Page 1

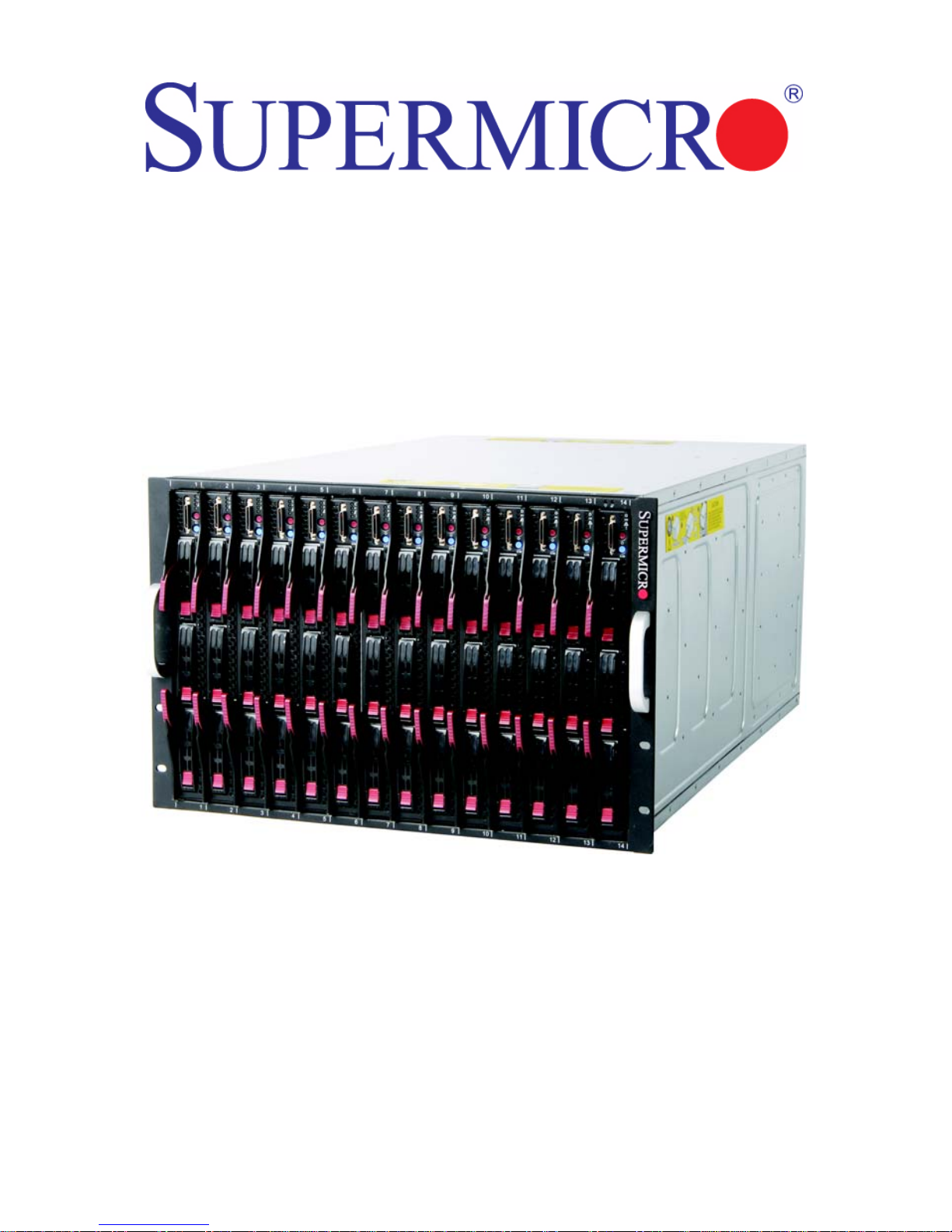

SuperBlade

®

User’s Manual

Revison 1.0c

Page 2

SuperBlade User’s Manual

The information in this User’s Manual has been carefully reviewed and i s believed to be accurate. The

vendor assumes no responsibility for any inaccuracies that may be contained in this document, makes no

commitment to update or to keep current the information in this manual, or to not ify any person or

organization of the u pdates. Plea se Note: For the most up-to-date version of this manual, please see

our web site at www.supermicro.com.

Super Micro Computer, Inc. (“Supermicro”) reserves the right to make changes to the product described

in this manual at any time and without notice. This product, including software, if any, and documentation

may not, in whole or in part, be copied, photocop ied, re produced, translated or redu ced t o any medi um or

machine without prior written consent.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO USE

THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY HARDWARE,

SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE COSTS OF

REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH HARDWARE,

SOFTWARE, OR DATA.

Any disputes arising between manufacturer and cu stomer shall be governed by the laws of Santa Clara

County in the State of California, USA. The State of California, Co unty of Santa Clara shall be the

exclusive venue for the resolution of any such disputes. Super Micro's total liabilit y for all claims will not

exceed the price paid for the hardware product.

FCC State ment: This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the manufacturer’s instruction manual, may cause harmful interference with radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference,

in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning

applies only to products containing CR (Manganese Dioxide) Lithium coin cells. Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate for further

details.

WARNING: HANDLING OF LEAD SOLDER MATERIALS USED IN THIS

PRODUCT MAY EXPOSE YOU TO LEAD, A CHEMICAL KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE BIRTH DEFECTS AND OTHER

REPRODUCTIVE HARM.

Manual Revison 1.0c

Release Date: February 18, 2009

Unless you request and receive written permission from Super Micro Computer, Inc., you may not copy

any part of this document.

Information in this document is subject to change without notice. Other products and companies referred

to herein are trademarks or registered trademarks of their respective companies or mark holders.

Copyright © 2009 by Super Micro Computer, Inc.

All rights reserv ed .

Printed in the United States of America

ii

Page 3

Preface

About this Manual

This manual is written for professional system integrators, Information Technology

professionals, service personnel and technicians. It provides information for the

installation and use of Supermicro's SuperBlade system. Installation and maintenance

should be performed by experienced professionals only.

Manual Organization

Chapter 1: Introduction

The first chapter provides a checklist of the main components included with the blade

system and describes the main features of the mainboard and enclosure. A quick start

procedure is also provided for your use.

Chapter 2: System Safety

You should familiarize yourself with this chapter for a general overview of safety

precautions that should be followed when installing and servicing the SuperBlade.

Chapter 3: Setup and Installation

Refer here for details on installing the SuperBlade system into a rack.

Chapter 4: System Modules

This chapter covers modules in the SuperBladeSuperBlade system. It also covers the

CMM module and configuring double-wide bays.

Chapter 5: Power Supply Modules

This chapter covers the system power supplies and their installation.

