Page 1

SUPER

SUPERSERVER 6016T-6RFT+

SUPERSERVER 6016T-6RF+

®

USER’S MANUAL

1.0a

Page 2

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software and documentation, is the property of Supermicro and/or its licensors, and is supplied only under a license.

Any use or reproduction of this product is not allowed, except as expressly permitted by the terms

of said license.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT , SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTW ARE, OR DA TA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for all

claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the manufacturer’s instruction manual, may cause harmful interference

with radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to the

State of California to cause birth defects and other reproductive harm.

Manual Revision 1.0

Release Date: August 26, 2013

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2013 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Page 3

Preface

About This Manual

This manual is written for professional system integrators and PC technicians.

It provides information for the installation and use of the SuperServer 6016T6RFT+/6016T-6RF+. Installation and maintenance should be performed by experienced technicians only.

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a checklist of the main components included with the

server system and describes the main features of the X8DTU-6TF+/X8DTU-6F+

serverboard and the SC819TQ-R700U chassis, which comprise the SuperServer

6016T-6RFT+/6016T-6RF+.

Preface

Chapter 2: Server Installation

This chapter describes the steps necessary to install the SuperServer into a rack and

check out the server confi guration prior to powering up the system. If your server

was ordered without processor and memory components, this chapter will refer you

to the appropriate sections of the manual for their installation.

Chapter 3: System Interface

Refer here for details on the system interface, which includes the functions and

information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

Chapter 4: Warning Statements

You should thoroughly familiarize yourself with this chapter for a general overview

of safety precautions that should be followed when installing and servicing the

SuperServer 6016T-6RFT+/6016T-6RF+.

iii

Page 4

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Chapter 5: Advanced Serverboard Setup

Chapter 5 provides detailed information on the X8DTU-6TF+/X8DTU-6F+

serverboard, including the locations and functions of connections, headers and

jumpers. Refer to this chapter when adding or removing processors or main memory

and when reconfi guring the serverboard.

Chapter 6: Advanced Chassis Setup

Refer to Chapter 6 for detailed information on the SC819TQ-R700U server chassis.

You should follow the procedures given in this chapter when installing, removing or

reconfi guring SATA or peripheral drives and when replacing system power supply

modules and cooling fans.

Chapter 7: BIOS

The BIOS chapter includes an introduction to BIOS and provides detailed information on running the CMOS Setup Utility.

Appendix A: BIOS Error Beep Codes

Appendix B: System Specifi cations

iv

Page 5

Notes

Preface

v

Page 6

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Table of Contents

Chapter 1 Introduction

1-1 Overview .........................................................................................................1-1

1-2 Serverboard Features .....................................................................................1-2

Processors ......................................................................................................1-2

Memory ...........................................................................................................1-2

UIO ..................................................................................................................1-2

Onboard SAS .................................................................................................. 1-2

Onboard Serial ATA ........................................................................................1-2

Rear I/O Ports ................................................................................................. 1-3

Graphics Controller ......................................................................................... 1-3

Other Features ................................................................................................ 1-3

1-3 Server Chassis Features ................................................................................1-3

System Power ................................................................................................. 1-3

Hard Drives ..................................................................................................... 1-3

PCI Expansion Slots ....................................................................................... 1-4

Front Control Panel .........................................................................................1-4

Cooling System ............................................................................................... 1-4

1-4 Contacting Supermicro ....................................................................................1-6

Chapter 2 Server Installation

2-1 Overview .........................................................................................................2-1

2-2 Unpacking the System .................................................................................... 2-1

2-3 Preparing for Setup .........................................................................................2-1

Choosing a Setup Location ............................................................................. 2-1

2-4 Warnings and Precautions .............................................................................. 2-2

Rack Precautions ............................................................................................ 2-2

Server Precautions .......................................................................................... 2-2

Rack Mounting Considerations .......................................................................2-3

Ambient Operating Temperature ................................................................2-3

Reduced Airfl ow .........................................................................................2-3

Mechanical Loading ...................................................................................2-3

Circuit Overloading .....................................................................................2-3

Reliable Ground .........................................................................................2-3

2-5 Installing the System into a Rack ................................................................... 2-4

Identifying the Sections of the Rack Rails ...................................................... 2-4

Installing the Inner Rails .................................................................................2-4

Installing the Outer Rails ................................................................................. 2-5

vi

Page 7

Table of Contents

Installing the Server into a Telco Rack ...........................................................2-6

2-6 Checking the Serverboard Setup .................................................................... 2-8

Chapter 3 System Interface

3-1 Overview .........................................................................................................3-1

3-2 Control Panel Buttons ..................................................................................... 3-1

3-3 Control Panel LEDs ........................................................................................3-2

3-4 Drive Carrier LEDs ..........................................................................................3-3

Chapter 4 Standardized Warning Statements for AC Systems

4-1 About Standardized Warning Statements .......................................................4-1

Warning Defi nition ...........................................................................................4-1

Installation Instructions .................................................................................... 4-4

Circuit Breaker ................................................................................................4-5

Power Disconnection Warning ........................................................................ 4-6

Equipment Installation .....................................................................................4-8

Restricted Area ................................................................................................4-9

Battery Handling ............................................................................................ 4-10

Redundant Power Supplies ..........................................................................4-12

Backplane Voltage ........................................................................................ 4-13

Comply with Local and National Electrical Codes ........................................ 4-14

Product Disposal ........................................................................................... 4-15

Hot Swap Fan Warning ................................................................................. 4-16

Power Cable and AC Adapter ...................................................................... 4-18

Chapter 5 Advanced Serverboard Setup

5-1 Handling the Serverboard ............................................................................... 5-1

Precautions .....................................................................................................5-1

Unpacking .......................................................................................................5-1

5-2 Processor and Heatsink Installation................................................................5-2

Installing LGA1366 Processors ....................................................................... 5-2

Installing the Heatsink .....................................................................................5-4

Removing the Heatsink ................................................................................... 5-5

5-3 Connecting Cables .......................................................................................... 5-6

Connecting Data Cables ................................................................................. 5-6

Connecting Power Cables ..............................................................................5-6

Connecting the Control Panel ......................................................................... 5-6

5-4 I/O Ports ..........................................................................................................5-7

5-5 Installing Memory ............................................................................................ 5-8

5-6 Adding PCI Cards ......................................................................................... 5-12

5-7 Serverboard Details ...................................................................................... 5-13

vii

Page 8

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

X8DTU-6TF+/X8DTU-6F+ Quick Reference ................................................. 5-14

5-8 Connector Defi nitions .................................................................................... 5-15

5-9 Jumper Settings ............................................................................................5-23

5-10 Onboard Indicators ........................................................................................5-25

5-11 SATA Port Connections .................................................................................5-27

5-12 Installing Software ......................................................................................... 5-28

SuperDoctor III .............................................................................................. 5-29

5-13 Onboard Battery ............................................................................................ 5-30

Chapter 6 Advanced Chassis Setup

6-1 Static-Sensitive Devices ..................................................................................6-1

Precautions .....................................................................................................6-1

6-2 Control Panel ..................................................................................................6-2

6-3 System Fans ...................................................................................................6-3

System Fan Failure .........................................................................................6-3

Hard Drive Installation ..................................................................................... 6-5

Hard Drive Backplane ..................................................................................... 6-6

DVD-ROM Drive Installation ........................................................................... 6-7

6-4 Power Supply .................................................................................................. 6-8

Power Supply Failure ......................................................................................6-8

Chapter 7 BIOS

7-1 Introduction ......................................................................................................7-1

Starting BIOS Setup Utility .............................................................................. 7-1

How To Change the Confi guration Data ......................................................... 7-1

Starting the Setup Utility ................................................................................. 7-2

7-2 Main Setup ...................................................................................................... 7-2

7-3 Advanced Setup Confi gurations......................................................................7-4

7-4 Security Settings ...........................................................................................7-25

7-5 Boot Confi guration ........................................................................................ 7-27

7-6 Exit Options ................................................................................................... 7-28

Appendix A BIOS Error Beep Codes

Appendix B System Specifi cations

viii

Page 9

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

The SuperServer 6016T-6RFT+/6016T-6RF+ is a comprised of two main subsystems: the SC819TQ-R700U 1U server chassis and the X8DTU-6TF+/X8DTU-6F+

dual processor serverboard. Please refer to our web site for information on operating

systems that have been certifi ed for use with the system (www.supermicro.com).

In addition to the serverboard and chassis, various hardware components have

been included with the 6016T-6RFT+/6016T-6RF+, as listed below:

• One slim DVD-ROM drive (DVM-TEAC-DVD-SBT)

• Five sets of 4-cm counter-rotating fans (FAN-0086L4)

• One air shroud (MCP-310-81901-0B)

• Two passive CPU heatsinks (SNK-P0037P)

• Riser Cards: (see Section 5-6 for details)

One RSC-R1UU-2E8

One RSC-R1UU-E8R+

• SATA Accessories

One SATA backplane (BPN-SAS-815TQ)

One SAS cable (CBL-00288L)

Four drive carriers (MCP-220-00075-0B)

• One rackmount kit (MCP-290-00062-0N)

• One SuperServer 6016T-6RFT+/6016T-6RF+ User's Manual

Note: For your system to work properly, please follow the links below to download

all necessary drivers/utilities for your server.

• Product drivers and utilities: ftp://ftp.supermicro.com

• Product safety info: http://super-dev/about/policies/safety_information.cfm

• If you have any questions, please contact our support team at:

