MiniScan MS-120X

and MS-220X

Integration Guide

MiniScan MS-120X and MS-220X Integration Guide

72-63538-02

Revision A

November 2003

© 2003 by Symbol Technologies, Inc. All rights reserved.

No part of this publication may be reproduced or used in any form, or by any electrical or

mechanical means, without permission in writing from Symbol. This includes electronic or

mechanical means, such as photocopying, recording, or information storage and retrieval

systems. The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware,

furnished to the user is on a licensed basis. Symbol grants to the user a non-transferable

and non-exclusive license to use each software or firmware program delivered hereunder

(licensed program). Except as noted below, such license may not be assigned,

sublicensed, or otherwise transferred by the user without prior written consent of Symbol.

No right to copy a licensed program in whole or in part is granted, except as permitted under

copyright law. The user shall not modify, merge, or incorporate any form or portion of a

licensed program with other program material, create a derivative work from a licensed

program, or use a licensed program in a network without written permission from Symbol.

The user agrees to maintain Symbol’s copyright notice on the licensed programs delivered

hereunder, and to include the same on any authorized copies it makes, in whole or in part.

The user agrees not to decompile, disassemble, decode, or reverse engineer any licensed

program delivered to the user or any portion thereof.

Symbol reserves the right to make changes to any software or product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any

Symbol Technologies, Inc., intellectual property rights. An implied license only exists for

equipment, circuits, and subsystems contained in Symbol products.

Symbol, Spectrum One, and Spectrum24 are registered trademarks of Symbol

Technologies, Inc. Other product names mentioned in this manual may be trademarks or

registered trademarks of their respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

http://www.symbol.com

2

Contents

About This Manual

Chapter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Notational Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Symbol Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Chapter 1. Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

MiniScan MS-120X and MS-220X Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Miniscan Block Diagram Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Scanning Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Smart Raster Scan Pattern (MS-220X only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Single Scan Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Beeper and LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2. Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting the Scanner on the Stand (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Assembling the Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Mounting the Stand (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Connecting the MiniScan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Mechanical Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

MS-1207WA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

MS-1204FZY, MS-1207FZY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

iii

MS-120X and MS-220X Integration Guide

MS-2204, MS-2204VHD, MS-2207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Location and Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Using the MiniScan as an Embedded Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Conveyor Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Software Development CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

123Scan CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Chapter 3. MS-1207WA Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electrical Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

MS-1207WA Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

MS-1207WA Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Usable Scan Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

TTL RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

USB Warning - Potential Host Side Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Chapter 4. MS-120XFZY Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Scan Angle Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

MS-1204FZY Electrical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

MS-1207FZY Electrical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Application Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

TTL RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

USB Warning - Potential Host Side Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

MS-120XFZY Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Usable Scan Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Chapter 5. MS-220X Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

MS-2204 Electrical Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

MS-2207 Electrical Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Application Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

TTL RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

USB Warning - Potential Host Side Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

MS-220X Decode Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

MS-220X 1D Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

MS-220X 1D Decode Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

iv

Contents

MS-220X 2D Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

MS-220X 2D Decode Distances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Usable Scan Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Chapter 6. MS-2204VHD Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Electrical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

MS-2204VHD Decode Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

MS-2204VHD 1D Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

MS-2204VHD 1D Decode Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

MS-2204VHD 2D Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

MS-2204VHD 2D Decode Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Usable Scan Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter 7. Scanning

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Scanning Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Scan the Entire Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Position at an Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Triggering Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Continuous (Default). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Level Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Pulse Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Blinking (MS-120XFZY Versions Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Host Trigger (MS-1204 and MS-2204 Versions Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Chapter 8. Maintenance and Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Chapter 9. Parameter Menus

Operational Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Default Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Set Default Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Scanning Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Beeper Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Beeper Tone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Beeper Frequency Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

v

MS-120X and MS-220X Integration Guide

Laser On Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Power Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

Trigger Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Scanning Mode (MS-2204 and MS-2207 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Aiming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Programmable Raster Height and Raster Expansion Speed

(MS-2204 and MS-2207 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Timeout Between Decodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Beep After Good Decode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Transmit “No Read” Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Parameter Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-24

Linear Code Type Security Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Bi-directional Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

UPC/EAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

Enable/Disable UPC-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-28

Enable/Disable UPC-E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-29

Enable/Disable UPC-E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

Enable/Disable EAN-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Enable/Disable EAN-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

