SUPER

H8QG7-LN4F

H8QGi-LN4F

®

USER’S MANUAL

Revision 1.0d

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

and makes no commitment to update or to keep current the information in this manual, or to notify

any person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software and

documentation, is the property of Supermicro and/or its licensors, and is supplied only under a

license. Any use or reproduction of this product is not allowed, except as expressly permitted by

the terms of said license.

IN NO EVENT WILL Super Micro Computer, Inc. BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OR INABILITY TO USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR, SUPER MICRO COMPUTER, INC. SHALL

NOT HAVE LIABILITY FOR ANY HARDWARE, SOFTWARE, OR DATA STORED OR USED

WITH THE PRODUCT, INCLUDING THE COSTS OF REPAIRING, REPLACING, INTEGRATING,

INSTALLING OR RECOVERING SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall be

the exclusive venue for the resolution of any such disputes. Supermicro's total liability for all claims

will not exceed the price paid for the hardware product.

FCC Statement: Refer to Supermicro's web site for FCC Compliance Information.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate

warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See

www.supermicro.com.

www.dtsc.ca.gov/hazardouswaste/perchlorate”.

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to

the State of California to cause birth defects and other

reproductive harm.

Manual Revision 1.0d

Release Date: March 07, 2014

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2014 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Preface

About This Manual

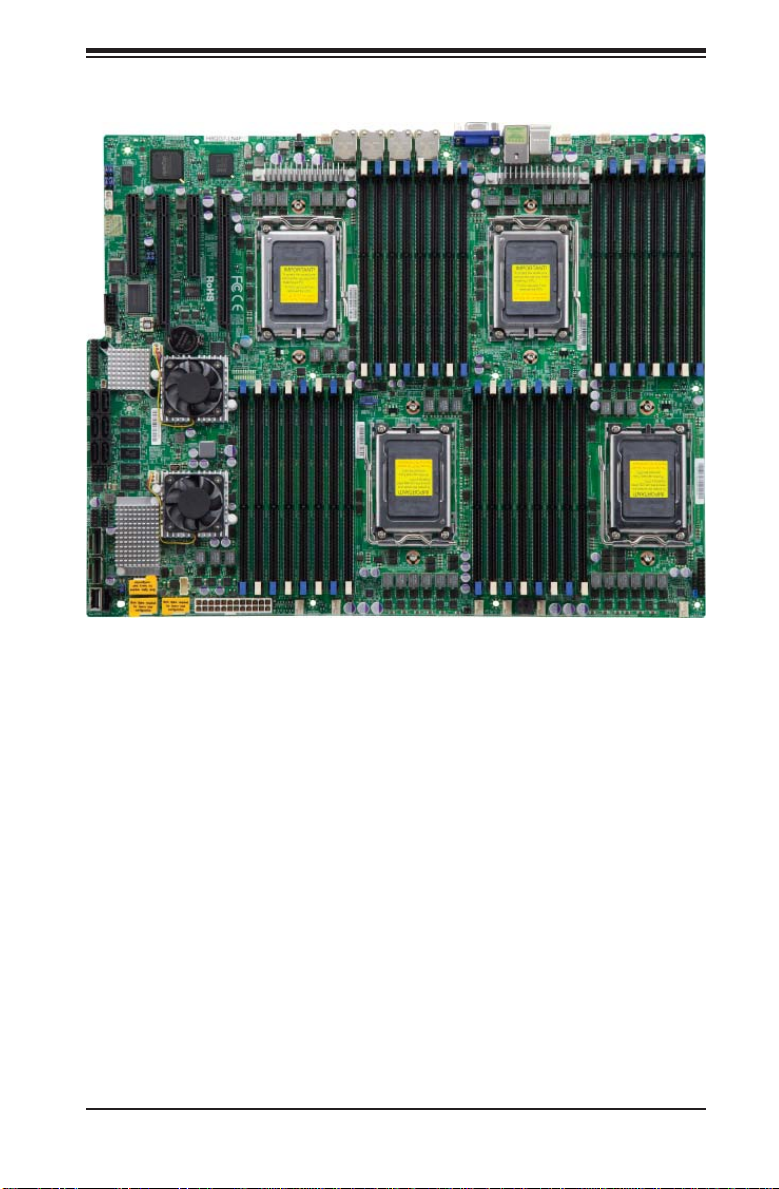

This manual is written for system integrators, PC technicians and

knowledgeable PC users. It provides information for the installation and use of the

H8QG7/i-LN4F serverboard.

The H8QG7/i-LN4F serverboard is based on the AMD® SR5690/SR5670/SP5100

chipsets and supports four AMD Socket G34 type processors with up to 1 TB of

DDR3 Registered ECC DDR3-1600/1333/1066 Mhz SDRAM or 256 GB of DDR3

Unbuffered ECC/non-ECC SDRAM in thirty-two (32) DIMMs. The only difference

between the H8QG7-LN4F and H8QGi-LN4F serverboards is that the H8QG7-LN4F

serverboard has SAS2 (LSI 2208) capability and the H8QGi-LN4F serverboard

does not.

Please refer to the motherboard specifi cations pages on our web site for updates on

supported processors (http://www.supermicro.com/aplus/). This product is intended

to be professionally installed.

Manual Organization

Preface

Chapter 1 includes a checklist of what should be included in your motherboard

box, describes the features, specifi cations and performance of the motherboard

and provides detailed information about the chipset.

Chapter 2 begins with instructions on handling static-sensitive devices. Read this

chapter when installing the processor(s) and memory modules and when installing

the motherboard in a chassis. Also refer to this chapter to connect the hard disk

drives, the various ports, and the power and reset buttons and the system LEDs.

If you encounter any problems, see Chapter 3, which describes troubleshooting

procedures for the video, the memory and the setup confi guration stored in CMOS.

For quick reference, a general FAQ (Frequently Asked Questions) section is

provided. Instructions are also included for contacting technical support. In addition,

you can visit our web site for more detailed information.

Chapter 4 includes an introduction to BIOS and provides detailed information on

running the CMOS Setup utility.

Appendix A provides BIOS Error Beep Code Messages.

Appendix B lists BIOS POST Checkpoint Codes.

iii

Table of Contents

Table of Contents

Chapter 1 Introduction

1-1 Overview .........................................................................................................1-1

Checklist ..........................................................................................................1-1

1-2 Contacting Supermicro ....................................................................................1-2

H8QG7/i-LN4F Quick Reference ....................................................................1-5

1-3 Chipset Overview ..........................................................................................1-10

AMD SR5690/SR5670/SP5100 Chipsets ..................................................... 1-10

HyperTransport Technology ..........................................................................1-10

1-4 PC Health Monitoring .................................................................................... 1-10

1-5 Power Confi guration Settings.........................................................................1-1 1

1-6 Power Supply ................................................................................................1-12

1-7 Super I/O ....................................................................................................... 1-13

Chapter 2 Installation

2-1 Standardized Warning Statements .................................................................2-1

About Standardized Warning Statements ....................................................... 2-1

2-2 Static-Sensitive Devices ..................................................................................2-4

Precautions .....................................................................................................2-4

Unpacking .......................................................................................................2-4

2-3 Processor and Heatsink Installation................................................................2-5

2-4 Mounting the Motherboard into a Chassis ...................................................... 2-7

2-5 Installing Memory ............................................................................................2-7

DIMM Module Population Confi guration .................................................. 2-10

2-6 PCI Expansion Cards .....................................................................................2-11

2-7 I/O Port and Control Panel Connections ......................................................2-12

Front Control Panel ....................................................................................... 2-12

2-8 Connector Defi nitions ................................................................................... 2-13

Power Connectors ...................................................................................2-13

Power Connector ......................................................................................2-13

Reset Connector ...................................................................................... 2-14

Power Fail LED ........................................................................................2-14

Overheat (OH)/Fan Fail/PWR Fail/UID LED ............................................ 2-14

NIC2 (Link/Activity) LED ...........................................................................2-14

NIC1 (Link/Activity) LED ...........................................................................2-14

HDD LED ..................................................................................................2-15

Power LED Connector ............................................................................. 2-15

NMI Button ...............................................................................................2-15

iv

H8QG7/i-LN4F SERVERBOARD USER'S MANUAL

NIC4 (LAN4) LED .....................................................................................2-15

NIC3 (LAN3) LED .....................................................................................2-15

Chassis Intrusion .....................................................................................2-15

Universal Serial Bus Ports .......................................................................2-16

USB Headers ........................................................................................... 2-16

SGPIO ......................................................................................................2-16

Standby Power Connector .......................................................................2-16

Fan Headers .............................................................................................2-17

ATX PS/2 Keyboard and PS/2 Mouse Ports ............................................2-17

LAN1/2/3/4 (Ethernet Ports) ..................................................................... 2-17

Power LED/Speaker ................................................................................. 2-18

Unit Identifi er Button ................................................................................. 2-18

Trusted Platform Module Header ............................................................. 2-18

2

Power SMB (I

C) ......................................................................................2-19

SMBus Header ......................................................................................... 2-19

Overheat LED ........................................................................................... 2-19

SATA DOM Power Connector ..................................................................2-19

Compact Flash Card PWR Connector ..................................................... 2-19

SAS Battery Backup Connector ............................................................... 2-20

Video Connector ....................................................................................... 2-20

2-9 Jumper Settings ............................................................................................ 2-21

Explanation of Jumpers ................................................................................ 2-21

CMOS Clear ............................................................................................. 2-21

I2C to PCI-Express Slot ...........................................................................2-22

Watch Dog Enable/Disable ...................................................................... 2-22

VGA Enable/Disable ................................................................................. 2-22

LAN1/2/3/4 Enable/Disable ..................................................................... 2-22

SAS Enable/Disable .................................................................................2-23

BMC Jumper ............................................................................................ 2-23

2-10 Onboard Indicators ........................................................................................2-23

LAN1/LAN2/LAN3/LAN4 LEDs ................................................................. 2-23

IPMI Dedicated LAN LEDs ....................................................................... 2-24

Power LED ............................................................................................... 2-24

IPMI LED .................................................................................................. 2-24

UID LED (LE1) ........................................................................................ 2-24

2-11 SATA Drive Connections ............................................................................... 2-25

SATA Ports ............................................................................................... 2-25

SAS Ports ................................................................................................. 2-25

v

Table of Contents

2-12 Enabling SATA RAID ..................................................................................... 2-26

Serial ATA (SATA)..........................................................................................2-26

Installing the OS/SATA Driver ....................................................................... 2-26

Building a Driver Diskette ......................................................................... 2-26

Enabling SATA RAID in the BIOS ................................................................. 2-27

Using the DotHill and Adaptec RAID Utility .................................................. 2-29

Installing the RAID Driver During OS Installation ......................................... 2-29

2-13 Installing Drivers ............................................................................................2-30

Supero Doctor III ........................................................................................... 2-31

2-14 Serverboard Battery ......................................................................................2-33

Chapter 3 Troubleshooting

3-1 Troubleshooting Procedures ........................................................................... 3-1

Before Power On ............................................................................................ 3-1

No Power ........................................................................................................3-1

No Video .........................................................................................................3-2

Memory Errors ............................................................................................... 3-2

Losing the System’s Setup Confi guration ....................................................... 3-2

3-2 Technical Support Procedures ........................................................................3-2

3-3 Frequently Asked Questions ........................................................................... 3-3

3-4 Returning Merchandise for Service.................................................................3-4

Chapter 4 BIOS

4-1 Introduction ......................................................................................................4-1

4-2 Main Menu ...................................................................................................... 4-2

4-3 Advanced Settings Menu ................................................................................ 4-3

4-6 Security Settings Menu .................................................................................4-16

4-5 Boot Settings Menu ....................................................................................... 4-17

4-8 Exit Menu ...................................................................................................... 4-18

Appendix A BIOS Error Beep Codes

Appendix B BIOS POST Checkpoint Codes

B-1 Uncompressed Initialization Codes ................................................................. B-1

B-2 Bootblock Recovery Codes .............................................................................B-2

B-3 Uncompressed Initialization Codes ................................................................. B-3

vi

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Checklist

Congratulations on purchasing your computer motherboard from an acknowledged

leader in the industry. Supermicro boards are designed with the utmost attention to

detail to provide you with the highest standards in quality and performance.

