®

SUPER

X7DWN+

USER’S MANUAL

Revision 1.0b

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software, if any,

and documentation may not, in whole or in part, be copied, photocopied, reproduced, translated or

reduced to any medium or machine without prior written consent.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for

all claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class

A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the manufacturer’s instruction manual, may cause harmful

interference with radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case you will be required to correct the interference at your

own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate

warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to

the State of California to cause birth defects and other

reproductive harm.

Manual Revision 1.0b

Release Date: Dec. 12, 2008

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2008 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Preface

This manual is written for system integrators, PC technicians and knowledge-

able PC users. It provides information for the installation and use of the

X7DWN+ motherboard.

About This Motherboard

The X7DWN+ supports dual Intel® Quad-Core and Dual-Core Xeon™

5400 Series/5300LV Series/5200 Series/5100LV Series processors with a front

side bus speed of up to 1.6 GHz. With two 64-bit Quad-Core and Dual-Core

processors built-in, the X7DWN+ offers substantial functionality enhancements to

the motherboards based on the Intel Core Microarchitecture core while remaining

compatible with the IA-32 software. The features include Intel Virtualization Tech-

nology, Enhanced Intel SpeedStep technology, Advanced Transfer Cache, and

Streaming SIMD Extensions 4.1 (SSE4.1). These features allow the motherboard

to operate at much higher speeds with better power management in much safer

thermal environments than the traditional motherboards. The X7DWN+ is ideal for

high performance quad-processor or dual-processor (DP) workstation and enter-

prise server environments. Please refer to our web site (http://www.supermicro.

com/products/) for updates on supported processors. This product is intended to

Preface

be professionally installed.

Manual Organization

Chapter 1 describes the features, specifi cations and performance of the main

board and provides detailed information about the chipset.

Chapter 2 provides hardware installation instructions. Read this chapter when

installing the processor, memory modules and other hardware components into

the system. If you encounter any problems, see Chapter 3, which describes

troubleshooting procedures for the video, the memory and the system setup

stored in the CMOS.

Chapt er 4 includes an introduction to BIOS and provides detailed information on

running the CMOS Setup utility.

Appendix A provides BIOS POST Codes. Appendix B and Appendix C list

Windows OS and other software Installation Instructions.

Conventions Used in the Manual

Special attention should be given to the following symbols for proper installation

and to prevent damage done to the components or injury to yourself:

iii

X7DWN+ User's Manual

Warni ng: Important information given to ensure proper system installation or

to prevent damage to the components.

Note: Additional Information given to differentiate various models or to ensure cor-

rect system setup.

iv

Notes

Preface

v

X7DWN+ User's Manual

Table of Contents

Preface

About This Manual ........................................................................................... iii

Manual Organization ........................................................................................ iii

Conventions Used in the Manual ....................................................................... iii

Chapter 1: Introduction

1-1 Overview ................................................................................................. 1-1

Checklist ................................................................................................... 1-1

Contacting Supermicro ............................................................................. 1-2

X7DWN+ Image ........................................................................ 1-3

X7DWN+ Layout ........................................................................ 1-4

Quick Reference ...................................................................................... 1-5

Motherboard Features ................................................................................ 1-6

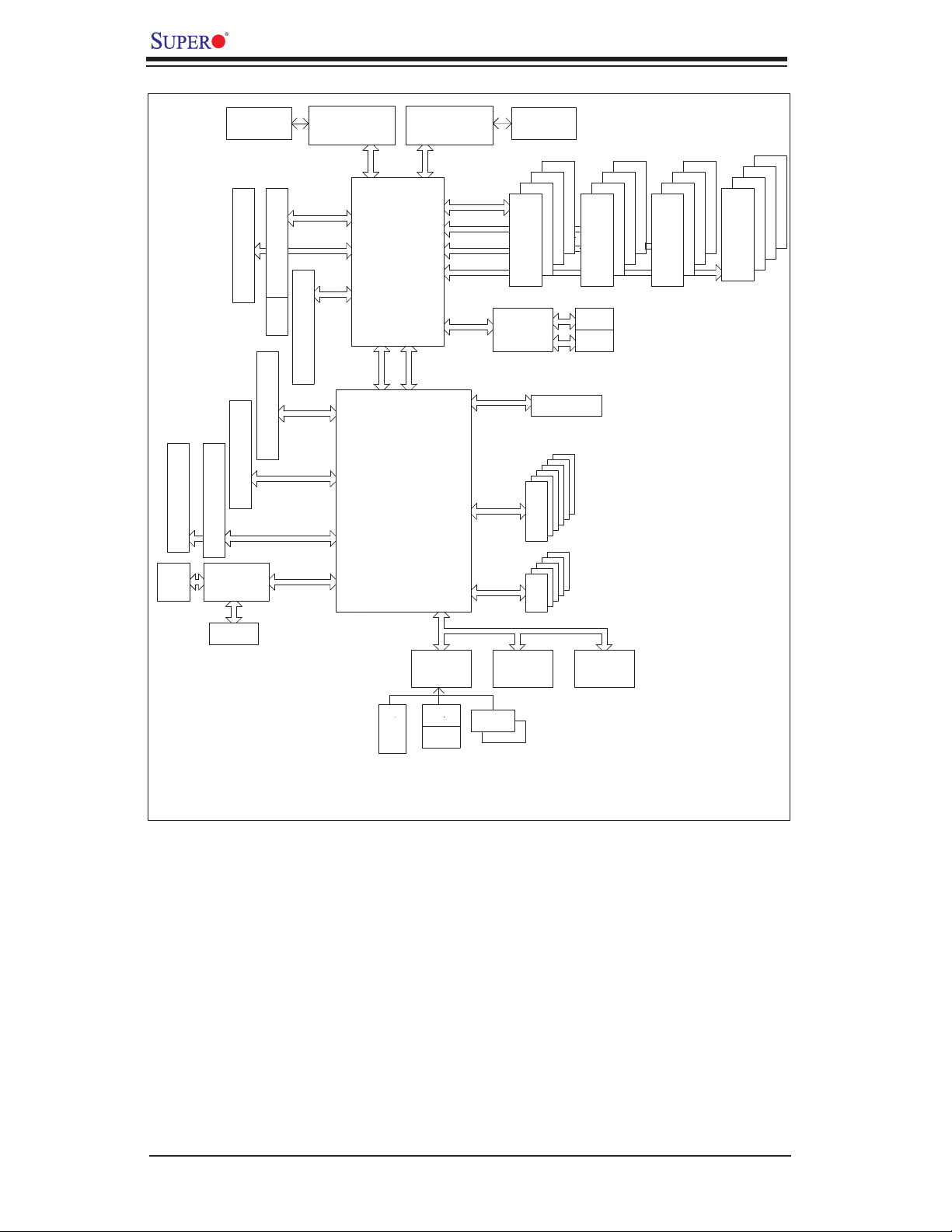

Intel 5400 Chipset: System Block Diagram ............................................. 1-8

1-2 Chipset Overview ................................................................................... 1-9

1-3 Special Features ................................................................................... 1-10

1-4 PC Health Monitoring ............................................................................ 1-10

1-5 ACPI Features ...................................................................................... 1-11

1-6 Power Supply ....................................................................................... 1-12

1-7 Super I/O ................................................................................................ 1-12

Chapter 2: Installation

2-1 Static-Sensitive Devices ......................................................................... 2-1

Precautions ................................................................................................ 2-1

Unpacking ................................................................................................ 2-1

2-2 Processor and Heatsink Installation ....................................................... 2-2

2-3 Installing DIMMs ..................................................................................... 2-6

2-4 Control Panel Connectors and IO Ports ................................................. 2-8

A. Back Panel Connectors/IO Ports .............................................................. 2-8

B. Front Control Panel ................................................................................... 2-9

C. Front Control Panel Pin Defi nitions ........................................................ 2-10

NMI Button ............................................................................................. 2-10

Power LED ............................................................................................. 2-10

HDD LED .............................................................................................. 2-11

NIC1/NIC2 LED ..................................................................................... 2-11

Overheat/Fan Fail LED ......................................................................... 2-12

Power Fail LED ........................................................................................ 2-12

Reset Button ......................................................................................... 2-13

vi

Preface

Power Button .......................................................................................... 2-13

2-5 Connecting Cables ............................................................................... 2-14

ATX Power Connector .......................................................................... 2-14

Processor Power Connector ................................................................. 2-14

Universal Serial Bus (USB0/1) ................................................................ 2-15

Chassis Intrusion .................................................................................... 2-15

Fan Headers .......................................................................................... 2-16

Keylock ..................................................................................................... 2-16

ATX PS/2 Keyboard and Mouse Ports ..................................................... 2-17

Serial Ports ............................................................................................. 2-17

Wake-On-Ring .......................................................................................... 2-18

Wake-On-LAN .......................................................................................... 2-18

GLAN (Ethernet Ports) ............................................................................. 2-19

Speaker/Power LED/Keylock Header .................................................... 2-19

Power Supply Failure ............................................................................... 2-20

Alarm Reset .............................................................................................. 2-20

Overheat LED/Fan Fail ............................................................................ 2-21

SMB Connector ........................................................................................ 2-21

