Suzuki K9K, M13 Service Manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

!

WARNING

lighted by these signal words.

!

WARNING

Indicates a potential hazard that could result in death or injury.

!

CAUTION

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

!

WARNING

This service manual is intended for authorized Suzuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

!

, and NOTE have special meanings. Pay special attention to the messages high-

CAUTION

!

WARNING

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing service on or near the air bag system components or wiring. Please observe all WARNINGS and “Service Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component on or

around air bag system components or wiring. Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, that is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

RECOMMENDATON OF GENUINE SUZUKI PARTS AND ACCESSORIES USE

SUZUKI strongly recommends the use of genuine SUZUKI parts* and accessories. Genuine SUZUKI parts and

accessories are built to the highest standards of quality and performance, and are designed to fit the vehicle's

exact specifications.

A wide variety of non-genuine replacement parts and accessories for SUZUKI vehicles are currently available in

the market. Using these par ts and accessories can affect the vehicle performance and shorten its useful life.

Therefore, installation of non-genuine SUZUKI parts and accessories is not covered under warranty.

Non-Genuine SUZUKI Parts and Accessories

Some parts and accessories may be approved by certain authorities in your country.

Some parts and accessories are sold as SUZUKI a uthorized replacement par ts and accessor ies. Some genuine SUZUKI parts and accessor ies are sold as re-use parts and accessories. These par ts and accessories are

non-genuine Suzuki parts and accessories and use of these parts are not covered under warranty.

Re-use of Genuine SUZUKI Parts and Accessories

The resale or re-use of the following items which could give rise to safety hazards for users is expressly forbidden:

1) Air bag components and all other pyrotechnic items, including their components (e.g. cushion, control

devices and sensors)

2) Seatbelt system, including their components (e.g. webbing, buckles, and retractors)

The air bag and seat belt pretensioner components contain explosive chemicals. These components should be

removed and disposed of properly by SUZUKI authorized service shop or scrap yard to avoid unintended explosion before scrapping.

*The parts remanufactured under SUZUKI's approval can be used as genuine SUZUKI parts in Europe.

TABLE OF CONTENTS

GENERAL INFORMATION

General Information 0A 0B 6E2

Maintenance and Lubrication 0B

HEATING AND AIR CONDITIONING 1A 6G

Heater and Ventilation 1A

Air Conditioning (Optional) 1B Cranking System (M13 Engine) 6G 6H

STEERING, SUSPENSION, WHEELS AND

TIRES

Steering, Suspension, Wheels and Tires 3 Charging System (K9K Engine) 6H2 3B 6K2

Front Wheel Alignment 3A Exhaust System (M13 Engine) 6K 3B1

Steering Gear Box (Manual Type) and

Linkage

Power Steering (P/S) System (if equipped) 3B1 3E 7B

Steering Wheel and Column 3C Manual Transmission (M13 Engine Model) 7A 3F 7C

Front Suspension 3D Manual Transmission (K9K Engine Model) 7A2 7C2

Rear Suspension 3E Automatic Transmission 7B 4B 7D

Wheels and Tires 3F Clutch (M13 Engine Model) 7C 7E

DRIVE SHAFT AND PROPELLER SHAFT Clutch (K9K Engine Model) 7C2 5 7F

Propeller Shafts 4B Transfer 7D 5E

BRAKE SYSTEM

Brakes 5 Rear Differential 7F 6-1 8G

Antilock Brake System (ABS) 5E ELECTRICAL SYSTEM 6-2 8G2

ENGINE Body Electrical System 8 6-3

Engine General Information and Diagnosis

(M13 Engine without VVT)

Engine General Information and Diagnosis

(K9K Engine)

Engine General Information and Diagnosis

(M13 Engine with VVT)

Engine Mechanical (M13 Engine without

VVT)

Engine Mechanical (K9K Engine) 6A2

Engine Mechanical (M13 Engine with VVT) 6A3

Engine Cooling (M13 Engine) 6B

Engine Cooling (K9K Engine) 6B2

Engine Fuel (M13 Engine) 6C

Engine Fuel (K9K Engine) 6C2

3B

6-1

6-2

6-3

6A1

Engine and Emission Control System

(M13 Engine)

Engine and Emission Control System

(K9K Engine)

Ignition System (Electronic Ignition System)

Cranking System (K9K Engine) 6G2

Charging System (M13 Engine) 6H 3A 6K

Exhaust System (K9K Engine) 6K2

TRANSMISSION, CLUTCH AND DIFFERENTIAL

Front Differential 7E 8

Immobilizer Control System (M13 Engine

Model) (if equipped)

Immobilizer Control System (K9K Engine

Model)

BODY SERVICE

Body Service 9 6C

RESTRAINT SYSTEM

Restraint System 10

Air Bag System 10B

6E

6E2

6F 1B 6G2

8G

8G2

0A 6E

6F

3 6H2

3C 7A

3D 7A2

6A1 9

6A2

6A3 10

6B 10B

6B2

6C2

NOTE:

For the screen toned Section in the above table, refer to the same section of the Service Manuals men-

tioned in FOREWORD of this manual.

(C)

(B)