Enable/Disable Bookland EAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-33

UPC/EAN Coupon Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

Decode UPC/EAN Supplementals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Transmit UPC-A Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

Transmit UPC-E Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Transmit UPC-E1 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

UPC-A Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-41

UPC-E Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-42

UPC-E1 Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-43

Convert UPC-E to UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-44

Convert UPC-E1 to UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-45

EAN Zero Extend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-46

UPC/EAN Security Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-47

Linear UPC/EAN Decode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-49

Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-50

Enable/Disable Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-50

Enable/Disable UCC/EAN-128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-51

Enable/Disable ISBT 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-52

Lengths for Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-52

Code 128 Decode Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-53

Code 128 Decode Performance Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-54

Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

Enable/Disable Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

Enable/Disable Trioptic Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-56

Convert Code 39 to Code 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-57

vi

Contents

Code 32 Prefix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-58

Set Lengths for Code 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-59

Code 39 Check Digit Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-61

Transmit Code 39 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-62

Enable/Disable Code 39 Full ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-63

Code 39 Decode Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-64

Code 39 Decode Performance Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-65

Code 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-66

Enable/Disable Code 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-66

Set Lengths for Code 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-67

Code 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-69

Enable/Disable Code 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-69

Set Lengths for Code 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-70

Code 11 Check Digit Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-72

Transmit Code 11 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-73

Interleaved 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-74

Enable/Disable Interleaved 2 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-74

Set Lengths for Interleaved 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-75

I 2 of 5 Check Digit Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-77

Transmit I 2 of 5 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

Convert I 2 of 5 to EAN-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-79

Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-80

Enable/Disable Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-80

Set Lengths for Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-81

Codabar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-83

Enable/Disable Codabar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-83

Set Lengths for Codabar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-84

CLSI Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-86

NOTIS Editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-87

MSI Plessey. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-88

Enable/Disable MSI Plessey. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-88

Set Lengths for MSI Plessey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-89

MSI Plessey Check Digits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-91

Transmit MSI Plessey Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-92

MSI Plessey Check Digit Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-93

PDF417/MicroPDF417 (MS-220X Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-94

Enable/Disable PDF417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-94

Enable/Disable MicroPDF417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-95

MicroPDF Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-96

Code 128 Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-97

RSS Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-98

RSS-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-98

RSS-Limited . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-99

RSS-Expanded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-100

vii

MS-120X and MS-220X Integration Guide

Convert RSS to UPC/EAN (MS-120X Versions Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-101

Composite (MS-2204 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-102

Composite CC-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-102

Composite CC-A/B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-103

Composite TLC-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-104

UPC Composite Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-105

Data Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-106

Transmit Code ID Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-106

Prefix/Suffix Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-108

Scan Data Transmission Format (MS-XX04). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-110

Scan Data Transmission Format (MS-XX07). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-112

Simple Serial Interface (SSI) Options (MS-1204/2204 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . .9-114

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-114

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-116

Check Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-118

Software Handshaking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-119

Host RTS Line State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-120

Decode Data Packet Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-121

Stop Bit Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-122

Intercharacter Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-123

Host Serial Response Time-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-123

Host Character Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-124

Event Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-125

Decode Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-126

Boot Up Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-127

Parameter Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-128

Macro PDF Features (MS-2204 and MS-2207 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-129

Transmit Symbols in Codeword Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-129

Transmit Unknown Codewords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-131

Escape Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-132

Delete Character Set ECIs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-133

ECI Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-134

Transmit Macro PDF User-Selected Fields

(MS-2204 and MS-2207 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-135

Transmit File Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-135

Transmit Block Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-136

Transmit Time Stamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-137

Transmit Sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-138

Transmit Addressee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-139

Transmit Checksum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-140

Transmit File Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-141

Transmit Macro PDF Control Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-142

Last Blocker Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-143

Numeric Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-144

viii

Contents

Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-146

Chapter 10. RS-232 Interface (MS-1207/MS-2207 Only)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

RS-232 Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

RS-232 Host Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

RS-232 Host Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Stop Bit Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Data Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Check Receive Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Hardware Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

Software Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

Host Serial Response Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

RTS Line State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

Beep on <BEL> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

Intercharacter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

Nixdorf Beep/LED Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

Ignore Unknown Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

Chapter 11. USB Interface (MS-1207/MS-2207 Only)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Connecting a USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