Please check that the following items have all been included with your motherboard.

If anything listed here is damaged or missing, contact your retailer.

• One (1) H8QG7/i-LN4F serverboard

• One (1) 9-pin Serial port DTK cable (CBL-010L) cable

• Two (2) Ipass to 4 SATA, 50-cm, W/50-cm SB, S, 26AWG I/O cables

(CBL-0097L-02) (H8QG7-LN4F only)

• Four (4) SATA CABLE 61-cm FLAT S-S PBF, 26AWG, flat I/O cables

(CBL-0044L) (H8QG7-LN4F only)

• Six (6) SA TA CABLE 61-cm FLA T S-S PBF, 26AWG, fl at I/O cables (CBL-0044L)

(H8QGi-LN4F only)

• One (1) MCP-260-00060-0N I/O shield with EMI gasket

Note: For your system to work properly, please follow the links below to download

all necessary drivers/utilities and the user’s manual for your motherboard.

• Supermicro product manuals: http://www.supermicro.com/support/manuals/

• Product drivers and utilities: ftp://ftp.supermicro.com

• Product safety information:

http://super-dev/about/policies/safety_information.cfm

• If you have any questions, please contact our support team at:

support@supermicor.com

1-1

H8QG7/i-LN4F Serverboard User’s Manual

1-2 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site:

Europe

Address: Super Micro Computer B.V.

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

Web Site:

www.supermicro.com

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

www.supermicro.com

Asia-Pacifi c

Address: Super Micro Computer, Inc.

3F, No. 150, Jian 1st Rd.

Zhonghe Dist., New Taipei City 235

Taiwan (R.O.C)

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3992

Email: support@supermicro.com.tw

Tel: +886-(2)-8226-3990

Web Site:

www.supermicro.com.tw

1-2

Figure 1-1. H8QG7/i-LN4F Image

Chapter 1: Introduction

1-3

H8QG7/i-LN4F Serverboard User’s Manual

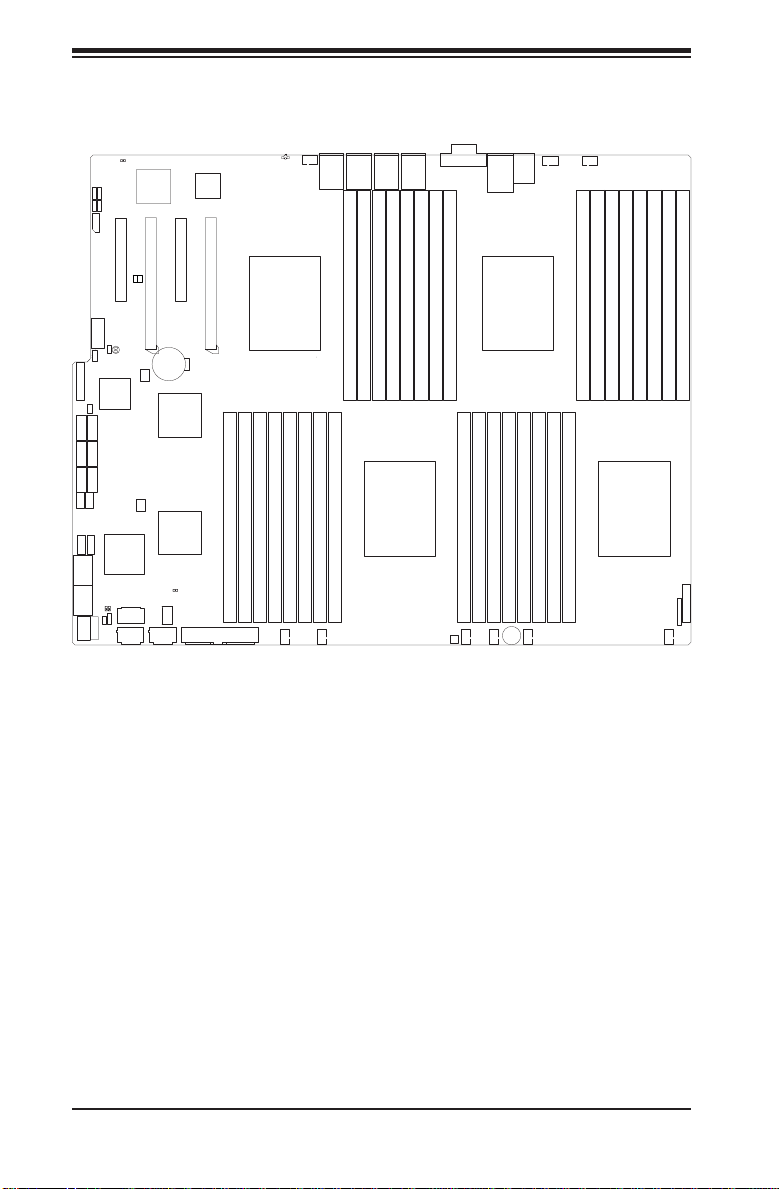

T-SGPIO1

USB2/3

JWD1JPG1

JTPM1

JSD1

SATA4

SATA2

SATA0

SAS4~7

SAS0~3

USB6

SATA5

SATA1SATA3

JPI2C1

JPL1

JPB1

JIPMB1

COM1

JSTBY1

SP5100

T-SGPIO2

USB4/5

LEDS2

JOH1

JL1

AMD

LEDS1

JPS1

DP1

BMC

SLOT1 PCI-E 2.0 X8

SLOT2 PCI-E 2.0 X16

JI2C1

JI2C2

JBT1

BATTERY

AFAN1

AFAN2

LSI

2208

SAS2

JPW4

JPW3 JPW2

Figure 1-2. H8QG7/i-LN4F Motherboard Layout

(not drawn to scale)

LAN4

LAN3

LAN2

P1-DIMM4A

P1-DIMM3B

CPU2

LAN1

P1-DIMM3A

P1-DIMM2B

P1-DIMM2A

P1-DIMM1B

VGA

P1-DIMM1A

P4-DIMM1A

JF2

SLOT3 PCI-E 2.0 X8

AMD

SR5690

AMD

SR5670

DP3

JS3

Intel

I350

SLOT4 PCI-E 2.0 X16

P2-DIMM1A

P2-DIMM1B

JPW1

UID/LE1

CPU1

P2-DIMM2A

P2-DIMM2B

P2-DIMM3A

FAN6

FAN9

/CPU1

P2-DIMM3B

P2-DIMM4A

FAN5

P1-DIMM4B

P2-DIMM4B

P4-DIMM1B

/CPU24

FAN

IPMI LAN

USB0/1

CPU3

P4-DIMM2A

P4-DIMM2B

FAN3

SPEAKER

MOUSE

KB/

P4-DIMM3A

P4-DIMM3B

FAN2

FAN8 FAN7

/CPU3

P3-DIMM4B

P4-DIMM4A

P4-DIMM4B

P3-DIMM4A

P3-DIMM3B

P3-DIMM3A

P3-DIMM2B

CPU4

P3-DIMM2A

P3-DIMM1B

/CPU4

FAN1

P3-DIMM1A

JF1

JD1

Notes:

Jumpers not indicated are for test purposes only.

Not all ports, jumpers or LED Indicators are available on all serverboards.

1-4

Chapter 1: Introduction

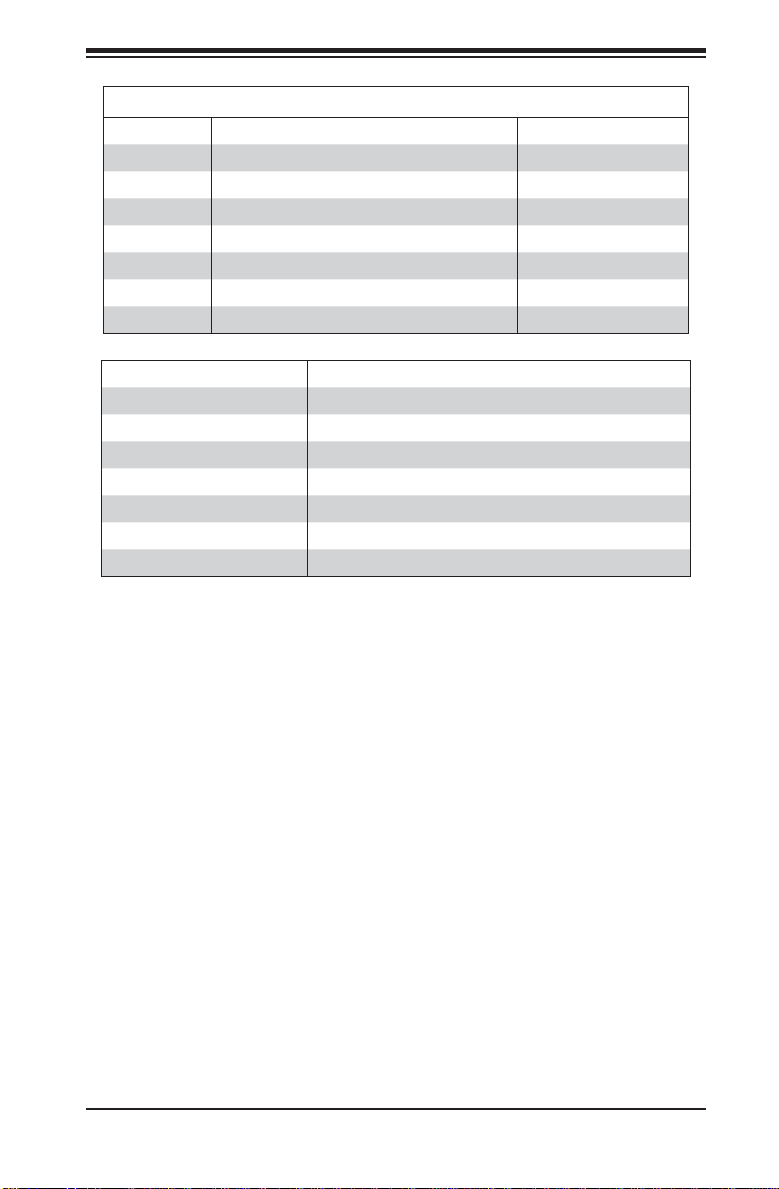

H8QG7/i-LN4F Quick Reference

Jumper Description Default Setting

JBT1 CMOS Clear (See Section 2-7)

