, apparatus,

machine, material, method, or process in which Symbol products might be used. An

implied license only exists for equipment, circuits, and subsystems contained in Symbol

products.

Symbol is a registered trademark of Symbol Technologies, Inc. Other product names

mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Page 3

Quick Reference

Installation Steps

When installing the 7875 Scanner/Scale, follow the installation

steps below. Skip step 4 if the unit does not have a scale.

1. Verify Checkstand Preparation, see page 1

- Checkstand Cutout

- Display Clearance

- Service Clearance

-Item Diverter

- Ventilation Requirements

- Electrical Wiring

- Cable Hole Requirements.

2. Connect the Cables, see page 7

- Power Supply

- Remote Display

- Interface Cables

- RS-232 Peripheral Cable.

3. Install 7875 in Checkstand, see page 10

- Set Communications Protocol Switch

- Put the 7875 in Checkstand Cutout

- Align the 7875 to the Checkstand.

4. Calibrate the Scale, see page 13

- Access Calibration Switch

-Exercise the Scale

- Perform Calibration

- Validate the Calibration

- Secure Calibration Switch.

5. Check the Scanner Operation, see page 20

- Modify Program Parameters

- Scan Valid Bar Code Tags.

1

Page 4

7875 Scanner / Scale

Verify Checkstand Preparation

Checkstand Cutout 7875-1000/2000

C

D

I

H

DD

CC

E

B

ABCDE

7875-1000

Scanner

7875-2000

Scanner/Scale

29.51 cm 50.95 cm 3.49 cm 0.95 cm 43.97 cm

11 5/8 in. 20 1/16 in. 1 3/8 in. 3/8 in. 17 5/16 in.

30.63 cm 50.95 cm 3.49 cm 1.27 cm 43.97 cm

12 1/16 in. 20 1/16 in. 1 3/8 in. 1/2 in. 17 5/16 in.

FGHI

7875-1000

Scanner

7875-2000

Scanner/Scale

3.49 cm 13.0 cm 18.10 cm 18.42 cm

1 3/8 in. 5 1/8 in. 7 1/8 in. 7 1/4 in.

3.49 cm 13.0 cm 17.78 cm 18.42 cm

1 3/8 in. 5 1/8 in. 7 in. 7 1/4 in.

B

E

C

A

*F

A

No electronics under 7875

F

* Recommended shelf to catch the 7875 if

dropped during installation, although 7875

must not be supported by this shelf.

G

2

Page 5

Quick Reference

Note: Dimension A for a 7875-2000 includes a spacer along

the side of the unit so that it fits an existing 7870-2000

cutout.

Checkstand Cutout – 7875-3000

D

H

G

D

C

E

B

ABCD

29.51 cm 40.96 cm 3.49 cm 0.95 cm

11 5/8 in. 16 1/8 in. 1 3/8 in. 3/8 in.

EFGH

37.34 cm 12.54 cm 18.10 cm 18.42 cm

14 3/4 in. 4 15/16 in. 7 1/8 in. 7 1/4 in.

C

No electronics under NCR 7875

B

A

A

F

Note: The 7875-3000 must sit on a shelf below the checkstand

surface. The shelf should be open at the front and back.

3

Page 6

7875 Scanner / Scale

t

Display Clearance

50

30

This area must b e clea r

for viewing optional

integrated display.

60

Service Clearance

Mounting surface for keyboard mus

be removable for servicing and

vertical window replacement.

B

A

All Installations

A

8.0 in. (20.3 cm) minimum if checkstand structure is not removable

for servicing. 1.0 in. (2.5 cm) minimum if checkstand structure is removable for servicing.

B

14.0 in. (35.6 cm) minimum if checkstand structure is not removable

for servicing. 7.0 in. (17.8 cm) minimum if checkstand structure is removable for servicing.

C

5.1in. (13.0 cm) minimum clearance to closest checkstand panel.

7875

must not be supported by this panel.

A

Installations Without Integrated Display

60

C

The

4

Page 7

Quick Reference

Item Diverter

7.25 in. (18.4 cm)

Item Diverter

(Must be removable to service

Scanner/Scale in checkstand)

Ventilation Requirements

The 7875 Scanner/Scale is designed to operate without an exhaust

fan in the checkstand; however, there must be adequate convection

airflow. The ambient temperature inside the checkstand cannot be

higher than 104° F (40° C). Also, the ambient temperature inside

the checkstand cannot be higher than 12.6° F (7° C) above the

ambient temperature outside the checkstand. For example, if the

ambient temperature outside the checkstand is 76° F (24.4° C), the

ambient temperature inside the checkstand cannot be greater than

88.6° F (31.4° C). If the checkstand contains other heat producing

equipment, you may need to use forced air to keep the temperature

within the specified range. However, air coming into or leaving the

checkstand

MUST NOT

enter or exit past the 7875 Scanner/Scale.

5

Page 8

7875 Scanner / Scale

Electrical Wiring to the Checkstand

Input Voltage

Neutral and

Ground Bus

L3

Main Service

Panel

N

G

Conduit

Circuit A: Checkstand

Note:

Feeder wiring and insulated ground from

main service panel to distribution panel

to be run in metal conduit.

Belt Control

Lighting

Misc. equip.

The electrical wiring must meet all

electrical codes, laws and regulations.

Motor

Checkstand

Frame

Belt

Isolated/Insulated

Ground Bus

Neutral

Bus

Distribution Panel

L2

L1

Circuit Breakers

Symbol circuits should be run in

separate metal conduits.

Note:

Circuit B: Terminal

Circuit C: Scanner/Scale

Receptacle should be easily

assessible and near the

Scanner/Scale.

Isolated Ground Receptacles

Symbol circuits must be dedicated to

Symbol equipment or other logically

connected electronic equipment

(modems, DAA, bridges, etc.)

Installation Type Input Voltage L1, L2 Circuit Breakers

U.S., Canada,

Japan

International 220 VAC to

100 VAC to

120 VAC

240 VAC

100 VAC to

120 VAC

220 VAC to

240 VAC

Standard single-pole;

value determined by

type of device branch

and by electrical code.