ENGINE MECHANICAL (K9K ENGINE) 6A2-5

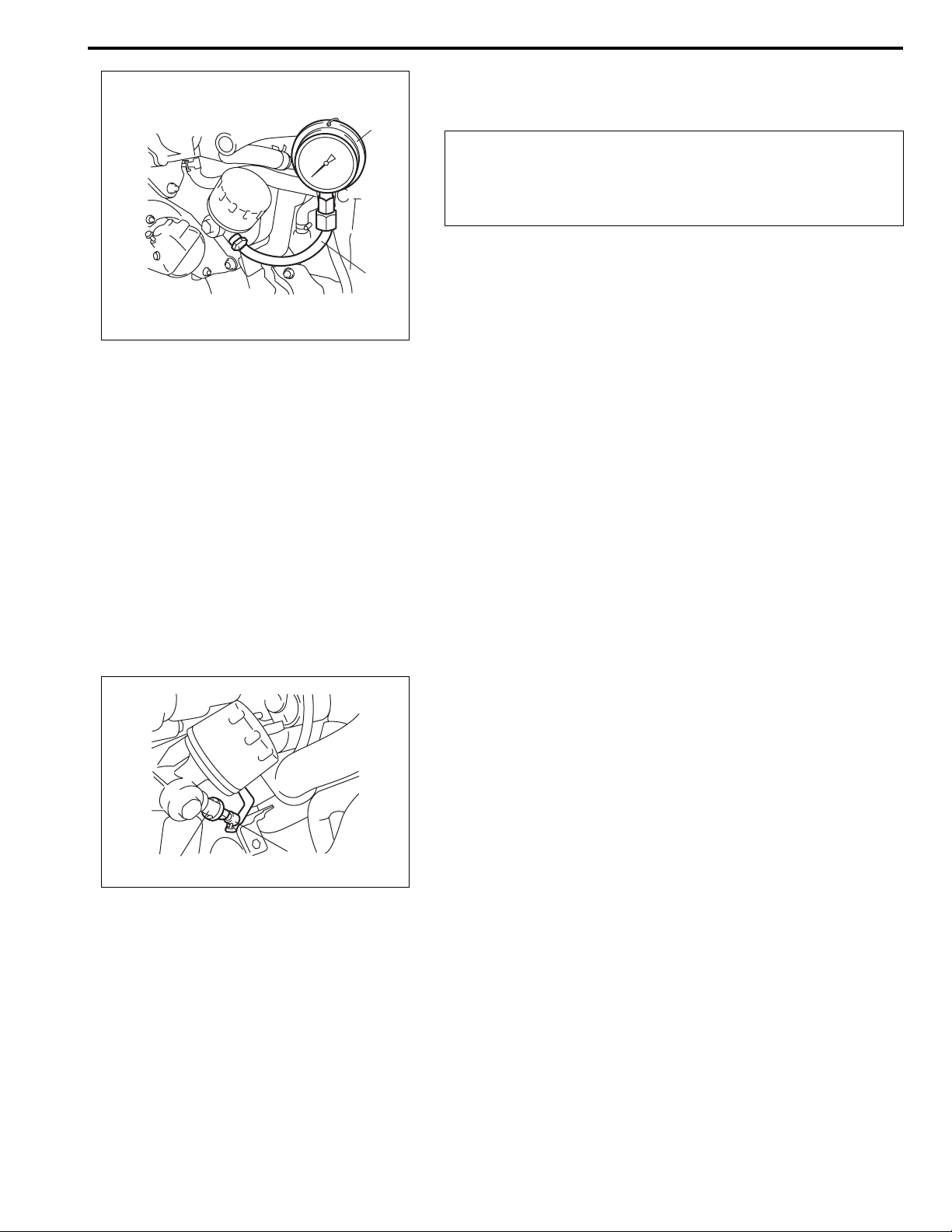

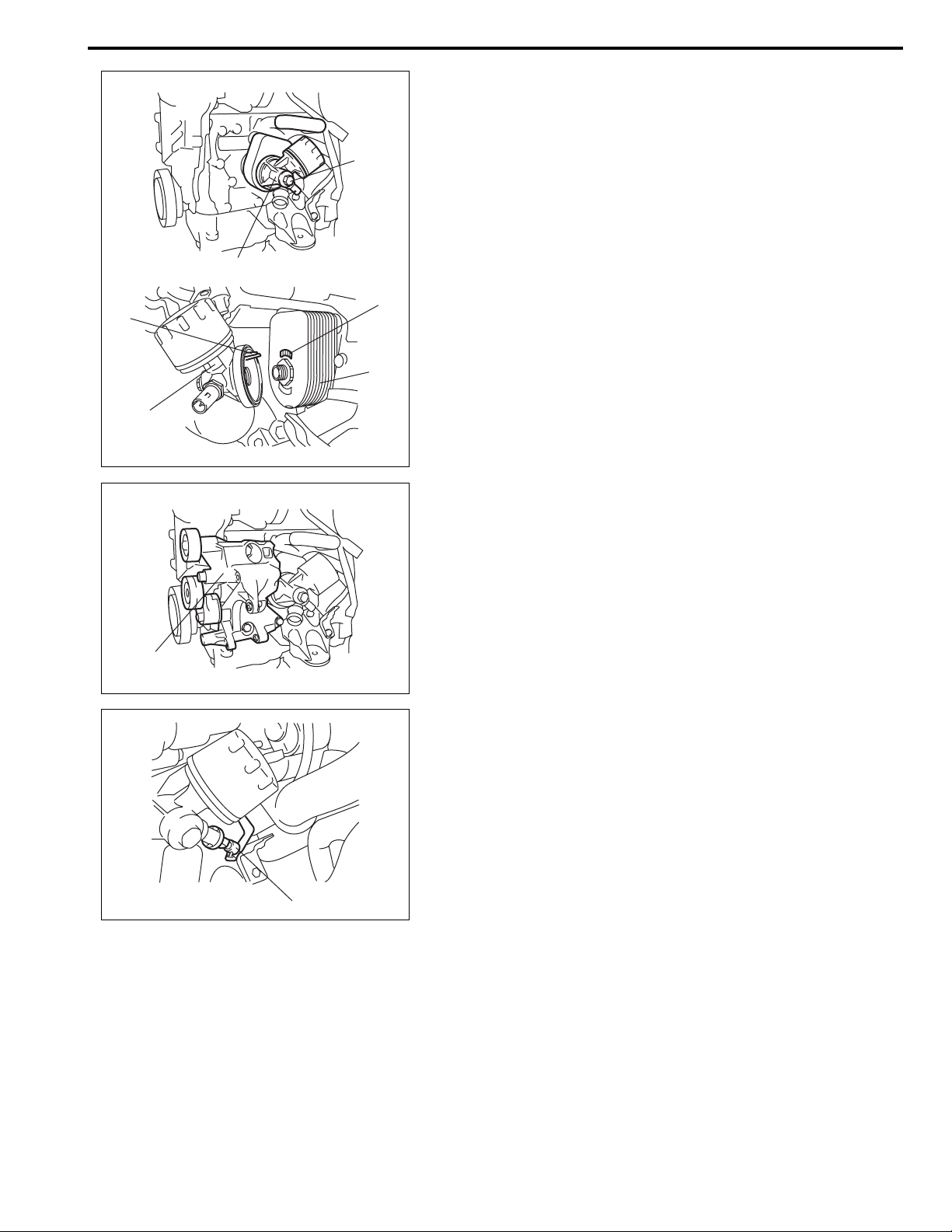

4) Install special tools (Oil pressure gauge) to vacated threaded

hole.

(A)

CAUTION:

Be careful not to make special tool touch exhaust mani-

fold when installing because exhaust manifold becomes

very hot.

Special tool

(A): 09915-77311

(B): 09915-77420

(C): 09915-77430

5) Start engine and warm it up to normal operating temperature.

NOTE:

Be sure to place transmission gear shift lever in “Neu-

tral” and set parking brake and block drive wheels.

1, (a)

6) After warming up, measure oil pressure.

Oil pressure specification:

2

100 – 140 kPa (1.0 – 1.4 kg/cm

, 14.2 – 20.0 psi) at idle

speed

330 – 370 kPa (3.3 – 3.7 kg/cm

2

, 46.9 – 52.5 psi) at 3,000 r/

min

7) Stop engine and remove oil pressure gauge and attachment.

8) Reinstall oil pressure switch (1), and tighten switch to specified torque.

Tightening torque

Oil pressure switch (a): 35 N·m (3.5 kg-m, 25.5 lb-ft)

9) Connect oil pressure switch coupler (2).

10) Install degassing tank to its bracket.

2

11) Start engine and check oil pressure switch for oil leakage.

If oil leakage is found, repair it.

6A2-6 ENGINE MECHANICAL (K9K ENGINE)

1

"1"

"2"

"3"

"4"

"5"

"6"

"7" "8"

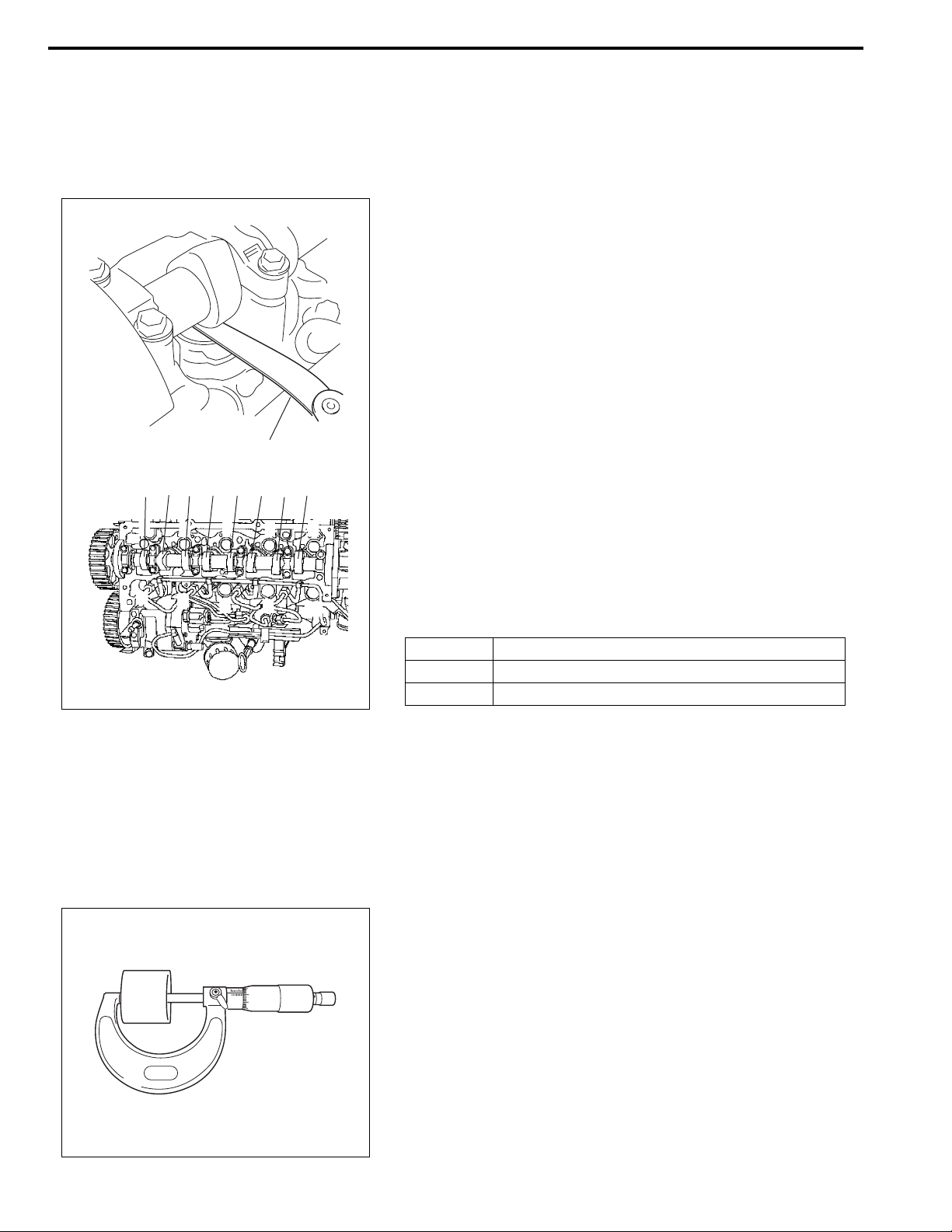

Valve Lash (Clearance)

Measurement of valve lash (clearance)

1) Disconnect negative (–) cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head

Cover Removal and Installation” in this section.

3) Turn crankshaft pulley clockwise until cam lobes become

perpendicular to tappet faces at valves “1” and “6” as shown

in figure.

4) Measure valve lashes with thickness gauge (1) according to

the following procedure.

a) Check valve lashes at valves “1” and “6”.

b) Turn camshaft by 90° (by turning crankshaft with wrench).

c) Make sure that cam lobes are perpendicular to tappet faces

at valves to be checked (in this case, “5” and “8”), if not,

adjust it by turning crankshaft. Check valve lashes.

d) In the same manner as b) – c), check valv e lashes at valves

“4” and “7”.

e) In the same manner as b) – c), check valv e lashes at valves

“2” and “3”.

If valve lash (clearance) is out of specification, record valve lash

(clearance) and adjust it to specification by replacing tappet.

Refer to “Replacement of tappet” under “Valve Lash (Clearance)”

in this section.

Valve lash (clearance) specification

When cold

Intake 0.125 – 0.250 mm (0.00493 – 0.00984 in.)

Exhaust 0.325 – 0.450 mm (0.01280 – 0.01771 in.)

Replacement of tappet

1) Measure valve lashes referring to “Measurement of Valve

Lash (Clearance)” under “Valve Lash (Clearance)” in this

section.

2) Remove tappet referring to “Camshaft and Tappet” in this

section.

3) Using micrometer, measure the thickness of the removed

tappet, and determine replacement tappet by calculating the

thickness of new tappet with the following formula and table.

Intake side

A = B + C – 0.1875 mm (0.007382 in.)

Exhaust side

A = B + C – 0.3875 mm (0.015256 in.)