Power SMB Connector ............................................................................. 2-22

VGA Connector ........................................................................................ 2-22

Compact Flash Card PWR Connector ..................................................... 2-23

T-SGPIO Headers .................................................................................... 2-23

2-6 Jumper Settings .................................................................................... 2-24

Explanation of Jumpers ......................................................................... 2-24

GLAN Enable/Disable ............................................................................ 2-24

Clear CMOS ............................................................................................. 2-25

Watch Dog ................................................................................................ 2-25

VGA Enabled/Disabled ............................................................................. 2-26

Memory Voltage Select ............................................................................ 2-26

3rd PWR Supply PWR Fault .................................................................... 2-27

I2C Bus to PCI-X/PCI-Exp. Slots Enable/Disable .................................... 2-27

Compact Flash Master/Slave Enable/Disable .......................................... 2-28

2-7 Onboard Indicators ............................................................................... 2-29

GLAN LEDs .............................................................................................. 2-29

Onboard Power LED ................................................................................ 2-29

2-8 Floppy, SIMSO, Serial ATA and Hard Disk Drive Connections ........... 2-30

Floppy Connector .................................................................................... 2-30

Serial ATA Ports........................................................................................ 2-31

SIMSO IPMI Slot ..................................................................................... 2-31

vii

X7DWN+ User's Manual

IDE Connectors ....................................................................................... 2-32

Chapter 3: Troubleshooting

3-1 Troubleshooting Procedures ................................................................... 3-1

Before Power On ....................................................................................... 3-1

No Power ................................................................................................... 3-1

No Video .................................................................................................. 3-1

Losing the System’s Setup Confi guration ................................................ 3-2

Memory Errors ........................................................................................... 3-2

3-2 Technical Support Procedures ................................................................ 3-2

3-3 Frequently Asked Questions ................................................................... 3-3

3-4 Returning Merchandise for Service ......................................................... 3-4

Chapter 4: BIOS

4-1 Introduction ............................................................................................... 4-1

4-2 Running Setup ......................................................................................... 4-2

4-3 Main BIOS Setup ..................................................................................... 4-2

4-4 Advanced Setup ........................................................................................ 4-6

4-5 Security Setup ....................................................................................... 4-25

4-6 Boot Setup .............................................................................................. 4-26

4-7 Exit .......................................................................................................... 4-27

Appendices:

Appendix A: BIOS POST Codes ..................................................................... A-1

Appendix B: Installing the Windows OS .........................................................B-1

Appendix C: Installing Other Software Programs and Drivers .......................C-1

viii

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Checklist

Congratulations on purchasing your computer motherboard from an acknowledged

leader in the industry. Supermicro boards are designed with the utmost attention

to detail to provide you with the highest standards in quality and performance.

Check that the following items have all been included with your motherboard. If

anything listed here is damaged or missing, contact your retailer.

The following items are included in the retail box.

One (1) Supermicro Mainboard

One (1) ribbon cable for IDE devices (CBL-0036L-03)

One (1) fl oppy ribbon cable (CBL-0022L)

Six (6) Serial ATA cables (CBL-0044Lx6)

One (1) I/O backpanel shield (CSE-PT07L)

One (1) Supermicro CD containing drivers and utilities

One (1) User's/BIOS Manual

1-1

X7DWN+ User's Manual

Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site: www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacifi c

Address: Super Micro, Inc.

4F, No. 232-1 Liancheng Road

Chung-Ho 235, Taipei Hsien, Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: 886-2-8228-1366, ext.132 or 139

1-2

X7DWN+ Image

Chapter 1: Introduction

Note: The drawings and pictures shown in this manual were based on the latest

PCB Revision available at the time of publishing of the manual. The motherboard

you’ve received may or may not look exactly the same as the graphics shown

in the manual.

1-3

X7DWN+ User's Manual

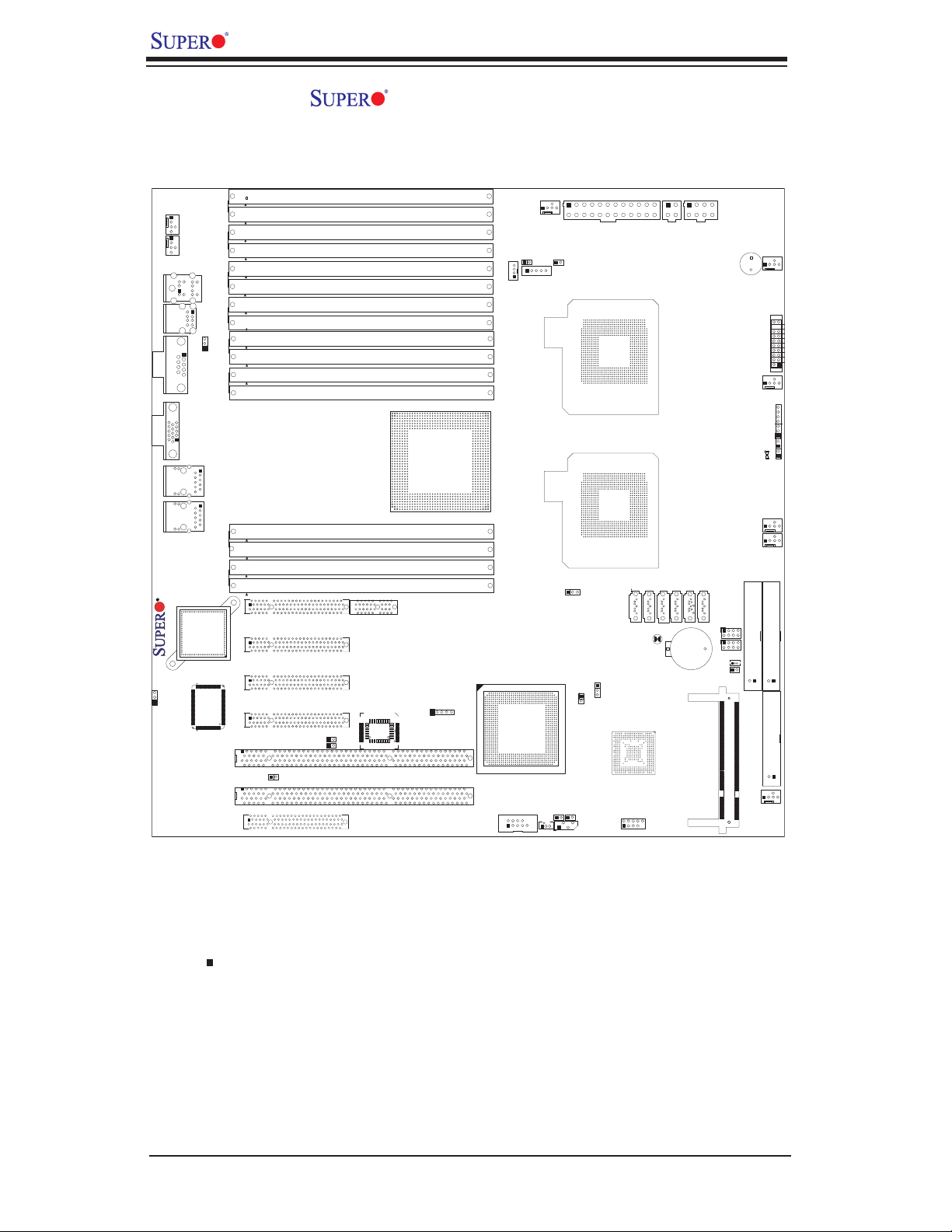

X7DWN+ Motherboard Layout

(not drawn to scale)

Fan5

Fan6

6

10

12

78

9

JKM1

34

5

85

JUSB1

96

COM1

JCOM1

5

15

10

J15

VGA

1

11

6

12

11

14

13

JLAN1

12

11

14

13

JLAN2

X7DWN+

LAN

CTRL

JPL1

12

11

KB/Mouse

41

USB0/1

1

2

LAN1

9

10

1

2

LAN2

S I/O

JP2

J34

J4J9B2

BANK4

J9B1

J33

J3

BANK3

J8B3

J8B2

J8B1

BANK2

J7B2

BANK1

A1

B1

J13

J12

J7B3

J2

J32

J7B1

J1

J31

J5

J6

J9

J14

B2 A2

A1

B1

J8

JWOR

A2

B2

Slot6 PCI-E2 x8

Slot5 PCI-E2 x8

Slot4 PCI-E x4

Slot3 PCI-E x8

J27

JI2C1

J28

1 1

JI2C2

Slot2 PCI-X 100/133MHz

Slot1 PCI-X 100/133MHz

Slot0 PCI-U

DIMM 4D

DIMM 4C

DIMM 4B

DIMM 4A

DIMM 3D

DIMM 3C

DIMM 3B

DIMM 3A

DIMM 2D

DIMM 2C

DIMM 2B

DIMM 2A

DIMM 1A

DIMM 1B

DIMM 1C

DIMM 1D

SEPC

BIOS

Intel 5400

(North Bridge)

J11

USB 4

JUSB 3

CPU FAN1

FAN7

JAR

JP3

SMBUS_PS

PSF

Intel ESB 2

(South Bridge)

COM2

JWOL

JCOM2

J3P

J17

3rd PWR Fail Detect

JWD

J7

JK1

JL1

1

J18

SMB

24-Pin PWR

JPW1

CPU1

CPU2

CMOS Clear

JPG1

VGA CTRL

USB 2/3

JUSB2

I-SATA0

JS1

4-Pin PWR

3

JPW2

I-SATA2

I-SATA1

JS2 JS3 JS4

JBT1

154

8-Pin PWR

2

4

JPW3

I-SATA3

JS5

Battery

BT1

I-SATA5

I-SATA4

JS6

T-SGPIO2

J30

J29

T-SGPIO1

JWF1

JCF1

J16

SP1

FAN2

FAN3

FAN8

JIDE2

SIMSO

Buzzer

+

FAN1

JF1

19

20

FP Ctrl Panel

2

1

JD1

7

1

PWRLED/SPK

1

JP1

1

LE1

JOH1

4

4

CPUFAN2

JIDE1

IDE#1

Compact Flash

1

J22

Floppy

1

1

FAN4

Notes:

1. Jumpers not indicated are for test purposes only.

2. See Chapter 2 for detailed information on jumpers, I/O ports and JF1 front

panel connections.