support@supermicro.com

1-1

Page 10

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

1-2 Serverboard Features

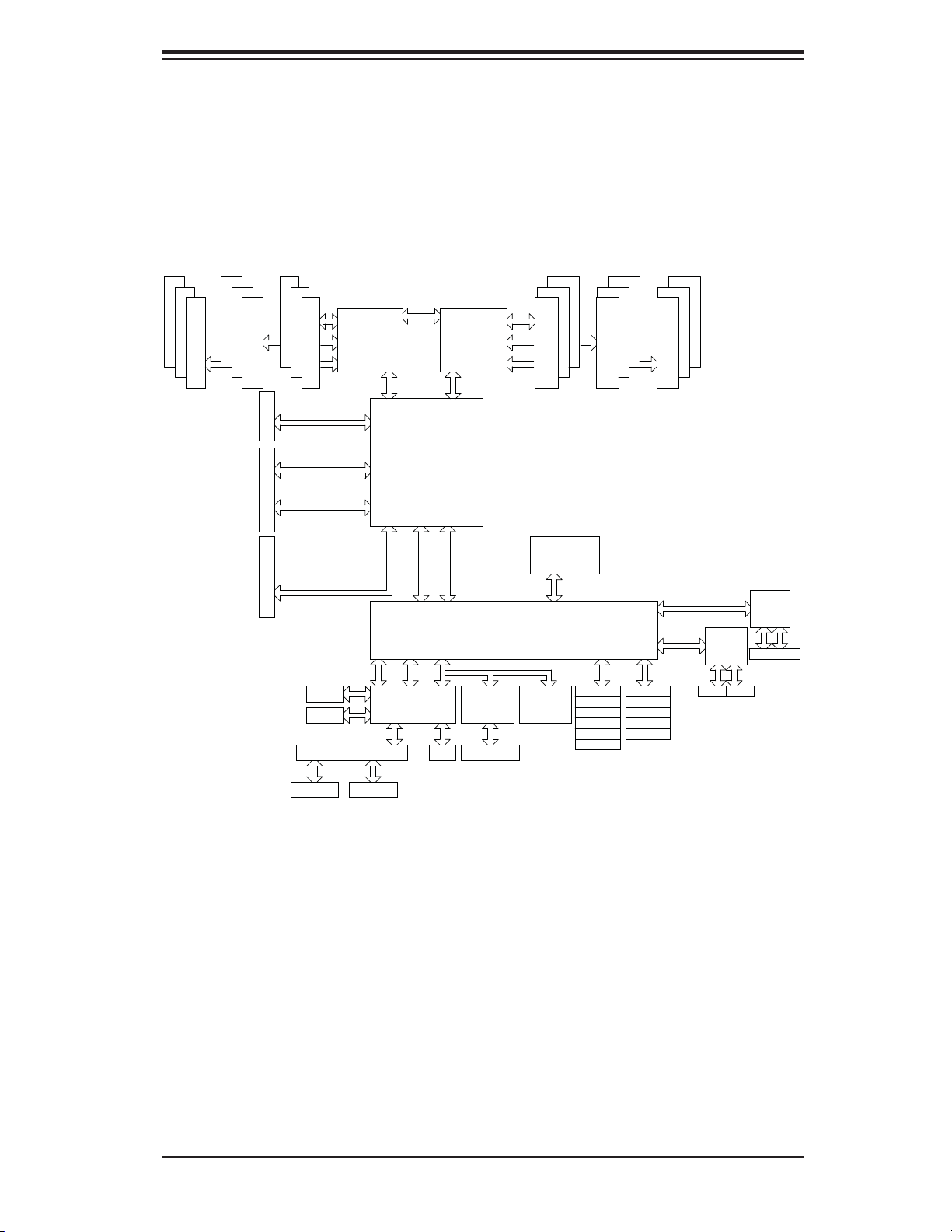

At the heart of the SuperServer 6016T-6RFT+/6016T-6RF+ lies the X8DTU-6TF+/

X8DTU-6F+, a dual processor serverboard based on the Intel® 5520 chipset. Below

are the main features of the serverboard. (See Figure 1-1 for a block diagram of

the chipset).

Processors

The X8DTU-6TF+/X8DTU-6F+ supports single or dual Intel® 5500/5600 Series

processors in LGA1366 sockets. Please refer to our web site for a complete listing

of supported processors.

Memory

The X8DTU-6TF+/X8DTU-6F+ features 18 DIMM sockets that can support up to 288

GB of registered ECC DDR3-1333/1066/800 or 48 GB of unbuffered ECC/non-ECC

DDR3-1333/1066/800 SDRAM. Please refer to Chapter 5 for installing memory.

UIO

The X8DTU-6TF+/X8DTU-6F+ is a spe cially- designed ser verboa rd that features

Super micro's UIO ( Universal I /O) technolog y. UIO ser verboar ds have a PCI Express 2.0 x8 slot that can support any one of several types of UIO card types to add

SAS por ts, SATA ports, add itional L AN p ort s or other addi tional f unctio ns to the

ser verbo ard. Thi s allow s the use r to tail or the se rve rboa rd to the ir own ne eds.

Note: the ser ver does n ot com e with a UI O card i nstal led.

Onboard SAS

An onboard LSI 2108 SAS controller in integrated into the X8DTU-6TF+/X8DTU6F+. The hot-swap SAS drives are connected to a backplane that provides power,

bus termination and confi guration settings.

Note: The operating system you use must have RAID support to enable the

hot-swap capability and RAID function of the SAS drives. RAID 0, 1, 5, 6,

10, 50 and 60 is suppor ted. Refer to the following ftp site for setup guidelines

<ftp://ftp.supermicro.com/driver/SAS/LSI/LSI _ SAS_EmbM RAID_ SWUG.pdf >.

Onboard Serial ATA

An on -c hip (IC H10R) SATA controller is i ntegrate d into the X8DTU-6TF+/X8DTU6F+ to provid e a six-por t, 3 Gb /sec SATA subsystem, whic h is R AID 0, 1, 5 and

1-2

Page 11

Chapter 1: Introduction

10 suppor ted ( R A ID 5 is s upp or te d wit h Win dows O S onl y). The SATA drives ar e

hot-swappable units.

Note: You must have RAID set up to enable the hot-swap capability of the SATA

drives. D ocum entati on on R AI D setup gui deline s can be fo und on our we b site.

Rear I/O Ports

The color-coded I/O ports include one COM port, a VGA (monitor) port, two USB

2.0 ports, PS/2 mouse and keyboard ports, one dedicated IPMI LAN port and two

gigabit Ethernet ports. The 6016T-6RFT+ (X8DTU-6TF+) includes two additional

Ethernet ports.

Graphics Controller

The X8DTU-6TF+/X8DTU-6F+ features an integrated Matrox G200eW graphics

chip.

Other Features

Other onboard features that promote system health include onboard voltage monitors, auto-switching voltage regulators, chassis and CPU overheat sensors, virus

protection and BIOS rescue.

1-3 Server Chassis Features

The 6016T-6RFT+/6016T-6RF+ is built upon the SC819TQ-R700U chassis. Details

on the chassis and on servicing procedures can be found in Chapter 6.The following

is a general outline of the main features of the chassis.

System Power

The SC819TQ-R700U features a redundant 700W power supply consisting of two

power modules. The system does not need to be shut down when replacing or

removing a single power supply module.

Hard Drives

The SC819TQ-R700U chassis was designed to support four hot-swap SAS or

SATA hard drives.

1-3

Page 12

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

PCI Expansion Slots

Two riser cards are included. The RSC-R1UU-E8R+ is located on the right side of

the chassis and supports one low- profi le PCI- E x4 card (in a x 8 slot). The RSC-

R1UU-2E8 is located on the left side of the chassis and supports two PCI- E x8

add- on cards. See our web site for details (http://www.supermicro.com/products/

nfo/UIO.cfm). See section 5-6 of this manual for details.

Front Control Panel

The chassis' control panel provides you with system monitoring and control. LEDs

indicate system power, HDD activity, network activity (2), overheat/fan/power failure

and UID (Unit Identifi er). A main power button and a UID button is also included.

Cooling System

The SC819TQ-R700U has an innovative cooling design that features fi ve sets

of 4-cm counter-rotating fans located in the middle section of the chassis. There

is a "Fan Speed Control Mode" setting in BIOS that allows chassis fan speed to

be determined by system temperature. The power supply module also includes a

cooling fan.

1-4

Page 13

Chapter 1: Introduction

Figure 1-1. Intel 5520 + IOH-36D/ICH10R Chipset:

System Block Diagram

Note: This is a general block diagram. Please see Chapter 5 for details.

PORT0

PORT

7,8,9,10

PORT

1,2

PORT

3,4

PORT

5,6

USB

QPI

PORT

8,10

BMC

QPI

IOH

36D

ESI

ESI

LPC

RJ45

Processor#0

QPI

PORT0

CLINK

CLINK

ICH10R

PS2 KB/MS

A

B

C

DDR3 DIMM

DDR3 DIMM

PCI-E x16

in x16 slot

PCI-E x8

in x4 slot

PCI-Ex8

B

C

DDR3 DIMM

Gen2 x16

Gen2 x4

Gen2 x8

Gen2 x8

(Lane Reversal)

COMA

COMB

VGA SWITCH

Processor#1

PORT1 PORT1

PCI

SIO

D

E

F

ATME L

AT25DF321

SPI

TPM

DDR3 DIMM

E

PCIE Port 1-4

PCIE Port 5-6

SATA

SATA #0

SATA #1

SATA #2

SATA #3

SATA #4

SATA #5

DDR3 DIMM

USB

F

USB 0/1

USB 2/3

USB 4/5

USB 6

USB 7

DDR3 DIMM

Gen1 x4

Gen1x2

KAWELA

RJ45 RJ45

KAWELA

RJ45 RJ45

VGA VGA

1-5

Page 14

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

1-4 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site:

Europe

Address: Super Micro Computer B.V.

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

Asia-Pacifi c

Address: Super Micro Computer, Inc.

www.supermicro.com

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

3F, No. 150, Jian 1st Rd.

Zhonghe Dist., New Taipei City 23511

Taiwan (R.O.C)

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3992

Web Site:

Technical Support:

Email: support@supermicro.com.tw

Tel: +886-(2)-8226-3990

www.supermicro.com.tw

1-6

Page 15

Chapter 2: Server Installation

Chapter 2

Server Installation

2-1 Overview

This chapter provides a quick setup checklist to get your 6016T-6RFT+/6016T-6RF+

up and running. Following these steps in the order given should enable you to have

the system operational within a minimum amount of time. This quick setup assumes

that your system has come to you with the processors and memory pre-installed. If

your system is not already fully integrated with a serverboard, processors, system

memory etc., please turn to the chapter or section noted in each step for details on

installing specifi c components.

2-2 Unpacking the System

You should inspect the box the 6016T -6RFT+/6016T-6RF+ was shipped in and note

if it was damaged in any way. If the server itself shows damage you should fi le a

damage claim with the carrier who delivered it.

Decide on a suitable location for the rack unit that will hold the 6016T-6RFT+/6016T6RF+. It should be situated in a clean, dust-free area that is well ventilated. Avoid

areas where heat, electrical noise and electromagnetic fi elds are generated. You

will also need it placed near a grounded power outlet. Be sure to read the Rack

and Server Precautions in the next section.

2-3 Preparing for Setup

The box the 6016T-6RFT+/6016T-6RF+ was shipped in should include two sets of

rail assemblies, two rail mounting brackets and the mounting screws you will need

to install the system into the rack. Follow the steps in the order given to complete

the installation process in a minimum amount of time. Please read this section in

its entirety before you begin the installation procedure outlined in the sections that

follow.

Choosing a Setup Location

• Leave enough clearance in front of the rack to enable you to open the front door

completely (~25 inches) and approximately 30 inches of clearance in the back

of the rack to allow for suffi cient airfl ow and ease in servicing.This product is for

2-1

Page 16

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

installation only in a Restricted Access Location (dedicated equipment rooms,

service closets and the like).

• This product is not suitable for use with visual display work place devices

acccording to §2 of the the German Ordinance for Work with Visual Display Units.

2-4 Warnings and Precautions

Rack Precautions

• Ensure that the leveling jacks on the bottom of the rack are fully extended to

the fl oor with the full weight of the rack resting on them.

• In single rack installation, stabilizers should be attached to the rack. In multiple

rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the

rack.

• You should extend only one component at a time - extending two or more si-

multaneously may cause the rack to become unstable.

Server Precautions

• Review the electrical and general safety precautions in Chapter 4.

• Determine the placement of each component in the rack before you install the

rails.

• Install the heaviest server components on the bottom of the rack fi rst, and then

work up.

• Use a regulating uninterruptible power supply (UPS) to protect the server from

power surges, voltage spikes and to keep your system operating in case of a

power failure.

• Allow the hot plug SAS/SATA drives and power supply modules to cool before

touching them.

• Always keep the rack's front door and all panels and components on the servers

closed when not servicing to maintain proper cooling.

2-2

Page 17

Chapter 2: Server Installation

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack environment may be greater than the ambient temperature of the

room. Therefore, consideration should be given to installing the equipment in an

environment compatible with the manufacturer’s maximum rated ambient temperature (Tmra).

Reduced Airfl ow

Equipment should be mounted into a rack so that the amount of airfl ow required

for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not

arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might have

on overcurrent protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply connections other than the direct connections to the branch circuit (i.e. the use of power

strips, etc.).

Warning! To prevent bodily injury when mounting or servicing this unit in a

rack, you must take special precautions to ensure that the system remains

stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in

the rack.