Appendix A: System Specifications

This appendix provides a summary of system specifications.

Appendix B: LED Descriptions

This appendix provides descriptions of LEDs in the SuperBlade system for your

reference.

iii

Page 4

SuperBlade User’s Manual

Notes

iv

Page 5

Table of Contents

Chapter 1 Introduction.......................................................................1-1

1-1 Overview.............................................................................................1-1

1-2 Quickstart Setup................................................................................1-1

1-3 OfficeBlade and Datacen terBlade Systems..................................1-2

DataCenterBlade ....................................................................................1-3

OfficeBlade .............................................................................................1-3

1-4 Product Checklist of Typical Components.....................................1-3

1-5 Blade Enclosure Features...............................................................1-4

Power......................................................................................................1-4

Middle Plane...........................................................................................1-5

LEDs.......................................................................................................1-5

Enclosure Cooling....................... .......................................... ..................1-5

1-6 Power Supply Features....................................................................1-6

Power Supply Modules...........................................................................1-6

Power Cord..........................................................................................1-6

Power Supply Failure...........................................................................1-6

1-7 Special Design Features..................................................................1-7

Operating System Support......................................................................1-7

Remote Management .............................................................................1-7

Computing Density/Power ......................................................................1-7

High-Efficiency Power Supplies..............................................................1-7

1-8 Contacting Supermicro.....................................................................1-8

1-9 Returning Merchandise for Service................................................1-9

Chapter 2 System Safety..................................................................2-1

2-1 Electrical Safety Precautions ...........................................................2-1

2-2 General Safety Precautions.............................................................2-2

2-3 Electrostatic Discharge Precautions..............................................2-2

2-4 Operating Precautions......................................................................2-2

Chapter 3 Setup and Installation.................................................3-1

3-1 Overview.............................................................................................3-1

3-2 Unpacking the System .....................................................................3-1

Choosing a Setup Location.....................................................................3-1

Rack Precautions....................................................................................3-2

v

Page 6

SuperBlade User’s Manual

Server Precautions .................................................................................3-2

Rack Mounting Considerations...............................................................3-2

Ambient Operating Temperature..........................................................3-2

Reduced Airflow...................................................................................3-2

Mechanical Loading.............................................................................3-2

Circuit Overloading...............................................................................3-3

Reliable Ground........................................ ...........................................3-3

Installing the System Into a Rack............................................................3-3

Rack Mounting Hardware .......................................................................3-3

Installation...............................................................................................3-4

Chapter 4 System Modules.............................................................4-1

4-1 Chassis Management Module.........................................................4-2

Module Redundancy...............................................................................4-3

Master/Slave Modules.................... .......................................... .. ... .......4-3

Module Installation..................................................................................4-4

Configuring the CMM.............................................. ... .............................4-4

CMM Functions.......................................................................................4-7

Local KVM............ ... ... .......................................... ................................4-8

Remote KVM over IP ...........................................................................4-8

Remote Storage (Virtual Media)...........................................................4-8

Serial Over LAN (SOL).........................................................................4-8

Monitoring Functions............................................................................4-8

Power Consumption Management.......................................................4-9

CMM Switches and Buttons....................................................................4-9

USB Switch........................................................................... ...............4-9

Reset Button ......................................................................................4-10

Firmware...............................................................................................4-10

Web-based Management Utility ............................................................4-10

Supported Browsers...........................................................................4-11

Network Connection/Login.................................................................4-11

Address Defaults................................................................................4-11

Home Page........................................................................................4-12

4-2 Double-Wide Modules....................................................................4-13

Chapter 5 Power Supply Modules..............................................5-1

5-1 Power Supply Modules.....................................................................5-1

Power Supply Failure..............................................................................5-3

Installing a Power Supply........................................................................5-3

Removing a Power Supply......................................................................5-4

vi

Page 7

5-2 Power Supply Fans...........................................................................5-4

5-3 Power Components..........................................................................5-5

Power Cord.............................................................................................5-5

Power Cable Tie and Clamp...................................................................5-6

Appendix A System Specifications...........................................A-1

A-1 Enclosure Specifications..................................................................A-1

A-2 Environmental Specifications..........................................................A-2

A-3 Address Defaults...............................................................................A-2

A-4 Power Supply Power Calculations.................................................A-3

Appendix B LED Descriptions......................................................B-1

B-1 Blade Enclosure LED Descriptions................................................B-1

B-2 Blade Module LED Descriptions.....................................................B-2

B-3 1/10 Gigabit Ethernet Module LED Descriptions.........................B-3

:

B-4 Gigabit Ethernet Module LED Descriptions..................................B-4

B-5 InfiniBand Switch LED Descriptions ..............................................B-5

vii

Page 8

SuperBlade User’s Manual

Notes

viii

Page 9

List of Figures

Figure 3-1. Positioning the Enclosure Template...............................................3-4

Figure 3-2. Securing the Rails to the Rack .......................................................3-4

Figure 3-3. Attaching the Optional Handles......................................................3-5

Figure 3-4. Enclosure Installed into Rack .........................................................3-6

Figure 4-1. Typical Blade System Module Configuration: Rear View ...............4-1

Figure 4-2. Chassis Management Modul e ........................................................4-2

Figure 4-3. Choose Internal Protocol................................................................4-5

Figure 4-4. Manually Configure the IP Address................................................4-6

Figure 4-5. Changing Settings..........................................................................4-7

Figure 4-6. USB Switch on Rear of CMM .........................................................4-9

Figure 4-7. Home Page...................................................................................4-12

Figure 4-8. Horizontal Spacers for Single Bays..............................................4-14

Figure 4-9. Modifying for a Double-Wide Module Bay (Steps 1 & 2)..............4-15

Figure 4-10. Modifying for a Double-Wide Module Bay (Steps 3 & 4) ............4-16

Figure 5-1. PWS-1K41-BR Power Supply.........................................................5-1

Figure 5-2. PWS-2K01-BR Power Supply.........................................................5-2

Figure 5-3. Power Supply Module.....................................................................5-4

Figure 5-4. Power Components ........................................................................5-5

Figure 5-5. Power Cable Tie and Clamp Parts .................................................5-6

Figure 5-6. Power Cable Tie and Clamp Assembly..........................................5-7

ix

Page 10

SuperBlade User’s Manual

Notes

x

Page 11

List of Tables

Table 4-1. Typical Blade System Module Configuration: Rear View.................4-1

Table 4-2. CMM Module Interface.....................................................................4-2

Table 4-3. CMM Module Features ....................................................................4-3

Table 4-4. CMM Reset Settings......................................................................4-10

Table 4-5. Address Defaults............................................................................4-11