3. " " indicates the location of Pin 1.

4. SEPC: Supermicro Enhanced Power Connector is specially designed to support

the Supermicro 2U Riser Card only.

5. For the system to function properly, make sure to unplug the power cables before

removing or installing components.

6 JIDE2 is for Compact Card Use only. For Compact Card to work properly,

please enable JCF1 by putting a jumper on it, and connect JWF1 to a power

supply connector.

1-4

Chapter 1: Introduction

Quick Reference ( X7DWN+)

Jumper Description Default Setting

J3P 3rd PWR Failure Detection Off (Disabled)

JBT1 CMOS Clear (See Chapter 2)

JCF1 Compact Card Master/Slave Select On (Master)

2

JI

C1/JI2C2 I2C Bus to PCI-X/PCI-E Slots Open (Disabled)

JP2 Memory Voltage Select Pins 1-2 (Auto)

JPG1 VGA Enable Pins 1-2 (Enabled)

JPL1 GLAN1/2 Enable Pins 1-2 (Enabled)

JWD Watch Dog Pins 1-2 (Reset)

Connector Description

COM1/COM2 COM1/COM2 Serial Port/Connector (JCOM1/JCOM2)

FAN 1-8 Fans 1-8 (Fans1-6, System Fans, Fans7/8: CPU Fans)

Floppy Floppy Disk Drive Connector (J22)

IDE1/IDE2 IDE1 Hard Drive (JIDE1)/Compact Flash Card (JIDE2)

I-SATA 0~5 Intel SATA 0-5 Connectors (JS1~JS6)

JAR Alarm Buzzer Reset

JD1 PWR LED(pins1-3)/SpeakerHeader (pins 4-7)

JF1 Front Control Panel Connector

JL1 Chassis Intrusion Header

JOH1 Overheat LED

JP3 Power Fault (Power Supply Failure) (PSF)

JPW1 Primary 24-Pin ATX PWR Connector

JPW2/JPW3 +12V 4-pin PWR (JWP2)/+12V 8-pin PWR (JPW3)

JWF1 Compact Card PWR Connector (Used if JFC1 is on.)

JWOL Wake-on-LAN Header

JWOR Wake-on-Ring Header

LAN1/LAN2 G-bit Ethernet Ports 1/2 (JLAN1/JLAN2)

LE1 PWR LED Indicator

SIMSO IPMI SIM (Supermicro Intelligent MGMT) Slot(J16)

SMB System Management Bus Header (J18)

SMB_PS Power System Management (I

2

C) Header (J17)

SP1 Internal Buzzer

T-SGPIO1/T-SGPIO2 Serial-Link General Purpose I/O Headers (J29/J30)

Keylock Keylock Header (JK1)

USB 0/1 Back Panel USB 0/1 (JPUSB1)

USB 2/3, USB4 Front Panel USB 2/3 (JPUSB2), USB 4 (JPUSB3)

VGA VGA Connector (J15)

1-5

X7DWN+ User's Manual

Motherboard Features

CPU

• Dual Intel® 64-bit LGA 771 Quad-Core/Dual-Core Xeon 5400 Series/5300LV

Series/5200 Series/5100LV Series processors at a front side bus speed of up

to 1.6 GHz

Memory

• 16 240-pin DIMM sockets support up to 128 GB DDR2 FBD (Fully Buffered)

ECC 800/667/533 Memory (See Section 2-3 in Chapter 2 for DIMM Slot

Population.)

Chipset

• Intel 5400 chipset, including: the 5400 Memory Control Hub (MCH) and the

Enterprise South Bridge 2 (ESB2).

Expansion Slots

• Two PCI-E2 x8 slots (Slot5/slot6) (Gen. 2.0)

• One PCI-E x8 slot (Slot3)

• One PCI-E x4 slot (Slot4)

• Two 64-bit PCI-X 133/100MHz slots (Slot1/Slot2)

• One PCI-U (Universal) slot (Slot0) (Gen. 2.0)

• SIMSO Slot (J16)

BIOS

• 8 Mb Phoenix

®

Flash ROM

• PCI 2.2, ACPI 1.0, Plug and Play (PnP), USB Keyboard support and SMBIOS

2.3

PC Health Monitor ing

• Onboard voltage monitors for CPU cores, chipset voltage, Memory voltage,

+1. 8V, +3. 3 V, +3.3V St a n db y, + 5V, +5V Stan d by, +12V, −12V and Vbatt

• Fan status monitor with fi rmware control

• CPU/chassis temperature monitors

• Platform Environment Control Interface (PECI) ready

• CPU fan auto-off in sleep mode

• CPU slow-down on temperature overheat

• CPU thermal trip support for processor protection, power LED

• Power-up mode control for recovery from AC power loss

• Auto-switching voltage regulator for CPU cores

• System overheat/Fan Fail LED Indicator and control

• Chassis intrusion detection

• System resource alert via Supero Doctor III

1-6

Chapter 1: Introduction

ACPI Fe at ur es

• Slow blinking LED for suspend state indicator

• Main switch override mechanism

• ACPI Power Management

• Keyboard Wakeup from Soft-off

Onboard I/O

• Intel ESB2 supports Six SATA2 ports (with RAID0, RAID1, RAID10, RAID5

supported in the Windows OS Environment)

• One SIMSO IPMI socket

• Intel 82575 Gigabit Ethernet controller supports two Giga-bit LAN ports

• One EIDE Ultra DMA /100 bus master interface

• One fl oppy port interface

• Two COM ports(1 header, 1 port)

• PS/2 mouse and PS/2 keyboard ports

• Up to fi ve USB 2.0 (Universal Serial Bus) (2 ports, 3 Headers)

• ES1000 (32 MB) Graphic Controller supports one VGA connector

• Super I/O: Winbond W83627HF w/Hardware Monitor support: W83793,

HECETA

Other

• External modem ring-on

• Wake-on-LAN (WOL)

• Wake-on-Ring (WOR)

• Console redirection

• Onboard Fan Speed Control by Thermal Management via BIOS

CD/Diskette Utilities

• BIOS fl ash upgrade utility and device drivers

Dimensions

• Ext. ATX 13.05" (L) x 13.68" (W) (331.5 mm x 347.47 mm)

1-7

X7DWN+ User's Manual

#1

VGA

CONN

#2

J12J13

PCI-X SLOT

PCI-X SLOT

ES1000

VRM

J5

J6

PCI-EXP X8 SLOT

J11

#3

J9

#4

J14

PCI-EXP X8 SLOT

PCI-EXPx8

PCI-E x8 SLOT

VGA

PROCESSOR#2

1666/1333/1067

MT/S

PCI-EXPx8

PCI-EXPx8

J8

PCI-E

PCI-EXP X8 SLOT

x8

SEPC

PCI-EXP X8 SLOT

PCI-EXPx4

PCI-X 133

PCI32/33MMZ

PORT

PORT

PORT

#0

PORT

#1,2

PORT

#5,6

#1,2

#3,4

PORT

MCH

Seaburg

PORT

#0#7,8

PCIEx8

PORTESI

#4

ESB2

PROCESSOR#1

1666/1333/1067

MT/S

FBD CHNL0

FBD CHNL1

FBD CHNL2

FBD CHNL3

PORT

PCI-E x4

#9

PCIEx4

VRM

#3

#2

#1 #1 #1

#0 #0 #0

FBD DIMM

IDE CONN

#5

#4

SATA

#4

USB

RJ45

RJ45

GB LAN

ATA 100

3.0 Gb/S

USB 2.0

ZOAR

RMII

#1

#0

#1

#0

#3

#2

#3

#2

#3

#2

FBD DIMM

#3

#2

FBD DIMM

#2

#1

#0

FBD DIMM

#3

FWH

LPC

TPM

DDR2

FDD

SIO

W83627

HF

MS

KB

COM1

COM2

Bloc k Diag ram o f the 5 40 0 Chips et

Note: This is a general block diagram. Please see the previous Motherboard Features

pages for details on the features of each motherboard.