A: Thickness of new tappet

B: Thickness of removed tappet

C: Measured valve lash (clearance)

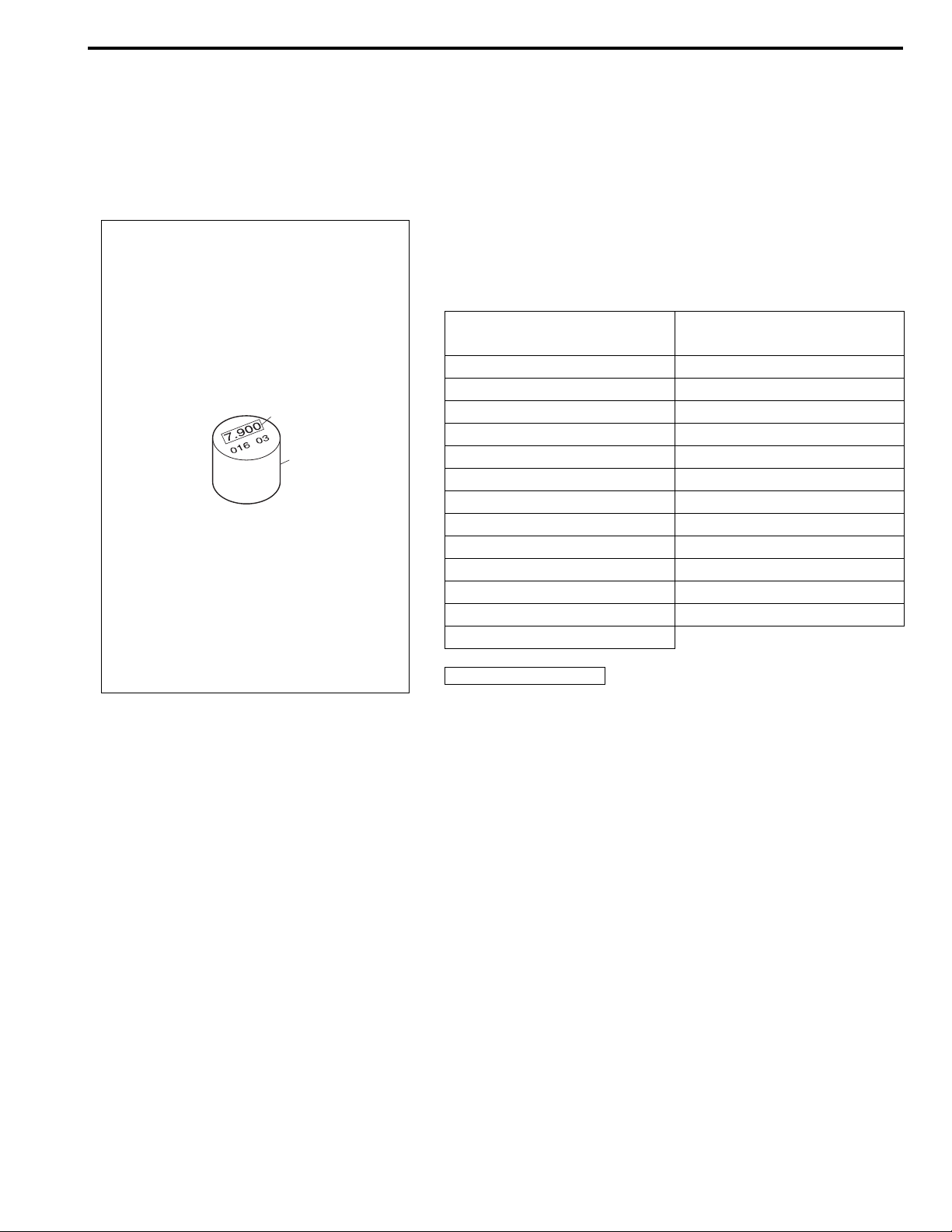

ENGINE MECHANICAL (K9K ENGINE) 6A2-7

Example of intake side:

When thickness of removed tappet is 7.8875 mm (0.310531 in.),

and measured valve lash (clearance) is 0.200 mm (0.00787 in.).

A = 7.8875 mm (0.310531 in.) + 0.200 mm (0.00787 in.) – 0.1875

mm (0.007382 in.) = 7.900 mm (0.31102 in.)

Calculated thickness of new tappet = 7.900 mm (0.31102 in.)

4) Select new tappet (1) with a thickness as close as possible

to calculated value.

Available new tappets

Thickness

mm (in.)

Thickness

mm (in.)

7.550 mm (0.29724 in.) 7.875 mm (0.31004 in.)

7.575 mm (0.29823 in.) 7.900 mm (0.31102 in.)

2

7.600 mm (0.29921 in.) 7.925 mm (0.31201 in.)

7.625 mm (0.30020 in.) 7.950 mm (0.31299 in.)

1

7.650 mm (0.30118 in.) 7.975 mm (0.31398 in.)

7.675 mm (0.30217 in.) 8.000 mm (0.31496 in.)

7.700 mm (0.30315 in.) 8.025 mm (0.31595 in.)

7.725 mm (0.30413 in.) 8.050 mm (0.31693 in.)

7.750 mm (0.30512 in.) 8.075 mm (0.31791 in.)

7.775 mm (0.30610 in.) 8.100 mm (0.31890 in.)

7.800 mm (0.30709 in.) 8.125 mm (0.31988 in.)

7.825 mm (0.30807 in.) 8.150 mm (0.32087 in.)

7.850 mm (0.30906 in.)

2. Tappet thickness

5) Install new tappet and camshaft referring to “Camshaft and

Tappet Removal and Installation” in this section.

6) Measure valve lashes again referring to “Measurement of

Valve Lash (Clearance)” under “Valve Lash (Clearance)” in

this section.

7) Install cylinder head cover referring to “Cylinder Head Cover

Removal and Installation” in this section.

6A2-8 ENGINE MECHANICAL (K9K ENGINE)

Repair Instructions

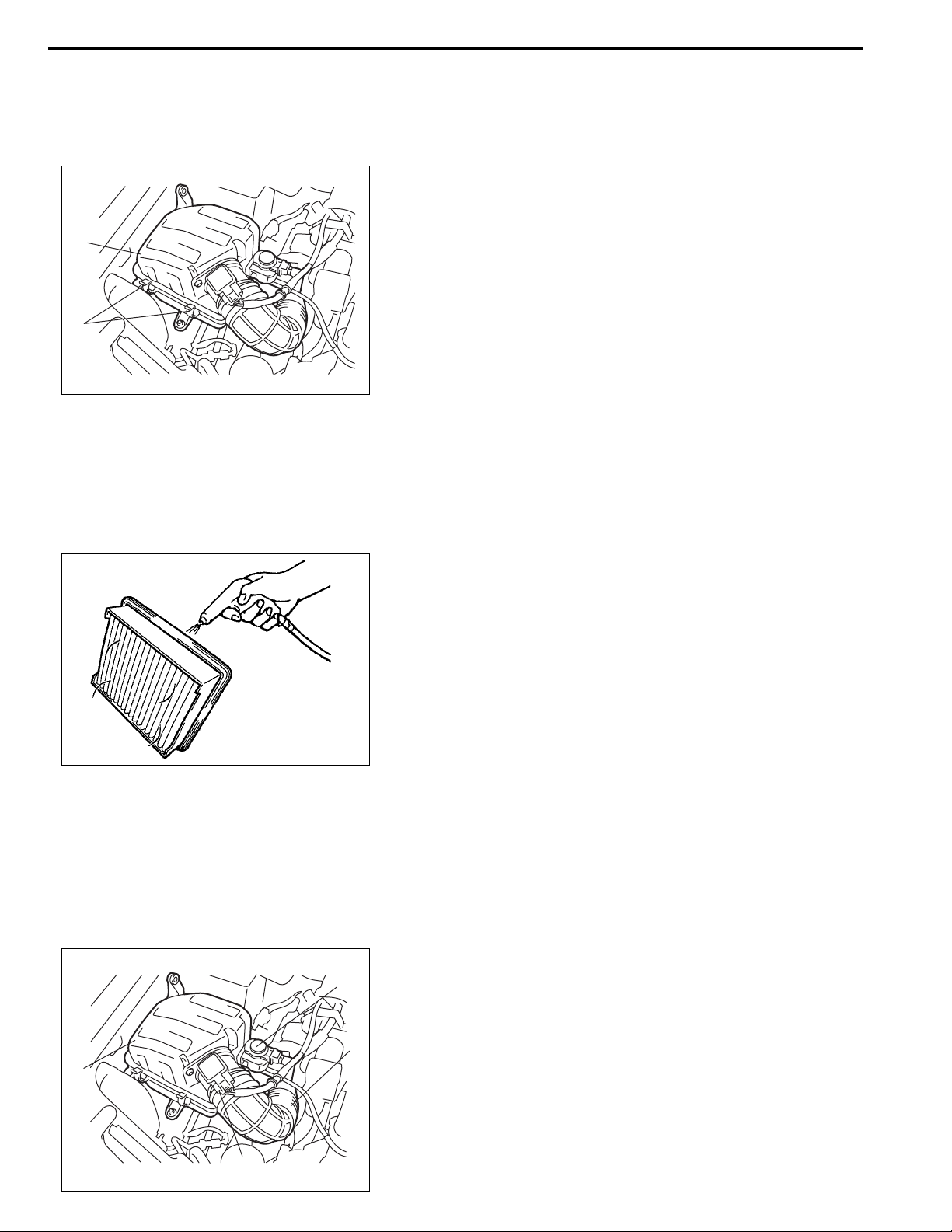

Air Cleaner Filter Removal and Installation

Removal

1) Open air cleaner case (2) unhooking its clamps (1).

2) Remove air cleaner filter from case.

2

Installation

Reverse removal procedure for installation.

1

Air Cleaner Filter Inspection and Cleaning

Inspection

Check filter for dirt. Replace if excessively dirty filter.

Cleaning

When cleaning filter, blow off dust by compressed air from air outlet side of filter. (i.e., the side facing up when installed in air

cleaner case.)

Air Cleaner Assembly Removal and Installation

Removal

1) Disconnect negative (–) cable at battery.

2) Remove boost pressure control solenoid valve (4) from air

cleaner assembly.

3) Disconnect MAF and IAT sensor connector (1).

4

2

3

1

4) Disconnect air cleaner outlet hose (2) from air cleaner

assembly (3).

5) Remove air cleaner assembly from vehicle.

