SWF SB Series, Multi-Heads E Series, DM-WU656-150, DM Series, DM-WU2X656-150 User Manual

...

MMEEEE--110011220011

USER

’’

S MANUAL

SSuunnSSttaarr CCOO..,, LLTTDD..

Operating Manual

••

SB Series

••

Multi-Heads E-Series

••

DM Series

••

K Series

1. THIS IS AN INSTRUCTION FOR SAFE USE OF AUTOMATIC

EMBROIDERY MACHINES. READ THOROUGHLY BEFORE USE.

2. CONTENTS IN THIS INSTRUCTION MAY CHANGE, WITHOUT

PRIOR NOTICE, FOR IMPROVEMENT OF MACHINE QUALITY AND

THUS MAY NOT CORRESPOND TO THE MACHINE YOU

PURCHASED. CONTACT YOUR SALES AGENT FOR INQUIRIES.

3. THIS IS DESIGNED AND MANUFACTURED AS AN INDUSTRIAL

MACHINE. IT SHOULD NOT BE USED FOR OTHER THAN

INDUSTRIAL PURPOSE.

CCoonntteennttss

1.0 Operation Box .......................................................................................................................... 1-1

1.1 Part Name and Function ................................................................................................................................ 1-1

2.0 Basic Steps Before Starting Embroidery ............................................................................. 2-1

2.1 Embroidery Machine Power-On .................................................................................................................. 2-1

2.2 Basic Steps ..................................................................................................................................................... 2-4

3.0 Operating Program Install ...................................................................................................... 3-1

3.1.0 SWF Install Program ..................................................................................................................................... 3-2

3.1.1 Install .............................................................................................................................................. 3-2

3.1.2 Backup ............................................................................................................................................. 3-4

3.1.3 Memory ........................................................................................................................................... 3-5

3.1.4 System ............................................................................................................................................. 3-7

3.2.0 Machine Setting Change ............................................................................................................................... 3-9

3.2.1 Embroidery Machine Specifications Setting ............................................................................... 3-10

3.2.2 Machine and Signal Setting .......................................................................................................... 3-13

4.0 Operating Program Screen Layout ........................................................................................ 4-1

4.1 Embroidery Screen ........................................................................................................................................ 4-1

4.2 Work Information Screen .............................................................................................................................. 4-2

4.3 Function Menu Button Screen ...................................................................................................................... 4-3

4.4.0 Work Progress Message and Clock ............................................................................................................. 4-4

4.4.1 Work Progress Messages ................................................................................................................ 4-4

4.4.2 Date and Time Change ................................................................................................................... 4-5

5.0 Function Menu Before Embroidery Begins .......................................................................... 5-1

5.1 Structure of the Menu Before Embroidery Begins ...................................................................................... 5-2

5.2 Design Call .................................................................................................................................................... 5-3

5.3.0 Input/Output ................................................................................................................................................. 5-11

5.3.1 FDD Input ..................................................................................................................................... 5-12

5.3.2 USB Input ..................................................................................................................................... 5-17

5.3.3 CF Card Input ............................................................................................................................... 5-19

5.3.4 Serial Input .................................................................................................................................... 5-21

5.4.0 Setting ..........................................................................................................................................................5-23

5.4.1 Basic Setting .................................................................................................................................. 5-25

5.4.2 EMB Parameter Setting ................................................................................................................ 5-31

5.4.3 M/C Parameter Setting ................................................................................................................. 5-35

5.4.4 Needle Setting (color) ................................................................................................................... 5-39

5.4.5 Frame offset setting ....................................................................................................................... 5-50

5.4.6 Options Setting .............................................................................................................................. 5-52

5.4.7 The Other Settings ....................................................................................................................... 5-60

5.5.0 Ready ........................................................................................................................................................... 5-67

5.5.1 Position .......................................................................................................................................... 5-68

5.5.2 Gauge ............................................................................................................................................. 5-69

5.5.3 Exclude .......................................................................................................................................... 5-70

5.5.4 Fastview ......................................................................................................................................... 5-71

5.5.5 Trace .............................................................................................................................................. 5-74

5.6.0 Repeat .......................................................................................................................................................... 5-75

5.6.1 General Repeat ............................................................................................................................. 5-76

5.6.2 Special Repeat .............................................................................................................................. 5-89

5.6.3 Repeat Load .................................................................................................................................. 5-96

5.7.0 Edit ................................................................................................................................................................5-97

5.7.1 Stitch Edit ..................................................................................................................................... 5-98

5.7.2 Design Divide ............................................................................................................................ 5-103

5.7.3 Design Filtering ........................................................................................................................... 5-108

5.7.4 Design Zoom In .......................................................................................................................... 5-109

5.8.0 Machine ..................................................................................................................................................... 5-111

5.8.1 Machine Service .......................................................................................................................... 5-112

5.8.2 Machine Information .................................................................................................................. 5-113

5.8.3 Machine Test ...............................................................................................................................5-113

5.8.4 Frame Origin ............................................................................................................................... 5-115

5.8.5 Error Information ....................................................................................................................... 5-116

5.8.6 Thread Break Information .......................................................................................................... 5-116

5.8.7 Memory Initial ............................................................................................................................ 5-116

5.9.0 TOOLS .......................................................................................................................................................5-117

5.9.1 Origin ........................................................................................................................................... 5-118

5.9.2 Holding ........................................................................................................................................ 5-118

5.9.3 Needle DN/UP ............................................................................................................................ 5-118

5.9.4 Language ..................................................................................................................................... 5-118

5.9.5 Sequin Lift / Sequin Feed ........................................................................................................... 5-118

5.9.6 Trim ............................................................................................................................................. 5-118

5.9.7 PF UP/DOWN ............................................................................................................................ 5-118

6.0 Function Menu During Embroidery Pause ........................................................................... 6-1

6.1 Structure of Function Menus ......................................................................................................................... 6-3

6.2 Design Call ................................................................................................................................................... 6-4

6.3 Setting ............................................................................................................................................................ 6-5

6.4 Float ............................................................................................................................................................... 6-6

6.5 Frame ............................................................................................................................................................. 6-7

6.6 Speed Code .................................................................................................................................................... 6-8

7.0 Troubleshooting .......................................................................................................................7-1

7.1.0 Error Messages and Handling ....................................................................................................................... 7-1

7.1.1 Main Shaft Motor and Others ......................................................................................................... 7-1

7.1.2 X, Y Motor-related Errors .............................................................................................................. 7-1

7.1.3 Color Change ................................................................................................................................... 7-2

7.1.4 Encoder ........................................................................................................................................... 7-2

7.1.5 Repeat Work .................................................................................................................................... 7-2

7.1.6 Floppy Diskette and Communications ........................................................................................... 7-3

7.1.7 Memory ........................................................................................................................................... 7-4

7.1.8 USB Memory .................................................................................................................................. 7-5

7.2 Fuse Install and Replace ................................................................................................................................ 7-6

7.3 Block Diagram ............................................................................................................................................... 7-8

11--11

① LCD Screen

It is a 6.4-inch LCD monitor. It displays all information necessary for embroidery work.

② Function Keys

They are used to select the functions displayed on the screen.

③ Start Button

It starts the embroidery work.

④ Stop Button

It stops the embroidery work under execution.

⑤ Number Keys

They are used to enter numbers upon parameter setting and to manually move the needle bar.

⑥ Laser Pointer Key

It turns on or turns out the laser pointer in case where the laser pointer is equipped.

⑦ ORG

This is used to return the frame to the origin.

⑧ SET

This is used to confirm the selection in case of setting or on the menu.

⑨ Main Shaft Speed Keys

They are used to adjust the main shaft speed in the middle of embroidery work. Use 'UP' to speed up. Use

‘DOWN’ to speed down.

1.1

Part Name and Function

The OP Box is an LCD-type monitor as shown in <Fig. 1.1-1>.

Cables and ports are located on the right, rear, and bottom sides.

1

Operation Box

[Fig. 1.1-1]

▶

Front

⑩

⑪

⑤

⑥

⑦

⑧

⑨

④③

②

①

11--22

The right side is protected by the connector cover against foreign materials including dust. Press the cover once to open.

① Keyboard Port

② VGA Port

③ Serial Port

This is used for serial communications.

④ LAN Port for Networking

⑤ USB Port

It is used to save and call designs in and out of the embroidery machine by using a USB memory.

⑥ USB Port (slave)

This is a reserve port for the USB-based communication with PC.

⑩ Frame Move Keys

They are used to move the frame in the four directions including Up, Down, Left, and Right. They are also used to

move around the menu on the screen.

⑪ Frame Speed Key

It is used to adjust the speed in three steps including high, medium, and low when moving the frame.

① Cable Connection for FDD

It is used to make connection to the external FDD using a cable.

② Cable Connection for Power Supply and Signal Transmission

[Fig. 1.1-2] [Fig. 1.1-3]

▶

Right

①

②

③

④

⑤

⑥

[Fig. 1.1-4]

▶

Rear

①

②

22--11

2

Basic Steps Before Starting Embroidery

2.1

Embroidery Machine Power-On

[Fig 2.1-1]

① Insert the power plug of the embroidery machine into the outlet

② Turn on the main power switch (‘ON’)

③ Turn on the operation switch, and then the LCD screen of the OP Box is turned on and the operating program is

displayed on the screen.

④ Use the frame move keys to check the appropriateness of the frame motion. Check the basic motions by referring

to ‘5.8.3 Motion Test’.

[ Warning ]

Make sure to pull off the power plug before A/S service activities begin.

Emergency Switch

Emergency Switch

Operation Switch

Main Power

Switch

※※

SB, Multi-Head E-Series Embroidery Machine

22--22

[Fig 2.1-2]

① Insert the power plug into the outlet.

② Check the NFB switch location as in <Fig. 2.1-2> and lift the NFB switch (make it ‘ON’).

③ Check the I/O switch location and press the I/O switch.

④ The LCD screen is on, and the embroidery operation program is displayed on the screen.

⑤ Use the frame move keys to check the normal operation of the frame. See ‘5.8.3 Operation Test’ to check the basic

operations.

[ Warning ]

Make sure to turn OFF the power or the NFB switch when repairing the machine.

I/O Switch

NFB Switch

※※

DM Series Small-Head Embroidery Machine

22--33

[Fig 2.1-3]

① Insert the power plug of the embroidery machine into the outlet

② Turn on the main power switch (‘ON’)

③ Turn on the operation switch, and then the LCD screen of the OP Box is turned on and the operating program is

displayed on the screen.

④ Use the frame move keys to check the appropriateness of the frame motion. Check the basic motions by referring

to ‘5.8.3 Motion Test’.

