Page 1

Parts Shipped QTY Optional Ac cessories Available Part #

MCP300 PUMP 1 1/2” Stem to 1/2” tube elbow PI221616S

Harness, incl. 2 brackets, Velcro strap, &

2 #8 x ¼” sheet metal screws

Tube Insert for 1/2in. OD Tubing - Part #

TSI375S

Quick-connect remove tool 1 1/2” Stem to 3/8” tube ID hose barb PI251612S

General Use

The MCP300 pump is a magnetically powered centrifugal pump,

featuring a watertight synchronous motor. It requires no maintenance

when used with de-mineralized water, and the appropriate anti-fungal

additives (20% common anti-freeze, or 5% Swiftech’s HydrX,

Zerex or RedLine coolant).

Although this pump is fully submersible, it is configured for inline use

rather than submersed. The pump is shipped with built-in anodized

aluminum quick-connect fittings for 1/2” OD tubing (3/8” ID), and also

supports larger or smaller sizes tubing with optional accessories listed

in the table above.

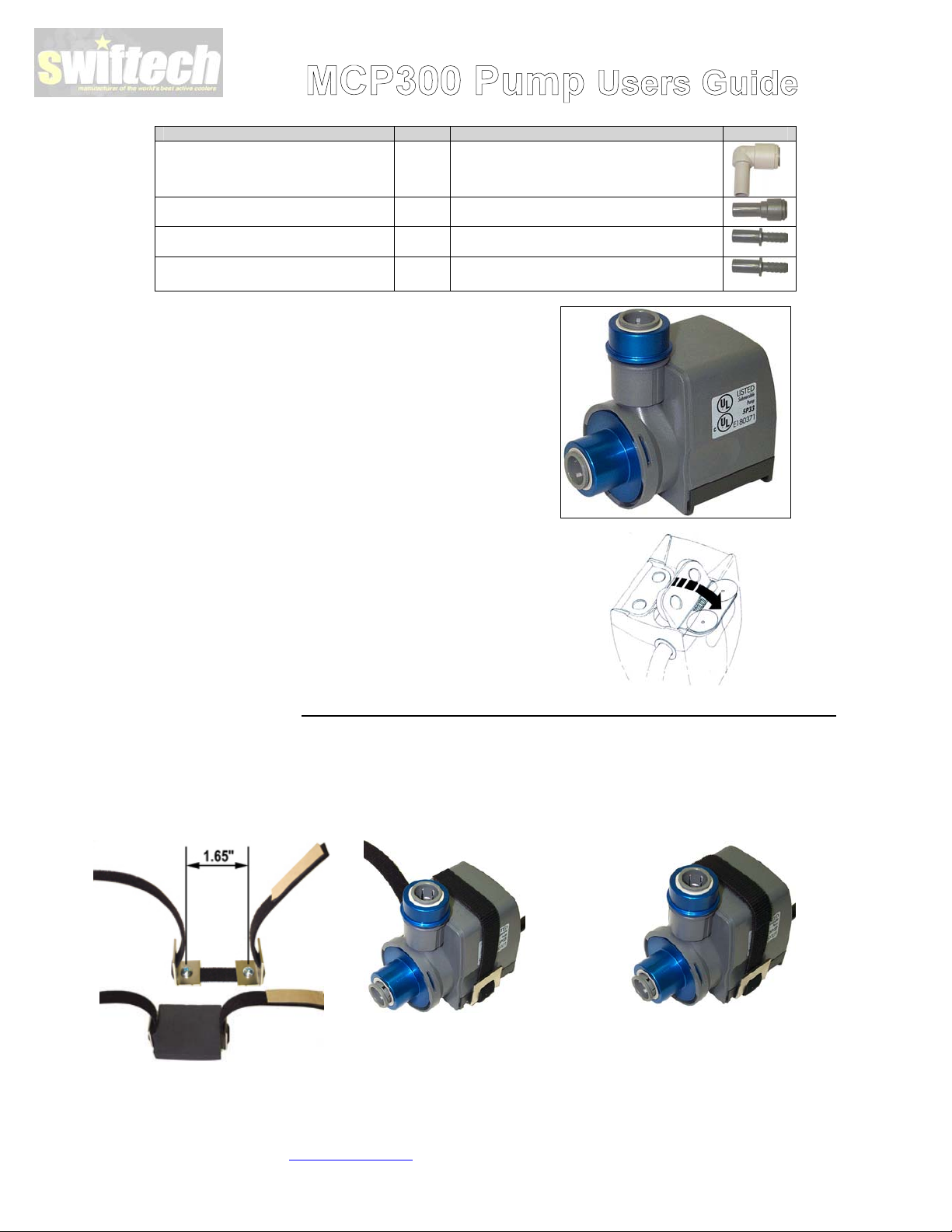

Physical installation

The pump can be installed either:

! Horizontally: using the built-in hinged brackets with suction

cups, or

! Vertically: using the provided Velcro harness and brackets.