European 220 VAC 220 VAC European double-pole.

6

Page 9

Quick Reference

Note: The 7875 outlet in the checkstand must be connected to

a circuit breaker switch. This switch must be located

close to the operator and is used as the On/Off switch

for the 7875.

Hole Requirements for Cables

To run the various cables through the checkstand, you may need to

drill holes in some of the panels. The holes must be large enough for

the connector on one end of the cable to pass through. Ensure there

are no sharp edges to cut the cable. The following table gives the

minimum hole size for each of the 7875 cables.

Cable Cable Length Minimum Hole Size

Power Cord – Outlet

to Power Supply

Power Cord – Power

Supply to the 7875

Interface Cable 8.0 m (26.24 ft.)

Remote Display Cable 8.0 m (26.24 ft.)

3.05 m (10 ft.) 3.18 cm (3/4 in.)

1.22 m (4 ft.) 1.52 cm (1/2 in.)

1.90 cm(3/4 in.)

4.0 m (12.12 ft.)

4.0 m (12.12 ft.)

1.90 cm (3/4 in.)

1.90 cm (3/4 in.)

1.90 cm (3/4 in.)

Connect the Cables

There are several cables associated with the 7875, some required

with every installation and some optional, depending on the system.

Make sure you have all the necessary cables for your installation.

Connect the cables according to one of the following two

illustrations.

7

Page 10

7875 Scanner / Scale

Single Cable Installation

AC

Power

Cord

Power

Supply

DC Power

Cable

Remote

Display

Check switch settings

C

R

Y

E

D

E

T

A

L

O

W

P

M

O

E

IS

P

R

D

R

X

E

A

N

M

N

A

A

C

5

S

V

5

7875

Scanner/Scale

Interface Cable

Host Terminal

DUAL PERIPHERAL PORTS

PORT 1

PORT 2

RS-232

Peripheral

8

Page 11

Quick Reference

Dual Cable Installation

AC

Power

Cord

Power

Supply

DC Power

Cable

Remote

Display

Chec k switch sett ing s

C

Y

R

E

D

T

E

A

L

O

W

P

M

O

IS

E

P

D

R

Scanner

Interface

Cable

X

A

M

A

5

V

5

/

R

T

E

R

N

O

N

A

P

C

X

S

U

A

7875

Scanner/Scale

Scale Interface

Cable

Host Terminal

DUAL PERIPHERAL PORTS

R

K

H

C

A

T

A

D

PORT 1

PORT 2

RS-232

Peripheral

9

Page 12

7875 Scanner / Scale

RS-232 Peripheral Cables

The cable on some RS-232 hand-held peripheral devices is not long

enough to connect to the 7875 (under the checkstand) and still

permit easy use of the device. In these cases, Symbol recommends

installing an extension cable. You can obtain one from Symbol or

you can make your own. If you make your own, it should be

approximately 39 inches (1 meter) long with 8-pin phone type

connectors on each end.

J1 P1

J1 Wire Number P1

111

222

333

444

555

666

777

888

Install 7875 in Checkstand

Set the Communications Protocol Switch

Before setting the 7875 into the cutout in the checkstand, verify that

the Communications Protocol Switch is properly set. Single cable

units have one switch, dual cable units have two. The switches are

located on the Interface Board and you can access them through

holes in the side of the unit. For RS-232 communications, both

switches must be toward the front (operator side) of the unit. For all

10

Page 13

Quick Reference

other communication protocols, both switches must be toward the

back (customer side) of the unit.

AUX PORT/

DATACHKR

DATACHKR OCIA/IBM

RS-232 RS-232

Make sure power is

off before changing

switch setting

Switches

SCANNER

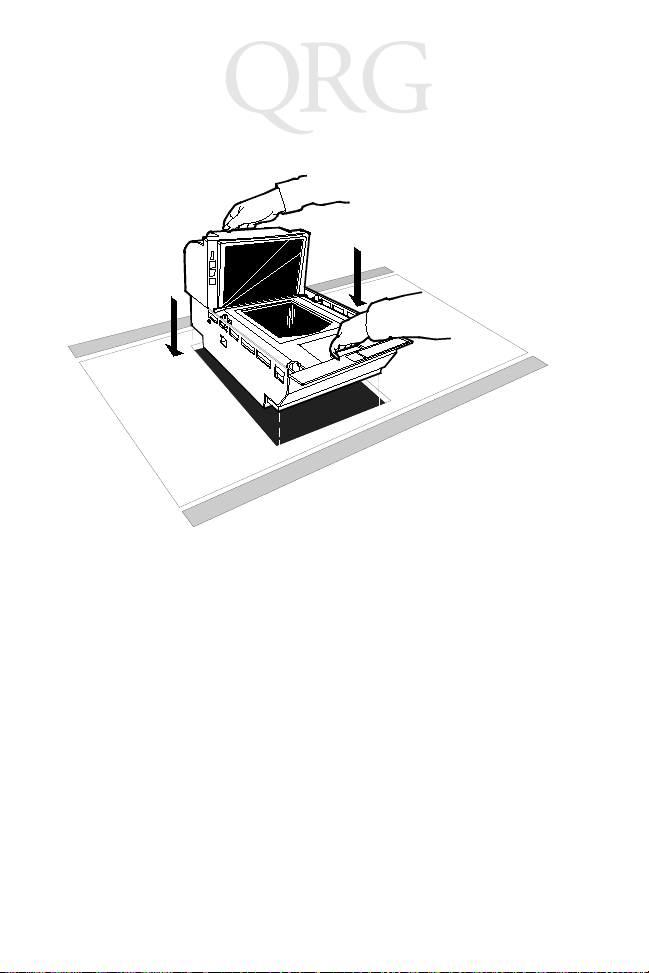

Installing 7875 into Checkstand Cutout

Grasp the 7875 Scanner/Scale and lower it into the checkstand

cutout. Be careful not to damage any of the cables. After the unit is

properly sitting on its supports, install the Top Plate.