[ Warning ]

Make sure to turn OFF the power or the NFB switch when repairing the machine.

Emergency

Switch

Emergency Switch

Operation Switch

Main Power

Switch

※※

DM Series Multi-Head Embroidery Machine

[Fig 2.1-4]

① Insert the power plug of the embroidery machine into the outlet

② Turn on the main power switch (‘ON’)

③ Turn on the operation switch, and then the LCD screen of the OP Box is turned on and the operating program is

displayed on the screen.

④ Use the frame move keys to check the appropriateness of the frame motion. Check the basic motions by referring

to ‘5.8.3 Motion Test’.

[ Warning ]

Make sure to turn OFF the power or the NFB switch when repairing the machine.

Emergency

Switch

Emergency Switch

Operation Switch

Main Power

Switch

※※

DM 56 Embroidery Machine

■ SWF/DM-WD920-55

■ SWF/DM-WU(2X)656-150

22--44

Turn on the power switch.

Does it have the machine operating program in the memory?

Is the frame move key pressed? Execute the machine installation program.

Are there designs saved in the memory for embroidery work?

Design call

Select a needle bar

Set the conditions necessary for

machine operation.

Do you want repeat embroidery?

Do you want ancillary work including gauge work?

Set the embroidery position

Do you want to set the frame off-set function?

Start embroidery work by using the bar switch or

the start button.

Set the repeat embroidery

Check gauge, outline sewing, and scope

Set the frame offset function

Save designs in the machine using a floppy

diskette or USB memory.

Were the previous designs saved?

Automatic design call

Automatic settings call

Do you want to change the settings?

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

2.2

Basic Steps

33--11

3

Operating Program Install

When the machine is shipped out, the operating program is pre-installed and pre-set. However, when the program

was damaged or the settings need to be changed or upgraded, the installation of the program is required. In this

case, the program can be re-installed or the set values can be initialized.

■Use the SWF Install Program

1. If the machine operating program was not installed, the automatic link to the install menu is conducted as in

<Fig. 3.0-2>.

2.

Upon booting, the logo appears on the screen for two seconds as in <Fig. 3.0-1>. In case of pressing the frame left

and right move keys together when the logo appears on the screen, the install screen appears next. <Fig. 3.0-3>.

Motion

Status of Frame Move Keys On the Logo Screen

Frame Move Key

Moving to the SWF Install

Program

When the left and right keys are pressed

together

[Fig. 3.0-3][Fig. 3.0-2]

[Fig. 3.0-1]

33--22

3.1.0

SWF Install Program

As in <Fig. 3.0-3>, SWF Install Program can conduct installation, backup, memory management, and system

setting.

3.1.1 Install

The machine operating program and the necessary data files can be installed in the OP Box using the input devices

(floppy diskette, USB).

1) Program : Embroidery Operating Program

Use the direction keys , as in <Fig. 3.0-3> to move to ‘PROGRAM’. Press , and

then the screen appears as in <Fig. 3.1.1-1>.

To use a floppy diskette for installation, insert the floppy diskette containing the operating program and then

press . To use a USB memory for installation, insert the USB memory into the USB port, and then

press . T o cancel installation, press .

CANCEL

F3

USB

F2

FDD

F1

SELECT

F7

F2

F1

[Fig. 3.1.1-1] [Fig. 3.1.1-2]

33--33

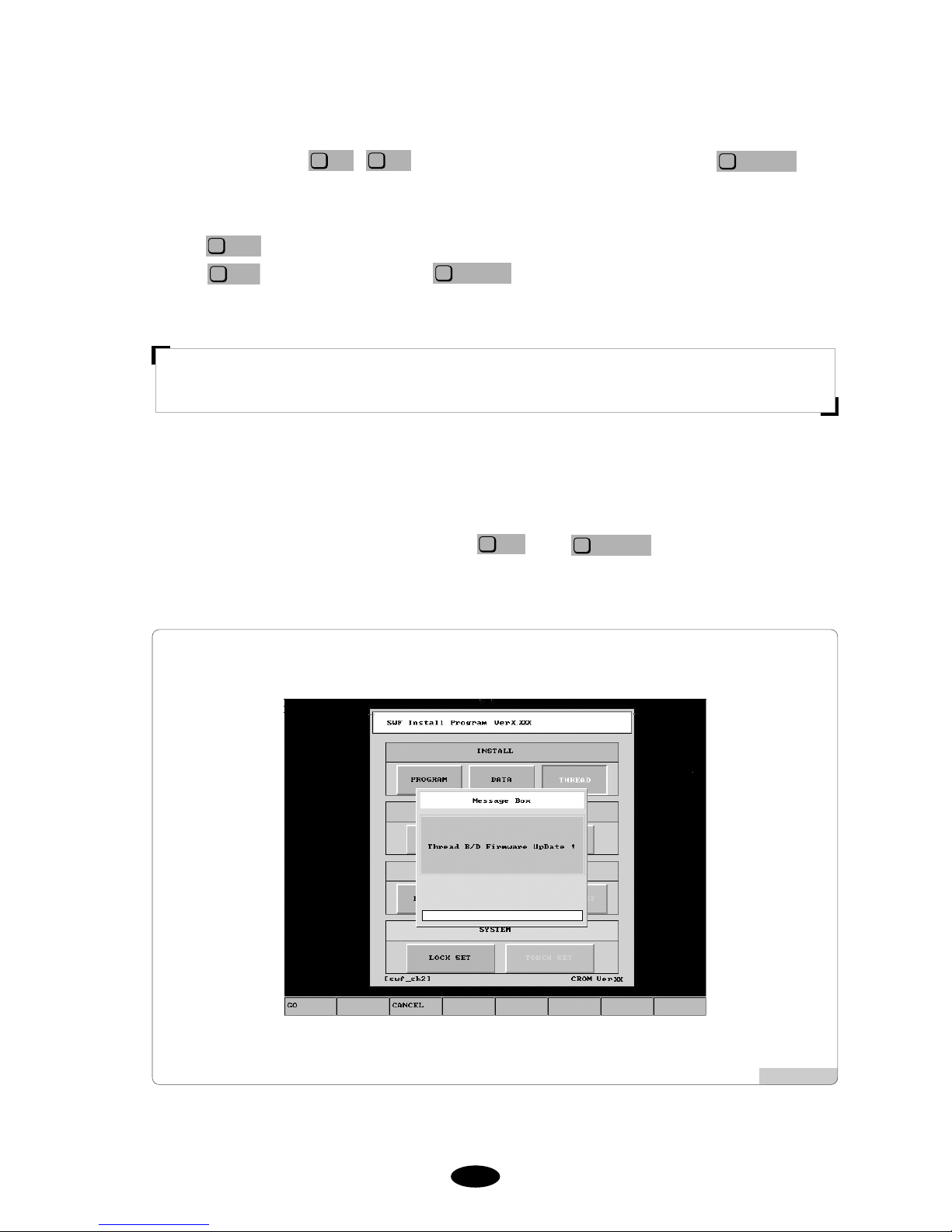

3) Program : Thread Sensing Board Program

<Fig. 3.1.1-3> automatically appears when the operating program and data is installed either via FDD or USB.

This screen can be viewed when selecting ‘THREAD’ in <Fig. 3.0-3>.

T o upgrade the thread sensing board program, press . Press to cancel.

CANCEL

F3

GO

F1

[Fig. 3.1.1-3]

2) Data : It is needed by the embroidery operating program.

Use the direction keys , as in <Fig. 3.0-3> to move to ‘DATA’ and press . Then

<Fig. 3.1.1-2> appears.

To use a floppy diskette for installation, insert the floppy diskette containing the operating program and then

press . To use a USB memory for installation, insert the USB memory into the USB port, and then

press . To cancel installation, press .

CANCEL

F3

USB

F2

FDD

F1

SELECT

F7

F2

F1

[ Caution ]

USB memory's file system should be FAT 16. If it is FAT 32, it cannot be used.

33--44

3.1.2 Backup

Backup is conducted in the opposite direction from installation. For possible loss of data, the operating program

and the data files should be saved in a floppy diskette. If there are no operating program and data files or if the

memory has been formatted, the backup function cannot be used.

1) Program

Use the direction keys , as in <Fig. 3.0-3> to move to ‘PROGRAM’ on the backup menu, and

press . Then <Fig. 3.1.2-1> appears.

To use a floppy diskette for backup, insert an empty floppy diskette and then press . To use a USB

memory for backup, insert the USB memory into the USB port, and then press . To cancel backup,

press .

CANCEL

F3

USB

F2

FDD

F1

SELECT

F7

F2

F1

2) Data

Use the direction keys , as in <Fig. 3.0-3> to move to ‘DATA’ on the backup menu, and press

. Then <Fig. 3.1.2-2> appears.

To use a floppy diskette for backup, insert an empty floppy diskette and then press . To use a USB

memory for backup, insert the USB memory into the USB port, and then press . To cancel the backup,

press .

CANCEL

F3

USB

F2

FDD

F1

SELECT

F7

F2

F1

[Caution]

USB memory's file system should be FAT 16. If it is FAT 32, it cannot be used.

[Fig. 3.1.2-1] [Fig. 3.1.2-2]

33--55

3.1.3 Memory

It has such functions as memory format and memory setting initialization.

1) Format

Use the direction keys , as in <Fig. 3.0-3> to move to ‘FORMAT’ on the memory menu, and

press . Then <Fig. 3.1.3-1> appears.

When pressing , the memory will be formatted, and all programs and data will be deleted. To cancel the

backup, press .

CANCEL

F3

GO

F1

SELECT

F7

F2

F1

2) Setting Initialization

Use the direction keys , as in <Fig. 3.0-3> to move to ‘PARA INIT’ on the memory menu, and

press . Then <Fig. 3.1.3-2> appears.

When pressing , all settings made in the operating program will be initialized. To cancel the

initialization, press .

CANCEL

F3

GO

F1

SELECT

F7

F2

F1

[Fig. 3.1.3-1]

[Fig. 3.1.3-2]

33--66

3) Machine Setting Initialization

Use the direction keys , as in <Fig. 3.0-3> to move to ‘PARA SET’ on the memory menu, and

press . Then <Fig. 3.1.3-3> appears.

When pressing , the machine setting will be initialized, and the screen for machine setting appears. To

cancel, press .

CANCEL

F3

GO

F1

SELECT

F7

F2

F1

[Fig. 3.1.3-3]

33--77

3.1.4 System

The function of entering the lock key is supported.

The embroidery machine operating program has the lock function. When the lock function is set, the operating

program can be used without problem for the set period of time. But when the set time frame passes, the lapse will

occur when opening the operating program. This intentionally causes inconvenience when the program is used after

the set time frame.