• When mounting this unit in a partially fi lled rack, load the rack from the bottom

to the top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

2-3

Page 18

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

2-5 Installing the System into a Rack

This section provides information on installing the 6016T-6RFT+/6016T-6RF+ into

a rack unit with the rack rails provided. If the system has already been mounted

into a rack, you can skip ahead to Sections 2-5 and 2-6. There are a variety of rack

units on the market, which may mean the assembly procedure will differ slightly.

You should also refer to the installation instructions that came with the rack unit

you are using.

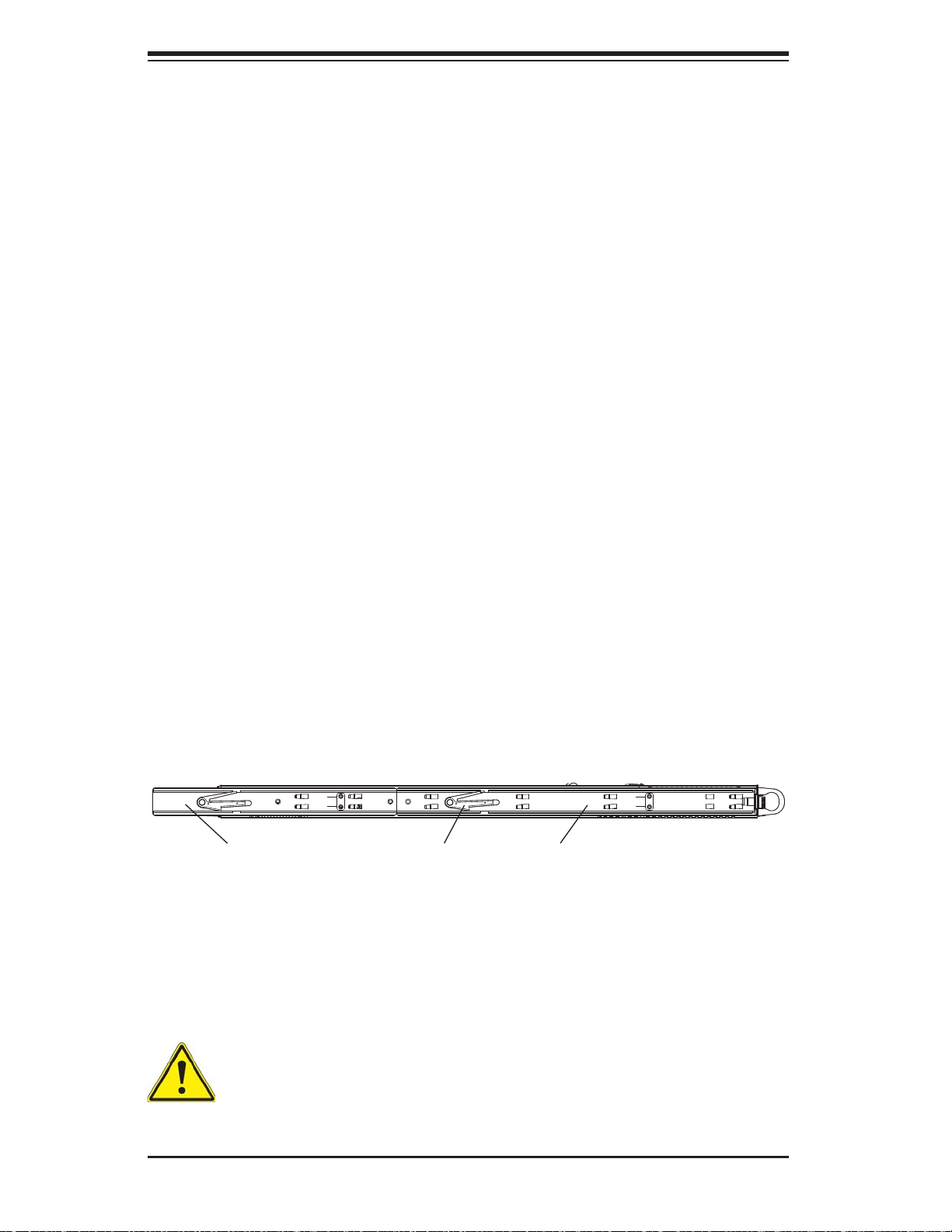

Identifying the Sections of the Rack Rails

You should have received two rack rail assemblies in the rack mounting kit. Each

assembly consists of two sections: an inner fi xed chassis rail that secures directly

to the server chassis and an outer fi xed rack rail that secures directly to the rack

itself (see Figure 2-1). Two pairs of short brackets to be used on the front side of

the outer rails are also included.

Installing the Inner Rails

Both the left and right side inner rails have been pre-attached to the chassis. Proceed to the next step.

Figure 2-1. Identifying the Sections of the Rack Rails

(left side rail shown)

Inner Rail Outer RailLocking Tab

Warning: do not pick up the server with the front handles. They are de-

signed to pull the system from a rack only.

2-4

Page 19

Chapter 2: Server Installation

Installing the Outer Rails

Installing the Outer Rails to the Rack

1. Measure the distance from the front rail to the rear rail of the rack.

2. Attach a short bracket to the front side of the right outer rail and a long

bracket to the rear side of the right outer rail.

3. Adjust both the short and long brackets to the proper distance so that the rail

can fi t snugly into the rack.

4. Secure the short bracket to the front side of the outer rail with two M4 screws

and the long bracket to the rear side of the outer rail with three M4 screws.

5. Repeat these steps for the left outer rail.

Locking Tabs

Both chassis rails have a locking tab, which serves two functions. The fi rst is to

lock the server into place when installed and pushed fully into the rack, which is

its normal position. Secondly, these tabs also lock the server in place when fully

extended from the rack. This prevents the server from coming completely out of the

rack when you pull it out for servicing.

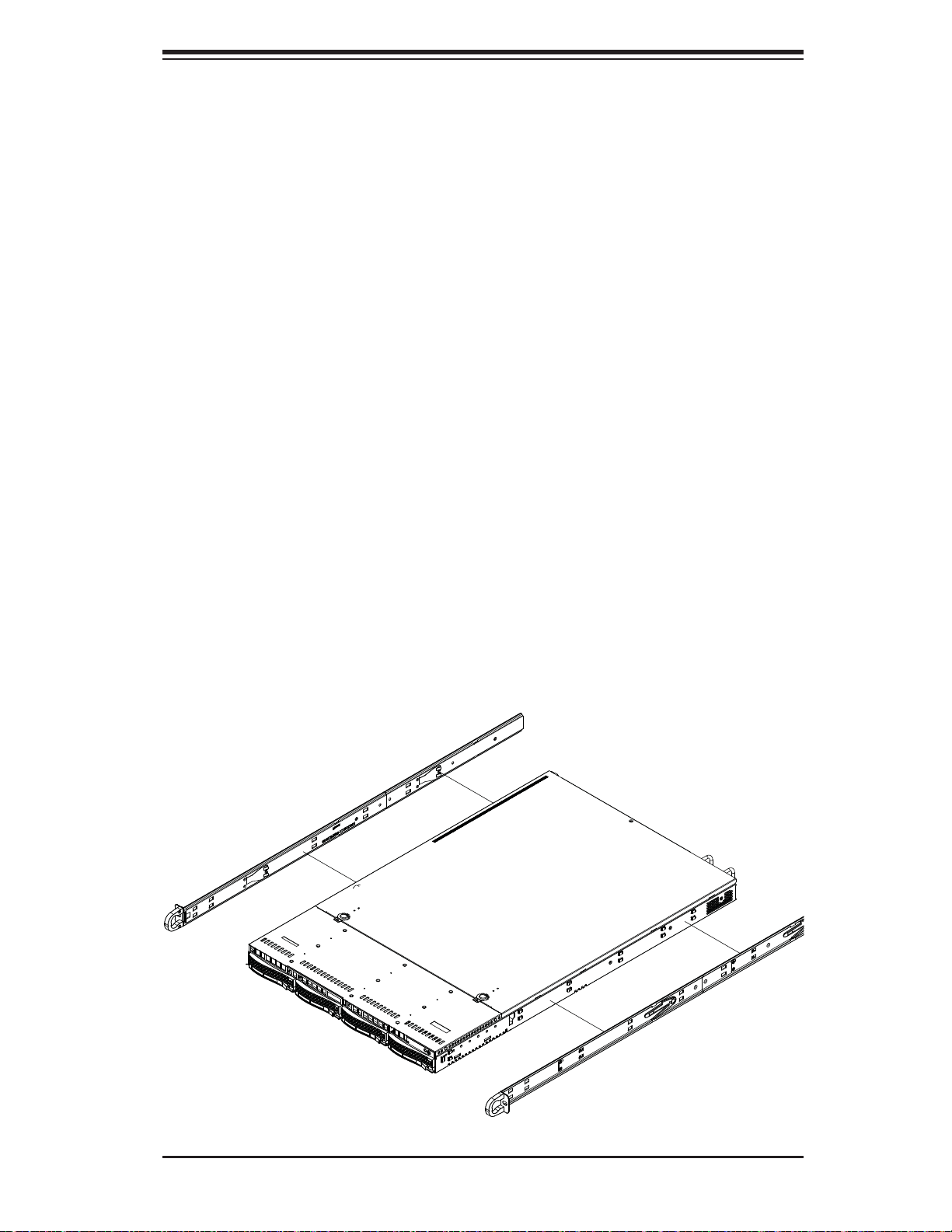

Figure 2-2. Installing the Rack Rails

2-5

Page 20

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Installing the Server into the Rack

Installing the Chassis into a Rack (Figure 2-3)

1. Confi rm that chassis includes the inner rails and rail extensions . Also, confi rm

that the outer rails are installed on the rack.

2. Line chassis rails with the front of the rack rails.

3. Slide the chassis rails into the rack rails, keeping the pressure even on both

sides (you may have to depress the locking tabs when inserting). When the

server has been pushed completely into the rack, you should hear the locking

tabs "click".

4. (Optional) Insert and tightening the thumbscrews that hold the front of the

server to the rack.