Table 4-6. Home Page Controls......................................................................4-12

Table 5-1. PWS-1K41-BR Power Supply Features...........................................5-1

Table 5-2. PWS-2K01-BR Power Supply Features...........................................5-2

Table 5-3. Power Components .........................................................................5-5

Table A-1. Enclosure Specification Features....................................................A-1

Table A-2. Environmental Specification Features.............................................A-2

Table A-3. Address Default Features................................................................A-2

Table A-4. Power Supply: Power Calculations (PWS-2K01-BR)......................A-3

Table A-5. Power Supply: Power Calculations (PWS-1K41-BR)......................A-3

Table B-1. Blade Enclosure: LED Descriptions.................................................B-1

Table B-2. Blade Module LED Indicators..........................................................B-2

Table B-3. 1/10 GbE Switch and 10-GbE Pass-Through Module

LED Indicators...................................................................................................B-3

Table B-4. Stacking LED Activity (SBM-GEM-X2C)..........................................B-3

Table B-5. Gigabit Ethernet Switch LED Indicators..........................................B-4

Table B-6. InfiniBand Switch LEDs...................................................................B-5

xi

Page 12

SuperBlade User’s Manual

Notes

xii

Page 13

Chapter 1

Introduction

1-1 Overview

The SuperBlade is a compact self-contained server that connects to a pre-cabled

enclosure that provides power, cooling, management and networking functions. One

enclosure can hold up to either ten or fourteen blade units, depending upon the blade

enclosure used.

In this manual, “blade system” refers to the entire system (including the enclosure and

blades units), “blade” or “blade unit” refers to a single blade module and “blade

enclosure” is the unit that the blades, power supplies and modules are housed in.

Each Blade unit is optimized to fit into either a specific ten-blade or fourteen-blade

enclosure.

Please refer to our web site for information on operating systems that have been

certified for use with the SuperBlade (www.supermicro.com/products/superblade/).

1-2 Quickstart Setup

This section covers how to quickly get your new SuperBlade system up and running.

Follow the procedure below to quickly setup your SuperBlade system.

1. Unpack the components of your SuperBlade system and check the packing list for

damaged or missing components.

2. Select a setup location for your system. See "Choosing a Setup Location" on

page 3-1 for details.

3. Setup any double-wide bays if you require any for double-wide modules in your

system. See Section 4-2: Double-Wide Modules on page 4-13 for details.

4. Mount the SuperBlade chassis in your server rack. See "Installing the System Into a

Rack" on page 3-3 for details.

5. Install the power supply modules into the rear of the SuperBlade chasssis. See

"Installing a Power Supply" on page 5-3 for details.

1-1

Page 14

SuperBlade User’s Manual

6. Install the CMM module and any InfiniBand or Ethernet modules into the rear of the

SuperBlade chassis.

a. For the CMM module, see "Module Installation" on page 4-4 for details.

b. For the InfiniBand and Ethernet modules, see the SuperBlade Network Modules

User’s Manual on your system’s CD-ROM.

c. Attach keyboard, mouse and video connections to your CMM module. See

"Local KVM" on page 4-8 for details.

d. Attach Ethernet connections for your InfiniBand or Ethernet modules. See the

SuperBlade Network Modules User’s Manual on your system’s CD-ROM for

details.

7. Setup your blade modules for use by doing the following:

a. Open the module case lids of each blade module. See the user’s manual for

your purchased blade module from your system’s CD-ROM for details.

b. Install memory into each module. See the the user’s manual for your purchased

blade module from your system’s CD-ROM for details.

c. Close the module case lids when you have installed your memory for each

blade module. See the the user’s manual for your purchased blade module from

your system’s CD-ROM for details.

d. Install the hard disk drives into each module. See the the user’s manual for your

purchased blade module from your system’s CD-ROM for details.

e. Install your blade modules into your SuperBlade chassis. See the the user’s

manual for your purchased blade module from your system’s CD-ROM for

details.

8. Connect the power cords for your SuperBlade system’s power supply and plug them

into your power source ONLY after you have installed and secured all system

components.

9. Power up your SuperBlade system. Check to be sure all components are operating

right and are not showing any fault LEDs or alarms in their operation.

10. Install your selected operating system for each blade module. See the the user’s

manual for your purchased blade module from your system’s CD-ROM for details.

11. Download a BIOS update for each of your blade modules from the Supermicro

website.

1-3 OfficeBlade and DatacenterBlade Systems

The SuperMicro SuperBlade family also includes both DatacenterBlade™ and

OfficeBlade™ systems, which use many of the same blades, modules and components.

You can specify your system to run in either Office Blade Mode or Enterprise Mode by

selecting a mode in the CMM O

the Web-based Management Utility. See Section 4-1: Chassis Management Module on

page 4-2 for details.

PERATION MODE section of the CMM STATUS screen of

1-2

Page 15

Chapter 1: Introduction

DataCenterBlade

The DatacenterBlade system is perfect for data center and HPC applications with

performance and density optimized to achieve 672 processing cores and 2TB DDR2

memory per 42U standard rack.

OfficeBlade

The OfficeBlade system is optimized for small-medium business as well as personal

HPC applications. With acoustically enhanced thermal and cooling technologies,

OfficeBlade can operate at or below 50dB with 10 DP server blades.

The following blades are suitable for use in Office Blade mode:

• SBI-7125C-S3

• SBI-7125C-S3E

• SBI-7125C-T3

For Office Blade Mode, it is recommended that no more than two 80W Intel Xeon 5400/

5200 series CPUs with 1333 FSB support be used in each blade module.

1-4 Product Checklist of Typical Components

• Blade Enclosure (x1): SBE-710E (10-blade) or SBE-714D/E (14-blade) series

• Blade Unit (minimum of 2, 10 or 14 maximum): See the the Supermicro website

(http://www.supermicro.com/products/superblade/) for a complete list of blades that

can mounted in your system.

• Power Supplies (x2): PWS-1K41-BR, PWS-2K01-BR or PWS-2K51-BR

• CMM Module (x1): SBM-CMM-001

• KVM Cable (x1): CBL-0218L

• Dummy Blade Units: MCP-650-00004-0N (10-blade enclosure) or

MCP-650-00005-0N (14-blade enclosure)

• Dummy Power Supplies: MCP-650-00001-0N

• Dummy CMM Modules: MCP-650-00002-0N

• Dummy GbE Switches: MCP-650-00003-0N

• SuperBlade CD-ROM with other SuperBlade component manuals

Optional components include:

• InfiniBand® Switch: SBM-IBS-001

• Blade IPMI Add-on Card: AOC-SIMPL

• Mezzanine Cards (required for operation with the InfiniBand Switch): AOC-IBH-001,

AOC-IBH-002 or AOC-IBH-003

• GbE Switches: SBM-GEM-001 (1-Gbps) or SBM-GEM-X2C (1/10-Gbps)

• GbE Pass Through Modules: SBM-GEM-002 (1-Gbps) or SBM-XEM-002 (10-Gbps)

• Extra CMM Module for redundancy: SBM-CMM-01

1-3

Page 16

SuperBlade User’s Manual

Additional modules will periodically become available. Please refer to http://

www.supermicro.com/products/superblade for the most current list of modules available

for the SuperBlade.

