Page 1

swisherinc.com

OWNER’S

MANUAL

MODEL NO.

WB80024

WB80024S

WB8524

Read and follow all Safety

Rules and Instructions

before operating this

equipment.

Rev. 02.14.02

THE PREDATOR

THE PREDATOR

THE PREDATORTHE PREDATOR

24” ROUGH CUT

24” ROUGH CUT

24” ROUGH CUT 24” ROUGH CUT

WALK BEHIND CUTTER

WALK BEHIND CUTTER

WALK BEHIND CUTTERWALK BEHIND CUTTER

Assembly

Operation

Service and Adjustment

Repair Parts

1602 CORPORATE DRIVE, P.O. BOX 67, WARRENSBURG, MISSOURI 64093

PHONE (660) 747-8183 FAX (660) 747-8650

Manufacturing quality lawn care equipment since 1945

ONWB824

Made In The

USA

Page 2

LIMITED WARRANTY

Excluded from this warranty are normal wear, normal adjustments,

this warranty, you must return the product to an authorized

service dealer. All transportation charges, damage, or loss incurred during transportation of parts

d

8183.

The model number, serial number, date of purchase, and the name of the authorized Swisher

warranty claim can be

THIS WARRANTY DOES NOT APPLY TO ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES AND ANY IMPLIED WARRANTIES ARE LIMITED TO THE SAME TIME

PERIODS STATED HEREIN FOR ALL EXPRESSED WARRANTIES. Some states do not

f consequential damages or limitations on how long an implied warranty

may last, so the above limitations or exclusions may not apply to you. This warranty gives you

is a

The manufacturer’s warranty to the original consumer purchaser is: This product is free from

defects in materials and workmanship for a period of one (1) year from the date of purchase by

the original consumer purchaser. We will repair or replace, at our discretion, parts found to be

defective due to materials or workmanship. This warranty is subject to the following limitations

and exclusions:

1) Engine Warranty All engines utilized on our products have a separate warranty

extended to them by the individual engine manufacturer. Any

engine service difficulty is the responsibility of the engine

manufacturer and in no way is Swisher Mower Co., Inc. or its

agents responsible for the engine warranty. The Briggs & Stratton

Engine Service Hot-Line is 1-800-233-3723. The Tecumseh

Engine Service Hot-Line is 1-800-558-5402.

2) Commercial Use The warranty period for any product used for commercial or rental

is limited to ninety (90) days from the date of original purchase.

3) Limitations This warranty applies only to products which have been properly

assembled, adjusted, and operated in accordance with the

instructions contained within this manual. This warranty does not

apply to any product of Swisher Mower Co., Inc., that has been

subject to alteration, misuse, abuse, improper assembly or

installation, shipping damage, or to normal wear of the product.

4) Exclusions

and normal maintenance.

In the event you have a claim under

submitted for replacement or repair under this warranty shall be borne by the purchaser. Shoul

you have any questions concerning this warranty, please contact us toll-free at 1-800-222-

dealer from whom you purchased the mower will be needed before any

processed.

allow the limitation o

specific legal rights and you may have other rights, which vary from state-to-state. This

limited warranty as defined by the Magnuson-Moss Act of 1975.

Page 3

SAFETY PRECAUTIONS AND DECALS

manual. When you see this symbol, carefully read the message that

This Safety Alert Symbol indicates important messages in this

follows and be alert to the possibility of personal injury.

Read this manual completely. This machine is capable of amputating hands and

feet, and throwing objects. Failure to observe the following safety instructions could

result in serious injury or death.

• Read the manual. Learn to operate this machine safely.

• Always disconnect the spark plug wire and place the wire where it cannot contact

the spark plug, to prevent accidentally starting the engine when setting up,

transporting, adjusting or making repairs.

• Keep all shields and guards in place.

• Understand the speed, steering and stability of this machine. Know the positions

and operations of all controls before you operate this machine. Check all of the

controls in a safe area before starting to work with this machine.

• Allow only responsible adults who are familiar with these instructions to operate

this machine. Never allow children to operate this machine.

• Clear the area of objects such as rocks, toys, wire, etc. that can be picked up and

thrown by the blade.