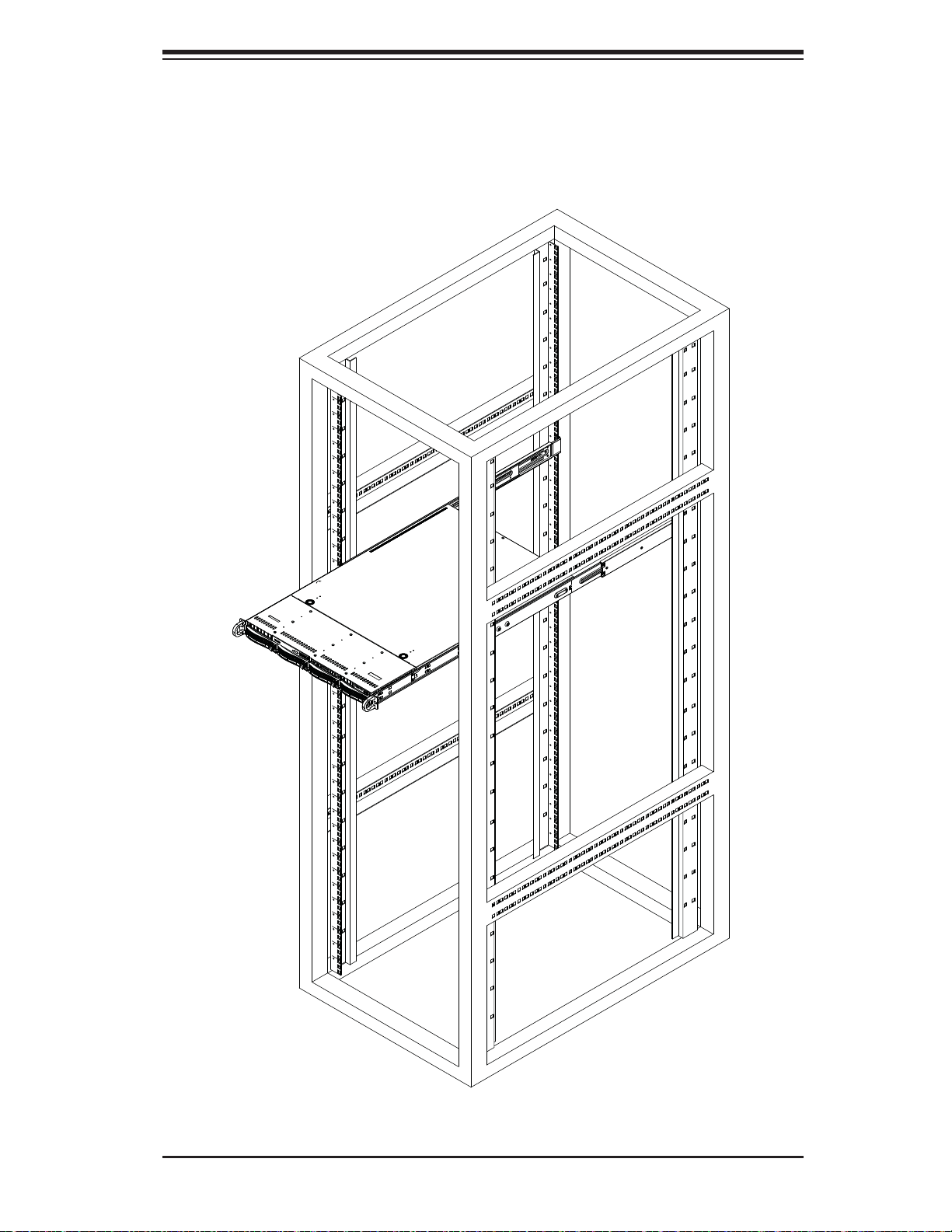

Installing the Server into a Telco Rack

To install the 6016T-6RFT+/6016T-6RF+ into a Telco type rack, use two L-shaped

brackets on either side of the chassis (four total).

1. First, determine how far follow the server will extend out the front of the rack.

Larger chassis should be positioned to balance the weight between front and

back. If a bezel is included on your server, remove it.

2. Then attach the two front brackets to each side of the chassis, then the two

rear brackets positioned with just enough space to accommodate the width of

the telco rack.

3. Finish by sliding the chassis into the rack and tightening the brackets to the

rack.

Note: Figure is for illustrative purposes only. Always install servers to the bottom

of a rack fi rst.

Stability hazard. The rack stabilizing mechanism must be in place, or the

rack must be bolted to the fl oor before you slide the unit out for servicing.

Failure to stabilize the rack can cause the rack to tip over.

2-6

Page 21

Chapter 2: Server Installation

Figure 2-3. Installing the Server into a Rack

2-7

Page 22

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

2-6 Checking the Serverboard Setup

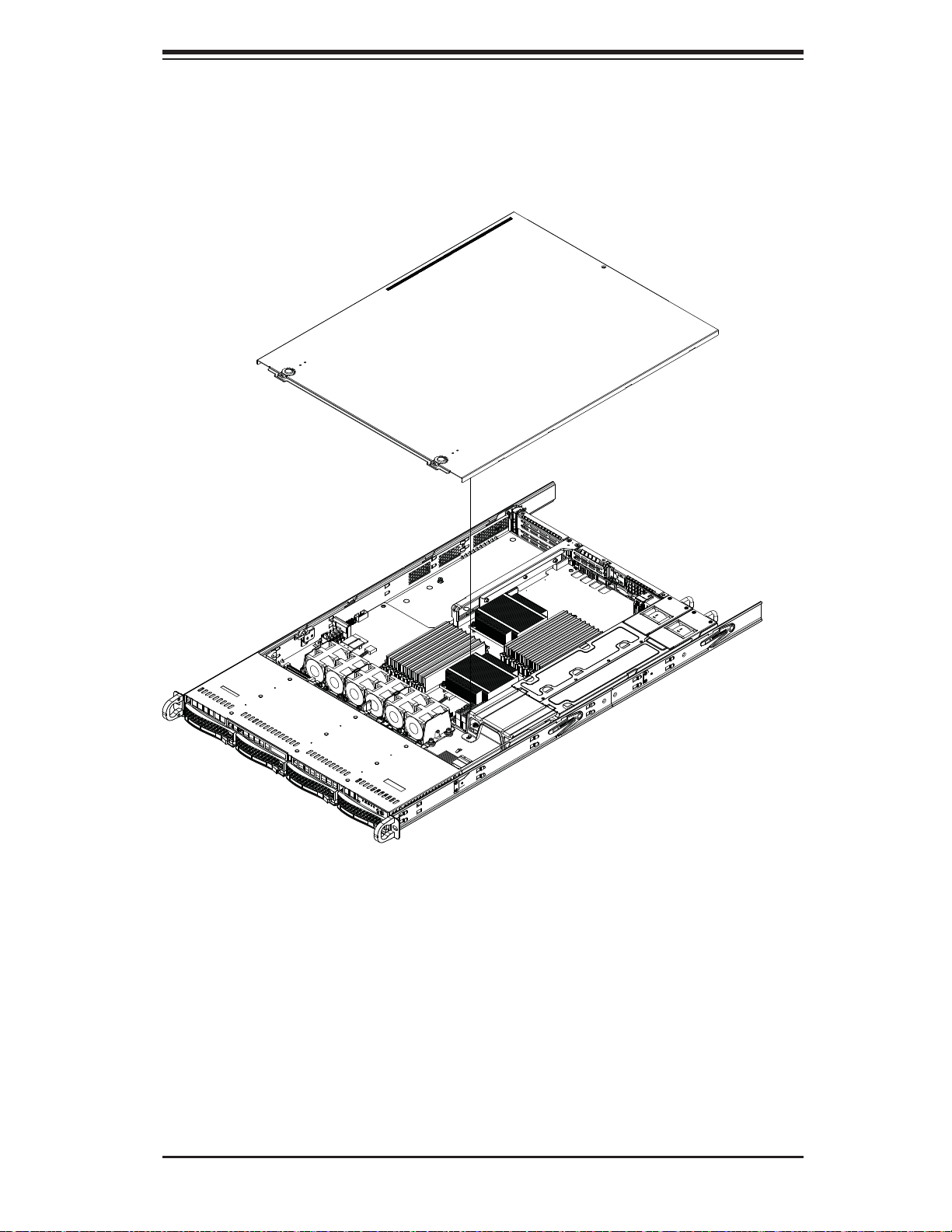

After you install the system in the rack, you will need to open the top cover to

make sure the serverboard is properly installed and all the connections have been

made.

Accessing the Inside of the System

1. First, grasp the two handles on either side and pull the system straight out

until it locks (you will hear a "click").

2. Next, press the two buttons on the top of the chassis to release the top cover.

3. Push the cover away from you (toward the rear of the chassis) until it stops.

You can then lift the top cover from the chassis to gain full access to the

inside of the server.

4. To remove the system from the rack completely, press the locking tabs in

the chassis rails (push the right-side tab down and the left-side tab up) to

continue to pull the system out past the locked position.

Checking the Components

1. You may have one or two processors already installed in the serverboard.

Each processor needs its own heatsink. See Chapter 5 for instructions on

processor and heatsink installation.

2. Your server system may have come with system memory already installed.

Make sure all DIMMs are fully seated in their slots. For details on adding

system memory, refer to Chapter 5.

3. If desired, you can install an add-on card to the system. See Chapter 5 for

details on installing PCI add-on cards.

4. Make sure all power and data cables are properly connected and not blocking

the chassis airfl ow. See Chapter 5 for details on cable connections.

2-8

Page 23

Chapter 2: Server Installation

Figure 2-4. Accessing the Inside of the System

2-9

Page 24

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

2-7 Checking the Drive Bay Setup

Next, you should check to make sure the peripheral drives and the hard drives and

backplane have been properly installed and all connections have been made.

Checking the Drives

1. All drives are accessable from the front of the server. The hard disk drives

can be installed and removed from the front of the chassis without removing

the top chassis cover.

2. A slim DVD-ROM drive should be preinstalled in your server. For servicing

the DVD-ROM drive, you will need to remove the top chassis cover. Refer to

Chapter 6 if you need to reinstall a DVD-ROM drive to the system.

3. Depending upon your system's confi guration, your system may have one or

more drives already installed. If you need to install hard drives, please refer to

Chapter 6.

Checking the Airfl ow

1. Airfl ow is provided by fi ve sets of 4-cm fans (each set of fans consists of

two fans that are mounted back to back). The system component layout was

carefully designed to direct suffi cient cooling airfl ow to the components that

generate the most heat.

2. Note that all power and data cables have been routed in such a way that they

do not block the airfl ow generated by the fans.

Providing Power

1. The last thing you must do is to provide input power to the system. Plug the

power cord from the power supply module into a high-quality power strip that

offers protection from electrical noise and power surges.

2. It is recommended that you use an uninterruptible power supply (UPS)

source.

2-10

Page 25

Chapter 3: System Interface

Chapter 3

System Interface

3-1 Overview

There are several LEDs on the control panel as well as others on the hard drive

carriers to keep you constantly informed of the overall status of the system as well

as the activity and health of specifi c components. There are also two buttons on

the chassis control panel and an on/off switch on the power supply. This chapter

explains the meanings of all LED indicators and the appropriate response you may

need to take.

3-2 Control Panel Buttons

There are three push-buttons located on the front of the chassis. These are (in order

from left to right) A UID button, a reset button and a power on/off button.

UID

Depressing the UID (unit identifi er) button illuminates an LED on both the front and

rear of the chassis for easy system location in large stack confi gurations. The LED

will remain on until the button is pushed a second time. Another UID button on the

rear of the chassis serves the same function.

Reset

The reset button reboots the system.

Power

The main power switch is used to apply or remove power from the power supply

to the server system. Turning off system power with this button removes the main

power but keeps standby power supplied to the system.

3-1

Page 26

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

3-3 Control Panel LEDs

The control panel located on the front of the SC819TQ chassis has fi ve LEDs. These

LEDs provide you with critical information related to different parts of the system.

This section explains what each LED indicates when illuminated and any corrective

action you may need to take.

UID/Overheat/Fan Fail/Power Fail

Blue: This LED turns on when either the front or the rear UID button is pushed.

Pushing either button a second time will turn this LED off.

Red: When this LED fl ashes quickly it indicates a fan failure. When fl ashing slowly

it indicates a power supply failure. When on continuously (on and not fl ashing) it

indicates an overheat condition, which may be caused by cables obstructing the

airfl ow in the system or the ambient room temperature being too warm. Check the

routing of the cables and make sure all fans are present and operating normally.

You should also check to make sure that the chassis covers are installed. Finally,

verify that the heatsinks are installed properly (see Chapter 5). This LED will remain

fl ashing or on as long as the overheat condition exists.

2

NIC2

Indicates network activity on GLAN2 when fl ashing .

1

NIC1

Indicates network activity on GLAN1 when fl ashing.

HDD

Indicates IDE channel activity . On the 6016T -6RFT+/6016T-6RF+ this light indicates

HDD and/or DVD-ROM drive activity when fl ashing.

3-2

Page 27

Chapter 3: System Interface

Power

Indicates power is being supplied to the system's power supply units. This LED

should normally be illuminated when the system is operating.

3-4 Drive Carrier LEDs

• Green: Each SAS/SATA drive carrier has a green LED. When illuminated,

this gre en LED indicate s drive acti vity. A connec tion to the SAS /SATA backplane en ables th is LED to bli nk on and of f whe n that par tic ular dr ive is bein g

acce ssed. Please refer to Chapter 6 for instructions on replacing failed SAS/

SATA drives.