USB Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

USB Host Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

USB Device Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

USB Country Keyboard Types (Country Codes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

USB Keystroke Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

USB CAPS Lock Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

USB Ignore Unknown Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Emulate Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

USB Keyboard FN 1 Substitution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Function Key Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Simulated Caps Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Convert Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

Chapter 12. 123Scan (MS-1207/MS-2207 Only)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Communication With the 123Scan PC Based Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . 12-1

123Scan Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

ix

MS-120X and MS-220X Integration Guide

Chapter 13. Advanced Data Formatting (MS-1207/MS-2207 Only)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Rules: Criteria Linked to Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Using ADF Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

ADF Bar Code Menu Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

Rule 1: The Code 128 Scanning Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Rule 2: The UPC Scanning Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Alternate Rule Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Rules Hierarchy (in Bar Codes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

Default Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

Special Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

Pause Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

Begin New Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

Save Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

Quit Entering Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-10

Disable Rule Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-11

Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-12

Code Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

Code Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

Message Containing A Specific Data String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-20

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-24

Send Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-24

Setup Field(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-27

Modify Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-32

Pad Data with Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-34

Pad Data with Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-38

Beeps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-42

Send Keystroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-43

Send Right Control Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-73

Send Graphic User Interface (GUI) Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-73

Turn On/Off Rule Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-79

Alphanumeric Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-80

Chapter 14. Simple Serial Interface (SSI) (MS-1204/MS-2204 Only)

Simple Serial Interface (SSI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Revision String. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

SSI Commands Not Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Chapter 15. Mounting Template

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

x

Contents

Appendix A. ASCII Character Sets

RS-232 ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

USB ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Glossary

Index

xi

MS-120X and MS-220X Integration Guide

xii

About This Manual

The MiniScan MS-120X and MS-220X Integration Guide provides general instructions for

mounting, setting up, and programming the MiniScan MS-120X and MS-220X.

Note: It is recommended that an opto-mechanical engineer perform an

opto-mechanical analysis prior to integration.

Chapter Descriptions

Topics covered in this guide are as follows:

• Chapter 1, Introduction, provides an overview of the MS-120X and MS-220X

scanners, and explains the theory of operation.

• Chapter 2, Installation, describes the mechanical, electrical, optical and other

environments related to installing the MS-120X and MS-220X scanners.

• Chapter 3, MS-1207WA Specifications, provides the technical and scanning

specifications for the MS-1207WA scanner.

• Chapter 4, MS-120XFZY Specifications, provides the technical and scanning

specifications for the MS-120XFZY scanner.

• Chapter 5, MS-220X Specifications, provides the technical and scanning

specifications for the MS-220X scanner.

• Chapter 6, MS-2204VHD Specifications, provides the technical and scanning

specifications for the MS-220XVHD scanner.

• Chapter 7, Scanning, provides information on scanning and trigger modes.

• Chapter 8, Maintenance and Troubleshooting, provides information on

maintaining and troubleshooting the MS-120X and MS-220X scanners.

xiii

MS-120X and MS-220X Integration Guide

• Chapter 9, Parameter Menus describes the programmable parameters, provides

bar codes for programming, and hexadecimal equivalents for host download

programming.

• Chapter 10, RS-232 Interface (MS-1207/MS-2207 Only) describes how to set up

the scanner for RS-232 operation.

• Chapter 11, USB Interface (MS-1207/MS-2207 Only) describes how to set up the

scanner for USB operation.

• Chapter 12, 123Scan (MS-1207/MS-2207 Only) provides information on the

123Scan program, a PC-based scanner configuration tool.

• Chapter 13, Advanced Data Formatting (MS-1207/MS-2207 Only) (ADF)

describes how to customize scanned data before transmitting to the host.

• Chapter 14, Simple Serial Interface (SSI) (MS-1204/MS-2204 Only) describes

scanner-specific updates to the Simple Serial Interface (SSI) Programmer’s Guide.

• Chapter 15, Mounting Template, provides a mounting template for the MS-120X

and MS-220X scanners.

• Appendix A, ASCII Character Sets, provides prefix and suffix values that can be

assigned for ASCII character data transmission.

Notational Conventions

The following conventions are used in this document:

• Bullets indicate:

• action items

• lists of alternatives

• lists of required steps that are not necessarily sequential

• Sequential lists (e.g., those that describe step-by-step procedures) appear as

numbered lists.