Note: It is important that the 7875 does not rock on its sup-

ports. Make sure all adjustable supports are securely

fastened and that the 7875 is sitting on all supports.

11

Page 14

7875 Scanner / Scale

Align the 7875 to the Checkstand

The leading edge of the Top Plate must be flush or up to 1/16 in.

(0.15 cm) below the top of the checkstand. The trailing edge of the

Top Plate must be flush or up to 1/16 in. (0.15 cm) above the top of

the checkstand.

Note: The four adjustable support posts on the Scale Hinge

Assembly are set at the factory. Do not attempt to adjust

the Top Plate using these posts. Adjust the 7875 supports to align the Top Plate with the checkstand.

If the Top Plate is properly aligned with the checkstand, an item

should easily slide from the checkstand onto the Top Plate and then

from the Top Plate onto the checkstand. The following illustration

shows this alignment.

12

Page 15

Quick Reference

Low Surface

High Surface

Correct Alignment

Bad Alignment

Scanner Too High

Bad Alignment

Scanner Too Low

Low Surface

High Surface

Calibrate the Scale

Note: To comply with governmental weights and measures

regulations, you must be certified to perform the calibration function. Also, you MUST calibrate the scale

when you install an 7875 Scanner/Scale.

Note: Your 7875 Scanner/Scale may not have an integrated

display, and may not have a remote display when connected to some host terminals. If this is the case, a Field

13

Page 16

7875 Scanner / Scale

Service Calibration Display is required unless your 7875

has voice enabled. Calibration information is NOT sent

to the host terminal. Contact your Symbol representative about calibrating the scale.

Note: The interface cable between the 7875 and host terminal

must be disconnected during calibration. Some hosts

may cause interference that invalidates scale calibration.

You can calibrate the scale after power is supplied for 30 minutes if

the ambient air conditions are 68° F (20° C) for at least 24 hours. If

this condition has not been met, the scale must be on for at least 6

hours before you can calibrate it. Also, you must use a certified

weight set to calibrate and certify the scale.

The EEPROM on the scale board maintains an audit trail of scale

calibration and programming activity. The audit trail contains an

event counter that records the number of times the scale has been

calibrated. You can display the audit trail count on an integrated,

remote, or Field Service Calibration Display by pressing the Scale

Zero Button on the Operator Display Panel. The display alternates

between Cal xxx and PAr xxx.

Exercise the Scale

You must exercise the scale before performing a calibration. Add

and remove weight to your scale in the order provided in the

following chart. In this building procedure you start with no weight

(0) and sequentially add and remove weight to obtain the values

shown in the chart. Perform this procedure four times

We ig h t

Feature Total Weight on Top Plate

9.995 kg 0.0 kg 2.5 kg 5.0 kg 10. 0 kg 5.0 kg 2.5 kg 0.0 kg

13.995 kg 0.0 kg 2.5 kg 5.0 kg 15.0 kg 5.0 kg 2.5 kg 0.0 kg

30.0 lb. 0.0 lb. 5.0 lb. 15.0 lb. 30.0 lb. 15.0 lb. 5.0 lb. 0.0 lb.

.

14

Page 17

Quick Reference

Access the Calibration Switch

The Calibration Switch is located below the Top Plate. Remove the

Top Plate to access to the Calibration Switch cover. Lift the cover up

to remove.

Calibration

Switch Cover

Remove the screw that secures the Calibration Switch cover. Also

remove the seal if one is present. Rotate the Calibration Switch

cover to access to the Calibration Switch.

Calibration Switch

Security Cover

Screw

Wire Seal

Calibration

Switch

15

Page 18

7875 Scanner / Scale

Calibrate the Scale

1. Press the Scale Zero Button to display the Cal and PAr values.

Record these values.

2. Access the Calibration Switch, then place the top plate on the

unit before pressing the switch. Raise the front edge of the Top

Plate just enough to reach the switch.

3. Press the switch, then immediately lower the Top Plate into

position. The display should show

Ready C-00 kg (00 lb.)

.

4. Follow the steps in the following chart.

Display Add Weight Remove Weight

Ready C-2.5 kg (05 lb.) 2.50 kg (5.00 lb.)

Ready C-05 kg (15 lb.) 2.50 kg (10.00 lb.)

Ready C-10 kg (30 lb.) 5.00 kg (15.00 lb.)

Ready C-00 kg (00 lb.) 10.00 kg (30.00 lb.)

Ready 0.000 kg (0.00 lb.)

Verify the Calibration

The scale accuracy test meets government requirements of testing

the accuracy of the scale after performing a scale calibration. It

contains a series of four tests that must be run in the continuous

sequence given.

Increasing Load Test

This test checks the scale’s accuracy when incrementally adding

weight to the center of the top plate. Use weights that correspond to

the 7875 weight feature

Weig ht

Step

1 9.995 kg 0.1 kg 0.1 ± 0.00 kg

Feature Add Weight

13.995 kg 0.1 kg 0.1 ± 0.00 kg

30.0 lb. 0.2 lb. 0.2 ± 0.00 lb.

.

Remove

Weight Display Result

16

Page 19

Quick Reference

Step

2 9.995 kg 2.5 kg 0.1 kg 2.5 ± 0.00 kg

3 9.995 kg 2.5 kg 5.0 ± 0.005 kg

4 9.995 kg 2.5 kg 7.5 ± 0.005 kg

5 9.995 kg 2.495 kg 9.995 ± 0.005 kg

Weigh t

Feature Add Weight

13.995 kg 2.5 kg 0.1 kg 2.5 ± 0.00 kg

30.0 lb. 5.0 lb. 0.2 lb. 5.0 ± 0.00 lb.

13.995 kg 4.5 kg 7.0 ± 0.005 kg

30.0 lb. 5.0 lb. 10.0 ± 0.01 lb.