• Red: The red LED to indicate a SAS/SATA drive failure. If one of the drives

fail, you should be notifi ed by your system management software. Please refer

to Chapter 6 for instructions on replacing failed SAS/SATA drives.

3-3

Page 28

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Notes

3-4

Page 29

Chapter 4: Warning Statements for AC Systems

Chapter 4

Standardized Warning Statements for AC Systems

4-1 About Standardized Warning Statements

The following statements are industry standard warnings, provided to warn the user

of situations which have the potential for bodily injury. Should you have questions

or experience difficulty, contact Supermicro's Technical Support department

for assistance. Only certifi ed technicians should attempt to install or confi gure

components.

Read this appendix in its entirety before installing or confi guring components in the

Supermicro chassis.

These warnings may also be found on our web site at http://www.supermicro.com/

about/policies/safety_information.cfm.

Warning Defi nition

Warning!

This warning symbol means danger. You are in a situation that could cause bodily

injury. Before you work on any equipment, be aware of the hazards involved with

electrical circuitry and be familiar with standard practices for preventing accidents.

警告の定義

この警告サインは危険を意味します。

人身事故につながる可能性がありますので、いずれの機器でも動作させる前に、

電気回路に含まれる危険性に注意して、標準的な事故防止策に精通して下さい。

此警告符号代表危险。

您正处于可能受到严重伤害的工作环境中。在您使用设备开始工作之前,必须充分

意识到触电的危险,并熟练掌握防止事故发生的标准工作程序。请根据每项警告结

尾的声明号码找到此设备的安全性警告说明的翻译文本。

此警告符號代表危險。

您正處於可能身體可能會受損傷的工作環境中。在您使用任何設備之前,請注意觸

電的危險,並且要熟悉預防事故發生的標準工作程序。請依照每一注意事項後的號

碼找到相關的翻譯說明內容。

4-1

Page 30

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

ןונקת תורהצהאהרהז

Warnung

WICHTIGE SICHERHEITSHINWEISE

Dieses Warnsymbol bedeutet Gefahr. Sie befi nden sich in einer Situation, die zu

Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit den

Gefahren elektrischer Schaltungen und den üblichen Verfahren zur Vorbeugung

vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung angegebenen

Anweisungsnummer nach der jeweiligen Übersetzung in den übersetzten

Sicherheitshinweisen, die zusammen mit diesem Gerät ausgeliefert wurden.

BEWAHREN SIE DIESE HINWEISE GUT AUF.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este símbolo de aviso indica peligro. Existe riesgo para su integridad física. Antes

de manipular cualquier equipo, considere los riesgos de la corriente eléctrica y

familiarícese con los procedimientos estándar de prevención de accidentes. Al

fi nal de cada advertencia encontrará el número que le ayudará a encontrar el texto

traducido en el apartado de traducciones que acompaña a este dispositivo.

GUARDE ESTAS INSTRUCCIONES.

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant entraîner des blessures ou des dommages corporels. Avant

de travailler sur un équipement, soyez conscient des dangers liés aux circuits

électriques et familiarisez-vous avec les procédures couramment utilisées pour

éviter les accidents. Pour prendre connaissance des traductions des avertissements

fi gurant dans les consignes de sécurité traduites qui accompagnent cet appareil,

référez-vous au numéro de l'instruction situé à la fi n de chaque avertissement.

CONSERVEZ CES INFORMATIONS.

ןה תואבה תורהצהא ינפמ שמתשמה תא ריהזהל תנמ לע ,היישעתה ינקת יפ לע תורהז הלבח

ה וא תולאש שיו הדימב .תירשפא תיזיפי ,יהשלכ היעבב תולקתרוציל שי הכימת תקלחמ םע רשק

רידגהל וא ןיקתהל םיאשר דבלב םיכמסומ םיאנכט .ורקימרפוס לש תינכט תאה .םיביכר

תרדגה וא תנקתה ינפל ואולמב חפסנה תא

אורקל שי .ורקימרפוס יזראמב םיביכרה

4-2

Page 31

Warning Statements for AC Systems

. ﻲﻓ ﻚﻧﺍ ﻥﺃ ﻦﻜﻤﻳ ﺔﻟﺎﺣ ﻲﻓ ﺐﺒﺴﺘﺗ ﺔﺑﺎﺻﺍ ﺔﻳﺪﺴﺟ ﺰﻣﺮﻟﺍ ﺍﺬﻫ ﻲﻨﻌﻳ ﺮﻄﺧ !ﺮﻳﺬﺤﺗ

ﻥﺃ ﻞﺒﻗ ﻱﺃ ﻰﻠﻋ ﻞﻤﻌﺗ ﺕﺍﺪﻌﻣ،ﻛﻢﻠﻋ ﻰﻠﻋ ﻦ ﻦﻋ ﺔﻤﺟﺎﻨﻟﺍ ﺮﻁﺎﺨﻤﻟﺎﺑ ﺮﺋﺍﻭﺪﻟﺍ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ

ﻛﻭﺔﻳﺍﺭﺩ ﻰﻠﻋ ﻦ ﺭﺎﻤﻤﻟﺎﺑﺕﺎﺳ ﺔﻴﺋﺎﻗﻮﻟﺍ ﻟ ﻊﻨﻤﻉﻮﻗﻭ ﻱﺃﺙﺩﺍﻮﺣ

ﻢﻗﺭ ﻡﺪﺨﺘﺳﺍ ﻥﺎﻴﺒﻟﺍ ﺹﻮﺼﻨﻤﻟﺍ ﺔﻳﺎﻬﻧ ﻲﻓ ﺮﻳﺬﺤﺗ ﻞﻛ ﺭﻮﺜﻌﻠﻟ ﺎﻬﺘﻤﺟﺮﺗ

안전을 위한 주의사항

경고!

이 경고 기호는 위험이 있음을 알려 줍니다. 작업자의 신체에 부상을 야기 할 수

있는 상태에 있게 됩니다. 모든 장비에 대한 작업을 수행하기 전에 전기회로와

관련된 위험요소들을 확인하시고 사전에 사고를 방지할 수 있도록 표준

작업절차를 준수해 주시기 바랍니다.

해당 번역문을 찾기 위해 각 경고의 마지막 부분에 제공된 경고문 번호를

참조하십시오

BELANGRIJKE VEILIGHEIDSINSTRUCTIES

Dit waarschuwings symbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat werken,

dient u zich bewust te zijn van de bij een elektrische installatie betrokken risico's

en dient u op de hoogte te zijn van de standaard procedures om ongelukken te

voorkomen. Gebruik de nummers aan het eind van elke waarschuwing om deze te

herleiden naar de desbetreffende locatie.

BEWAAR DEZE INSTRUCTIES

4-3

Page 32

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Installation Instructions

Warning!

Read the installation instructions before connecting the system to the power source.

設置手順書

システムを電源に接続する前に、設置手順書をお読み下さい。

警告

将此系统连接电源前,请先阅读安装说明。

警告

將系統與電源連接前,請先閱讀安裝說明。

Warnung

Vor dem Anschließen des Systems an die Stromquelle die Installationsanweisungen

lesen.

¡Advertencia!

Lea las instrucciones de instalación antes de conectar el sistema a la red de

alimentación.

Attention

Avant de brancher le système sur la source d'alimentation, consulter les directives

d'installation.

אורקל שי רוקמל תכרעמה רוביח ינפל הנקתה תוארוה תאחתמ.

ﻟﺍ ﺕﺍﺩﺎﺷﺭﺇ ﺮﻗﺍﺐﻴﻛﺮﺘ ﻞﻴﺻﻮﺗ ﻞﺒﻗ ﻰﻟﺇ ﻡﺎﻈﻨﻟﺍ ﺔﻗﺎﻄﻠﻟ ﺭﺪﺼﻣ

시스템을 전원에 연결하기 전에 설치 안내를 읽어주십시오.

Waarschuwing

Raadpleeg de installatie-instructies voordat u het systeem op de voedingsbron

aansluit.

4-4

Page 33

Chapter 4: Warning Statements for AC Systems

Circuit Breaker

Warning!

This product relies on the building's installation for short-circuit (overcurrent)

protection. Ensure that the protective device is rated not greater than: 250 V, 20 A.

サーキット・ブレーカー

この製 品 は、短絡(過電流)保護装置がある建物での設置を前提としています。

保護装置の定格が250V、20Aを超えないことを確認下さい。

警告

此产品的短路(过载电流)保护由建筑物的供电系统提供,确保短路保护设备的额定电

流不大于250V,20A。

警告

此產品的短路(過載電流)保護由建築物的供電系統提供,確保短路保護設備的額定電

流不大於250V,20A。

Warnung

Dieses Produkt ist darauf angewiesen, dass im Gebäude ein Kurzschluss-

bzw. Überstromschutz installiert ist. Stellen Sie sicher, dass der Nennwert der

Schutzvorrichtung nicht mehr als: 250 V, 20 A beträgt.

¡Advertencia!

Este equipo utiliza el sistema de protección contra cortocircuitos (o sobrecorrientes)

del edifi cio. Asegúrese de que el dispositivo de protección no sea superior a: 250

V, 20 A.

Attention

Pour ce qui est de la protection contre les courts-circuits (surtension), ce produit

dépend de l'installation électrique du local. Vérifi ez que le courant nominal du

dispositif de protection n'est pas supérieur à :250 V, 20 A.

¥²¢¢¥§²±¯°³«¢©§¥¦¢©§³©°³§©¥«£§³ª§±¯§

60VDC, 20 A §±³¢¥¢¥§²±¯°¢©§¨§±¢²¤§

ϩΕϱ

ΏΙΕ

ϡΕ ϱΕϝ

ΓέϱιϕϝέΉ

ϭΩϝϩϡΕϱϡ

Ρϝ

ΙΩωϡ

ϯϝω ΩϡΕωϱΝΕϥϡϝΫ

ϩ

ϯϥΏϡϝ

20A, 250VDC :ϥϡ

έΙϙαϱϝϱΉϕϭϝ

4-5

ίϩΝϝ

ϡϱϱϕΕ

ϥ ϥϡ ΩϙΕ

Page 34

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

경고!

이 제품은 전원의 단락(과전류)방지에 대해서 전적으로 건물의 관련 설비에

의존합니다. 보호장치의 정격이 반드시 250V(볼트), 20A(암페어)를 초과하지

않도록 해야 합니다.

Waarschuwing

Dit product is afhankelijk van de kortsluitbeveiliging (overspanning) van

uw electrische installatie. Controleer of het beveiligde aparaat niet groter

gedimensioneerd is dan 220V, 20A.

Power Disconnection Warning

Warning!

The system must be disconnected from all sources of power and the power cord

removed from the power supply module(s) before accessing the chassis interior to

install or remove system components.

電源切断の警告

システムコンポーネントの取り付けまたは取り外しのために、シャーシー内部にアクセス

するには、

システムの電源はすべてのソースから切断され、電源コードは電源モジュールから取り

外す必要があります。

警告

在你打开机箱并安装或移除内部器件前,必须将系统完全断电,并移除电源线。

警告

在您打開機殼安裝或移除內部元件前,必須將系統完全斷電,並移除電源線。

Warnung

Das System muss von allen Quellen der Energie und vom Netzanschlusskabel

getrennt sein, das von den Spg.Versorgungsteilmodulen entfernt wird, bevor es

auf den Chassisinnenraum zurückgreift, um Systemsbestandteile anzubringen oder

zu entfernen.