Related Documents

The following documents provide more information for the MiniScan MS-120X and

MS-220X scanners.

• MiniScan Family of Scanners Quick Reference Guide, p/n 72-58809-xx

• Simple Serial Interface (SSI) Programmer’s Guide, p/n 72-40451-xx

• Simple Serial Interface (SSI) Developer’s Guide, p/n 72-50705-xx

xiv

About This Guide

Service Information

If you have a problem with your equipment, contact the Symbol Support Center. Before

calling, have the model number, serial number, and several of your bar code symbols at

hand.

Call the Support Center from a phone near the scanning equipment so that the service

person can try to talk you through your problem. If the equipment is found to be working

properly and the problem is symbol readability, the Support Center will request samples of

your bar codes for analysis at our plant.

If your problem cannot be solved over the phone, you may need to return your equipment

for servicing. If that is necessary, you will be given specific directions.

Note: Symbol Technologies is not responsible for any damages incurred

during shipment if the approved shipping container is not used.

Shipping the units improperly can possibly void the warranty. If the

original shipping container was not kept, contact Symbol to have

another sent to you.

Symbol Support Center

For service information, warranty information or technical assistance contact or call the

Symbol Support Center in:

United States

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

1-800-653-5350

United Kingdom

Symbol Technologies

Symbol Place

Winnersh Triangle, Berkshire RG41 5TP

United Kingdom

0800 328 2424 (Inside UK)

+44 118 945 7529 (Outside UK)

Canada

Symbol Technologies Canada, Inc.

2540 Matheson Boulevard East

Mississauga, Ontario, Canada L4W 4Z2

905-629-7226

Asia/Pacific

Symbol Technologies Asia, Inc (Singapore

Branch)

230 Victoria Street #05-07/09

Bugis Junction Office Tower

Singapore 188024

Tel : +65-6796-9600

Fax : +65-6337-6488

xv

MS-120X and MS-220X Integration Guide

Australia

Symbol Technologies Pty. Ltd.

432 St. Kilda Road

Melbourne, Victoria 3004

1-800-672-906 (Inside Australia)

+61-3-9866-6044 (Outside Australia)

Denmark/Danmark

Symbol Technologies AS

Dr. Neergaardsvej 3

2970 Hørsholm

7020-1718 (Inside Denmark)

+45-7020-1718 (Outside Denmark)

Finland/Suomi

Oy Symbol Technologies

Kaupintie 8 A 6

FIN-00440 Helsinki, Finland

9 5407 580 (Inside Finland)

+358 9 5407 580 (Outside Finland)

Germany/Deutchland

Symbol Technologies GmbH

Waldstrasse 66

D-63128 Dietzenbach, Germany

6074-49020 (Inside Germany)

+49-6074-49020 (Outside Germany)

Austria/Österreich

Symbol Technologies Austria GmbH

Prinz-Eugen Strasse 70 / 2.Haus

1040 Vienna, Austria

01-5055794-0 (Inside Austria)

+43-1-5055794-0 (Outside Austria)

Europe/Mid-East Distributor Operations

Contact your local distributor or call

+44 118 945 7360

France

Symbol Technologies France

Centre d'Affaire d'Antony

3 Rue de la Renaissance

92184 Antony Cedex, France

01-40-96-52-21 (Inside France)

+33-1-40-96-52-50 (Outside France)

Italy/Italia

Symbol Technologies Italia S.R.L.

Via Cristoforo Columbo, 49

20090 Trezzano S/N Navigilo

Milano, Italy

2-484441 (Inside Italy)

+39-02-484441 (Outside Italy)

Latin America Sales Support

2730 University Dr.

Coral Springs, FL 33065 USA

1-800-347-0178 (Inside United States)

+1-954-255-2610 (Outside United States)

954-340-9454 (Fax)

xvi

Mexico/México

Symbol Technologies Mexico Ltd.

Torre Picasso

Boulevard Manuel Avila Camacho No 88

Lomas de Chapultepec CP 11000

Mexico City, DF, Mexico

5-520-1835 (Inside Mexico)

+52-5-520-1835 (Outside Mexico)

About This Guide

Netherlands/Nederland

Symbol Technologies

Kerkplein 2, 7051 CX

Postbus 24 7050 AA

Varsseveld, Netherlands

315-271700 (Inside Netherlands)

+31-315-271700 (Outside Netherlands)

South Africa

Symbol Technologies Africa Inc.