• Be sure the area is clear of other people before mowing. Be aware of the mower

discharge direction and do not point at anyone. Stop the machine if anyone enters

the mowing area. Children are often attracted to the machine and the mowing

activity. Never assume that children will remain where you last saw them.

Keep children under the watchful care of another responsible adult.

• No riders!

• Do not put hands or feet near or under rotating parts. Keep clear of the discharge

opening at all times.

• Do not mow in reverse. Always look down and behind before and while backing.

Page 4

•

Turn off the blades when not mowing. Before leaving the machine, turn off the

blades and stop the engine.

• Watch for traffic when operating near or crossing roadways.

• Do not operate the mower if it has been dropped or damaged in any manner or if

the mower vibrates excessively. Excessive vibration is an indication of damage.

Repair mower as necessary.

• Dress properly. Do not operate the mower when barefoot or wearing open

sandals. Wear only solid shoes with good traction when mowing.

• Do not operate the machine while under the influence of alcohol or drugs.

• Operate self-propelled machines up and down slopes. There is significant risk of

overturns when operating across slopes. Operate walk-behind machines across

slopes. There is a significant risk of slipping under a walk-behind machine when

operating up and down slopes.

• Never tamper with safety devices. Check their proper operation regularly.

• Stop and inspect the equipment if you strike an object. Repair, if necessary,

before restarting.

• Never make adjustments or repairs with the engine running.

• Mower blades are sharp and can cut. Wrap the blades or wear gloves, and use

extra caution when servicing them.