If the computer is moved, or shipped, we recommend always using the

harness for safety, in either horizontal or vertical installation.

Horizontal Installation, using built-in suction cups: unfold the

brackets as shown in Figure 1, and place pump in convenient location.

Harness installation (recommended): Y

! Drill two holes 1/8” in diameter, 1.65”

inc h apart.

! Install harness with provided screws.

! Peel-off protective paper, and stick

provided neoprene pad in between t he

brackets

OU MUST FIRST REMOVE THE HINGED BRACKETS BY TWISTING THEM GENTLY OUT OF THEIR SOCKET.

! Install pump as shown fig. 3.

!

1 1/2” Stem to 3/8” tube OD quick connect

2 1/2” Stem to 1/2” tube ID hose barb PI251616S

Peel-off protective paper, and

fold flap with sticker over top of

the pump. Sticker keeps flap in

position for next step.

PI061612S

Figure 1

! Apply firm tension on second flap and fold over to

finalize installation.

!

Thanks to strong Velcro hold, and neoprene

pad, “floating” retention now provides secure

and vibration free installation.

Figure 2 Figure 3 Figure 4

Copyright Swiftech 2001 – All rights reserved – Last revision date: Nov 7, 2002

Rouchon Industries, Inc., dbA Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769

Page 1

Information subject to change without notice

Page 2

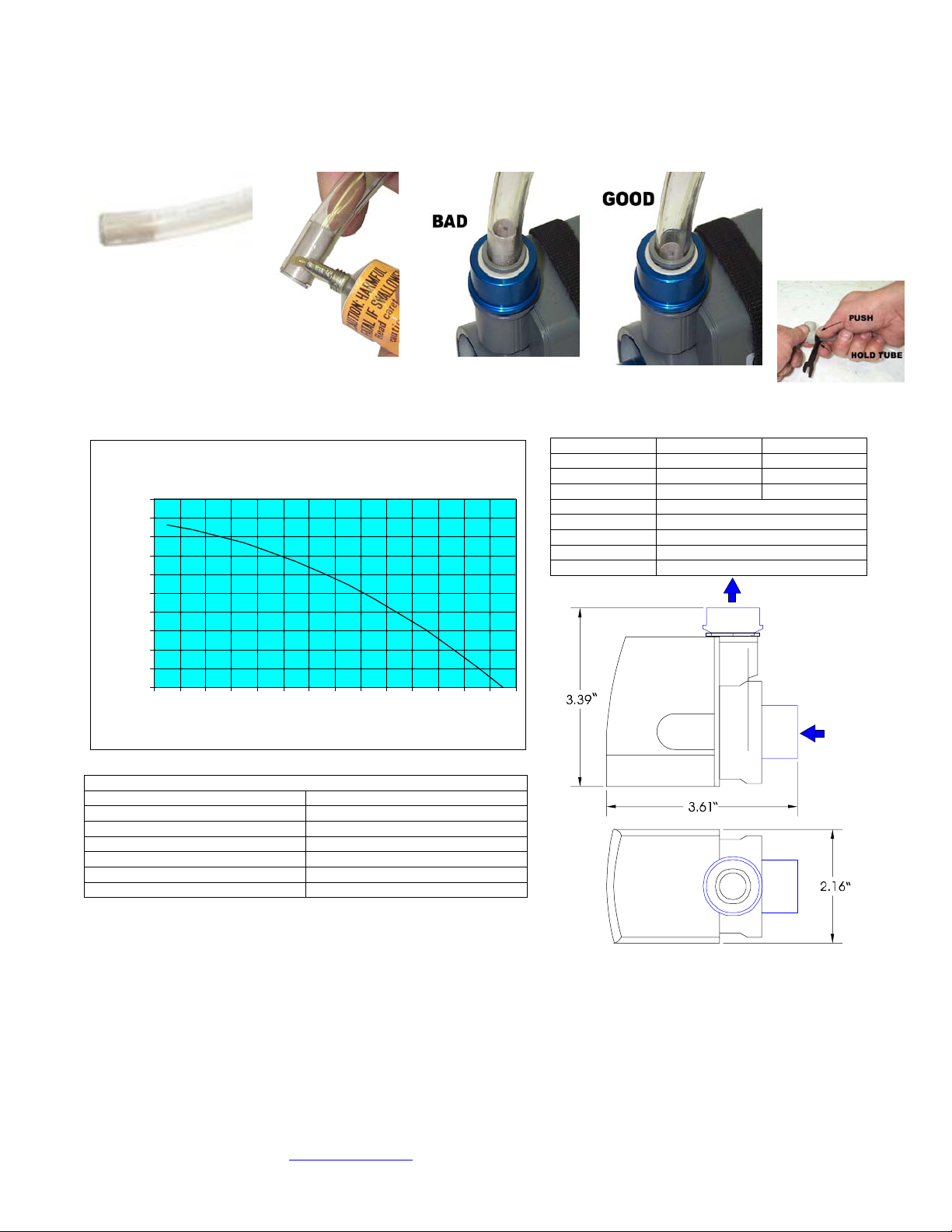

Connecting the tubing

Cut the end of the tubes perfectly square. It is absolutely

imperative to use the provided tube inserts with clear vinyl

(soft) tubing, as shown in figure 5 below. A little bit of

grease spread around the perimeter of the tubing as shown

in fig. 6 will help insert them into the fittings.

Make sure that the tubes are fully inserted into the fitting. The tip

of the plastic tube inserts should be flush with the inlet and outlet

openings, as shown in figure 8 below. Inserting the tubes

requires a firm push, accompanied by a twisting motion.

YOU MUST USE TUBE

INSERT W ITH SOFT

TUBING

Performance & Specifications

Figure 5 Figure 6 Figure 7 Figure 8 Figure 9

MCP300 PERFORMANCE

100

90

80

70

60

50

40

30

Head Height Inch

20

10

0

0 26 52 79 105 132 158 184 211 237 264 290 317 332