1-8

Chapter 1: Introduction

1-2 Chipset Overview

Built upon the functionality and the capability of the 5400 chipset, the X7DWN+

motherboard provides the performance and feature set required for quad-pro-

cessor or dual-processor-based high-end systems with confi guration options

optimized for complex storage platforms. The 5400 chipset supports single or

dual Intel Quad-Core/Dual-Core Xeon 5400 Series/5300LV Series/5200 Series/

5100LV Series processor with front side bus speeds of up to 1.6 GHz. The chipset

consists of the 5400 Memory Controller Hub (MCH) for the host bridge and the

631xESB/632xESB I/O Controller Hub (Enterprise South Bridge 2-ESB2) for the

I/O subsystem.

The In tel 5 40 0 MCH (No r th Br idg e)

The 5400 MCH (North Bridge) provides two FSB processing interfaces, four fully

buffered (FBD) DIMM memory channels, PCI-Express bus interfaces confi gurable

to form x8 or x16 ports, an EB2 South Bridge Interface (ESI) and SMBus Interfaces

for system management, and DIMM Serial Presence Detect (SPD). The peak

bandwidth for each FBD channel is 8 GB/s for DDR2 800/667 FBD memory, giving

a total memory size of 128 MB for 4 FBD channels. The PCI-Express interfaces

can be confi gured to form x8 or x16 ports that can operate up to Gen-2 speeds

in x16 confi guration for enhanced graphics applications.

The In tel 6 31xESB/632 x ESB I /O Con trol ler H ub- ES B2 (Sout h Bri dge)

The 631xESB/632xESB I/O Controller Hub (Enterprise South Bridge 2) integrates

an Ultra ATA 100 Controller, six Serial ATA host controller ports, one EHCI host

controller, six external USB 2.0 ports, an LPC interface controller, and a fl ash

BIOS interface controller. Additionally, the ESB 2 chip also contains a PCI interface

controller, Azalia/'97 digital controller, integrated LAN controller, an ASF control-

ler and an ESI for communication with the MCH. The Intel ESB2 offers the data

buffering and interface arbitration capabilities required for a high-end system to

constantly operate effi ciently and maintain peak performance.

Compliant with the ACPI platform, the ESB2 supports the Full-On, Stop-Grant,

Suspend-to-RAM, Suspend-to-Disk, and Soft-Off power management states.

Combined with the functionality offered by the onboard LAN controller, the ESB2

also supports alert systems for remote management.

With the 5400 chipset built in, the X7DWN+ offers a superb solution for intense

computing and complex I/O environments, and is ideal for high-end server sys-

tems.

1-9

X7DWN+ User's Manual

1-3 Special Features

Recovery from AC Power Loss

BIOS provides a setting for you to determine how the system will respond when

AC power is lost and then restored to the system. You can choose for the system

to remain powered off (in which case you must hit the power switch to turn it back

on) or for it to automatically return to a power- on state. See the Advanced BIOS

Setup section to change this setting. The default setting is Last State.

1-4 PC Health Monitoring

This section describes the PC health monitoring features of the X7DWN+. All

have an onboard System Hardware Monitor chip that supports PC health moni-

toring.

Onboard Voltage Monitors for CPU Core, Chipset Voltage, Memory Voltage, +1.8V,

+5V, +3.3V, +3.3V Standby, +5V Standby, +12V, −12V and VBatt. Once a voltage

becomes unstable, a warning is given or an error message is sent to the screen.

Users can adjust the voltage thresholds to defi ne the sensitivity of the voltage

monitor.

An onboard voltage monitor will scan the following voltages continuously:

Fan Statu s Moni tor wi th Firmw are Con trol

The PC health monitor can check the RPM status of the cooling fans. The onboard

CPU and chassis fans are controlled by Thermal Management via BIOS (under

Hardware Monitoring in the Advanced Setting).

Environ ment al Te mper ature Co ntro l

The thermal control sensor monitors the CPU temperature in real time and will

turn on the thermal control fan whenever the CPU temperature exceeds a user-

defi ned threshold. The overheat circuitry runs independently from the CPU. Once

it detects that the CPU temperature is too high, it will automatically turn on the

thermal fan control to prevent any overheat damage to the CPU. The onboard

chassis thermal circuitry can monitor the overall system temperature and alert

users when the chassis temperature is too high.

CPU Fan Auto -O f f in Slee p Mode

The CPU fan becomes active when the power is turned on. It continues to operate

when the system enters the Standby mode. When in the sleep mode, the CPU will

not run at full power, thereby generating less heat.

System Resource Aler t

This feature is available when used with Supero Doctor III in the Windows OS

environment or used with Supero Doctor II in Linux. Supero Doctor is used to

notify the user of certain system events. For example, you can also confi gure

1-10

Chapter 1: Introduction

Supero Doctor to provide you with warnings when the system temperature, CPU

temperatures, voltages and fan speeds go beyond a pre-defi ned range.

1-5 ACPI Features

ACPI stands for Advanced Confi guration and Power Interface. The ACPI specifi -

cation defi nes a fl exible and abstract hardware interface that provides a standard

way to integrate power management features throughout a PC system, including

its hardware, operating system and application software. This enables the system

to automatically turn on and off peripherals such as CD-ROMs, network cards,

hard disk drives and printers.

In addition to enabling operating system-directed power management, ACPI

provides a generic system event mechanism for Plug and Play and an operating

system-independent interface for confi guration control. ACPI leverages the Plug

and Play BIOS data structures while providing a processor architecture-indepen-

dent implementation that is compatible with both Windows 2000 and Windows

2003 Operating Systems.

Sl ow Blinkin g LED for Sus pend -S tate I ndica tor

When the CPU goes into a suspend state, the chassis power LED will start blinking

to indicate that the CPU is in suspend mode. When the user presses any key, the

CPU will wake-up and the LED will automatically stop blinking and remain on.

Main Switch Override Mechanism

When an ATX power supply is used, the power button can function as a system

suspend button to make the system enter a SoftOff state. The monitor will be

suspended and the hard drive will spin down. Pressing the power button again

will cause the whole system to wake-up. During the SoftOff state, the ATX power

supply provides power to keep the required circuitry in the system "alive." In case

the system malfunctions and you want to turn off the power, just press and hold

the power button for 4 seconds. This option can be set in the Power section of

the BIOS Setup routine.

External Modem Ring- On

Wake-up events can be triggered by a device such as the external modem ringing

when the system is in the SoftOff state. Note that external modem ring-on can

only be used with an ATX 2.01 (or above) compliant power supply.

Wake - On- L AN ( WOL)

Wake-On-LAN is defi ned as the ability of a management application to remotely

power up a computer that is powered off. Remote PC setup, up-dates and asset

tracking can occur after hours and on weekends so that daily LAN traffi c is kept

to a minimum and users are not interrupted. The motherboard has a 3-pin header

(WOL) to connect to the 3-pin header on a Network Interface Card (NIC) that has

1-11

X7DWN+ User's Manual

WOL capability. In addition, an onboard LAN controller can also support WOL

without any connection to the WOL header. The 3-pin WOL header is to be used

with a LAN add-on card only.

Note: Wake-On-LAN requires an ATX 2.01 (or above) compliant power supply.

1-6 Power Supply

As with all computer products, a stable power source is necessary for proper and

reliable operation. It is even more important for processors that have high CPU

clock rates.

The X7DWN+ can accommodate 24-pin ATX power supplies. Although most

power supplies generally meet the specifi cations required by the CPU, some are

inadequate. In addition, the 12V 4-pin and the 12V 8-pin power connections are

also required to ensure adequate power supply to the system. Also your power

supply must supply 1.5A for the Ethernet ports.

Note: The + 12V 8-pin CPU Power Connector (JPW3) is also required to support

Intel 64-bit CPUs. Failure to provide this extra power will result in CPU PWR Failure.

See Section 2-5 for details on connecting the power supply.

It is strongly recommended that you use a high quality power supply that meets

ATX power supply Specifi cation 2.02 or above. It must also be SSI compliant

(For more information, please refer to the web site at http://www.ssiforum.org/).

Additionally, in areas where noisy power transmission is present, you may choose

to install a line fi lter to shield the computer from noise. It is recommended that

you also install a power surge protector to help avoid problems caused by power

surges.

1-7 Super I/O

The disk drive adapter functions of the Super I/O chip include a fl oppy disk drive

controller that is compatible with industry standard 82077/765, a data separator,

write p r e -compensation circuitry, dec o d e logic, data rat e selection, a clock genera-

tor, drive interface control logic and interrupt and DMA logic. The wide range of

functions integrated onto the Super I/O greatly reduces the number of components

required for interfacing with fl oppy disk drives. The Super I/O supports 360 K, 720

K, 1.2 M, 1.44 M or 2.88 M disk drives and data transfer rates of 250 Kb/s, 500

Kb/s or 1 Mb/s. It also provides two high-speed, 16550 compatible serial com-

munication ports (UARTs). Each UART includes a 16-byte send/receive FIFO,

a programmable baud rate generator, complete modem control capability and a

processor interrupt system. Both UARTs provide legacy speed with baud rate of

up to 115.2 Kbps as well as an advanced speed with baud rates of 250 K, 500 K,

or 1 Mb/s, which support higher speed modems.