1, (a)

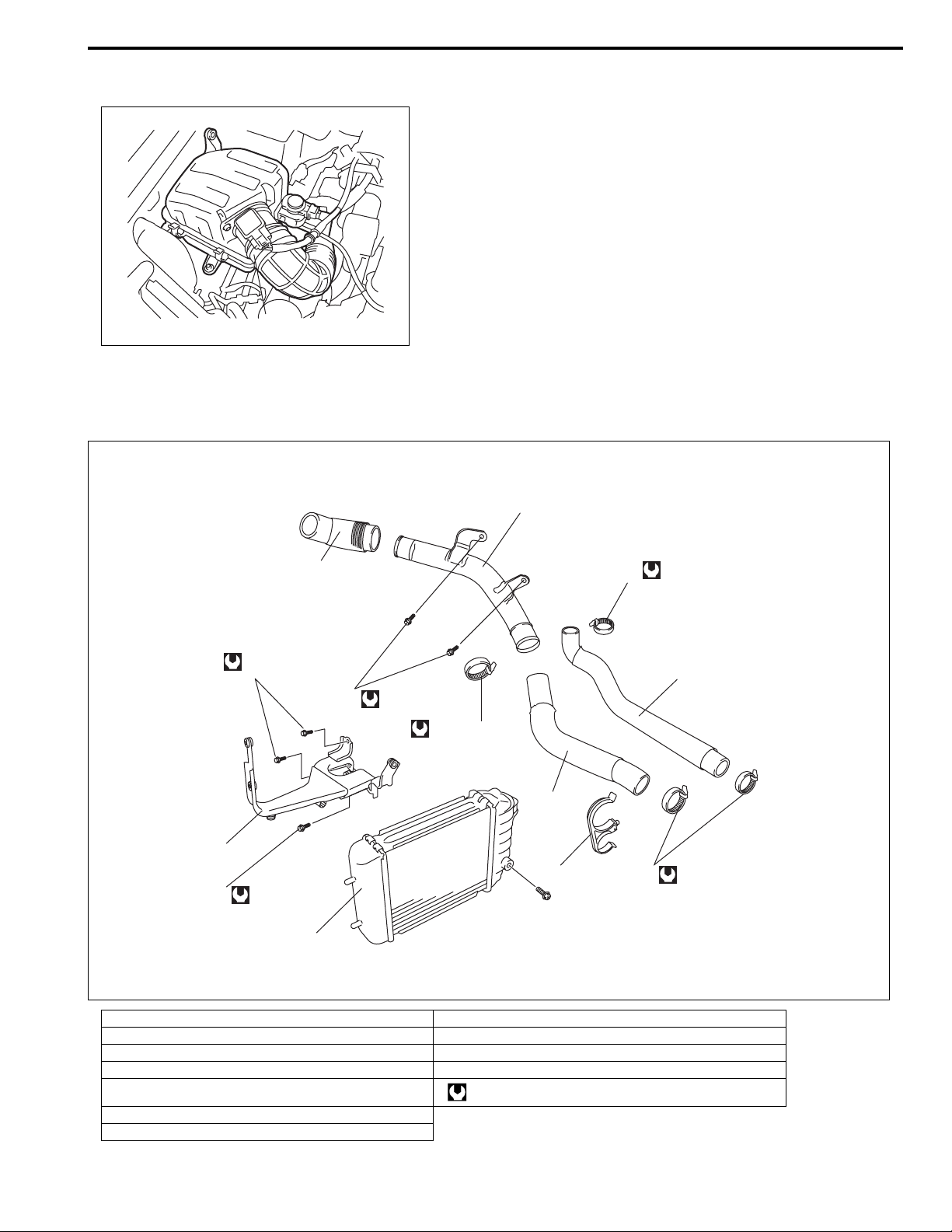

Intercooler Components

ENGINE MECHANICAL (K9K ENGINE) 6A2-9

Installation

Reverse removal procedure for installation noting the following.

• Tighten air cleaner outlet hose clamp (1) to specified torque.

Tightening torque

Air cleaner outlet hose clamp (a):

2.5 N·m (0.25 kg-m, 2.0 lb-ft)

8

25 N·m (2.5 kg-m)

2

25 N·m (2.5 kg-m)

8

6

7

11

28 N·m (2.8 kg-m)

9

4 N·m (0.4 kg-m)

4

3

1

10

9

5 N·m (0.5 kg-m)

5

4 N·m (0.4 kg-m)

1. Intercooler 8. Intercooler bracket bolt

2. Intercooler bracket 9. Intercooler hose clamp No.1

3. Intercooler hose clamp 10. Intercooler hose clamp No.2

4. Intercooler outlet hose No.1 11. Intercooler outlet pipe bolt

5. Intercooler inlet hose Tightening torque

6. Intercooler outlet pipe

7. Intercooler outlet hose No.2

6A2-10 ENGINE MECHANICAL (K9K ENGINE)

3

4

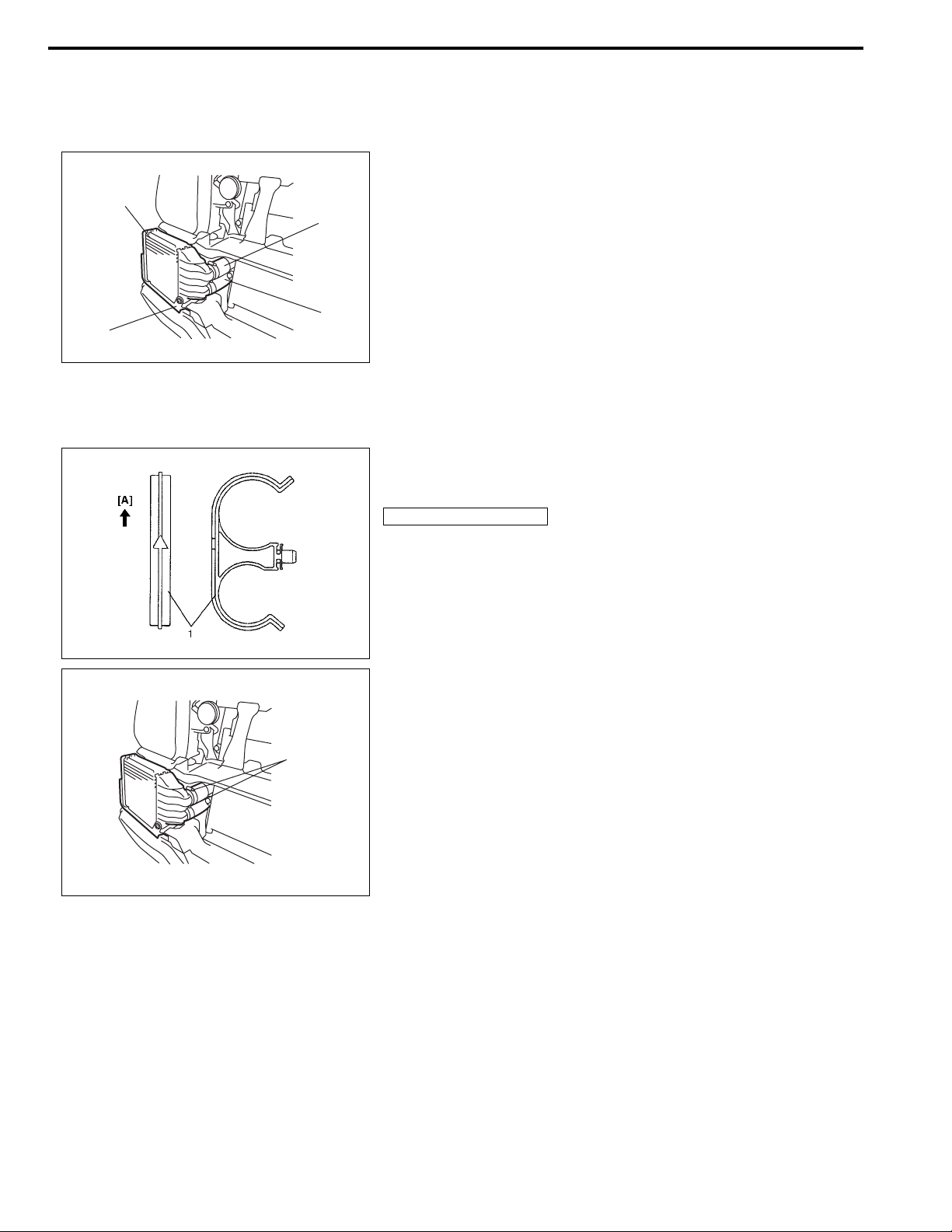

Intercooler Removal and Installation

Removal

1) Remove front bumper.

2) Remove intercooler inlet hose (1) and outlet hose (2) from

intercooler.

2

1

3) Remove intercooler (3) and its bracket (4).

Installation

Reverse removal procedure for installation noting the following.

• Install intercooler hose clamp (1) in specified direction as

shown in figure.

1, (a)

[A]: Upper side

• Tighten intercooler bracket bolts and intercooler hose

clamps (1) to specified torque.

Tightening torque

Intercooler bracket bolt: 25 N·m (2.5 kg-m, 18.0 lb-ft)

Intercooler hose clamp No.1 (a): 4 N·m (0.4 kg-m, 3.0 lb-ft)

• Install front bumper.