13.995 kg 3.0 kg 10.0 ± 0.005 kg

30.0 lb. 10.0 lb. 20.0 ± 0.01 lb.

13.995 kg 3.995 kg 13.995 ± 0.005 kg

30.0 lb. 10.0 lb. 30.0 ± 0.01 lb.

Remove

Weight Display Result

Note: Do NOT remove any weight from the Top Plate.

Over-Capacity Test

This test checks for the proper indication from the scale when too

much weight is placed on the top plate.

Note: This test must immediately follow the increasing load

test; do not remove any of the weights prior to running

this test.

Place additional weight on the center of the top plate as shown in

the following chart. Use the weight that corresponds to the 7875

weight feature. The display shows a series of dashes to indicate an

over-capacity condition.

Weigh t

Step

1 9.995 kg 0.04 kg --.---

Feature

13.995 kg 0.04 kg --.---

30.0 lb. 0.08 lb. --.---

Add

Weigh t

Remove

Weight Display Result

17

Page 20

7875 Scanner / Scale

Step

2 9.995 kg 0.04 kg 9.995 ± 0.005 kg

Weig ht

Feature

13.995 kg 0.04 kg 13.995 ± 0.005 kg

30.0 lb. 0.08 lb. 30.0 ± 0.01 lb.

Add

Weig ht

Remove

Weight Display Result

Note: Do NOT remove any weight from the Top Plate.

Decreasing Load Test

This test checks the scale’s accuracy when incrementally removing

weight from the top plate. Use weights that correspond to the 7875

weight feature.

Note: This test must immediately follow the over-capacity test;

do not remove any of the weights prior to running this

test.

Step

1 9.995 kg 2.495 kg 7.5 ± 0.005 kg

2 9.995 kg 5.0 kg 2.5 ± 0.00 kg

3 9.995 kg 0.1 kg 2.5 kg 0.1 ± 0.00 kg

4 9.995 kg 0.1 kg 0.0 ± 0.00 kg

Weig ht

Feature Add Weight

13.995 kg 3.995 kg 10.0 ± 0.005 kg

30.0 lb. 10.0 lb. 20.0 ± 0.01 lb.

13.995 kg 7.5 kg 2.5 ± 0.00 kg

30.0 lb. 15.0 lb. 5.0 ± 0.00 lb.

13.995 kg 0.1 kg 2.5 kg 0.1 ± 0.00 kg

30.0 lb. 0.2 lb. 5.0 lb. 0.2 ± 0.00 lb.

13.995 kg 0.1 kg 0.0 ± 0.00 kg

30.0 lb. 0.2 lb. 0.0 ± 0.00 lb.

Remove

Weight Display Result

18

Page 21

Quick Reference

Shift Test

This test involves moving a weight off the center point of the top

plate to check for continued accuracy.

1. Place 5.00 kg (15.00 lb.) of weight in position 1 on the Top

Plate.

2. Move the weight to position 2 on the Top Plate. The display

should show 5.00 ± 0.005 kg (15.00 ± 0.01 lb.).

3. Repeat step 2 for positions 3, 4, and 5.

4. Move the weight to position 1 again.

5. Remove all weights. The display should read 0.000 ± 0.000kg

(0.00 ± 0.00 lb.).

6. Raise and hold up the Top Plate. Record the Cal and PAr values shown on the display.

5

2

1

34

19

Page 22

7875 Scanner / Scale

Secure the Calibration Switch

When you perform a scale calibration, seal the Calibration Switch

cover with a lead/wire seal using a lead/wire seal press or a film/

paper seal (obtained locally). The type of seal you use depends on

your local laws; also, Weights and Measures officials may be

required to attach the seal.

Note: In the United States and Canada, the audit trail can serve

as an acceptable security seal.

Check the Scanner Operation

Make any necessary programming changes to the 7875, then scan

some bar codes to assure the scanner is working properly. The 7875

does not have an On/Off switch. Use the circuit breaker switch in

the checkstand to turn the unit on or off.

Setting the Program Parameters

Caution: Some host terminals can corrupt the 7875 program if

they are running and are connected to the 7875 while

you are making program changes. Either turn off the

host terminal or disconnect the interface cable before

scanning any programming tags.

To make changes to the program parameters, enter information

from the Programming Worksheets on page 29. The Programming

Worksheets identify all the available program parameters. Each

worksheet relates to a specific programming mode. Most

programming options have defaults, identified by a heavy box, that

are determined at the factory. Scanning the

tag after applying power to the unit sets the parameters to these

values.

20

Default

tag as the first

Page 23

Quick Reference

Change the 7875 program by scanning the proper sequence of

programming tags included with the unit. To make program

changes:

1. Enter the Base Programming state by scanning the

ming Mode

ing power.

2. Select a Programming Worksheet and enter its parameter data

by scanning the appropriate Hex tags.

3. Save the program by scanning the

Note: In most cases the factory-determined defaults are the

tag; this must be the first tag scanned after apply-

Save and Reset

correct parameter setting. However, if you do need to

make changes, first set all parameters to default values,

then make any necessary changes to the appropriate parameters.

Program-

tag.

Scan Sample Tags

Scan some sample tags to verify that the 7875 is communicating

with the host terminal. Following are four tags that you can use,

providing the programming options are enabled.

21

Page 24

7875 Scanner / Scale

UPC-A

77062 37920

1

4

Code 39

17706237920

Code 128

17706237920

017706237920

Interleaved 2 of 5

22

Page 25

Quick Reference

Operating the Scanner

The 7875 is a fixed-position device installed in a checkout counter,

and is not moved by the operator during operation. The 7875 is

maintained and serviced by trained service personnel only. The

operator has no access to any laser module components.

The7875 does not have a power switch. Turn it on and off using

the circuit breaker switch, located in the checkstand, that supplies

power to the unit. Be sure this switch is in the On position.

The Status Indicator on the Operator Display Panel is red when the

7875 is ready. To scan, slide an item from the checkstand across the

scanner, and back onto the checkstand. With a good scan, the Status

Indicator flashes green, then turns red. Nothing happens if the bar

code is not read.