If the lock function is enabled, the logo will be displayed as in <Fig. 3.1.4-1>, not as <Fig. 3.0-1>. In case of <Fig.

3.1.4-1>, the operating program can be used without problem for 10 days, and the logo screen will stay for only 2

seconds. However, after 10 days, as in <Fig. 3.1.4-2>, lapse will occur before running the operating program. Time

lapse will also occur when conducting the second batch of embroidery after finishing the first batch of embroidery

work. Likewise after the set time frame, inconvenience occurs when using the operating program.

To resolve the inconvenience, it is required to receive new lock key from the sales agent and enter it to the system.

Otherwise, the time lapse will get lengthened further over the passage of time.

[Fig. 3.1.4-1] [Fig. 3.1.4-2]

[ Caution ]

There are two types of a lock key: limited and unlimited use. For more inquires on the lock key, contact the

distributor’s shop.

33--88

[Example] Re-entry of Lock Key

Press the start switch as in <Fig. 3.1.4-2>.

Then <Fig. 3.0-3> appears.

Use the direction keys , as in <Fig. 3.0-3> to move to ‘Lock Set’ on the system menu.

Press and then <Fig. 3.1.4-3> appears.

Call the distributor’s shop and give it the old code displayed on the user screen as in <Fig. 3.1.4.3>.

(ex : 4 1 0 4 3 2 1 2 3).

The distributor’s shop will give a new lock code.

Use the key pad to enter the new lock code.

Select and press the set key.

OK

F7

SELECT

F7

F2

F1

[Fig. 3.1.4-3]

33--99

3.2.0

Machine Setting Change

The machine setting is the function to conduct the basic specifications setup and adjust the machine settings.

<Fig. 3.2.0-1> appears in either one of the following cases:

1. Memory formatting was conducted and a system was newly installed.

2. Initialization was conducted using the SWF install program (See ‘3.1.3 Memory’).

In the above cases, when the main power switch is turned on, the first screen which appears is <Fig. 3.2.0-1>. On

<Fig. 3.2.0-1>, 12 parameters can be set. When ‘SETTING’ is selected, the screen for selecting the encoder signal

appears.

On <Fig. 3.2.0-1>, to make settings for each item, press the buttons on the right side.

Use , to move to a desired item and press . Then the screen like ‘Fig. 3.2.1

Embroidery Machine Specifications Setting’ appears where the setting of each item is possible. When the setting is

completed for all items, press . <Fig. 3.2.0-2> appears to check the set specifications.

NEXT

F7

SELECT

F7

F2

F1

[Fig. 3.2.0-1] [Fig. 3.2.0-2]

33--1100

3.2.1 Embroidery Machine Specifications Setting

10 specifications can be set.

[Fig. 3.2.1-1] [Fig. 3.2.1-2]

① Head Setting ② Color Count Setting

[Fig. 3.2.1-3]

[Fig. 3.2.1-4]

③ Trimming Method Setting ④ Y-frame Size Setting

33--1111

[Fig. 3.2.1-5] [Fig. 3.2.1-6]

⑤ X-frame Size Setting ⑥ X-space Extension

[Fig. 3.2.1-7] [Fig. 3.2.1-8]

⑦ Wheel Type Select ⑧ Sequin Type Select

33--1122

[Fig. 3.2.1-9] [Fig. 3.2.1-10]

⑨ X Satin Default Setting ⑩ Y Satin Default Setting

[Fig. 3.2.1-11]

⑪ Cording Setting

33--1133

3.2.2 Machine and Signal Setting

Press in <Fig. 3.2.0-1>, and then <Fig. 3.2.2-1> appears.

1) Main Shaft Encoder Signal Setting

Press the select button and set the machine at 100°. While adjusting the encoder, fix the machine when the beep

sound is issued, and ‘On’ is displayed on the screen. Press the select button to conclude the setting.

2) Needle Bar Position Setting

Press the select button and move to the highest number needle bar (ex: 9 color → No. 9). Adjust the potentio

meter, and when the beep sound is issued and ‘On’ is displayed, fix the machine. Press the start button and then

the select button again to conclude the setting.

3) X, Y Limit Setting

Press the select button and manually move the X, Y frame. Check the On/Off status of the sensor and press the

select button to conclude the setting.

4) Wiper Signal Setting

Press the select button and manually move the wiper. When the beep sound is issued, check the abnormality of

the sensor and press the select button again to conclude the setting.

SETTING

F6

[Fig. 3.2.2-1]

[ Warning ]

When the machine setting is wrong, it may cause problem to the machine. Unless there is clear information,

please refrain from changing the default setting.

44--11

<Fig. 4.0-1> is the initial screen of the machine operating program. The screen is composed of (1) embroidery

screen, (2) work information screen, and (3) main function button screen.

4.1

Embroidery Screen

This shows the called embroidery design. When the machine operating program is first installed or when there is no

design called, the SWF logo appears on this screen.

[Fig. 4.0-1] Initial Screen of SWF Machine Operating Programa

4

Operating Program Screen Layout

Embroidery

Screen

Work

Information

Screen

Main Function

Button Screen

44--22

Information Description

Remarks

- # : Design name/memory saving number

- ST . : Total number of stitches of a selected design

This shows all information related to the currently called design.

- X, Y length from the design starting position (central line)

- X, Y length of the selected design (unit: mm)

- Number of colors used for the selected design

- Number of jumps for the selected design

- P: reverse effect (X, Y, XY reverse)

- 0 ANG: rotation shape according to the angle of the selected design

- X 100%: value for X enlargement

- Y 100%: value for Y enlargement

- Current needle bar / next needle bar

- Frame’s return to the origin

※ As in ‘5.4.2 EMB Parameter Setting’, when ‘3) Auto Origin Return’

is selected, it is green. When ‘No’ is selected, it is gray.

- shaft’ s stop position. Either in the middle of embroidery or when it is

not 100°, its color gets gray.

※ [Warning] When changing the needle bar, its angle must be 100°.

- Time taken so far for embroidery (hh:mm)

- ST : Accumulative number of stitches made so far

- WK : Number of work finished. Whenever a work is finished, the

figure increases by one.

- X : Current X-shaft position

- Y : Current Y-shaft position

- ST: Number of stitches made so far

- %: Progress of stitching in %

- Set embroidery speed

- Current embroidery speed

- Frame moving speed : low / mid / high

4.2

Work Information Screen

44--33

4.3

Function Menu Button Screen

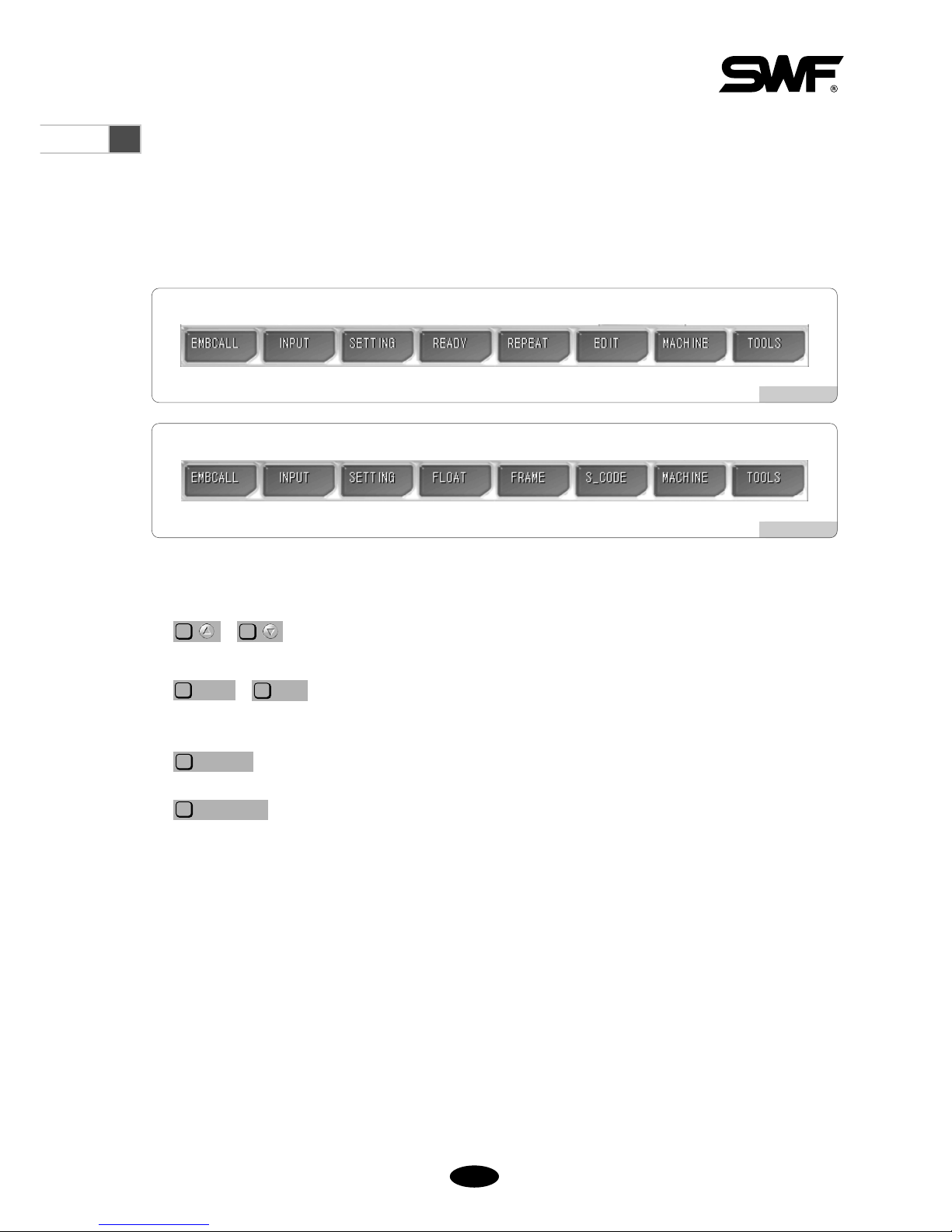

There are eight menus related to embroidery work. When each button is pressed, related sub-menu appears.

Depending on whether the machine is in operation, there are two types of menu buttons including ‘Function menus

before embroidery begins’ as in <Fig. 4.3-1> and the ‘Function menus during the pause of embroidery work’ as in

<Fig. 4.3-2>. More details will be dealt with in the section of each button.

[Fig. 4.3-1]

[Fig. 4.3-2]

◆ Frequently Used Buttons on Menu (the number assigned to a key could be different on each screen)

, :

When selecting a menu, they are used to move to the desired menu for selection.

, : If there are more menus which cannot be displayed in one screen, they are used to

move to the previous or next screens.

