Page 1

AS1020S-8

USER’S MANUAL

1.0

Page 2

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates.

The manufacturer reserves the right to make changes to the product described in this manual at

any time and without notice. This product, including software, if any, and documentation may not,

in whole or in part, be copied, photocopied, reproduced, translated or reduced to any medium or

machine without prior written consent.

IN NO EVENT WILL THE MANUFACTURER BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, THE VENDOR SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING

THE COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING

SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. The manufacturer's total liability for

all claims will not exceed the price paid for the hardware product.

Manual Revision 1.0

Release Date: December 28, 2005

Unless you request and receive written permission from the manufacturer, you may not copy any

part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2005

All rights reserved.

Printed in the United States of America

Page 3

Preface

About This Manual

This manual is written for professional system integrators and PC technicians. It

provides information for the installation and use of the AS1020S-8 server. Installa-

tion and maintenance should be performed by experienced technicians only.

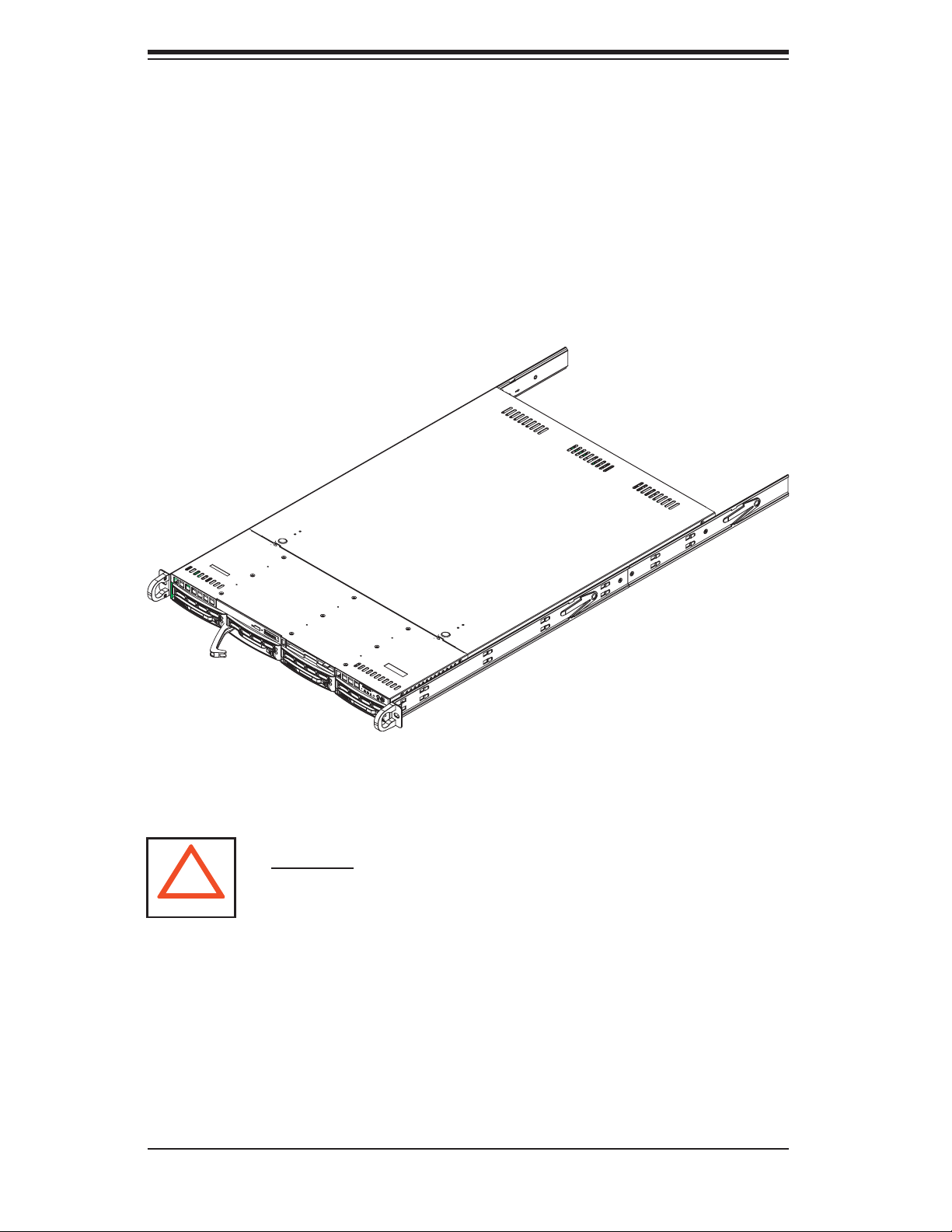

The AS1020S-8 is a high-end server based on the SC813S+-500 1U chassis and

the H8DSR-8, a dual processor serverboard that supports AMD Opteron processors

and up to 16/32 GB of registered ECC DDR400/333 SDRAM.

Preface

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a checklist of the main components included with the

server system and describes the main features of the H8DSR-8 serverboard and

the SC813S+-500 chassis, which comprise the 1020S-8.

Chapter 2: Server Installation

This chapter describes the steps necessary to install the 1020S-8 into a rack and

check out the server confi guration prior to powering up the system. If your server

was ordered without processor and memory components, this chapter will refer you

to the appropriate sections of the manual for their installation.

Chapter 3: System Interface

Refer here for details on the system interface, which includes the functions and

information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

iii

Page 4

AS1020S-8 User's Manual

Chapter 4: System Safety

You should thoroughly familiarize yourself with this chapter for a general overview

of safety precautions that should be followed when installing and servicing the

1020S-8.

Chapter 5: Advanced Serverboard Setup

Chapter 5 provides detailed information on the H8DS8-R serverboard, including the

locations and functions of connections, headers and jumpers. Refer to this chapter

when adding or removing processors or main memory and when reconfi guring the

serverboard.

Chapter 6: Advanced Chassis Setup

Refer to Chapter 6 for detailed information on the SC813S+-500 server chassis.

You should follow the procedures given in this chapter when installing, removing or

reconfi guring SCSI or peripheral drives and when replacing system power supply

units and cooling fans.

Chapter 7: BIOS

The BIOS chapter includes an introduction to BIOS and provides detailed informa-

tion on running the CMOS Setup Utility.

Appendix A: BIOS POST Codes

Appendix B: Software Installation

Appendix C: System Specifi cations

iv

Page 5

Notes

Preface

v

Page 6

AS1020S-8 User's Manual

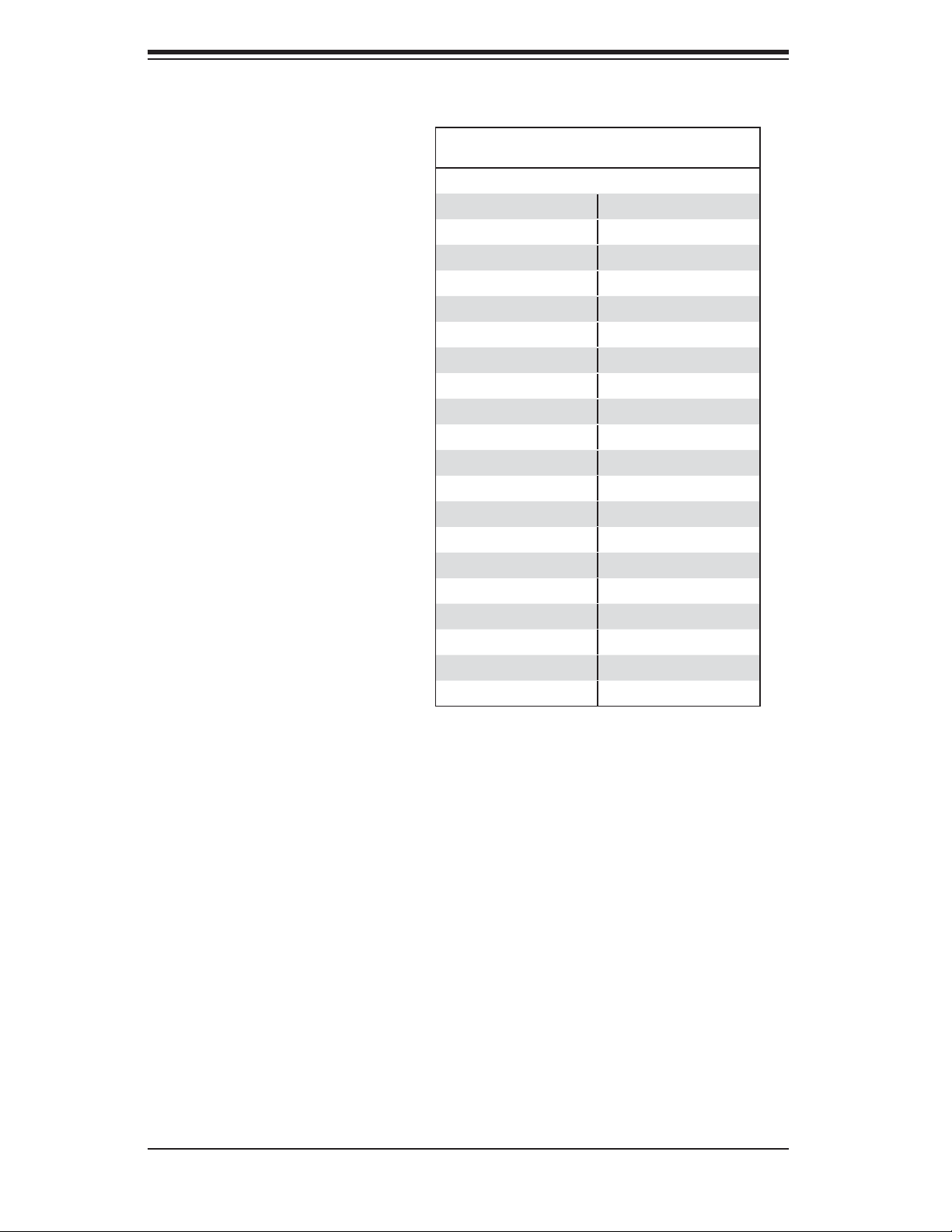

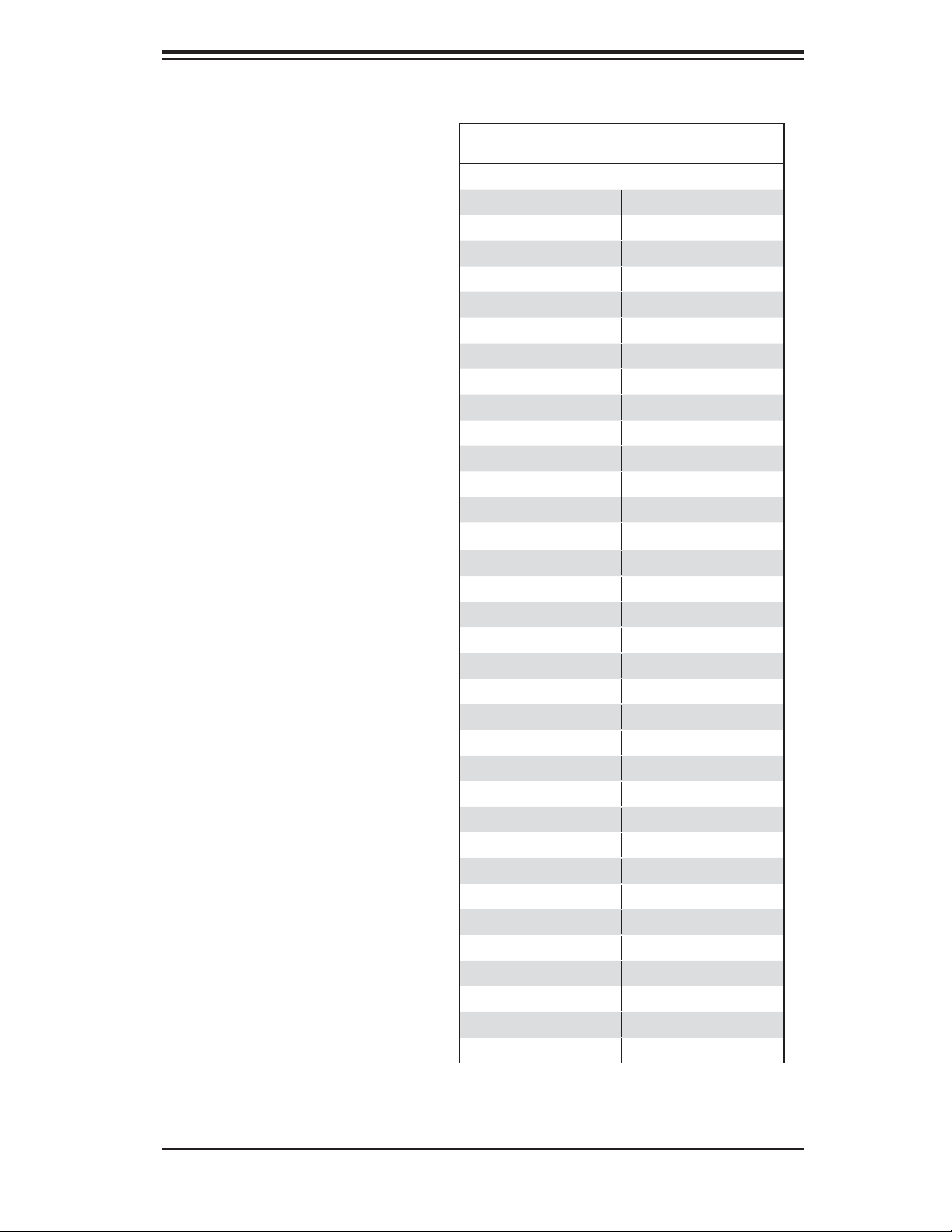

Table of Contents

Preface

About This Manual ...................................................................................................... iii

Manual Organization ................................................................................................... iii

Chapter 1: Introduction

1-1 Overview ......................................................................................................... 1-1

1-2 Serverboard Features ..................................................................................... 1-2

1-3 Server Chassis Features ................................................................................ 1-3

Chapter 2: Server Installation

2-1 Overview .......................................................................................................... 2-1

2-2 Unpacking the System ................................................................................... 2-1

2-3 Preparing for Setup ........................................................................................ 2-1

Choosing a Setup Location ...................................................................... 2-2

Rack Precautions ..................................................................................... 2-2

Server Precautions ................................................................................... 2-2

Rack Mounting Considerations ................................................................ 2-3

2-4 Installing the System into a Rack ................................................................... 2-4

2-5 Checking the Serverboard Setup ................................................................... 2-8

2-6 Checking the Drive Bay Setup ....................................................................... 2-9

Chapter 3: System Interface

3-1 Overview ......................................................................................................... 3-1

3-2 Control Panel Buttons .................................................................................... 3-1

Reset ........................................................................................................ 3-1

Power ....................................................................................................... 3-1

3-3 Control Panel LEDs ........................................................................................ 3-2

Overheat/Fan Fail .................................................................................... 3-2

NIC2 ......................................................................................................... 3-2

NIC1 ......................................................................................................... 3-3

HDD .......................................................................................................... 3-3

Power ....................................................................................................... 3-3

3-4 SCSI Drive Carrier LEDs ................................................................................ 3-3

Chapter 4: System Safety

4-1 Electrical Safety Precautions .......................................................................... 4-1