1-12

Chapter 1: Introduction

The Super I/O supports one PC-compatible printer port (SPP), Bidirectional Printer

Port (BPP), Enhanced Parallel Port (EPP) or Extended Capabilities Port (ECP).

The Super I/O provides functions that comply with ACPI (Advanced Confi guration

and Power Interface), which includes support of legacy and ACPI power manage-

ment through an SMI or SCI function pin. It also features auto power management

to reduce power consumption.

1-13

X7DWN+ User's Manual

Notes

1-14

Chapter 2: Installation

Chapter 2

Installation

2-1 Static-Sensitive Devices

Electrostatic Discharge (ESD) can damage electronic com ponents. To prevent

damage to your system board, it is important to handle it very carefully. The fol-

lowing measures are generally suffi cient to protect your equipment from ESD.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing the board from the antistatic

bag.

• Handle the board by its edges only; do not touch its components, peripheral

chips, memory modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their antistatic bags when not

in use.

• For grounding purposes, make sure your computer chassis provides excellent

conductivity between the power supply, the case, the mounting fasteners and

the motherboard.

• Use only the correct type of onboard CMOS battery as specifi ed by the

manufacturer. Do not install the onboard battery upside down to avoid possible

explosion.

Unpacking

The motherboard is shipped in antistatic packaging to avoid static damage. When

unpacking the board, make sure the person handling it is static protected.

2-1

X7DWN+ User's Manual

!

2-2 Processor and Heatsink Installation

When handling the processor package, avoid placing

dire ct pre ssu re on t he labe l are a of the f an.

Notes: 1. Always connect the power cord last and always remove it before adding,

removing or changing any hardware components. Make sure that you install the

processor into the CPU socket before you install the CPU heatsink.

2. Intel's boxed Xeon CPU package contains the CPU fan and heatsink assembly.

If you buy a CPU separately, make sure that you use only Intel-certifi ed multi-

directional heatsink and fan.

3. The Intel Xeon LGA 771 heatsink and fan comes with a push-pin design and

no tool is needed for installation.

4. Make sure to install the motherboard into the chassis before you install the

CPU heatsink and fan.)

5. When purchasing an LGA 771 CPU or when receiving a motherboard with an

LGA 771 CPU pre-installed, make sure that the CPU plastic cap is in place and

none of the CPU pins are bent; otherwise, contact the retailer immediately.

6. Refer to the MB Features Section for more details on CPU support.

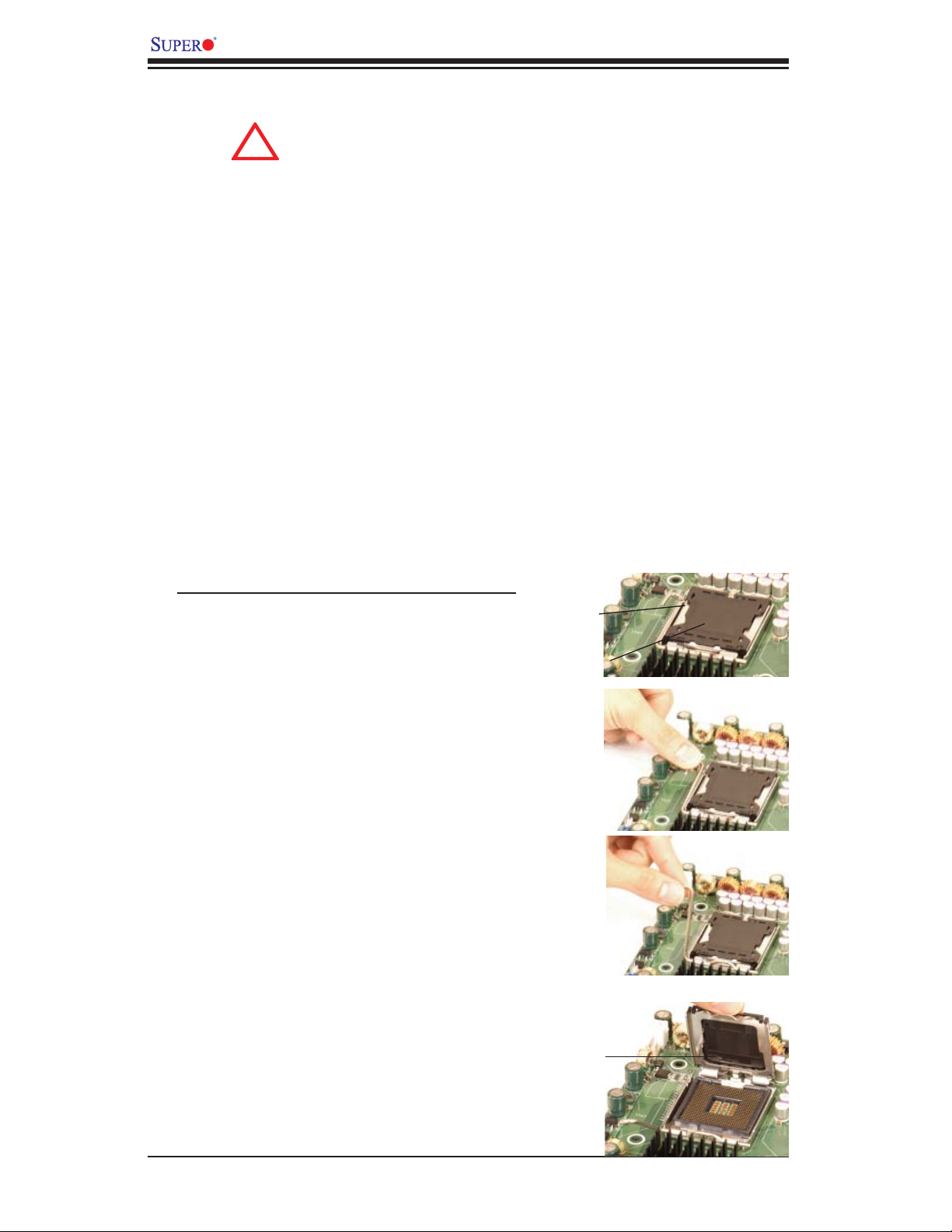

Installation of the LGA771 Processor

Socket Clip

Load Plate

1. Press the socket clip to release

the load plate, which covers the CPU

socket, from its locking position.

2. Gently lift the socket clip to open

the load plate.

Load Plate

2-2

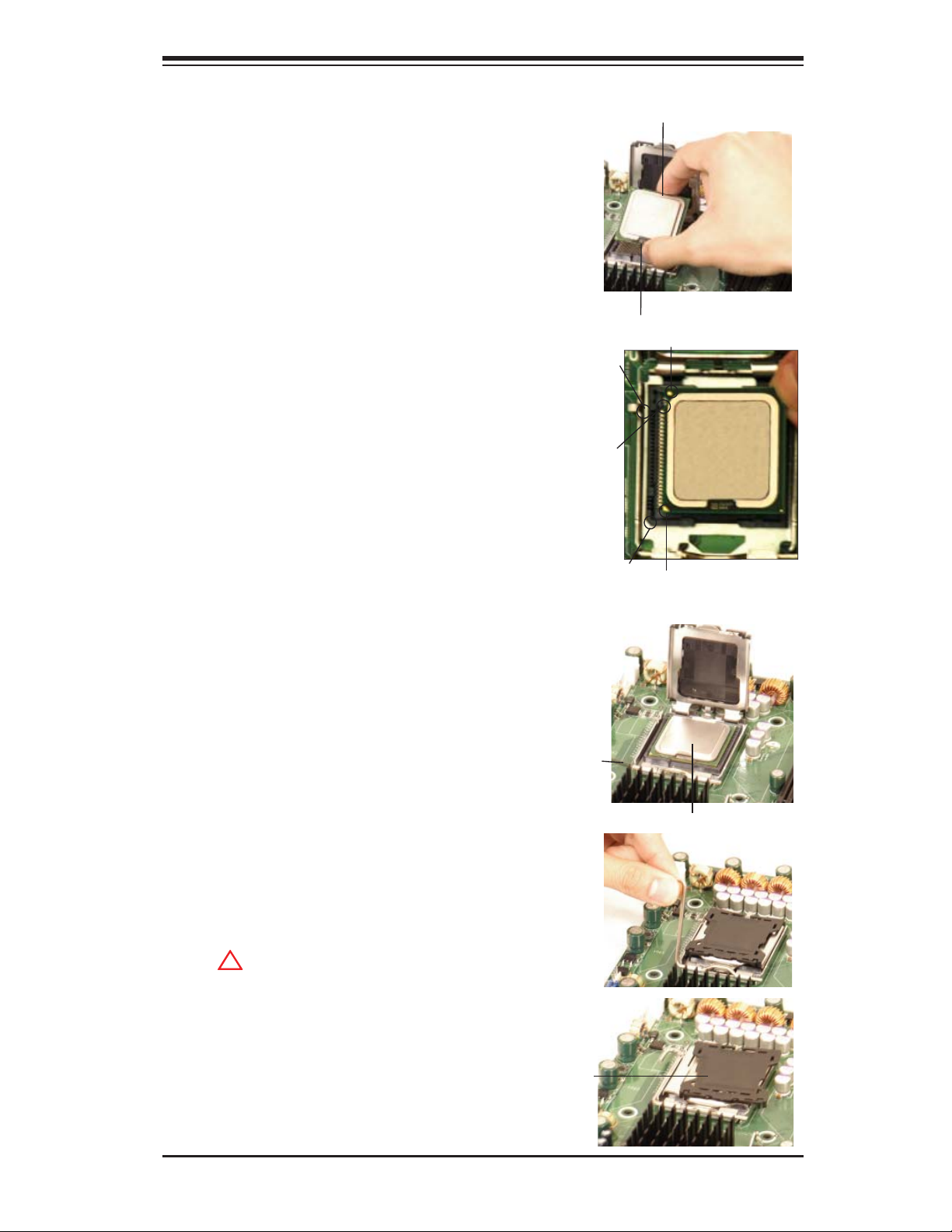

3. Use your thumb and your index fi nger

!

to hold the CPU at the North Center

Edge and the South Center Edge of

the CPU.