: It is used to select a menu or execute a command.

:

The command which is going to be executed can be closed.

The window where the command was executed can be closed.

The command can be cancelled.

The move to the prior execution screen is possible.

PREVIOUS

F8

SELECT

F7

>>

F4

<<

F3

F2

F1

44--44

4.4.0

Work Progress Message and Clock

There are the message window at the bottom of <Fig. 4.4.0-1> and the clock window at the right top of the screen.

The message window displays the embroidery information in progress. The clock window displays the time.

4.4.1 Work Progress Messages

[Fig. 4.4.0-1]

Message Situation

“Stop by the stop switch”

“Stop by detecting the upper thread break”

“Stop due to color code and stop code”

“Stop due to the detection of the frame outside the limit”

“Design close”

“Stop by the back stitch”

“Frame feed under way”

“Stop the frame feed”

“Offset position stop”

“Needle bar replacement”

“Choice of the feed unit during the non-stitching operation”

“Start switch → machine operation”

“Design data loading under way”

When the stop switch is pressed

When the machine is stopped after the thread break is sensed

When the machine is stopped due to the stop code

When the frame moves beyond the set motion limit

When the embroidery work is finished

When the machine is stopped after the back stitch

When the frame is in motion

When the frame is stopped in the middle of feeding

When the machine is stopped at the offset position

When the needle bar is replaced

When the non-stitching operation is conducted

When a test is conducted in the test mode

When embroidery designs are called

44--55

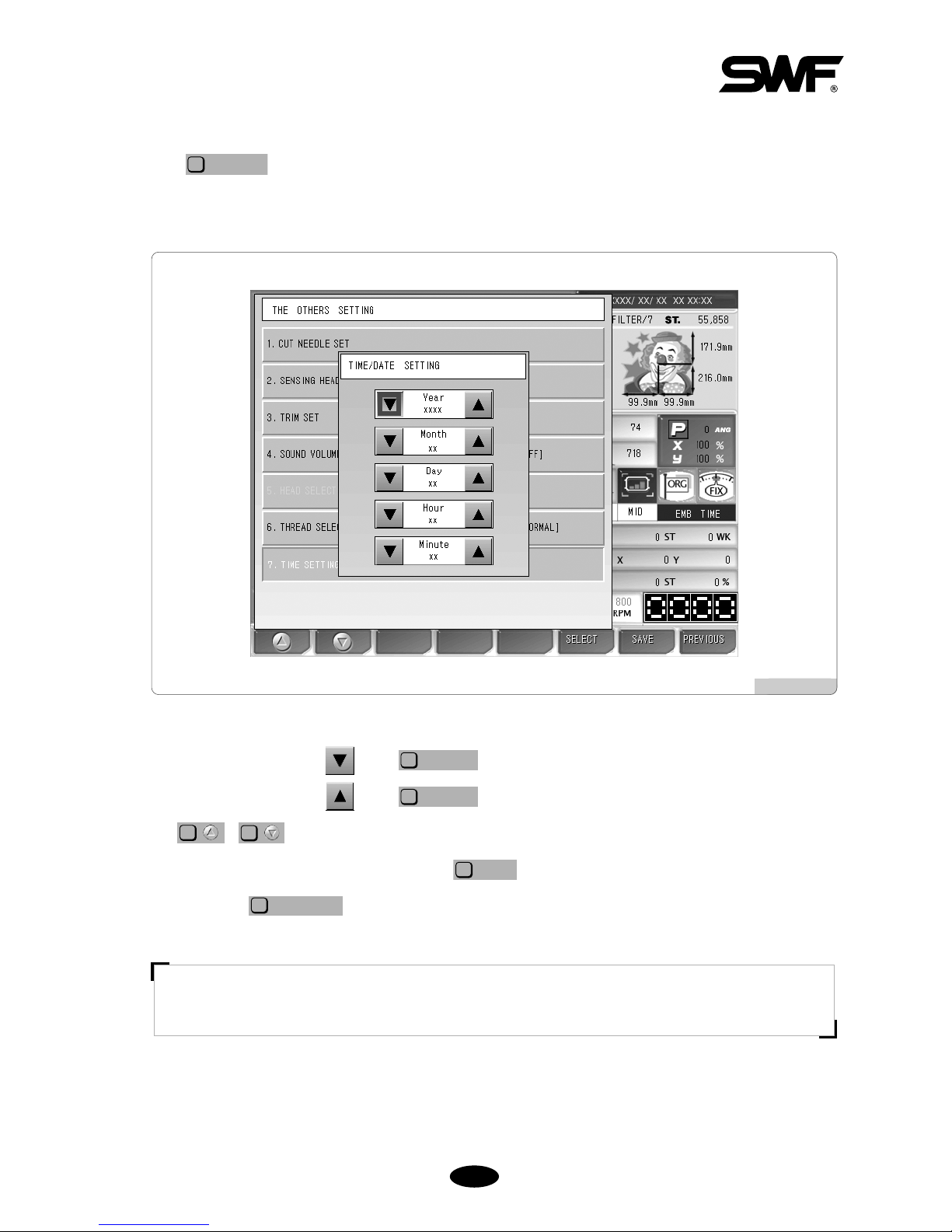

4.4.2 Date and Time Change

Press to change time or date displayed at the right top of the screen, and select ‘7. TIME SETTING’.

When the menu is selected, the date and time setting is possible as in <Fig. 4.4.2-1>.

SETTING

F3

When the cursor is located at , press to reduce the figures for date and time.

When the cursor is located at , press to increase the figures for date and time.

Use , to move around the menu.

When the date and time setting is completed, press for application.

T o cancel, press .

PREVIOUS

F8

SAVE

F6

F2

F1

SELECT

F6

SELECT

F6

[ Note ]

If the lock is set up, the date and time setting cannot be made.

[Fig. 4.4.2-1]

55--11

Prior to embroidery work, various settings should be made. In particular, when the machine operating program is

installed, various parameters should be set including design call. Of course, there is no problem in conducting

embroidery in default setting. Nevertheless, it would be better for you to learn more about the functions of the

program to produce better quality embroidery.

Basically, use ~ on the OP Box to use functions. Press each key corresponding to each function menu.

5

Function Menu Before Embroidery Begins

EMBCALL

F1

INPUT

F2

SETTING

F3

READY

F4

REPEAT

F5

EDIT

F6

MACHINE

F7

F1

G

F1

55--22

5.1

Structure of the Menu Before Embroidery Begins

★Design Call

Input

Setting

Ready

Repeat

★Edit

Machine

Tools

Design

FDD Input

USB

CF Card

Serial

★Basic Setting

Embroidery Parameter Setting

Machine Parameter Setting

Needle Setting

★Frame Offset Setting

Option Setting

The Others Settings

Position

★Gauge

★Exclude

Fastview

Trace

General Repeat

Special Repeat

Repeat Load

Stitch Edit

Design Divide

Design Filtering

Design Zoom In

Machine Service

Machine Information

Machine Test

Frame Origin

Error Information

Thread Break Information

Memory Initial

Origin

Holding

Needle DN

Needle UP

Language

Sequin Lift

Sequin Feed

Trim

Delete

Copy

Output

Export

Format

Select

Needle Select

Needle Convert

Needle Color

Cut Needle Set

Sensing Head Set

Trim Set

Sound Volume

Head Select

Thread Select

Time Setting

Jump Test

Wiper Test

Picker Test

Trim Test

Holding Test

Thread Sensing Test

Preview

Delete

Copy

※ [ Caution ] : The functions marked with ‘★’ cannot be used during the repeat work.

55--33

5.2

Design Call

- This function is to call back the embroidery designs saved in the memory. The function

can be used to copy and delete designs or export them to the external devices.

<Fig. 5.2-1> is the screen where no designs are stored in the memory or there is no design called out. If there is a

design called out previously, the previous work’s design is displayed as in <Fig. 5.2-2>.

If there are no designs called as in <Fig. 5.2-1>, several function buttons cannot be used. The buttons whose letters

are pale cannot be used until the designs are called later.

If is pressed on the screen as in <Fig. 5.2-2>, embroidery designs stored in the memory appear as

in <Fig. 5.2-3>. Up to 100 designs can be stored in the memory. Up to 20 designs can be displayed on one screen.

Let’s get to know more about embroidery design call through [Exercise 5.2-1].

EMBCALL

F1

[Fig. 5.2-1]

[Fig. 5.2-2]

55--44

[Exercise 5.2-1] Call the design from #35 Room.

Press .

When the design call button is pressed, the designs stored at each room are displayed as in <Fig. 5.2-3>. The

screen displays the room numbers and embroidery designs. Each screen shows up to 20 designs. The design we

would like to call is located at the #35 room, so we have to move to the next screen. Press to move

to the next screen.

>>

F6

EMBCALL

F1

Use , , , to move to the screen where #35 room is displayed.

As in <Fig. 5.2-4> below, 20 designs are displayed.

F2F2F2

F1

[ Note ]

The number of stitches unused indicates the memory space currently unused.

[Fig. 5.2-3]

[Fig. 5.2-4]

55--55

Go to # 35 room in <Fig. 5.2-4> and press . (the square room with slashes)

Then a new window appears as in <Fig. 5.2-5>. On the left-hand side, the chosen design is displayed. On the

right-hand side of the screen, the information on the design is displayed. On the screen, such buttons as

, , , are enabled.

SELECT

F4

EXPORT

F3

COPY

F2

DELETE

F1

SELECT

F7

Press .

The selected embroidery design will be called and displayed on the initial screen as in <Fig. 5.2-6>.

SELECT

F4

[ Note ]

On the embroidery information section, “OPTION NORMAL”might be seen. “Normal”refers to common embroidery

data. Sometimes, “Sequin”might be displayed. It means that it is the embroidery design including the sequin code.

[Fig. 5.2-5]

[Fig. 5.2-6]

55--66

[Exercise 5.2-2] Copy the design from #35 Room to #69 Room.

Repeat ~ of [Exercise 5.2-1] from “Call the design”from #35 Room.

Press in <Fig. 5.2-5>.

As in <Fig. 5.2-7>, message windows will appear, and the empty room numbers and the up/down, copy, and

cancel buttons are displayed. Empty rooms are the space where new embroidery data can be saved. It is possible

to move to the target room number by using , .

Use , to move to #69 Room and press .

COPY

F7

F2

F1F2F1

COPY

F2

[ Note ]

If it is desired to cancel the copy, press .

PREVIOUS

F8

The embroidery data in #35 Room was copied in #69 Room. As in <Fig. 5.2-8>, the design was moved to

#69 Room.

[Fig. 5.2-7]

[Fig. 5.2-8]

55--77

[Exercise 5.2-3] Delete the design in #69 Room.