Block B2

Rutherford Estate

1 Scott Street

Waverly 2090 Johannesburg

Republic of South Africa

11-809 5311 (Inside South Africa)

+27-11-809 5311 (Outside South Africa)

Norway/Norge

Symbol’s registered and mailing address:

Symbol Technologies Norway

Hoybratenveien 35 C

N-1055 OSLO, Norway

Symbol’s repair depot and shipping address:

Symbol Technologies Norway

Enebakkveien 123

N-0680 OSLO, Norway

+47 2232 4375

Spain/España

Symbol Technologies S.L.

Avenida de Bruselas, 22

Edificio Sauce

Alcobendas, Madrid 28108

Spain

Telephone: +34.91.324.4000

Service Telephone: +34.91.324.4000

Fax: +34.91.324.4010

xvii

MS-120X and MS-220X Integration Guide

Sweden/Sverige

“Letter” address:

Symbol Technologies AB

Box 1354

S-171 26 SOLNA

Sweden

Visit/shipping address:

Symbol Technologies AB

Solna Strandväg 78

S-171 54 SOLNA

Sweden

Switchboard: 08 445 29 00 (domestic)

Call Center: +46 8 445 29 29 (international)

Support E-Mail:

Sweden.Support@se.symbol.com

If you purchased your Symbol product from a Symbol Business Partner, contact that

Business Partner for service.

For the latest version of this guide go to:http://www.symbol.com/manuals.

xviii

Chapter 1

Introduction

!

Caution

Use of controls, adjustments or procedures other than those specified here

can result in hazardous laser light exposure.

Overview

The MiniScan family of industrial fixed-mount scanners are specifically designed for standalone applications, and OEM applications such as kiosks.

1-1

MS-120X and MS-220X Integration Guide

Figure 1-1. MiniScan Family of Scanners

MS-120X and MS-220X scanners provide easy and flexible integration of bar code

scanning into a host device, and include the following models:

•The MS-1207WA has a 60

o

scan angle that accommodates wide 1D bar codes

within close range, including RSS codes. This scanner is ideal for high-volume,

near-contact scanning in applications such as kiosks, ATMs, assembly lines,

warehouse and shipping.

•The MS-120XFZY offers premium scanning performance on all types of 1D codes

including poorly printed and low contrast symbols and RSS codes, appropriate for

applications where the print quality is inconsistent or poor, such as a warehouse

environment. The MS-120XFZY can be used in OEM devices and applications

such as warehouse and shipping, diagnostic equipment, vending machines,

gaming, library and document tracking systems.

•The MS-220X is an advanced, high-performance, 1D/2D fixed mount industrial

scanner specifically designed for manufacturing, warehousing, security, ID

verification, and OEM applications. This scanner offers a high-speed "smart" raster

pattern optimized for 1D/2D applications, and its high scan rate ensures fast and

reliable data on all 1D symbols including poorly printed bar codes, and 2D codes

such as PDF417, Micro-PDF, RSS and composite codes.

1-2

MiniScan MS-120X and MS-220X Features

• Stand-alone or OEM applications

• Quick and easy integration for OEM devices

• Excellent scanning performance on all types of bar codes

• Rugged IP54 sealed housing with integrated beeper

• RS-232 or multi-interface (USB, Synapse, TTL RS-232)

• Easy programming and configuration

• Flexible mounting options.

Typical Applications

MiniScan is the perfect solution for the following applications:

Fixed Mount Standalone Applications

• Manufacturing / warehouse

• Conveyer belts

• Security / ID verification

•POS.

Introduction

OEM Applications

• Kiosks / ATMs

• Music listening stations

• Security / ID verification

• Lottery terminals / gaming.