4. Align CPU Pin1 (the CPU corner

marked with a triangle) against the

socket corner marked with a triangle

cutout.

Chapter 2: Installation

North Center Edge

5. Align the CPU key, the semi-circle

cutout below a gold dot, against the

socket key, which is the notch on the

same side of the triangle cutout on the

socket.

6. Once aligned, carefully lower the

CPU straight down into the socket. (Do

not drop the CPU on the socket. Do not

move the CPU horizontally or vertically.

Do not rub the CPU against the surface

or against any pins of the socket to avoid

damaging the CPU or the socket.)

7. With the CPU inside the socket,

inspect the four corners of the CPU

to make sure that the CPU is properly

installed.

8. Use your thumb to gently push the

socket clip down to the clip lock.

Socket Key

(Socket Notch)

CPU Key (semi-

circle cutout)

below the circle.

Corner with a

triangle cutout

Socket clip

South Center Edge

gold dot

CPU Pin1

9. If the CPU is properly installed

CPU in the CPU socket

into the socket, the plastic cap will be

automatically released from the load

plate when the clip is pushed in the clip

lock. Remove the plastic cap from the

motherboard.

(Warni ng: Please save the

plastic cap. The motherboard must be

shipped with the plastic cap properly

installed to protect the CPU socket pins.

Shipment without the plastic cap prop-

erly installed will cause damage to the

socket pins.)

Plastic cap

is released

from the

load plate

if the CPU

is properly

installed.

2-3

X7DWN+ User's Manual

!

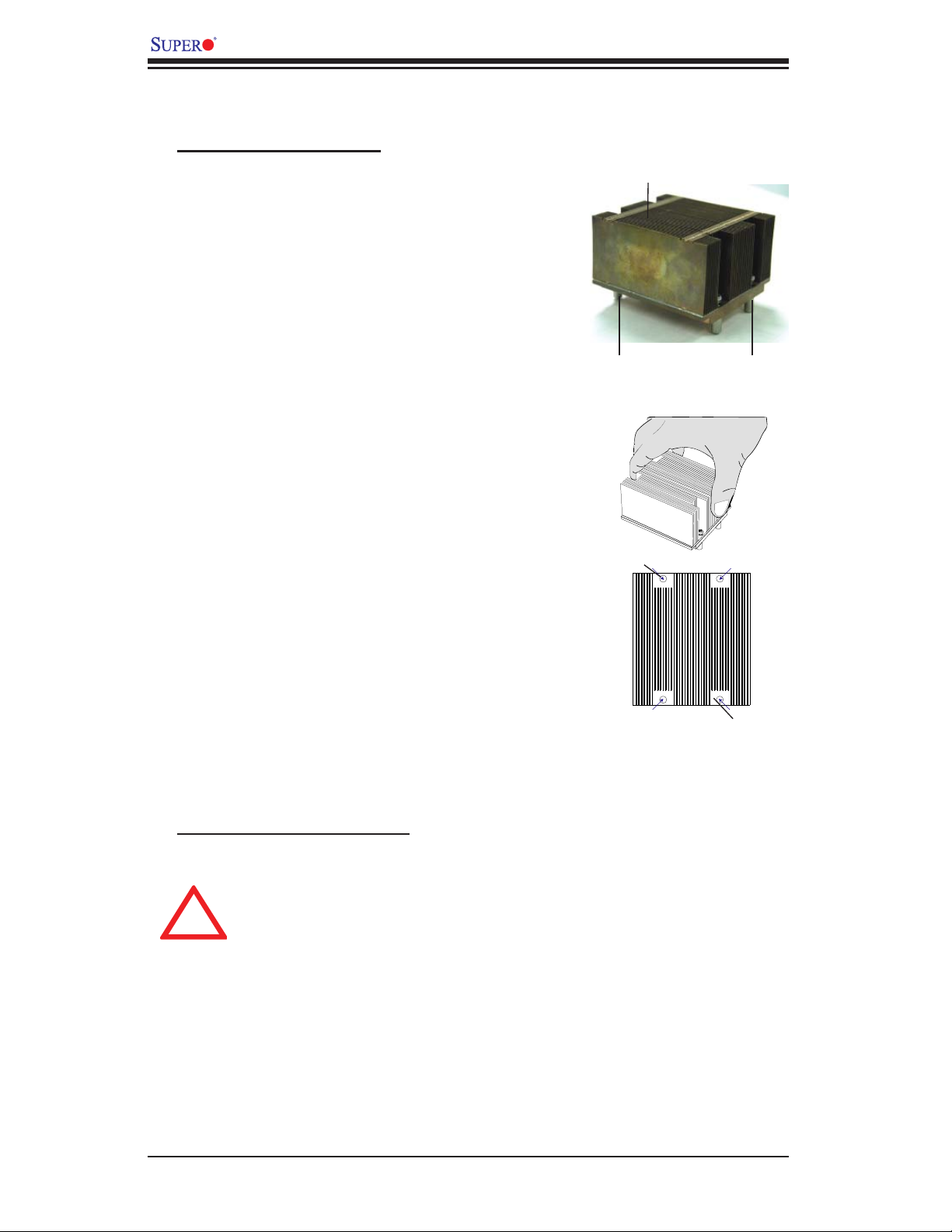

Installation of the Heatsink

CEK Heatsink Installation

1. Do not apply any thermal grease to the

heatsink or the CPU die because the re-

quired amount has already been applied.

2. Place the heatsink on top of the CPU so

that the four mounting holes are aligned

with those on the retention mechanism.

3. Screw in two diagonal screws (ie the #1

and the #2 screws) until just snug (-do not

fully tighten the screws to avoid possible

damage to the CPU.)

4. Finish the installation by fully tightening

all four screws.

CEK Passive Heatsink

Screw#1 Screw#2

Screw#1

To Un-install the Heatsink

Warni ng: We do not recommend

that the CPU or the heatsink be

removed. However, if you do need

to uninstall the heatsink, please

follow the instructions below to

uninstall the heatsink to prevent

damage done to the CPU or the

CPU socket.