Repeat ~ of [Exercise 5.2-1] “Call the design from #35 Room”.

Use the direction keys to go to #69 Room and press .

Press in <Fig. 5.2-5>.

As in <Fig. 5.2-9>, the message window appears asking “Do you want to delete?”

DELETE

F1

SELECT

F7

[ Note ]

If you do not want to delete it, press .

PREVIOUS

F8

Press .

When compared with <Fig. 5.2-8>, the design in #69 Room was deleted as in <Fig. 5.2-10>. #69 Room

becomes available for design storage.

YES

F1

[Fig. 5.2-9]

[Fig. 5.2-10]

55--88

[Exercise 5.2-4] Copy the design of #35 Room using floppy diskette or USB.

Repeat ①~③ of [Exercise 5.2-1] “Call the design from #35 Room.”

Insert a floppy diskette into the floppy drive or a USB memory into the USB port.

Press in <Fig. 5.2-5>.

As in <Fig. 5.2-11>, the message window appears asking for selecting the output device. If is

pressed, the design will be saved in the floppy diskette. If is pressed, the design will be saved in the

USB memory.

USB

F2

FDD

F1

EXPORT

F3

[ Caution ]

If a floppy diskette is removed from the disk drive while being used, the data in the diskette might be deleted

or the diskette itself can be damaged.

[ Caution ]

The file system of the USB memory shall be FAT16, not FAT32.

[Fig. 5.2-11]

55--99

Press or .

The message asking for the saving method appears as in <Fig. 5.2-12>. If is pressed, it is saved in

the floppy diskette in the SWF method. If is pressed, it is saved in the Tajima method.

T—CODE

F2

SWF

F1

USB

F2

FDD

F1

Press .

The green bar at the bottom of the message shows the progress as in <Fig. 5.2-13>. When the copy is

completed, the entire bar becomes green.

SWF

F1

[Fig. 5.2-12]

[Fig. 5.2-13]

55--1100

<Fig. 5.2-14> shows the status of the floppy diskette where the design was copied.

To check the status, see 5.3.0) Input - “FDD Input”. When saving designs in a floppy diskette, the file is saved

as SWF000.SST. The names of files copied to a floppy diskette include SWF000.SST, SWF001.SST. or

SWF000.DST , SWF001.DST, etc.

[Fig. 5.2-14]

55--1111

[Fig. 5.3.0-1]

5.3.0

Input/Output

- This function is to enter designs from external devices to the OP Box. The designs can be

copied from such external devices as a floppy diskette, USB memory, CF (Compact Flash)

card, and serial communications.

On the initial screen, press and the sub-menu appears as in <Fig. 5.3.0-1>. The sub-menu buttons

include Floppy Diskette, USB, CF Card, and Serial.

INPUT

F2

55--1122

5.3.1 FDD Input

When the Floppy Diskette button is pressed, the brief information on the designs saved in the floppy diskette is

displayed. Diskette formatting, design preview, design input, and design deletion can be performed.

Insert the floppy diskette containing embroidery design files into FDD.

Select “Floppy”in <Fig. 5.3.0-1>, and <Fig. 5.3.1-1> appears on the screen.

Up to 10 designs can be displayed on one screen. If the total number of designs saved is over 10, scroll bar and

scroll up/down buttons can be used to see next screens. Such information as file name, total # of stitches, and

creation date is displayed for each design. As in <Fig. 5.3.1-1>, use , and select #63 Room

and press . Then <Fig. 5.3.1-3> appears, and such functions as preview, delete, and

copy can be performed.

SELECT

F7

F2

F1

[ Caution ]

If a floppy diskette is removed from the disk drive while being used, the data in the diskette might be deleted

or the diskette itself can be damaged.

[Fig. 5.3.1-1]

55--1133

[Exercise 5.3.1-1] Conduct the design preview for ““63.SST””saved in the floppy diskette

and copy it in #12 Room.

In <Fig. 5.3.1-2>, select and press .

Then, the window appears as in <Fig. 5.3.1-3>.

SELECT

F7

[Fig. 5.3.1-2] [Fig. 5.3.1-3]

Select the room number.

Use the Room Up/Down buttons , to select the room number. When the buttons are pressed,

the empty rooms are displayed in order. Select #12 Room.

F2

F1

Press .

As in <Fig. 5.3.1-4>, the design is displayed on the pre-view window.

PREVIEW

F1

[Fig. 5.3.1-4]

55--1144

Press .

As in <Fig. 5.3.1-5>, the status bar at the bottom of the window turns green, showing the copying progress.

When the bar is completely green, it means that copy is finished, and the window disappears.

COPY

F3

As in <Fig. 5.3.1-6>, the design copied in #12 Room can be checked. To check the design copied, see “5.2 Design

Call”.

[Fig. 5.3.1-5]

[Fig. 5.3.1-6]

55--1155

[Exercise 5.3.1-2] Delete ““63.SST””in a floppy diskette.

Select as in <Fig. 5.3.1-2> and press .

Press .

Then, <Fig. 5.3.1-7> appears. The message asking “Do you want to delete?”appears on the screen. If you want

to delete it, press . If you do not want to delete it, press .

NO

F2

YES

F1

DELETE

F2

SELECT

F7

Press .

As in <Fig. 5.3.1-8>, the files are deleted.

YES

F1

[Fig. 5.3.1-7]

[Fig. 5.3.1-8]

55--1166

[Exercise 5.3.1-3] Floppy Diskette Format

Press the format button as in <Fig. 5.3.1-1>.

[ Caution ]

If a floppy diskette is removed from the disk drive while being used, the data in the diskette might be deleted

or the diskette itself can be damaged.

55--1177

You can move to the embroidery design folder by pressing , as in <Fig. 5.3.2-1>.

When pressing , as in <Fig. 5.3.2-2>, the design files contained in the chosen folder are displayed.

T o move to the upper -level folder, press the “”folder on the left-hand side.

DIR/FILE

F3

F2

F1

[Fig. 5.3.2-2]

5.3.2 USB Input

This function is to enter embroidery designs saved in the USB memory to the OP Box.

Insert the USB memory containing embroidery design files into the USB port.

When “USB”is selected in <Fig. 5.3.0-1>, <Fig. 5.3.2-1> appears.

[ Caution ]

The file system of the USB memory shall be FAT16, not FAT32.

[Fig. 5.3.2-1]

55--1188

When a design is selected in <Fig. 5.3.2-2>, <Fig. 5.3.2-3> appears.

When a USB memory is used, the preview function is directly performed. Input and Delete function keys appear at

the bottom. Preview, Delete, and Copy function can be used in the same way as in “5.3.1 FDD Input”.

[Fig. 5.3.2-3]

55--1199

5.3.3 CF Card Input

This function is to import the embroidery design files saved in the C/F card to the OP Box.

Connect a C/F card containing embroidery design files to the C/F card reader and insert the USB plug of the C/F

card reader into the USB port of the OP Box.

When “C/F Card”is chosen in <Fig. 5.3.0-1>, <Fig. 5.3.3-1> appears.

Use , in <Fig. 5.3.3-1> to move to the folder which has embroidery designs.

When is pressed, the design files in the chosen folder are displayed as in <Fig. 5.3.3-2>.

T o move to the upper -level folder, select the “”folder on the left-hand side.

DIR/FILE

F3

F2

F1

[Fig. 5.3.3-1]

[Fig. 5.3.3-2]

55--2200

When a design is chosen in <Fig. 5.3.3-2>, <Fig. 5.3.3-3> appears.

In the USB memory, the preview function can be directly performed. Copy and Delete buttons also exist at the

bottom. Preview, Delete, and Copy functions can be used in the same way as explained in “5.3.1 FDD Input”.

[Fig. 5.3.3-3]

55--2211

5.3.4 Serial Input

This function is to import embroidery designs from embroidery design program Wings to

the OP Box.

Use the serial cable to connect to the OP Box. Call embroidery designs from Wings after establishing the

connection. When the screen appears, press “File”on the menu and select “Export”on the file menu. When

selecting “Other”on the export menu, the Export Output window appears. If driver has not been installed, press

“Add Driver.”When the “Add Wings I/O Driver”window appears, open the Sunstar.wio file, the Sunstar-

dedicated driver. Select the driver newly added to the Design Output window and press OK. Select the desired

format and press OK.

While designs are exported from the Wings program, select “Serial”in <Fig. 5.3.0-1> and then <Fig. 5.3.4-1>

appears. Preview and Delete functions cannot be used. Select a room number by using , and

press . Then <Fig. 5.3.4-2> appears.

COPY

F3

F2

F1

[Fig. 5.3.4-1]

55--2222

T o check the designs copied after design loading, see “5.2 Design Call”.

[Fig. 5.3.4-2]

55--2233

[Fig. 5.4.0-1]

•Basic setting: Sets zoom-out, zoom-in, and angle.

•EMB parameter setting : Sets parameters related to embroidery .

•M/C parameter setting: Sets parameters related to machine.

•Needle setting: Selects or changes the needle bar .

•Frame offset setting: Designates the off-set point on designs.

•Options setting: Sets option devices such as coding and boring.

•The Others Settings: Determine needle type and set thread sensing.

5.4.0

Setting

- On the setting menu, overall setups regarding embroidery can be made. There are seven

sub-menus under the setting menu, which include basic setting, embroidery parameter,

machine parameter, needle bar , prime of fset, options, and other settings.

On the initial screen, press among main function buttons, and <Fig. 5.4.0-1> appears.

SETTING

F3

55--2244

※ Setting Tips

To conduct basic, embroidery parameter, machine parameter, frame off-set, and options setting, press each

button, and? <Fig. 5.4.0-2> appears to enter values for setting.

- <Fig. 5.4.0-2> is the screen where X scale can be set using the basic setting.

- On the very top, there is title “X Scale”and the line below displays the setting scope of X Scale in red print.

- The next line is the space to enter a desired value.

- Use the number buttons to enter a desired value

- Press to correct the entered value.

- Press to apply the entered value.

- Press to cancel the entered value.

PREVIOUS

F8

[Fig. 5.4.0-2]

Item

Scope

Value

55--2255

5.4.1 Basic Setting

Press the basic setting button in <Fig. 5.4.0-1>, and the nine basic settings appear on the screen as in <Fig. 5.4.1-1>.

Press , to see the next menu.

When is pressed, the existing setting becomes initialized.

Press to select a menu. If the setting exit is desired, press .

PREVIOUS

F8

SELECT

F7

DEFAULT

F3

F2

F1

[Fig. 5.4.1-1]

55--2266

① X Scale

Enlarges or reduces a design in the X-axis direction.