4-6

Page 35

Chapter 4: Warning Statements for AC Systems

ילמשח קותינ ינפמ הרהזא

!הרהזא

¡Advertencia!

El sistema debe ser disconnected de todas las fuentes de energía y del cable

eléctrico quitado de los módulos de fuente de alimentación antes de tener acceso

el interior del chasis para instalar o para quitar componentes de sistema.

Attention

Le système doit être débranché de toutes les sources de puissance ainsi que de

son cordon d'alimentation secteur avant d'accéder à l'intérieur du chassis pour

installer ou enlever des composants de systéme.

למשחה תורוקמ לכמ תכרעמה תא קתנל שי ריסהל שיו קפסהמ ילמשחה לבכ תא

נקתה ךרוצל זראמה לש ימינפה קלחל השיג ינפלת רסה ואת .םיביכר

ﻞﺼﻓ ﺐﺠﻳ ﻡﺎﻈﻨﻟﺍ ﻊﻴﻤﺟ ﻦﻣﺭﺩﺎﺼﻣ ﺔﻗﺎﻄﻟﺍ ﺔﻟﺍﺯﺇﻭ ءﺎﺑﺮﻬﻜﻟﺍ ﻚﻠﺳ ﻦﻣ ﺓﺪﺣﻭ ﺩﺍﺪﻣﺍ

ﺔﻗﺎﻄﻟﺍ ﻞﺒﻗ

ﺯﺎﻬﺠﻟﺍ

경고!

시스템에 부품들을 장착하거나 제거하기 위해서는 섀시 내부에 접근하기 전에

반드시 전원 공급장치로부터 연결되어있는 모든 전원과 전기코드를 분리해주어야

합니다.

Waarschuwing

Voordat u toegang neemt tot het binnenwerk van de behuizing voor het installeren

of verwijderen van systeem onderdelen, dient u alle spanningsbronnen en alle

stroomkabels aangesloten op de voeding(en) van de behuizing te verwijderen

ﻰﻟﺇ ﻝﻮﺻﻮﻟﺍ ﺔﻴﻠﺧﺍﺪﻟﺍ ﻖﻁﺎﻨﻤﻟﺍ ﻟﻞﻜﻴﻬﻠ ﺔﻟﺍﺯﺇ ﻭﺃ ﺖﻴﺒﺜﺘﻟ ﺕﺎﻧﻮﻜﻣ

4-7

Page 36

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Equipment Installation

Warning!

Only trained and qualifi ed personnel should be allowed to install, replace, or service

this equipment.

機器の設置

トレーニングを受け認定された人だけがこの装置の設置、交換、またはサービスを許可

されています。

警告

只有经过培训且具有资格的人员才能进行此设备的安装、更换和维修。

警告

只有經過受訓且具資格人員才可安裝、更換與維修此設備。

Warnung

Das Installieren, Ersetzen oder Bedienen dieser Ausrüstung sollte nur geschultem,

qualifi ziertem Personal gestattet werden.

¡Advertencia!

Solamente el personal califi cado debe instalar, reemplazar o utilizar este equipo.

Attention

Il est vivement recommandé de confier l'installation, le remplacement et la

maintenance de ces équipements à des personnels qualifi és et expérimentés.

!הרהזא

שר דבלב ךמסומ תווצתא ףילחהל ,ןיקתהל יא .דויצה רובע תוריש תתל וא דויצה

ﻦﻴﺑﺭﺪﻤﻟﺍﻭ ﻭ ﺐﻴﻛﺮﺘﻟﻝﺍﺪﺒﺘﺳﺍ ﻭﺃ ﺔﻣﺪﺧ ﺯﺎﻬﺠﻟﺍ ﺍﺬﻫ ﺢﻤﺴﻳ ﻥﺃ ﺐﺠﻳ ﻂﻘﻓ ﻦﻴﻠﻫﺆﻤﻟﺍ ﻦﻴﻔﻅﻮﻤﻠﻟ

경고!

훈련을 받고 공인된 기술자만이 이 장비의 설치, 교체 또는 서비스를 수행할 수

있습니다.

4-8

Page 37

Chapter 4: Warning Statements for AC Systems

Waarschuwing

Deze apparatuur mag alleen worden geïnstalleerd, vervangen of hersteld door

geschoold en gekwalifi ceerd personeel.

Restricted Area

Warning!

This unit is intended for installation in restricted access areas. A restricted access

area can be accessed only through the use of a special tool, lock and key, or other

means of security. (This warning does not apply to workstations).

アクセス制限区域

このユ ニットは、アクセス制限区域に設置されることを想定しています。

アクセス制限区域は、特別なツール、鍵と錠前、その他のセキュリティの手段を用いての

み出入りが可能です。

警告

此部件应安装在限制进出的场所,限制进出的场所指只能通过使用特殊工具、锁和

钥匙或其它安全手段进出的场所。

警告

此裝置僅限安裝於進出管制區域,進出管制區域係指僅能以特殊工具、鎖頭及鑰匙

或其他安全方式才能進入的區域。

Warnung

Diese Einheit ist zur Installation in Bereichen mit beschränktem Zutritt vorgesehen.

Der Zutritt zu derartigen Bereichen ist nur mit einem Spezialwerkzeug, Schloss und

Schlüssel oder einer sonstigen Sicherheitsvorkehrung möglich.

¡Advertencia!

Esta unidad ha sido diseñada para instalación en áreas de acceso restringido.

Sólo puede obtenerse acceso a una de estas áreas mediante la utilización de una

herramienta especial, cerradura con llave u otro medio de seguridad.

Attention

Cet appareil doit être installée dans des zones d'accès réservés. L'accès à une

zone d'accès réservé n'est possible qu'en utilisant un outil spécial, un mécanisme

de verrouillage et une clé, ou tout autre moyen de sécurité.

4-9

Page 38

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

תלבגומ השיג םע רוזא

!הרהזא

תרזעב תנתינ השיגה .השיג תלבגה םהב שיש םירוזאב הדיחיה תא ןיקתהל שי

.('דכו לוענמ ,חתפמ) דבלב החטבא ילכ

. ﺺﻴﺼﺨﺗ ﺓﺪﺣﻮﻟﺍ ﻩﺬﻫ ﻲﻓ ﺎﻬﺒﻴﻛﺮﺘﻟ ﻖﻁﺎﻨﻣ ﺓﺭﻮﻈﺤﻣ ﻢﺗ

ﺻﻮﻟﺍ ﻦﻜﻤﻳﻰﻟﺇ ﻝﻮ ﺔﻘﻄﻨﻣ ﺓﺭﻮﻈﺤﻣ ﻂﻘﻓ ﻡﺍﺪﺨﺘﺳﺍ ﻝﻼﺧ ﻦﻣ ،ﺔﺻﺎﺧ ﺓﺍﺩﺃ

ﻭﺃ ﻱﺃ ﻼﻟ ﻯﺮﺧﺃ ﺔﻠﻴﺳﻭﻥﺎﻣﻷ ﺡﺎﺘﻔﻣﻭ ﻞﻔﻗ

경고!

이 장치는 접근이 제한된 구역에 설치하도록 되어있습니다. 특수도구, 잠금 장치 및

키, 또는 기타 보안 수단을 통해서만 접근 제한 구역에 들어갈 수 있습니다.

Waarschuwing

Dit apparaat is bedoeld voor installatie in gebieden met een beperkte toegang.

Toegang tot dergelijke gebieden kunnen alleen verkregen worden door gebruik te

maken van speciaal gereedschap, slot en sleutel of andere veiligheidsmaatregelen.

Battery Handling

Warning!

There is the danger of explosion if the battery is replaced incorrectly. Replace the

battery only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer's instructions

電池の取り扱い

電池交換が正しく行われなかった場合、破裂の危険性があります。交換する電池はメー

カーが推奨する型、または同 等のものを使用 下さい。使用済電池は製造元の指示に従

って処 分して 下さい。

警告

电池更换不当会有爆炸危险。请只使用同类电池或制造商推荐的功能相当的电池更

换原有电池。请按制造商的说明处理废旧电池。

警告

電池更換不當會有爆炸危險。請使用製造商建議之相同或功能相當的電池更換原有

電池。請按照製造商的說明指示處理廢棄舊電池。

4-10

Page 39

Chapter 4: Warning Statements for AC Systems

!הרהזא

Warnung

Bei Einsetzen einer falschen Batterie besteht Explosionsgefahr. Ersetzen Sie die

Batterie nur durch den gleichen oder vom Hersteller empfohlenen Batterietyp.

Entsorgen Sie die benutzten Batterien nach den Anweisungen des Herstellers.

Attention

Danger d'explosion si la pile n'est pas remplacée correctement. Ne la remplacer

que par une pile de type semblable ou équivalent, recommandée par le fabricant.

Jeter les piles usagées conformément aux instructions du fabricant.

¡Advertencia!

Existe peligro de explosión si la batería se reemplaza de manera incorrecta.

Reemplazar la batería exclusivamente con el mismo tipo o el equivalente

recomendado por el fabricante. Desechar las baterías gastadas según las

instrucciones del fabricante.

תנכס תמייקץוציפ .הניקת אל ךרדב הפלחוהו הדימב הללוסה לש ףילחהל שי

גוסב הללוסה תא מ םאותה תרבחלמומ ןרציתצ.

תוללוסה קוליס תושמושמה עצבל שי .ןרציה תוארוה יפל

ﺮﻄﺧ ﻙﺎﻨﻫ ﻦﻣ ﻝﺍﺪﺒﺘﺳﺍ ﺔﻟﺎﺣ ﻲﻓ ﺭﺎﺠﻔﻧﺍ ﺔﻳﺭﺎﻄﺒﻟﺍ ﺔﺤﻴﺤﺻ ﺮﻴﻏ ﺔﻘﻳﺮﻄﺑ ﻚﻴﻠﻌﻓ

ﺔﻳﺭﺎﻄﺒﻟﺍ ﻝﺍﺪﺒﺘﺳﺍ

ﻂﻘﻓ ﻉﻮﻨﻟﺍ ﺲﻔﻨﺑ ﺎﻬﻟﺩﺎﻌﻳ ﺎﻣ ﻭﺃ ﺎﻤﻛﺖﺻﻭﺃ ﺔﻌﻨﺼﻤﻟﺍ ﺔﻛﺮﺸﻟﺍ ﻪﺑ

ﺕﺎﻳﺭﺎﻄﺒﻟﺍ ﻦﻣ ﺺﻠﺨﺗ ﻟ ﺎﻘﻓﻭ ﺔﻠﻤﻌﺘﺴﻤﻟﺍﺔﻌﻧﺎﺼﻟﺍ ﺔﻛﺮﺸﻟﺍ ﺕﺎﻤﻴﻠﻌﺘ

경고!

배터리가 올바르게 교체되지 않으면 폭발의 위험이 있습니다. 기존 배터리와

동일하거나 제조사에서 권장하는 동등한 종류의 배터리로만 교체해야 합니다.

제조사의 안내에 따라 사용된 배터리를 처리하여 주십시오.

Waarschuwing

Er is ontploffi ngsgevaar indien de batterij verkeerd vervangen wordt. Vervang de

batterij slechts met hetzelfde of een equivalent type die door de fabrikant aanbevolen

wordt. Gebruikte batterijen dienen overeenkomstig fabrieksvoorschriften afgevoerd

te worden.

4-11

Page 40

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

דחא קפסמ רתוי םייק םא

!הרהזא

Redundant Power Supplies

Warning!

This unit might have more than one power supply connection. All connections must

be removed to de-energize the unit.

