Swingline Stack-and-Shred 750X Instruction Manual

TM/MC

™

Stack-and-Shred

Hands Free Cross-Cut Shredder

Déchiqueteuse coupe croisée automatique

Trituradora manos libres de corte transversal

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

To register this product go to www.swingline.com/register

Pour enregistrer ce produit allez sur www.swingline.com/register

Para registrar este producto vaís en www.swingline.com/register

750X

™

English 4

Français 10

Español 16

U

U

D

J

U

U

TM/MC

U

C

U

E

U

Q

I

H

U

F

U

A

U

U

L

U

B

U

R

G

U

M

U

U

K

N

U

U

O

R

U

P

U

T

U

U

S

U

L

U

L

1 3

2

U

V

U

5 64

7 8 9

10

11

4

TM/MC

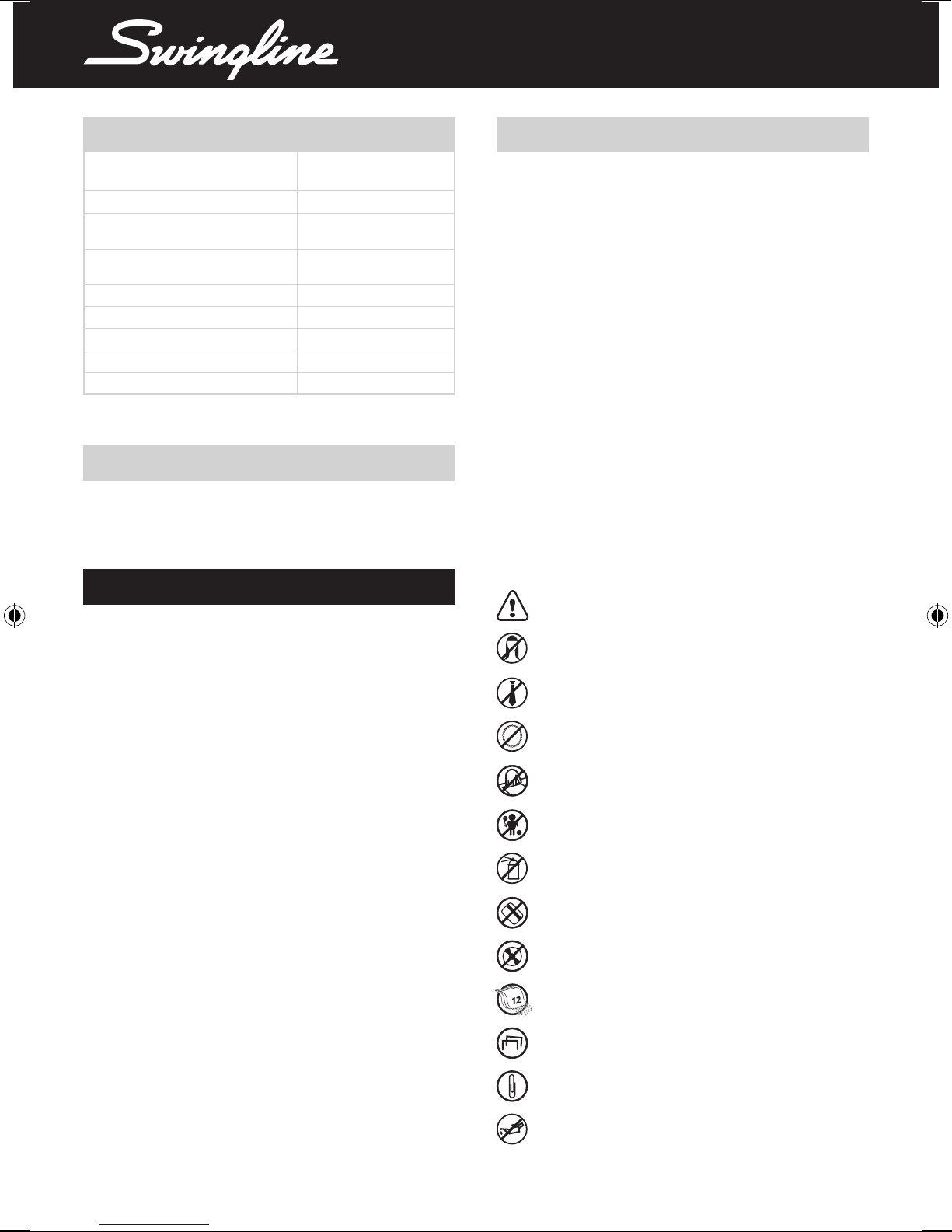

Specifications

Model Number

Sheet Capacity

Manual Feed Slot

Sheet Capacity

Auto-feed Chamber

Duty Cycle

Run Time from Cold

Volts / Hz

Amperage

Motor Watts

* XX may be blank, alphanumeric or symbol.