JI2C1/JI2C2 I2C to PCI-E Slot Enable/Disable Pin 2-3 (Disabled)

JPB1 BMC Enable/Disable Pins 1-2 (Enabled)

JPG1 VGA Enable/Disable Pins 1-2 (Enabled)

JPL1 LAN 1/2/3/4 Enable/Disable Pins 1-2 (Enabled)

JPS1 SAS Controller Enable/Disable (only on H8QG7-LN4F) Pins 1-2 (Enabled)

JWD1 Watch Dog Pins 1-2 (Reset)

LED Description

LAN Ports LEDs for the LAN Ethernet ports

Dedicated IPMI LAN LEDs for the dedicated IPMI LAN Ethernet port

LE1 LED for UID Button

DP1 LED for IPMI Heartbeat

DP3 LED for Serverboard Power-On

LEDS1 SAS Activity LED (H8QG7-LN4F only)

LEDS2 SAS Fault LED (H8QG7-LN4F only))

1-5

H8QG7/i-LN4F Serverboard User’s Manual

Connector Description

COM1 COM1 Serial Header

FAN 1-9 Chassis/CPU Fan Headers

IPMI LAN Dedicated IPMI LAN Port

JD1 Speaker Header

JF1 Front Panel Connector

JF2 NIC3/NIC4 (LAN3/4) LED Connectors

JIPMB1 System Management Bus Header (SMBus)

JL1 Chassis Intrusion Header

JOH1 Overheat Warning Header

2

JPI2C1 Power I

JPW1 24-pin Main ATX Power Connector

JPW2/3/4 +12V 8-pin CPU Power Connectors

JS3 SAS Battery Backup Cable Port

JSD1 SATA DOM (Device_On_Module) Power Connector

JTPM1 Trusted Platform Module Header

JWF1 Compact Flash Card Power Connector

JSTBY1 Standby Power Connection header

LAN1/2/3/4 Gigabit Ethernet (RJ45) Ports

PS2 Mouse/Keyboard PS2 Mouse/Keyboard connectors

SAS0~3, SAS4~7 SAS Ports (only on H8QG7-LN4F)

SATA0 ~ SATA5 SATA Ports

T-SGPIO1/T-SGPIO2 Serial General Purpose Input/Output Header for SATA

UID Unit Identifi er Button

USB0/1, USB6, USB2/3, USB4/5 Universal Serial Bus (USB) Ports, Type-A Ports and Headers

VGA VGA Connector

C Header

1-6

Chapter 1: Introduction

Motherboard Features

CPU

• Quad AMD Opteron 6000 series (AMD Socket G34 type) processors

Note: You must install at least two processors for full functions to be supported.

Memory

• The H8QG7/i-LN4F serverboard has thirty-two (32) single/dual/tri/quad

channel DIMM slots supporting up to 256 GB of ECC/Non-ECC UDIMM or

up to 1 TB of ECC RDIMM/LRDIMM DDR3-1600/1333/1066 Mhz speed,

1 GB, 2 GB, 4 GB, 8 GB, 16 GB or 32 GB size, 1.35V or 1.5V SDRAM

Note: Refer to Section 2-5 before installing memory and our web site for recommended DIMMs.

Chipset

• One SR5690, one SR5670 and SP5100 Southbridge chipsets

Expansion Slots

• Two (2) PCI-E 2.0 x16 slots

• Two (2) PCI-E 2.0 x8 slots

BIOS

• 16 Mb AMI BIOS® SPI Flash ROM

• APM 1.2, DMI 2.3, PCI 2.2, ACPI 1.0 (ACPI 2.0 is BIOS supported), SMBIOS

2.3, Real Time Clock Wakeup, Plug and Play (PnP), BIOS resume hot keys,

PC Health Monitoring

• Onboard voltage monitors

• Fan status monitor with fi rmware/software on/off and speed control

• Watch Dog

• Environmental temperature monitoring via BIOS

• Power-up mode control for recovery from AC power loss

• System resource alert (via included utility program)

• Auto-switching voltage regulator for the CPU core

• CPU thermal trip support

2

• I

C temperature sensing logic

1-7

H8QG7/i-LN4F Serverboard User’s Manual

ACPI Features

• Microsoft OnNow

• Slow blinking LED for suspend state indicator

• BIOS support for USB keyboard

• Wake-On-LAN (WOL)

• Internal/external modem ring-on

• Hardware BIOS Virus protection

Onboard I/O

• Six (6) SATA ports supported by an on-chip SATA controller (RAID 0, 1 and 10

supported)

• Eight (8) SAS ports supported by an LSI 2208 SAS2 controller

(RAID 0, 1, 5, 6, 10, 50 and 60) (H8QG7-LN4F only)

• One (1) Fast UART 16550 compatible serial header

• Seven (7) USB (Universal Serial Bus 2.0) ports (2x rear, 4x header,

1x type A)

• Four (4) LAN ports supported by an onboard Intel® i350 quad port Ethernet

controller for 10/100/1000Base-T

• One (1) dedicated IPMI LAN port

• Two (2) PS-2 Keyboard and Mouse Ports

• One (1) VGA port supported by an onboard Matrox

(with 16 MB DDR2 memory)

®

G200eW graphics controller

Other

• Onboard power LED

• Chassis intrusion detection

CD Utilities

• BIOS fl ash upgrade utility

• Super Doctor III

• IPMI 1.5 / 2.0 (Optional)

Dimensions

• SWTX format: (LxW) 13" x 16.48" (330 x 419 mm)

1-8

Chapter 1: Introduction

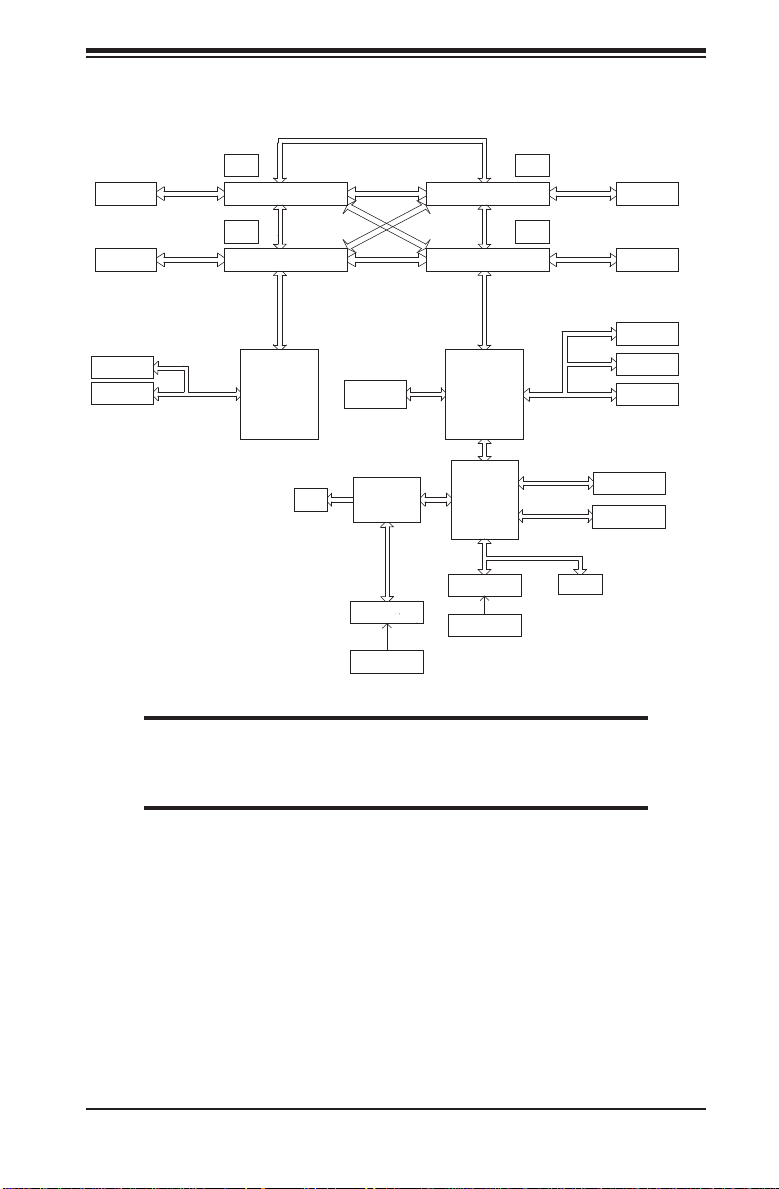

Figure 1-3. SR5690/SR5670/SP5100 Chipset:

System Block Diagram

HT Link

VRM

8x DIMM

DDR3-1600/1333/1066

DDR3-1600/1333/1066 DDR3-1600/1333/1066

8x DIMM

SLOT#1

PCIE_(X8)

SLOT#2

PCIE_(X16)

G34-SOCKET #4

HT Link

VRM VRM

G34-SOCKET #2

16/16-1GHz

HT Link

AMD

SR5670#2

VGA

HT Link

HT Link

LAN

Intel I350

Winbond

WPCM450

H/W_MONITOR

W83795

9_FAN_CONN.

PCIE (x4)

HT Link

G34-SOCKET #3

HT Link

G34-SOCKET #1

16/16-1GHz

HT Link

AMD

SR5690#1

AMD

SP5100

LPC BUS

LPC SIO

W83627DHG-P

KEYBOARD/

MOUSE

VRM

CH 1A, 1B, 2A, 2B, 3A, 3B, 4A, 4BCH 1A, 1B, 2A, 2B, 3A, 3B, 4A, 4B

DDR3-1600/1333/1066

PCIE (X8)

PCIE (X8)

PCIE (X16)

SATA

SATA PORT X6

USB

USB PORT X7

FWH

8x DIMM

8x DIMM

LSI

SAS2 2208

SLOT#3

PCIE_(X8)

SLOT#4

PCIE_(X16)

Note: This is a general block diagram and may not exactly represent

the features on your motherboard. See the previous pages for the

actual specifi cations of your motherboard.

1-9

H8QG7/i-LN4F Serverboard User’s Manual

1-3 Chipset Overview

The H8QG7/i-LN4F serverboard is based on the AMD SR5690/SR5670/SP5100

chipset. This chipset functions as a Media and Communications Processor (MCP).

Controllers for the system memory are integrated directly into AMD Opteron

processors.

AMD SR5690/SR5670/SP5100 Chipsets

The AMD SR5690/SR5670/SP5100 are each a single-chip, high-performance

HyperTransport peripheral controllers. They include a 42 or 30-lane PCI Express

interface, an AMD Opteron 16-bit Hyper T ransport interface link, a six-port Serial A TA

interface and a seven-port USB 2.0 interface. This hub connects directly to the CPU.

HyperTransport Technology

HyperTransport technology is a high-speed, low latency point to point link that was

designed to increase the communication speed by a factor of up to 48x between

integrated circuits. This is done partly by reducing the number of buses in the

chipset to reduce bottlenecks and by enabling a more effi cient use of memory

in multi-processor systems. The end result is a signifi cant increase in bandwidth

within the chipset.

1-4 PC Health Monitoring

This section describes the PC health monitoring features of the H8QG7/i-LN4F

serverboard. The serverboard has an onboard System Hardware Monitor chip that

supports PC health monitoring.