Blade systems install into standard racks. Up to six 7U blade systems may be installed

into a 19" industry standard 42U rack.

1-5 Blade Enclosure Features

Supermicro's SBE-710E blade enclosure is designed to house up to 10 blade units,

while the SBE-714D/E blade enclosure houses up to 14 blade units. Both accommodate

either two or four power supplies. The enclosure mid-plane allows the blade units to

share certain functions such as power, cooling and networking.

NOTE: The SBE-714 blade enclosure is available in two versions:

• D-series enclosures support only one CMM, and one 1-Gb Ethernet

switch, one 1/10-Gb Ethernet switch or 1Gb pass-through module. The

InfiniBand switch is not supported.

• E-series enclosures support up to two CMM modules.They also

support any combination of the Ethernet switches or 1-Gb Ethernet

pass-through modules. In addition, they support optionally either an

InfiniBand switch or a 10Gb Ethernet pass-through module in support

The following is a general outline of the main features for all blade server enclosures.

Power

The typical blade enclosure features a 2500W, 2000W or 1400W power system

composed of two active power supply modules. An alternate configuration (and required

for a full 10 or 14-blade system) features a total of four power supply modules for three

active and one backup. This power redundancy feature allows you to replace a failed

power module while the backup module takes over to keep the system running. You

must have either two or four power supply modules installed in the blade enclosure (four

is recommended in a full system).

The Chassis Management Module assumes the worst case (maximum) power for any

model of blade prior to applying power. If the power supplies cannot supply that amount

of power, given the current load on the power supplies, then the CMM will not allow that

unit to power up. After a blade is powered up, the blade’s BIOS calculates the actual

power load required by the blade based upon the installed devices and informs the

CMM of its requirements. The CMM then adjust the remaining power for additional

blades based upon the actual power used by the blades th at are powered on.

1-4

Page 17

Chapter 1: Introduction

Middle Plane

The middle plane connects the various capabilities of the blades, such as the Gigabit

(GbE) switch(es) to Network Interface Controller(s), the Chassis Management Module

(CMM) to the USB devices and the InfiniBand Switch to the Host Channel Adapters.

These devices all connect to the middle plane through high density connectors that

provide both signals and power. This type of configuration reduces the amount of

system cabling and simplifies the task of setting up the system. It provides an alternative

signals route to support redundant power, CMM, network and IPMI functions.

NOTE: Signaling information can NOT be physically routed from one blade to

another.

LEDs

Two LEDs are located at the right top of the enclosure above the last or right most blade.

The left LED provides Power Status information and the right LED is the Fault LED, as

described in Table B-1 in Appendix B.

Enclosure Cooling

The cooling for the entire blade system is provided by the fans in the power supply

modules. For example, the 2000W power supply modules have four fans per module,

whereas the 1400W power supply modules have two fans per module. If a power supply

fails, its fans will continue to operate to provide continuous cooling. For this reason, a

failed power supply should remain installed in the enclosure until a replacement unit is

ready.

NOTE: You must install dummy power supplies (MCP-650-00001-0N) in any

open power supply slots in order to prevent air flow leaks that would reduce

cooling efficiency in the blade system’s enclosure.

For overheat problems, check that there are no obstructions (such as poorly routed

cables), check that all fans are operating normally and make sure the ambient room

temperature is not too warm (refer to Section A-2: Environmental Specifications on

page A-2 for the maximum operating temperature). You can also use either of the blade

management software utilities to increase the fan speed and maximize system cooling.

In the event of a power overload, you will have to add additional power supply modules

to take up the load. Otherwise, you will not be able to power up all the blade modules.

The blade BIOS plus CMM firmware calculates the load to determine if the power

supplies can adequately handle the total system configuration.

1-5

Page 18

SuperBlade User’s Manual

1-6 Power Supply Features

The SuperBlade enclosure comes standard with one CMM module and either two or

four power supplies. Information on the power supplies is summarized below. See

Section 4-1: Chassis Management Module on page 4-2 for details on the CMM module

and Chapter 5 for details on the power supplies.

If you install only two power supplies in the enclosure, they should be installed in the

lower rather than the upper power bays. The reason for this counter-intuitive installation

is that the power supplies in the lower bays provide increased airflow across the

memory modules within each blade module.

Power Supply Modules

Each power supply module has its own power cord. Four modules are required when

the full complement of blade units are installed into an enclosure. An LED on the back of

a power supply will be red when AC power is present and green when the power is on.

Supermicro's high-efficiency blade system power supplies deliver continuous redundant

power at 90%+ peak efficiency. Each power supply module includes a management

module that monitors the power supplies and the power enclosure.

Power Cord

Each 2000W power supply module has a C-20 type socket (IEC-60320-C20) for AC

power and the power cord must have a C-19 type connector (IEC-60320-C19) to

connect to the power supply. Each 1400W power supply module has a C-14 type socket

(IEC-60320-C14) for AC power and the power cord must have a C-13 type connector

(IEC-60320-C13) to connect to the power supply.

WARNING: Please note that ONLY the recommended power cord or an

equivalent 14 Gauge power cord should be used for the 1400 Watt power supply .

Typical C13/C14 cords are only 16 Gauge wiring and pose a fire hazard if they

are used.

A plastic locking clip partially covering the socket was designed to prevent the power

supply module from being removed with the power cord still connected.

Refer to Appendix A for power/amperage calculation tables.Refer to the SuperMicro

web site for further details on power cords.

Power Supply Failure

If a power supply or a fan in a power supply fails, the system management software will

notify you of the situation. In either case, you will need to replace the power supply

module with another identical one. Please note that if a power supply fails, its fans will

continue to operate to provide system cooling. For this reason, a failed power supply

should remain installed in the enclosure until a replacement unit is ready.

See Chapter 5 for the procedure on replacing power supplies.

1-6

Page 19

Chapter 1: Introduction

1-7 Special Design Features

Supermicro's SuperBlade offers special design features, some of which no other blade

server can duplicate. These features give you extraordinary flexibility in configuring a

blade system for your own particular needs.