Swingline

Stack-and-Shred 750X

1757578XX*

12 sheets (20lb)

750 sheets (20lb)

Continuous

Continuous

120V / 60Hz

3.5 Amps

380 Watts

Introduction

Thank you for choosing this shredder from Swingline. Please

review these instructions to ensure you are operating the

shredder correctly.

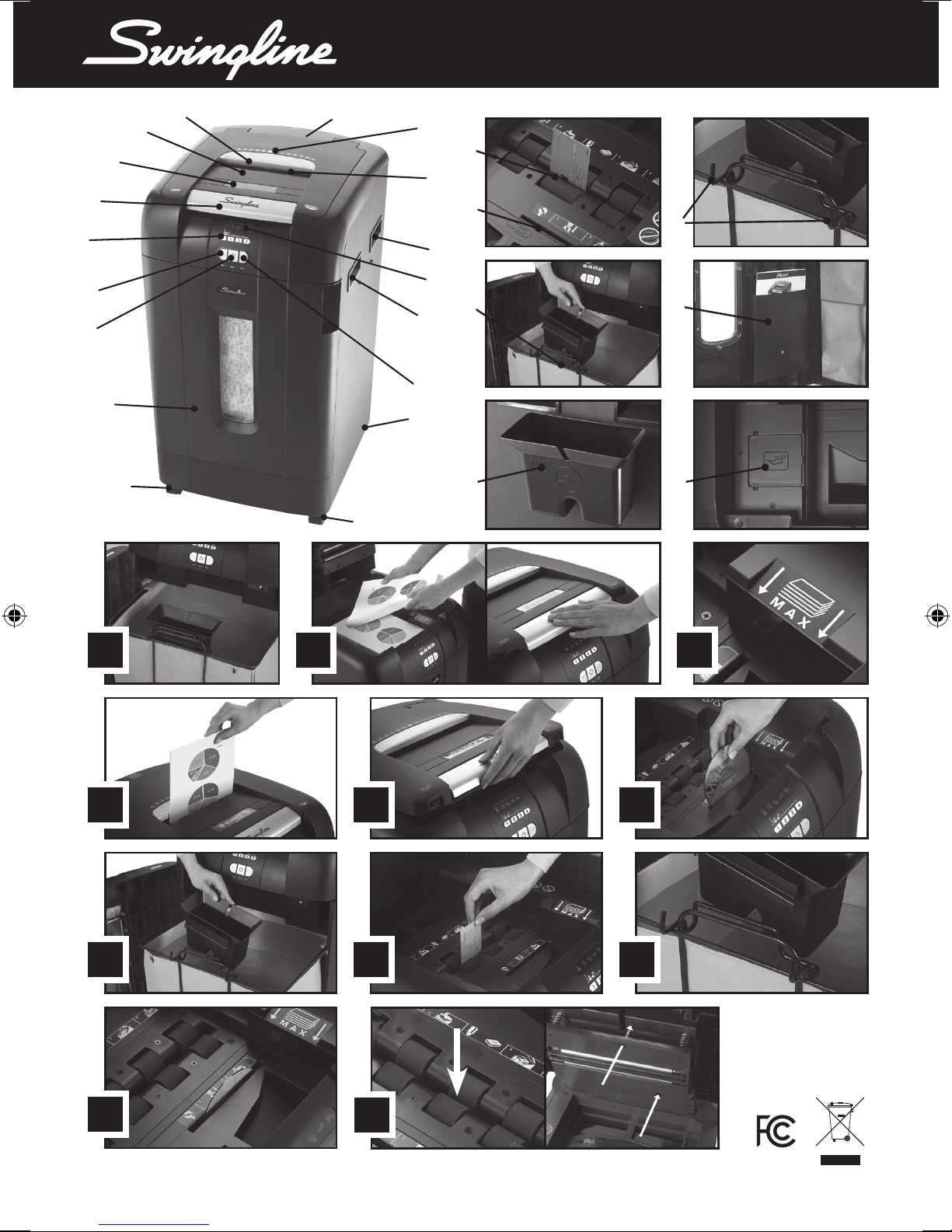

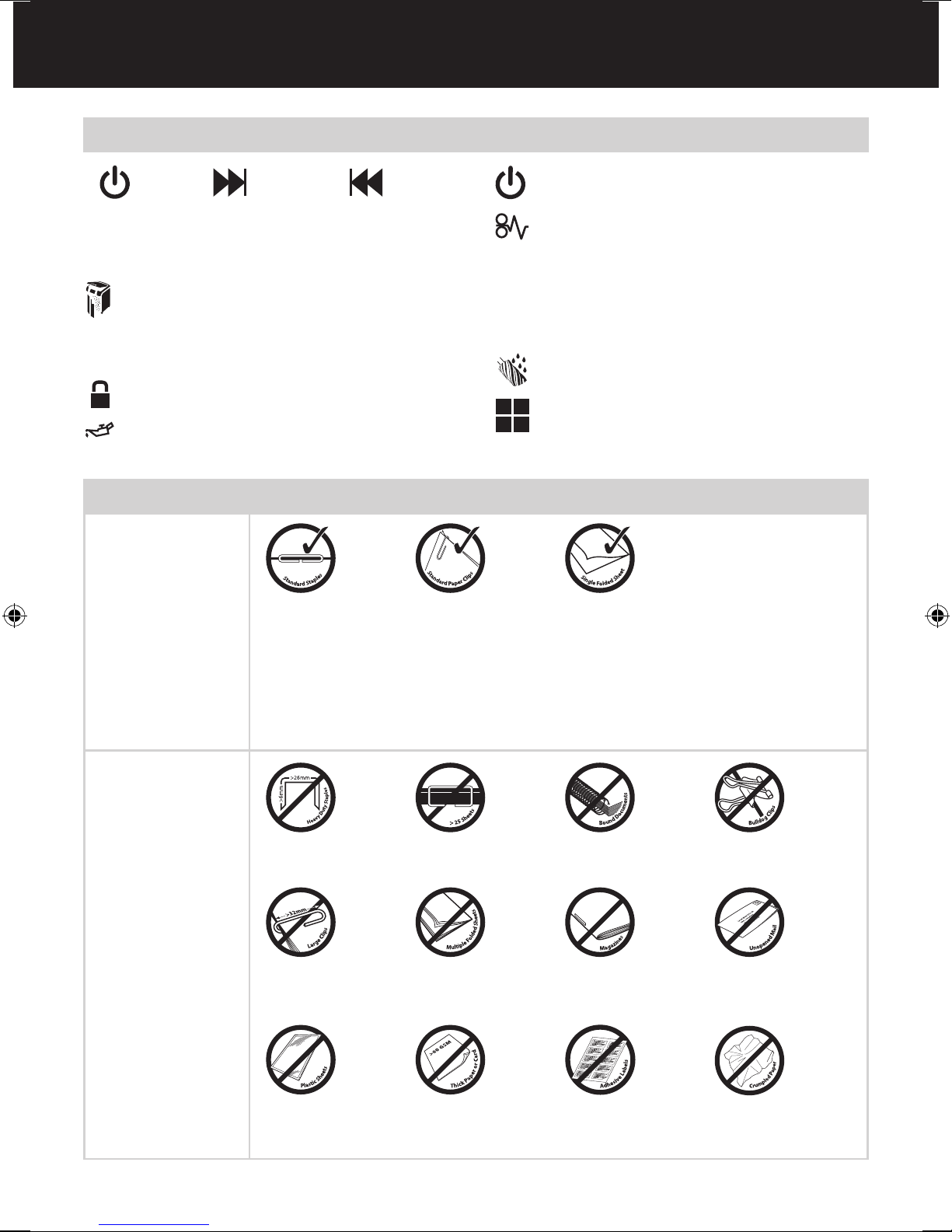

Description of Product Parts

U

A

ON/OFF switch (at the rear of the shredder)

U

Important safety symbols

B

(see Safety First section below)

U

Jam free indicator

C

U

Paper loading door handle

D

U

Paper loading door

E

U

Door for bin

F

U

Continuous jam boost button

G

U

Auto button

H

U

Reverse button

I

U

Paper loading door locking mechanism –

J

PIN password buttons

U

Indicator panel

K

U

Casters

L

U

Manual feed entry slot

M

U

Credit card entry slot

N

U

CD entry slot

O

U

CD bin ‘in use’ location

P

U

Paper stack viewing window

Q

U

Handles to move product

R

U

CD bin in storage location

S

U

Comb bind removal hooks

T

U

Internal storage pockets

U

U

Oil reservoir cap

V

Safety First

To guard against injury, the following basic safety precautions

must be observed in the set-up of this product.

• Ensure the machine is plugged into an easily accessible

power outlet, and ensure the cable is not likely to trip up a

passer by.

• Any attempt to repair this unit by unqualied personnel will

invalidate the warranty. Please return to supplier.

• Unplug your shredder before moving it or when it is not in

use for an extended period of time.

• Do NOT operate with a damaged power supply cord or plug,

after it malfunctions, or after it has been damaged in any

manner.

• Do NOT overload electrical outlets beyond capacity as this

can result in re or electrical shock.

• The socket-outlet should be near the equipment and should

be easily accessible.

• Do NOT alter the attachment plug. The plug is congured for

the appropriate electrical supply.

• Do NOT use near water.

• Do NOT use aerosol dusters or cleaners.

• Do NOT spray anything into the shredder.

• Do NOT load the auto-feed chamber with unopened junk

mail, magazines, bound documents etc.