Onboard Voltage Monitors

The onboard voltage monitor will continuously scan crucial voltage levels. Once

a voltage becomes unstable, it will give a warning or send an error message to

the screen. Users can adjust the voltage thresholds to defi ne the sensitivity of the

voltage monitor. Real time readings of these voltage levels are all displayed in BIOS.

Fan Status Monitor with Firmware/Software Speed Control

The PC health monitor can check the RPM status of the cooling fans. The onboard

fans are controlled by thermal management via BIOS.

1-10

Chapter 1: Introduction

CPU Overheat/Fan Fail LED and Control

This feature is available when the user enables the CPU overheat/Fan Fail warning

function in the BIOS. This allows the user to defi ne an overheat temperature. When

this temperature is exceeded or when a fan failure occurs, the Overheat/Fan Fail

warning LED is triggered.

Auto-Switching Voltage Regulator for the CPU Core

The 6-phase-switching voltage regulator for the CPU core can support up to

AMD Opteron 6000SE series processors. This will allow the regulator to run cooler

and thus make the system more stable.

1-5 Power Confi guration Settings

This section describes the features of your motherboard that deal with power and

power settings.

Microsoft OnNow

The OnNow design initiative is a comprehensive, system-wide approach to system

and device power control. OnNow is a term for a PC that is always on but appears

to be off and responds immediately to user or other requests.

Slow Blinking LED for Suspend-State Indicator

When the CPU goes into a suspend state, the chassis power LED will start blinking

to indicate that the CPU is in suspend mode. When the user presses any key, the

CPU will wake-up and the LED will automatically stop blinking and remain on.

BIOS Support for USB Keyboard

If a USB keyboard is the only keyboard in the system, it will function like a normal

keyboard during system boot-up.

1-11

H8QG7/i-LN4F Serverboard User’s Manual

Main Switch Override Mechanism

The power button can function as a system suspend button. When the user

depresses the power button, the system will enter a SoftOff state. The monitor

will be suspended and the hard drive will spin down. Depressing the power button

again will cause the whole system to wake-up. During the SoftOff state, the power

supply provides power to keep the required circuitry in the system alive. In case the

system malfunctions and you want to turn off the power, just depress and hold the

power button for 4 seconds. The power will turn off and no power will be provided

to the motherboard.

Wake-On-LAN (WOL)

Wake-On-LAN is defi ned as the ability of a management application to remotely

power up a computer that is powered off. Remote PC setup, up-dates and access

tracking can occur after hours and on weekends so that daily LAN traffi c is kept

to a minimum and users are not interrupted. The motherboard has a 3-pin header

(WOL) to connect to the 3-pin header on a Network Interface Card (NIC) that has

WOL capability. Wake-On-LAN must be enabled in BIOS.

1-6 Power Supply

As with all computer products, a stable power source is necessary for proper and

reliable operation. It is even more important for processors that have high CPU

clock rates.

The H8QG7/i-LN4F serverboard requires the use of proprietary power supplies.

Please refer to the pinout information for the power connectors in Section 6 of

Chapter 2 for detailed information on power requirements.

In areas where noisy power transmission is present, you may choose to install a

line fi lter to shield the computer from noise. It is recommended that you also install

a power surge protector to help avoid problems caused by power surges.

Warning: To prevent the possibility of explosion, do not use the wrong type of

onboard CMOS battery or install it upside down.

1-12

Chapter 1: Introduction

1-7 Super I/O

The Super I/O includes a data separator, write pre-compensation circuitry, decode

logic, data rate selection, a clock generator, drive interface control logic and interrupt

and DMA logic. The wide range of functions integrated onto the Super I/O greatly

reduces the number of components required for interfacing with fl oppy disk drives.

The Super I/O provides a high-speed, 16550 compatible serial communication

header (UART), which supports serial infrared communication. The UART includes a

16-byte send/receive FIFO, a programmable baud rate generator, complete modem

control capability and a processor interrupt system. The UART also provides legacy

speed with baud rate of up to 115.2 Kbps as well as an advanced speed with baud

rates of 250 K, 500 K, or 1 Mb/s, which support higher speed modems.

The Super I/O provides functions that comply with ACPI (Advanced Confi guration

and Power Interface), which includes support of legacy and ACPI power management

through a SMI or SCI function pin. It also features auto power management to reduce

power consumption.

The IRQs, DMAs and I/O space resources of the Super I/O can be fl exibly adjusted

to meet ISA PnP requirements, which support ACPI and APM (Advanced Power

Management).

1-13

H8QG7/i-LN4F Serverboard User’s Manual

Notes

1-14

Chapter 2: Installation

Chapter 2

Installation

2-1 Standardized Warning Statements

About Standardized Warning Statements

The following statements are industry standard warnings, provided to warn the user

of situations which have the potential for bodily injury. Should you have questions

or experience difficulty, contact Supermicro's Technical Support department

for assistance. Only certifi ed technicians should attempt to install or confi gure

components.

Read this section in its entirety before installing or confi guring components in the

Supermicro chassis.

These warnings may also be found on our web site at http://www.supermicro.

com/about/policies/safety_information.cfm.

Battery Handling

Warning!

There is a danger of explosion if the battery is replaced incorrectly. Replace the

battery only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer's instructions

電池の取り扱い

電池交換が正しく行われなかった場合、破裂の危険性があります。交換する電池はメー

カーが推奨する型、または 同 等 のものを使 用 下さい 。 使用済電池は製造元の指示に従

って処 分して下さい。

警告

电池更换不当会有爆炸危险。请只使用同类电池或制造商推荐的功能相当的电池更

换原有电池。请按制造商的说明处理废旧电池。

警告

電池更換不當會有爆炸危險。請使用製造商建議之相同或功能相當的電池更換原有

電池。請按照製造商的說明指示處理廢棄舊電池。

2-1

H8QG7/i-LN4F Serverboard User's Manual

!הרהזא

Warnung

Bei Einsetzen einer falschen Batterie besteht Explosionsgefahr. Ersetzen Sie die

Batterie nur durch den gleichen oder vom Hersteller empfohlenen Batterietyp.

Entsorgen Sie die benutzten Batterien nach den Anweisungen des Herstellers.

Attention

Danger d'explosion si la pile n'est pas remplacée correctement. Ne la remplacer

que par une pile de type semblable ou équivalent, recommandée par le fabricant.

Jeter les piles usagées conformément aux instructions du fabricant.

¡Advertencia!

Existe peligro de explosión si la batería se reemplaza de manera incorrecta.

Reemplazar la batería exclusivamente con el mismo tipo o el equivalente

recomendado por el fabricante. Desechar las baterías gastadas según las

instrucciones del fabricante.

תנכס תמייקץוציפ .הניקת אל ךרדב הפלחוהו הדימב הללוסה לש ףילחהל שי

גוסב הללוסה תא מ םאותה תרבחלמומ ןרציתצ.

תוללוסה קוליס תושמושמה עצבל שי .ןרציה תוארוה יפל

ﺮﻄﺧ ﻙﺎﻨﻫ ﻦﻣ ﻝﺍﺪﺒﺘﺳﺍ ﺔﻟﺎﺣ ﻲﻓ ﺭﺎﺠﻔﻧﺍ ﺔﻳﺭﺎﻄﺒﻟﺍ ﺔﺤﻴﺤﺻ ﺮﻴﻏ ﺔﻘﻳﺮﻄﺑ ﻚﻴﻠﻌﻓ

ﺔﻳﺭﺎﻄﺒﻟﺍ ﻝﺍﺪﺒﺘﺳﺍ

ﺕﺎﻳﺭﺎﻄﺒﻟﺍ ﻦﻣ ﺺﻠﺨﺗ ﻟ ﺎﻘﻓﻭ ﺔﻠﻤﻌﺘﺴﻤﻟﺍﺔﻌﻧﺎﺼﻟﺍ ﺔﻛﺮﺸﻟﺍ ﺕﺎﻤﻴﻠﻌﺘ

ﻂﻘﻓ ﻉﻮﻨﻟﺍ ﺲﻔﻨﺑ ﺎﻬﻟﺩﺎﻌﻳ ﺎﻣ ﻭﺃ ﺎﻤﻛﺖﺻﻭﺃ ﺔﻌﻨﺼﻤﻟﺍ ﺔﻛﺮﺸﻟﺍ ﻪﺑ

경고!

배터리가 올바르게 교체되지 않으면 폭발의 위험이 있습니다. 기존 배터리와

동일하거나 제조사에서 권장하는 동등한 종류의 배터리로만 교체해야 합니다.

제조사의 안내에 따라 사용된 배터리를 처리하여 주십시오.

Waarschuwing

Er is ontploffi ngsgevaar indien de batterij verkeerd vervangen wordt. Vervang de

batterij slechts met hetzelfde of een equivalent type die door de fabrikant aanbevolen

wordt. Gebruikte batterijen dienen overeenkomstig fabrieksvoorschriften afgevoerd

te worden.

2-2

Chapter 2: Installation

רצומה קוליס

Product Disposal

Warning!

Ultimate disposal of this product should be handled according to all national laws

and regulations.

製品の廃棄

この製品を廃棄処分する場合、国の関係する全ての法律・条例に従い処理する必要が

あります。

警告

本产品的废弃处理应根据所有国家的法律和规章进行。

警告

本產品的廢棄處理應根據所有國家的法律和規章進行。

Warnung

Die Entsorgung dieses Produkts sollte gemäß allen Bestimmungen und Gesetzen

des Landes erfolgen.

¡Advertencia!

Al deshacerse por completo de este producto debe seguir todas las leyes y

reglamentos nacionales.

Attention

La mise au rebut ou le recyclage de ce produit sont généralement soumis à des

lois et/ou directives de respect de l'environnement. Renseignez-vous auprès de

l'organisme compétent.

!הרהזא

ו תויחנהל םאתהב תויהל בייח הז רצומ לש יפוס קוליס.הנידמה יקוח

ﻲﺋﺎﻬﻨﻟﺍ ﺺﻠﺨﺘﻟﺍ ﻦﻣ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﻪﻌﻣ ﻞﻣﺎﻌﺘﻟﺍ ﻲﻐﺒﻨﻳ ﻟ ﺎﻘﻓﻭ ﻊﻴﻤﺠﺔﻴﻨﻁﻮﻟﺍ ﺢﺋﺍﻮﻠﻟﺍﻭ ﻦﻴﻧﺍﻮﻘﻟﺍ ﺪﻨﻋ

경고!

이 제품은 해당 국가의 관련 법규 및 규정에 따라 폐기되어야 합니다.

Waarschuwing

De uiteindelijke verwijdering van dit product dient te geschieden in overeenstemming

met alle nationale wetten en reglementen.

2-3

H8QG7/i-LN4F Serverboard User's Manual

2-2 Static-Sensitive Devices

Electrostatic Discharge (ESD) can damage electronic com ponents. To prevent

damage to your system board, it is important to handle it very carefully. The following

measures are generally suffi cient to protect your equipment from ESD.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing the board from the antistatic

bag.

• Handle the board by its edges only; do not touch its components, peripheral

chips, memory modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their antistatic bags when not

in use.

• For grounding purposes, make sure your computer chassis provides excellent

conductivity between the power supply, the case, the mounting fasteners and

the motherboard.