冗長電源装置

このユニットは複数の電源装置が接続されている場合があります。

ユニットの電源を切るためには、すべての接続を取り外さなければなりません。

警告

此部件连接的电源可能不止一个,必须将所有电源断开才能停止给该部件供电。

警告

此裝置連接的電源可能不只一個,必須切斷所有電源才能停止對該裝置的供電。

Warnung

Dieses Gerät kann mehr als eine Stromzufuhr haben. Um sicherzustellen, dass

der Einheit kein trom zugeführt wird, müssen alle Verbindungen entfernt werden.

¡Advertencia!

Puede que esta unidad tenga más de una conexión para fuentes de alimentación.

Para cortar por completo el suministro de energía, deben desconectarse todas las

conexiones.

Attention

Cette unité peut avoir plus d'une connexion d'alimentation. Pour supprimer toute

tension et tout courant électrique de l'unité, toutes les connexions d'alimentation

doivent être débranchées.

.קפס לש דחא רוביחמ רתוי שי הדחיל תא ריסהל שיןקורל תנמ לע םירוביחה לכ

חיה תאי.הד

4-12

Page 41

Chapter 4: Warning Statements for AC Systems

. ﺪﻗ ﺍﺬﻬﻟ ﻥﻮﻜﻳ ﻟﺍﺯﺎﻬﺠ ﺕﻻﺎﺼﺗﺍ ﺓﺪﻋ ﺕﺍﺪﺣﻮﺑ ﺔﻗﺎﻄﻟﺍ ﺩﺍﺪﻣﺍ

ﺔﻟﺍﺯﺇ ﺐﺠﻳ ﺕﻻﺎﺼﺗﻻﺍ ﺔﻓﺎﻛ ﻝﺰﻌﻟ ﻟﺍﺓﺪﺣﻮ ﻦﻋ ءﺎﺑﺮﻬﻜﻟﺍ

경고!

이 장치에는 한 개 이상의 전원 공급 단자가 연결되어 있을 수 있습니다. 이 장치에

전원을 차단하기 위해서는 모든 연결 단자를 제거해야만 합니다.

Waarschuwing

Deze eenheid kan meer dan één stroomtoevoeraansluiting bevatten. Alle

aansluitingen dienen verwijderd te worden om het apparaat stroomloos te maken.

Backplane Voltage

Warning!

Hazardous voltage or energy is present on the backplane when the system is

operating. Use caution when servicing.

バックプレーンの電圧

システムの稼働中は危険な電圧または電力が、バックプレーン上にかかっています。

修理する際には注意ください。

警告

当系统正在进行时,背板上有很危险的电压或能量,进行维修时务必小心。

警告

當系統正在進行時,背板上有危險的電壓或能量,進行維修時務必小心。

Warnung

Wenn das System in Betrieb ist, treten auf der Rückwandplatine gefährliche

Spannungen oder Energien auf. Vorsicht bei der Wartung.

¡Advertencia!

Cuando el sistema está en funcionamiento, el voltaje del plano trasero es peligroso.

Tenga cuidado cuando lo revise.

Attention

Lorsque le système est en fonctionnement, des tensions électriques circulent sur

le fond de panier. Prendre des précautions lors de la maintenance.

4-13

Page 42

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

ירוחאה לנפב חתמ

ךלהמב רהזיהל שי .תכרעמה לועפת ןמזב ירוחאה לנפב חתמ תנכס תמייק

זא!הרה

.הדובעה

ﻙﺎﻨﻫ ﺮﻄﺧ ﻦﻣ ﻲﺋﺎﺑﺮﻬﻜﻟﺍ ﺭﺎﻴﺘﻟﺍ ﻰﻠﻋ ﺓﺩﻮﺟﻮﻤﻟﺍ ﺔﻗﺎﻄﻟﺍﻭﺃ ﺔﺣﻮﻠﻟﺍ

ﻥﻮﻜﻳ ﺎﻣﺪﻨﻋﻡﺎﻈﻨﻟﺍ ﻞﻤﻌﻳ ﺪﻨﻋ ﺍﺭﺬﺣ ﻦﻛ ﺔﻣﺪﺧ ﺯﺎﻬﺠﻟﺍ ﺍﺬﻫ

경고!

시스템이 동작 중일 때 후면판 (Backplane)에는 위험한 전압이나 에너지가 발생

합니다. 서비스 작업 시 주의하십시오.

Waarschuwing

Een gevaarlijke spanning of energie is aanwezig op de backplane wanneer het

systeem in gebruik is. Voorzichtigheid is geboden tijdens het onderhoud.

Comply with Local and National Electrical Codes

Warning!

Installation of the equipment must comply with local and national electrical codes.

地方および国の電気規格に準拠

機器の取り付けはその地方および国の電気規格に準拠する必要があります。

警告

设备安装必须符合本地与本国电气法规。

警告

設備安裝必須符合本地與本國電氣法規。

Warnung

Die Installation der Geräte muss den Sicherheitsstandards entsprechen.

¡Advertencia!

La instalacion del equipo debe cumplir con las normas de electricidad locales y

nacionales.

4-14

Page 43

Chapter 4: Warning Statements for AC Systems

יצראה למשחה יקוח םואית

Attention

L'équipement doit être installé conformément aux normes électriques nationales

et locales.

!הרהזא

תנקתה םייצראהו םיימוקמה למשחה יקוחל תמאות תויהל תבייח דויצה.

ﺕﺍﺪﻌﻤﻟﺍ ﺐﻴﻛﺮﺗ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﻠﻟ ﻞﺜﺘﻤﻳ ﻥﺃ ﺐﺠﻳ ﻦﻴﻧﺍﻮﻘﺔﻴﻨﻁﻮﻟﺍﻭ ﺔﻴﻠﺤﻤﻟﺍ ﺔﻘﻠﻌﺘﻤﻟﺍ

ءﺎﺑﺮﻬﻜﻟﺎﺑ

경고!

현 지역 및 국가의 전기 규정에 따라 장비를 설치해야 합니다.

Waarschuwing

Bij installatie van de apparatuur moet worden voldaan aan de lokale en nationale

elektriciteitsvoorschriften.

Product Disposal

Warning!

Ultimate disposal of this product should be handled according to all national laws

and regulations.

製品の廃棄

この製品を廃棄処分する場合、国の関係する全ての法律・条例に従い処理する必要が

あります。

警告

本产品的废弃处理应根据所有国家的法律和规章进行。

警告

本產品的廢棄處理應根據所有國家的法律和規章進行。

Warnung

Die Entsorgung dieses Produkts sollte gemäß allen Bestimmungen und Gesetzen

des Landes erfolgen.

4-15

Page 44

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

רצומה קוליס

¡Advertencia!

Al deshacerse por completo de este producto debe seguir todas las leyes y

reglamentos nacionales.

Attention

La mise au rebut ou le recyclage de ce produit sont généralement soumis à des

lois et/ou directives de respect de l'environnement. Renseignez-vous auprès de

l'organisme compétent.

!הרהזא

ו תויחנהל םאתהב תויהל בייח הז רצומ לש יפוס קוליס.הנידמה יקוח

ﻲﺋﺎﻬﻨﻟﺍ ﺺﻠﺨﺘﻟﺍ ﻦﻣ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻪﻌﻣ ﻞﻣﺎﻌﺘﻟﺍ ﻲﻐﺒﻨﻳ ﻟ ﺎﻘﻓﻭ ﻊﻴﻤﺠﺔﻴﻨﻁﻮﻟﺍ ﺢﺋﺍﻮﻠﻟﺍﻭ ﻦﻴﻧﺍﻮﻘﻟﺍ ﺪﻨﻋ

경고!

이 제품은 해당 국가의 관련 법규 및 규정에 따라 폐기되어야 합니다.

Waarschuwing

De uiteindelijke verwijdering van dit product dient te geschieden in overeenstemming

met alle nationale wetten en reglementen.

Hot Swap Fan Warning

Warning!

The fans might still be turning when you remove the fan assembly from the chassis.

Keep fi ngers, screwdrivers, and other objects away from the openings in the fan

assembly's housing.

ファン・ホットスワップの警告

シャーシから冷却ファン装置を取り外した際、ファンがまだ回転している可能性がありま

す。ファンの開口部に、指、ドライバー、およびその他のものを近づけないで下さい。

警告

当您从机架移除风扇装置,风扇可能仍在转动。小心不要将手指、螺丝起子和其他

物品太靠近风扇

4-16

Page 45

Chapter 4: Warning Statements for AC Systems

警告

當您從機架移除風扇裝置,風扇可能仍在轉動。小心不要將手指、螺絲起子和其他

物品太靠近風扇。

Warnung

Die Lüfter drehen sich u. U. noch, wenn die Lüfterbaugruppe aus dem Chassis

genommen wird. Halten Sie Finger, Schraubendreher und andere Gegenstände

von den Öffnungen des Lüftergehäuses entfernt.

¡Advertencia!

Los ventiladores podran dar vuelta cuando usted quite ell montaje del ventilador

del chasis. Mandtenga los dedos, los destornilladores y todos los objetos lejos de

las aberturas del ventilador

Attention

Il est possible que les ventilateurs soient toujours en rotation lorsque vous retirerez

le bloc ventilateur du châssis. Prenez garde à ce que doigts, tournevis et autres

objets soient éloignés du logement du bloc ventilateur.

!הרהזא

יקלח תא םיריסמ רשאכ שי .םידבוע ןיידע םיררוואמהו ןכתי ,זראמהמ ררוואמה

קיחרהללררוואמה ךותב םיחתפהמ םינוש הדובע ילכו תועבצאה תא חוטב קחרמ

ﻦﻜﻤﻤﻟﺍ ﻦﻣ ﺡﻭﺍﺮﻤﻟﺍ ﻥﺃ ﻝﺍﺰﺗ ﻻ ﺔﻟﺍﺯﺇ ﺪﻨﻋﺭﻭﺪﺗ ﺔﻠﺘﻛ ﺔﺣﻭﺮﻤﻟﺍ ﻞﻜﻴﻬﻟﺍ ﻦﻣ ﺐﺠﻳ ءﺎﻘﺑﺇ

ﻊﺑﺎﺻﻷﺍ ﻭﻲﻏﺍﺮﺒﻟﺍ ﺕﺎﻜﻔﻣ

. ءﺎﻴﺷﻷﺍ ﻦﻣ ﺎﻫﺮﻴﻏﻭ ﺍﺪﻴﻌﺑ ﻦﻋ ﺕﺎﺤﺘﻔﻟﺍ ﻲﻓ ﺔﻠﺘﻛ ﺔﺣﻭﺮﻤﻟﺍ

경고!

섀시로부터 팬 조립품을 제거할 때 팬은 여전히 회전하고 있을 수 있습니다. 팬

조림품 외관의 열려있는 부분들로부터 손가락 및 스크류드라이버, 다른 물체들이

가까이 하지 않도록 배치해 주십시오.

Waarschuwing

Het is mogelijk dat de ventilator nog draait tijdens het verwijderen van het

ventilatorsamenstel uit het chassis. Houd uw vingers, schroevendraaiers

en eventuele andere voorwerpen uit de buurt van de openingen in de

ventilatorbehuizing.

4-17

Page 46

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Power Cable and AC Adapter

Warning!

When installing the product, use the provided or designated connection cables,

power cables and AC adaptors. Using any other cables and adaptors could cause

a malfunction or a fi re. Electrical Appliance and Material Safety Law prohibits the

use of UL or CSA -certifi ed cables (that have UL/CSA shown on the code) for any

other electrical devices than products designated by Supermicro only.