4-2 General Safety Precautions ........................................................................... 4-2

vi

Page 7

Table of Contents

4-3 ESD Precautions ............................................................................................ 4-3

4-4 Operating Precautions .................................................................................... 4-4

Chapter 5: Advanced Serverboard Setup

5-1 Handling the Serverboard .............................................................................. 5-1

5-2 Mounting the Serverboard into a Chassis ...................................................... 5-2

5-3 Processor and Heatsink Installation ............................................................... 5-2

5-4 Connecting Cables ......................................................................................... 5-5

Connecting Data Cables .......................................................................... 5-5

Connecting Power Cables ....................................................................... 5-5

Connecting the Control Panel .................................................................. 5-6

5-5 I/O Ports ......................................................................................................... 5-6

5-6 Installing Memory ........................................................................................... 5-7

5-7 Adding PCI Cards ........................................................................................... 5-9

5-8 Serverboard Details ...................................................................................... 5-10

H8DSR-8 Serverboard Layout ............................................................... 5-10

H8DSR-8 Quick Reference .................................................................... 5-11

5-9 Connector Defi nitions ................................................................................... 5-12

Primary ATX Power Connector .............................................................. 5-12

Processor Power Connector .................................................................. 5-12

Secondary Power Connector ................................................................. 5-12

NMI Button ............................................................................................. 5-12

Power LED ............................................................................................. 5-13

HDD LED ............................................................................................... 5-13

NIC1 LED ............................................................................................... 5-13

NIC2 LED ............................................................................................... 5-13

Overheat/Fan Fail LED .......................................................................... 5-13

Power Fail LED ...................................................................................... 5-14

Reset Button .......................................................................................... 5-14

Power Button .......................................................................................... 5-14

Universal Serial Bus (USB0/1) ............................................................... 5-14

USB2/3 Headers .................................................................................... 5-15

Serial Ports ............................................................................................. 5-15

Fan Headers .......................................................................................... 5-15

ATX PS/2 Keyboard and Mouse Ports .................................................. 5-15

Power LED/Speaker ............................................................................... 5-16

JLAN1/2 (Ethernet Ports) ....................................................................... 5-16

IPMB Header .......................................................................................... 5-16

SMB Power ............................................................................................ 5-16

vii

Page 8

AS1020S-8 User's Manual

Overheat LED ........................................................................................ 5-17

Wake-On-Ring ........................................................................................ 5-17

Wake-On-LAN ........................................................................................ 5-17

Chassis Intrusion .................................................................................... 5-17

JSLED .................................................................................................... 5-17

5-10 Jumper Settings ............................................................................................ 5-18

Explanation of Jumpers ......................................................................... 5-18

CMOS Clear ........................................................................................... 5-18

PCI-X Slot Frequency Select ................................................................. 5-19

Onboard Speaker Enable/Disable ......................................................... 5-19

Watch Dog ............................................................................................. 5-19

SCSI Controller Enable/Disable ............................................................. 5-20

SCSI Termination Enable/Disable .......................................................... 5-20

VGA Enable/Disable ............................................................................... 5-20

Power Force On ..................................................................................... 5-20

2

I

C to PCI Enable/Disable ...................................................................... 5-21

5-11 Onboard Indicators ....................................................................................... 5-21

JLAN1/JLAN2 LEDs ............................................................................... 5-21

+3.3V Power LED .................................................................................. 5-21

SCSI Activity LEDs ................................................................................. 5-22

POST Code LEDs .................................................................................. 5-22

5-12 Floppy, IDE and SCSI Drive Connections .................................................... 5-23

Floppy Connector ................................................................................... 5-23

IDE Connector ........................................................................................ 5-24

SCSI Connectors ................................................................................... 5-25

Chapter 6: Advanced Chassis Setup

6-1 Static-Sensitive Devices ................................................................................. 6-1

6-2 Control Panel .................................................................................................. 6-2

6-3 System Fans ................................................................................................... 6-3

Accessing the Drive Bays ........................................................................ 6-4

System Fan Failure .................................................................................. 6-5

Replacing System Fans ........................................................................... 6-3

6-4 Drive Bay Installation/Removal ...................................................................... 6-4

SCSI Drive Installation ............................................................................. 6-5

CD-ROM and Floppy Drive Installation .................................................... 6-7

6-5 Power Supply ................................................................................................. 6-8

Power Supply Failure ............................................................................... 6-8

Removing/Replacing the Power Supply ................................................... 6-8

viii

Page 9

Table of Contents

Chapter 7: BIOS

7-1 Introduction ..................................................................................................... 7-1

7-2 Main Menu ...................................................................................................... 7-2

7-3 Advanced Settings Menu ............................................................................... 7-2

7-4 Boot Menu .................................................................................................... 7-14

7-5 Security Menu ............................................................................................... 7-16

7-6 Exit Menu ...................................................................................................... 7-16

Appendices:

Appendix A: BIOS Error Beep Codes ...................................................................... A-1

Appendix B: BIOS POST Checkpoint Codes .......................................................... B-1

Appendix C: System Specifi cations ........................................................................ C-1

ix

Page 10

AS1020S-8 User's Manual

Notes

x

Page 11

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

The AS1020S-8 is a high-end dual processor server that is comprised of two main

subsystems: the SC813S+-500 1U server chassis and the H8DSR-8 dual AMD

processor serverboard. Please refer to our web site for information on operating

systems that have been certifi ed for use with the 1020S-8.

In addition to the serverboard and chassis, various hardware components have

been included with the 1020S-8:

One (1) slim fl oppy drive [FPD-TEAC-S(B)]

One (1) slim CD-ROM drive [CDM-TEAC-24(B)]

Four (4) 4-cm counter-rotating chassis fans (FAN-0083)

Two (2) heatsink retention modules with 4 screws (BKT-0005)

Two (2) CPU backplates, pre-installed (BKT-0004)

One (1) 1U chassis air shroud (CSE-PT70)

One (1) rackmount kit (CSE-PT51)

SCSI Accessories

One (1) SCSI backplane [CSE-SCA-813S]

One (1) SCSI cable (CBL-0063)

Four (4) SCA SCSI drive carriers [CSE-PT39(B)]

Two (2) passive heatsinks for 1U systems (optional, SNK-P0012)

Two (1) CD containing drivers and utilities

Note: (B) indicates the item is available in black.

1-1

Page 12

AS1020S-8 User's Manual

1-2 Serverboard Features

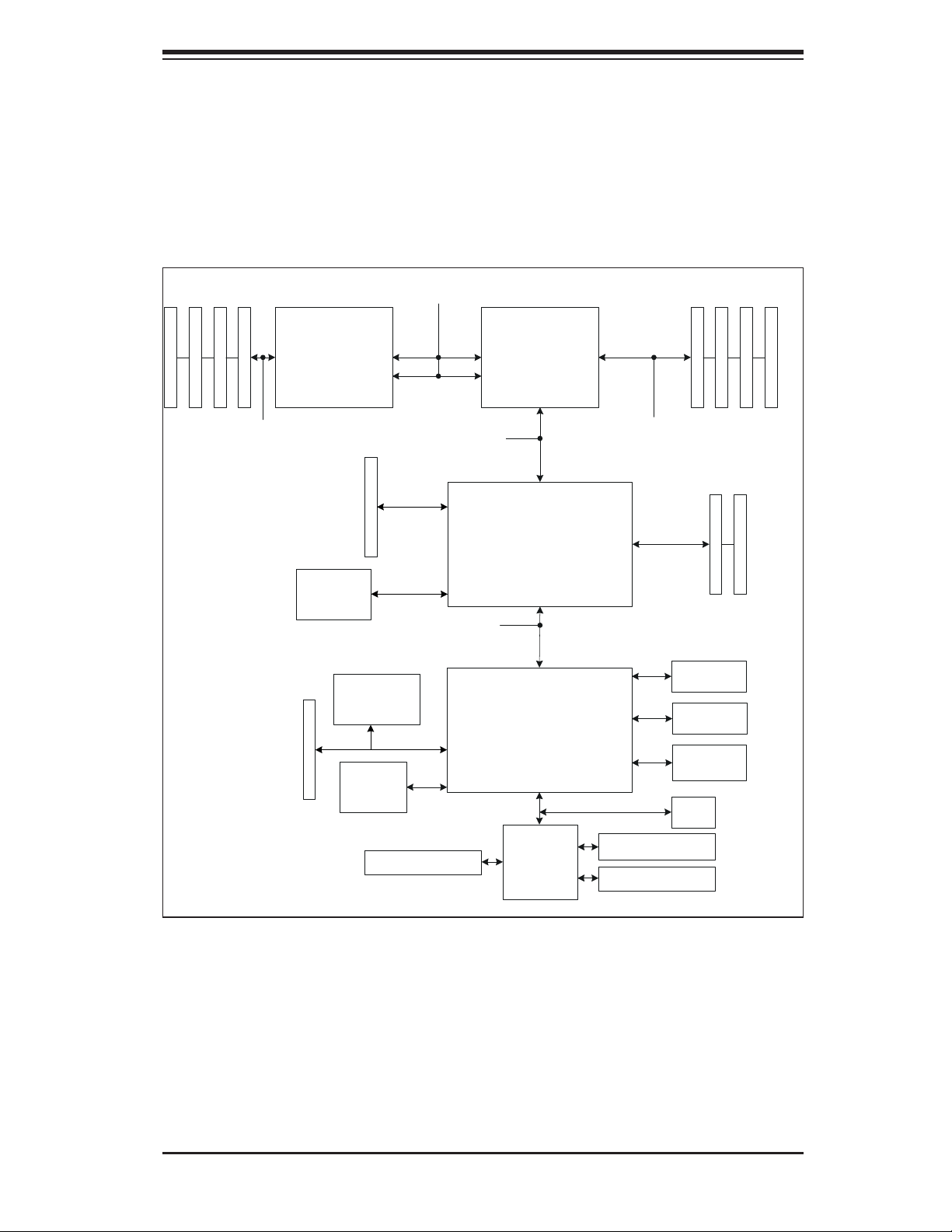

At the heart of the 1020S-8 lies the H8DSR-8, a dual processor serverboard based

on the Serverworks HT-2000/1000 chipset. Below are the main features of the

H8DSR-8. (See Figure 1-1 for a block diagram of the HT-2000/1000 chipset).

Processors

The H8DSR-8 supports single or dual 940-pin AMD Opteron 200 Series processors.

Please refer to the serverboard description pages on our web site for a complete

listing of supported processors (www.supermicro.com/aplus/).

Memory

The H8DSR-8 has eight 184-pin DIMM slots that can support up to 16 GB of regis-

tered ECC DDR400 SDRAM or up to 32 GB of registered ECC DDR333 SDRAM.

The memory is an interleaved confi guration, which requires modules of the same

size and speed to be installed in pairs.

Onboard SCSI

Onboard SCSI is provided with an Adaptec AIC-7902W SCSI chip, which supports

dual channel, Ultra320 SCSI at a throughput of 320 MB/sec for each channel. The

H8DSR-8 provides two LVD Ultra320 SCSI ports.

Onboard Controllers/Ports

One fl oppy drive controller and one ATA/100 controller are provided to support up

to three hard drives or ATAPI devices. The color-coded I/O ports include one COM

port (an additional COM header is located on the serverboard), a VGA (monitor) port,

two USB 2.0 ports, PS/2 mouse and keyboard ports and two G-bit Ethernet ports.

ATI Graphics Controller

The H8DS8 features an integrated ATI video controller based on the Rage XL

graphics chip.

Other Features

Other onboard features that promote system health include onboard voltage moni-

tors, a chassis intrusion header, auto-switching voltage regulators, chassis and CPU

overheat sensors, virus protection and BIOS rescue.

1-2

Page 13

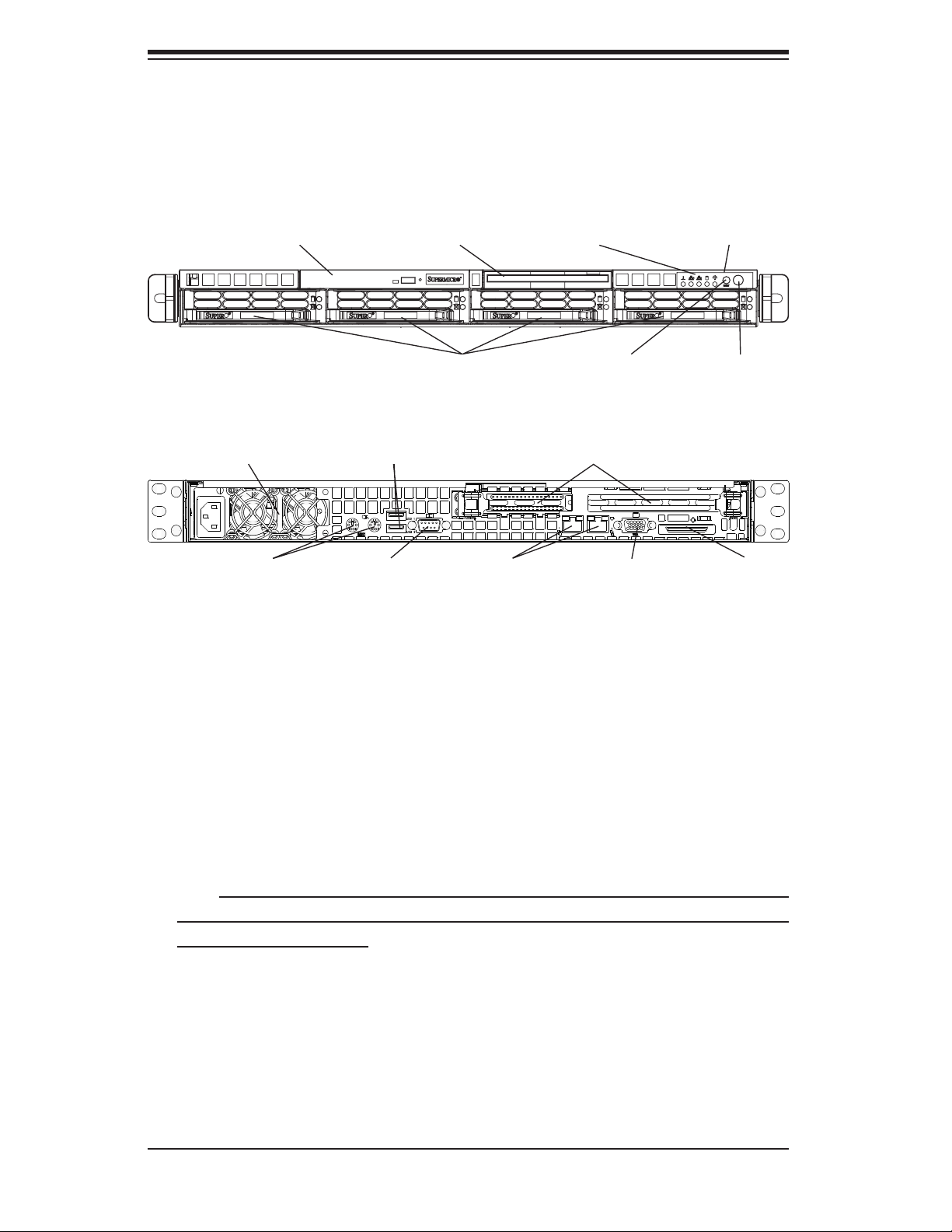

Chapter 1: Introduction

1-3 Server Chassis Features

The 1020S-8 is a high-end, scaleable server platform. The following is a general

outline of the main features of the SC813S+-500 server chassis.