• Use only the correct type of CMOS onboard battery as specifi ed by the

manufacturer. Do not install the CMOS onboard battery upside down, which

may result in a possible explosion.

Unpacking

The motherboard is shipped in antistatic packaging to avoid static damage. When

unpacking the board, make sure the person handling it is static protected.

2-4

Chapter 2: Installation

2-3 Processor and Heatsink Installation

Warning: Exercise extreme caution when handling and installing the processor. Always

connect the power cord last and always remove it before adding, removing or changing

any hardware components.

Installation Procedure

Follow the procedures as listed below to install the motherboard into a chassis.

1. Install the processor(s) and the heatsink(s).

2. Install the motherboard in the chassis.

3. Install the memory and add-on cards.

4. Finally, connect the cables and install the drivers.

Installing the Processors

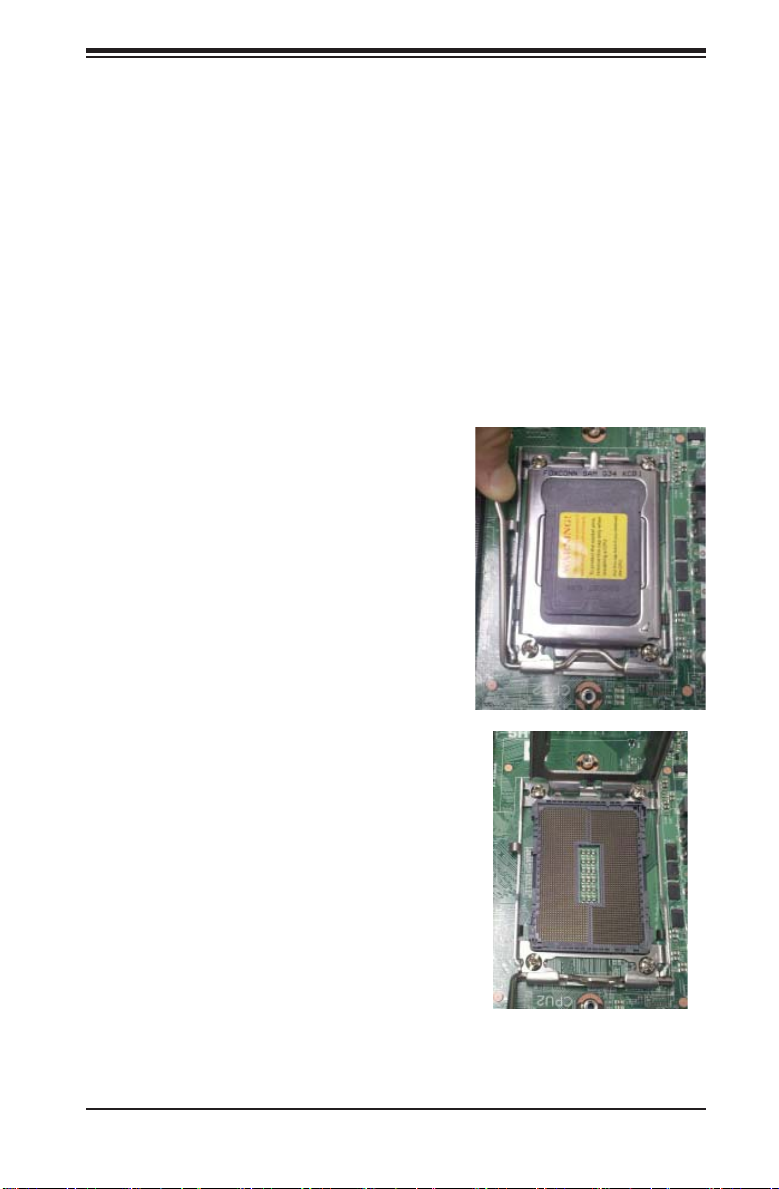

1. Begin by removing the cover plate

that protects the CPU. Lift the

lever on the CPU socket until it

points straight up.

2. With the lever raised, lift open the

silver CPU retention plate.

2-5

H8QG7/i-LN4F Serverboard User's Manual

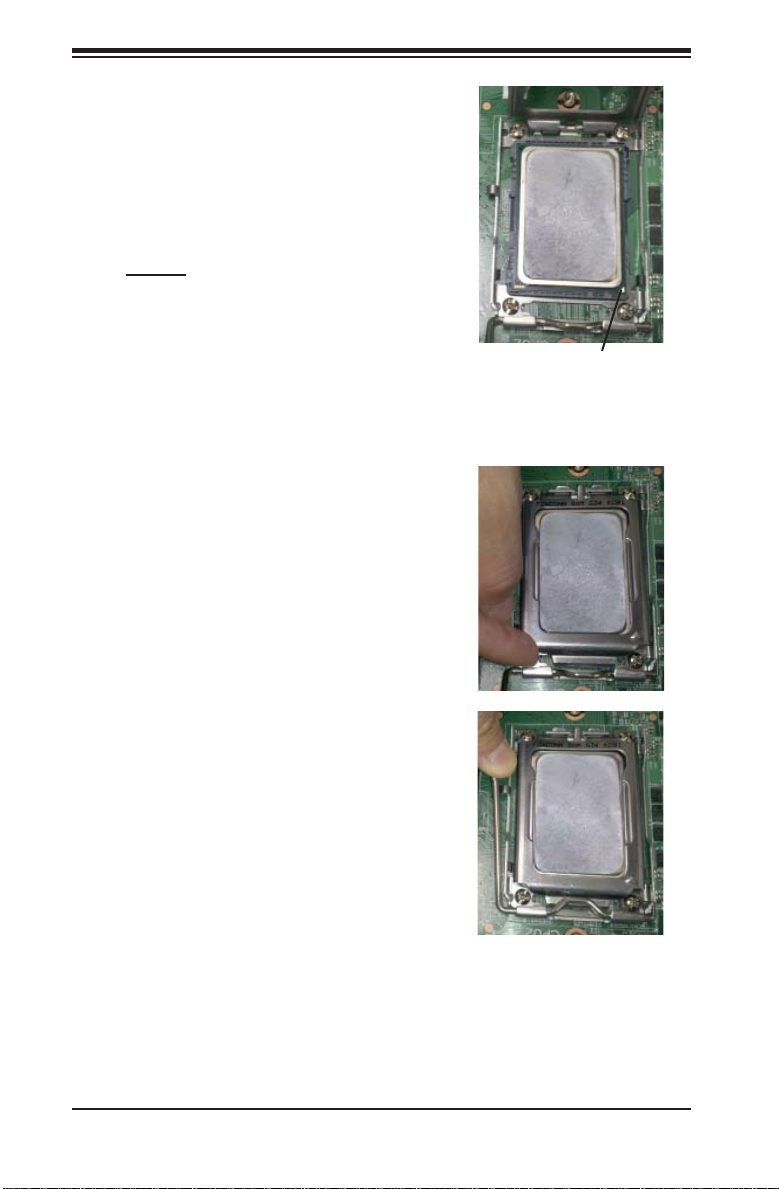

3. Use your thumb and your index

fi nger to hold the CPU. Locate

and align pin 1 of the CPU socket

with pin 1 of the CPU. Both are

marked with a triangle.

4. Align pin 1 of the CPU with pin

1 of the socket. Once aligned,

carefully place the CPU into the

socket. Do not drop the CPU

on the socket, move the CPU

horizontally or vertically or rub the

CPU against the socket or against

any pins of the socket, which

may damage the CPU and/or the

socket.

5. With the CPU inserted into the

socket, inspect the four corners

of the CPU to make sure that it is

properly installed and fl ush with

the socket. Then, gently lower

the silver CPU retention plate into

place.

Triangle

6. Carefully press the CPU socket

lever down until it locks into its

retention tab. For a dual-CPU

system, repeat these steps to

install another CPU into the

CPU#2 socket (and into CPU#2,

#3 and #4 sockets for a quadCPU confi guration).

Note: In single and dual-CPU confi gurations, memory must be installed in the DIMM

slots associated with the installed CPU(s).

2-6

Chapter 2: Installation

Installing the Heatsinks

We recommend the use of active type heatsinks (except for 1U systems). Use any

onboard fan header for the CPU's heatsink fan. To install the heatsink, please follow

the installation instructions that are included with your heatsink package.

Note: Make sure the heatsink is placed so that the fi ns of the heatsink are in the

direction of the airfl ow in your system.

2-4 Mounting the Motherboard into a Chassis

All motherboards have standard mounting holes to fi t different types of chassis.

Make sure that the locations of all the mounting holes for both the motherboard

and the chassis match. Although a chassis may have both plastic and metal

mounting fasteners, metal ones are highly recommended because they ground

the motherboard to the chassis. Make sure that the metal standoffs click in or are

screwed in tightly.

Check the Compatibility of the Motherboard Ports and the I/O Shield

7. The H8QG7/i-LN4F serverboard requires a chassis that can support a board

of 16.48" x 13" in size.

8. Make sure that the I/O ports on the motherboard align with their respective

holes in the I/O shield at the rear of the chassis.

Mounting the Motherboard onto the Tray in the Chassis

1. Carefully mount the motherboard onto the motherboard tray by aligning the

motherboard mounting holes with the raised metal standoffs in the tray.

2. Insert screws into all the mounting holes in the motherboard that line up with

the standoffs.

3. Then use a screwdriver to secure the motherboard to the mainboard

tray - tighten until just snug (if too tight you might strip the threads). Metal

screws provide an electrical contact to the motherboard ground to provide a

continuous ground for the system.

2-5 Installing Memory

Warning: Exercise extreme caution when installing or removing memory modules to

prevent any possible damage.

Installing Memory

1. Insert each memory module vertically into its slot, paying attention to the

notch along the bottom of the module to prevent inserting the module

incorrectly (see Figure 2-1).

2-7

H8QG7/i-LN4F Serverboard User's Manual

2. Install to slots CPU1/DIMM1A, CPU1/DIMM2A, CPU1/DIMM3A and CPU1/

DIMM4A, etc. Always install in groups of four and in the numerical order of

the DIMM slots. See support information below.

3. Gently press down on the memory module until it snaps into place.

4. With four DIMMs installed, repeat step 2 to populate the CPU2 DIMM

slots. Always install four DIMMs to both CPU DIMM slots for more effi cient

operation.

Note: Memory modules of 1 GB, 2 GB, 4 GB, 8 GB, 16 GB or 32 GB size are

supported. It is highly recommended that you remove the power cord from the

system before installing or changing memory modules. Please refer to our web site

for memory that has been tested on the H8QG7/i-LN4F serverboard.

Memory Support

The H8QG7/i-LN4F serverboard supports thirty-two (32) single/dual/tri/quadchannel, DDR3-1600/1333/1066 Mhz registered UDIMM/RDIMM/LRDIMM SDRAM

memory modules.

Populating four adjacent slots at a time with memory modules of the same size and

type will result in interleaved (128-bit) memory, which is faster than non-interleaved

(64-bit) memory.

Maximum Memory

The H8QG7/i-LN4F serverboard supports a maximum memory of up to 256 GB of

UDIMM or up to 1 TB of RDIMM/LRDIMM SDRAM.

Figure 5-3. Installing DIMM into Slot

To Install: Insert

Notch

module vertically and

press down until it

snaps into place.

Pay attention to the

Front View

alignment notch at

the bottom.