Status Indicator

23

Page 26

7875 Scanner / Scale

Operating the Scale

The 7875 typically takes from 1.0 to 2.0 seconds to weigh an item,

depending on the item’s weight. Heavier items take longer. Before

weighing an item, make sure the scale displays all zeros. If not, press

the Scale Zero Button.

Note: Place the item you are weighing in the center of the Top

Plate. The item must fit completely on the Top Plate, and

not hang over onto the checkstand.

When the scale weighs an item, the Status Indicator flashes green

and a good weigh tone sounds. Nothing happens if the scale cannot

weigh an item.

Status Indicator

Integrated Display

Scale Zero Button

Top Plate

24

Page 27

Quick Reference

Cleaning

Keep the scan windows clean to keep the read rate exceptionally

high. During normal operation the scan windows can accumulate

dirt, which degrades performance to the point where the scanner

cannot read bar codes. The Please Clean Window indicator flashes

when the scan windows need cleaning. Use a soft cloth moistened

with a common, non-abrasive, liquid window cleaner to clean the

scan windows. Be sure to spray the cleaner onto the cloth, not

directly onto the 7875.

Note: Scale problems can occur from debris collecting under

the Top Plate. Be sure to keep the plastic subplate clean

to prevent interference with the Top Plate when weighing items.

Top Plate

Wiping Action

25

Plastic Subplate

Page 28

7875 Scanner / Scale

Correcting Scanner Problems

Problem

Scanner does

not operate

Scanner does

not operate

Scanner does

not operate

Scanner does

not read tags

Scanner reads

only two tags

Status

Indicator Tone

Red Off

Green Off

Red Flashing Green

Flashing

Red Flashing

Red Flashing

Red On Off 7875 is

Off No power

Off Sleep

Off Communi-

Off Internal

Possible

Cause Corrective Action

to the unit

mode

cations is

IBM 468x

and scanner is offline

failure

not communicating with

host terminal

Check electrical outlet for

proper power.

Verify the circuit breaker

switch is in the ON position.

Pass something in front of

the motion detector.

Verify that the IBM terminal is turned on.

Verify that the IBM terminal is recognizing the

7875.

Verify that the Interface

Cable is properly connected.

Remove power from the

7875 and then supply

power again. If the problem is not corrected, have

scanner repaired.

Verify that the Interface

Cable is properly connected.

Remove power from the

7875 and then supply

power again. If the problem is not corrected, have

scanner or host terminal

repaired.

26

Page 29

Quick Reference

Correcting Scale Problems

Problem Possible Cause Corrective Action

Error code 5---displays

Error code 4---displays

Error code 4---displays

Scale display is

blank

Scale drift Verify that nothing is on the scale.

Possible scale error Press Scale Zero button and retry. If

Slight vibration to

scale when calibrating

Top Plate is being

prevented from

moving down.

Lift the Top Plate and verify that no

objects are under it. Push Scale

Zero button. If error code persists,

have unit repaired.

error code persists, have unit repaired.

Calibrate scale, not permitting any

external scale movement while the

weights are on the scale.

Remove interference around edge

of Top Plate and checkstand.

Remove any foreign objects from

under the Top Plate.

27

Page 30

7875 Scanner / Scale

Determining the Communication Protocol

Use the following procedure to determine the communications

protocol programmed in your 7875.

1. Apply power to the 7875.

2. Scan the

scanned after applying power. Scan the

read tone for this tag sounds (three beeps).

If the 7875 has the Voice feature enabled, the communications

protocol is given audibly. If the Voice feature is not enabled,

the Status indicator flashes green and the 7875 beeps, identifying the communication protocol. Following are the number

of beeps that sound for each communication protocol.

1 Short, high-pitched beep OCIA NCR Short

1 Beep OCIA NCR Long

2 Beeps OCIA Non-NCR

3 Beeps IBM 468x

6 Beeps RS-232

7 Beeps OCIA Single-Cable

8 Beeps OCIA Dual-Cable

Diagnostic Mode

tag; this must be the first tag

Hex 3

Beeper Indications

Beep Sequence Indication

tag. The good

3. Remove power from the 7875.

28

Page 31

Quick Reference

Programming Worksheets

This section describes the options used to program your scanner/

scale using the bar codes in the

and letters in boxes represent Hex bar codes to scan when selecting

each option.

10

COMMUNICATIONS PROTOCOL

Protocol

0 1 2 3 4 5

OCIA

NCR Short

(Datachecker)

OCIA

NCR Long

Programming Tags Guide

OCIA

Non NCR

(Casio

4-Bit Parallel)

IBM 468x

Port 4A

(Slot Scanner)

IBM 468x

(HHBCR)

Port 4B

. Numbers

RS-232

6 7 A B C

OCIA

Single Cable

11

GOOD READ TONE

Tone On/Off

A

Tone Frequency

B

(Hertz)

Tone Length

C

(Milliseconds)

Tone Volume

D

Not-On-File

E

Tone Volume

IBM 1520

OCIA NCR

Dual Cable

0 1

Off On

B

C

D

E

OCIA

Non NCR

Dual Cable

When entering Tone Frequency, the adjustment can be

incremented upward by scanning the

time you scan the

increases one unit. Scan the

to end this mode.

When entering Tone Length, the adjustment can be

incremented upward by scanning the

time you scan the

one unit. Scan the

this mode.

When entering Tone Volume, the adjustment can be

incremented upward by scanning the

time you scan the

one unit. Scan the

this mode.

When entering Not-On-File Tone Volume, the adjustment

can be incremented upward by scanning the

Each time you scan the

increases one unit. Scan the

to end this mode.

(BCR)

4-Bit Parallel

Hex B tag, the tone frequency

Hex C tag, the tone length increases

End tag or a valid Hex tag to end

Hex D tag, the tone Volume increases

End tag or a valid Hex tag to end

Hex E tag, the tone Volume

Hex B tag. Each

End tag or a valid Hex tag

Hex C tag. Each

Hex D tag. Each

End tag or a valid Hex tag

29

TEC

Hex E tag.