The default is 100%, and the value can be adjusted from 50% to 200% by the unit of 1% .

② Y Scale

Enlarges or reduces a design in the Y-axis direction.

The default is 100%, and the value can be adjusted from 50% to 200% by the unit of 1% .

< 100% > < Y-axis 200% >

< 100% > < X-axis 200% >

< 100% >

< Enlarge Both X and Y >

< X, Y-axis 200% >

55--2277

③ Angle

Turns around the embroidery design according to the rotation angle value set.

The default is 0°, and the value can be adjusted from 0°to 359°by the unit of 1°.

④ Mirror

Reverses a design based on X, Y, or X,Y axes.

The default is “0”or “normal work”.

< 0°> < 90°>

< No > < X-axis >

< No > < Y-axis >

< No > < X_Y-axis >

Value Description

0 Basic Setting

1 X-axis reverse

2 Y-axis reverse

3 X, Y -axis reverse

55--2288

⑤ X Satin

In case where the embroidery design is a satin stitch, this function can set the satin width.

This function determines the satin stitch length in the X-axis direction. The value can be

increased by the unit of 0.1mm.

⑥ Y Satin

This function sets the Y-axis satin width.

⑦ Start stitch

This function sets the starting stitch number for the embroidery design to be worked. It enables skipping as

many as stitches desired for embroidery work.

For instance, there is a design with a total of 10,000 stitches below. The design on the left side has entire

stitches embroidered. On the right side, the design has only 5,000 stitches since the starting stitch number

was set at 5,000.

[Fig. 5.4.1-4]

Start Point

Start

Point

Finish

Point

Finish

Point

The embroidery

skipped part

(5,000 stitches)

Basic Design

(a total of 10,000 stitches)

When the number of

starting stitch is set at 5,000

[Fig. 5.4.1-3][Fig. 5.4.1-2]

55--2299

⑧ Offset Function

This function determines whether to use the automatically designated off-set function or not.

[Fig. 5.4.1-5]

★ Setting Tips to Use Frame Offset Work Function

1. Select “Yes”for the question asking the frame coordinates setting in the basic setting situation.?

2. Go to “Setting”→“Frame Offset Setting”and determine the starting position, the offset middle

position, and the stop position after design completion (offset) (5.4.5 Frame Offset Setting)

3. To use the offset function during embroidery work, go to “Main Function Menu”→“Setting”→

“5.4.5 Frame Offset Setting,”and enter the desired value to “Frame Offset Position”.

※ The above three settings shall be made to carry out the frame offset work.

Embroidery

Starting Point

<Embroidery Begins> <Embroidery Is Finished>

Frame Move

Needle Bar Position After

Embroidery Is Completed

Frame

Frame

55--3300

⑨ Jump Convert

This function is to move the frame after trimming, in the case where repeat jumps take place and they occur

more than the set value.

For instance, let’s assume that the set value is 5. Then, the machine conducts jump stitches without trimming

until 4 stitches. If the repeat jump with over 5 stitches is found, conduct trimming first and move 5 stitches

back and start embroidery again. The default is 3 stitches and the value can be adjusted from 0 to 10 by the

unit of 1 stitch.

[Fig. 5.4.1-6] “Trimming by Jump Frequency”When Value is 5

[ Caution ]

If ‘0[st]’is chosen, when repeat jump takes place, there will be no trimming regardless of the number of

stitches for the number of repeat jump.

When the value is 4 [stitches]

When the value is 5 [stitches]

(The thread is linked to the next design without trimming)

(The thread moves to the next design after trimming)

55--3311

[Fig. 5.4.2-1] [Fig. 5.4.2-2]

[Fig. 5.4.2-3]

5.4.2 EMB Parameter Setting

<Fig. 5.4.2-1>, <Fig. 5.4.2-2>, and <Fig. 5.4.2-3> are the screens showing the parameter setting. For setting, use

the number keys to enter the desired values within the scope same as the basic setting.?

Press , to view the next menu.

turns back the set values to default values of the operating program.

When is pressed, the next menu is displayed.

<Fig. 5.4.2-1>, the initial screen, shows eight setting menus. When is pressed first, the following eight

setting menus appear as in <Fig. 5.4.2-2>. Press again and the last embroidery parameter setting menus

appear as in <Fig. 5.4.2-3>. When is pressed once again, the initial screen returns as in <Fig. 5.4.2-1>.

is used to select menu. Press to exit from setting.

PREVIOUS

F8

SELECT

F7

NEXT

F4

NEXT

F4

NEXT

F4

NEXT

F4

DEFAULT

F3

F2

F1

55--3322

① T otal Stitch Clean

“ ST” as in “4.2.0 Work Information Screen” is the function to accumulate the total number of stitches

worked so far from the beginning of machine use or from the information initialization. This function

initializes the total stitch number into zero.

② T otal W ork Clear

“ WK” as in “4.2.0 Work Information Screen” is the function to accumulate the total number of

embroidery works produced so far from the beginning of machine use or from the information initialization.

This function initializes the total work number into zero.

(When initialization is desired, press “0” and then press . If initialization is not desired, press .)

③ Auto Origin Return

This function makes the frame return to the origin after embroidery work is completed.

- The default is “Yes (1)”. If the return to the origin is not desired, enter “No (0)”.

④ Jump Change Data

This function sets the needle width to change the regular code to the jump code.

- The default is 8.0 mm, and the scope of adjustment is from 5.0 to 12.7 mm and it can be set by the unit of

0.1 mm. For instance, if the distance between two needles is longer than the set value when the frame

moves from one needle to the other needle, it becomes a jump stitch.

⑤ Auto Backtack

The function sets the bartack performance to create stitch for embroidery beginning (thread release

prevention).

- The default is “EndBack” It can be changed to “No(0”), “Start Bartack(1)”, “End Bartack(2)”, and

“All(3)”.

⑥ Jump Convert (Length)

If the total stitch length of the repeat jump code is above the set value, trimming is primarily performed

before carrying out the next work. This function can set the maximum jump stitch length.

- The default is “No.” The scope of adjustment is from 1mm to 50mm by the unit of 1mm.

⑦ Applique

This function is used to set up the needle bar. If the needle bar is repeatly entered for needle bar setting, and

applique is “Yes”, the machine automatically stops without trimming when the needle bars overlap.

- The default is “Yes.”

55--3333

⑧ Auto Back Stitch

When thread break is sensed, this function sets the number of backward stitches.

- The default is 0 and the scope of adjustment is from 0 to 5 by the unit of 1 stitch.

⑨ Auto Start After Trimming

The function sets up whether embroidery automatically begins after jump code and trimming or trimming by

suspension code.

- The default is “Yes.” If automatic start is not desired, enter “0” to choose “No.”

⑩ Auto Start After Frame Back

The function is to determine whether the machine is automatically started when the frame reaches “⑫ All

Needle Bars’ Starting Position After Back Stitching.”

- The default is “Yes.” If automatic start is not desired, enter “0” to choose “No.”

⑪ All Head Swing After Stitch Back

The function is to decide whether the heads with broken thread are operated only or whether the needle bars

of all heads are operated in case where the frame is moved backward from the machine stop point, and the

embroidery work is begun with the bar switch.

- The default is “single.” To operate the needle bars of all heads, press “0” to select “All.”

⑫ All Head Startpoint After F .B

When all or multiple needle bars are simultaneously in operation and the machine is stopped due to the

detection of a problem (thread break) affecting one needle bar, it is possible to conduct the back-stitching for

the concerned needle bar with the problem to correct the part where stitching did not occur. After that, if all

the needle bars are operated from the point which is located before the problem area, the embroidery will be

overlapped on the problem area, making correction. The function is to set the relative position of the entire

needle bar motion, and the value can be set at the range from 1 to 20[st]. The default is 2[st].

⑬ Frame Forward / Back Moving Unit

This function is to set the number of stitches to move by the one-time operation of the bar switch when the

frame is moved forward and backward with the bar switch.

- The default is 1[st]. It can be set at the range of 1 to 10[st] by the unit of 1[st].

⑭ Optimize Method

The part where embroidery is conducted in the form of running stitch in a certain distance away from the

outline is called a gauge. This function is to set the distance between gauge and outline.

- The default is 10[mm], and the setting range is from 1 to 30[mm].

55--3344

⑮ Software Limit Setting

This function is to set whether to use the virtual frame limit setting function.

- The default is “No.”

⒃ Thread Break Moving

This function is to set the length of automatic backward movement of the frame in case where the machine is

stopped due to the sensing of thread break in order to make the upper thread placement much easier.

- The default is 0[mm], and the setting range is from 0 to 50mm. The value can be set by the unit of 1[mm].

⒔ Lock Stitch

This function is to set the execution of multiple backtacks to prevent thread release upon trimming.

- The default value is 1 stitch, and the value can be set at the odd number within the range of 1 to 5 stitches.

⒕ Auto Start After Color Change

When the thread color change code appears during embroidery, change the needle bar according to the needle

bar setting. This function is to determine whether embroidery is automatically started after the needle bar

change.

- The default value is “Yes (1).”

55--3355

5.4.3 M/C Parameter Setting

<Fig. 5.4.3-1>, <Fig. 5.4.3-2> and <Fig. 5.4.3-3> are the screens showing machine parameter setting. As with the

basic setting, use the number buttons and enter the desired value within the permissible range.

Press , to view the next menu.

changes the saved settings to default values.

Press to move to the next page.

<Fig. 5.4.3-1> shows eight setting menus on the first screen. When is pressed, as in <Fig. 5.4.3-2>, the

next eight setting menus appear. When is pressed again, as in <Fig. 5.4.3-3>, the last setting menu

appears. When is pressed, as in <Fig.5.4.3-1>, the initial screen appears.

Press to select menus and press to exit from setting.

PREVIOUS

F8

SELECT

F7

NEXT

F4

NEXT

F4

NEXT

F4

NEXT

F4

DEFAULT

F3

F2

F1

[Fig. 5.4.3-1] [Fig. 5.4.3-2]

[Fig. 5.4.3-3]

55--3366

① Max. speed

This function sets the maximum embroidery speed.

– SB Series Embroidery Machine: The default value is 1200[rpm], and the speed can be adjusted from the

minimum speed to 1200[rpm] by 10[rpm] each time.

– Multi-head E-Series Embroidery Machine: The default is 900[rpm], and the speed can be adjusted from

the minimum speed to 1200[rpm] by 10[rpm] each time.

– DM Series Embroidery Machine: The default is 1500[rpm], and the speed can be adjusted from the

minimum speed to 1500[rpm] by 10[rpm] each time.

② Min. speed

This function sets the minimum embroidery speed.