Although this shredder has been designed to comply with

UL 60950 safety standards including the “probe accessibility

tests”, do not operate the shredder near children or pets.

4

m

Safety First

This means you should be careful because long hair can

become entangled in the cutters.

This means be careful of ties and other loose clothing

which could become entangled in the cutters.

This means be careful of loose jewellery which could

become entangled in the cutters.

This means don’t reach into the feed opening of the

cutting head.

This means keep children away from shredder.

This means no aerosols.

This means do not insert credit cards into the manual

feed slot. Use internal credit card position.*

This means do not insert CDs/DVDs into the manual

feed slot. Use internal CD/DVD position.*

Sheet capacity of manual feed entry slot.

This means the shredder can accept small staples.

This means the shredder can accept small paperclips.

This means no oil lubrication, use Swingline oil sheets only.

(*See CD/DVD Shredding on page 7and Credit Card shredding sections

on page 8).

Control Panel and Indicators

Auto

U

Jam Free indicator – This alerts the user when too

C

Continuous

Jam Boost

much paper is fed into the manual feed slot (see section

on Jam Free Technology).

Paper Loading Door/Bin Door Open or Bin Full

indicator – This means either:

• Loading door is open

• Bin is open

• Bin is full

Reverse

Power On indicator – This means the machine is

turned on.

Paper jam indicator – This means there is a paper jam

in the auto feed chamber.

If this symbol is ashing the shredder is attempting to

clear a paper jam automatically.

If this symbol is permanently illuminated red please

follow the instructions under ‘Rare Occasion of

Jamming’.

Oiling in Operation indicator

Lock indicator – This means the paper loading door is

locked (during shredding).

Oil level indicator

Loading Door Locking Mechanism – PIN Password

132

4

Buttons – Enter a four digit code to lock the loading

door during shredding.