System Power

The SC813S+-500 features a single redundant 500W power supply. If it fails, the

system will shut down and you will need to replace the power supply unit.

SCSI Subsystem

The SCSI subsystem supports up to six 80-pin SCA Ultra320 SCSI hard drives,

which are hot-swappable. Any standard 3.5" drives are supported. SCA = Single

Connection Attachment.) The SCSI drives are connected to a duale channel SCA

backplane with SAF-TE. A RAID controller card can be used with the SCA back-

plane to provide data security.

Note: The operating system you use must have RAID support to enable the hot-

swap capability of the SCSI drives.

PCI Expansion Slots

The SC813S+-500 chassis supports the use of one low profi le expansion card

(PCI-X 133 MHz or PCI-Express x8) and one full-height, half-length expansion card

(PCI-X 100 MHz or PCI-Express x8). (PCI-X riser cards have been preinstalled,

PCI-E riser cards are sold separately.)

Front Control Panel

The control panel provides you with system monitoring and control. LEDs indicate

system power, HDD activity, network activity and overheat/fan fail. A main power

button and a system reset button are also included.

I/O Backplane

The I/O backplane on the SC813S+-500 provides two PCI expansion slots, one

COM port, a VGA port, two USB 2.0 ports, PS/2 mouse and keyboard ports and

two gigabit Ethernet ports.

1-3

Page 14

AS1020S-8 User's Manual

Cooling System

The SC813S+-500 chassis has an innovative cooling design that includes four 4-

cm counter-rotating fans located in the middle section of the chassis. The power

supply module also includes a cooling fan. All chassis and power supply fans

operate continuously.

A setting in BIOS (see Chapter 7) is used to control the system fan speed. This

setting uses voltage control to allow fans to run at different speeds. [The recom-

mended setting for the 1020S-8 is "3-pin (Server)".]

1-4

Page 15

Chapter 1: Introduction

Figure 1-1. Serverworks HT-2000/1000 Chipset:

System Block Diagram

Note: This is a general block diagram. Please see Chapter 5 for details.

144 -bit, 266 - 400 M T/s

133 MHz PCI-X Slot

100 MH z PC I- X/ PC I Slot

(ZCR)

AMD

Opter on

TM

Processor (2)

2x Gigabit

Ethernet

Adaptec

AIC-7902 W

SATA

Drives (4)

16 x 16 @ 1 GB (x2)

16 x 16 @ 1 GB

8 x 8 @ 800 MB

AMD

Opter on

Processor (1)

ServerWorks

HT-2000

ServerWorks

HT-1000

LPC Link

184-pin DI MM s184-pin DI MM s

TM

144 -bit , 266 - 400 MT/s

x8 PC I- Ex press Slots

ATA100

USB 2.0

ATI Rage

XL 8 MB

BIOS

Serial Ports

1-5

ADI

ADM1026

Super I/O

Floppy Dis k D rive

PS/2 Kybd/M ouse

Page 16

AS1020S-8 User's Manual

Notes

1-6

Page 17

Chapter 2: Server Installation

Chapter 2

Server Installation

2-1 Overview

This chapter provides a quick setup checklist to get your 1020S-8 up and running.

Following these steps in the order given should enable you to have the system

operational within a minimum amount of time. This quick setup assumes that your

1020S-8 system has come to you with the processors and memory preinstalled. If

your system is not already fully integrated with a serverboard, processors, system

memory etc., please turn to the chapter or section noted in each step for details

on installing specifi c components.

2-2 Unpacking the System

You should inspect the box the system was shipped in and note if it was damaged

in any way. If the server itself shows damage you should fi le a damage claim with

the carrier who delivered it.

Decide on a suitable location for the rack unit that will hold the 1020S-8. It should

be situated in a clean, dust-free area that is well ventilated. Avoid areas where

heat, electrical noise and electromagnetic fi elds are generated. You will also need

it placed near a grounded power outlet. Read the Rack and Server Precautions in

the next section.

2-3 Preparing for Setup

The box the 1020S-8 was shipped in should include two sets of rail assemblies, two

rail mounting brackets and the mounting screws you will need to install the system

into the rack. Follow the steps in the order given to complete the installation process

in a minimum amount of time. Please read this section in its entirety before you

begin the installation procedure outlined in the sections that follow.

2-1

Page 18

AS1020S-8 User's Manual

Choosing a Setup Location

- Leave enough clearance in front of the rack to enable you to open the front door

completely (~25 inches).

- Leave approximately 30 inches of clearance in the back of the rack to allow for

suffi cient airfl ow and ease in servicing.

- This product is for installation only in a Restricted Access Location (dedicated

equipment rooms, service closets, etc.).

!

Warnings and Precautions!

!

Rack Precautions

• Ensure that the leveling jacks on the bottom of the rack are fully extended to the

fl oor with the full weight of the rack resting on them.

• In single rack installation, stabilizers should be attached to the rack.

• In multiple rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the

rack.

• You should extend only one component at a time - extending two or more simul-

taneously may cause the rack to become unstable.

Server Precautions

• Review the electrical and general safety precautions in Chapter 4.

• Determine the placement of each component in the rack before you install the

rails.

• Install the heaviest server components on the bottom of the rack fi rst, and

then work up.

• Use a regulating uninterruptible power supply (UPS) to protect the server from

power surges, voltage spikes and to keep your system operating in case of a

power failure.

• Allow the hot plug SCSI drives and power supply units to cool before touching

them.

• Always keep the rack's front door and all panels and components on the servers

closed when not servicing to maintain proper cooling.

2-2

Page 19

Chapter 2: Server Installation

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating tem-

perature of the rack environment may be greater than the ambient temperature

of the room. Therefore, consideration should be given to installing the equip-

ment in an environment compatible with the manufacturer’s maximum rated

ambient temperature (Tmra).

Reduced Airfl ow

Equipment should be mounted into a rack so that the amount of airfl ow required

for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does

not arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might

have on overcurrent protection and power supply wiring. Appropriate consid-

eration of equipment nameplate ratings should be used when addressing this

concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply con-

nections other than the direct connections to the branch circuit (i.e. the use of

power strips, etc.).

2-3

Page 20

AS1020S-8 User's Manual

2-4 Installing the System into a Rack

This section provides information on installing the server into a rack unit with the

rack rails provided. If the server has already been mounted into a rack, you can

skip ahead to Sections 2-5 and 2-6. There are a variety of rack units on the market,

which may mean the assembly procedure will differ slightly. You should also refer

to the installation instructions that came with the rack unit you are using.

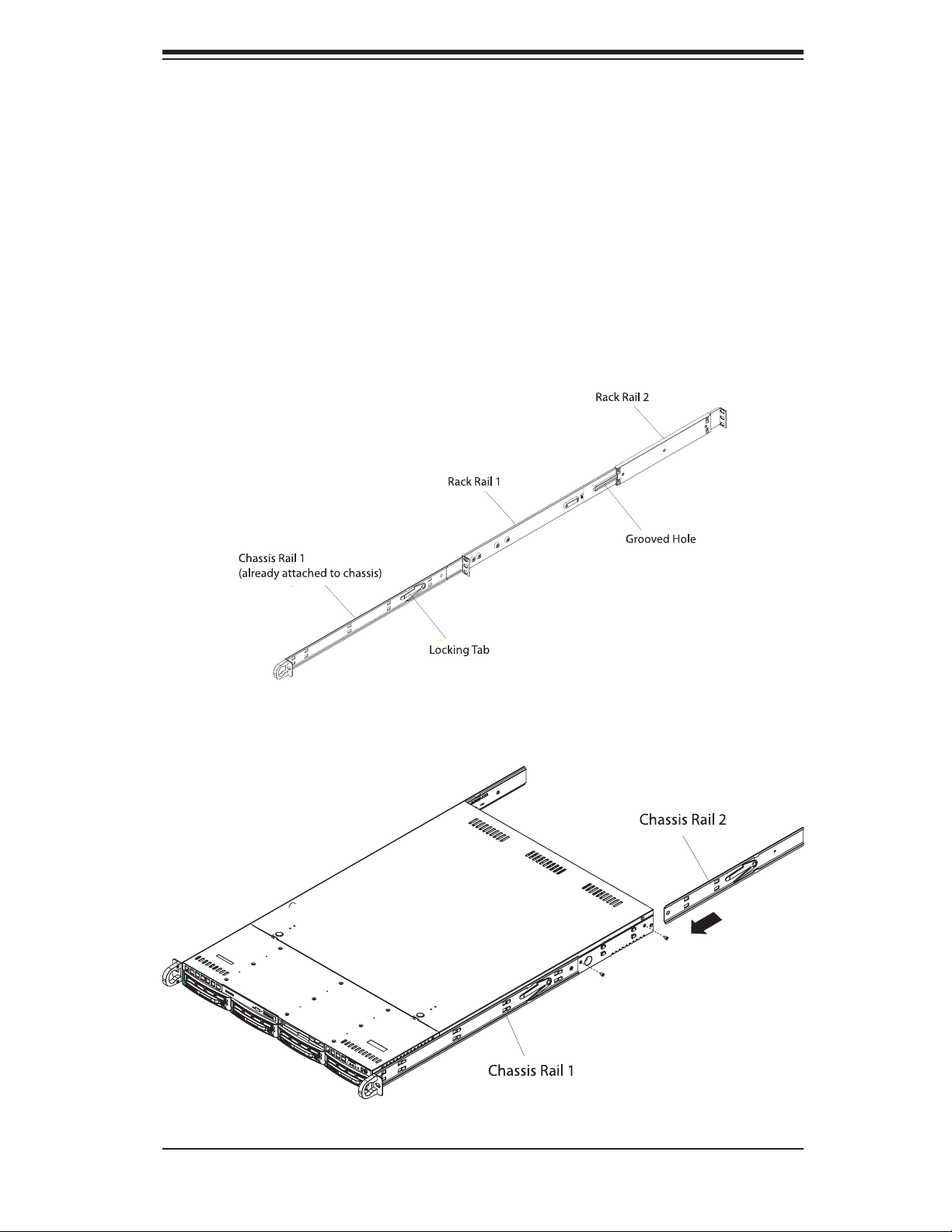

Identifying the Sections of the Rails

You should have received a rack mounting kit with the 1020S-8. The kit includes

two sets of chassis rails (four pieces total, two of which are already installed on

the chassis) and two sets of rack rails (four pieces total). Figure 2-1 displays the

two right-side chassis rails and the two right-side rack rails. Note that two of the

four chassis rails (Chassis Rail 1) are already attached to the chassis.

Installing the Rack Rails

Begin by joining one set of rack rails corresponding to either the left or the right side

of the rack. Do this by aligning the studs of one rail with the holes of the other rail.

Push the studs into the grooved holes and then push the rail to slide the studs to

the end of the groove. Repeat this with the rack rails used for the other side.

Next, determine where you want to place the server in the rack. (See Rack and

Server Precautions in Section 2-3.) Position the assembled rack rails at the

desired location in the rack. Screw the assembly securely to the rack using the

brackets provided. Attach the other assembly to the other side of the rack, making

sure both are at the exact same height and with the rail guides facing inward.

Locking Tabs: Both of the two chassis rails on each side have a locking tab (four

total), which serves two functions. The fi rst is to lock the server into place when

installed and pushed fully into the rack, which is its normal operating position.

Secondly, these tabs also lock the server in place when extended from the rack.

This prevents the server from coming completely out of the rack when you pull it

out for servicing. The two sets of locking tabs mean there are two locked positions

when the chassis is extended from the rack, allowing easy access when servicing

the system. Note that on one side, you push the locking tab up to release it and

on the other side you push it down to release.

2-4

Page 21

Chapter 2: Server Installation

Installing the Chassis Rails

Two of the chassis rails (Chassis Rail 1) should have already been preattached

- one to each side of the chassis. Attach the second set of chassis rails (Chassis

Rail 2) directly to the chassis with the screws provided. Chassis Rail 2 should

be positioned just behind Chassis Rail 1 (see Figure 2-2). Do this for both sides

of the chassis.

Figure 2-1. Identifying the Sections of the Rails

Figure 2-2. Installing Chassis Rails

2-5

Page 22

AS1020S-8 User's Manual

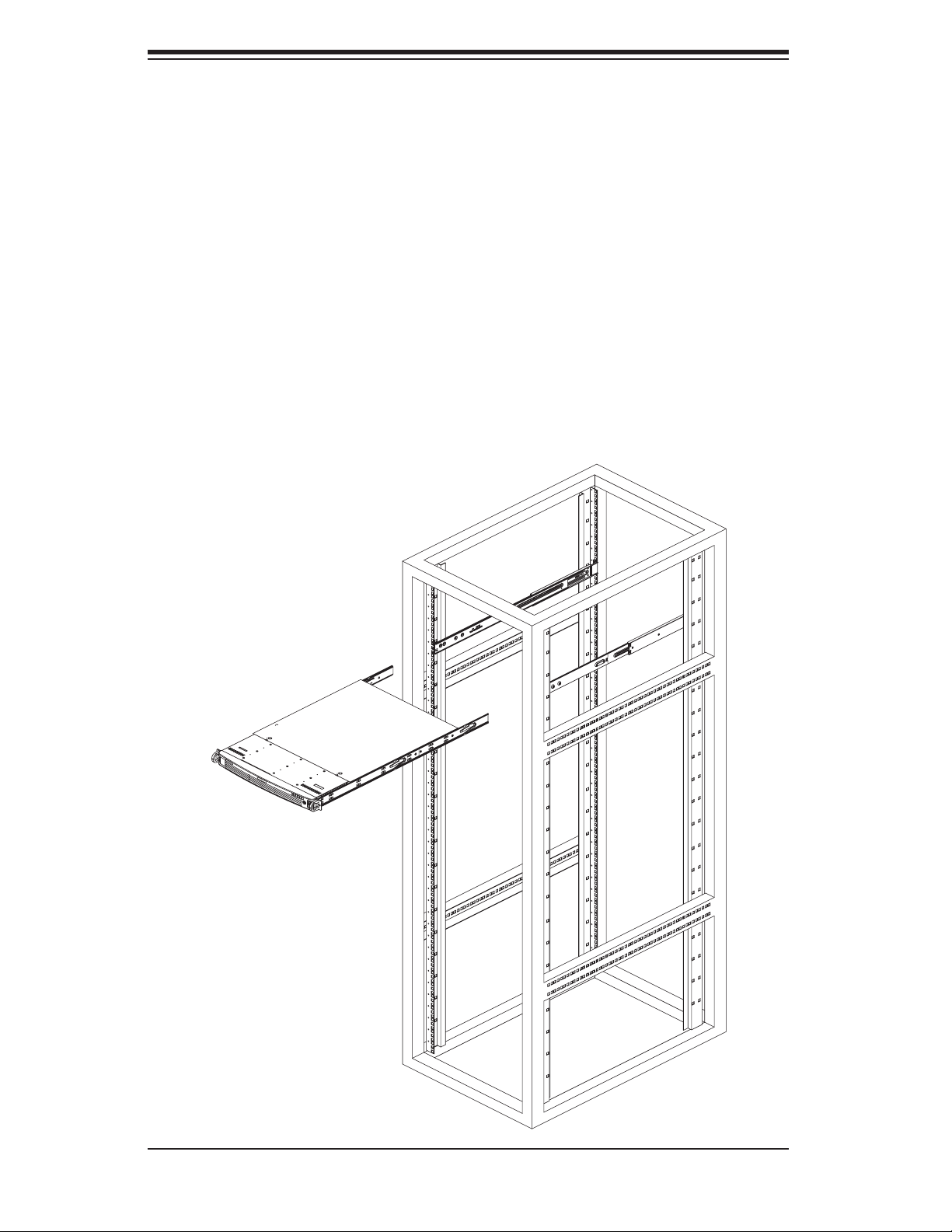

Installing the Server into the Rack

You should now have rails attached to both the chassis and the rack unit. The

next step is to install the server into the rack. Do this by lining up the rear of the

chassis rails with the front of the rack rails. Slide the chassis rails into the rack

rails, keeping the pressure even on both sides (you may have to depress the lock-

ing tabs when inserting). See Figure 2-3.