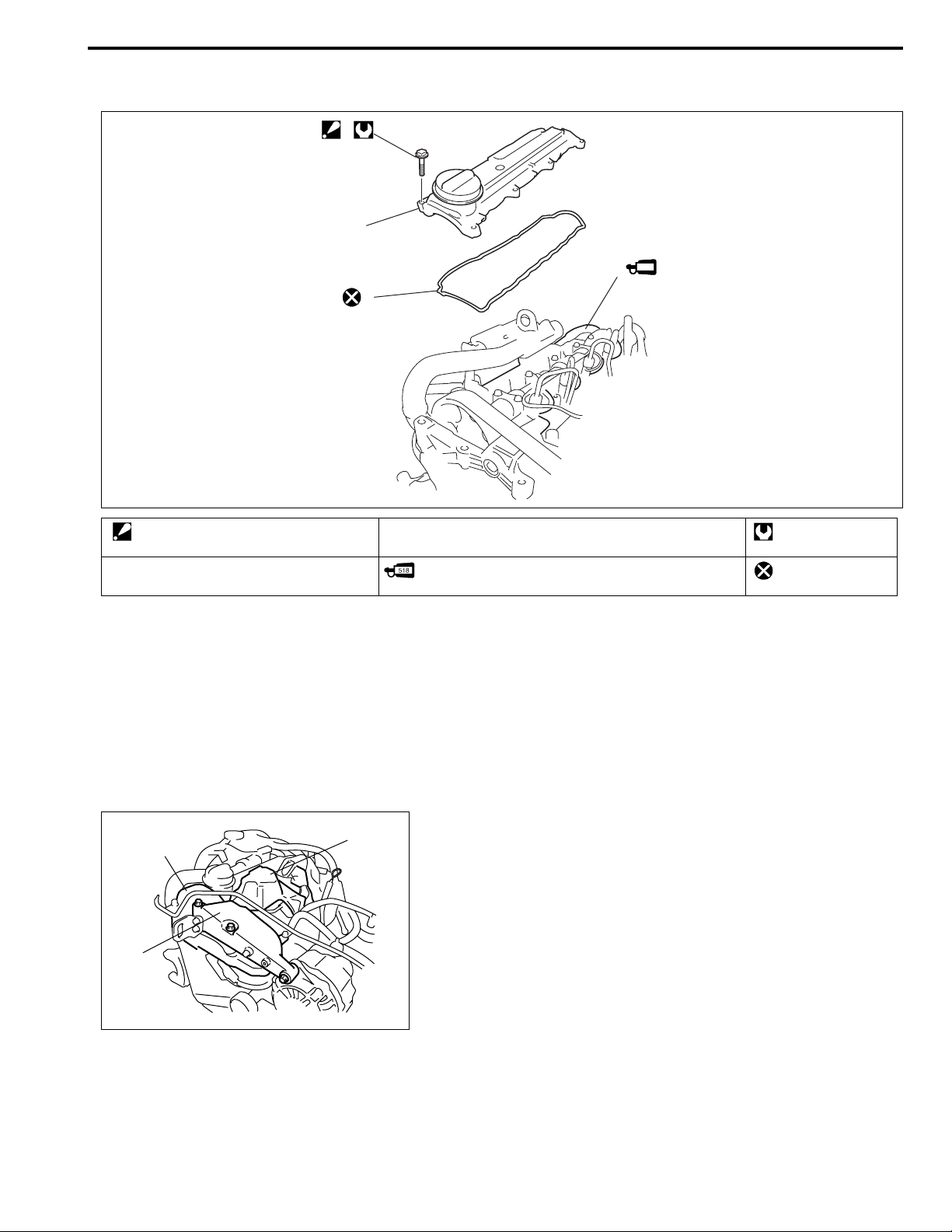

Cylinder Head Cover Components

1

2

3

ENGINE MECHANICAL (K9K ENGINE) 6A2-11

518

4

1. Cylinder head cover bolt

: Tighten 12 N·m (1.2 kg-m, 9.0 lb-ft) by

the specified procedure.

2. Cylinder head cover 4. Cylinder head

3. Cylinder head cover gasket

: Apply Loctite 518® referring to “Installation” under “Cylinder Head Cover Removal and Installation”.

Cylinder Head Cover Removal and Installation

Removal

1) Disconnect negative (–) cable at battery .

2) Remove drive belt referring to “Generator Drive Belt

1

3

2

3) Remove injector cover (1), generator upper bracket (2), tim-

4) Disconnect breather hose from cylinder head cover.

Tightening torque

Do not reuse.

Removal and Installation” in Section 6H2.

ing belt upper cover (3) and injector return hose cover .

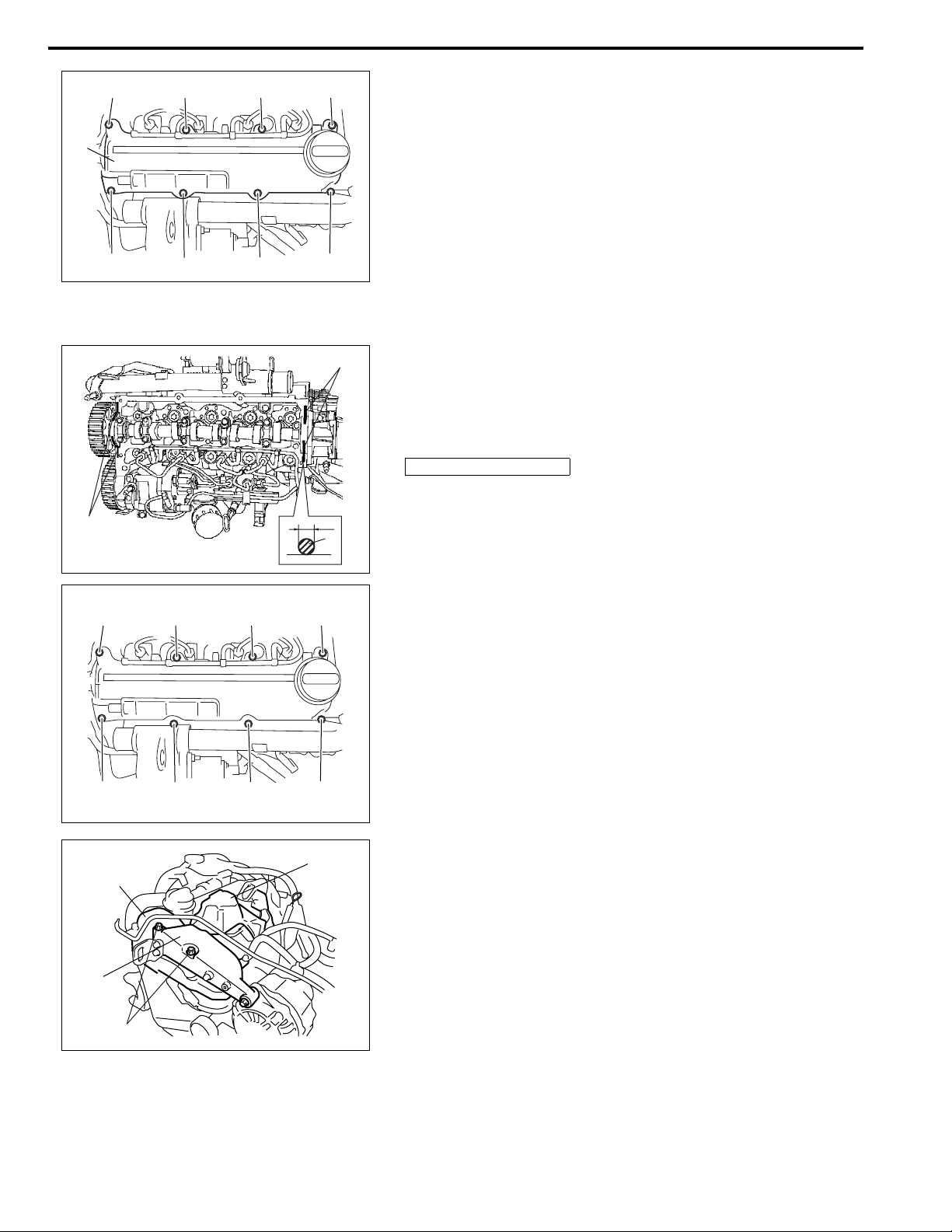

6A2-12 ENGINE MECHANICAL (K9K ENGINE)

“A”

“1”

“5”

“7”

“3”

5) Loosen cylinder head cover bolts in such order (“1” to “8”) as

shown in the figure and remove them.

6) Remove cylinder head cover (1).

1

“2”

“6”

“8”

“4”

Installation

“A”

1) Remove oil, old sealant and dust from sealing surfaces. After

cleaning, apply sealant “A” to cylinder head sealing surface

area as shown in the figure.

“A”: Loctite 518®

“a”: 2 mm (0.08 in.)

“a”

“A”

“8”, (a)

“7”, (a)

1

2

(a)

“4”, (a)

“3”, (a)

“2”, (a)

“1”, (a)

“6”, (a)

“5”, (a)

3

2) Install cylinder head cover to cylinder head as follows.

a) Fit cylinder head cover to cylinder head with new gasket.

b) Tighten cylinder head cover bolts temporarily by hand.

c) Tighten cylinder head cover bolts specified torque by

numerical order as shown in figure.

Tightening torque

Cylinder head cover bolt (a):

Tighten 12 N·m (1.2 kg-m, 9.0 lb-ft) by the specified procedure

3) Connect breather hose to cylinder head cover.

4) Install injector return hose cover, timing belt upper cover (1),

generator upper bracket (2) and injector cover (3).

Tightening torque

Generator upper bracket bolt (a):

40 N·m (4.0 kg-m, 29.0 lb-ft)

5) Install drive belt referring to “Generator Drive Belt Removal

and Installation” in Section 6H2.

6) Connect negative (–) cable at battery.

ENGINE MECHANICAL (K9K ENGINE) 6A2-13

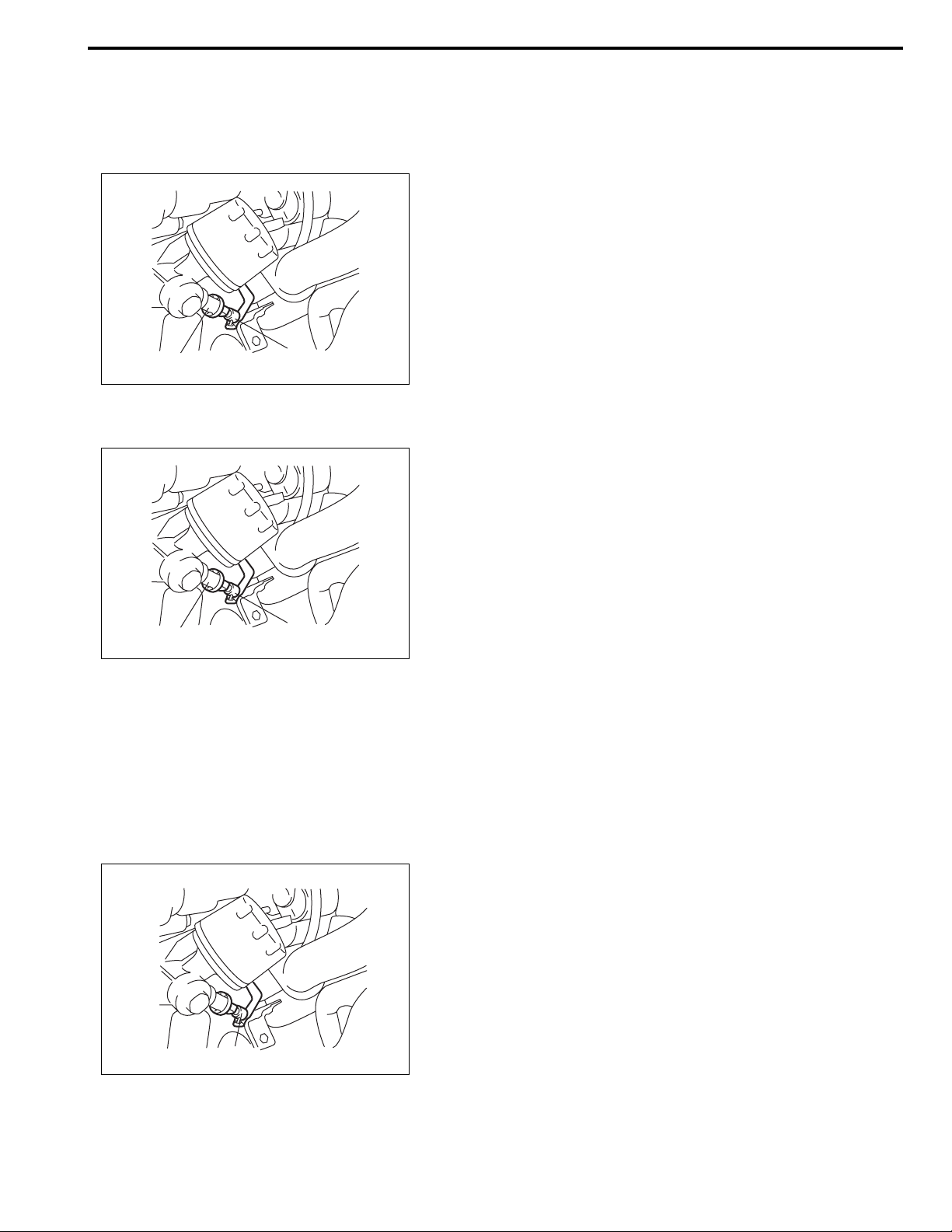

Oil Pressure Switch Removal and Installation

Removal

1) Disconnect negative (–) cable at battery .