1-3

MS-120X and MS-220X Integration Guide

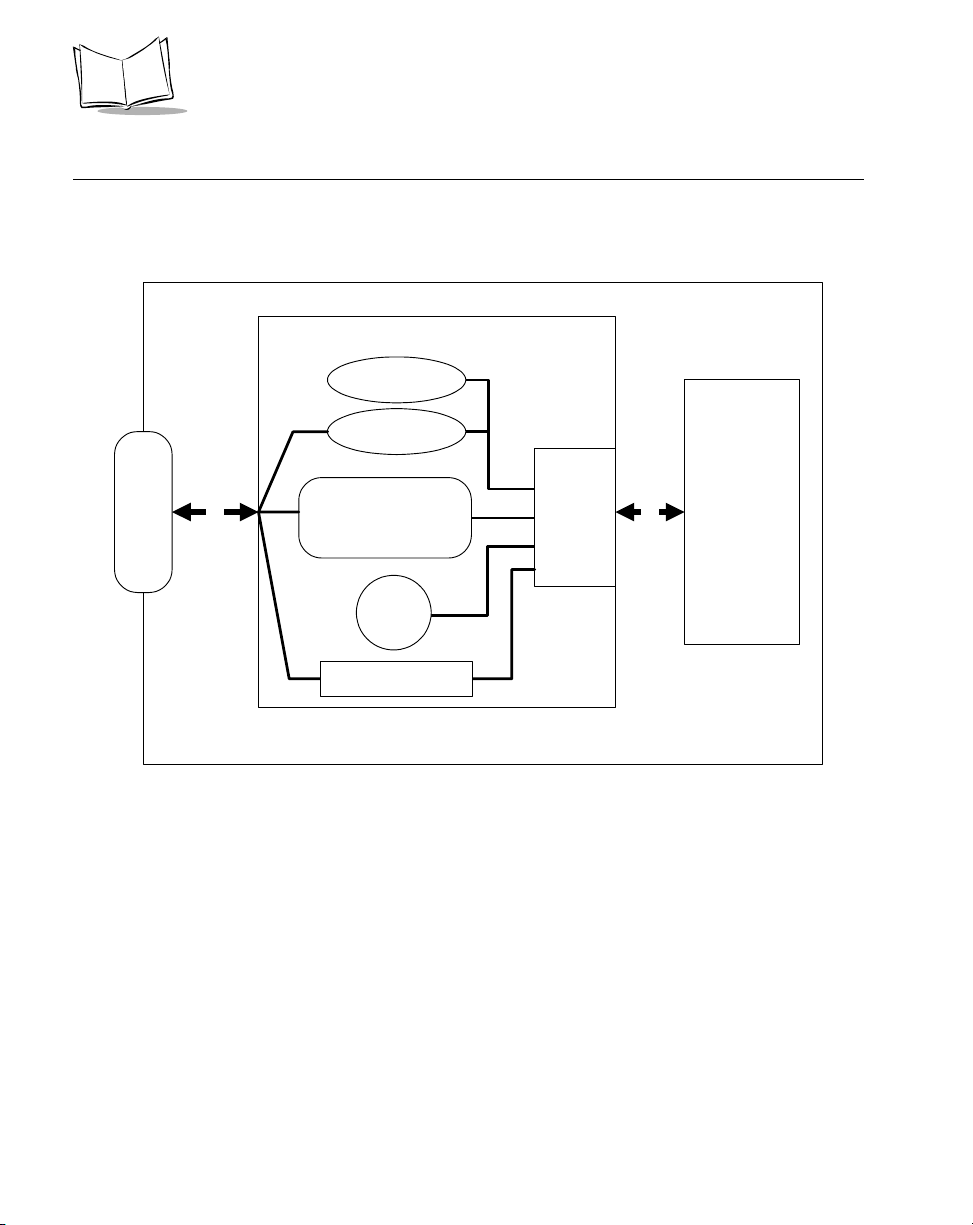

Block Diagram

The MiniScan block diagram illustrates the functional relationship of the MiniScan

components. A detailed description of each component in the block diagram is also

provided.

Interface Board

Beeper

External Beeper

DB9

flex flex

Interface Circuit

MS-XX04 = RS232

MS-XX07 = TTL-RS232,

Synapse, USB

Red/

Green

LED

External Trigger

Interface

Scan

Engine

Figure 1-2. MiniScan Block Diagram

Miniscan Block Diagram Descriptions

Decoded Scan Engine - The scan engine emits a beam of laser light that reflects off the

bar code to be decoded. Black bars absorb light, white spaces reflect light. The scan engine

collects the reflected light and processes the signal through several analog filters. The

filtered signal is digitized into a Digitized Barcode Pattern (DBP). Timing information is

analyzed by the decoder micro-controller to decode and transmit the data contained in the

bar code. Data transmission is carried out using Symbol's proprietary SSI Interface.