When the server has been pushed completely into the rack, you should hear the

locking tabs "click".

Figure 2-3. Installing the Server into a Rack

2-6

Page 23

Chapter 2: Server Installation

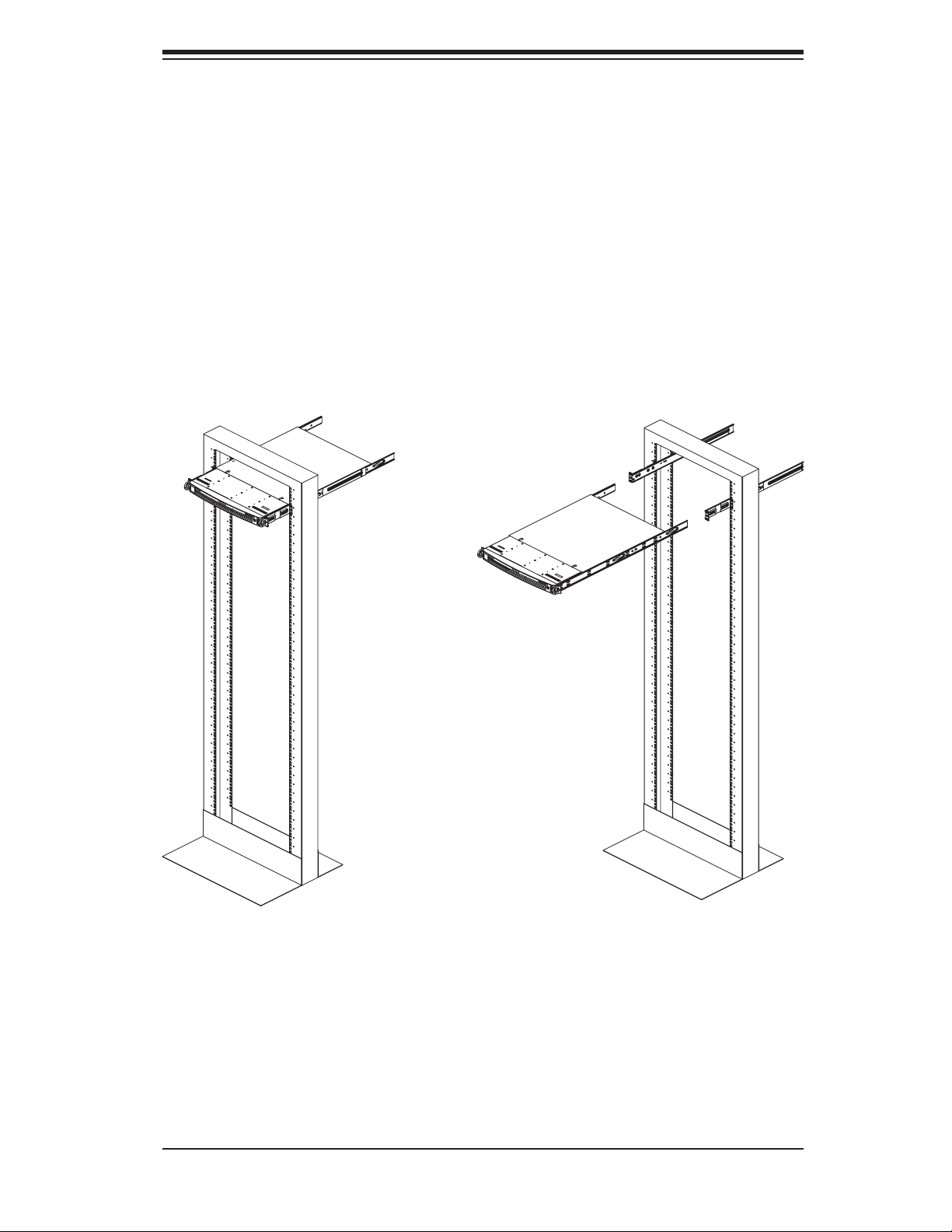

Installing the Server into a Telco Rack

If you are installing the 1020S-8 into a Telco type rack, follow the directions given

on the previous pages for rack installation. The only difference in the installation

procedure will be the positioning of the rack brackets to the rack. They should be

spaced apart just enough to accommodate the width of the telco rack.

Figure 2-4. Installing the Server into a Telco Rack

2-7

Page 24

AS1020S-8 User's Manual

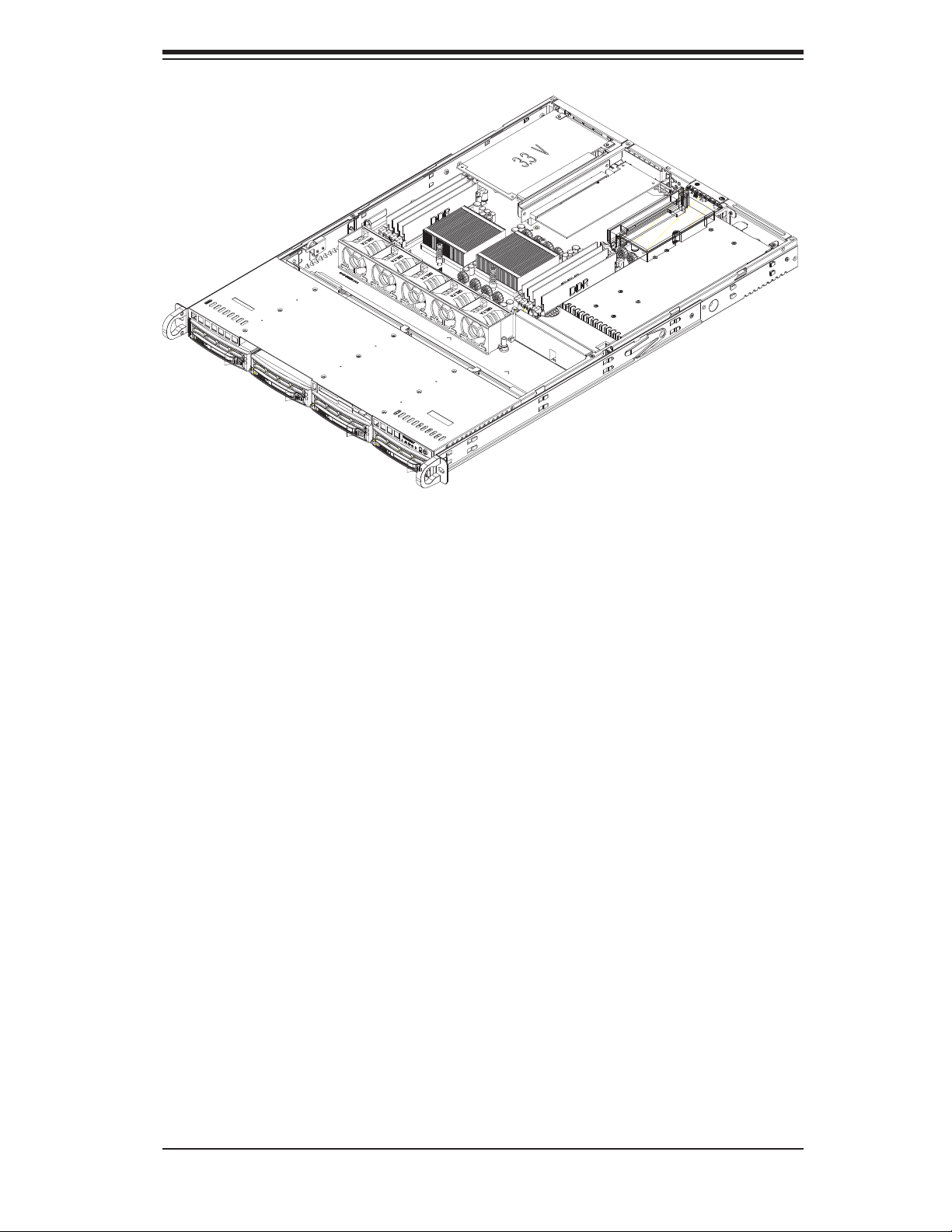

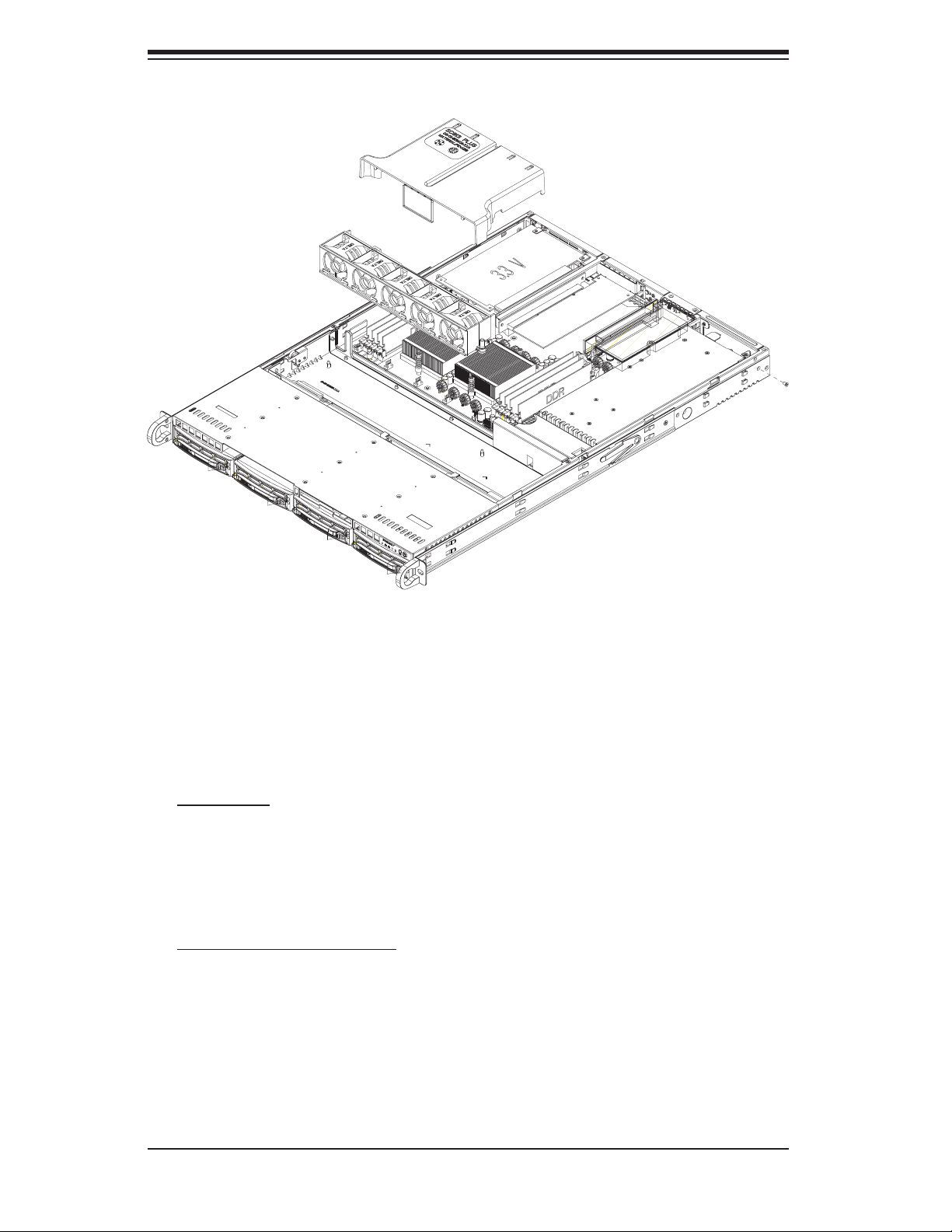

2-5 Checking the Serverboard Setup

After you install t he 1020S- 8 i n the rack, you will ne e d to open the unit to make su re

the serverboard is properly installed and all the connections have been made.

1. Accessing the inside of the server (see Figure 2-5)

First, grasp the two handles on either side and pull the unit straight out until it

locks (you will hear a "click"). Next, depress the two buttons on the top of the

chassis to release the top cover. There is a large rectangular recess in the

middle front of the top cover to help you push the cover away from you until it

stops. You can then lift the top cover from the chassis to gain full access to the

inside of the server.

2. Check the CPUs (processors)

You may have one or two processors already installed into the serverboard. Each

processor needs its own heatsink. See Chapter 5 for instructions on processor

and heatsink installation.

3. CPU Speed

The CPU speed should automatically be detected so you will not need to change

any jumpers or settings in the BIOS Setup utility.

4. Check the system memory

Your server system may have come with system memory already installed. Make

sure all DIMMs are fully seated in their slots. For details on adding system

memory, refer to Chapter 5.

5. Installing add-on cards

If desired, you can install add-on cards to the system. See Chapter 5 for details

on installing PCI add-on cards.

6. Check all cable connections and airfl ow

Make sure all power and data cables are properly connected and not blocking

the chassis airfl ow. See Chapter 5 for details on cable connections.

2-8

Page 25

Chapter 2: Server Installation

Figure 2-5. Accessing the Inside of the 1020S-8

2-6 Checking the Drive Bay Setup

Next, you should check to make sure the peripheral drives and the SCSI drives

have been properly installed and all connections have been made.

1. Accessing the drive bays

All drives are accessable from the front of the server. For servicing the CD-ROM

and fl oppy drives, you will need to remove the top chassis cover. The SCSI

disk drives can be installed and removed from the front of the chassis without

removing the top chassis cover or powering down the system.

2. CD-ROM and fl oppy disk drives

A slim CD-ROM and a fl oppy drive should be preinstalled in your server. Refer

to Chapter 6 if you need to reinstall a CD-ROM and/or fl oppy disk drive to the

system.

3. Check the SCSI disk drives

Depending upon your system's confi guration, your system may have one or

more drives already installed. If you need to install SCSI drives, please refer to

Chapter 6.

2-9

Page 26

AS1020S-8 User's Manual

4. Check the airfl ow

Airfl ow is provided by four 4-cm counter-rotating fans. The system component

layout was carefully designed to direct the airfl ow to the components that gener-

ate the most heat. Note that all power and data cables have been routed in such

a way that they do not block the airfl ow generated by the fans.

5. Supplying power to the system

The last thing you must do is to provide power to the system. Plug the power

cord from the power supply module into a high-quality power strip that offers

protection from electrical noise and power surges. It is recommended that you

use an uninterruptible power supply (UPS). Finish by depressing the power

button on the front of the chassis to start the system.