Operating System Support

Both Microsoft Windows and Linux operating systems are supported by the SuperBlade.

Furthermore, you may have different operating systems running on different blade units

within the same blade enclosure.

Remote Management

The Chassis Management Module (CMM) can manage the whole enclosure and any

individual Blade module by switching around to it.

Using an optional SIMBL add-on card provides separate IPMI controls for any Blade

module that has one installed in it. If your application needs to manage individual blade

units at the same time, just add a SIMBL add-on card to each Blade module.

Computing Density/Power

Each SuperBlade mainboard supports two or four processors and 48 to 64 GB of main

memory. This translates to a maximum potential of 56 processors and 896 GB of

memory per 14-blade enclosure or 336 processors and 5.376 TB of memory for a full

rack.

Dual and quad core processors are supported in the blade module systems.

High-Efficiency Power Supplies

A reliable source of power is critical in server systems and even more so in a blade

system, where up to ten systems (blades) share the same power source. SuperBlade

power supplies have been designed to operate at up to 93%+ peak efficiency and

provide redundancy with a backup unit that activates automatically when any other

power supply fails. Using high-efficiency power supplies results in a measurable

reduction in wasted energy consumption and generated heat.

1-7

Page 20

SuperBlade User’s Manual

1-8 Contacting Supermicro

Headquarters

Address: Super Micro Computer , Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email:

Web Site: www.supermicro.com

marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

‘s-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

sales@supermicro.nl (General Information)

Email:

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacific

Address: Super Micro Computer , Inc.

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: +886-2-8228-1366, ext. 132 or 139

1-8

Page 21

Chapter 1: Introduction

1-9 Returning Merchandise for Service

A receipt or copy of your invoice marked with the date of purchase is required before

any warranty service will be rendered. Y ou can obtain service by calling your vendor for

a Returned Merchandise Authorization (RMA) number. When returning to the

manufacturer, the RMA number should be prominately displayed on the outside of the

shipping carton, and mailed prepaid or hand-carried. Shipping and handling charges will

be applied for all orders that must be mailed when service is complete.

This warranty only covers normal consumer use and does not cover damages incurred

in shipping or from failure due to the alteration, misuse, abuse or improper maintenance

of products.

During the warranty period, contact your distributor first for any product problems.

For faster service, RMA authorizations may be requested online at:

http://www. supermicro.com/support/rma/

1-9

Page 22

SuperBlade User’s Manual

Notes

1-10

Page 23

Chapter 2

System Safety

2-1 Electrical Safety Precautions

Basic electrical safety precautions should be followed to protect yourself from harm and

the SuperBlade from damage:

• Be aware of how to power on/off the enclosure power supplies and the individual

blades as well as the room's emergency power-off switch, disconnection switch or

electrical outlet. If an electrical accident occurs, you can then quickly remove power

from the system.

• Do not work alone when working with high voltage components.

• Power should always be disconnected from the blade module when removing or

installing such system components as the mainboard, memory modules and

processors.

• When working around exposed electrical circuits, another person who is familiar

with the power-off controls should be nearby to switch off the power if necessary.

• Use only one hand when working with powered-on electrical equipment. This is to

avoid making a complete circuit, which will cause electrical shock. Use extreme

caution when using metal tools, which can easily damage any electrical components

or circuit boards they come into contact with.

• Do not use mats designed to decrease electrostatic discharge as protection from

electrical shock. Instead, use rubber mats that have been specifically designed as

electrical insulators.

• The power supply power cords must include a grounding plug and must be plugged

into grounded electrical outlets. Power input requires 110-240 V AC, depending upon

your power supply module. See Section 5-1: Power Supp ly Modu le s on page 5-1 in

Chapter 5 for details.

• Mainboard Battery: This battery must be replaced only with the same or an

equivalent type recommended by the manufacturer (CR2032 Lithium 3V battery).

Dispose of used batteries according to the manufacturer's instructions.

WARNING: There is a danger of explosion if the onboard battery is installed

upside down, which will reverse its polarities.

• Mainboard replaceable soldered-in fuses: Self-resetting PTC (Positive Temperature

Coefficient) fuses on the mainboard must be replaced by trained service technicians

only. The new fuse must be the sa me or equivalent as the one replaced. Contact

technical support for details and support.

2-1

Page 24

SuperBlade User’s Manual

2-2 General Safety Precautions

Follow these rules to ensure general safety:

• Keep the area around the SuperBlade clean and free of clutter.

• Place the blade module cover and any system components that have been removed

away from the system or on a table so that they won't accidentally be stepped on.

• While working on the system, do not wear loose clothing such as neckties and

unbuttoned shirt sleeves, which can come into contact with electrical circuits or be

pulled into a cooling fan.

• Remove any jewelry or metal objects from your body, which are excellent metal

conductors that can create short circuits and harm you if they come into contact with

printed circuit boards or areas where power is present.

• After accessing the inside of the system, replace the blade module's cover before

installing it back into the blade enclosure.

2-3 Electrostatic Discharge Precautions

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic components and printed circuit

boards.

The following measures are generally sufficient to neutralize this difference before

contact is made to protect your equipment from ESD:

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their antistatic bags until

ready for use.

• Touch a grounded metal object before removing the board from the antistatic bag.

• Do not let components or PCBs come into contact with your clothing, which may

retain a charge even if you are wearing a wrist strap.

• Handle a board by its edges only; do not touch its components, peripheral chips,

memory modules or contacts.

• When handling chips or modules, avoid touching their pins.

• Put the mainboard and peripherals back into their antistatic bags when not in use.

• For grounding purposes, make sure the blade enclosure provides excellent

conductivity between the power supplies, the blade modules and the mainboard.

2-4 Operating Precautions

Care must be taken to assure that the cover of the blade unit is in place when the blade

is operating to assure proper cooling. Out of warranty damage to the blade can occur if

this practice is not strictly followed.

Any drive carrier without a hard drive installed must remain fully installed in the drive bay

when the blade module is operating to ensure proper airflow.

2-2

Page 25

Chapter 3

Setup and Installation

3-1 Overview

This chapter provides a quick setup procedure for your SuperBlade. Following these

steps in the order given should enable you to have the system operational within a

minimum amount of time. This quick setup assumes that the processor(s) and memory

have already been installed. If not, please turn to Chapter 4 for details on installing

specific components.

3-2 Unpacking the System

You should inspect the box the SuperBlade was shipped in and note if it was damaged

in any way. If the server itself shows damage you should file a damage claim with the

carrier who delivered it.