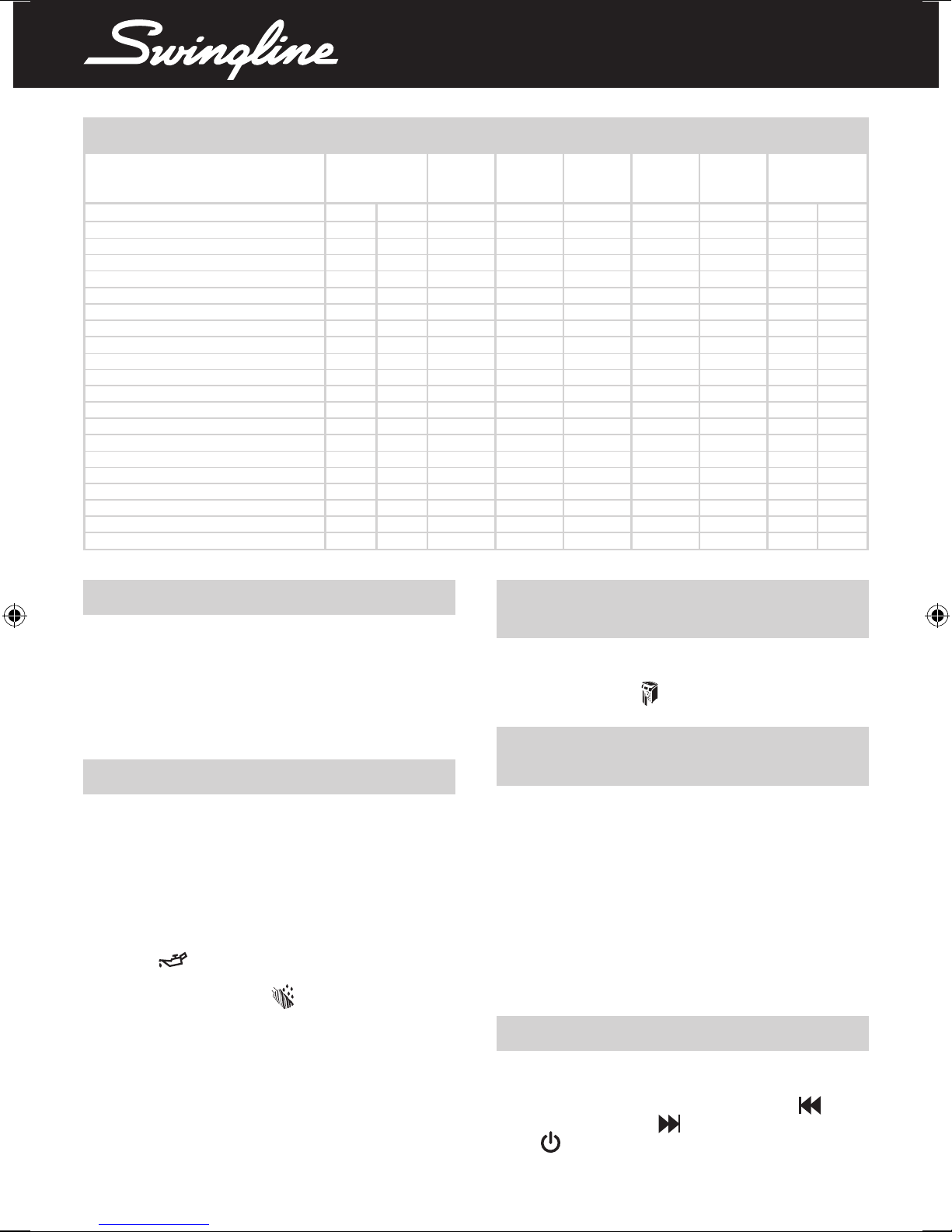

Swingline Stack-and Shred™ 750X Shredding Capability

Stack-and-Shred

750X CAN shred the

following:

• Stapled paper

1inch/25mm within the corner

• 26/6 and 24/6 or smaller

staples

• Small sized paper loaded

centrally

• 750 sheets color printing

• Paper clip paper

1inch/25mm within the corner

• Capable of shredding small/

medium (max wire thickness

= 0.9 mm) paper clips

• 750 sheets plain paper

• >27lb paper (through manual

feed slot ONLY)

• Tabloid (11 x 17”) folded in

half max. 2 sheets

• 750 sheets single sided

printed paper

• 20lb paper

- Letter - 8.5 x 11”

- Tabloid single sheet folded

in half to make Letter

Although the Stackand-Shred 750X will

accept fastened sheets,

Swingline recommends

that staples and paper

clips are removed and

folded paper un-folded

prior to shredding to

extend the life of the

product.

Stack-and-Shred

750X CANNOT shred

the following:

• Heavy Duty Staples. Check the

staple leg length is not greater

than 1/4”.

• Large clips. Check the length

of the paperclip is not longer

than 1.25”.

• Plastic sheets, laminated

documents, plastic folders,

glossy paper or a sheet covered

with print on both sides.

• A document with more than

25 sheets held together by a

staple or clip.

• Multiple folded sheets*

(e.g. Tabloid sheets folded

in half).

• Thick paper or card* • Adhesive labels • Crumpled sheets*

* We recommend you feed these types of documents through the manual feed slot. However, the Stack-

and-Shred 750X can automatically shred folded and crumpled sheets if attened out prior to loading.