2-10

Page 27

Chapter 3: System Interface

Chapter 3

System Interface

3-1 Overview

There are several LEDs on the control panel as well as others on the SCSI drive

carriers to keep you constantly informed of the overall status of the system as well

as the activity and health of specifi c components. There are also two buttons on

the chassis control panel. This chapter explains the meanings of all LED indica-

tors and the appropriate response you may need to take.

3-2 Control Panel Buttons

There are two push-buttons located on the front of the chassis. These are (in

order from left to right) a reset button and a power on/off button.

Reset:

Power: The main power switch is used to apply or remove power from the

power supply to the server system. Turning off system power with this button

removes the main power but keeps standby power supplied to the system.

Use the reset switch to reboot the system.

3-1

Page 28

AS1020S-8 User's Manual

3-3 Control Panel LEDs

The control panel located on the front of the SC813S-500 chassis has fi ve LEDs.

These LEDs provide you with critical information related to different parts of the

system. This section explains what each LED indicates when illuminated and any

corrective action you may need to take.

Overheat/Fan Fail: When this LED fl ashes it indicates a fan failure. When

on continuously (on and not fl ashing) it indicates an overheat condition, which

may be caused by cables obstructing the airfl ow in the system or the ambient

room temperature being too warm. Check the routing of the cables and make

sure all fans are present and operating normally. You should also check to make

sure that the chassis covers are installed. Finally, verify that the heatsinks are

installed properly (see Chapter 5). This LED will remain fl ashing or on as long as

the overheat condition exists.

2

NIC2: Indicates network activity on GLAN2 when fl ashing .

1

NIC1: Indicates network activity on GLAN1 when fl ashing.

3-2

Page 29

Chapter 3: System Interface

HDD: Indicates IDE channel activity. On the 1020S-8, this light indicates

SCSI and/or CD-ROM drive activity when fl ashing.

Power: Indicates power is being supplied to the system's power supply

units. This LED should normally be illuminated when the system is operating.

3-4 SCSI Drive Carrier LEDs

Each SCSI drive carrier has two LEDs.

Green: When illuminated, the green LED on the front of the SCSI drive car-

rier indicates drive activity. A connection to the SCSI SCA backplane enables this

LED to blink on and off when that particular drive is being accessed.

Red: The SAF-TE compliant backplane activates the red LED to indicate a

drive failure. If one of the SCSI drives fail, you should be notifi ed by your system

management software. Please refer to Chapter 6 for instructions on replacing failed

SCSI drives.

3-3

Page 30

AS1020S-8 User's Manual

Notes

3-4

Page 31

Chapter 4: System Safety

Chapter 4

System Safety

4-1 Electrical Safety Precautions

!

Basic electrical safety precautions should be followed to protect yourself from

harm and the AS1020S-8 from damage:

Be aware of the locations of the power on/off switch on the chassis as well as

the room's emergency power-off switch, disconnection switch or electrical

outlet. If an electrical accident occurs, you can then quickly remove power

from the system.

Do not work alone when working with high voltage components.

Power should always be disconnected from the system when removing or

installing main system components, such as the serverboard, memory

modules and the CD-ROM and fl oppy drives (not necessary for SCSI drives).

When disconnecting power, you should fi rst power down the system with the

operating system and then unplug the power cords from all the power supply

modules in the system.

When working around exposed electrical circuits, another person who is

familiar with the power-off controls should be nearby to switch off the power

if necessary.

Use only one hand when working with powered-on electrical equipment. This

is to avoid making a complete circuit, which will cause electrical shock.

Use extreme caution when using metal tools, which can easily damage any

electrical components or circuit boards they come into contact with.

Do not use mats designed to decrease electrostatic discharge as protection

from electrical shock. Instead, use rubber mats that have been specifi cally

designed as electrical insulators.

The power supply power cord must include a grounding plug and must be

plugged into grounded electrical outlets.

4-1

Page 32

AS1020S-8 User's Manual

Serverboard Battery: CAUTION - There is a danger of explosion if the onboard

battery is installed upside down, which will reverse its polarities (see Figure

4-1). This battery must be replaced only with the same or an equivalent type

recommended by the manufacturer. Dispose of used batteries according to

the manufacturer's instructions.

CD-ROM Laser: CAUTION - this server may have come equipped with a CD-

ROM drive. To prevent direct exposure to the laser beam and hazardous

radiation exposure, do not open the enclosure or use the unit in any

unconventional way.

4-2 General Safety Precautions

!

Follow these rules to ensure general safety:

Keep the area around the 1020S-8 clean and free of clutter.

The 1020S-8 weighs approximately 38 lbs (17.3 kg) when fully loaded. When

lifting the system, two people at either end should lift slowly with their feet

spread out to distribute the weight. Always keep your back straight and lift

with your legs.

Place the chassis top cover and any system components that have been

removed away from the system or on a table so that they won't accidentally

be stepped on.

While working on the system, do not wear loose clothing such as neckties and

unbuttoned shirt sleeves, which can come into contact with electrical circuits

or be pulled into a cooling fan.

Remove any jewelry or metal objects from your body, which are excellent metal

conductors that can create short circuits and harm you if they come into

contact with printed circuit boards or areas where power is present.

After accessing the inside of the system, close the system back up and secure

it to the rack unit with the retention screws after ensuring that all connections

have been made.

4-2

Page 33

4-3 ESD Precautions

!

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic com ponents and printed

circuit boards. The following measures are generally suffi cient to neutralize this

difference before contact is made to protect your equipment from ESD:

Use a grounded wrist strap designed to prevent static discharge.

Keep all components and printed circuit boards (PCBs) in their antistatic

bags until ready for use.

Chapter 4: System Safety

Touch a grounded metal object before removing any board from its antistatic

bag.

Do not let components or PCBs come into contact with your clothing, which

may retain a charge even if you are wearing a wrist strap.

Handle a board by its edges only; do not touch its components, peripheral

chips, memory modules or contacts.

When handling chips or modules, avoid touching their pins.

Put the serverboard and peripherals back into their antistatic bags when

not in use.

For grounding purposes, make sure your computer chassis provides excellent

conductivity between the power supply, the case, the mounting fasteners and

the serverboard.

4-3

Page 34

AS1020S-8 User's Manual

4-4 Operating Precautions

!

Care must be taken to assure that the chassis cover is in place when the 1020S-8

is operating to ensure proper cooling. Out of warranty damage to the 1020S-8

system can occur if this practice is not strictly followed.

Figure 4-1. Installing the Onboard Battery

LITHIUM BATTERY

LITHIUM BATTERY

OR

BATTERY HOLDER BATTERY HOLDER

4-4

Page 35

Chapter 5: Advanced Serverboard Setup

Chapter 5

Advanced Serverboard Setup

This chapter covers the steps required to install processors and heatsinks to the

H8DSR-8 serverboard, connect the data and power cables and install add-on

cards. All serverboard jumpers and connections are described and a layout and

quick reference chart are included in this chapter. Remember to close the chas-

sis completely when you have fi nished working on the serverboard to protect and

cool the system suffi ciently.

5-1 Handling the Serverboard

Static electrical discharge can damage electronic com ponents. To prevent dam-

age to printed circuit boards, it is important to handle them very carefully (see

Chapter 4). Also note that the size and weight of the serverboard can cause

it to bend if handled improperly, which may result in damage. To prevent the

serverboard from bending, keep one hand under the center of the board to sup-

port it when handling. The following measures are generally suffi cient to protect

your equipment from static discharge.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing any board from its antistatic

bag.

• Handle a board by its edges only; do not touch its components, peripheral chips,

memory modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the serverboard, add-on cards and peripherals back into their antistatic

bags when not in use.

Unpacking

The serverboard is shipped in antistatic packaging to avoid static damage. When

unpacking the board, make sure the person handling it is static protected.

5-1

Page 36

AS1020S-8 User's Manual

5-2 Mounting the Serverboard into a Chassis

All serverboards and motherboards have standard mounting holes to fi t different

types of chassis. Make sure that the locations of all the mounting holes for both

the serverboard and the chassis match. Although a chassis may have both plastic

and metal mounting fasteners, metal ones are highly recommended because they

ground the serverboard to the chassis. Make sure that the metal standoffs click in

or are screwed in tightly.

1. Check the compatibility of the serverboard ports and the I/O shield

The H8DSR-8 serverboard requires a chassis that can support extended ATX

boards of 12" x 13.05" in size, such as the SC813S+-500. Make sure that the I/O

ports on the serverboard align with their respective holes in the I/O shield at the

rear of the chassis.

2. Mounting the serverboard onto the mainboard tray in the chassis

Carefully mount the serverboard onto the mainboard tray by aligning the serverboard

mounting holes with the raised metal standoffs in the tray. Insert screws into all

the mounting holes in the serverboard that line up with the standoffs. Then use a

screwdriver to secure the serverboard to the mainboard tray - tighten until just snug

(if too tight you might strip the threads). Metal screws provide an electrical contact

to the serverboard ground to provide a continuous ground for the system.

5-3 Processor and Heatsink Installation

Exercise extreme caution when handling and installing the proces-

!

Installing the Processor (install to the CPU#1 socket fi rst)

sor. Always connect the power cord last and always remove it be-

fore adding, removing or changing any hardware components.

1. Lift the lever on CPU socket #1 until

it points straight up.

5-2

Page 37

2. Use your thumb and your index fi n-

ger to hold the CPU. Locate pin 1 on

the CPU socket and pin 1 on the CPU.

Both are marked with a triangle.

3. Align pin 1 of the CPU with pin 1

of the socket. Once aligned, carefully

place the CPU into the socket. Do not

drop the CPU on the socket, move the

CPU horizontally or vertically or rub the

CPU against the socket or against any

pins of the socket, which may damage

the CPU and/or the socket.

Chapter 5: Advanced Serverboard Setup

Triangles

4. With the CPU inserted into the

socket, inspect the four corners of the

CPU to make sure that it is properly

installed and fl ush with the socket.

5. Gently press the CPU socket lever

down until it locks in the plastic tab.

For a dual-processor system, repeat

these steps to install another CPU into

the CPU#2 socket.

Note: if using a single processor, only

CPU 1 DIMM slots are addressable.

5-3

Page 38

AS1020S-8 User's Manual

Installing the Heatsinks

To install the heatsink (SNK-P0012, optional), do not apply any thermal compound

to the heatsink or CPU die - the proper amount has already been applied. Place the

heatsink directly on the CPU so that the two mounting holes are aligned with those

on the CPU backplate. Make sure the heatsink sits completely fl at on the CPU - if

not completely fl at, the space between the two will degrade the heat dissipation

function of the heatsink, which may cause the processor to overheat. Screw in the

two screws until just snug (do not fully tighten), then fi nish by fully tightening both

screws (see Figure 5-1).

Figure 5-1. Installing Heatsinks

5-4

Page 39

Chapter 5: Advanced Serverboard Setup

5-4 Connecting Cables

Now that the processors are installed, the next step is to connect the cables to

the serverboard. These include the data (ribbon) cables for the peripherals and

control panel and the power cables.

Connecting Data Cables

The ribbon cables used to transfer data from the peripheral devices have been

carefully routed in preconfi gured systems to prevent them from blocking the fl ow

of cooling air that moves through the system from front to back. If you need to

disconnect any of these cables, you should take care to reroute them as they

were originally after reconnecting them (make sure the red wires connect to the

pin 1 locations). If you are confi guring the system, keep the airfl ow in mind when

routing the cables. The following data cables (with their serverboard connector

locations noted) should be connected. See the serverboard layout diagram in this

chapter for connector locations.

CD-ROM cable (JIDE1)

Floppy Drive cable (JFDD1)

SCSI cables (JA1, JB1)

Control Panel cable (JF1, see next page)

Connecting Power Cables

The H8DSR-8 has a 20-pin primary power supply connector "J1B4" for connec-

tion to the ATX power supply. Connect the appropriate connector from the power

supply to J1B4 connector to supply power to the serverboard. See the Connector

Defi nitions section in this chapter for power connector pin defi nitions.

In addition, your power supply must be connected to the 8-pin Processor Power

connection at JPW2. For systems with heavy loads, an additional 4-pin power

connection has been included at J32.

5-5

Page 40

AS1020S-8 User's Manual

Connecting the Control Panel

JF1 contains header pins for various front control panel connectors. See Figure

5-2 for the pin locations of the various front control panel buttons and LED indica-

tors and refer to section 5-9 for details. Note that even and odd numbered pins

are on opposite sides of each header.

All JF1 wires have been bundled into single keyed ribbon cable to simplify their

connection. The red wire in the ribbon cable plugs into pin 1 of JF1. Connect

the other end of the cable to the Control Panel printed circuit board, located just

behind the system status LEDs in the chassis.

See the Connector Defi nitions section in this chapter for details and pin descrip-

tions of JF1.

Figure 5-2. Front Control Panel Header Pins (JF1)

5-5 I/O Ports

Ground

x (key)

Power LED

HDD LED

NIC1

NIC2

OH/Fan Fail LED

Power Fail LED

Ground

Ground

20 19

NMI

x (key)

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Reset Button

Power Button

2 1

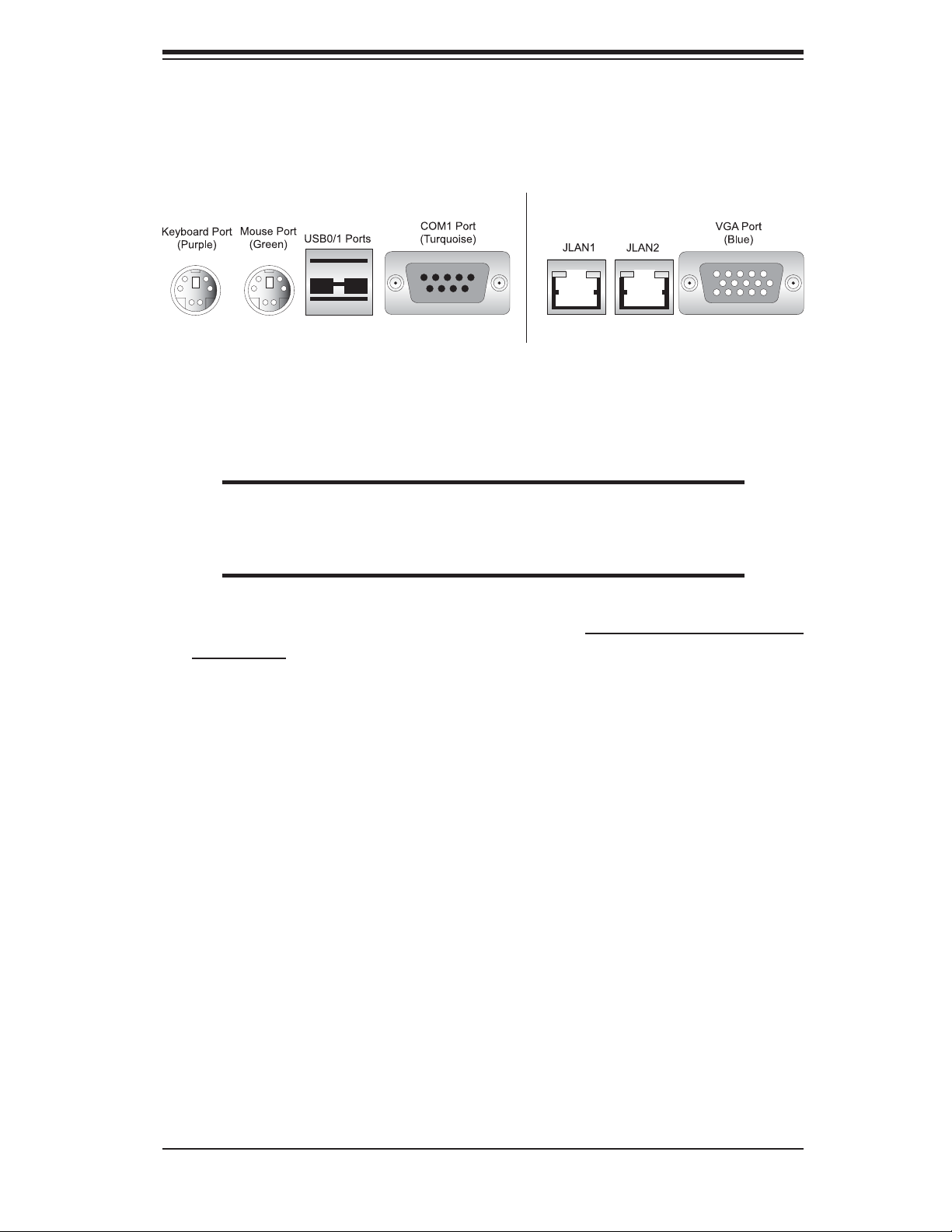

The I/O ports are color coded in conformance with the PC 99 specifi cation. See

Figure 5-3 below for the colors and locations of the various I/O ports.