Decide on a suitable location for the rack unit that will hold the SuperBlade. It should be

situated in a clean, dust-free area that is well ventilated. Avoid areas where heat,

electrical noise and electromagnetic fields are generated. You will also need it placed

near a grounded power outlet. Read the "Rack Precautions" and "Server Precautions" in

the next section.

The box the SuperBlade was shipped in should include two sets of rail assemblies, two

handles and the mounting screws you will need to install the system into the rack.

Follow the steps in the order given to complete the installation process in a minimum

amount of time. Please read this section in its entirety before you begin the

installation procedure outlined in the sections that follow.

Choosing a Setup Location

The following are important considerations for choosing a setup location:

• Leave enough clearance in front of the rack to enable you to remove the blade units

(~25 inches).

• Leave approximately 30 inches of clearance in the behind or to the rear of the rack

to allow for sufficient airflow and ease in servicing.

• This product is intended for installation only in a Restricted Access Location

(dedicated equipment rooms, service closets and the like). This is because the

SuperBlade enclosure does not provide any physical security measures.

• This product is not suitable for use with visual display work place devices according

to §2 of the German Ordinance for Work with Visual Display Units.

WARNING: Please read the following Important Warnings and Precautions!

3-1

Page 26

SuperBlade User’s Manual

Rack Precautions

The following are important precautions concerning rack setup:

• The enclosure unit is heavy and requires at least two people to lift it.

• Ensure that the leveling jacks on the bottom of the rack are fully extended to the

floor with the full weight of the rack resting on them.

• In single rack installation, stabilizers should be attached to the rack.

• In multiple rack installations the racks frames should be grounded to the same earth

ground as the electrical source for the power supplies by means of a grounding

strap.

Server Precautions

The following are important precautions concerning server setup:

• Review the electrical and general safety precautions in Chapter 2.

• Determine the placement of each component in the rack before you install the rails.

• Install the heaviest server components on the bottom of the rack first, and then work

up.

• Use a regulating uninterrupted power supply (UPS) to protect the server from power

surges, voltage spikes and to keep your system operating in case of a power failure.

• Allow the hot plug hard drives and power supply units to cool before touching them.

• Always keep the rack's front door and all panels and components on the servers

closed when not servicing to maintain proper cooling.

Rack Mounting Considerations

Below are listed important considerations for rack mounting.

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of

the rack environment may be greater than the ambient temperature of the room.

Therefore, consideration should be given to installing the equipment in an environment

compatible with the manufacturer’s maximum rated ambient temperature. Refer to

Appendix E for operating temperature specifications.

Reduced Airflow

Equipment should be mounted into a rack so that the amount of airflow required for safe

operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not arise

due to uneven mechanical loading.

3-2

Page 27

Chapter 3: Setup and Installation

Circuit Overloading

Consideration should be given to the connection of the equipment to the power supply

circuitry and the effect that any possible overloading of circuits might have on

over-current protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern. See the

power calculation tables in Appendix A.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself should

be grounded. Particular attention should be given to power supply connections other

than the direct connections to the branch circuit (such as the use of power strips and so

on).

NOTE: It is recommended that you seek the advice and assistance of a

licensed electrician that can advise you on best practices for insuring that the

electrical supply and the rack are joined to a Common Bonding Network.

Professional documents on grounding techniques include:

• ANSI/TIA-942 – Telecommunications Infrastructure Standard for Data Centers

• J-STD-607-A-2002 – Commercial Building Grounding (Earthing) and Bonding

Requirements for Telecommunications

• IEEE Std 1100™-2005 (IEEE Emerald Book) – IEEE Recommended Practice for

Powering and Grounding Electronic Equipment

Installing the System Into a Rack

This section provides information on installing the SuperBlade into a rack. There are a

variety of rack units on the market, meaning the procedure may differ slightly. Refer to

the Enclosure Template that was included with the system for help.

Rack Mounting Hardware

The following is a list of rack mounting hardware you will need for rack setup and

installation:

• Two rail assemblies (one for each side of the enclosure)

• Two handles

• Four roundhead screws for fastening the enclosure ears to the rack

• Eight flathead screws and washers for mounting the rails to the rack

3-3

Page 28

SuperBlade User’s Manual

Installation

Use the procedure below for installing an enclosure in a rack.

Installing an enclosure:

1. Decide where you want to place the blade enclosure into the rack (see "Rack

Mounting Considerations" in the previous section).

2. Position the Enclosure Template at the front of the enclosure to determine the

locations of the screws for the enclosure rails (see Figure 3-1).

Figure 3-1. Positioning the Enclosure Template

3. The two enclosure rail sections are screwed together to keep them immobile during

shipping. Release these screws just enough to allow the rails to slide apart. Note the

arrow on the rail, which indicates the end that attaches to the front of the rack.

4. Slide the rails apart far enough to match the depth of the rack. Position the rails with

the template and secure the front of each to the front of the rack with two flathead

screws, then secure the back of each rail to the rear of the rack with two flathead

screws (see Figure 3-2). Note that the rails are left/right spe cific and very heavy.

Figure 3-2. Securing the Rails to the Rack

5. (Optional step) Add the front left and right handles to the enclosure using five

screws to secure each handle. Install a thumbscrew through the bottom hole of

each handle (see Figure 3-3).

3-4

Page 29

Chapter 3: Setup and Installation

NOTE: These handles are optional and need only be installed when mounting

the system into a short rack. When mounting into a deep rack, they are

unnecessary and regular screws should be used instead of thumbscrews.

Be aware that these handles are not to be used for lifting the system, they

are only to be used to slide the system within the rack.

6. With one person on either side (see the descriptive label on the side of the

enclosure), lift the enclosure and slide it into the installed rails.

WARNING: Be sure that the enclosure is empty of all blades, power supplies,

switches and management modules BEFORE lifting. These should be installed

AFTER the enclosure is mounted in the rack. Injury and damage may occur if

components are not removed from the rack prior to installation.

7. After pushing the enclosure all the way into the rack, use two roundhead screws on

each side of the server to lock it into place.

Figure 3-3. Attaching the Optional Handles

8. The enclosure is now securely installed in the rack (see Figure 3-4).

3-5

Page 30

SuperBlade User’s Manual

Figure 3-4. Enclosure Installed into Rack

3-6

Page 31

Chapter 4

System Modules

In addition to the blade units, your blade system comes equipped with one or more

system modules. The modules fit into the rear of the enclosure into bays above and/or

below the power supplies. This chapter describes the various blade modules that may

be part of your blade system. Module configurations can be customized; you can install

two of the same type module for redundancy purposes or you may omit a module

altogether (except for the CMM, which is a required module). Figure 4-1 shows a typical

module configuration in a blade system. See Chapter 5 for information on power supply

modules.