– The default is 300[rpm], and the value can be adjusted at the range from 300 [rpm] to the maximum

speed by the unit of 10[rpm].

③ EMB speed

This function sets the embroidery speed.

– The default is 800[rpm], and the value can be adjusted at the range from the maximum speed to the

minimum speed by the unit of 10[rpm].

④ Inching speed

This function sets the starting speed for embroidery work.

– The default is 100[rpm], and the value can be adjusted at the range from 50[rpm] to 200[rpm] by the unit

of 10[rpm].

⑤ Jump speed

This function sets the range of the jump stitch speed, which is characterized by frame move without sewing.

– The default is 1000[rpm], and the value can be adjusted at the range from 300[rpm] to 1000[rpm] by the

unit of 10[rpm].

⑥ Slow Speed

This function sets the embroidery speed during slow operation.

– The default is 650[rpm], and the value can be adjusted at the range from the minimum speed to the

maximum speed by the range of 10[rpm].

⑦ After Trimming Inching Stitch

When the color change signal is issued or when embroidery work for one design is completed, the closing is

conducted. At this time, the function sets the number of stitches to be made during slow operation.

– The default is 3 stitches, and the value can be adjusted at the range from 2 to 10 stitches by the unit of 1.

⑧ Auto Trimming

This function is to enable the automatic trimming function.

– The default is “Yes”, and to turn off the automatic trimming function, choose “No”.

55--3377

⑨ Auto Color Change

This function is to enable the automatic color change function.

– The default is “Yes”, and to turn off the automatic color change function, choose “No.”

⑩ Bottom Dead Point Stop

This function is to enable the needle bat to stop at the lowest point when the embroidery work is completed.

– The default is “No,” and select “Yes (1)” to make the needle bar stop at the lowest stop position.

⑪ Frame Setting

This is to set the types of embroidery frame.

⑫ Frame Speed Setting

This is to set the frame move speed during frame feeding, such as automatic return to origin and offset move.

– The default is “High Speed(1)”. To set the low speed, enter “Low Speed (0)”.

⑬ Frame Move Method (Trimming)

This is to shake the frame left or right to separate the thread from embroidery materials

after trimming.

– The default is X(1). To set the move direction along the Y-axis direction, select Y(2). If no direction is

selected, choose “NO(0)”.

⑭ Inching stitch

When starting embroidery, the machine starts operation at the inching speed. This function is to set the

number of stitches to be made during inching operation.

– The default is 2 stitches, and the value can be adjusted at the range from 2 to 10 stitches by the unit of 1

stitch.

⑮ Needle Move Function (Offset)

This function is to lift the needle bar by activating the jump motor when it moves to the offset position.

– The default is Yes(1), and when the function is unnecessary, select No(0).

⒃ Power On Auto Origin

This function is to automatically find the origin after the power is on.

– The default is “No”. If “Yes” is chosen, but the origin setting is wrong or the machine develops problems,

all settings shall be initialized. For setting initialization, see “2) Program setting Initialization of 3.1.3

Memory”.

55--3388

⒔ Start / End Filter

This function is to prevent thread break by conducting automatic filtering for the stitch of 0.5mm or shorter,

when starting or closing embroidery.

– The default is 0.0[mm], and the value can be adjusted from 0.0[mm] to 0.5[mm] by the unit of 0.1[mm].

⒕ Speed Switching Data

When the stitch value becomes higher than the set value, the embroidery speed is slowed down. It sets the

width of a stitch.

– The default is 4.0[mm]. The value can be set at the range of 3.0[mm] ~6.0[mm] by the unit of 1.0[mm].

⒖ Thread Break Sensor

If the sensor detects the repeat breaks of the upper thread at the set length, the machine will stop its

operation. This is to prevent false detection associated with sensor’s malfunction.

– The default is 3[st], and under this setting, the thread sensor does not work. The value can be adjusted

from 0 to 10[st] by the unit of 1[st].

⒗ Thread Break Method

This function is to set the sensitivity of the sensor when it detects thread.

– The default is Low(0), and the other options to choose include High(2) and Medium(1).

Thread Length Trimmed

Frame Start Angle For “A” Area

When the embroidery width is 1.9mm or below, this function sets the rotation angle of the main shaft when

the frame starts moving.

– The default is 240。, and the value can be adjusted from 230。to 250。by the unit of 1。.

Frame Start Angle For “B” Area

When the embroidery width is 2.0mm or above, this function sets the rotation angle of the main shaft when

the frame starts moving.

– The default is 240。, and the value can be adjusted from 230。to 250。by the unit of 1。.

Picker Off Time (Trimming)

This function is to set the length of the remaining upper thread at the needle when automatic trimming is

conducted.

– The default is 13[ang]. If the value set is smaller than the default, the remaining upper thread will be

short, and vice versa. The value can be adjusted from 0 to 60[ang] by the unit of 1[ang].

55--3399

5.4.4 Needle setting (color)

This function is to enable automatic change of needle bars when the thread color change code appears. It is also

able to change the colors of the embroidery design displayed on the screen.

<Fig. 5.4.4-1> and <Fig. 5.4.0-1> appears when the needle bar setting button is pressed to set the needle bars. The

needle bar setting can be divided into three steps including needle bar selection, change, and color change.

■To understand the above, let’s look at the head section of the SWF multi-head embroidery machine as

in <Fig. 5.4.4-2>.

As in <Fig. 5.4.4-2>, the multi-head embroidery machine has needle bars for each of which unique number is

designated. Each number is matched one or one to the standard needle bar on the “Needle Bar Number Change

Menu” as in <Fig. 5.4.4-1>. If the standard needle bar and the changed needle bar are same, the needle bar with a

unique number on the head section as in <Fig. 5.4.4-2> will operate. The unique numbers can be virtually changed

by pressing the change button. Here is an example for clearer understanding.

•Select: This is the menu where the order of changing needle bars is set when the color change code appears

during embroidery. Up to 300 color change codes can be applied.

•Change: This enables the user to change the 1 or 1 match between the needle bar table and the needle bar

at the his/her discretion.

•Color change: This function is to change the colors of each needle bar.

[Fig. 5.4.4-1] [Fig. 5.4.4-2]

55--4400

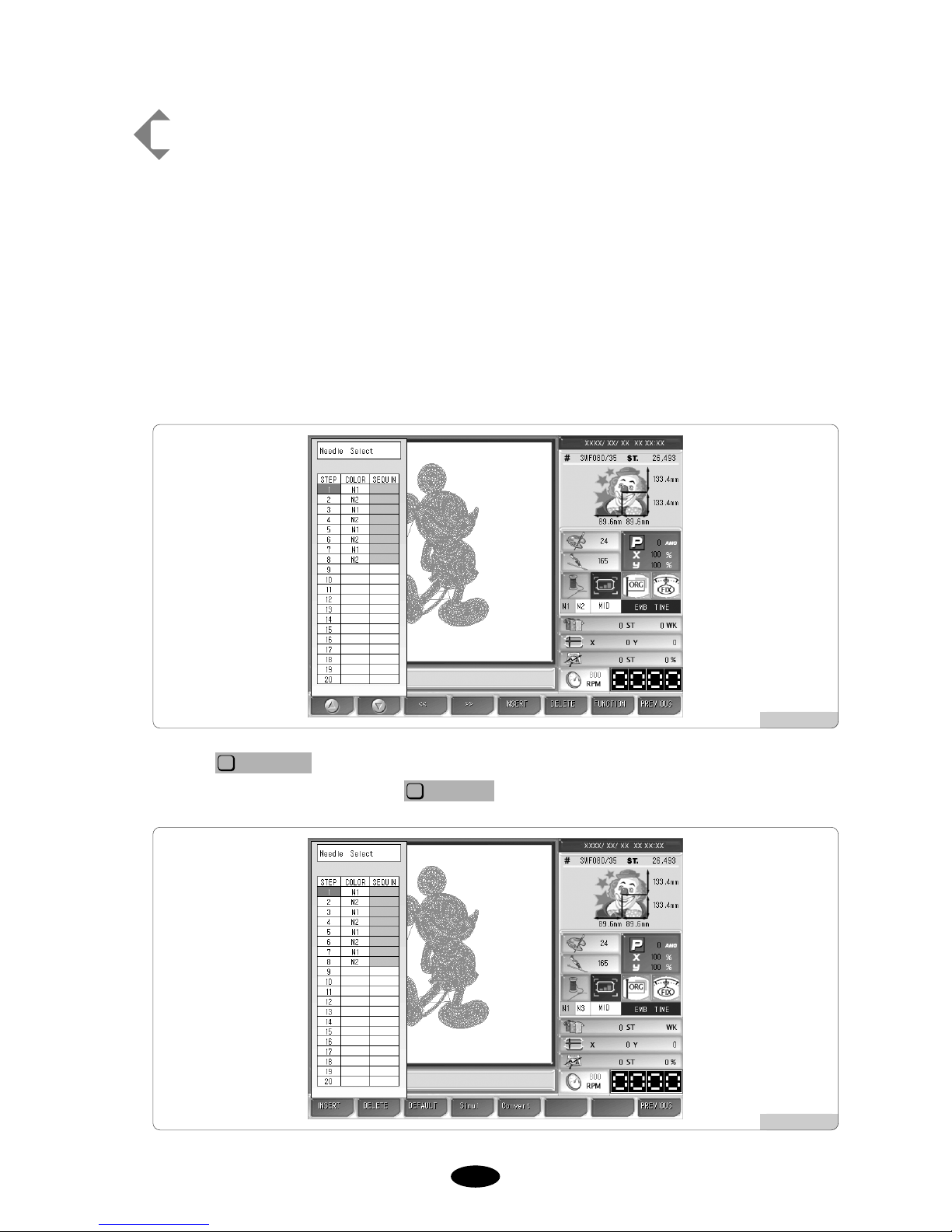

(1) Needle select

This function is to determine the changing order of needle bars when the color change signal appears during

embroidery. Press “Needle Bar Select” in <Fig. 5.4.4-1>, and the necessary buttons for needle bar choice are

enabled as in <Fig. 5.4.4-3>. Let’s take an example to explain how to use the function.

[Fig. 5.4.4-3]

[ Note ]

Once the needle bar setting is completed, the set values become default and remain preserved even after the

power is turned off. When other embroidery design is called, the needle bar setting values are unchanged. As

such, when the design is changed or other setting is desired, the needle bar setting shall be adjusted again.

■ Keys Used for Needle Bar Selection

: They are used to move to the desired needle bar.

: They are used to see the previous or next screens.

: This is used to insert the number of a needle bar in between the figures of needle bar entered.

: This is used to delete the number of a needle bar chosen from the already entered needle bar

numbers.

: This is used to conduct the simulation expression function, the needle bar change function,

and the needle bar color change.