Screw#2

2-4

Chapter 2: Installation

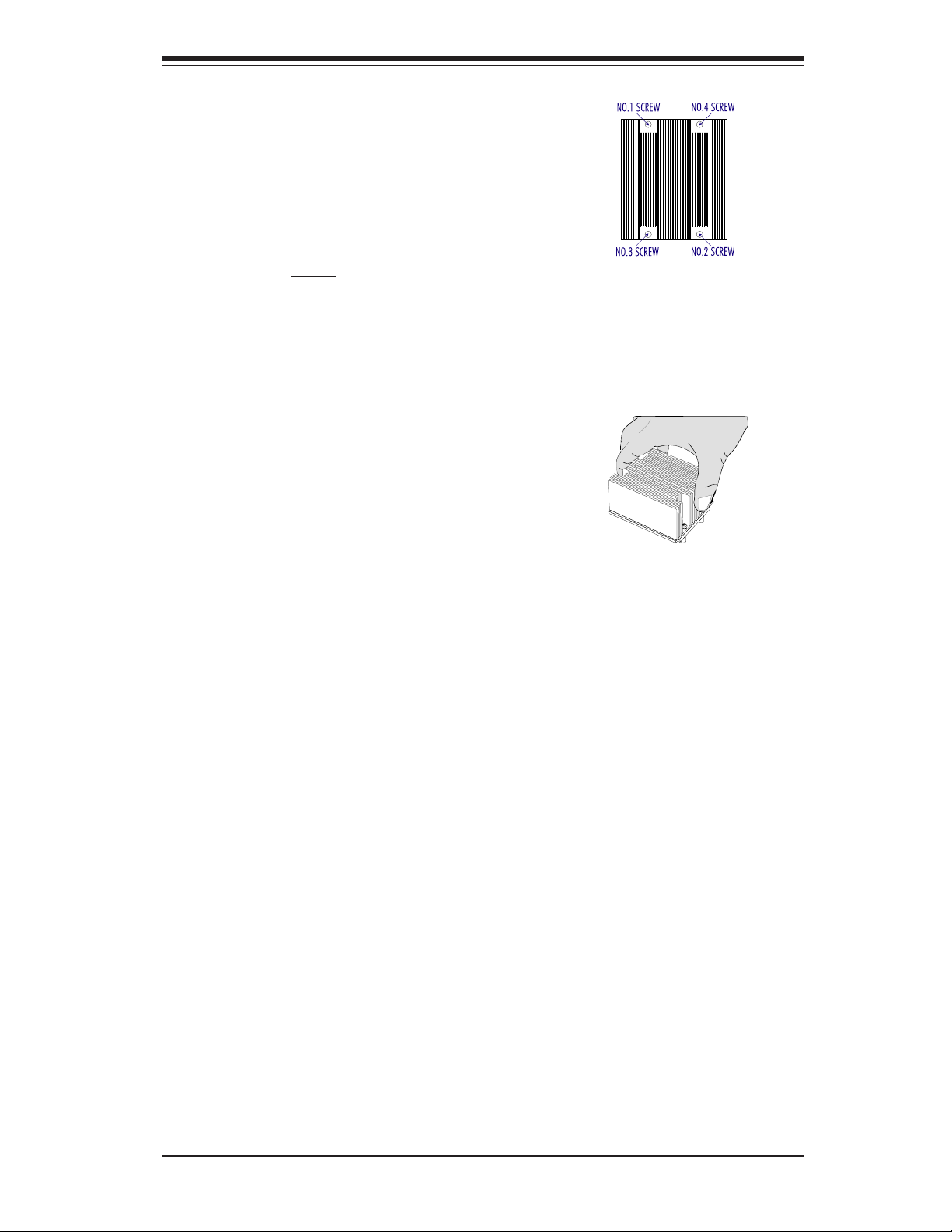

1. Unscrew and remove the heatsink screws

from the motherboard in the sequence as show

in the picture on the right.

2. Hold the heatsink as shown in the picture

on the right and gently wriggle the heatsink to

loosen it from the CPU. (Do not use excessive

force when wriggling the heatsink.)

3. Once the CPU is loosened, remove the

heatsink from the CPU socket.

4. Clean the surface of the CPU and the

heatsink to get rid of the old thermal grease.

Reapply the proper amount of thermal grease

on the surface before you re-install the CPU

and the heatsink.

Screw#1

Screw#2

Mounting the Motherboard in the Chassis

All motherboards have standard mounting holes to fi t different types of chassis.

Make sure that the locations of all the mounting holes for both motherboard and

chassis match. Make sure that the metal standoffs click in or are screwed in

tightly. Then, use a screwdriver to secure the motherboard onto the motherboard

tray. Note: some components are very close to the mounting holes. Please take

precautionary measures to avoid damaging these components when you install

the motherboard to the chassis.

2-5

X7DWN+ User's Manual

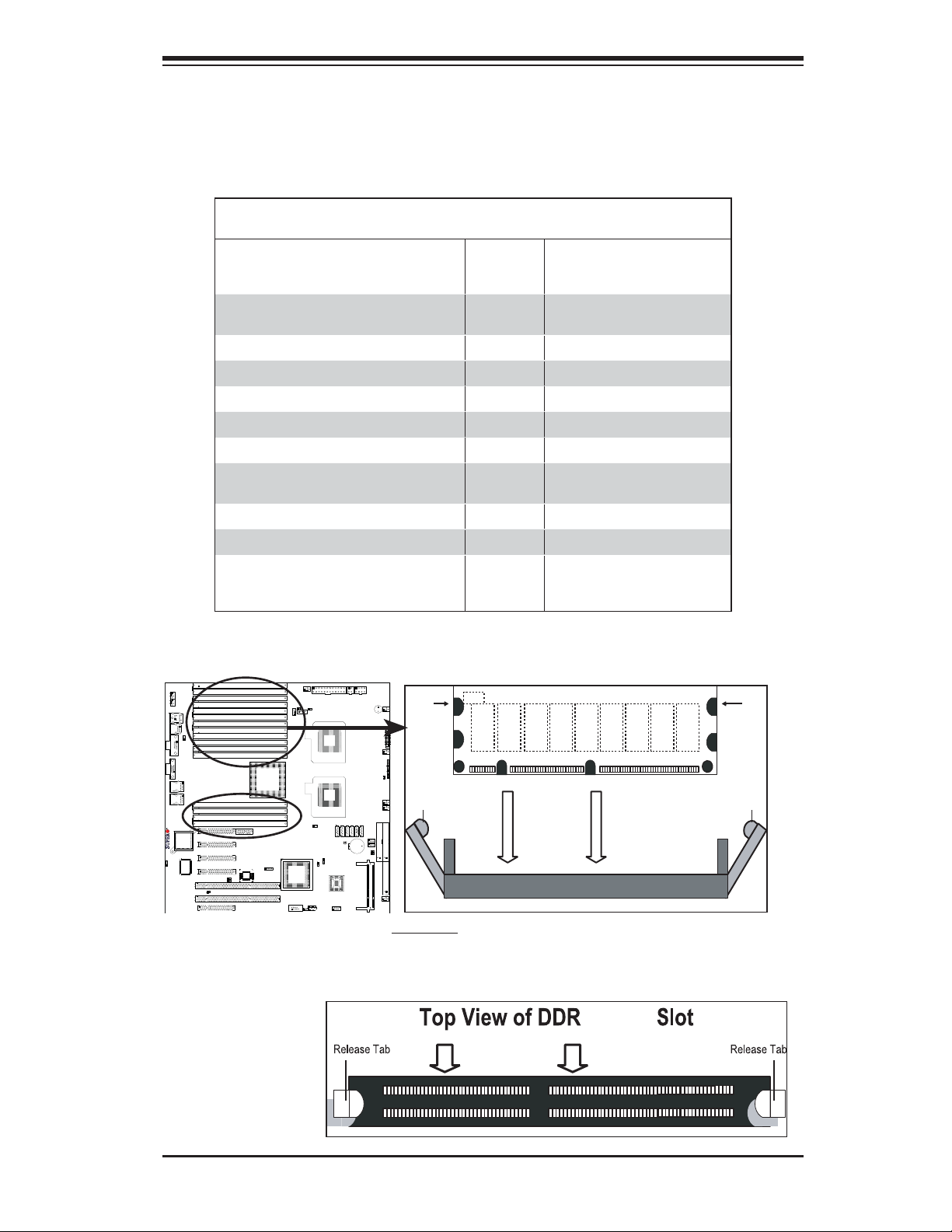

2-3 Installing DIMMs

Note: Check the Supermicro web site for recommended memory modules.

CAUTION

Exercise extreme care when installing or removing DIMM

modules to prevent any possible damage. Also note that the

memory is interleaved to improve performance (see step 1).

DIMM Installation

1. Insert the desired number of DIMMs into the memory slots, starting with DIMM

#1A. The memory scheme is interleaved, so you must install (a) pair(s) of

modules of the same type and same speed at a time, beginning with Bank

1, Bank 2 and so on. For optimal memory performance, please install four

modules at a time with the maximum of 16 modules. (See the Memory Instal-

lation Table Below.)

2. Insert each DIMM module vertically into its slot. Pay attention to the notch along

the bottom of the module to prevent inserting the DIMM module incorrectly.

3. Gently press down on the DIMM module until it snaps into place in the slot.

Repeat for all modules (see step 1 above).

Memory Support

The X7DWN+ supports up to 128 GB fully buffered (FBD) ECC DDR 2 800/667/533

in 16 DIMMs.