5-6

Page 41

Figure 5-3. Rear Panel I/O Ports

5-6 Installing Memory

Chapter 5: Advanced Serverboard Setup

CAUTION

Exercise extreme care when installing or removing memory modules

to prevent any possible damage.

1. Insert each memory module vertically into its slot, beginning with CPU1 slot 1A,

then 1B, etc.. Pay attention to the notch along the bottom of the module to prevent

inserting the module incorrectly (see Figure 5-4). See support information below.

2. Gently press down on the memory module until it snaps into place.

Note: each processor has its own built-in memory controller, so CPU2 DIMMs can-

not be addressed if only a single CPU is installed. 128 MB, 256 MB, 512 MB, 1

GB and 2 GB* memory modules are supported.

*With Opteron 246 C-stepping CPUs and above.

Support

The H8DSR-8 supports single or dual-channel, registered ECC DDR400/333/266

SDRAM.

Both interleaved and non-interleaved memory are supported, so you may populate

any number of DIMM slots (see note on previous page). The CPU2 DIMM slots

can only be accessed when two CPUs are installed (however, the CPU2 DIMM slots

are not required to be populated when two CPUs are installed).

Populating two adjacent slots at a time with memory modules of the same size and

type will result in interleaved (128-bit) memory, which is faster than non-interleaved

(64-bit) memory.

5-7

Page 42

AS1020S-8 User's Manual

Optimizing memory performance

If two processors are installed, it is better to stagger pairs of DIMMs across both

sets of CPU DIMM slots, e.g. fi rst populate CPU1 slots 1A and 1B, then CPU2 slots

1A, and 1B, then the next two CPU1 slots, etc. This balances the load over both

CPUs to optimize performance.

Maximum memory (two CPUs): 32 GB for DDR333/266 and 16 GB for DDR400.

If only one CPU is installed, maximum supported memory is halved (16 GB for

DDR333/266 and 8 GB for DDR400).

Figure 5-4. Side and Top Views of DDR Installation

To Install:

Insert module vertically

and press down until it

snaps into place. The

release tabs should

close - if they do not

you should close them

yourself.

Note the notch in the slot and on the bottom of the DIMM.

These prevent the DIMM from being installed incorrectly.

To Remove:

Use your thumbs to

gently push each release tab outward to

release the DIMM from

the slot.

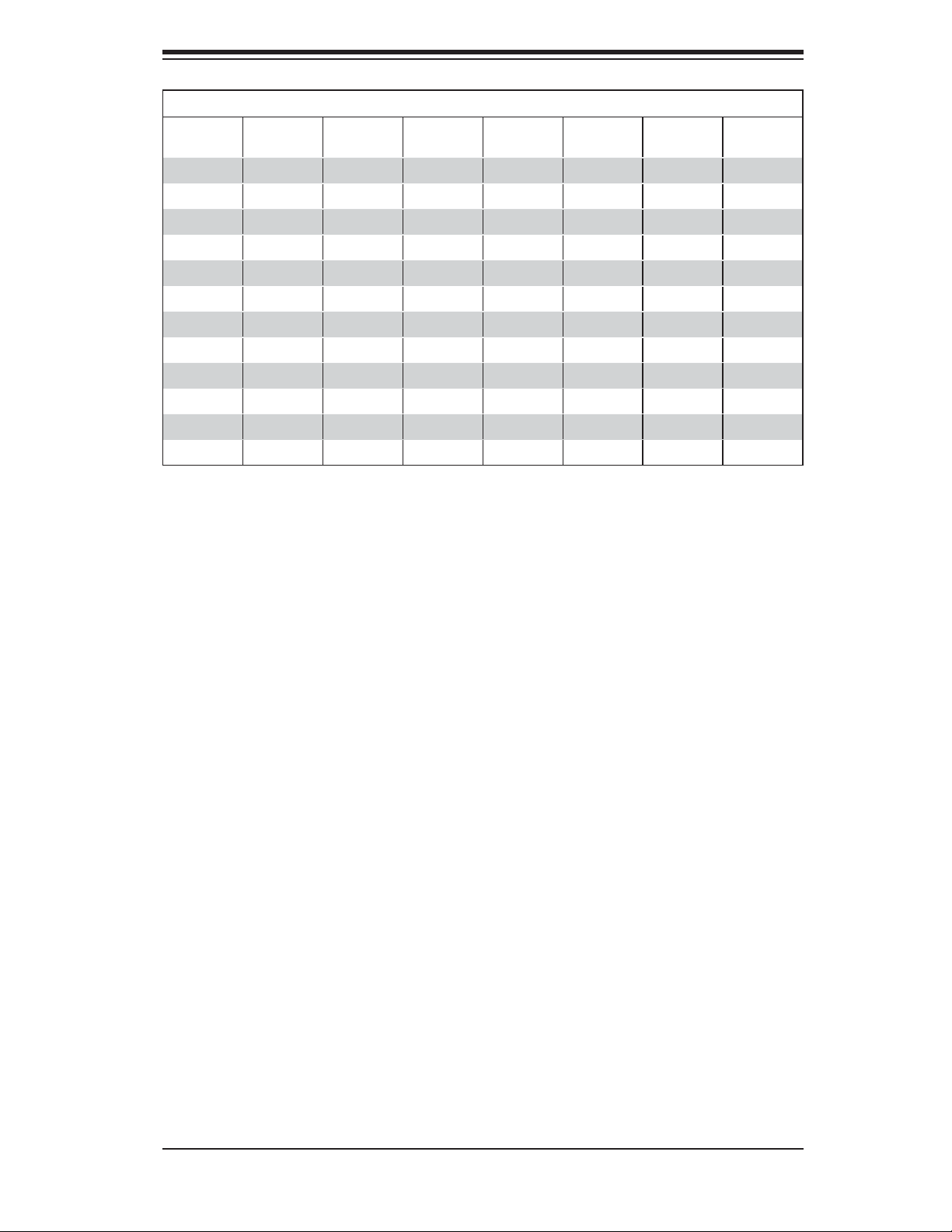

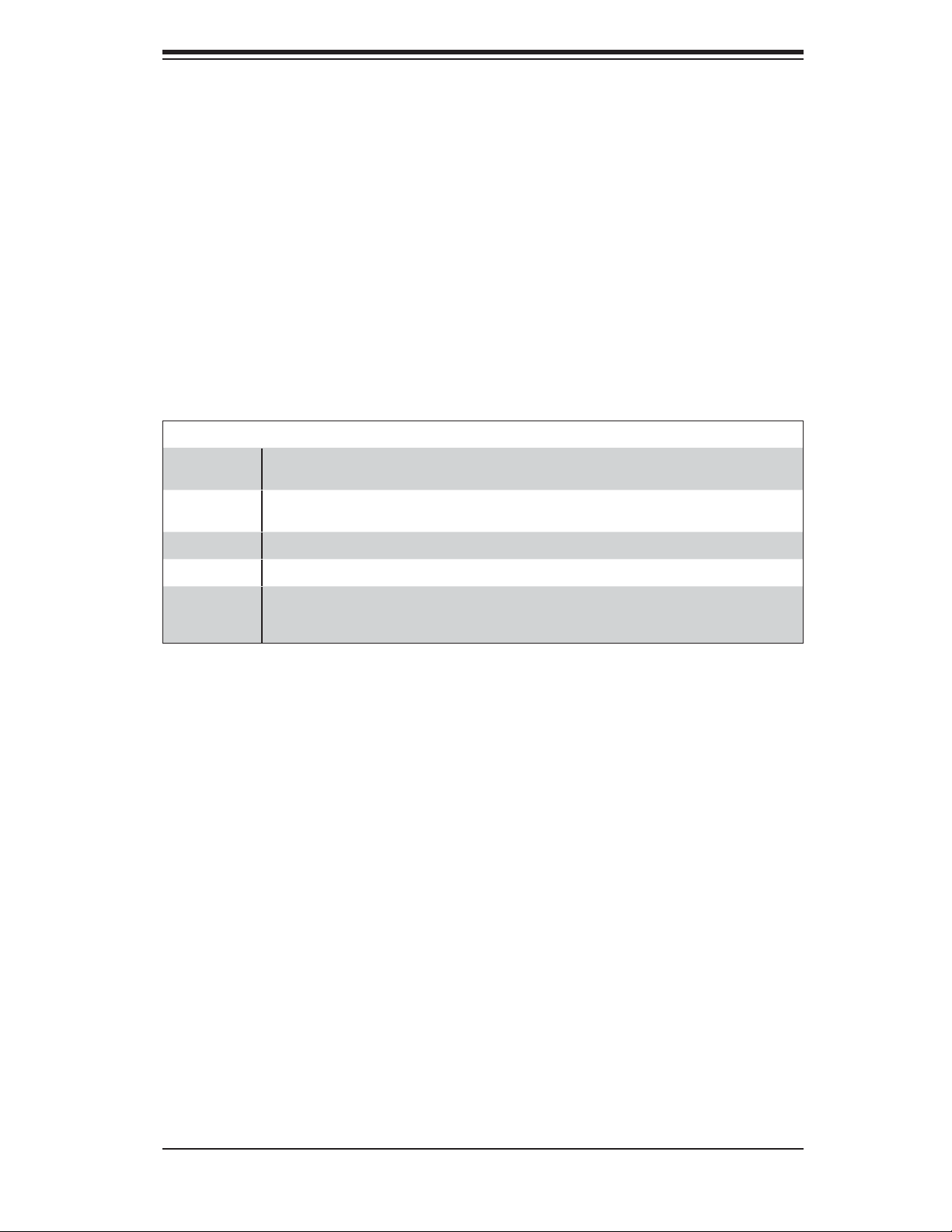

Populating Memory Banks for 64-bit Operation

CPU1

DIMM1A

X

XX

XX

X X

CPU1

DIMM1B

CPU1

DIMM2A

X

XX

XX

CPU1

DIMM2B

CPU2

DIMM1A

CPU2

DIMM1B

CPU2

DIMM2A

CPU2

DIMM2B

5-8

Page 43

Chapter 5: Advanced Serverboard Setup

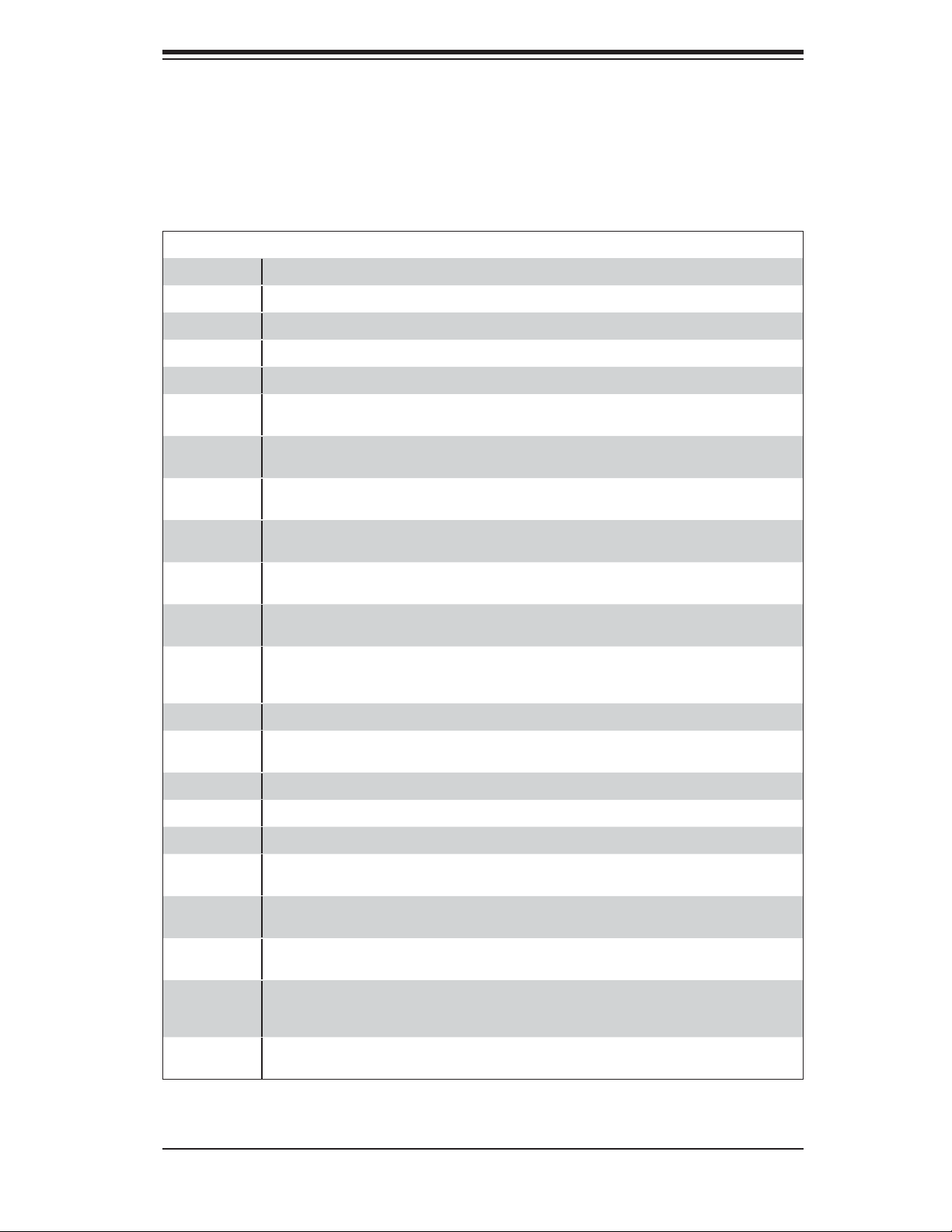

Populating Memory Banks for 128-bit Operation

CPU1

DIMM1A

XX

XX XX

XX XX

XX XXXX

XXXX

XXXXXX

XXXX XX

XXXXXXXX

CPU1

DIMM1B

CPU1

DIMM2A

XX

XXXX

XX XX

XXXXXX

CPU1

DIMM2B

CPU2

DIMM1A

CPU2

DIMM1B

CPU2

DIMM2A

CPU2

DIMM2B

Notes: X indicates a populated DIMM slot. If adding four DIMMs (with two CPUs installed), the confi gurations with DIMMs spread over both CPUs (and not like in row 5) will

result in optimized performance.