Page 5

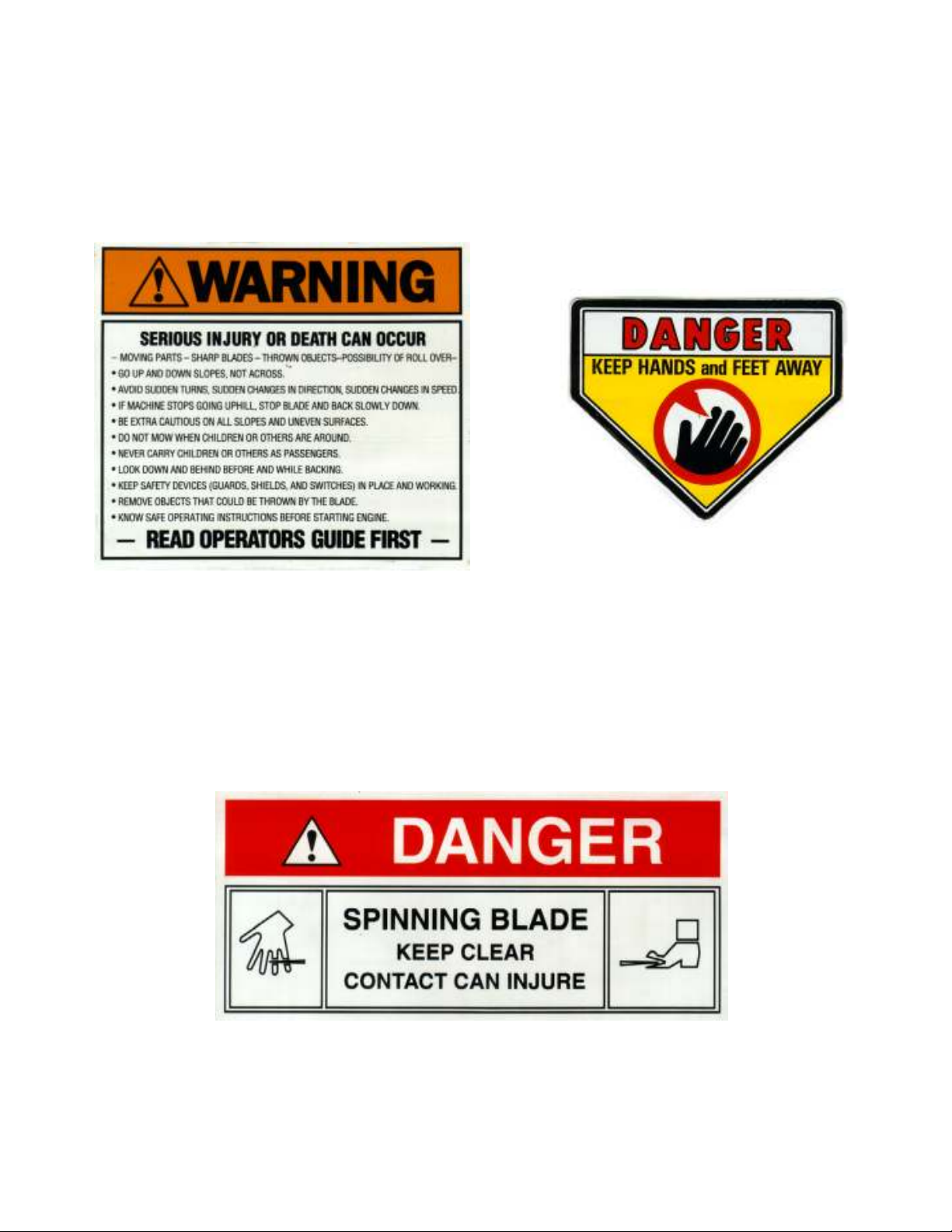

SAFETY PRECAUTIONS AND DECALS

Replace decal immediately if damaged. Order by part number from Swisher Mower and Machine Co. Inc.

D55 – DANGER DECAL

OD45 – WARNING DECAL

D29 – SPINNING BLADE DECAL

Page 6

OPERATING YOUR NEW CUTTER

The operation of any cutter can produce foreign objects to be thrown into the eyes,

resulting in severe eye damage. Always wear certified safety glasses or widevision safety goggles before starting any cutting machine and while operating such

a machine.

The operation of any cutter produces sound waves that are damaging to the

human ear. Ear protection is recommended.

CAUTION!

Tragic accidents can occur if the operator is not alert to the presence of

children. Children are often attracted to the machine and the mowing

activity.

Never assume that children will remain where you last saw them.

INTENDED USE

This is not a lawn mower. The Predator is designed for cutting overgrown brush, weeds,

and other types of organic growth. This unit is capable of clearing small saplings of 11/2” in diameter or less.

PROPULSION

The Predator is self-propelled, and is controlled by a “GROUND CONTROL” bail. To

engage the drive, put the transaxle in a gear and activate the lower bail. Releasing the

bail will disengage the self-propel.

Under most conditions cutting should be done in a low gear (1

should be used for conditions where weeds and brush are thinned out or not as tall. In

confined areas the machine can be pushed forwards or backwards by releasing the

“GROUND CONTROL” bail, placing the transaxle in neutral, and pushing the machine.

TRAVEL SPEED

lever at the rear of the machine or by changing the engine speed with the engine throttle.

Do not adjust speed with blades engaged. To shift the cutter into reverse, release

“GROUND CONTROL” bail, disengage blade, and rotate the shift lever to the left.

When the lever stops lift up and continue to turn it to the left until it stops again.

will not engage while cutter is in the “reverse” gear.

can be varied by choosing a higher or lower gear using the gearshift

st

or 2nd). Upper gears

Blade

Page 7

BLADE ENGAGE

An “OPERATOR PRESENCE” bail and a “BLADE ENGAGE” lever control engaging

the Predator’s blade. Both devices must be activated before the blade will work.

Releasing the “OPERATOR PRESENCE” bail will disengage both the blade and the

“BLADE ENGAGE” lever.

STARTING THE ENGINE

• See engine manufacturer’s instructions for the type and amount of oil and fuel

used. Engine must be level to accurately check and fill oil.

• Make sure unit is level, blades disengaged, and transaxle in “NEUTRAL”.

• Check spark plug wire, oil, and fuel.

• Turn key switch to the “ON” position.

• Set engine idle to the “CHOKE” position.

• With feet clear of cutter deck, pull engine coil rope. Do not pull rope recklessly.

• Set engine speed by moving “CHOKE” to the desired RPM.

STOPPING

• Bring cutter to a complete stop.

• Disengage the blade.

• Place transaxle in the “NEUTRAL” position.

