Supermicro SBI-7125C-T3 User Manual

SBI-7125C-T3

Blade Module

User’s Manual

Revison 1.0c

SBI-7125C-T3 blade module User’s Manual

The information in this User’s Manual has been carefully reviewed and i s believed to be accurate. The

vendor assumes no responsibility for any inaccuracies that may be contained in this document, makes no

commitment to update or to keep current the information in this manual, or to not ify any person or

organization of the u pdates. Plea se Note: For the most up-to-date version of this manual, please see

our web site at www.supermicro.com.

Super Micro Computer, Inc. (“Supermicro”) reserves the right to make changes to the product described

in this manual at any time and without notice. This product, including sof tware and documentation, is the

property of Supermicro and/or its licensors, and is supplied only u nder a l i cense. An y use or reprodu ct ion

of this product is not allowed, except as expressly permitted by the terms of said license.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO USE

THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY HARDWARE,

SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE COSTS OF

REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH HARDWARE,

SOFTWARE, OR DATA.

Any disputes arising between manufacturer and cu stomer shall be governed by the laws of Santa Clara

County in the State of California, USA. The State of California, Co unty of Santa Clara shall be the

exclusive venue for the resolution of any such disputes. Super Micro's total liabilit y for all claims will not

exceed the price paid for the hardware product.

FCC State ment: This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the manufacturer’s instruction manual, may cause harmful interference with radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference,

in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning

applies only to products containing CR (Manganese Dioxide) Lithium coin cells. Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate for further

details.

WARNING: HANDLING OF LEAD SOLDER MATERIALS USED IN THIS

PRODUCT MAY EXPOSE YOU TO LEAD, A CHEMICAL KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE BIRTH DEFECTS AND OTHER

REPRODUCTIVE HARM.

Manual Revison 1.0c

Release Date: May 18, 2011

Unless you request and receive written permission from Super Micro Computer, Inc., you may not copy

any part of this document.

Information in this document is subject to change without notice. Other products and companies referred

to herein are trademarks or registered trademarks of their respective companies or mark holders.

Copyright © 2011 by Super Micro Computer, Inc.

All rights reserv ed .

Printed in the United States of America

ii

Preface

About this Manual

This manual is written for professional system integrators, Information Technology

professionals, service personnel and technicians. It provides information for the

installation and use of Supermicro's SBI-7125C-T3 blade module. Installation and

maintenance should be performed by experienced professionals only.

Manual Organization

Chapter 1: Introduction

The first chapter provides a checklist of the main components included with

SBI-7125C-T3 blade module and describes their main features.

Chapter 2: System Safety

You should familiarize yourself with this chapter for a general overview of safety

precautions that should be followed when installing and servicing SBI-7125C-T3 blade

module.

Chapter 3: Setup and Installation

Refer to this chapter for details on installing the SBI-7125C-T3 blade module into the

SuperBlade chassis. Other sections cover the installation and placement of memory

modules and the installation of hard disk drives into the blade module.

Chapter 4: Blade Module Features

This chapter coves features and component information about SBI-7125C-T3 blade

module. Included here are descriptions and information for mainboard components,

connectors, LEDs and other features of the blade module.

Chapter 5: RAID Setup Procedure

RAID setup and operations for SBI-7125C-T3 blade module are covered in this chapter.

Chapter 6: BIOS

BIOS setup is covered in this chapter for SBI-7125C-T3 blade module.

Appendix A: BIOS POST Codes

BIOS POST Codes for SBI-7125C-T3 blade module are explained in this appendix.

Appendix B: iSCSI Setup Procedure

The iSCSI setup procedure for the blade module is described in this appendix.

iii

SBI-7125C-T3 Blade Module User’s Manual

Notes

iv

Table of Contents

Chapter 1 Introduction.......................................................................1-1

1-1 Overview.............................................................................................1-1

1-2 Product Checklist of Typical Components.....................................1-1

1-3 Blade Module Features....................................................................1-2

Processors..............................................................................................1-2

Memory...................................................................................................1-2

Storage....................................................................................................1-3

Density....................................................................................................1-3

1-4 Contacting Supermicro.....................................................................1-4

Chapter 2 System Safety..................................................................2-1

2-1 Electrical Safety Precautions ...........................................................2-1

2-2 General Safety Precautions.............................................................2-2

2-3 Electrostatic Discharge Precautions..............................................2-2

2-4 Operating Precautions......................................................................2-2

Chapter 3 Setup and Installation.................................................3-1

3-1 Overview.............................................................................................3-1

3-2 Installing Blade Modules..................................................................3-1

Powering Up a Blade Unit.......................................................................3-1

Powering Down a Blade Unit ..................................................................3-1

Removing a Blade Unit from the Enclosure............................................3-1

Removing/Replacing th e Bl ade Cover....................................................3-2

Installing a Blade Unit into the Enclosure ...............................................3-2

3-3 Processor Installation .......................................................................3-4

3-4 Onboard Battery Installation............................................................3-5

3-5 Memory Installation...........................................................................3-6

Populating Memory Slots........................................................................3-6

DIMM Installation....................................................................................3-7

3-6 Hard Disk Drive Installation.............................................................3-8

3-7 Installing the Operating System......................................................3-9

Installing with an External USB CD-ROM Drive....................................3-10

Installing via PXE Boot..........................................................................3-10

Installing via Virtual Media (Drive Redirection) .....................................3-10

3-8 Management Software ...................................................................3-11

v

SBI-7125C-T3 Blade Module User’s Manual

3-9 Configuring and Setting up RAID.................................................3-11

Chapter 4 Blade Module Features..............................................4-1

4-1 Control Panel.....................................................................................4-2

Power Button ..........................................................................................4-3

KVM Button.............................................................................................4-3

LED Indicators ........................................................................................4-3