Maximum Flow Rate Gal/Hr

(submersed condition - 5/8" ID output)

Description Part #

Pump body – 115 V MCP300-B115

Pump body – 230 V MCP300-B230

Inlet fitting MCP300-IL

Outlet fitting MCP300-OL

Inlet O’Ring MCP-90653

Outlet O’Ring MCP-90651

Replacement parts

Tube removal:

Push in collet squarely

against face of fitting

using the provided

quick-connect remove

tool as shown below:

tube can now be safely

pulled out. Do not

attempt to pull tube out

without pushing

squarely against the

collet.

Voltage 115 V version 230 V version

Hz 60 50

RPM 3600 3000

Watts 22 25

Inlet/Outlet OD ½”

Max Head 86” / 220 cm

Flow L/Hr 400-1300

Flow Gal/Hr 100-340

MTBF 50,000 hours

Outlet

Inlet

WARRANT Y: This product is guaranteed for a period of 24 months from date of purchase for def ects in material, and workmanship. Guarantee

consis ts in replacing defective parts with new or rec onditioned parts. Guarantee is considered void in case of improper use (*), handling or

negligence on the part of user. Or iginal invoice s howing date and place of purchase is required for exercise of the warranty.

(*) WARNING: DO NOT ATTEMPT TO LEAK-TEST THIS PUMP USING COMPRESSED AIR OR CITY WATER PRESSURE. THIS WILL CAUSE EXCESSIVE

INTERNAL PRESSURE, RESULTING IN IMMEDIATE AND IRREVERSIBLE DAMAGE TO THE PUMP, AND VOID YOUR WARRANTY. LEAK-TESTING CAN

ONLY BE PERFORMED BY RUNNING THE PUMP ITSELF AND/OR GRAVITY FEEDING THE CIRCUIT. EXCESSIVE INTERNAL PRESSURE CAN ALSO

BUILT-UP WHEN USING THERMO-ELECTRIC DEVICES WITHOUT APPROPRIATE COOLING TO THE DEVICE, AND IS NOT COVERED BY OUR

WARRANTY.

DISCLAIMER: Swiftech assumes no liability whatsoever, expressed or implied, for the use of this product, and more specifically for any, and all

damages caused by the use of this product to any other devices in a personal computer, whether due to product failure, leak, electrical shorts, and

or elec tro-magnetic emissions.

Copyright Swiftech 2001 – All rights reserved – Last revision date: Nov 7, 2002

Rouchon Industries, Inc., dbA Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769

Information subject to change without notice

Page 2

Loading...

Loading...