• Bound documents • Bulldog clips

• Magazines or other documents

bound by multiple staples

or clips

• Unopened mail*

5

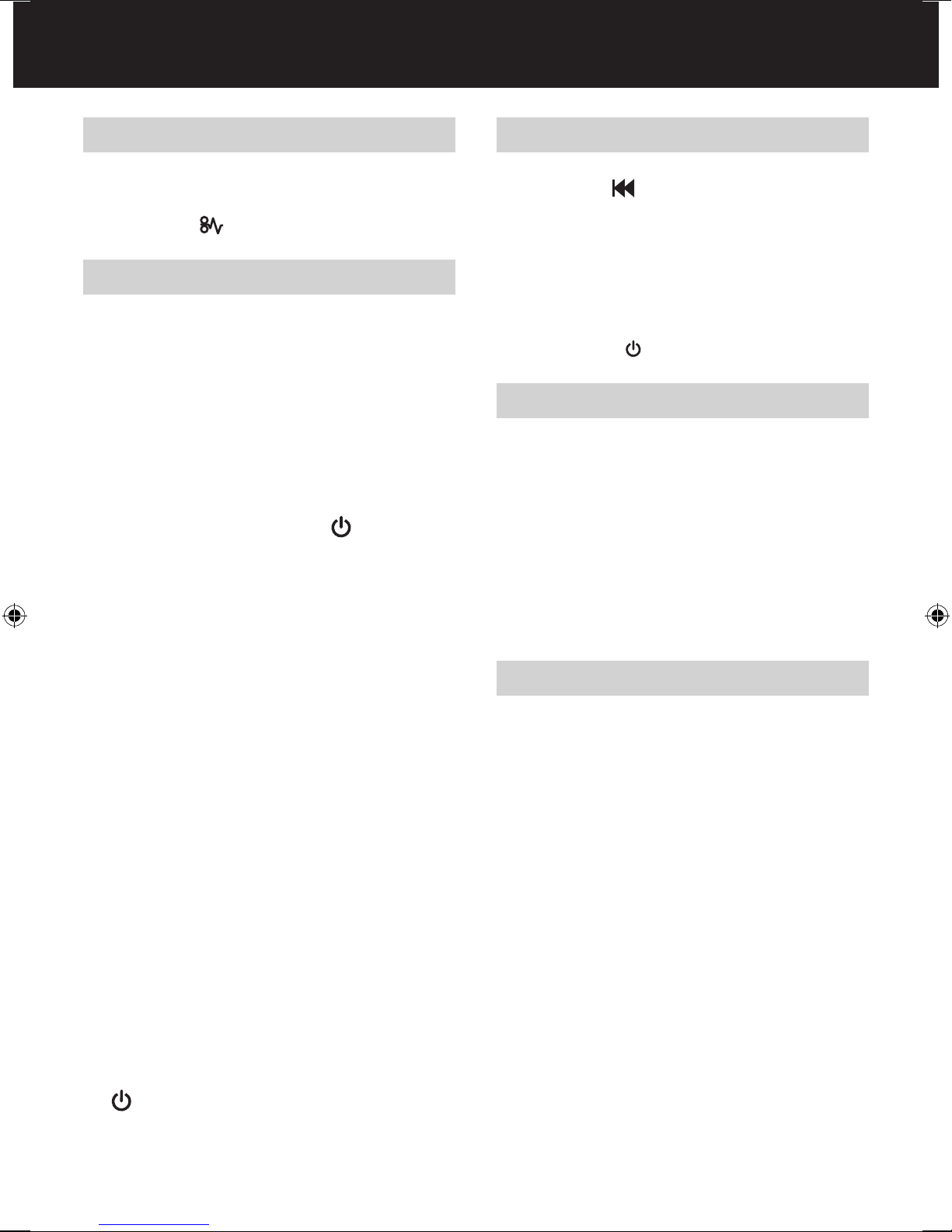

Autofeed Operation light flash

TM/MC

Illuminated Icons Explained

Lock Bin Full/ Oiling in Oil Paper Auto Jam

Door Open Operation Level Jam Free

Indicator

Colour of symbol Green Red Red Green Red Red Blue Green Red

Power ON/OFF switch OFF

Sleep mode

Power ON/OFF switch ON

Stand by

Auto mode light light

Continuous jam boost mode light light light

Reverse mode light light light

Paper loading door open light light light

Bin full/bin open light light light

Paper jam light light light

Paper jam clearance flash light light

Too many sheets are being fed into manual feed slot light light

Cutters are self-cleaning flash light light

Entering PIN password flash light

Paper loading door is locked light light

Incorrect PIN password has been entered flash x3 light

Correct PIN password re-entered flash x3 light

Oil Level Too Low light light light

Auto/Manual Oiling light light light

Auto-feed Technology

The Stack-and-Shred 750X has been designed to automatically

shred up to 750 sheets from the auto-feed chamber and up

to 12 sheets through the manual feed slot. The auto-feed

mechanism has been designed to handle paper fastened with

staples and paper clips and to only pull a few sheets of paper

into the cutting mechanism to minimize the risk of paper jams.

Initial Setup

The shredder is designed to automatically lubricate the cutting

mechanism as required to ensure the product continues to

work to its maximum performance and to extend the product

life. Please follow the operation instruction before turning

on the shredder for the rst time. The 2oz bottle of oil* is

sufcient to allow the shredder to start for the rst time and

to operate continuously for about one hour’s shredding before

the reservoir will need relling. When the ‘Oil Rell’ indicator is

illuminated (

oil reservoir using a bottle of standard Swingline oil (1760049).

The automatic oiling operation (

seconds and you will hear the distribution pump during this

time. Auto-oiling operates after 15 minutes of shredding time.

), ip up the oil reservoir cap (V) and rell the

) last approximately two

Bin or Loading Door Open Safety

Function

As a safety precaution, if the bin or loading door is opened

during shredding, the shredder will stop and the bin full

indicator will illuminate (

).

Jam Free Technology in Manual

Feed Slot

Sensors in the paper feed area measure the thickness of

paper about to be shredded. The ability to shred or not is

communicated through red and green lighting. Green means

that the stack of paper is within the shredders sheet capacity

and OK to shred. Red means that you have too much paper,

remove some sheets in order to shred.

By preventing you from shredding more sheets of paper than

the shredder is capable of handling, paper jams are prevented.

This prevents wasting time reversing paper to unblock jams

and the mess they can create.

Rare Occasions of Jamming

* ACCO Brands accepts no liability for product performance or safety

when other types or brands of lubricants are used on any part(s) of

this machine.

6

In the unlikely event of the shredder jamming, the Stack-

and-Shred 750X will stop shredding. Check that the bin is

not full then try clearing the jam using the reverse (

and continuous jam boost (

mode (

). If this is unsuccessful follow the reverse function

) buttons then return to Auto

)

instructions.

Automatic Jam Clearance

Reverse Function

In the unlikely event of the shredder jamming, the Stack-and-

Shred 750X will automatically reverse and forward the engine

three times to clear a jam. During this operation the Paper Jam

indicator will ash (

).