KVM Connector.......................................................................................4-3

4-2 Mainboard...........................................................................................4-4

Jumpers..................................................................................................4-6

CMOS Clear............................................................................................4-6

4-3 Blade Unit Components...................................................................4-6

Memory Support .....................................................................................4-7

Hard Disk Drives.....................................................................................4-7

Chapter 5 RAID Setup Procedure...............................................5-1

5-1 RAID Configurations.........................................................................5-1

5-2 Preparing for Setup...........................................................................5-1

5-3 RAID Software...................................................................................5-1

Chapter 6 BIOS.......................................................................................6-1

6-1 Introduction.........................................................................................6-1

System BIOS ..........................................................................................6-1

How To Change the Configuration Data .................................................6-1

Starting the Setup Utility........... ... ............................................................6-1

6-2 BIOS Updates....................................................................................6-2

Flashing BIOS.........................................................................................6-2

6-3 Running Setup...................................................................................6-3

6-4 Main BIOS Setup...............................................................................6-4

6-5 Advanced Setup................................................................................6-5

Boot Features Submenu.........................................................................6-7

Memory Cache Submenu..................................................... ..................6-8

PCI Configuration Submenu.................................................................6-10

Advanced Chipset Control Submenu....................................................6-11

Advanced Processor Options Submenu...............................................6-12

I/O Device Configuration Submenu ......................................................6-14

DMI Event Logging Submenu...............................................................6-15

Console Redirection Submenu.............................................................6-16

Hardware Monitor Submenu.................................................................6-17

vi

Table of Contents

IPMI Submenu.......................................... .......................................... ..6-19

6-6 Security.............................................................................................6-20

6-7 Boot...................................................................................................6-21

Boot Priority Order/Excluded from Boot Order......................................6-22

6-8 Exit.....................................................................................................6-22

Appendix A BIOS POST Codes....................................................A-1

A-1 BIOS POST Messages....................................................................A-1

A-2 BIOS POST Codes...........................................................................A-3

Recoverable POST Errors............................................ ..........................A-4

Terminal POST Errors.............. .......................................... ... ..................A-4

Appendix B iSCSI Setup Procedure..........................................B-1

vii

SBI-7125C-T3 Blade Module User’s Manual

Notes

viii

List of Figures

Figure 1-1. Full Rack of Blade Enclosures and Blade Servers.........................1-3

Figure 3-1. Inserting a Blade into the Enclosure...............................................3-3

Figure 3-2. Locking the Blade into Position.......................................................3-3

Figure 3-3. Installing a Processor in a Socket...................................................3-5

Figure 3-4. Installing the Onboard Battery.................. ... ... ................................3-6

Figure 3-5. 6-slot DIMM Numbering..................................................................3-7

Figure 3-6. Installing a DIMM into a Memory Slot........................... ..................3-8

Figure 3-7. Installing a Hard Drive in a Carrier..................................................3-9

Figure 4-1. SBI-7125C-T3 Blade Unit Front View.............................................4-1

Figure 4-2. Blade Control Panel........................................................................4-2

Figure 4-3. B7DCL Mainboard..........................................................................4-4

Figure 4-4. Intel 5100/Intel ICH9R Chipset: Block Diagram..............................4-5

Figure 4-5. Exploded View of a SBI-7125C-T3 Blade Module..........................4-6

Figure 6-1. Main BIOS Setup Menu..................................................................6-4

Figure 6-2. Advanced Setup Menu ...................................................................6-5

Figure 7. Boot Features Submenu....................................................................6-7

Figure 6-1. Memory Cache Submenu...............................................................6-8

Figure 6-2. PCI Configuration Submenu.........................................................6-10

Figure 6-3. Advanced Chipset Control Submenu............................................6-11

Figure 6-4. Advanced Processor Options Submenu.......................................6-12

Figure 6-5. I/O Device Configuration Submenu..............................................6-14

Figure 6-6. DMI Event Logging Submenu.......................................................6-15

Figure 6-7. Console Redirection Submenu.....................................................6-16

Figure 6-8. Hardware Monitor Submenu.........................................................6-17

Figure 6-9. Security Menu...............................................................................6-20

Figure 6-10. Boot Menu ..................................................................................6-21

Figure 6-11. Exit Menu....................................................................................6-22

Figure B-1. Microsoft MPIO Multipathing Support for iSCSI Check Box...........B-2

Figure B-2. Configure iSCSI Network Boot Support Check Box.......................B-3

ix

SBI-7125C-T3 Blade Module User’s Manual

Notes

x

List of Tables

Table 1-1. SBI-7125C-T3 Blade Specification Features...................................1-2

Table 3-1. Populating Six Memory Slots for Interleaved Operation..................3-6

Table 4-1. SBI-7125C-T3 Blade Unit Features.................................................4-1

Table 4-2. Blade Control Panel.........................................................................4-2

Table 4-3. Blade Module LED Indicators ..........................................................4-3

Table 4-4. B7DCL Mainboard Layout................................................................4-5

Table 4-5. Main Components of a SBI-7125C-T3 Blade Module......................4-7

Table 6-1. Main BIOS Setup Menu Options......................................................6-4

Table 6-2. Advanced Setup Menu Options.......................................................6-5

Table 6-3. Boot Features Submenu Menu Options...........................................6-7

Table 6-4. Memory Cache Submenu Menu Options.........................................6-9

Table 6-5. PCI Configuration Submenu Menu Options...................................6-10

Table 6-6. Advanced Chipset Control Submenu Menu Options .....................6-11

Table 6-7. Advanced Processor Options Submenu Menu Options.................6-13

Table 6-8. I/O Device Configuration Submenu Menu Options........................6-14

Table 6-9. DMI Event Logging Submenu Menu Options.................................6-15

Table 6-10. Console Redirection Submenu Menu Options.............................6-17

Table 6-11. Hardware Monitor Submenu Menu Options.................................6-1 8

Table 6-12. IPMI Submenu Menu Options......................................................6-19

Table 6-13. Security Menu Options.................................................................6-20

Table 6-14. Exit Menu Options........................................................................6-23

Table A-1. BIOS POST Messages....................................................................A-1

Table A-2. Terminal POST Errors.....................................................................A-4

Table A-3. Boot Block Flash ROM Terminal POST Errors................................A-8

xi

SBI-7125C-T3 Blade Module User’s Manual

Notes

xii

Chapter 1

Introduction

1-1 Overview

The SBI-7125C-T3 blade module are compact self-contained servers that connect into a

pre-cabled enclosure that provides power, cooling, management and networking

functions. One enclosure for the SBI-7125C-T3 blade module can hold ten blade units.