Page 32

7875 Scanner / Scale

12

TIMERS

Lockout Time

A

(Milliseconds)

Restart

B

Lockout Timer

Active Time

C

(Minutes)

13

UPC/EAN

A

Version D

B

Extend UPC-A

C

To EAN-13

UPC/EAN

0 1 2 3 4 6 75

450 600 750 900 1050 1200 1350 1500

0 1

Off On

0 1 2 3

0153060

No Time-out ( Always Active)

Note: We recommend that you do not set the Active Time

parameter to 0. Leaving the laser light on all the time reduces

its life expectancy.

0 1

Disable Enable

0 1

None D-1

0 1

Disable Enable

2 3

D-2 D-3

4 5

D-4 D-5

Extend UPC-E

D

To UPC-A

Periodical Codes

E

Periodical Code

Extension

Send Data

0 1

Disable Enable

0 1

Disable Enable

0 1

2-Digit

5-Digit

Only

Only

0 1

Data As

Decoded

2

2-Digit &

5-Digit

Periodical Code

Data Only

30

2

2CF Hex

If Periodical Data

Not Decoded

Page 33

Quick Reference

1 4

CODE 39

Code 39

A

0 1

Disable Enable

Minimum Characters Allowed

B

Full ASCII

C

Check Digit Present

D

Transmit Check Digit

E

Allow One-Character Tags

F

1 5

INTERLEAVED 2 OF 5

Interleaved 2 of 5

A

Bar Code Length

B

Value 1 Characters

Value 2 Characters

Check Digit Present

C

0 1

Disable Enable

0 1

Range

Specific

Check

Check

0 1

Disable Enable

2 - F 4

0 1

Disable

Enable

0 1

Disable Enable

0

Disable Enable

0 1

Disable Enable

Minimum

Minimum

Default

1

0 - 5 0 - 9

Character 1 Character 2

Default

0 8

0 - 5 0 - 9

Character 1 Character 2

Default

1 6

Transmit Check Digit

D

0 1

Disable Enable

31

Page 34

7875 Scanner / Scale

1 7

CODE 128

Code 128

A

Minimum Data Characters Allowed

B

UCC 128

C

1 6

LABEL IDENTIFIERS

Identifier Type

A

Default Prefix

0

0 1

Disable Enable

1 2 3 4 5

0 1

Disable Enable

2

None

3

Unique Prefix

Common Byte 1

B

Common Byte 2

C

Bar Code Type

D

Common Byte

Unique Identifier

Version Number

(UPC-D Only)

0 - 7

Hex Character

0 - 7

Hex Character

0 1 2 3 4

UPC-A UPC-D UPC-E EAN-8 EAN-13

5 6 7

Code 39 Code 128 Interleaved

0 1 2 3

None Common Byte 1 Common Byte 2 Both Common Bytes

0 - 7

Hex Character

0

Do Not Include

0 - F

Hex Character

0 - F

Hex Character

2 of 5

0 - F

Hex Character

1

Include

Default

5 D

Default

4 2

Default: Varies according to

Bar Code Type.

32

Page 35

Quick Reference

2 0

RS-232 PARAMETERS - SET 1

Baud Rate

A

Parity

B

Stop Bits And

C

Character

Length

Handshake

D

2 1

RS-232 PARAMETERS - SET 2

BCC Options

A

Interface Control

B

Check Digit

C

0

300160021200324004480059600619200

0

Odd1Even4None

0

1 Stop Bit

7-Bit Character

0

RTS Low

CTS Ignored

3 4 5

Raise RTS

Ignore CTS

0

Disable1Enable

0

None1ACK/NAK2XOn/XOff3ACK/NAK & XOn/XOff

Disable UPC-A

Disable EAN-8

Disable EAN-13

Disable UPC-E

Note: Check Digit parameter also applies to UPC-E

8-Bit Character

RTS High

CTS Ignored

RTS Low

Wait for CTS

0

when using for OCIA communications.

Note: Parity must be Odd or Even on a

1

1 Stop Bit

1

Raise RTS

Wait for CTS

RTS High

Wait for CTS

Default: 7870/7875-1000 - Disable

7870/7875-2000 - Enable

1

Enable UPC-A

Enable EAN-8

Enable EAN-13

Disable UPC-E

7870/7875;

None is selected.

7-Bit Character

Odd is used if

2

2 Stop Bits

2

2

Disable UPC-A

Disable EAN-8

Disable EAN-13

Enable UPC-E

3

2 Stop Bits

8-Bit Character

3

Enable UPC-A

Enable EAN-8

Enable EAN-13

Enable UPC-E

33

Page 36

7875 Scanner / Scale

2 2

RS-232 PREFIX BYTE

Prefix Byte

A

0

Disable1Enable24 Comma Prefix On34 Comma Prefix Off

ASCII Code

B

2 3

RS-232 TERMINATOR BYTE

Terminator Byte

A

ASCII Code

B

2 4

RS-232 COMMUNICATIONS OPTIONS

Message Delay

Scanner or

Scanner/Scale Format

Normal or

Eavesdrop Mode

0 - 7

Hex Character

(ASCII Code Chart)

0

Disable1Enable

0 - 7

Hex Character

(ASCII Code Chart)

Scanner Only5Scanner/Scale

Normal Mode7Eavesdrop Mode

0 - F

Hex Character

(ASCII Code Chart)

Note: A Terminator Byte is required on a

7870/7875. If you select

Disable , it is ignored and an

ETX (03) is sent.