To Remove: Use

your thumbs to gently

Release Tab Release Tab

Note: Notch should align with

the receptive key point on

the slot.

push the release tabs

near both ends of the

module. This should

release it from the

Top View of DDR3 Slot

slot.

2-8

Notch

Chapter 2: Installation

Memory Population for Optimal Performance

-For a Motherboard with One CPU (CPU1) Installed

# DIMMS CPU Channel 1 Channel 2 Channel 3 Channel 4

4 DIMMs CPU1 P1-1A P1-2A P1-3A P1-4A

8 DIMMs CPU1 P1-1A P1-1B P1-2A P1-2B P1-3A P1-3B P1-4A P1-4B

-For a Motherboard with Two CPUs (CPU1 & CPU2) Installed

Memory Population for Optimal Performance

# DIMMS CPU Channel 1 Channel 2 Channel 3 Channel 4

8 DIMMs

16 DIMMs

CPU1 P1-1A P1-2A P1-3A P1-4A

CPU2 P2-1A P2-2A P2-3A P2-4A

CPU1 P1-1A P1-1B P1-2A P1-2B P1-3A P1-3B P1-4A P1-4B

CPU2 P2-1A P2-1B P2-2A P2-2B P2-3A P2-3B P2-4A P2-4B

Memory Population for Optimal Performance – For a Motherboard with

Four CPUs (CPU1, CPU2, CPU3 & CPU4) Installed

# DIMMS CPU Channel 1 Channel 2 Channel 3 Channel 4

CPU1 P1-1A P1-2A P1-3A P1-4A

16 DIMMs

32 DIMMs

CPU2 P2-1A P2-2A P2-3A P2-4A

CPU3 P3-1A P3-2A P3-3A P3-4A

CPU4 P4-1A P4-2A P4-3A P4-4A

CPU1 P1-1A P1-1B P1-2A P1-2B P1-3A P1-3B P1-4A P1-4B

CPU2 P2-1A P2-1B P2-2A P2-2B P2-3A P2-3B P2-4A P2-4B

CPU3 P3-1A P3-1B P3-2A P3-2B P3-3A P3-3B P3-4A P3-4B

CPU4 P4-1A P4-1B P4-2A P4-2B P4-3A P4-3B P4-4A P4-4B

2-9

H8QG7/i-LN4F Serverboard User's Manual

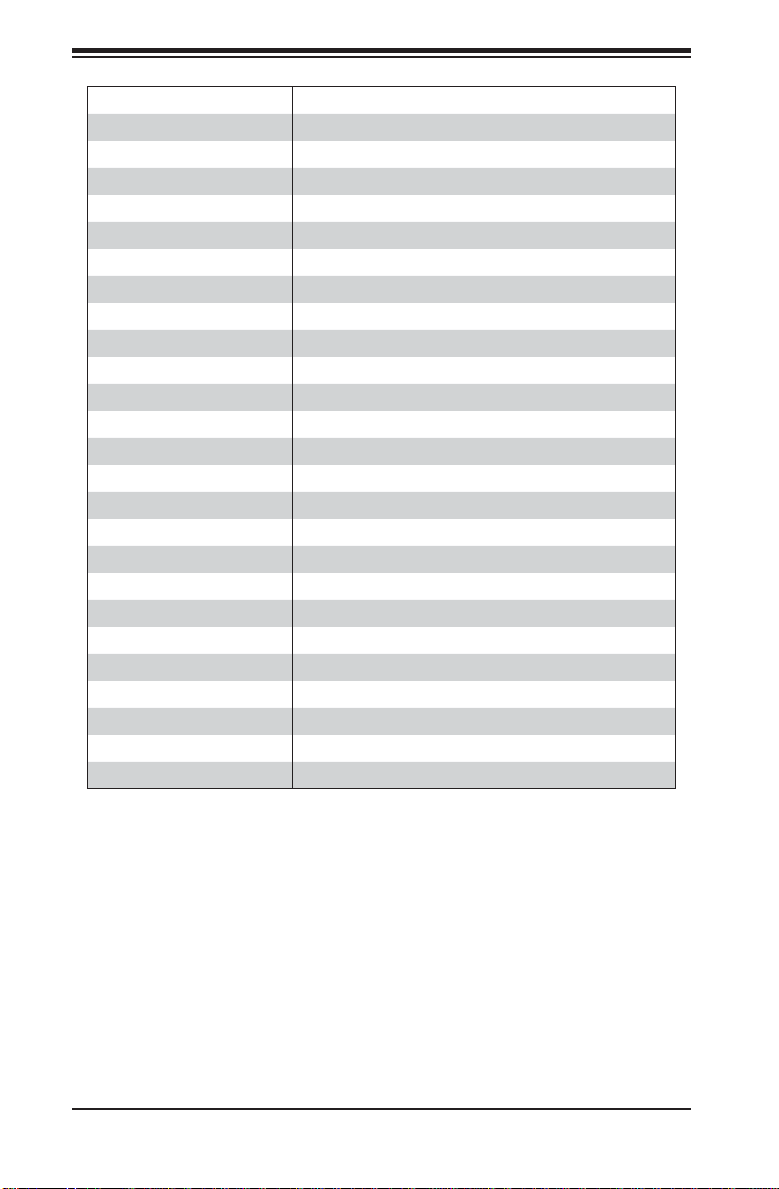

DIMM Module Population Confi guration

For memory to work properly, follow the tables below for memory installation:

Per Channel DIMM Populations Options

DIMM Type DIMM A DIMM B Max. MHz,

1.5V DIMMs

UDIMM

RDIMM

LRDIMM

SR or DR Empty

SR SR

DR DR

SR or DR Empty

SR SR

DR DR

QR Empty 1333 MHz 1066 MHz 32 GB

QR QR 1066 MHz 800 MHz 64 GB

QR Empty 1333 MHz 32 GB

QR QR 64 GB

1600 MHz

1600 MHz 8 GB

1333 MHz 16 GB

1600 MHz

1600 MHz 16 GB

1600 MHz 32 GB

Note 1: Due to OS limitations, some operating systems may not show more than

4 GB of memory.

Note 2: Due to memory allocation to system devices, the amount of memory that

remains available for operational use will be reduced when 4 GB of RAM is used.

The reduction in memory availability is disproportional.

Max. MHz,

1.35V DIMMs

1333 MHz

1333 MHz

Max. GB/

Channel

8 GB

16 GB

2-10

Chapter 2: Installation

2-6 PCI Expansion Cards

A riser card is used to support one standard size (full height full length) PCI

expansion card.

Installing a PCI Expansion Card

1. Confi rm that you have the correct riser card for your chassis model and the

add-on card includes a standard bracket.

2. Remove the chassis cover.

3. Install the riser card by the sliding card into the appropriate slot in the

motherboard.

4. Choose the PCI slot shield in which to place the add-on card.

5. In that slot, open the PCI slot shield lever and slide the shield sideways.

6. From inside the chassis, remove the PCI slot shield.

7. Slide the add-on card into the riser card and attach the add-on card bracket

in place of the PCI slot shield.

8. Secure the add-on card by closing the PCI slot shield lever.

9. Connect cables to the add-on card as necessary.

2-11

H8QG7/i-LN4F Serverboard User's Manual

2-7 I/O Port and Control Panel Connections

The I/O ports are color coded to make setting up your system easier. See Figure

2-2 below for the colors and locations of the various I/O ports.

Figure 2-2. I/O Port Locations and Defi nitions

2

1

4

3 6 7 8 9

5

10

Rear I/O Ports

1. Keyboard 6. LAN1

2. PS/2 Mouse 7. LAN2

3. USB0/1 8. LAN3

4. IPMI LAN 9. LAN4

5. VGA Port 10. UID

Front Control Panel

JF1 contains header pins for various front control panel connectors. See Figure 2-3

for the pin defi nitions of the various connectors. Refer to Section 2-6 for details.

Figure 2-3. JF1: Front Control Panel Header (JF1)

20 19

Ground

x (key)

Power LED

HDD LED

NIC1 (Link) LED

NIC2 (Link) LED

OH/PWR Fail/Fan Fail/UID LED

Power Fail LED

Ground

Ground

NMI

x (key)

3.3V

Vcc

NIC1 (Activity) LED

NIC2 (Activity) LED

Vcc

3.3V

Reset

Power

2 1

2-12

2-8 Connector Defi nitions

Chapter 2: Installation

Power Connectors

A 24-pin main power supply

connector(JPW1) and three 8-pin

CPU PWR connectors (JPW2/JPW3/

JPW4) on the motherboard. These

power connectors meet the SSI EPS

12V specifi cation. In addition to the

24-pin ATX power connector, the 12V

8-pin CPU PWR connectors at JPW2/

JPW3/JPW4 must also be connected

to your power supply. See the table on

the right for pin defi nitions.

Warning: To prevent damage to the

power supply or motherboard, please

use a power supply that contains a 24pin and three 8-pin power connectors.

Be sure to connect these connectors

to the 24-pin (JPW1) and the three

8-pin (JPW2,JPW3 and JPW4) power

connectors on the motherboard. Failure

in doing so will void the manufacturer

warranty on your power supply and

motherboard.

ATX Power 24-pin Connector

Pin Defi nitions

Pin# Defi nition Pin# Defi nition

13 +3.3V 1 +3.3V

14 -12V 2 +3.3V

15 COM 3 COM

16 PS_ON 4 +5V

17 COM 5 COM

18 COM 6 +5V

19 COM 7 COM

20 Res (NC) 8 PWR_OK

21 +5V 9 5VSB

22 +5V 10 +12V

23 +5V 11 +12V

24 COM 12 +3.3V

12V 8-pin PWR Connector

Pin Defi nitions

Pins Defi nition

1 through 4 Ground

5 through 8 +12V

Required Connection

Power Connector

The Power Connector is located on

pins 1 and 2 of JF1. Momentarily

contacting both pins will power on/off

the system. This button can also be

confi gured to function as a suspend

button (with a setting in the BIOS - see

Chapter 4). To turn off the power when

set to suspend mode, press the button

for at least 4 seconds. Refer to the

table on the right for pin defi nitions.

2-13

Power Button

Pin Defi nitions

(JF1)

Pin# Defi nition

1 Power

2 Ground

H8QG7/i-LN4F Serverboard User's Manual

Reset Connector

The reset connector is located on pins

3 and 4 of JF1 and attaches to the

reset switch on the computer chassis.

See the table on the right for pin

defi nitions.

Power Fail LED

The Power Fail LED connection is

located on pins 5 and 6 of JF1. Refer to

the table on the right for pin defi nitions.

Overheat (OH)/Fan Fail/PWR Fail/

UID LED

Connect an LED cable to pins 7 and

8 of JF1 to use the Overheat/Fan Fail/

Power Fail and UID LED connections.

The Red LED on pin 8 provides

warnings of an overheat, fan failure

or power failure. The Blue LED on pin

8 works as the UID LED indicator for

the front panel UID switch. Refer to the

table on the right for pin defi nitions.