Operation

1 After unpacking the product pull out the shredder bag frame

and remove the CD shard tray, which sits on top of the bag

frame. Store this tray on the product as shown and use

when you shred CDs (see g 1 on page 3).

2 Lift up the loading door (E) and open oil ap (V).

3 Remove oil cap and ll up the reservoir using the 2oz bottle

of oil provided. Replace the cap.

4 Connect the shredder to power supply.

5 Check that the on/off switch at the back of the machine is

switched to the ‘ON’ position.

6 Press and hold down the Auto button (

to start the pump and prime the system. Only required

when the product is used for the rst time.

7 To load the shredder, simply lift the loading door handle (see

g 5) to open the loading door and insert documents. You

can open the door further to 90 degrees for easier access

if required. Load up to 750 sheets at a time into the feed

chamber (see g 2).

Do not ll above the MAX level, this could damage the

shredder (see g 3).

8 The shredder will start the shredding cycle automatically

ONLY after closing the loading door (see g 2).

If there is paper in the Autofeed chamber after rst attempt,

open and re-close the paper loading door a second time.

Attention: If required you can now lock the loading door by

entering a 4 digit code (see Locking the Paper Loading Door

section).

9 If you only have up to 12 sheets to shred, you can use the

manual feed slot, provided the auto feed chamber is empty

(see g 4).

J Insert paper to be shredded into the feed area. The

shredder will detect the paper and start automatically.

K If the shredder is left in auto mode for more than 2 minutes

without being used, the shredder will automatically turn back to

standby mode in order to save power.

L The shredder will automatically ‘wake up’ from sleep mode

when paper is inserted into the shred mouth or you open

the loading door. There is no need to press the Auto button

(

).

) for 5 seconds

1 Should you wish to reverse paper out whilst shredding, a

reverse button (

2 Reverse the paper out then turn the machine off using the

ON/OFF switch at the rear of the shredder. Remove the

paper from the manual feed slot (if being used) or open the

loading door, remove the remaining stack of paper, then pull

the jammed paper free of the cutting mechanism.

3 To resume shredding, turn the shredder on using the ON/

OFF switch at the rear of the shredder. Return the switch to

the auto position (

) has been tted for your convenience.

).

Locking the Paper Loading Door

For additional security the paper loading door can be locked

during the shredding of condential material.

To lock shredder:

1

Place documents in tray. Close paper loading door (see g 2).

2

Press any 4 digits. REMEMBER YOUR CODE!

Shredder unlocks automatically when:

• 4 digit code is re-entered.

• Shredding is complete.

• Shredder is inactive for 30 minutes (but documents remain

in tray).

CD/DVD Shredding

A separate CD/DVD tray is provided to collect the shredded

CD/DVD shards. Ensure that this is correctly mounted onto the

standard shredder bag frame before shredding (see g 7).

1 Lift up the paper loading door (see g 5).

2 Always insert CDs/DVDs in the CD/DVD slot (see g 6).

Only shred one CD/DVD at a time.

3 Close the paper loading door (see g 2).

4 Empty the CD/DVD bin after 8 CDs/DVDs to avoid waste

spilling over into the paper waste bin.

5 Remove the CD/DVD tray before recommencing to shred

paper and store on the side of the shredder (see g 7).

7

TM/MC

Credit Card Shredding

The Stack-and-Shred 750X can shred credit cards. Switch the

shredder to auto mode, then;

1 Lift up the paper loading door (see g 5).

2 Insert the credit card into the roller as shown in g 8. Only

shred one credit card at a time.

3 Close the paper loading door (see g 2).

Swingline encourages customers to recycle shredded

paper. Please note that shredded paper cannot be

recycled if mixed with credit card shards. If recycling,

please separate shredded paper and credit cards.

Bin Full

The shredder will not function when the bin is full and the bin

full symbol (

• Open the door and pat down the paper chips, then slide out

the waste sack support frame.

• Carefully remove the waste bag from the frame.

) is illuminated. You should empty the bin.

Self-Cleaning Cutters

After emptying and replacing a full bin, the shredder will run

in forward for 4 seconds, stop for 2 seconds and then reverse

for 4 seconds to clear away any remaining paper from the

cutter mechanism. This unique ‘self-cleaning’ mechanism is

additional jam prevention technology from Swingline.

Maintenance

The rollers on the auto-feed mechanism may become dirty over

time, please wipe clean with a dry cloth to maintain maximum

product performance (see g 10).

The auto-start infra-red sensor, located in the paper feed

entry-slot, can occasionally become covered in paper-dust

causing the shredder to run despite no paper being fed into

the machine. Switch the shredder off at the rear of the

machine and carefully clean the sensor using a cotton-swab

(see g 11).

Service

We recommend these machines are serviced every 6 to 12

months by a Swingline service engineer – see back of this

booklet for the contact details of your local service center and

for enquiries about maintenance contracts.