• Turn key to “OFF” position.

• Remove keys to avoid irresponsible usage.

CUTTER HEIGHT ADJUSTMENT

• There are two height settings.

• Place two 6” wooden blocks under the deck on the side being adjusted.

• Remove nuts and bolts from the side runner.

• Slide runner to the other position.

Replace the nuts and bolts making certain they are secure.

•

• Repeat to other side. Runners should be at the same height.

BREAKING IN YOUR CUTTER

• Start engine properly.

• Slowly, engage blade control.

• Under supervision, allow blades to rotate and engine to idle for 5 minutes.

• Disengage blades.

• Shift through each gear. While in each gear engage the “GROUND CONTROL”

and travel 20 yards to ensure transaxle works properly.

CAUTION!

Disconnect spark

plug wire and place

the wire where it

cannot connect the

spark plug before

servicing unit.

Page 8

BEGIN CUTTING

• Make sure area is clear of all bystanders.

• Make sure that all guards, belt guides, and the spark plug wire are properly

attached.

• Start engine, setting desired engine speed.

• Slowly, engage blade.

• Move transaxle into low gear and activate “GROUND CONTROL” bail.

• Turning is done by rotating the handles left or right. This machine has significant

weight and may take more effort to turn than one may expect. Turning could take

practice.

CAUTION!

Chock wheels

when parking

on a hillside.

BACKING UP

• Disengage blade.

• Check safety behind you.

• Move transaxle into “REVERSE” position.

• Activate “GROUND CONTROL” bail.

TRANSPORTING

• Disengage blade.

• Shut off engine and remove keys.

• Using 3 persons to lift cutter is recommended.

• Secure in place while unit is being transported.

• Unit should be left in low gear to avoid any slight rolling.

SUGGESTED PRACTICES

• Always operate engine at full throttle when cutting to assure the best cutting

performance and proper discharge of material.

• If grass is wet, allow it to dry out. Wet grass clumps will collect on the bottom of

the deck.

• Go Slow when cutting dense areas. Some dense areas may need to be gone over

twice. Better results occur if the second cut is 90 degrees to the first cut.

Page 9

OVERALL ASSEMBLY

Some parts are grouped together in the

REPLACEMENT PARTS list (i.e. nuts, bolts,

washers, etc.)

Page 10

BLADE IDLER(2455) & BRAKE CONFIGURATION(2462

TRANSMISSION IDLER CONFIGURATION

Page 11

ENGINE-PULLEY CONFIGURATION

BLADE

CONFIGURATION

BELT

CONFIGURATION

WIRING

CONFIGURATION

Page 12

REPLACEMENT PARTS

ITEM NO. PART NO. DESCRIPTION

1 SEE DETAIL ENGINE PULLEY CONFIGURATION

2 2450* MOTOR BASE WELDMENT

2451* ADJUSTABLE BELT GUIDE

3 2418* FRONT GUARD

NB310 1/4-20 X 1/2 SSC BOLT

5 2448TK BRUSH GUARD

6 NB596 5/16-18 X 3/4 FLANGE BOLT

7 NB503 5/16-18 X 1 3/4 BOLT

8 2449* DECK WELDMENT

9 2406 RUBBER DEBRIS GUARD

10 2424TK RUBBER FLAP STRAP

11 2453* REAR COVER ASSEMBLY

2452* REAR COVER WELDMENT

2417* REAR COVER LATCH

2069 EXTENSION SPRING

NB501 5/16-18 X 1 BOLT

NB170 5/16-18 NUT

B99S SPACER

2077 YELLOW PLASTIC GRIP

12 SEE DETAIL BLADE CONFIGURATION

BA50 BA 50 BELT

13 SEE DETAIL BLADE IDLER…CONFIG.

14 2410 TRANSAXLE PULLEY

NB192 SET SCREW

2414 TRANSAXLE BELT

15 2447TK SKID RUNNER

17 2401L / 2401R POWER TRAX TIRE/WHEEL (SHOWN)