5-7 Adding PCI Cards

1. PCI slots:

The H8DSR-8 has four PCI expansion slots, which includes two x8 PCI-Express,

one 64-bit 133 MHz PCI-X and one 64-bit 100 MHz PCI-X slots. An additional slot

(slot #7) supports a low profi le IPMI 2.0 card.

The 1020S-8 includes two riser cards to accommodate up to two PCI-X/PCI-E cards

in the following confi guration: one low profi le expansion card (PCI-X 133 MHz or

PCI-Express x8) and one full-height, half-length expansion card (PCI-X 100 MHz

or PCI-Express x8).

2. PCI card installation:

Before installing a PCI add-on card, make sure you install it into the appropriate

riser card. Begin by removing the screw from the backpanel PCI slot shield that

corresponds to the slot you wish to populate. Insert the PCI card into the correct

riser card, pushing down with your thumbs evenly on both sides of the card. Fin-

ish by securing the card to the chassis with the same screw you removed from

the PCI shield. Follow this procedure when adding a card to the other riser card.

Note: the PCI slot shields help promote proper airlow in the chassis and shield the

inside of the system from EMI (electromagnetic interference). For these reasons,

make sure there is always a shield covering each unused slot.

5-9

Page 44

AS1020S-8 User's Manual

5-8 Serverboard Details

Figure 5-5. H8DSR-8 Serverboard Layout

(not drawn to scale)

DA2

DA1

VGA

JPXBO

JPXAO

JPA2

JPA3

LAN2 LAN1

PCI #7: 133 MHz PCI-X

PCI #6: 100 MHz PCI-X ZCR

U320 SCSI CHB

JB1

COM2

JA1

JPA1

AIC-7902W

U320 SCSI CHA

Speaker

JD1

J22

JI2C1

JI2C2

Battery

HT-1000

Rage

XL

JPG1

COM1

BIOS

USB0/1

1UIPMI

DB8/7/6/5/4/3/2/1

Mouse

DP1

JOH1

JWOR

JPF

JWD

IPMB

KB

JBT1

JIDE1

JWOL

SATA0

SATA1SATA2SATA3

JFDD1

USB2/3

JL1

JSLED1

CPU2 DIMM 1A

CPU2 DIMM 1B

FAN5

JP17

JWF1

CPU2 DIMM 1A

CPU2 DIMM 2B

FAN4

PCI-Express x8

CPU2

PCI-Express x8

FAN3

HT-2000

CPU1

FAN2 FAN1

CPU1 DIMM 2A

CPU1 DIMM 1A

CPU1 DIMM 2B

JF1

JAR

J3P

JP10

J24

CPU1 DIMM 1B

J32

J1B4

JPW2

Notes:

Jumpers not indicated are for test purposes only.

5-10

Page 45

Chapter 5: Advanced Serverboard Setup

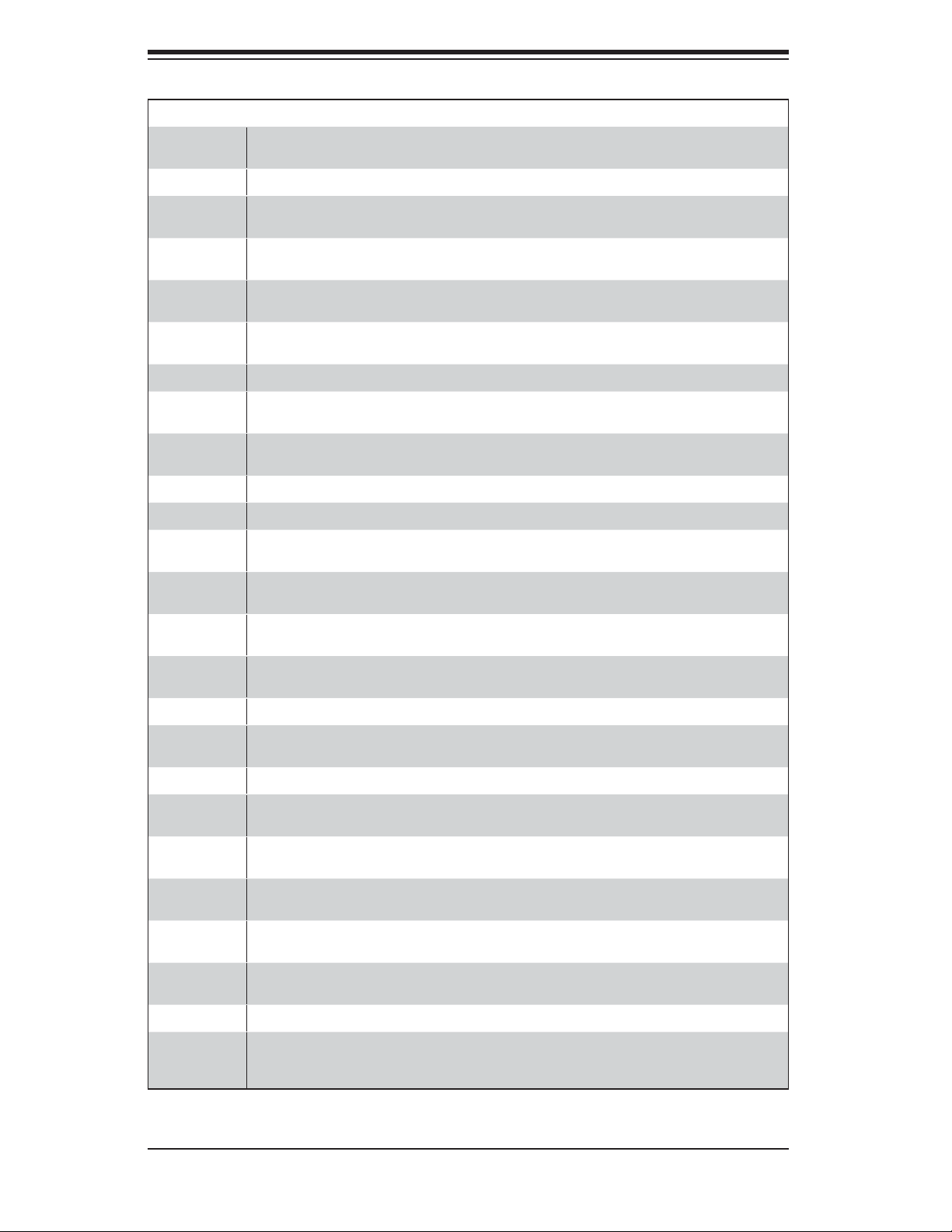

H8DSR-8 Quick Reference

Jumpers Description Default Setting

JBT1 CMOS Clear See Section 5-10

JD1 Onboard Spkr En/Disable Pins 6-7 (Enabled)

2

C1/2 I2C to PCI Enable/Disable Closed (Enabled)

JI

JPA1 SCSI Enable/Disable Pins 1-2 (Enabled)

JPA2, JPA3 SCSI Channel A/B Term. Open (Enabled)

JPF Power Force On Open (Normal)

JPG1 VGA Enable/Disable Pins 1-2 (Enabled)

JPXAO/JPXBO PCI-X Slot Freq. Select Open (Auto)

JWD Watch Dog Pins 1-2 (Reset)

Connectors Description

1UIPMI IPMI 2.0 Header

COM1/COM2 COM1/2 Serial Port/Header

FAN1-5 Fan Headers

J1B4 Primary ATX Power Connector

J22 IPMB Header

J24 System Management Bus (PS) Header

J32 Secondary Power Connector

JA1 Ultra320 SCSI Channel A Connector

JB1 Ultra320 SCSI Channel B Connector

JD1 Power LED/Speaker Header

JF1 Front Panel Headers

JFDD1 Floppy Disk Drive Connector

JIDE1 IDE#1 Connector

JL1 Chassis Intrusion Header

JLAN1/2 Gigabit Ethernet (RJ45) Ports

JOH1 Overheat LED Header

JPW2 Processor Power Connector

JSLED1 SCSI LED Activity Header

JWOL Wake-On-LAN Header

JWOR Wake-On-Ring Header

SATA0-3 Serial ATA Connectors (SATA0/1/2/3)

USB0/1/2/3 Universal Serial Bus Ports (0/1) and Headers (2/3)

VGA Video (Monitor) Port

Onboard LEDs Description

DA1/DA2 SCSI Channel A/B Activity LEDs

DB1-DB8 POST Code LEDs

DP1 +3.3V Standby Power LED

5-11

Page 46

AS1020S-8 User's Manual

5-9 Connector Defi nitions

Primary ATX Power

Connector

The main power supply connector on

the H8DSR-8 (J1B4) meets the SSI

(Superset ATX) specification. You

can only use a 20-pin power supply

cable on the serverboard. Make sure

that the orientation of the connector

is correct. You must also use the

processor power connector (JPW2,

below.) See the table on the right for

pin defi nitions.

Processor Power Connector

The header at JPW2 must also be

connected to the power supply to

provide power for the processor(s).

See the table on the right for pin

defi nitions.

ATX Power 20-pin Connector

Pin Defi nitions (J1B4)

Pin# Defi nition Pin # Defi nition

11 +3.3V 1 +3.3V

12 -12V 2 +3.3V

13 COM 3 COM

14 PS_ON 4 +5V

15 COM 5 COM

16 COM 6 +5V

17 COM 7 COM

18 -5V 8 PWR_OK

19 +5V 9 5VSB

20 +5V 10 +12V

Required Connection

Processor Power

Pin Defi nitions (JPW2)

Pins Defi nition

1 through 4 Ground

5 through 8 +12V

Required Connection

Secondary Power

Connection

In addition to the Primary ATX power

connector (above), a Secondary

12v 4-pin connector (J32) has been

included for use with heavy-load sys-

tems. See the table on the right for

pin defi nitions.

NMI Button

The non-maskable interrupt button

header is located on pins 19 and 20

of JF1. Refer to the table on the right

for pin defi nitions.

5-12

Secondary Power

Pin Defi nitions (J32)

Pins Defi nition

1 & 2 Ground

3 & 4 +12V

NMI Button

Pin Defi nitions (JF1)

Pin# Defi nition

19 Control

20 Ground

Page 47

Chapter 5: Advanced Serverboard Setup

Power LED

The Power LED connection is located

on pins 15 and 16 of JF1. Refer to the

table on the right for pin defi nitions.

HDD LED

The HDD (IDE Hard Disk Drive) LED

connection is located on pins 13 and

14 of JF1. Attach the IDE hard drive

LED cable to display disk activity.

Refer to the table on the right for pin

defi nitions.

NIC1 LED

Power LED

Pin Defi nitions (JF1)

Pin# Defi nition

15 Vcc

16 Control

HDD LED

Pin Defi nitions (JF1)

Pin# Defi nition

13 Vcc

14 HD Active

The NIC1 (Network Interface Control-

ler) LED connection is located on pins

11 and 12 of JF1. Attach the NIC1

LED cable to display network activity.

Refer to the table on the right for pin

defi nitions.

NIC2 LED

The NIC2 (Network Interface Control-

ler) LED connection is located on pins

9 and 10 of JF1. Attach the NIC2

LED cable to display network activity.

Refer to the table on the right for pin

defi nitions.

Overheat/Fan Fail LED

Connect an LED to the OH connection

on pins 7 and 8 of JF1 to provide ad-

vanced warning of chassis overheat-

ing. Refer to the table on the right for

pin defi nitions.

NIC1 LED

Pin Defi nitions (JF1)

Pin# Defi nition

11 Vcc

12 NIC1 Active

NIC2 LED

Pin Defi nitions (JF1)

Pin# Defi nition

9 Vcc

10 NIC2 Active

OH/Fan Fail LED

Pin Defi nitions (JF1)

Pin# Defi nition

7 Vcc

8 Control

5-13

Page 48

AS1020S-8 User's Manual

Power Fail LED

The Power Fail LED connection is lo-

cated on pins 5 and 6 of JF1. See the

table on the right for pin defi nitions.

Note: This feature is only available when using

redundant power supplies.

Power Fail LED

Pin Defi nitions (JF1)

Pin# Defi nition

5 Vcc

6 Control

Reset Button

The Reset Button connection is

located on pins 3 and 4 of JF1 and

attaches to the reset switch on the

computer chassis. See the table on

the right for pin defi nitions.

Power Button

The Power Button connection is

located on pins 1 and 2 of JF1. Mo-

mentarily contacting both pins will

power on/off the system. This button

can also be confi gured to function

as a suspend button (see the Power

Button Mode setting in BIOS). To turn

off the power when set to suspend

mode, depress the button for at least

4 seconds. Refer to the table on the

right for pin defi nitions.

Reset Button

Pin Defi nitions (JF1)

Pin# Defi nition

3 Reset

4 Ground

Power Button

Pin Defi nitions (JF1)

Pin# Defi nition

1 PW_ON

2 Ground

USB0/1 (Universal Serial

Bus Ports)

Two Universal Serial Bus ports

(USB2.0) are located to the right of

the mouse port. See the table on the

right for pin defi nitions.

5-14

Universal Serial Bus Ports

Pin Defi nitions (USB0/1)

USB0

Pin # Defi nition

1 +5V 1 +5V

2 PO- 2 PO-

3 PO+ 3 PO+

4 Ground 4 Ground

USB1

Pin # Defi nition

Page 49

Chapter 5: Advanced Serverboard Setup

USB2/3 Headers

Two additional USB2.0 head-

ers (USB2/3) are included on the

serverboard. These may be con-

nected to provide front side access.

USB cables (not included) are needed

for the connections. See the table on

the right for pin defi nitions.

Serial Ports

The COM1 serial port is located be-

side the USB. COM2 is a header lo-

cated near the IDE1 header. See the

table on the right for pin defi nitions.

Extra Universal Serial Bus Headers

Pin Defi nitions (USB2/3)

USB2

Pin # Defi nition

1 +5V 1 +5V

2 PO- 2 PO-

3 PO+ 3 PO+

4 Ground 4 Ground

5 Key 5 No connection

Serial Port Pin Defi nitions

Pin # Defi nition Pin # Defi nition

1 DCD 6 DSR

2RXD 7RTS

3 TXD 8 CTS

4 DTR 9 RI

5 Ground 10 NC

USB3/4

Pin # Defi nition

(COM1/COM2)

Fan Headers

The H8DSR-8 has five 3-pin fan

headers. Fan speed is controlled via

Thermal Management with a BIOS

setting. See the table on the right for

pin defi nitions.

ATX PS/2 Keyboard and

PS/2 Mouse Ports

The ATX PS/2 keyboard and the PS/2

mouse ports are located to the left of

the COM1 port. See the table on the

right for pin defi nitions.

Note: NC indicates no connection.