1-4

Introduction

Interface Board - The interface board adapts the scan engine's interface into usable

signals and data for the intended host. It also contains a beeper and red/green LED for

audio/visual feedback, and provides for an external trigger and external beeper.

• The MS-1204/2204 interface board converts TTL level SSI signals to proper

RS-232 levels for connection to any RS-232 compliant host.

• The MS-1207/2207 interface board converts the scan engine's data to Synapse,

USB, or TTL level RS-232. A separate host adapter cable (p/n 25-62186-xx) is

available to convert the TTL level RS-232 output to standard RS-232 levels. All

interface types are auto-detected based on the host cable attached.

DB9 - The DB9 connector provides a sealed outlet for the various interface signals used

between a MiniScan scanner and the host. It also maintains pin compatibility with the

previous generation LS 1220 MiniScan host cables.

1-5

MS-120X and MS-220X Integration Guide

Scanning Patterns

The MiniScan generates different scanning patterns based on the software command

received at the interface. The patterns are Smart Raster and Single Scan Line (standard

and high density). The raster pattern can be used to read 1D bar codes and PDF symbols.

Smart Raster Scan Pattern (MS-220X only)

The MS-220X can create a single line which opens vertically to read PDF417 symbols

using the Smart Raster feature. This feature autodetects the type of bar code being

scanned and adjusts its pattern accordingly, providing optimal performance on 1D,

PDF417, RSS, and Composite codes.

Stage 1: “Slab” Raster Pattern

Stage 2: Open Raster Pattern

1-6

Figure 1-3. Raster Scan Pattern

Introduction

Single Scan Line

Standard Single Scan Line (MS-120X versions)

The MS-120X scanner emits a single scan line to quickly decode quality 1D bar codes.

Figure 1-4. Single Scan Line Scan Pattern

High Density Single Scan Line (MS-220X versions)

The High Density single scan line appears as a "mini" raster and scans multiple areas of

1D codes to swiftly and accurately capture data on poorly printed and damaged bar codes.

Figure 1-5. High Density Single Scan Line Scan Pattern

1-7

MS-120X and MS-220X Integration Guide

Beeper and LED Definitions

Table 1-1 provides standard beeper definitions, and Table 1-2 provides LED definitions.

Table 1-1. Standard Beeper Definitions

Beeper Sequence Indication

Standard Use

1 Beep - short high tone A bar code symbol was decoded (if decode beeper is enabled).

1 Beep - long high tone Thermal shutdown.

3 Beeps - short high tone

(MS-220X only)

Parameter Menu Scanning

2 Beeps - short high tone Correct entry scanned or correct menu sequence performed.

1 Beep - hi/lo/hi/lo tone Successful program exit with change in the parameter setting.

2 Beeps - lo/hi tone Input error, incorrect bar code, or Cancel scanned, wrong entry,

Communication

Power-on or reset. Occurs immediately after the scanner is turned

on, indicating that the system software is working properly. If three

beeps occur during normal operation, it is due to a reset and any

work in progress is lost. If this occurs often, contact the Symbol

Support Center.

incorrect bar code programming sequence; remain in program

mode.

4 Beeps - short high tone Communication error.

4 Beeps - hi/hi/hi/lo Receive error.

3 Beeps - lo/hi/lo ADF transmit error.

Table 1-2. LED Definitions

LED Indication

Red Scanner is on.

Green A bar code was successfully decoded.

1-8

Chapter 2

Installation

Overview

This chapter provides information on unpacking, mounting, and installing the MiniScan, and

includes physical and electrical considerations.

Unpacking

Remove the MiniScan from its packing and inspect for damage. If the scanner is damaged,

call the Symbol Support Center at the telephone number listed on page xv.

KEEP THE PACKING. It is the approved shipping container and should be used if the

equipment needs to be returned for servicing.