電源コードとACアダプター

製品を設置する場合、提供または指定された接続ケーブル、電源コードとACアダプター

を使用下さい。他のケーブルやアダプタを使用すると故障や火災の原因になることがあ

ります。電気用品安全法は、ULまたはCSA認定のケーブル(UL/CSEマークがコードに表

記)をSupermicroが指定する製品以外に使用することを禁止しています。

警告

安装此产品时,请使用本身提供的或指定的连接线,电源线和电源适配器.使用其它线

材或适配器可能会引起故障或火灾。除了Supermicro所指定的产品,电气用品和材

料安全法律规定禁止使用未经UL或CSA认证的线材。(线材上会显示UL/CSA符号)。

警告

安裝此產品時,請使用本身提供的或指定的連接線,電源線和電源適配器.使用其它線

材或適配器可能會引起故障或火災。除了Supermicro所指定的產品,電氣用品和材

料安全法律規定禁止使用未經UL或CSA認證的線材。(線材上會顯示UL/CSA符號)。

Warnung

Bei der Installation des Produkts, die zur Verfügung gestellten oder benannt

Anschlusskabel, Stromkabel und Netzteile. Verwendung anderer Kabel und Adapter

kann zu einer Fehlfunktion oder ein Brand entstehen. Elektrische Geräte und

Material Safety Law verbietet die Verwendung von UL-oder CSA-zertifi zierte Kabel,

UL oder CSA auf der Code für alle anderen elektrischen Geräte als Produkte von

Supermicro nur bezeichnet gezeigt haben.

¡Advertencia!

Al instalar el producto, utilice los cables de conexión previstos o designados, los

cables y adaptadores de CA. La utilización de otros cables y adaptadores podría

ocasionar un mal funcionamiento o un incendio. Aparatos Eléctricos y la Ley de

Seguridad del Material prohíbe el uso de UL o CSA cables certifi cados que tienen

UL o CSA se muestra en el código de otros dispositivos eléctricos que los productos

designados por Supermicro solamente.

4-18

Page 47

Chapter 4: Warning Statements for AC Systems

אתמו םיילמשחמ י

Attention

Lors de l'installation du produit, utilisez les bables de connection fournis ou désigné.

L'utilisation d'autres cables et adaptateurs peut provoquer un dysfonctionnement

ou un incendie. Appareils électroménagers et de loi sur la sécurité Matériel interdit

l'utilisation de UL ou CSA câbles certifi és qui ont UL ou CSA indiqué sur le code

pour tous les autres appareils électriques que les produits désignés par Supermicro

seulement.

AC

!הרהזא

AC רשא

םימאתמו םיקפס ,םילבכב שמתשהל שי ,רצומה תא םיניקתמ רשאכ

וא הלקתל םורגל לוכי רחא םאתמ וא לבכ לכב שומיש .ךכ םשל וקפוסו ודעונ

טב יקוחו למשח ירישכמב שומיש יקוח יפ לע .ילמשח רצק רוסיא םייק ,תוחי

UL ב וא- CSA לש דוק םהילע עיפומ ראשכ)

ב םיכמסומה םילבכב שמתשהל-

UL/CSA( רחא ילמשח רצומ לכ רובע.דבלב ורקימקרפוס ידי לע ןיוצ אלש

ﺐﻴﻛﺮﺗ ﺪﻨﻋ ﻡﺍﺪﺨﺘﺳﺍ ﺐﺠﻳ ﺯﺎﻬﺠﻟﺍ ﻭ،ﻞﻴﺻﻮﺘﻟﺍ ﺕﻼﺑﺎﻛ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺕﻼﺑﺎﻜﻟﺍ

ﺕﻻﻮﺤﻣﻭ ﺩﺩﺮﺘﻤﻟﺍ ﺭﺎﻴﺘﻟﺍ

. ﻥﺃ ﻱﺃ ﻡﺍﺪﺨﺘﺳﺍ ﺕﻼﺑﺎﻛ ﺕﻻﻮﺤﻣﻭ ﻯﺮﺧﺃ ﺐﺒﺴﺘﻳ ﻲﻓ ﻞﻄﻋ ﺙﻭﺪﺣ ﻖﻳﺮﺣ ﻭﺃ . ﻲﺘﻟﺍ

ﻚﻟ ﺎﻫﺮﻴﻓﻮﺗ ﻢﺗ ﺞﺘﻨﻤﻟﺍ ﻊﻣ

UL ﻭﺃ CSA ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺓﺰﻬﺟﻷﺍ ﺩﺍﻮﻣﻭ ﻥﻮﻧﺎﻗ ﺔﻣﻼﺴﻟﺍ ﻡﺍﺪﺨﺘﺳﺍ ﺮﻈﺤﻳ ﺕﻼﺑﺎﻜﻟﺍ

ﻞﺒﻗ ﻦﻣ ﺓﺪﻤﺘﻌﻣ

Supermicro ﺓﺰﻬﺟﺃ ﻯﺮﺧﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺮﻴﻏ ﺕﺎﺠﺘﻨﻤﻟﺍ ﺔﻨﻴﻌﻤﻟﺍ ﻞﺒﻗ ﻦﻣ ﻱﻷ

(UL/CSA ﻞﻤﺤﺗ ﻲﺘﻟﺍﺔﻣﻼﻋ )

경고!

제품을 설치할 때에는 제공되거나 지정된 연결케이블과 전원케이블, AC어댑터를

사용해야 합니다. 그 밖의 다른 케이블들이나 어댑터들은 고장 또는 화재의 원인이

될 수 있습니다. 전기용품안전법 (Electrical Appliance and Material Safety

Law)은 슈퍼마이크로에서 지정한 제품들 외에는 그 밖의 다른 전기 장치들을

위한 UL또는 CSA에서 인증한 케이블(전선 위에 UL/CSA가 표시)들의 사용을

금지합니다.

Waarschuwing

Bij het installeren van het product, gebruik de meegeleverde of aangewezen kabels,

stroomkabels en adapters. Het gebruik van andere kabels en adapters kan leiden

tot een storing of een brand. Elektrisch apparaat en veiligheidsinformatiebladen wet

verbiedt het gebruik van UL of CSA gecertifi ceerde kabels die UL of CSA die op

de code voor andere elektrische apparaten dan de producten die door Supermicro

alleen.

4-19

Page 48

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Notes

4-20

Page 49

Chapter 5: Advanced Serverboard Setup

Chapter 5

Advanced Serverboard Setup

This ch apter cover s the ste ps requi red to inst all pro ces sors a nd heats inks to the

X8DTU-6TF+/X8DTU-6F+ ser verboard, co nnect the data and power c ables and

instal l ad d - o n c ar ds . A ll se rver bo ard j um pe r s and c o nn ec t io ns a re d es cr i be d an d

a layout and quick reference chart are included in this chapter. Remember to

close t h e ch as si s c o mp lete ly w he n you h ave fi nished wo r ki ng o n t he se rverb o ar d

to protec t and co ol the sys tem suf fi ciently.

5-1 Handling the Serverboard

Static electrical discharge can damage electronic com ponents. To prevent damage

to printed circuit boards, it is important to handle them very carefully (see Chapter 4).

Also note that the size and weight of the serverboard can cause it to bend if handled

improperly, which may result in damage. To prevent the serverboard from bending,

keep one hand under the center of the board to support it when handling.

The following measures are generally suffi cient to protect your equipment from

static discharge.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing any board from its antistatic

bag.

• Handle a board by its edges only; do not touch its components, peripheral chips,

memory modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the serverboard, add-on cards and peripherals back into their antistatic

bags when not in use.

Unpacking

The serverboard is shipped in antistatic packaging to avoid static damage. When

unpacking the board, make sure the person handling it is static protected.

5-1

Page 50

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

5-2 Processor and Heatsink Installation

Warning: When handling the processor, avoid placing direct pressure on the label

area of the fan. Also, do not place the serverboard on a conductive surface, which can

damage the BIOS battery and prevent the system from booting up.

IMPORTANT! Always co nne c t the p owe r c or d last a nd r emove i t fi rst before add-

ing, remov ing or ch anging any ha rdware c ompo nents. M ake sure that you i nstall

the pro cessor into th e CPU socket before you install t he heatsink and fa n. The

X8DTU-6TF+/X8DTU-6F+ can sup port ei ther one or t wo proce ssors. If i nstalling

one pro cess or only, insta ll it into th e CPU1 socket.

Note:

When purchasing a CPU or when receiving a serverboard with a CPU pre-installed,

make sure that the CPU plastic cap is in place and none of the CPU pins are bent;

otherwise, contact the retailer immediately.

Installing LGA1366 Processors

1. Starting with CPU1, press the

socket clip to release the load

plate, which covers the CPU

socket, from its locked position.

2. Gently lift the socket clip to open

the load plate.

3. Hold the plastic cap at its north

and south center edges to remove

it from the CPU socket.

Note: The photos on this page and

succeeding pages are for illustration

purposes only. They do not necessarily

refl ect the exact product(s) described

in this manual.

Socket Clip Load Plate

Plastic Cap

5-2

Holding the north & south edges

Page 51

Chapter 5: Advanced Serverboard Setup

1. After removing the plastic cap, use

your thumb and the index fi nger

to hold the CPU at the north and

south center edges.

2. Align the CPU key (the semi-circle

cutout) with the socket key (the

notch below the gold color dot on

the side of the socket).

3. Once the CPU and the socket are

aligned, carefully lower the CPU

straight down into the socket.

Do not rub the CPU against the

surface of the socket or its pins to

avoid damaging the CPU or the

socket.

4. With the CPU in the socket, inspect the four corners of the CPU

to make sure that it sits level and

is properly installed.

CPU

CPU Socket

CPU

Align CPU keys with socket keys.

5. Once the CPU is securely seated

in the socket, lower the CPU load

plate to the socket.

6. Use your thumb to gently push the

socket clip down to the clip lock.

7. Repeat for the CPU2 socket for a

dual-processor confi guration.

Important! Please save the plastic

cap. The serverboard must be shipped

with the plastic cap properly installed to

protect the CPU socket pins. Shipment

without the plastic cap properly installed

may cause damage to the socket pins.

Load Plate

5-3

Page 52

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

Installing the Heatsink

1. Place the heatsink on top of the

CPU so that the four mounting

holes are aligned with those on the

retention mechanism.

Thermal Grease

2. Remove the thin layer of protective

fi lm from the copper core of the

heatsink.

Warning: The CPU may overheat if the

protective fi lm is not removed from the

heatsink.

3. Apply the proper amount of thermal grease on the CPU. If your

heatsink came with a thermal pad,

please ignore this step.

CPU

Screw#4

4. Screw in two diagonal screws (i.e.

the #1 and the #2 screws) until

just snug (do not over-tighten the

screws, which may damage the

CPU.)

5. Finish the installation by fully tightening all four screws.

Screw#1 Screw#2Screw#3

5-4

Page 53

Chapter 5: Advanced Serverboard Setup

Removing the Heatsink

Warning: We do not recommend removing the CPU or the heatsink. If you do need

to remove the heatsink, please follow the instructions below to prevent damage to the

CPU or other components.

1. Unplug the power cord from the power supply.

1. Unscrew and remove the heatsink screws in the

sequence shown in the picture below.

2. Hold the heatsink and gently wiggle it to loosen it

from the CPU. (Do not use excessive force when

doing this!)

3. Once the heatsink is loosened, remove it from

the CPU.

4. Clean the surface of the CPU and the heatsink

to get rid of the old thermal grease. Reapply the

proper amount of thermal grease before you reinstall the heatsink.

Screw#4

Screw#1 Screw#2Screw#3

5-5

Page 54

SUPERSERVER 6016T-6RFT+/6016T-6RF+ User's Manual

5-3 Connecting Cables

Now that the processors are installed, the next step is to connect the cables to