In this manual, “blade system” refers to the entire system (including the enclosure and

blades units), “blade” or “blade unit” refers to a single blade module and “blade

enclosure” is the chassis that the blades, power supplies and modules are housed

within.

Please refer to our web site for information on operating systems that have been

certified for use with the SuperBlade (www.supermicro.com/products/superblade/).

1-2 Product Checklist of Typical Components

Your blade module ships with its mainboard already installed in its chassis. Memory,

hard disk drives and the CPU must all be installed by the user after shipment. See

Chapter 3: "Setup and Installation" on page 3-1 for details on installation of these

components.

1-1

SBI-7125C-T3 Blade Module User’s Manual

1-3 Blade Module Features

Table 1-1 lists the main features of the SBI-7125C-T3 blade module. See the

proceeding section for components typically included in a blade system and other

optional components. Specific details on the features of the SBI-7125C-T3 blade

module can be found in Chapter 4: "Blade Module Features" on page 4-1.

Table 1-1. SBI-7125C-T3 Blade Specification Features

Mainboard

Processors

FSB Speed 1333/1066 MHz front side (system) bus speed

Chipset Intel 5100/Intel ICH9R

Graphics Controller Onboard Matrox G200eW graphics chip

BIOS 16 Mb Phoenix® Flash ROM

Memory Capacity

SATA Controller Intel ICH9R on-chip controller for three Serial ATA drives

Hard Drive Bays Includes three hot-swap drive bays for 2.5" SATA disk drives

B7DCL (proprietary form factor)

Chassis Dimensions (HxWxD): 11.32” x 1.67” x 18.9”

Dual or quad core Intel™ Xeon® 5400/5300/5200/5100/5000 sequence

processors. Please refer to our web site for a complete listing of supported

processors.

Six 240-pin DIMM sockets supporting up to 48 GB of ECC Registered

DDR2-667/533 SDRAM.

Processors

The SBI-7125C-T3 blade module support dual 771-pin Intel Xeon 5400/5300/5200/

5100/5000 series processors.

Refer to the Supermicro web site for a complete listing of supported processors (http://

www.supermicro.com/products/superblade). Please note that you will need to check the

detailed specifications of a particular blade module for a list of the CPUs it supports.

Details on installation of the processor into the SBI-7125C-T3 blade module are found in

Chapter 3: "Setup and Installation" on page 3-1.

Memory

The SBI-7125C-T3 blade module has six 240-pin DIMM sockets that can support up to

48 GB of ECC Registered DDR2-667/533 SDRAM. Memory is interleaved, which

requires modules of the same size and speed to be installed in groups (of two or three).

Please refer to the Supermicro web site for a list of supported memory

(www.supermicro.com/products/superblade). The detailed specifications for a blade

module will contain a link to a list of recommended memory sizes and manufacturers.

Details on installation of memory modules into the SBI-7125C-T3 blade module are

found in Chapter 3: "Setup and Installation" on page 3-1.

1-2

Chapter 1: Introduction

Storage

The SBI-7125C-T3 blade module can have three 2.5-inch SATA (Serial ATA) hard disk

drives in front-mounted easy removable carriers. See Chapter 3: "Setup a nd

Installation" on page 3-1 for storage installation details.

Density

A maximum of ten blade modules may be installed into a single blade enclosure. Each

blade enclosure is a 7U form factor, so a standard 42U rack may accommodate up to six

enclosures with 60 blade modules, or the equivalent of 60 1U servers. With the inclusion

of six CMM modules, twelve Gigabit Ethernet switches and six InfiniBand switches, this

would occupy up to 84U space in a conventional 1U server configuration.

Figure 1-1 displays a view of a full rack with six blade enclosures in it, each with ten

blades to an enclosure.

Figure 1-1. Full Rack of Blade Enclosures and Blade Servers

1-3

SBI-7125C-T3 Blade Module User’s Manual

1-4 Contacting Supermicro

Headquarters

Address: Super Micro Computer , Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email:

Web Site: www.supermicro.com

marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

‘s-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

sales@supermicro.nl (General Information)

Email:

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacific

Address: Super Micro Computer , Inc.

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: +886-2-8228-1366, ext. 132 or 139

1-4

Chapter 2

System Safety

2-1 Electrical Safety Precautions

Basic electrical safety precautions should be followed to protect yourself from harm and

the SuperBlade from damage:

• Be aware of how to power on/off the enclosure power supplies and the individual

blades as well as the room's emergency power-off switch, disconnection switch or

electrical outlet. If an electrical accident occurs, you can then quickly remove power

from the system.

• Do not work alone when working with high voltage components.

• Power should always be disconnected from the blade module when removing or

installing such system components as the mainboard, memory modules and

processors.

• When working around exposed electrical circuits, another person who is familiar

with the power-off controls should be nearby to switch off the power if necessary.

• Use only one hand when working with powered-on electrical equipment. This is to

avoid making a complete circuit, which will cause electrical shock. Use extreme

caution when using metal tools, which can easily damage any electrical components

or circuit boards they come into contact with.