2-1

MS-120X and MS-220X Integration Guide

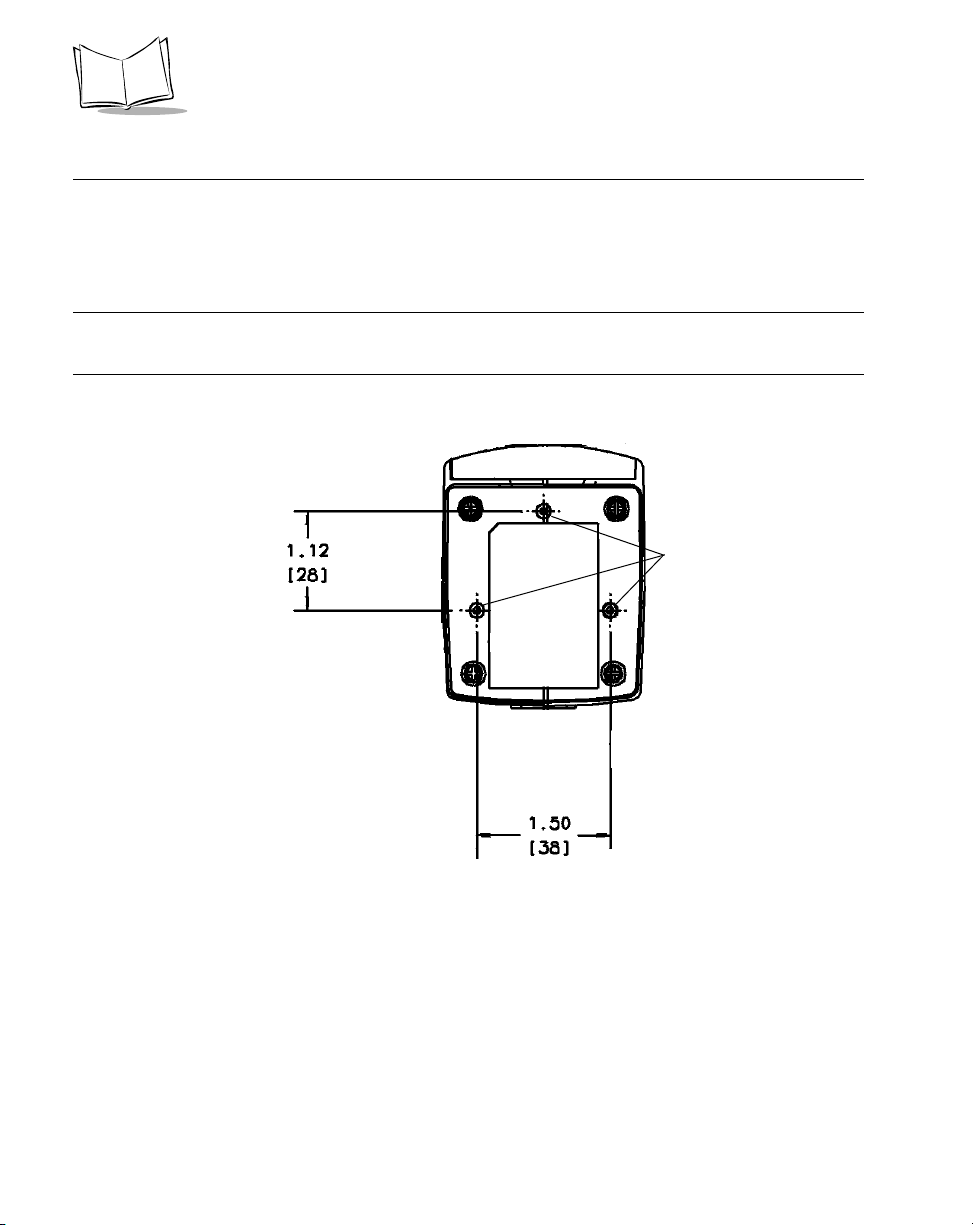

Mounting

There are three mounting holes (threaded inserts) on the bottom of the chassis.

Figure 2-1 provides mounting dimensions for the MiniScan scanner housing. For a

mounting template, see Mounting Template on page 15-1.

Note: Use only non-magnetic M3x.5 screws with a maximum length of

3.6M to mount the MiniScan scanner chassis.

Threaded Inserts

2-2

Note:

Dimensions are in

inches [mm].

Figure 2-1. MS-120X/MS-220X Mounting Dimensions

Loading...

Loading...