2) Detach degassing tank from its bracket.

3) Disconnect oil pressure switch connector (1).

4) Remove oil pressure switch (2).

1, (a)

2

1

Installation

1) Install oil pressure switch (1) with new gasket.

2) Tighten oil pressure switch (1) to specified torque.

Tightening torque

Oil pressure switch (a): 35 N·m (3.5 kg-m, 25.5 lb-ft)

3) Connect oil pressure switch connector (2).

4) Install degassing tank to its bracket.

2

5) Start engine and check for oil leakage.

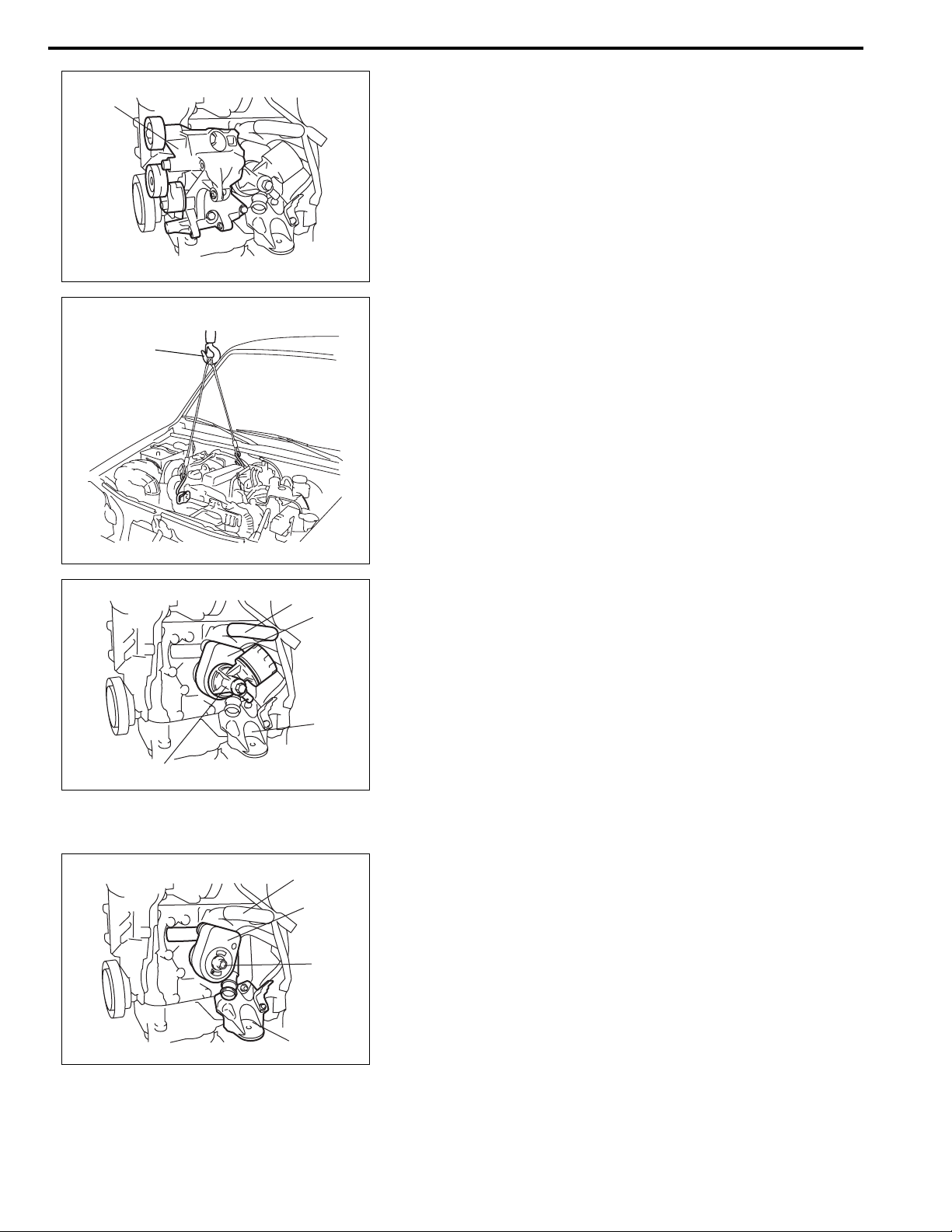

Heat Exchanger Removal and Installation

Removal

1) Disconnect negative (–) cable at battery .

2) Drain engine coolant referring to “Coolant Replacement” in

Section 6B2.

3) Detach degassing tank from its bracket.

4) Disconnect oil pressure switch connector (1).

5) Remove generator referring to “Generator Dismounting and

Remounting” in Section 6H2.

6) Remove compressor referring to “Compressor” in Section

1B.

7) Remov e radiator outlet hose.

1

6A2-14 ENGINE MECHANICAL (K9K ENGINE)

1

1

8) Remove compressor bracket (1).

9) Install lifting device (1).

4

3

10) Remove oil filter unit bracket (1).

11) Disconnect heat exchanger hose (4).

12) Remove engine left mounting bracket (2), and then remove

heat exchanger (3).

2

1

Installation

3

1

1) Install heat exchanger (1) with new gasket.

Tightening torque

Heat exchanger bolt (a): 45 N·m (4.5 kg-m, 32.5 lb-ft)

(a)

2) Install engine left mounting bracket (2) referring to “Main

Bearings, Crankshaft and Cylinder Block Removal and

installation” in this section.

3) Connect heat exchanger hose (3).

2

ENGINE MECHANICAL (K9K ENGINE) 6A2-15

4) Install oil filter unit bracket (1) as shown in figure.

NOTE:

(a)

Be sure to align lug (2) of oil filter unit bracket (1) with

hole (3) of heat exchanger (4).

Tightening torque

Oil filter unit bracket bolt (a): 45 N·m (4.5 kg-m, 32.5 lb-ft)

1

2

1

3

4

5) Install generator and compressor bracket (1) referring to

“Generator Drive Belt Tensioner Components” in section

6H2.

6) Install compressor referring to “Compressor” in Section 1B.

7) Install generator referring to “Generator Dismounting and

Remounting” in Section 6H2.

1

8) Connect oil pressure switch connector (1).

9) Install degassing tank to its bracket.

10) Refill engine coolant referring to “Coolant Replacement” in

section 6B2.

11) Check engine oil level referring to “Engine Oil and Filter” in

Section 0B.

12) Check to make sure that there is no oil leakage and coolant

leakage at each connection.

1

6A2-16 ENGINE MECHANICAL (K9K ENGINE)

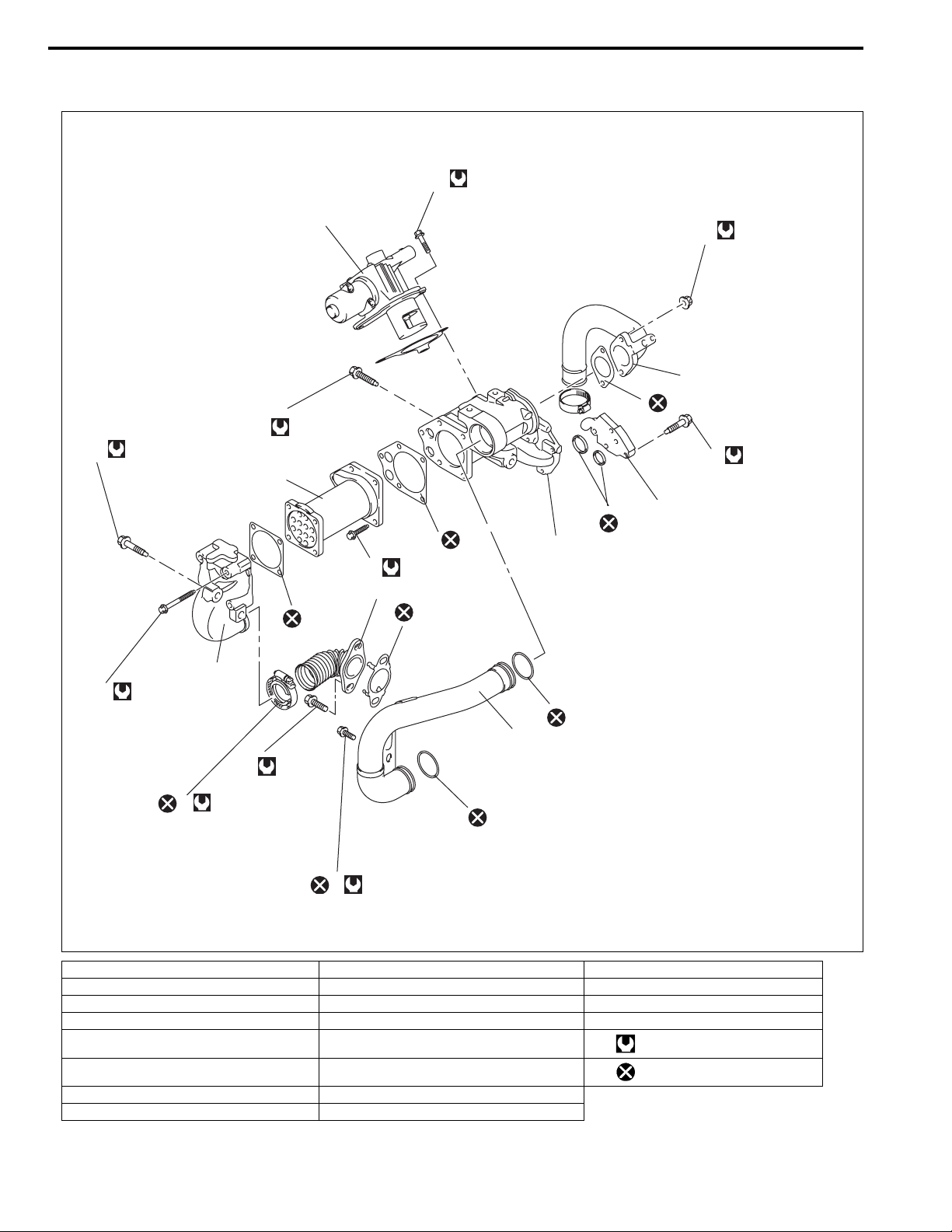

EGR Valve and Intake Pipe Components

14

12 N·m (1.2 kg-m)

16

21 N·m (2.1 kg-m)

17

21 N·m (2.1 kg-m)

3

7

18

10

6

20

10

12

12 N·m (1.2 kg-m)

1

10

10

5

19

15

11 N·m (1.1 kg-m)

12 N·m (1.2 kg-m)

2

12 N·m (1.2 kg-m)

11

4

42 N·m

8

(4.2 kg-m)