• Do not use mats designed to decrease electrostatic discharge as protection from

electrical shock. Instead, use rubber mats that have been specifically designed as

electrical insulators.

• The power supply power cords must include a grounding plug and must be plugged

into grounded electrical outlets. Power input requires 110-240 V AC, depending upon

your power supply module.

• Mainboard Battery: This battery must be replaced only with the same or an

equivalent type recommended by the manufacturer (CR2032 Lithium 3V battery).

Dispose of used batteries according to the manufacturer's instructions.

WARNING: There is a danger of explosion if the onboard battery is installed

upside down, which will reverse its polarities.

• Mainboard replaceable soldered-in fuses: Self-resetting PTC (Positive Temperature

Coefficient) fuses on the mainboard must be replaced by trained service technicians

only. The new fuse must be the sa me or equivalent as the one replaced. Contact

technical support for details and support.

2-1

SBI-7125C-T3 Blade Module User’s Manual

2-2 General Safety Precautions

Follow these rules to ensure general safety:

• Keep the area around the SuperBlade clean and free of clutter.

• Place the blade module cover and any system components that have been removed

away from the system or on a table so that they won't accidentally be stepped on.

• While working on the system, do not wear loose clothing such as neckties and

unbuttoned shirt sleeves, which can come into contact with electrical circuits or be

pulled into a cooling fan.

• Remove any jewelry or metal objects from your body, which are excellent metal

conductors that can create short circuits and harm you if they come into contact with

printed circuit boards or areas where power is present.

• After accessing the inside of the system, replace the blade module's cover before

installing it back into the blade enclosure.

2-3 Electrostatic Discharge Precautions

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic components and printed circuit

boards.

The following measures are generally sufficient to neutralize this difference before

contact is made to protect your equipment from ESD:

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their antistatic bags until

ready for use.

• Touch a grounded metal object before removing the board from the antistatic bag.

• Do not let components or PCBs come into contact with your clothing, which may

retain a charge even if you are wearing a wrist strap.

• Handle a board by its edges only; do not touch its components, peripheral chips,

memory modules or contacts.

• When handling chips or modules, avoid touching their pins.

• Put the mainboard and peripherals back into their antistatic bags when not in use.

• For grounding purposes, make sure the blade enclosure provides excellent

conductivity between the power supplies, the blade modules and the mainboard.

2-4 Operating Precautions

Care must be taken to assure that the cover of the blade unit is in place when the blade

is operating to assure proper cooling. Out of warranty damage to the blade can occur if

this practice is not strictly followed.

Any drive carrier without a hard drive installed must remain fully installed in the drive bay

when the blade module is operating to ensure proper airflow.

2-2

Chapter 3

Setup and Installation

3-1 Overview

This chapter covers the setup and installation of the blade module and its components.

3-2 Installing Blade Modules

Up to ten SBI-7125C-T3 blade module may be installed into a single blade enclosure.

Blade modules with Windows and Linux operating systems may be mixed together in

the same blade enclosure.

Powering Up a Blade Unit

Each blade unit may be powered on and off independently from the rest of the blades

installed in the same enclosure. A blade unit may be powered up in two ways:

• Press the power button on the blade unit.

• Use IPMIView or the web-browser based management utility to apply power using

either a CMM module, or by the use of an onboard BMC chip in the blade module.

Powering Down a Blade Unit

A blade unit may be powered down in either of five ways:

• Press the power button on the blade unit.

• Use IPMIView or the web-browser based management utility to power down (if you

have Operator or Admin privileges on the CMM).

• Use IPMItool when connected to the CMM to power down (if you have Operator or

Admin privileges on the CMM).

• Use IPMIview or a browser connected to the onboard BMC chip in the blade to

power down.

• Use IPMItool to use a Command Line Interface (CLI) to the onboard BMC chip (if

you have Operator or Admin privileges).

Removing a Blade Unit from the Enclosure

Although the blade system may continue to run, individual blades should always be

powered down before removing them from the enclosure.

Removing a Blade Unit from the Enclosure

1. Power down the blade unit (see "Powering Down a Blade Unit" above).

2. Squeeze both handles to depress the red sections then pull out both handles

completely and use them to pull the blade unit from the enclosure.

3-1

SBI-7125C-T3 Blade Module User’s Manual

NOTE: Blade Modules can be Hot-Plugged from the enclosure.

Removing/Replacing the Blade Cover

The blade cover must be removed to access the mainboard when you need to install or

remove processors, memory units, the onboard battery and so on.

Removing/Replacing the Blade Cover

1. Remove the blade unit from the enclosure (see "Removing a Blade Unit from the

Enclosure" above).

2. Depress the two buttons on the cover while pushing the cover toward the rear of the

blade unit. When it stops, lift the cover off the blade unit.

3. To replace the cover, fit the six grooves in the cover into the studs in the sides of the

blade, then slide the cover toward the front of the blade to lock it into place.

Installing a Blade Unit into the Enclosure

Make sure the cover of the blade unit has been replaced first before installing a blade

unit in the enclosure.