: This is used to apply the setting or move back to the previous step.

PREVIOUS

F8

FUNCTION

F7

DELETE

F6

INSERT

F5

>>

F4

<<

F3

F2

F1

55--4411

[Exercise 5.4.4-1] Needle Select

Call the design in #37 Room and set the order of needle bars like 73-5-1-6-4-2-1.

Call the design in #35 Room as in <Fig. 5.2-6>.

(For design call, see “5.2 Design Call”.)

Press .

Use the up/down buttons on the setting menu to move to “Needle Bar Parameter setting” and press

.

Move to the needle bar choice menu.

As in <Fig. 5.4.4-4>, Add, Delete, Function, and Previous keys become enabled. The cursor is located on No. 1

for order choice.

SELECT

F7

SETTING

F3

[Fig. 5.4.4-4]

55--4422

Use the number buttons and enter 7.

As in <Fig. 5.4.4-5>, 7 is entered in No. 1, and the cursor moves to No. 2 for entry.

Repeat the above method and enter 3, 5, 1, 6, 4, 2, 1 in order by using the number buttons.

Make sure of the accurate setting and press .

PREVIOUS

F8

[Fig. 5.4.4-5]

55--4433

Press .

As in <Fig. 5.4.4-7>, “6” is copied, and the needle bars increase by one.

INSERT

F5

[Exercise 5.4.4-2] Add, Delete needle bars

The order of needle bar is 7-3-5-1-6-4-2-1. Insert #7 needle bar

(between #1 and #6) and delete #4 needle bar.

The precondition of this exercise is that [Exercise 5.4.4-1] shall be conducted first.

Move to the needle bar choice menu.

Use the direction buttons to move to #5 needle bar position.

As in <Fig. 5.4.4-6>, the cursor is located at the place which is taken by “6”.

[Fig. 5.4.4-6]

[Fig. 5.4.4-7]

55--4444

Use the direction buttons and move the cursor to “4” under #7 needle bar.

As in <Fig. 5.4.4-9>, the cursor will move to the “4” position.

Press the number button “9”.

As in <Fig. 5.4.4-8>, “9” is inserted.

[Fig. 5.4.4-8]

[Fig. 5.4.4-9]

55--4455

Press .

As in <Fig. 5.4.4-10>, number “4” is deleted, and number “2” is placed under #7 needle bar.

DELETE

F6

Press to apply the setting.

PREVIOUS

F8

[Fig. 5.4.4-10]

55--4466

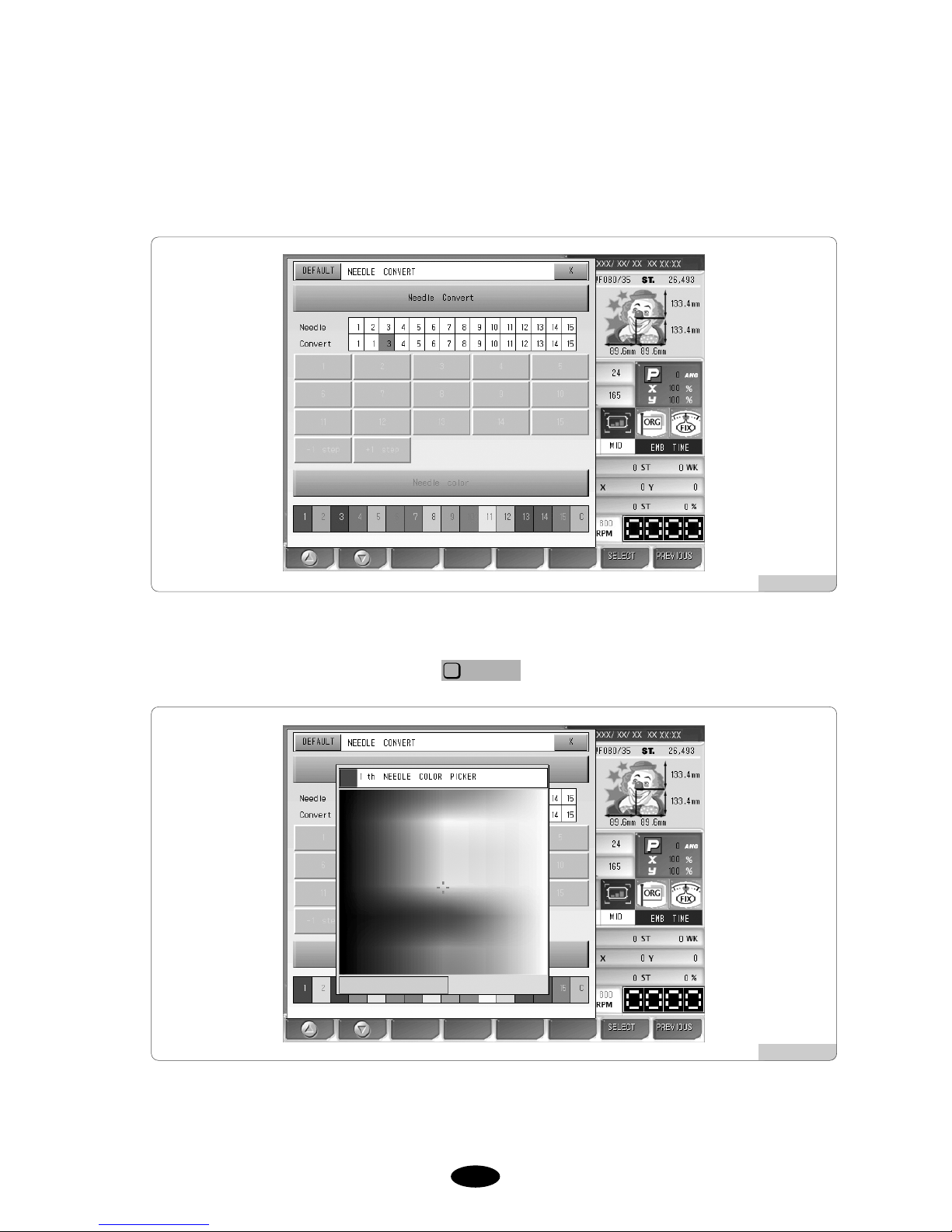

(2) Needle convert

This function is to virtually change the needle bar numbers fixed as in <Fig. 5.4.4-2>.

Let’s assume that the needle bar numbers are set as 1, 2, 1, 2, 1, 2, 1, 2, 1, 2 according to the order of color

change. If it is desired to change the needle bars designated as No. 2 into No. 1, this function enables making the

change all at once. Press the needle bar change button, and change No. 2 to No. 1. Then, with one-time

operation, all needle bar colors can be changed.

<Fig. 5.4.4-11> shows the screen when the needle bar change button is pressed. Let’s get to know more about

how to use the function via an exercise.

[Fig. 5.4.4-11]

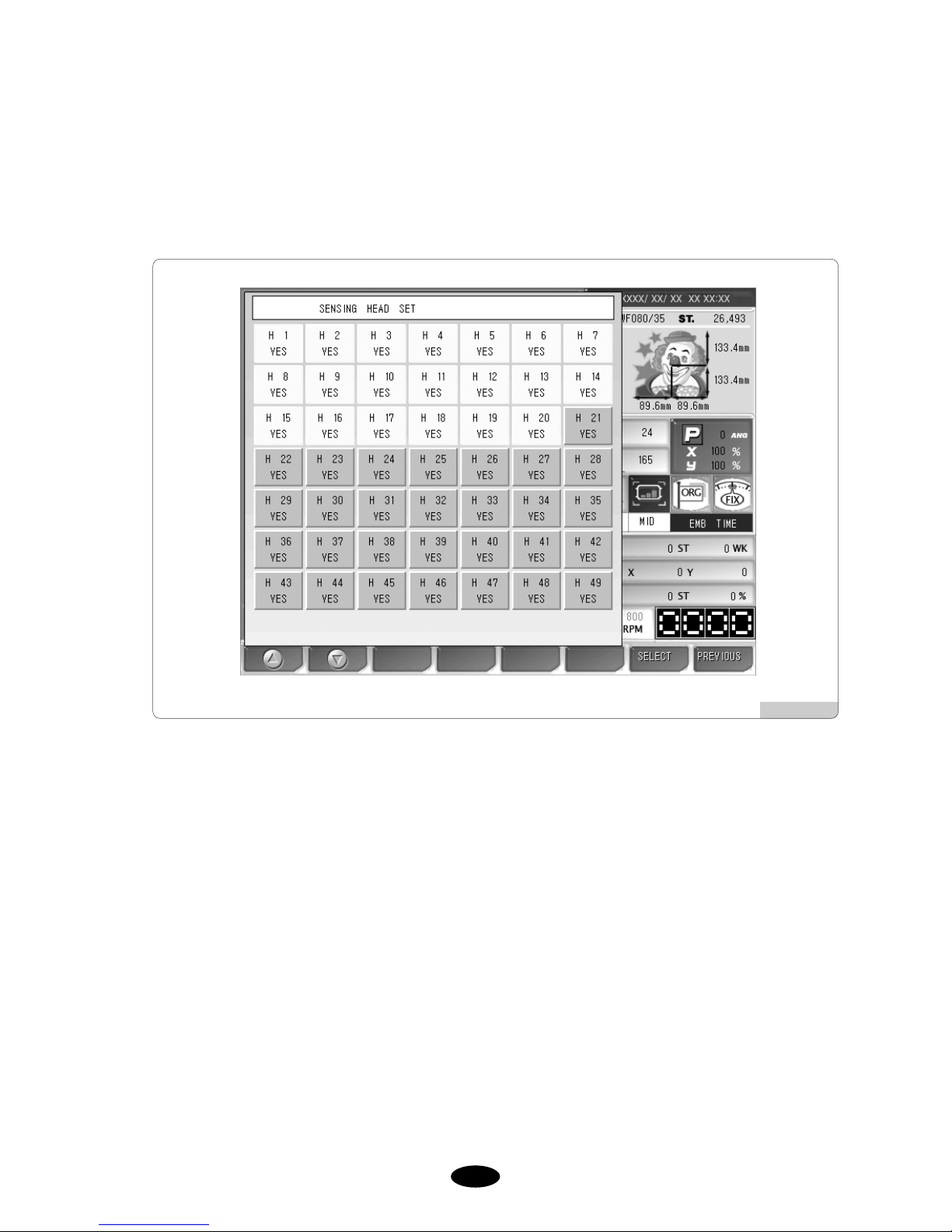

■ Buttons and Keys Used for Needle Bar and Color Change

Needle convert

Needle color

Number keypad: Enter the needle bar number.

- 1 decrease: Select the needle bar position by decreasing the needle bar order