WARNING: All module bays must be populated either with a module or a dummy

module cover to maintain proper airflow.

Figure 4-1. Typical Blade System Module Configuration: Rear View

1

1

Table 4-1. Typical Blade System Module Configuration: Rear View

Item# Description

1

1Gb Ethernet Switch Module or 1Gb Pass-through Module (Optional) or 1/10 Gb Ethernet

Switch

24

5

5

5

5

3

2 CMM (Chassis Management Module) (x1 standard, x2 optional)

3 InfiniBand Switch (shown),10 Gb Pass-through Module (optiona l)

4 Empty bay with dummy cover

5 Power Supply (x2 required, x4 optional depending upon system requirem ents)

4-1

Page 32

SuperBlade User’s Manual

NOTE: See the SuperBlade Network Modules User’s Manual on your enclosed

CD-ROM disc for details on all 1Gb Ethernet modules, 1Gb pass-through

modules, 1/10Gb Ethernet modules, 10Gb Ethernet pass-through modules and

InfiniBand modules for the SuperBlade system.

4-1 Chassis Management Module

The Chassis Management Module (CMM) (Figure 4-2) is a required module in a blade

system. This “command” module communicates with the blade units, the power supplies

and the blade switches. Used in conjunction with the Web Interface or IPMI View

management software, the CMM provides administrator control over individual blade

units, power supplies, cooling fans and networking switches and monitors onboard

temperatures, power status, voltage levels and fan speeds.

The CMM provides a dedicated, local and remote KVM (keyboard/video/mouse)

connection over an out of band TCP/IP Ethernet network during any server state

(functioning, blue-screen, powered down, BIOS and so on). It also supports Virtual

Media (VM) redirection for CD, floppy and USB mass storage devices and configures

such information as the switch IP addresses. A summary of CMM features is shown in

Table 4-3.

8

1 2 3 4 5 6 7

Item# Description

1 Power LED

2 Activity LED

Figure 4-2. Chassis Management Module

9

Table 4-2. CMM Module Interface

3 Fault LED

4 Ethernet Port

5 VGA (Monitor) Port

4-2

Page 33

Chapter 4: System Modules

Table 4-2. CMM Module Interface (Continued)

Item# Description

6 USB Ports

7 Reset Button

8 Module Release Handle

9 USB 2.0/1.1 Switch (accessed at back of module, see Figure 4-6)

Table 4-3. CMM Module Features

Feature Description

Management Capabilities Can manage 10 to 14 blade units, network modules and 4 power supplies

Ports One Ethernet port, one VGA port and two USB port s

Basic Functions Supported

System Management System management interface provided via dedicated LAN

Power Consumption Approximately 20W

Operating System Firmware (upgradable)

Local KVM, remote KVM, remote storage, Serial-over-LAN (SOL), blade

monitoring and control

Module Redundancy

A blade system must have one CMM and may have two for redundancy. Since the CMM

uses its own processor , all monitoring and control functions are carried out regardless of

the operation or power status of the blade units. CMM modules can only be installed in

the upper and/or lower right module bays.

The redundancy feature is automatic when two CMM modules have been installed into a

blade system.

Master/Slave Modules

When a blade system has two CMM modules, they are assigned a master/slave status.

This is done automatically according to the following criteria:

Determining Master/Slave status:

1. The CMM installed in the upper bay will be the master, however...

2. If the master CMM is powered down or removed, the second (slave) CMM module

will then immediately be assigned as the master.

NOTE: The Slave CMM keeps the same log/status as the Master CMM.

4-3

Page 34

SuperBlade User’s Manual

Module Installation

Make sure the cover to the module has been installed before proceeding. Follow the

anti-static precautions described in Chapter 2.

Installing the Module:

1. Remove the dummy cover from the bay you want to place the module in.

2. Place the module's release handle in the open position.

3. Slide the module into the module bay until it stops.

4. Push the release handle to the closed position.

5. After the module has been installed and the handle locked, it will turn on and a

POST test will run to verify it is working properly.

Removing the Module:

1. Pull out the release handle to the open position.

2. Pull the module out of the bay.

3. Replace immediately with another module or with a dummy module cover to

maintain airflow integrity.

Configuring the CMM

To access/configure the CMM, you first have to configure the IP settings of the CMM

depending on you network environment. The below procedure for this configuration just

serves as a reference for getting the CMM setup. If your system has Linux OS, please

follow similar instructions to get the CMM setup.

Requirements are:

• Computer system with LAN (RJ45) port

• RJ -45 Ethernet cable

The default IP of the CMM is 192.168.100.100. Configure the Computer system

(connected through Ethernet-LAN to the CMM) to the same address range (for example

192.168.100.101).

Configuring the CMM in Windows OS:

1. Go to S

2. Right-click on LAN to view properties.

TART J CONTROL PANEL J NETWORK CONNECTIONS

4-4

Page 35

Chapter 4: System Modules

3. Choose “Internet Protocol (TCP/IP)” under the GENERAL tab and click on

P

ROPERTIES (seeFigure 4-3 ).

Figure 4-3. Choose Internal Protocol

4-5

Page 36

SuperBlade User’s Manual

4. Manually configure the IP address of the computer system to be in the same

address range as the CMM (see Figure 4-4).

Example:

• IP address: 192.168.100.101

• Subnet Mask: 255.255.255.0

• Default Gateway: 192.168.100.1

Figure 4-4. Manually Configure the IP Address

5. Once the IP address for the computer system is configured, the CMM can be

accessed through the web browser by entering the default IP address

192.168.100.100 of the CMM into the browser’s address bar.

4-6

Page 37

Chapter 4: System Modules

6. Now, the IP address, subnet mask and default gateway of the CMM can be changed

according to the network environment (see Figure 4-5). Please refer to the

Web-based Management Utility User’s Manual on your system’s CD-ROM for more

information.

Figure 4-5. Changing Settings

WARNING: Don't change any other setting, unless you are familiar with it.

CMM Functions

The following sections describe local functions and remote functions of the CMM. With

only minor exceptions, all of the remote functions can be performed by one of three

mechanisms: web-based access to the CMM module, access to the CMM using

IPMIview, a client tool implemented in Java, or via IPMItool commands (DOS

commands or shell scripted commands).

When the web based browser is used, the CMM acts as a web server , requiring a higher

bandwidth connection to the CMM. If there are any bandwidth constraints, IPMI will

provide a superior experience. Additionally, since graphical updates are provided by

client-side Java, IPMIview can also be a superior user experience.

IPMItool on the other hand can provide the ability to issue similar/identical commands to

many SuperBlade enclosures/CMM’s to manage all of them in a similar way.