0 - F

Hex Character

(ASCII Code Chart)

0

No Delay110ms Delay250ms Delay

4

6

0 2

0 3

Default

Default

34

Page 37

Quick Reference

3 0

SCALE PARAMETERS

Model Number

IBM Address

Speak Display Price

3 2

MISCELLANEOUS PARAMETERS

5-Second Weight Display Timer

IBM Tone Control

(Good Read Tone Control)

OCIA Price Display

IBM Rexmit Control

OCIA Blank Display in Price Mode

Enable/Disable Voice Messages

IBM Tag Data Format

3

Scanner/Scale4Scanner Only

5

Address 6A6Address 6B7Address 6E

B

Toggle On and Off

1

Disable2Enable

3

Disable4Enable

5

Disable6Enable

7

3 Times8Forever

9

DisableAEnable

Default: Enabled

D

Toggle

E

HexFASCII

35

Page 38

7875 Scanner / Scale

3 6

Dual Cable Interface Options

Scale Type

A

0

No Adapter -

Exit Parameter

1

Avery2Weightronix3Tec

Parallel

4

Casio

Parallel

5

Datachecker6Toledo

ASCII Code Chart

ASCII Code Chart

30

NULL

SOH

STX

ETX

EOT

ENQ

ACK

BEL

BS

HT

LF

VT

FF

CR

S0

S1

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

DLE

DC1

DC2

DC3

DC4

NAK

SYN

ETB

CAN

EM

SUB

ESC

FS

GS

RS

US

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

0

SP

31

1

!

32

2

"

33

3

#

34

4

$

35

5

%

36

6

&

37

7

'

38

8

(

39

)

9

3A

*

:

3B

;

+

3C

,

<

3D

-

=

3E

.

>

3F

/

?

50

40

41

42

43

44

45

46

47

48

49

4A

4B

4C

4D

4E

4F

P

@

51

Q

A

52

R

B

53

S

C

54

T

D

55

U

E

56

V

F

57

W

G

58

X

H

59

Y

I

5A

Z

J

5B

[

K

5C

\

L

5D

]

M

5E

^

N

5F

_

O

70

60

61

62

63

64

65

66

67

68

69

6A

6B

6C

6D

6E

6F

p

71

q

a

72

r

b

73

s

c

74

t

d

75

u

e

76

v

f

77

w

g

78

x

h

79

y

i

7A

z

j

7B

{

k

7C

|

l

7D

}

m

7E

n

7F

DEL

o

36

Page 39

Quick Reference

Regulatory Information

Radio Frequency Interference Requirements

This device has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the Federal Communications Commissions Rules and

Regulation. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

However, there is no guarantee that interference will not occur in a particular

installation. If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Radio Frequency Interference Requirements - Canada

This Class B digital apparatus complies with Industry Canada Standard ICES-003.

Cet appareil numérique de la classe B est conform à la norme NMB-003 d’Industrie

Canada.

Voluntary Control Council for Interference (VCCI) Radio Frequency Interference Statement

Scale Regulatory

Country, state, and local regulatory agency notification of an installation of a weighing

instrument or Point of Service terminal’s device is required. Failure to comply with

government Weights and Measures regulations can result in criminal prosecution of

individuals and can jeopardize the ability to conduct normal business. The 7875

Scanner/Scale has been certified in many countries. Contact the NCR office of Weights

& Measures and Laser Safety for specific country approvals.

37

Page 40

7875 Scanner / Scale

CE Marking and European Union Compliance

Products intended for sale within the European Union are marked with the

CE Mark which indicates compliance to applicable Directives and

European Normes (EN), as follows. Amendments to these Directives or

ENs are included:

Applicable Directives

• Electromagnetic Compatibility Directive 89/336/EEC

• Low Voltage Directive 73/23/EEC

Applicable Standards

• EN 55 022 - Limits and Methods of Measurement of Radio Interference Characteristics of Information technology Equipment

Warning:

product may cause radio interference in which case the user may be

required to take adequate measures.

• EN 50 082-1:1997 - Electromagnetic Compatibility - Generic Immunity Standard, Part 1: Residential, commercial, Light Industry

• IEC 1000-4-2(1995-01) - Electromagnetic compatibility (EMC) - Part 4:Testing

and measurement techniques - Section 2: Electrostatic discharge immunity test.

• IEC 1000-4-3(1995-03) - Electromagnetic compatibility (EMC) - Part 4:Testing

and measurement techniques - Section 3: Radiated, radio-frequency, electromagnetic field immunity test.

• EN 60 950 + Amd 1 + Amd 2 - Safety of Information Technology Equipment

Including Electrical Business Equipment

• EN 60 825-1 (EN 60 825) - Safety of Devices Containing Lasers

This is a Class A product. In a domestic environment this

Laser Devices

Symbol products using lasers comply with US 21CFR1040.10, Subchapter J and

IEC825/EN 60 825 (or IEC825-1/EN 60 825-1, depending on the date of

manufacture). The laser classification is marked on one of the labels on the product.

Class 1 Laser devices are not considered to be hazardous when used for their intended

purpose. The following statement is required to comply with US and international

regulations:

Caution: Use of controls, adjustments or performance of procedures other than those

specified herein may result in hazardous laser light exposure.

Class 2 laser scanners use a low power, visible light diode. As with any very bright light

source, such as the sun, the user should avoid staring directly into the light beam.

Momentary exposure to a Class 2 laser is not known to be harmful.

38

Page 41

Quick Reference

Scanner Labeling

This laser module

does not comply

with 21CFR1040.

Use only as a

component.

Class IIa Laser Product. Avoid Long-term Viewing of direct Laser Light.

Appareil à Laser de classe IIa Eviter Toute Exposition

Prolongèe de la vue à la lumiè re laser directe.