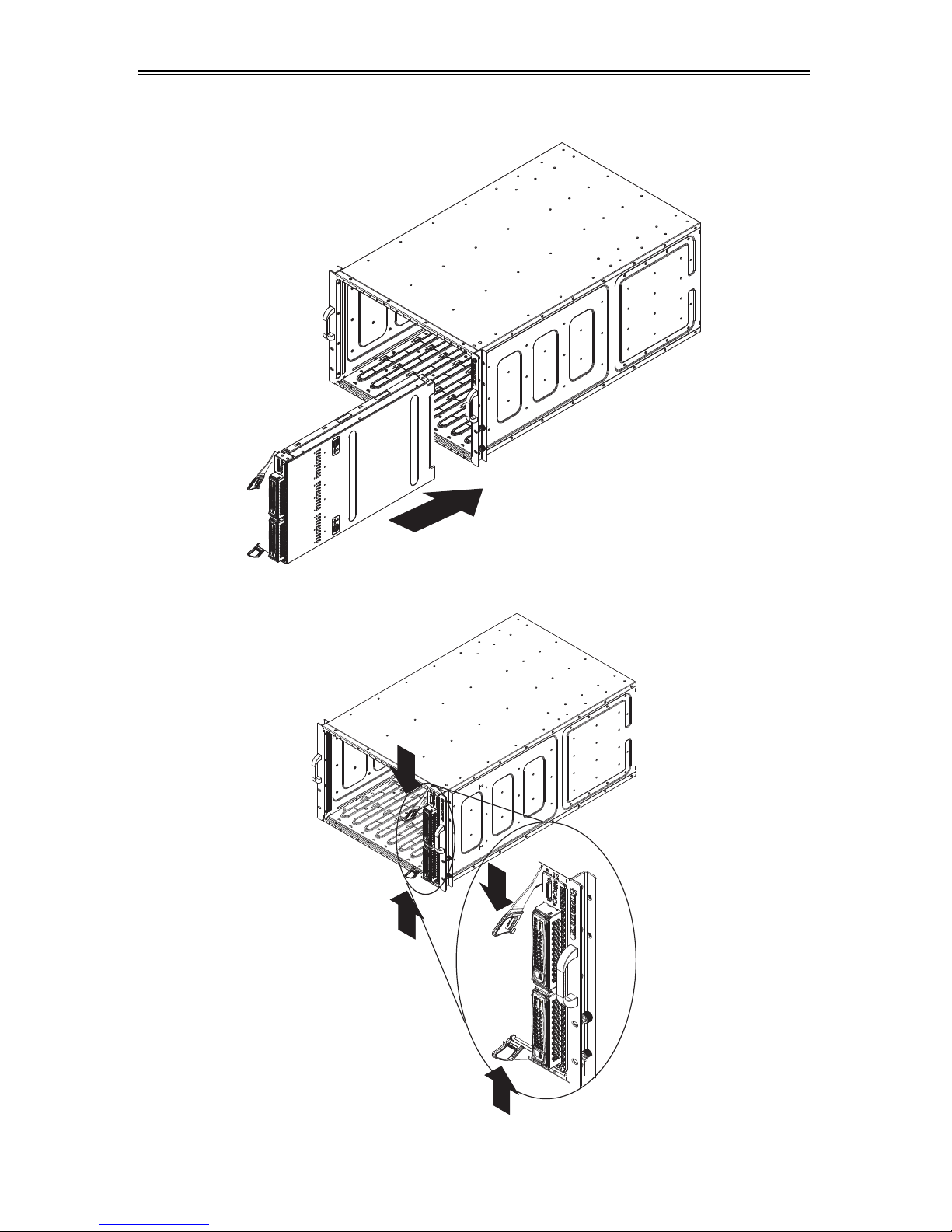

Installing a Blade Unit into the Enclosure

1. Slowly push the blade unit into its bay with the handles fully pulled out (see

Figure 3-1).