5 N·m (0.5 kg-m)

9

20

10N·m (1.0 kg-m)

13

1. EGR pipe 9. EGR pipe clamp 17. EGR valve body bolt

2. EGR cooler pipe 10. Gasket 18. Intake pipe No.1

3. EGR cooler 11. EGR cooler pipe bolt 19. Intake No.1 nut

4. Intake pipe No.2 12. EGR cooler bolt 20. O-ring

5. EGR valve body 13. Intake pipe No.2 bolt Tightening torque

6. EGR cooler water pipe 14. EGR valve bolt

7. EGR valve 15. EGR cooler water pipe bolt

8. EGR pipe bolt 16. EGR cooler pipe bolt

20

Do not reuse.

ENGINE MECHANICAL (K9K ENGINE) 6A2-17

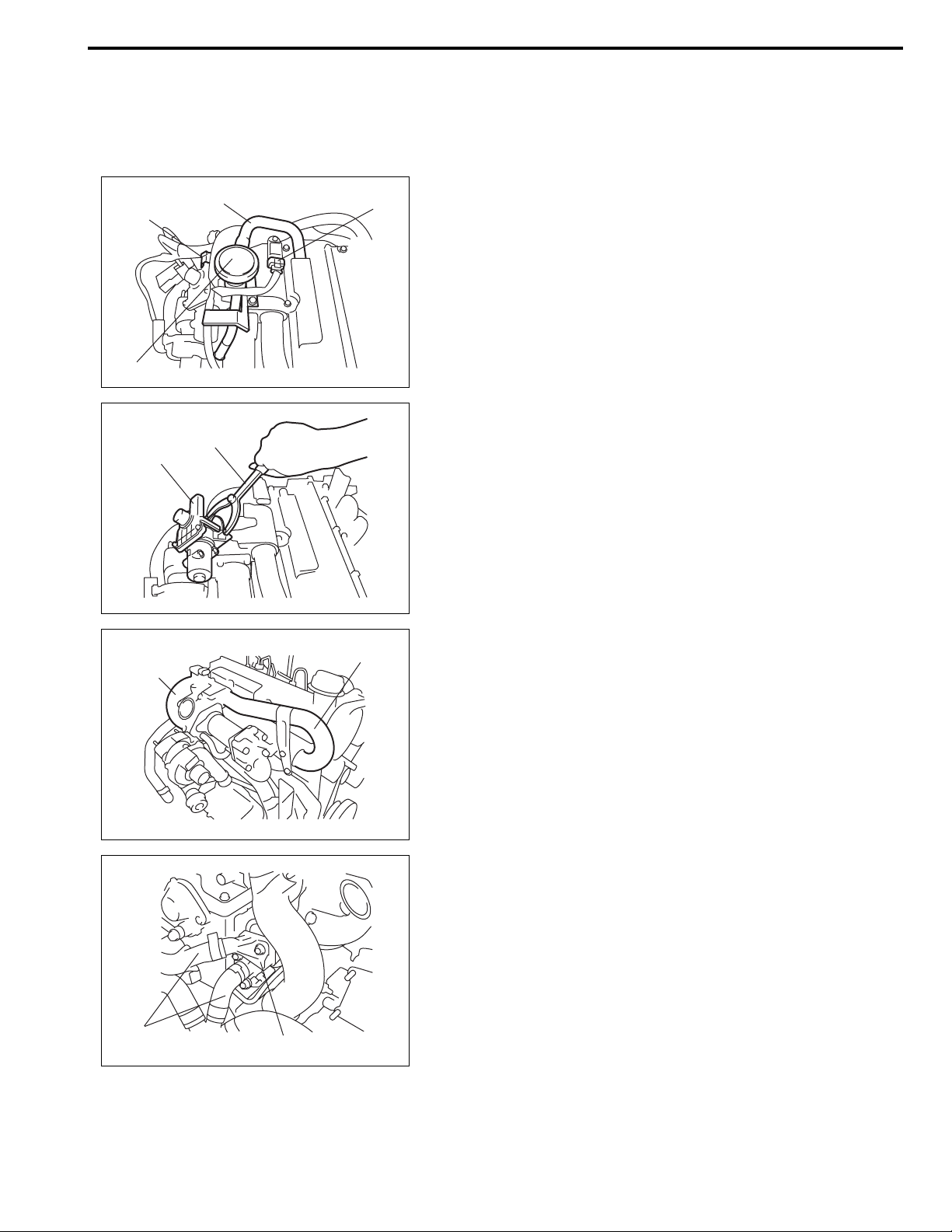

EGR Valve and Intake Pipe Removal and

Installation

Removal

1) Disconnect negative (–) cable at battery .

3

1

2

2) Disconnect EGR valve connector (1) and boost pressure

sensor connector (2).

3) Disconnect hose (3) from oil vapor recirculation valve (4),

and then remove oil vapor recirculation valve.

4

4) Remove EGR valve (1) with gasket using special tool.

(A)

1

Special tool

(A): 09916-48130

2

1

5) Remove intake pipe No.1 (1) and No.2 (2).

6) Disconnect hoses (2) from EGR cooler water pipe (1), and

then remove EGR cooler water pipe.

2

1

6A2-18 ENGINE MECHANICAL (K9K ENGINE)

1

2

1

7) Remove EGR valve body (1) with EGR pipe (2).

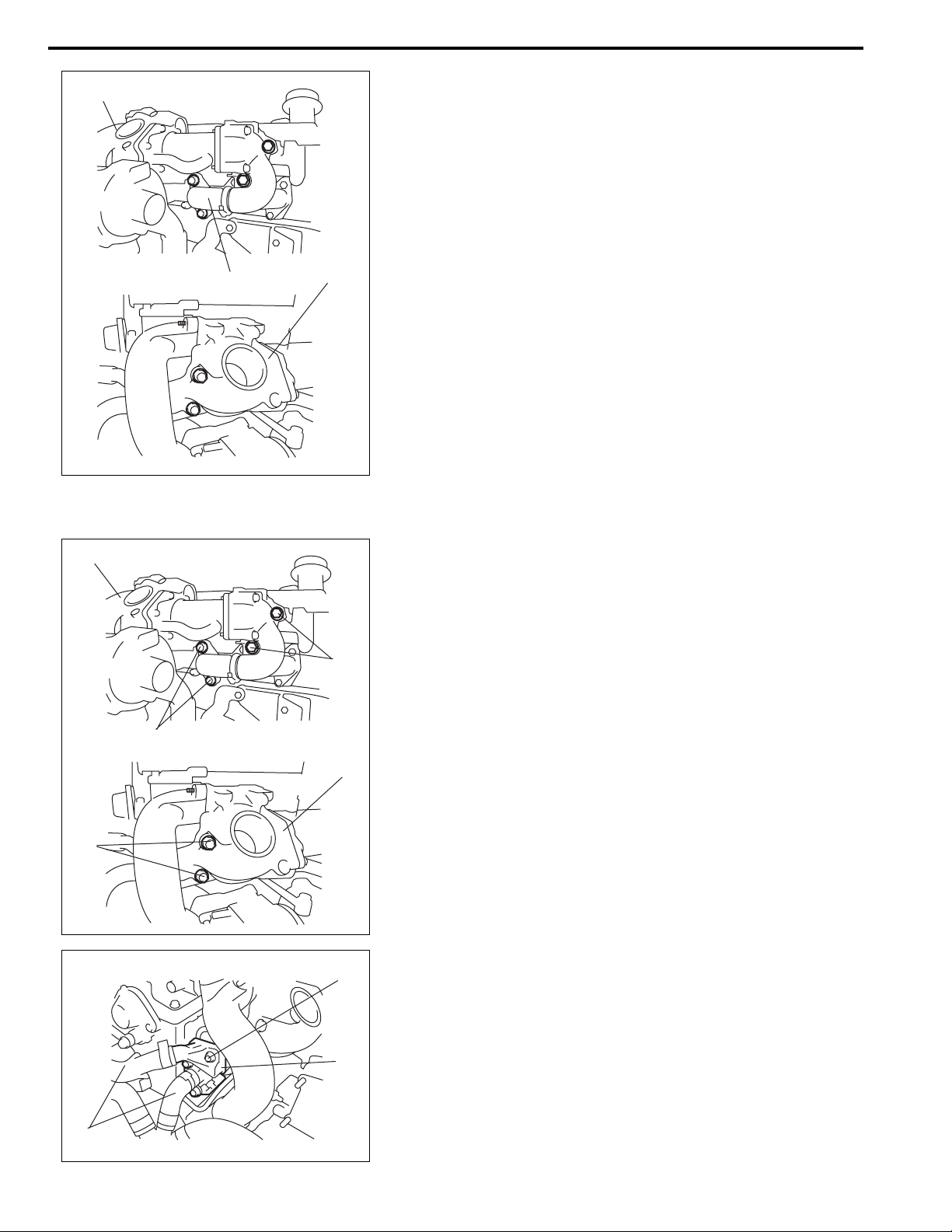

Installation

(c)

1

1) Install EGR valve body assembly (1) with new gasket and

EGR pipe bolt.