Shredder Accessories

We recommend that a paper waste bag for recycling shredded

paper is used on all models.

Accessory Part Number Box Qty

Recycling Waste Bag 1765032 50 bags

Plastic Waste Bag 40060 100 bags

Oil* Rell Bottle 1760049 8

Comb Bind Removal Hooks

Note – Use only on standard comb bind strips.

1 Open bin door.

2 Place document onto the comb bind hooks (see g 9).

3 Pull down on the document to remove comb strip.

* ACCO Brands accepts no liability for product performance or safety

when other types or brands of lubricants are used on any part(s) of

this machine.

8

FCC Class B Notice

Note: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to If this equipment does cause harmful

interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

Limited Warranty

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CANADA CLASS B NOTICE

This Class B digital apparatus complies with Canadian ICES-003

MODIFICATIONS

Any modifications made to this device may void the authority granted

to the user by the FCC and/or by Industry Canada to operate this

equipment.

ACCO is a registered trademark of ACCO Brands.

Copyright © 2011 ACCO Brands. All rights reserved.

Issue August 2012

Fusion is a registered trademark of ACCO Brands.

Limited 2 year Cutter Warranty for Stack and Shred 750X

Shredder and Limited 2 Year Warranty for all other Parts

ACCO Brands USA LLC, 300 Tower Parkway, Lincolnshire, IL 60069

(in Canada, ACCO Brands Canada Inc., 5 Precidio Court, Brampton,

ON L6S-6B7; and in Mexico, ACCO Mexicana, S.A. de C.V. Av. Circuito

Industrial Norte #6 Parque Industrial Lerma 52000, Lerma Edo. De

México) (each, respectively, “ACCO Brands”) warrants to the original

purchaser that the cutters of this Swingline™ Stack and Shred 750X

Shredder are free from defects in workmanship and material under

normal use and service for a period of 2 years after purchase and all

other parts are free from defects in workmanship and material under

normal use and service for a period of 2 years after purchase.

ACCO Brands’ obligation under this warranty is limited to replacement or

repair, at ACCO Brands’ option, of any warranted part found defective by

ACCO Brands without charge for material or labor. Any replacement, at

ACCO Brands’ option, may be the same product or a substantially similar

product that may contain remanufactured or refurbished parts. This

warranty shall be void in the following circumstances:

(i) if the product has been misused,

(ii) if the product has been damaged by negligence or accident, or

(iii) if the product has been altered by anyone other than ACCO Brands or

ACCO Brands’ authorized agents.

For warranty execution, please call:

1-800-541-0094 in the USA

1-800-263-1063 in Canada

01-(55)-1500-5700 / 5778 in Mexico

Or go to www.swingline.com.

TO THE EXTENT ALLOWED BY APPLICABLE LAW, THIS WARRANTY IS IN

LIEU OF ALL OTHER EXPRESSED WARRANTIES. REPRESENTATIONS OR

PROMISES INCONSISTENT WITH OR IN ADDITION TO THIS WARRANTY

ARE UNAUTHORIZED AND SHALL NOT BE BINDING ON ACCO BRANDS.

TO THE EXTENT PERMITTED BY APPLICABLE LAWS, ANY IMPLIED

WARRANTIES (IF APPLICABLE) ARE LIMITED IN DURATION TO THE

DURATION OF THIS WARRANTY. SOME STATES AND JURISDICTIONS

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. TO

THE EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL

ACCO BRANDS BE LIABLE FOR ANY SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL OR SIMILAR DAMAGES, WHETHER OR

NOT FORSEEABLE. SOME STATES AND JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF SPECIAL, INCIDENTAL, PUNITIVE,

EXEMLARY, CONSEQUENTIAL, OR SIMILAR DAMAGES, SO THE ABOVE

EXCLUSION OR LIMITATION MAY NOT APPLY TO YOU.

FOR CONSUMERS WHO HAVE THE BENEFIT OF CONSUMER

PROTECTION LAWS OR REGULATIONS IN THEIR JURISDICTION OF

PURCHASE OR, IF DIFFERENT, IN THEIR JURISDICTION OF RESIDENCE,

THE BENEFITS CONFERRED BY THIS WARRANTY ARE IN ADDITION

TO ALL RIGHTS AND REMEDIES CONVEYED BY SUCH CONSUMER

PROTECTION LAWS AND REGULATIONS.

To the extent permitted by law, this warranty is not transferable and

will automatically terminate if the original product purchaser sells or

otherwise disposes of the product.

This warranty gives you specic legal rights. Other rights, which vary

from jurisdiction to jurisdiction, may exist. In addition some jurisdictions

do not allow (i) the exclusion of certain warranties, (ii) limitations on how

long an implied warranty lasts and/or (iii) the exclusion or limitation of

certain types of costs and/or damages, so the above limitations may

not apply.

9

Loading...

Loading...