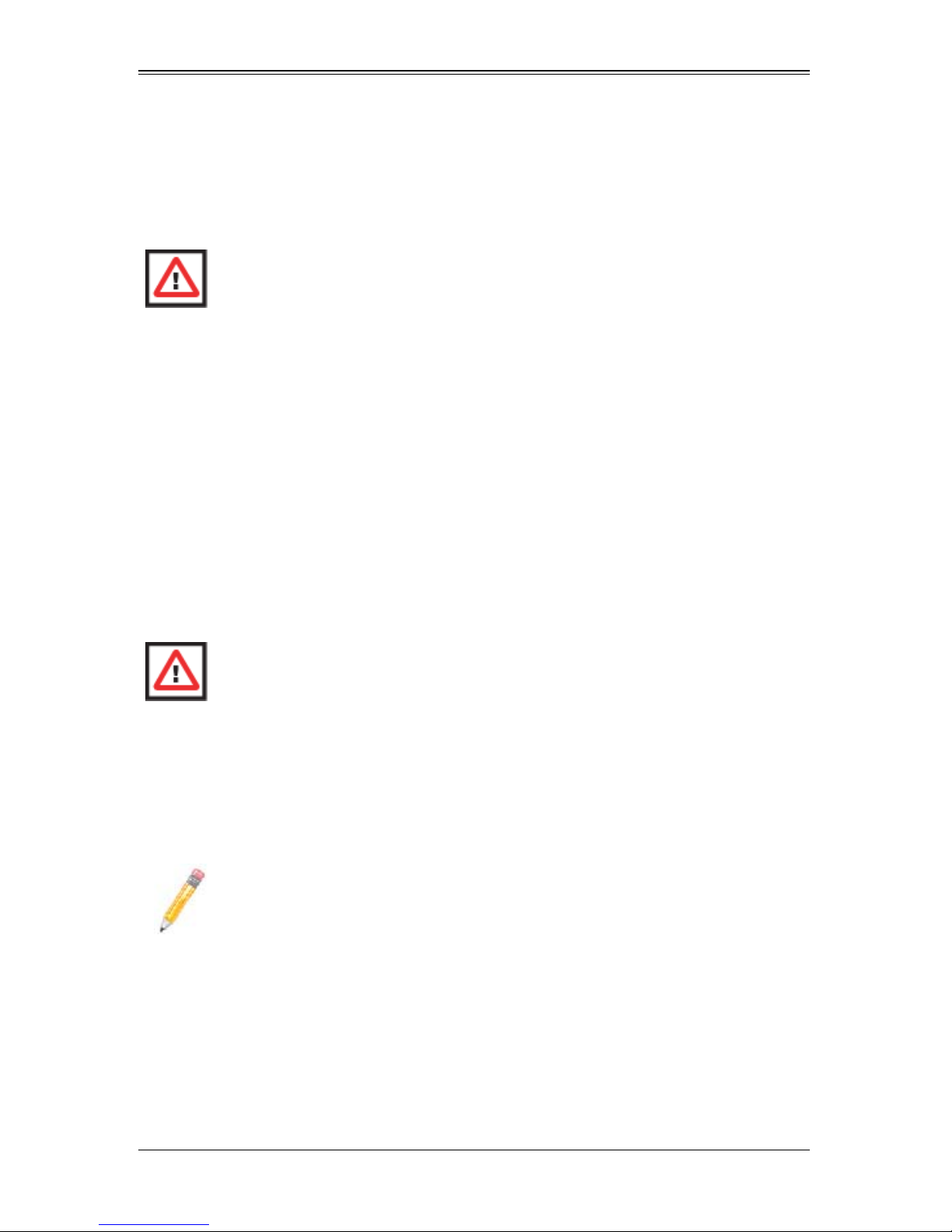

2. When the blade stops, push the handles back in to their locked position, making

sure the notches in both handles catch the lip of the enclosure (see Figure 3-2).

NOTE: Blade Modules can be Hot-Plugged into the enclosure.

WARNING: Use extreme caution when inserting a blade module into the

enclosure. If the blade's power connector becomes damaged, it can damage

pins on other blade bays that it is inserted into.

3-2

Chapter 3: Setup and Installation

Figure 3-1. Inserting a Blade into the Enclosure

Figure 3-2. Locking the Blade into Position

3-3

SBI-7125C-T3 Blade Module User’s Manual

3-3 Processor Installation

One or two processors may be installed to the mainboard of each blade unit. See

Chapter 1 for general information on the features of the blade unit and the Supermicro

web site for further details including processor, memory and operating system support.

WARNING: This action should only be performed by a trained service

technician. Allow the processor heatsink to cool before removing it.

Removing a Processor

1. Power down and remove the blade unit from the enclosure (see Section 3-2:

Installing Blade Modules on page 3-1 for details).

2. Remove the cover of the blade unit (see "Removing/Replacing the Blade Cover" on

page 3-2).

3. Loosen the four screws that secure the heatsink to the mainboard.

4. Remove the heatsink by gently rotating it back-and-forth sideways with your fingers

to release it from the processor. Set the heatsink aside and upside-down so that

nothing comes into contact with the thermal grease on its underside.

5. Raise the lever of the processor socket up until the processor is released from the

socket, then lift the silver cover plate and remove the processor.

WARNING: This action should only be performed by a trained service

technician.