Fan Header

Pin Defi nitions

(FAN1-5)

Pin# Defi nition

1 FAN2 Power

2 FAN2 Tachometer

3 Ground

4 Ground

5 FAN1 Tachometer

6 FAN1 Power

PS/2 Keyboard and Mouse Port

Pin Defi nitions

(KB/Mouse)

Pin # Defi nition Pin # Defi nition

1 Data 4 VCC

2 NC 5 Clock

3 Ground 6 NC

5-15

Page 50

AS1020S-8 User's Manual

Power LED/Speaker

On JD1, pins 1, 2, and 3 are for the

power LED and pins 4 through 7 are

for the speaker. See the tables on the

right for pin defi nitions.

Note: The speaker connector pins are

for use with an external speaker. If

you wish to use the onboard speaker,

you should close pins 6 and 7 with a

jumper.

JLAN1/2 (Ethernet Ports)

Two Gigabit Ethernet ports (desig-

nated JLAN1 and JLAN2) are located

beside the VGA port. These ports

accept RJ45 type cables.

PWR LED Connector

Pin Defi nitions (JD1)

Pin# Defi nition

1 +Vcc

2 -Vcc

3 -Vcc

Speaker Connector

Pin Defi nitions (JD1)

Pin# Defi nition

4 Red wire, Speaker data

5 No connection

6 Buzzer signal

7 Speaker data

IPMB Header

The Intelligent Platform Management

Bus (IPMB) header is located at J22.

Connect the appropriate cable here to

utilize IPMB on your system. See the

table on the right for pin defi nitions.

SMB Power (I2C)

The header at J24 is for SMB, which

may be used to monitor the status of

the power supply. See the table on the

right for pin defi nitions.

5-16

IPMB

Pin Defi nitions (J22)

Pin# Defi nition

1 Data

2 Ground

3 Clock

4N/A

SMB Power (I2C)

Pin Defi nitions (J24)

Pin# Defi nition

1 Clock

2 SMB Data

3N/A

4N/A

5N/A

Page 51

Chapter 5: Advanced Serverboard Setup

Overheat LED

Connect an LED to the JOH1 header

to provide warning of a chassis over-

heating condition. See the table on the

right for pin defi nitions.

Wake-On-Ring

The Wake-On-Ring header is desig-

nated JWOR. This function allows

your computer to receive and "wake-

up" by an incoming call to the modem

when in suspend state. See the table

on the right for pin defi nitions. You

must have a Wake-On-Ring card and

cable to use this feature.

Overheat LED

Pin Defi nitions (JOH1)

Pin# Defi nition

1 +5V

2 OH Active

Wake-On-Ring

Pin Defi nitions

(JWOR)

Pin# Defi nition

1 Ground (Black)

2 Wake-up

Wake-On-LAN

The Wake-On-LAN header is desig-

nated JWOL1. See the table on the

right for pin defi nitions. You must

have a LAN card with a Wake-On-LAN

connector and cable to use the Wake-

On-LAN feature.

Chassis Intrusion

A Chassis Intrusion header is located

at JL1. Attach the appropriate cable

to inform you of a chassis intrusion.

JSLED

The SCSI LED header is designated

JSLED. This header is used to display

all SATA activity. See the table on the

right for pin defi nitions. Pins 6-9 are

no connection. Pin 10 is absent.

Wake-On-LAN

Pin Defi nitions

(JWOL1)

Pin# Defi nition

1 +5V Standby

2 Ground

3 Wake-up

Chassis Intrusion

Pin Defi nitions (JL1)

Pin# Defi nition

1 Intrusion Input

Pin# Defi nition Pin# Defi nition

1 SATA0 Act. 6 NC

2 SATA1 Act. 7 NC

3 SATA2 Act. 8 NC

4 SATA3 Act. 9 NC

5 Common

2 Ground

SCSI LED Activity Header

Pin Defi nitions (JSLED)

5-17

Page 52

AS1020S-8 User's Manual

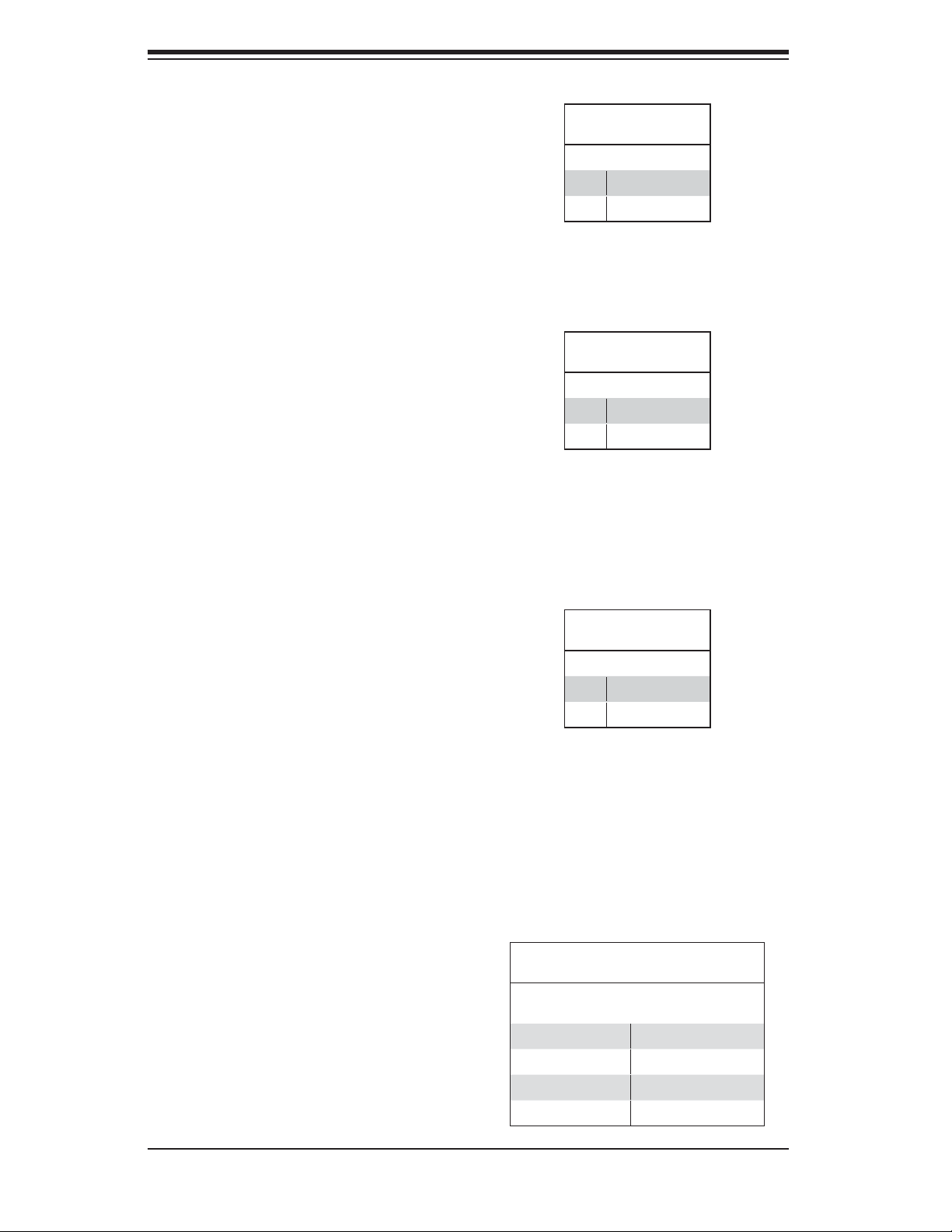

5-10 Jumper Settings

Explanation of

Jumpers

To modify the operation of the

serverboard, jumpers can be used to

choose between optional settings.

Jumpers create shorts between two

pins to change the function of the

connector. Pin 1 is identifi ed with

a square solder pad on the printed

circuit board. See the diagram at

right for an example of jumping pins

1 and 2. Refer to the serverboard

layout page for jumper locations.

Note 1: On two-pin jumpers,

"Closed" means the jumper is on

and "Open" means the jumper is

off the pins.

CMOS Clear

Connector

321

Pins

Jumper

321

Setting

JBT1 is used to clear CMOS and will also clear any passwords. Instead of pins,

this jumper consists of contact pads to prevent accidentally clearing the contents

of CMOS.

To clear CMOS,

1) First power down the system and unplug the power cord(s).

2) With the power disconnected, short the CMOS pads with a metal object such as

a small screwdriver for at least four seconds.

3) Remove the screwdriver (or shorting device).

4) Reconnect the power cord(s) and power on the system.

Notes:

Do not use the PW_ON connector to clear CMOS.

The onboard battery does not need to be removed when clearing CMOS, however

you must short JBT1 for at least four seconds.

JBT1 contact pads

5-18

Page 53

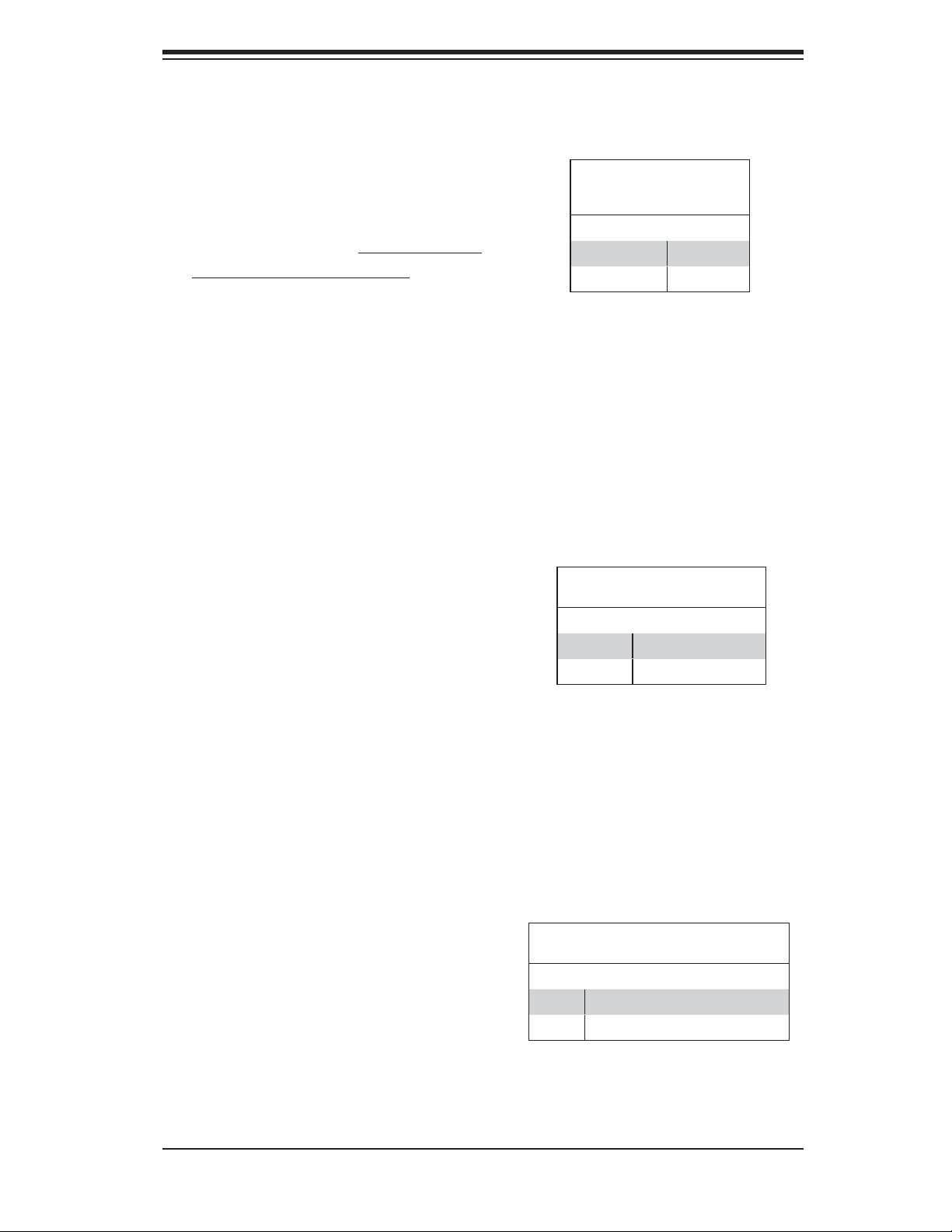

PCI-X Slot Frequency Select

Jumpers JPXAO and JPXBO are

used to set the speed of PCI-X slots

#7 and #6, respectively. The recom-

mended (default) setting is open for

Auto. See the table on the right for

jumper settings.

Onboard Speaker Enable/

Disable

The JD1 header allows you to use

either an external speaker or the

internal (onboard) speaker. To use

the internal (onboard) speaker, close

pins 6 and 7 with a jumper. To use an

external speaker, connect the speaker

wires to pins 4 through 7 of JD1. See

the table on the right for settings and

the table associated with the Power

LED/Speaker connection (previous

section) for pin defi nitions.

Chapter 5: Advanced Serverboard Setup

PCI-X Slot

Frequency Select

Jumper Settings

(JPXAO/JPXBO)

Jumper Setting Defi nition

Pins 1-2 66 MHz PCI-X

Pins 2-3 66 MHz PCI

Open Auto

Onboard Speaker Enable/Disable

Pin Defi nitions (JD1)

Pins Defi nition

6-7 Jump for onboard speaker

4-7 Attach external speaker wires

Watch Dog

JWD1 controls the Watch Dog function.

Watch Dog is a system monitor that

can reboot the system when a software

application hangs. Pins 1-2 will cause

WD to reset the system if an applica-

tion has frozen. Pins 2-3 will generate

a non-maskable interrupt signal for the

application that is frozen. See the table

on the right for jumper settings. Watch

Dog must also be enabled in BIOS.

5-19

Watch Dog

Jumper Settings (JWD1)

Jumper Setting Defi nition

Pins 1-2 Reset

Pins 2-3 NMI

Open Disabled

Note: When enabled, the user needs to

write their own application software in or-

der to disable the Watch Dog Timer.

Page 54

AS1020S-8 User's Manual

SCSI Controller Enable/

Disable

Jumper JPA1 is used to enable or dis-

able the Adaptec AIC-7902W SCSI

controller. The default setting is on pins

1-2 to enable SCSI. See the table on

right for jumper settings.

SCSI Termination Enable/

Disable

Jumpers JPA2 and JPA3 are used to

enable or disable termination for SCSI

channels A and B, respectively. The

default setting is open to enable termi-

nation. See the table on right for pin

defi nitions.

Note: In order for the SCSI drives to

function properly, please do not change

the default setting (enabled) set by the

SCSI Enable/Disable

Jumper Settings (JPA1)

Both Jumpers Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

SCSI Term. Enable/Disable

Jumper Settings (JPA2/JPA3)

Jumper Setting Defi nition

Open Enabled

Closed Disabled

manufacturer.)

VGA Enable/Disable

JPG1 allows you to enable or disable

the VGA port. The default position is

on pins 1 and 2 to enable VGA. See

the table on the right for jumper set-

tings.

Power Force On

JPF allows you to enable or disable the

Power Force On function. If enabled,

system power will always stay on. If

disabled (the default setting), the user

needs to depress the power button to

power up the system.

VGA Enable/Disable

Jumper Settings (JPG1)

Jumper Setting Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

Power Force On

Jumper Settings (JPF

Jumper Setting Defi nition

Closed Force On

Open Disabled

5-20

Page 55

I2C to PCI Enable/Disable

JI2C1/2 pair of jumpers allow you to

connect the System Management Bus

to any one of the PCI slots. The default

setting is closed for both jumpers to en-