2415 SNOW HOG TIRE/WHEEL

18 2412 PEERLESS TRANSAXLE

19 2422TK SAFETY SWITCH MOUNT

NB250 1/4-20 X 3/4 BOLT

20 2456 GEARSHIFT LEVER

2427 GEARSHIFT GRIP

2423* GEARSHIFT MOUNT

NB596 5/16-18 X 3/4 FLANGE BOLT

NB503 5/16-18 X 1 3/4 BOLT

NB620 1/4-28 X 3/4 BOLT

21 2402TK HANDLE

22 2429TK BLADE ENGAGE BAIL

23 2458TK GROUND CONTROL BAIL

2432 TRANSAXLE CABLE

24 2431 BLADE LATCH & CABLE ASSY

NB278 1/4-20 X 1 3/4 BOLT

Page 13

ITEM NO. PART NO. DESCRIPTION

NB180 1/4-20 NYLOC NUT

25 T30F FINGER BELT GUIDE

26 NB213Z 1/2-13 NUT

27 NB566 3/8-16 NUT

28 NB107 3/8-16 X 1 1/2 BOLT

29 NB182 3/8-16 NYLOC NUT

30 T30V V-BELT IDLER PULLEY

31 NB275 5/16 SAE WASHER

32 B527 4" IDLER PULLEY

33 NB164 3/8-16 X 3 BOLT

34 BP370S BRAKE SPRING CLIP

35 9039 BRAKE PAD

36 BT297 BRAKE SPRING

37 2454TK BLADE IDLER WELDMENT

38 NB131 1/2-13 X 3 BOLT

39 2460TK TRANSAXLE IDLER WELDMENT

40 B27 FLAT SIDE IDLER PULLEY

41 2462 SEE …BRAKE ASSY DETAIL

43 9092 SAFETY SWITCH

44 NB621 E-CLIPS

45 NB524 1/4-20 FLANGE NUT

NB154Z 1/4-20 X 3/4 BOLT

46 2434 3/16 X 1 1/2 KEYSTOCK

47 T2SM SPRING

48 NB517 5/16-18 X 1 3/4 CARRIAGE BOLT

49 BB105S ENGINE PULLEY SPACER

50 2437 1/4 X 1 1/2 KEYSTOCK

51 BB105 LOWER ENGINE PULLEY

52 699 BELLEVILLE WASHER

53 NB166 3/8-24 X 1 1/4 BOLT

54 2411 UPPER ENGINE PULLEY

55 2413 BELT GUIDE

56 NB175 3/4-16 JAM NUT

57 6114 BLADE DRIVE PULLEY

58 NB179 THIN WASHER

59 6104RS PULLEY SPACER

60 9078 BLADE SHAFT

61 9091TK STRONG BEARING HOUSING

62 B98 SEALED BEARING

63 NB179 THIN WASHER

64 NB216 3/8-24 CENTER LOCK NUT

65 9008 BLADE MOUNT PLATE

66 90916 24" TOUGH BLADE

67 NB166 3/8-24 X 1 1/4 BOLT

68 NB607 BELLEVILLE WASHER SERRATED

69 NB238 3/8-24 X 1 BOLT

Page 14

swisherinc.com

OWNER’S

MANUAL

MODEL NO.

PREDATOR

24” WALK BEHIND

Each cutter has its own model number. Each engine has its

own model number. The model number for the cutter will be

found on the right hand side of the drive belt housing. The

model number for the engine will be found on the top of the

blower fan housing.

All cutter parts listed herein may be ordered directly from

Swisher Mower & Machine Co. Inc. or your nearest Swisher

dealer.

All engine parts may be ordered from the nearest dealer of the

engine supplied with your cutter

.

WB80024

WB80024S

WB8524

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INFORMATION AVAILABLE:

* PRODUCT – WALK BEHIND PREDATOR

* SERIAL NUMBER - _______________

* MODEL NUMBER - _______________

* ENGINE MODEL NUMBER - _______________

TYPE - _______________

* PART NUMBER

* PART DESCRIPTION

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER MOWER & MACHINE CO. INC.

1602 CORPORATE DRIVE P.O. BOX 67

WARRENSBURG, MO 64093

SWISHER MOWER & MACHINE CO. INC.

Loading...

Loading...