Installing a Processor

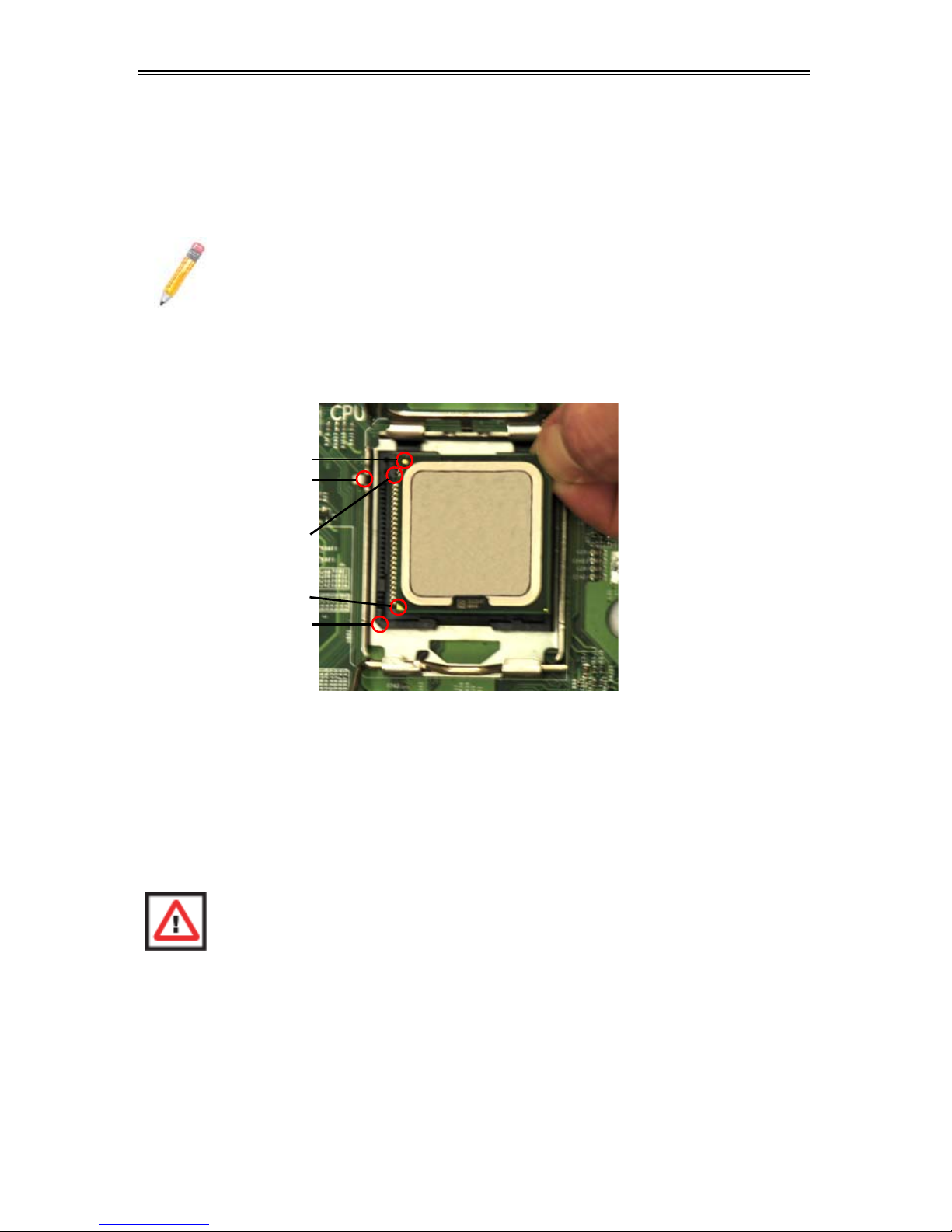

1. If present, remove the protective black PnP cap from the processor socket.

2. Raise the lever of the processor socket until it reaches its upper limit.

3. Lift the silver cover plate completely up and out of the way.

NOTE: Be careful not to damage the pins protruding from the CPU socket.

4. Align pin 1 of the processor with pin 1 of the socket (both are marked with a small

gold triangle) and gently seat the processor into the socket (Figure 3-3).

5. Check to make sure the processor is flush to the socket and fully seated.

6. Lower the socket lever until it locks.

7. To install the heatsink, apply thermal grease to the top of the processor. (If

reinstalling a heatsink, first clean off the old thermal grease with a clean, lint-free

cloth.)

3-4

Chapter 3: Setup and Installation

Gold dot

Socket key

CPU key

Notched corner

CPU pin

8. Place the heatsink on the processor then tighten two diagonal screws until snug,

then the other two screws.

9. When all four screws are snug, tighten them all to secure the heatsink to the

mainboard.

NOTE: Do not overtighten the screws as this may damage the processor or the

heatsink.

10. Replace the cover on the blade unit and finish by installing the unit back into the

blade enclosure.

Figure 3-3. Installing a Processor in a Socket

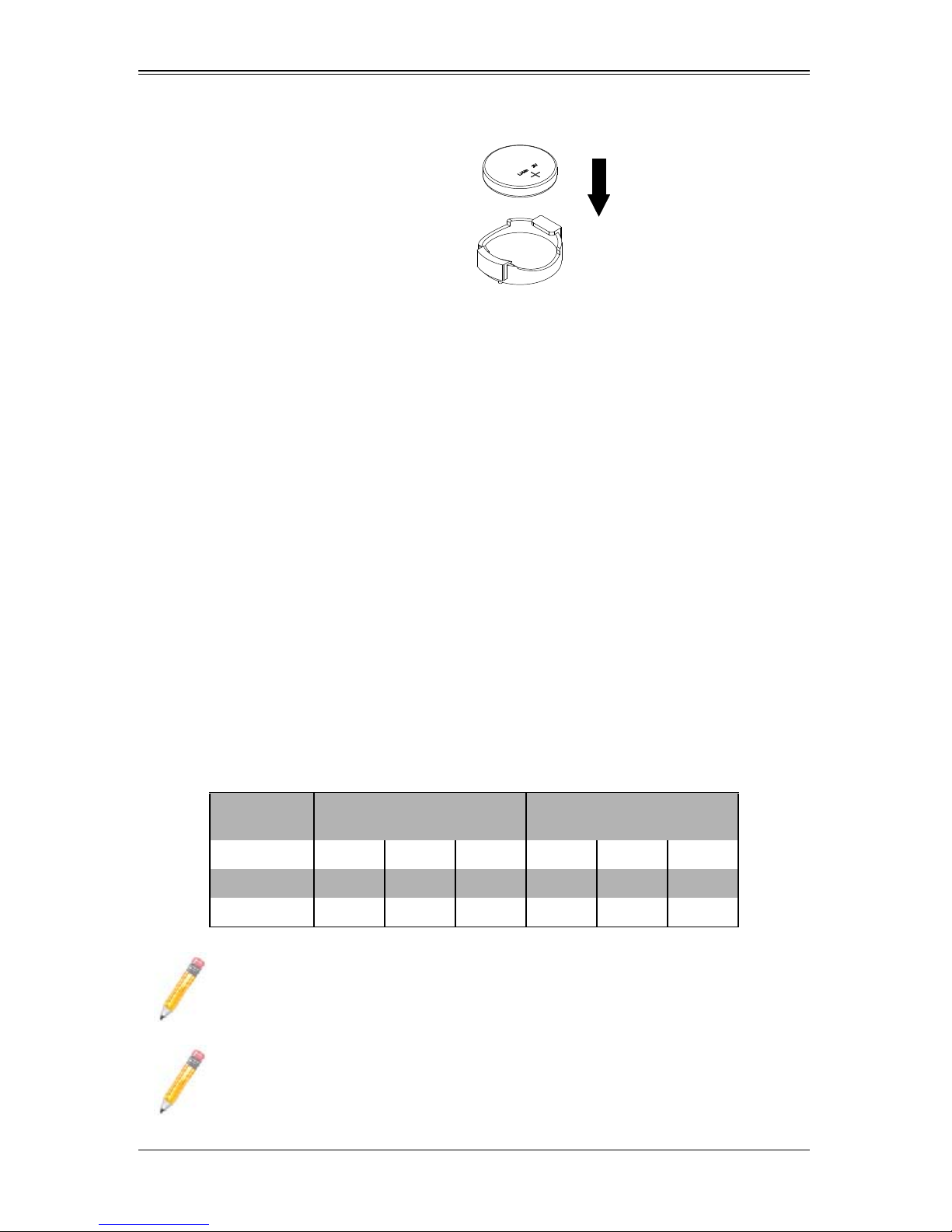

3-4 Onboard Battery Installation

A battery is included on the mainboard to supply certain volatile memory components

with power when power has been removed from the blade module. If this battery dies, it

must be replaced with an equivalent CR2032 Lithium 3V battery. Dispose of used

batteries according to the manufacturer's instructions. See Figure 3-4 for a diagram of

installing a new onboard battery.