Tightening torque

EGR pipe bolt (a): 42 N·m (4.2 kg-m, 30.5 lb-ft)

(b)

EGR cooler pipe bolt (b): 21 N·m (2.1 kg-m, 15.5 lb-ft)

EGR valve body bolt (c): 21 N·m (2.1 kg-m, 15.5 lb-ft)

(a)

1

(a)

2) Install EGR cooler water pipe assembly (1), and then connect hoses (2) to EGR cooler water pipe assembly.

Tightening torque

EGR cooler water pipe assembly bolt (a):

1

2

12 N·m (1.2 kg-m, 9.0 lb-ft)

ENGINE MECHANICAL (K9K ENGINE) 6A2-19

1

2

Tightening torque

Intake pipe No.1 nut: 11 N·m (1.1 kg-m, 8.0 lb-ft)

4) Apply engine oil to new O-ring, and install intake pipe No.2

(2) with new O-ring.

3) Install intake pip e No.1 with new gasket.

(a)

Tightening torque

Intake pipe No.2 bolt (a): 10 N·m (1.0 kg-m, 7.5 lb-ft)

3

2

5) Install EGR valve (1) with new gasket.

Tightening torque

4

EGR valve bolt (a): 12 N·m (1.2 kg-m, 9.0 lb-ft)

6) Install oil vapor recirculation valve (5), and then connect

5

hose (2) to oil vapor recirculation valve.

7) Connect EGR valve connector (3) and boost pressure sensor connector (4).

1

(a)

8) Connect negative (–) cable at battery.

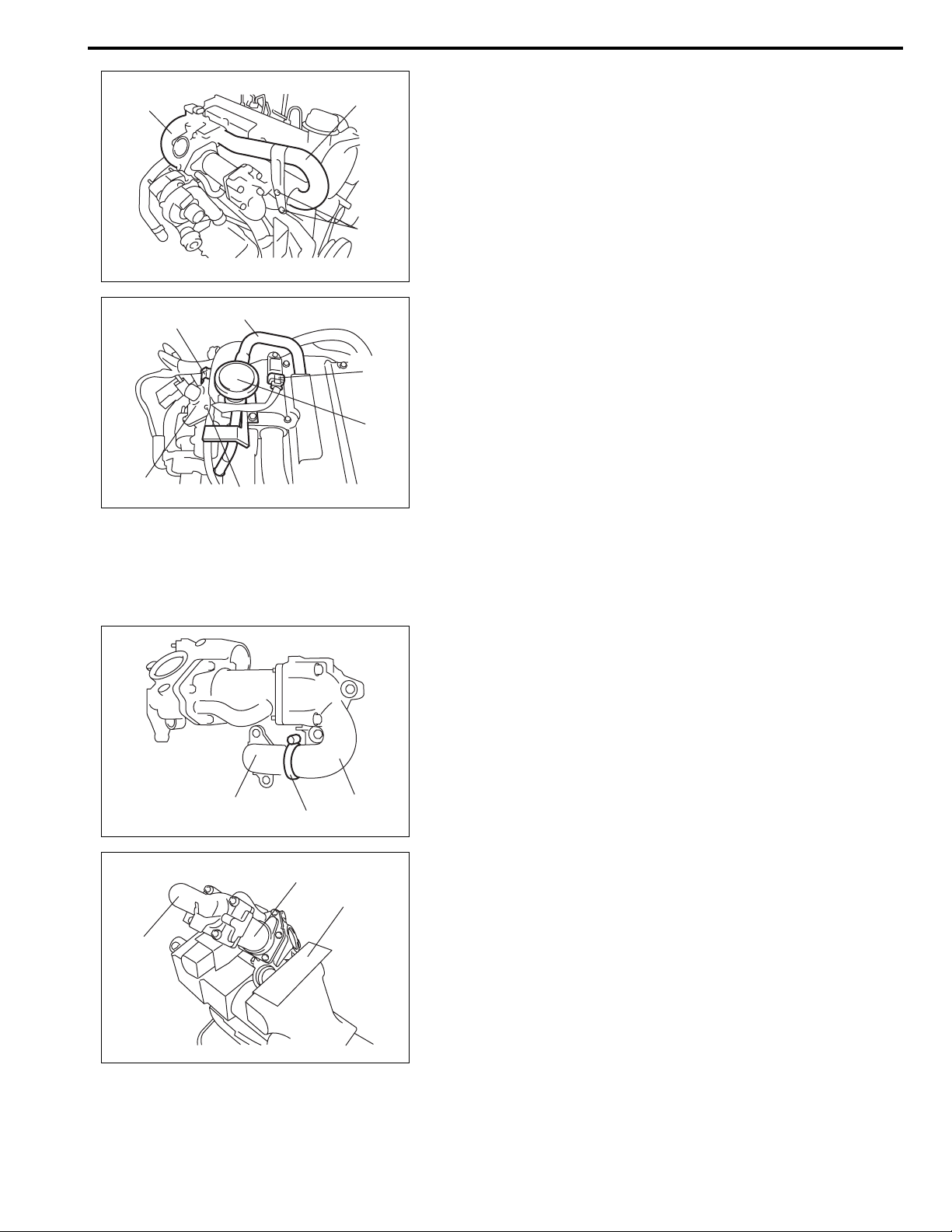

EGR Valve Disassembly and Reassembly

Disassembly

1) Remove clamp (1) and EGR pipe (2) from exhaust gas

cooler pipe (3).

2

1

3

2

3

2) Hold EGR valve body with soft jawed vise (1), and remove

1

exhaust gas cooler (2) with gasket.

3) Remove EGR cooler (3) with gasket.

6A2-20 ENGINE MECHANICAL (K9K ENGINE)

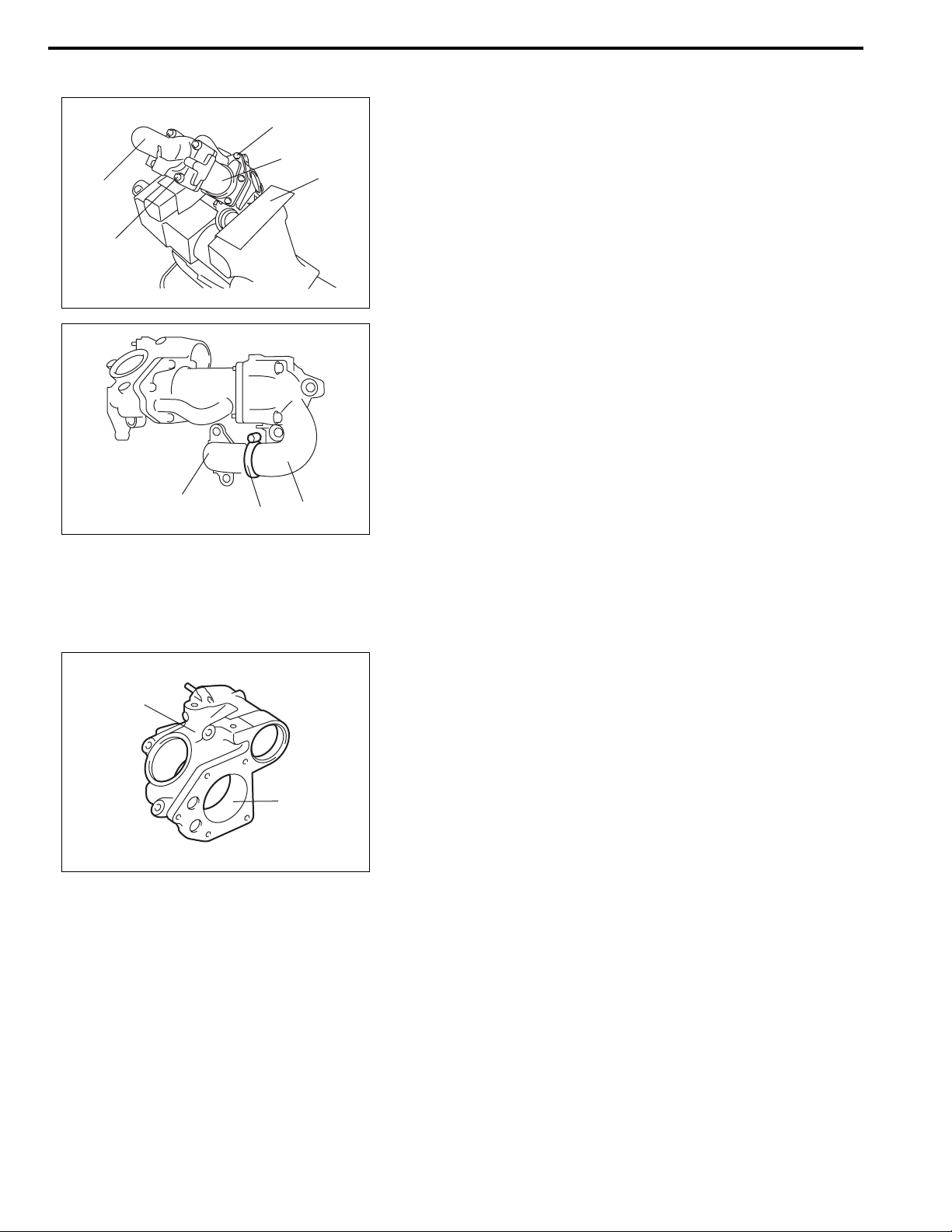

Reassembly

(a)

3

2

1

1) Hold EGR valve body with soft jawed vise (1), and install

EGR cooler (3) with new gasket.

2) Install EGR cooler pipe (2) with new gasket.

Tightening torque

EGR cooler bolt (a): 12 N·m (1.2 kg-m, 9.0 lb-ft)

EGR cooler pipe bolt (b): 12 N·m (1.2 kg-m, 9.0 lb-ft)

(b)

3) Install EGR pipe (1) to EGR cooler pipe (2), and then install

EGR pipe clamp (3).

Tightening torque

EGR pipe clamp (a): 5 N·m (0.5 kg-m, 4.0 lb-ft)

1

3, (a)

2

EGR Valve and Intake Pipe Inspection

EGR valve body

Check inside (1) of EGR valve body (2) for wear or damaged.

2

1

EGR valve

Refer to “EGR Valve Inspection” in Section 6E2.

Loading...

Loading...