Reset Button

Pin Defi nitions

(JF1)

Pin# Defi nition

3 Reset

4 Ground

PWR Fail LED

Pin Defi nitions

(JF1)

Pin# Defi nition

5 3.3V

6 Power Fail LED

OH/Fan Fail/ PWR Fail (Red) LED

and UID (Blue) LED

Pin Defi nitions (JF1)

Pin# Defi nition

7 Vcc

8 OH/Fan Fail/PWS Fail (Red) LED

and UID (Blue) LED

OH/Fan Fail/PWR Fail

LED Status (Red LED)

State Indication

Off Normal

On Overheat

Flashing Fan Fail

NIC2 (Link/Activity) LED

The LED connections for LAN2 link/

activity are on pins 9 and 10 of JF1.

Attach LAN LED cables to display

network activity. See the table on the

right for pin defi nitions.

NIC1 (Link/Activity) LED

The LED connections for LAN1 link/

activity are on pins 11 and 12 of JF1.

Attach LAN LED cables to display

network activity. See the table on the

right for pin defi nitions.

2-14

NIC2 LED

Pin Defi nitions

(JF1)

Pin# Defi nition

9 Activity

10 Link

NIC1 LED

Pin Defi nitions

(JF1)

Pin# Defi nition

11 Activity

12 Link

Chapter 2: Installation

HDD LED

The HDD LED connections are located

on pins 13 and 14 of JF1. Attach a

hard-drive LED cable to display HDD

or SATA activities. Refer to the table on

the right for pin defi nitions.

Power LED Connector

The Power LED connector is on pins

15 and 16 of JF1. See the table on the

right for pin defi nitions.

NMI Button

The non-maskable interrupt button

header is located on pins 19 and 20

of JF1. Refer to the table on the right

for pin defi nitions.

NIC4 (LAN4) LED

The LED connections for LAN4 are on

pins 1 and 2 of JPK1. Attach LAN LED

cables to display network activity. See

the table on the right for pin defi nitions.

HDD LED

Pin Defi nitions

(JF1)

Pin# Defi nition

13 Vcc

14 HDD LED

Power LED

Pin Defi nitions

(JF1)

Pin# Defi nition

15 3.3V

16 Power LED

NMI Button

Pin Defi nitions

(JF1)

Pin# Defi nition

19 NMI

20 Ground

NIC4 LED

Pin Defi nitions

(JPK1)

Pin# Defi nition

1 Activity

2 Link

NIC3 (LAN3) LED

The LED connections for LAN3 are on

pins 3 and 4 of JPK1. Attach LAN LED

cables to display network activity. See

the table on the right for pin defi nitions.

Chassis Intrusion

A Chassis Intrusion header is located

at JL1. Attach the appropriate cable to

inform you of a chassis intrusion.

2-15

NIC3 LED

Pin Defi nitions

(JPK1)

Pin# Defi nition

3 Activity

4 Link

Chassis Intrusion

Pin Defi nitions

(JL1)

Pin# Defi nition

1 Battery voltage

2 Intrusion signal

H8QG7/i-LN4F Serverboard User's Manual

Universal Serial Bus Ports

Two Universal Serial Bus ports (USB

2.0) are located beside the Keyboard

and Mouse PS2 ports (USB0/1).

One additional Type A port (USB6) is

included on the motherboard. See the

table on the right for pin defi nitions.

USB Headers

Four USB 2.0 headers (USB2/3

and USB4/5) are also included on

the motherboard. These may be

connected to provide front side access.

A USB cable (not included) is needed

for the connection. See the table on the

right for pin defi nitions.

SGPIO

The T-SGPIO1/ T-SGPIO2 (Serial

General Purpose Input/Output)

headers provide a bus between the

SATA controller and the backpane to

provide SATA enclosure management

functions. Connect the appropriate

cable from the backplane to the

T-SGPIO1 header to utilize SATA

management functions on your system.

Universal Serial Bus Ports

Pin Defi nitions (USB 0/1, USB6)

USB0/1

Pin# Defi nition

1 +5V 1 +5V

2 PO- 2 PO3 PO+ 3 PO+

4 Ground 4 Ground

Universal Serial Bus Headers

Pin Defi nitions

(USB2/3, USB4/5)

JUSB2, JUSB3

Pin# Defi nition Pin# Defi nition

1 +5V 2 +5V

3 PO- 4 PO5 PO+ 6 PO+

7 Ground 8 Ground

9 Key 10 NC

Note: NC indicates no connection.

SGPIO Header Pin Defi nitions

(T-SGPIO1/T-SGPIO2)

Pin# Defi nition Pin# Defi nition

1 NC 2 Data

3 Ground 4 Data

5 Load 6 Ground

7 CLK 8 NC

USB6

Pin# Defi nition

Standby Power Connector

The Standby Power connection

header is located at JSTBY1 on the

motherboard. See the table on the right

for pin defi nitions. (You must also have

a cable to use this feature.)

2-16

Standby Power

Pin Defi nitions

(JSTBY1)

Pin# Defi nition

1 +5V Standby

2 Ground

3 Wake-up

Fan Headers

This motherboard has nine fan headers

(Fan1 to Fan9). These 4-pin fans

headers are backward compatible with

3-pin fans. However, fan speed control

is available for 4-pin fans only. The fan

speeds are controlled by IPMI. See the

table on the right for pin defi nitions

Chapter 2: Installation

Fan Header

Pin Defi nitions

Pin# Defi nition

1 Ground

2 +12V

3 Tachometer

4 PWR Modulation

ATX PS/2 Keyboard and PS/2

Mouse Ports

The ATX PS/2 keyboard and PS/2

mouse are located next to the

Back Panel USB Ports 0~3 on the

motherboard. See the table at right for

pin defi nitions.

LAN1/2/3/4 (Ethernet Ports)

Four Gigabit Ethernet ports

(designated LAN1, LAN2, LAN3 and

LAN4) are located beside the VGA

port. Additionally, there is a dedicated

LAN for IPMI on top of the two rear

USB ports. These Ethernet ports

accept RJ45 type cables.

PS/2 Keyboard/Mouse Pin

Defi nitions

PS2 Keyboard

Pin# Defi nition

1 KB Data 1 Mouse Data

2 No Connection 2 No Connection

3 Ground 3 Ground

4 Mouse/KB

VCC (+5V)

5 KB Clock 5 Mouse Clock

6 No Connection 6 No Connection

VCC: with 1.5A PTC (current limit)

PS2 Mouse

Pin# Defi nition

4 Mouse/KB

VCC (+5V)

LAN Ports (LAN1/2/3/4)

Pin Defi nition

Pin# Defi nition Pin# Defi nition

1 P2V5SB 10 SGND

2 TD0+ 11 Act LED

3 TD0- 12 P3V3SB

4 TD1+ 13 Link 100 LED

5 TD1- 14 Link 1000 LED

6 TD2+ 15 Ground

7 TD2- 16 Ground

8 TD3+ 17 Ground

9 TD3- 18 Ground

NC indicates no connection.

(Yellow, +3V3SB)

(Yellow, +3V3SB)

2-17

H8QG7/i-LN4F Serverboard User's Manual

Power LED/Speaker

On the JD1 header, pins 1~3 are used

for power LED indication, and pins 4-7

are for the speaker. See the tables

on the right for pin defi nitions. If you

wish to use the onboard speaker, you

should close pins 6~7 with a jumper.

Connect a cable to pins 4~7 of JD1 to

use an external speaker.

Unit Identifi er Button

There is a Unit Identifi er (UID) button

on the rear I/O of the board. There is

also another UID button located on the

control panel. When you push either

UID button, both Rear UID and Front

Panel UID Indicators will illuminate.

Push either button again to turn off

both indicators. These UID indicators

provide easy identifi cation of a system

unit that may be in need of service.

PWR LED Connector

Pin Defi nitions

Pin Setting Defi nition

Pin 1 Anode (+)

Pin2 Cathode (-)

Pin3 NA

Speaker Connector

Pin Defi nitions

Pin Setting Defi nition

Pins 4~7 External Speaker

Pins 6~7 Internal Speaker

UID Button

Pin Defi nitions

Pin# Defi nition

1 Ground

2 Ground

3 Button In

4 Ground

Trusted Platform Module Header

This header is used to connect a

Trusted Platform Module (TPM),

available separately from a third-party

vendor. A TPM is a security device that

allows encryption and authentication of

hard drives, disallowing access if the

TPM associated with it is not installed

in the system. See the table on the

right for pin defi nitions.

2-18

Trusted Platform Module Header

Pin Defi nitions (JTPM1)

Pin# Defi nition Pin# Defi nition

1 LCLK 2 GND

3 LFRAME 4 No Pin

5 LRESET 6 VCC5

7 LAD3 8 LAD2

9 VCC3 10 LAD1

11 LAD0 12 GND

13 RSV0 14 RSV1

15 SB3V 16 SERIRQ

17 GND 18 CLKRUN

19 LPCPD 20 RSV2

Chapter 2: Installation

Power SMB (I2C)

The Power System Management Bus

(I2C) connector (JPI2C1) monitors

the power suppply, fan and system

temperatures. See the table on the

right for pin defi nitions.

SMBus Header

The JIPMB1 header at SMBus is

for the System Management Bus.

Connect the appropriate cable here

to utilize SMB on the system. See the

table on the right for pin defi nitions.

Overheat LED

Connect an LED to the JOH1

header to provide warning of chassis

overheating. See the table on the right

for pin defi nitions.

Power SMB I2C

Pin Defi nitions

(JPI2C1)

Pin# Defi nition

1 Clock

2 Data

3 PWR Fail

4 Ground

5 +3.3V

SMBus Header

(SMBus)

Pin Defi nitions

(JIPMB1)

Pin# Defi nition

1 Data

2 Ground

3 Clock

4 No Connection

Overheat LED

Pin Defi nitions

(JOH1)

Pin# Defi nition

1 3.3V

2 OH Active

SATA DOM Power Connector

A power connector for SATA DOM

(Disk_On_Module) devices is located

at JSD1. Connect an appropriate cable

here to provide power support for your

DOM devices.

Compact Flash Card PWR

Connector

A Compact Flash Card Power

Connector is located at JWF1.

2-19

SATA DOM Power

Connector Pin

Defi nitions

(JSD1)

Pin# Defi nition

1 +5V

2 Ground

3 Ground

H8QG7/i-LN4F Serverboard User's Manual

SAS Battery Backup Connector

A SAS battery backup connector (JS3)

provides power backup support for

cache data of onboard SAS devices

during a power outage. Cache data

can be retained for up to 48-hours. See

the table on the right for pin defi nitions.

Video Connector

A Video (VGA) connector is located on

the IO backplane. This connector is

used to provide video and CRT display .

SAS Battery Backup Connector

Pin Defi nitions (JS3)

Pin# Defi nition Pin# Defi nition

2 INPLACE2 1 INPLACE1

4 BBSTATUS

_3V3

6 Ground 5 Ground

8 PFAIL_N 7 PWRGD_P1V5

10 BBE_3V3 9 Ground

12 BBSTROBE

_3V3

14 Ground 13 Data

16 BBU_SMDA

_3V3

18 Ground 17 Data

20 BBU_SMBCL

_3V3

3 Data

11 Data

15 Ground

19 Ground

2-20

Chapter 2: Installation

2-9 Jumper Settings

Connector

Pins

3 2 1

Explanation of Jumpers

To modify the operation of the

motherboard, jumpers can be used

to choose between optional settings.