Class IIa Producto Laser. Tratè De no ver directamente èl Rayo

Laser por mucho tiempò. (IEC CLASS 1 LASER PRODUCT)

C

39

Page 42

7875 Scanner / Scale

In accordance with Clause 5, IEC 0825 and EN60825, the following information is

provided to the user:

ENGLISH HEBREW

CLASS 1 CLASS 1 LASER PRODUCT

CLASS 2 LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

DANISH

KLASSE 1 KLASSE 1 LASERPRODUKT

KLASSE 2 LASERLYF CLASSE 1 PRODOTTO AL LASER DI CLAS SE 1

SE IKKE IND I STRÅLEN CLASSE 2 LUCE LASER

KLASSE 2 LASERPRODUKT NON FISSARE IL RAGGIOPRODOTTO

AL LASER DI CLASSE 2

DUTCH

KLASSE 1 KLASSE-1 LASERPRODUKT

KLASSE 2 LASERLICHT KLASSE 1 LASERPRODUKT, KLASSE 1

NIET IN STRAAL STAREN KLASSE 2 LASERLYS IKKE STIRR INN I LYSSTRÅLEN

KLASSE-2 LASERPRODUKT LASERPRODUKT, KLASSE 2

FINNISH PORTUGUESE

LUOKKA 1 LUOKKA 1 LASERTUOTE CLASSE 1 PRODUTO LASER DA CLASSE 1

LUOKKA 2 LASERVALO

ÄLÄ TUIJOTA SÄDETTÄ CLASSE 2 LUZ DE LASER NÃO FIXAR O RAIO LUMINOSO

LUOKKA 2 LASERTUOTE PRODUTO LASER DA CLASSE 2

FRENCH SPANISH

CLASSE 1 PRODUIT LASER DE CLASSE 1 CLASE 1 PRODUCTO LASER DE LA CLASE 1

CLASSE 2 LUMIERE LASER CLASE 2 LUZ LASER

NE PAS REGARDER LE RAYON FIXEMENT NO MIRE FIJAMENTE EL HAZ

PRODUIT LASER DE CLASSE 2 PRODUCTO LASER DE LA CLASE 2

GERMAN SWEDISH

KLASSE 1 LASERPRODUKT DER KLASSE 1 KLASS 1 LASERPRODUKT KLASS 1

KLASSE 2 LASERSTRAHLEN KL ASS 2 LASERLJUS STIRRA INTE MOT STRÅLEN

NICHT DIREKT IN DEN LASERSTRAHL SCHAUEN LASERPRODUKT KLASS 2

LASERPRODUKT DER KLASSE 2

ITALIAN

NORWEGIAN

40

Page 43

Quick Reference

Service Information

Before you use your unit, it must be configured to operate in your facility’s network and

run your applications.

If you have a problem with running your unit or using your equipment, contact your

facility’s Technical or Systems Support. If there is a problem with the equipment, they

will contact the Symbol Support Center:

United States 1-800-653-5350 Canada 905-629-7226

United Kingdom 0800 328 2424 Asia/Pacific 337-6588

Australia 1-800-672-906 Austria 1-505-5794

Denmark 7020-1718 Finland 9 5407 580

France 01-40-96-52-21 Germany 6074-49020

Italy 2-484441 Mexico 5-520-1835

Netherlands 315-271700 Norway 66810600

South Africa 11-4405668 Spain 9-1-320-39-09

Sweden 84452900

Latin America Sales Support 1-800-347-0178 Inside US

Europe/Mid-East Distributor Operations Contact local distributor or call

+1-561-483-1275 Outside US

+44 118 945 7360

Warranty

Symbol Technologies, Inc. (“Symbol”) manufactures its hardware products in

accordance with industry-standard practices. Symbol warrants that for a period of

twelve (12) months from date of shipment, products will be free from defects in

materials and workmanship.

This warranty is provided to the origin al owner only and is not transferable to any third

party. It shall not apply to any product (i) which has been repaired or altered unless

done or approved by Symbol, (ii) which has not been maintained in accordance with

any operating or handling instructions supplied by Symbol, (iii) which has been

subjected to unusual physical or electrical stress, misuse, abuse, power shortage,

negligence or accident or (iv) which has been used other than in accordance with the

product operating and handling instructions. Preventive maintenance is the

responsibility of customer and is not covered under this warranty.

Wear items and accessories having a Symbol serial number, will carry a 90-day limited

warranty. Non-serialized items will carry a 30-day limited warranty.

41

Page 44

Warranty Coverage and Procedure

During the warranty period, Symbol will repair or replace defective products returned

to Symbol Technologies. For warranty service in North America, call the Symbol

Support Center at 1-800-653-5350. International customers should contact the local

Symbol office or support center. If warranty service is required, Symbol will issue a

Return Material Authorization Number. Products must be shipped in the original or

comparable packaging, shipping and insurance charges prepaid. Symbol will ship the

repaired or replacement product freight and insurance prepaid in North America.

Shipments from the US to other locations will be made F.O.B. Symbol’s manufacturing

plant. Shipments from Symbol’s repair facilities outside the US will be made F.O.B.

Symbol’s repair facility.

Symbol will use new or refurbished parts at its discretion and will own all parts

removed from repaired products. Customer will pay for the replacement product in

case it does not return the replaced product to Symbol within 3 days of receipt of the

replacement product. The process for return and customer’s charges will be in

accordance with Symbol’s Exchange Policy in effect at the time of the exchange.

Customer accepts full responsibility for its software and data including the appropriate

backup thereof.

Repair or replacement of a product during warranty will not extend the original

warranty term.

Symbol’s Customer Service organization offers an array of service plans, such as onsite, depot, or phone support, that can be implemented to meet customer’s special

operational requirements and are available at a substantial discount during warranty

period.

General

Except for the warranties stated above, Symbol disclaims all warranties, express or

implied, on products furnished hereunder, including without limitation implied

warranties of merchantability and fitness for a particular purpose. The stated express

warranties are in lieu of all obligations or liabilities on part of Symbol for damages,

including without limitation, special, indirect, or consequential damages arising out of

or in connection with the use or performance of the product.

Seller’s liability for damages to buyer or others resulting from the use of any product,

shall in no way exceed the purchase price of said product, except in instances of injury

to persons or property.

Some states (or jurisdictions) do not allow the exclusion or limitation of incidental or

consequential damages, so the proceeding exclusion or limitation may not apply to you.

70-37658-01

Revision A — April 1999

Symbol Technologies, Inc. One Symbol Plaza Holtsville, NY 11742-1300

Loading...

Loading...