WARNING: There is a danger of explosion if the onboard battery is installed

upside down, which reverses its polarities.

3-5

SBI-7125C-T3 Blade Module User’s Manual

Lithium Battery

Battery Holder

Figure 3-4. Installing the Onboard Battery

3-5 Memory Installation

The mainboard of each blade unit must be populated with DIMMs (Dual In-line Memory

Modules) to provide system memory. The DIMMs should all be of the same size and

speed and from the same manufacturer due to compatibility issues. See details

below on supported memory and our web site (www.supermicro.com/products/

superblade for recommended memory.

Populating Memory Slots

The mainboard of a SBI-7125C-T3 blade module has six memory slots. Both interleaved

and non-interleaved memory are supported, so you may populate any number of DIMM

Populating two slots at a time (DIMM1A + DIMM1B, DIMM2A + DIMM2B, etc.) with

memory modules of the same size and of the same type will result in dual-channel,

interleaved memory, which is faster than single-channel, non-interleaved memory. See

Table 3-1: "Populating Six Memory Slots for Interleaved Operation" on page 3-6 for

details.

For an interleaved configuration, memory modules of the same size and speed

must be installed in pairs. You should not mix DIMMs of different sizes and

speeds.

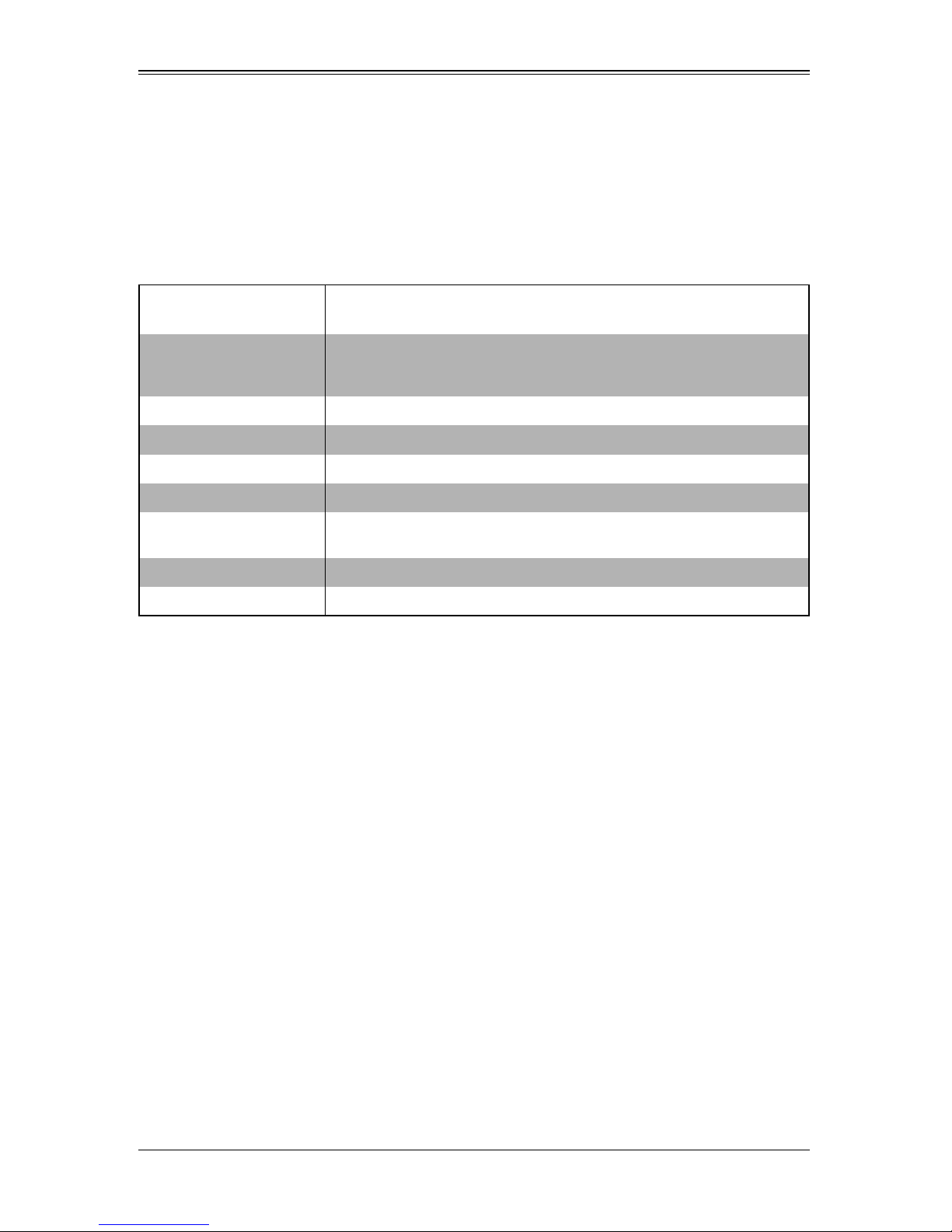

Table 3-1. Populating Six Memory Slots for Interleaved Operation

Number

of DIMMs

2 DIMMs 1A --- --- 1B --- --4 DIMMs 1A 2A --- 1B 2B --6 DIMMs1A2A3A1B2B3B

NOTE: The DIMM slot number specified in Table 3-1 equals the DIMM slot to

be populated. The “---” notation indicates that the DIMM slot should be left

unpopulated.

Channel 0 Channel 1

NOTE: Though multiple DIMM memory module types and speeds may be

supported, you need to use DIMM memory modules of the same speed and

type.

3-6

Loading...

Loading...