Note 1: Due to OS limitations, some operating systems may not show more than

4 GB of memory.

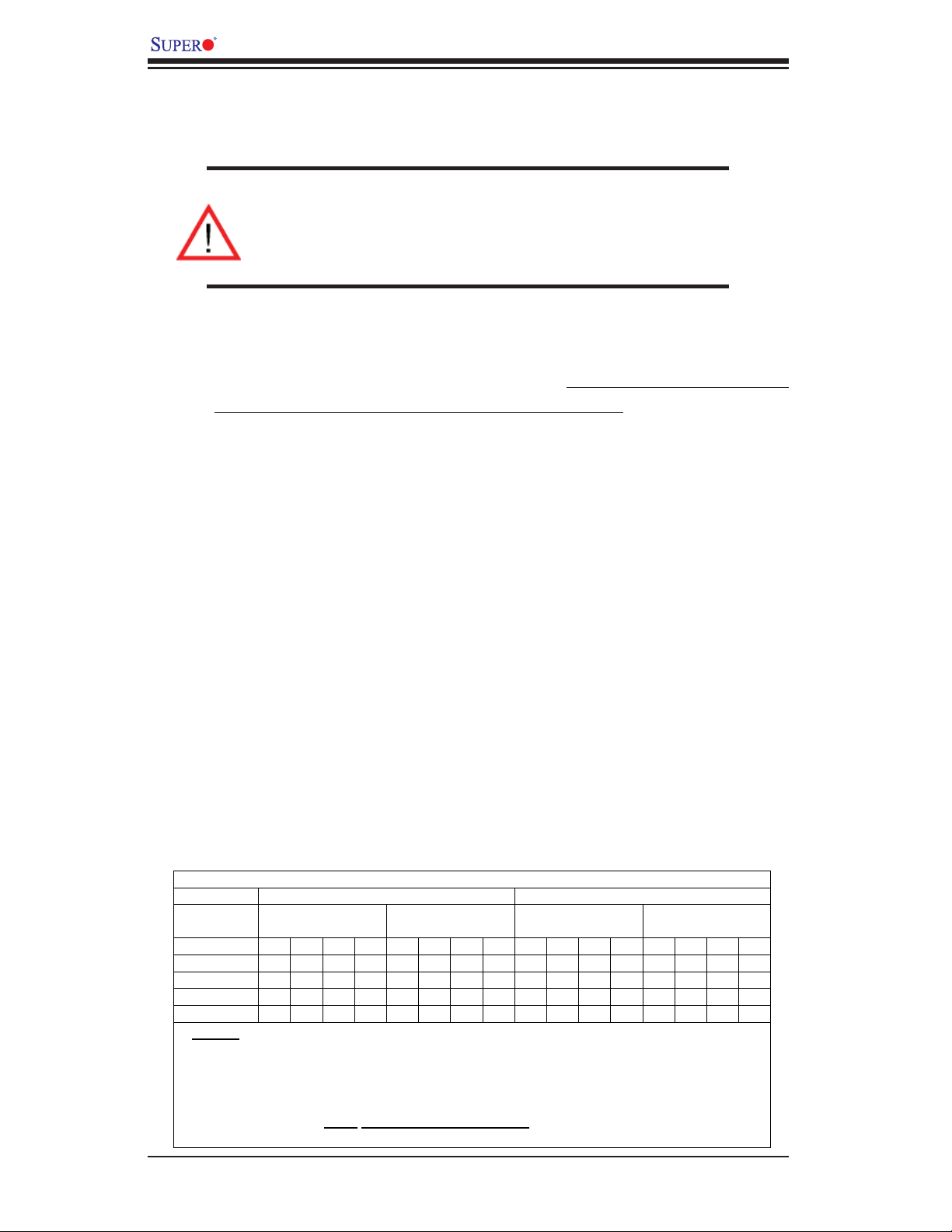

DIMM Module Population Confi guration

To optimize memory support, follow the table below for memory installation:

Optimized DIMM Population Configurations

Branch 0 Branch 1

Number of

DIMMs

2 DIMMs 1A

4 DIMMs 1A

8 DIMMs 1A 1B

12 DIMMs 1A 1B 1C

16 DIMMs 1A 1B 1C 1D 2A 2B 2C 2D 3A 3B 3C 3D 4A 4B 4C 4D

(*Notes: i. DIMM slot# specified: DIMM slot to be populated; “---“: DIMM slot not to

be populated. ii. Both FBD 533 MHz, 667MHz and 800MHz DIMMs are supported;

however, you need to use the memory modules of the same speed and of the same

type on a motherboard. iii. Interleaved memory is supported when pairs of DIMM

modules are installed. For optimal memory performance, please install pairs of

memory modules in both

you need to follow the restrictions listed above. )

Bank 1

(Channel 0)

--- --- ---

--- --- ---

--- ---

Bank 2

(Channel 1)

2A

2A

2A 2B

---

2A 2B 2C

--- --- --- --- --- --- --- --- --- --- ---

--- --- ---

--- ---

Bank 3

(Channel 2)

3A

3A 3B

---

3A 3B 3C

--- --- ---

--- ---

---

Bank 4

(Channel 3)

--- --- ---

4A

4A 4B

4A 4B 4C

--- ---

---

Branch 0 and Branch 1. iv. For memory to work properly,

2-6

Chapter 2: Installation

Note 2: Due to memory allocation to system devices, memory remaining avail-

able for operational use will be reduced when 4 GB of RAM is used. The reduc-

tion in memory availability is disproportional. (See the Memory Availability Table

below.)

Possible System Memory Allocation & Availability

System Device Size Physical Memory

Firmware Hub fl ash memory (System

BIOS)

Local APIC 4 KB 3.99GB

Area Reserved for the chipset 2 MB 3.99GB

I/O APIC (4 Kbytes) 4 KB 3.99GB

PCI Enumeration Area 1 256 MB 3.76GB

PCI Express (256 MB) 256 MB 3.51GB

PCI Enumeration Area 2 (if needed)

-Aligned on 256-MB boundary-

VGA Memory 16 MB 2.85GB

TSEG 1 MB 2.84GB

Memory available for the OS & other

applications

1 MB 3.99GB

512 MB 3.01GB

Remaining (-Available)

(4 GB Total System Memory)

2.84GB

Installing and Removing DIMMs

Notch

DIMM2 FBD

Notch

X7DWN+

To Remove:

Use your thumbs

to gently push

the release tabs

near both ends of

the module. This

should release it

from the slot.

Release

Tab

Note: Notch

should align

with the

receptive point

on the slot

Release

Tab

To Ins tall : Insert module vertically and press down until it

snaps into place. Pay attention to the alignment notch at

the bottom.

2 FBD

2-7

X7DWN+ User's Manual

123

4

5

678

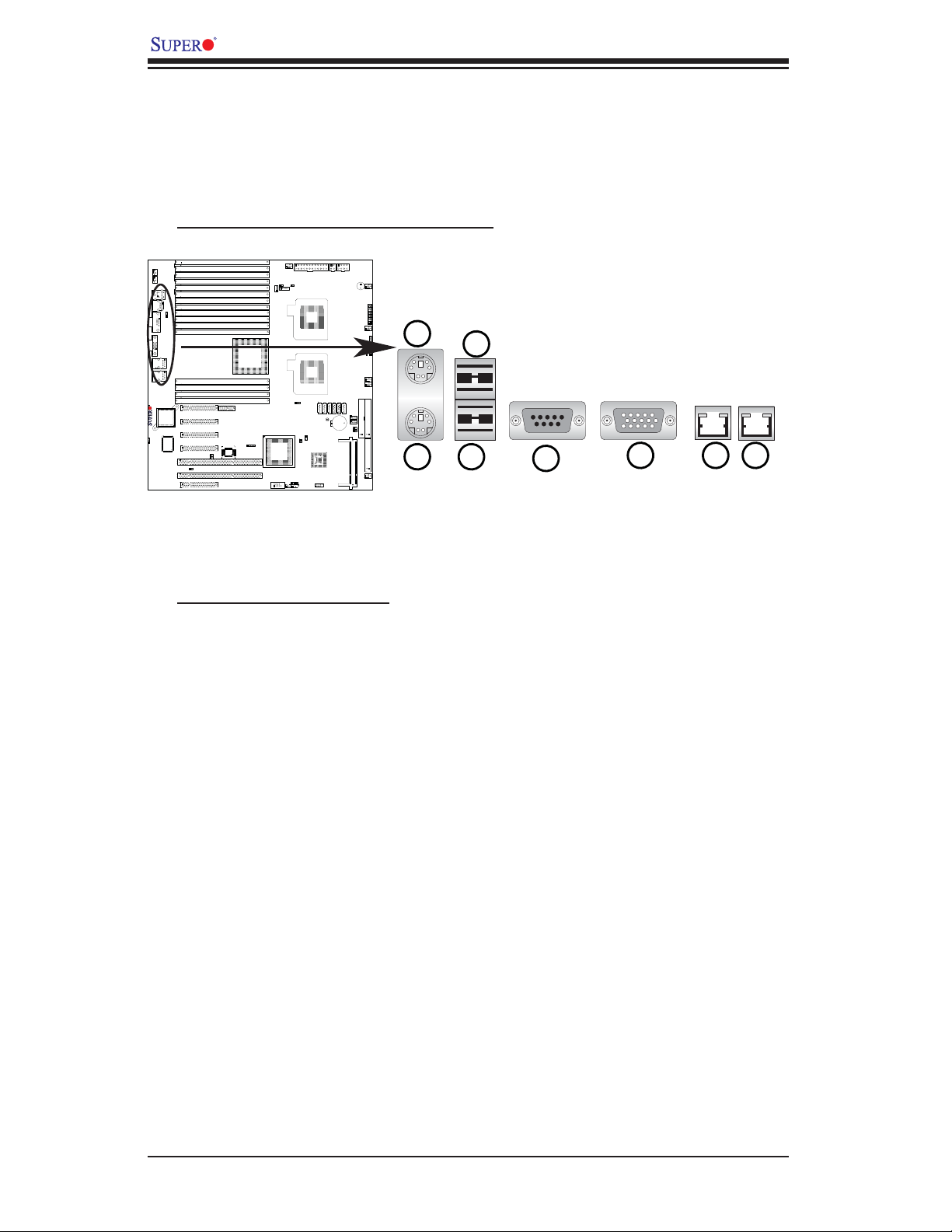

2-4 Control Panel Connectors/IO Ports

The I/O ports are color coded in conformance with the PC 99 specifi cation. See

Figure 2-3 below for the colors and locations of the various I/O ports.

A. Back Panel Connectors/IO Ports

X7DWN+

Back Panel I/O Port Locations and Defi nitions

Back Panel Connectors

1. Keyboard (Purple)

2. PS/2 Mouse (Green)

3. Back Panel USB Port 0

4. Back Panel USB Port 1

5. COM Port 1 (Turquoise)

6. VGA Port (Blue)

7. Gigabit LAN 1

8. Gigabit LAN 2

(See Section 2-5 for details.)

2-8

Loading...

Loading...