Jumpers create shorts between two

pins to change the function of the

connector. Pin 1 is identifi ed with a

square solder pad on the printed circuit

board. See the diagram at right for

an example of jumping pins 1 and 2.

Refer to the motherboard layout page

for jumper locations.

Note: On two-pin jumpers, "Closed"

means the jumper is on and "Open"

means the jumper is off the pins.

CMOS Clear

JBT1 is used to clear CMOS, which will also clear any passwords. Instead of pins,

this jumper consists of contact pads to prevent accidentally clearing the contents

of CMOS.

To Clear CMOS

1. First power down the system and unplug the power cord(s). It is also

recommended that you remove the onboard battery from the serverboard.

2. With the power disconnected, short the CMOS pads with a metal object such

as a small screwdriver.

3. Remove the screwdriver (or shorting device).

4. Reconnect the power cord(s) and power on the system.

Note 1. For an ATX power supply, you must completely shut down the system,

remove the AC power cord, and then short JBT1 to clear CMOS.

Note 2. Be sure to remove the onboard CMOS Battery before you short JBT1 to

clear CMOS.

Note 3. Clearing CMOS will also clear all passwords.

Note 4: Do not use the PW_ON connector to clear CMOS.

Jumper

3 2 1

Setting

JBT1 contact pads

2-21

H8QG7/i-LN4F Serverboard User's Manual

I2C to PCI-Express Slot

JI2C1/JI2C2 allows you to enable the

I2C bus to communicate with the PCIExpress slot. For the jumpers to work

properly, please set both jumpers to

the same setting. If enabled, both

jumpers must be enabled. If disabled,

both jumpers must be disabled. See

the table on the right for jumper

settings.

Watch Dog Enable/Disable

JWD1 enables the Watch Dog

function, a system monitor that takes

action when a software application

freezes the system. Jumping pins 1-2

will have WD reboot the system if a

program freezes. Jumping pins 2-3 will

generate a non-maskable interrupt for

the program that has frozen. See the

table on the right for jumper settings.

Watch Dog must also be enabled in

BIOS.

I2C to PCI-Express Slot

Jumper Settings

(JI2C1/JI2C2)

Jumper Setting Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

Watch Dog

Jumper Settings (JWD1)

Jumper Setting Defi nition

Pins 1-2 Reset

Pins 2-3 NMI

Open Disabled

Note: when Watch Dog is enabled, the user must write

their own application software to disable the Watch Dog

Timer.

VGA Enable/Disable

JPG1 allows you to enable or disable

the VGA port. The default position is on

pins 1 and 2 to enable VGA. See the

table on the right for jumper settings.

LAN1/2/3/4 Enable/Disable

Change the setting of jumper JPL1

to enable or disable the LAN1/2/3/4

Ethernet ports. See the table on the

right for jumper settings. The default

setting is enabled.

2-22

VGA Enable/Disable

Jumper Settings (JPG1)

Jumper Setting Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

LAN1/2/3/4 Enable/Disable

Jumper Settings

(JPL1/JPL2)

Jumper Setting Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

Chapter 2: Installation

SAS Enable/Disable

JPS1 allows you to enable or disable

the SAS controller. The default

positio n is on pins 1 and 2 to en able

SAS. See the table on the right for

jumper settings.

BMC Jumper

JPB1 is used to enable or disable

theBMC (Baseboard Management

Control) Chip and the onboard IPMI

connection.This jumper is used

together with the IPMI settings in the

BIOS. The default position is on pins

1 and 2 to Enable BMC. See the table

on the right for jumper settings.

2-10 Onboard Indicators

LAN1/LAN2/LAN3/LAN4 LEDs

The Ethernet ports (located beside the

VGA port) have two LEDs. On each Gb

LAN port, one LED blinks to indicate

activity while the other may be green,

amber or off to indicate the speed of

the connection. See the table on the

right for the functions associated with

the connection speed LED.

SAS Enable/Disable

Jumper Settings (JPS1)

Jumper Setting Defi nition

Pins 1-2 Enabled

Pins 2-3 Disabled

BMC Jumper Enable (JPB1)

Jumper Settings

Jumper Setting Defi nition

Pins 1-2 Enabled (default)

Pins 2-3 Disabled

Link Speed

LED

Color Status Defi nition

Off No Connections

Yellow Flashing Active

GLAN LED

GLAN Activity Indicator

(Right) LED Settings

Activity

LED

2-23

LAN Connection Speed

Indicator (Left) LED Settings

LED Color Defi nition

Off 10 MHz

Green 100 MHz

Amber 1 GHz

H8QG7/i-LN4F Serverboard User's Manual

IPMI Dedicated LAN LEDs

A dedicated IPMI LAN is also included

on the H8QG7/i-LN4F serverboard.

The amber LE D on th e r ight i ndi c ates

activity, while the green LED on

the left indicates the speed of the

connec tion. See th e table at rig ht for

more information.

Power LED

DP3 is an Onboard Power LED.

When this LED is lit, it means power

is present on the serverboard. Be

sure to turn off the system and unplug

the power cord(s) before removing or

installing components.

IPMI LED

The serverboard contains an IPMI LED

(DP1) located near the corner above

the PCI-E slots. When this LED is lit,

it means a connection is active for the

built-in IPMI on the serverboard.

Note: This LED is not installed on nonIPMI boards.

IPMI LAN

Activity LEDLink LED

IPMI LAN

Link/Speed LED (Left)

& Activity LED (Right)

Color Status Defi nition

Off Off No Connection

Green:

Solid

Amber

Blinking

Link/

Speed

(Left)

Activity

(Right)

Power LED (DP3)

State System Status

On Standby power present

on motherboard

Off No power connected

IPMI LED (DP1)

State System Status

On Active connection

Off No connection

100 Mb/s

Active

UID LED (LE1)

A rear UID LED Indicator, located

at LE1, works in conjunction with

the rear UID switch to provide easy

identifi cation for a unit that might be in

need of service. Refer to Page 2-18 for

further UID details.

2-24

2-11 SATA Drive Connections

Chapter 2: Installation

SATA Ports

There are no jumpers to configure

the SATA ports, which are designated

SATA0 through SATA5. See the table

on the right for pin defi nitions.

SAS Ports

There are eight SAS ports included

on the H8QG7-LN4F serverboard

only. See the table on the right for pin

defi nitions.

Note: JPS1 must be set correctly to

enable the SAS controller.

SATA Ports Pin Defi nitions

(SATA0-SATA3)

Pin# Defi nition Pin# Defi nition

1 Ground 5 RXN

2 TXP 6 RXP

3 TXN 7 Ground

4 Ground

SAS Ports

Pin Defi nitions

(SAS0 ~ SAS7)

Pin# Defi nition Pin# Defi nition

1 Ground 2 TXP

3 TXN 4 Ground

5 RXN 6 RXP

7 Ground

2-25

H8QG7/i-LN4F Serverboard User's Manual

2-12 Enabling SATA RAID

Now that the hardware is set up, you must install the operating system and the

SATA RAID drivers, if you wish to use RAID with your SATA drives. The installation

procedure differs depending on whether you wish to have the operating system

installed on a RAID array or on a separate non-RAID drive. See the instructions

below for details.

Serial ATA (SATA)

Serial ATA (SATA) is a physical storage interface that employs a single cable with a

minimum of four wires to create a point-to-point connection between devices. This

connection is a serial link that supports a SATA transfer rate up to 300 MBps. The

serial cables used in SATA are thinner than the traditional cables used in Parallel

ATA (PATA) and can extend up to one meter in length, compared to only 40 cm for

PATA cables. Overall, SATA provides better functionality than PATA.

Installing the OS/SATA Driver

Before installing the OS (operating system) and SATA RAID driver, you must decide

if you wish to have the operating system installed as part of a bootable RAID array

or installed to a separate non-RAID hard drive. If on a separate drive, you may

install the driver either during or after the OS installation. If you wish to have the

OS on a SATA RAID array, you must follow the procedure below and install the

driver during the OS installation.

Building a Driver Diskette

You must fi rst build a driver diskette from Supermicro drivers for your system.

Drivers can be found at ftp://ftp.supermicro.com. (You will have to create this disk

on a computer that is already running and with the OS installed.)

Building a Driver Diskette

1. Install your system drives from the FTP website. A display as shown in Figure

2-6 will appear.

2. Click on the icon labeled “Build Driver Diskettes and Manuals” and follow the

instructions to create a fl oppy disk with the drivers on it.

3. Once it’s been created, remove the fl oppy and insert the installation CD for

the Windows Operating System you wish to install into the CD-ROM drive of

the new system you are about to confi gure.

Note: You need to have an external USB fl oppy when building the driver diskette.

Window’s Vista, Windows 2008 or later Windows OS systems can use a USB stick

instead of a fl oppy.

2-26

Chapter 2: Installation

Enabling SATA RAID in the BIOS

Before installing the Windows operating system, you must change some settings

in the BIOS. Boot up the system and hit the <Delete> key to enter the BIOS Setup

Utlility. After the setup utility loads,

1. Use the arrow keys to move to the "Exit" menu. Scroll down using the arrow

keys to "Load Optimal Defaults" and press <Enter>. Select "OK" to confi rm,

then <Enter> to load the default settings.

2. Use the arrow keys to move to the "Advanced" menu, then scroll down to

"IDE confi guration". On this submenu, scroll down to "OnChip SATA Type"

and choose the "RAID" option (Figure 2-4). “RAID Codebase” submenu

appears. This setting allows you to select the codebase for your RAID setup.

Options are either Adaptec or DotHill.

Figure 2-4. BIOS Setup Screen

3. Press the <Esc> key twice and scroll to the "Exit" menu. Select "Save

Changes and Exit" and press <Enter>, then press <Enter> again to verify.

4. After exiting the BIOS Setup Utility, the system reboots. When prompted

during the startup, to use the DotHilll RAID Utility program press the

<CTRL+R> key (Figure 2-5), or to use the Adaptec RAID Utility program

press the <CTRL+A> key (Figure 2-6).

2-27

H8QG7/i-LN4F Serverboard User's Manual

Figure 2-5. DotHill RAID Utility Program Screen

Figure 2-6. Adaptec RAID Utility Program Screen

2-28

Chapter 2: Installation

Using the DotHill and Adaptec RAID Utility

The RAID Utility program allows you to defi ne the drives you want to include in the

RAID array and the mode and type of RAID.

Installing the RAID Driver During OS Installation

Y ou may also use the procedure below to install the RAID driver during the Windows

OS installation:

1. With the Windows OS installation CD-ROM in the CD drive, restart the

system.

2. Press <Enter> again to continue with the Windows setup.

3. When you see the prompt, hit the <F6> key to enter Windows setup.

4. Eventually a blue screen will appear with a message that begins “Windows

could not determine the type of one or more storage devices . . .” When you

see the screen, hit the <S> key to “Specify Additional Device”, then insert the

driver diskette you just created into the fl oppy drive.

5. Highlight “Manufuacturer Supplied Hardware Support Disk” and hit the

<Enter> key.

6. Highlight the fi rst “Adaptec RAID” driver shown and press the <Enter> key to

install it.

2-29

H8QG7/i-LN4F Serverboard User's Manual

2-13 Installing Drivers

The Supermicro Website contains drivers and utilities for your system at ftp://ftp.

supermicro.com, some of which must be installed, such as the chipset driver. After