In addition to accessing the SuperBlade capabilities through CMM, they can also be

accessed directly on a blade by blade basis if the blades are equipped with SIMBL to

provide IPMI control of each individual blade.

4-7

Page 38

SuperBlade User’s Manual

Local KVM

KVM stands for Keyboard/Video/Mouse. With KVM, a user can control multiple blades

with a single keyboard/video/mouse setup. The maximum video resolution the KVM can

support is 1280 x 1024 @ 60 Hz.

To Use: Connect your keyboard, mouse and monitor to the USB and VGA connectors

on the CMM module, then push the KVM button on the control panel of the blade

module you wish to access. The KVM LED on the blade will then illuminate and you can

interface directly with that blade. To access a different blade module, simply push the

KVM button on that blade's control panel.

Remote KVM over IP

Remote KVM over IP is independent from local KVM (although local KVM can operate in

parallel with Remote KVM). Remote KVM encrypts all communication between the

remote user and the CMM.

To Use: Remote KVM over IP is initiated with the management software (IPMI View or

Web-based utility). Attach the LAN cable to the LAN port on the CMM module then refer

to "Web-based Management Utility" on page 4-10 to login and use either utility.

Remote Storage (Virtual Media)

The Remote Storage function allows the user to connect to a remote storage device

(such as a floppy , hard disk, CD-ROM or USB storage device) and access the device as

if it were local. This can be used not only to read and write to remote storage devices but

to load an operating system from a remote drive.

Serial Over LAN (SOL)

Serial Over LAN allows you to redirect the input and output of a serial port via IPMI in

order to manage blade modules from a remote location.

To Use: Serial Over LAN can be activated via the Web-based Management utility. See

the Web-based Management Utility User’s Manual on your system’s CD-ROM for the

procedure to initiate SOL.

Monitoring Functions

Used in conjunction with IPMI or the Web-based Management utility, the CMM module

can monitor and provide information on the hardware health of the blade modules and

the system as a whole. In addition to the monitoring functions, you can remotely power

on, power off or reboot a system.

Health information includes:

• Temperature levels

• Fan speeds

• Voltage levels

• Power status

4-8

Page 39

Chapter 4: System Modules

Power Consumption Management

The CMM module’s firmware can also control all power on/off activity in the whole blade

system. This is done by using the Power button, via a SIMBL add-on card or from any

other use of remote management software.

Once a blade module is installed in the enclosure the installed CMM immediately

receives information on the rated Max Power Consumption value of the new blade

module. The CMM then calculates whether there is enough power for this new blade

module by comparing the Max Power Consumption value of the new blade module with

the calculated Remaining Power value of the system.

If there is enough power, the CMM will power on the blade. However if there is not

enough power in the blade system, then the new blade module is not powered on and

the front panel LED on the enclosure will blink.

After the blade is powered on, the CMM then collects the actual power consumption of

this individual blade and updates the calculated Remaining Power value for the system.

The CMM also reserves power for all the networking and chassis management modules

installed on the system.

NOTE: Blade modules with a SIMBL add-on card installed in them provide

individual IPMI for each Blade unit. It communicates with the CMM and is

connected to the Gb Ethernet switch module for remote web or IPMI View

access.

WARNING: One CMM module must be running to control the power systems

and prevent overloading.

CMM Switches and Buttons

The various switches and buttons found on the CMM are described below.

USB Switch

Figure 4-6. USB Switch on Rear of CMM

The USB ports on the CMM can function in either 2.0 or 1.1 mode (the default is 1.1). A

switch located on the PCB at the back of the CMM module is used to change the USB

mode (see Figure 4-6).

4-9

Page 40

SuperBlade User’s Manual

To access the switch, you need to remove the CMM from the enclosure. Pull the CMM

out and locate the switch near the large gray connector. The settings are silk screened

on the PCB. After setting the switch, insert the CMM module back into its bay.

Reset Button

The Reset button located on the front of the CMM module is used to reset the following

software settings to their defaults:

Table 4-4. CMM Reset Settings

Software Setting Default

User Name and Password Reset to ADMIN and ADMIN (case sensitive)

IP Address Reset to 192.168.100.100

Gateway Address Reset to 0.0.0.0

Subnet Mask Reset to 255.255.255.0

To reset these values, press and hold the Reset button for five seconds.

Firmware

The firmware for the CMM switch resides in the module. This firmware can be updated

with the web-based management utility.

Within the utility, go to the M

AINTENANCE > UPDATE FIRMWARE screen in the Web-based

Management Utility . Here you can enter the name of the firmware you want to update or

click on B

ROWSE to select the firmware file. Finish by clicking the UPLOAD button.

NOTE: This process is not reversible once the firmware is updated, so proceed

with caution. It might take a few minutes to complete this procedure. See the

the user’s manual for your purchased blade module on your system’s CD-ROM

for further details.

Web-based Management Utility

System management may be performed with either of three software packages:

IPMIview, IPMItool or a Web-based Management utility. Any of these utilities are

designed to provide an administrator with a comprehensive set of functions and

monitored data to keep tabs on the system and perform management activities.

The Web-based Management Utility is a web-based interface that consolidates and

simplifies system management for Supermicro SuperBlade systems. The Web-based

Management Utility aggregates and displays data from the CMM module.

NOTE: Full documentation on the Web-based Management Utility may be

found on the CD-ROM included with your system.

4-10

Page 41

Chapter 4: System Modules

The Web-based Management Utility provides the following key management features:

• Enables IT administrators to view in-depth hardware configuration and status

information using a single intuitive interface.

• Provides an OS-independent, remote graphical console.

• Allows remote users to map local media (floppy, CD-ROM, removable disks and

hard drives) or ISO images on a shared network drive to a blade server.

Supported Browsers

The following browsers have been tested for use with the Web-based Management

Utility. It is recommended that you use the most current revision of the browser you

choose. The minimum browser revisions supported by the Web-based Management

Utility are shown below:

• Internet Explorer 7

• Firefox 2.0.0.7

• Netscape 9.03b

Network Connection/Log in

To log into the Web-based Management Utility:

1. Launch a web browser.

2. In the address field of the browser, enter the IP address that you assigned to the

Chassis Management Module and hit the <E

NTER> key.

3. When the browser makes contact with Supermicro’s Chassis Management Module,

enter your username and password, then click L

OGIN.

4. The WEB-BASED MANAGEMENT UTILITY HOME PAGE will then display as shown in

Figure 4-7.

Address Defaults

Table 4-5 shows the default addresses that are initially set for the CMM. Afterwards, you

can change these values within the program (see the Web-based Management Utility

User’s Manual on your system’s enclosed CD-ROM for more details).

Table 4-5. Address Defaults

Default Description

Default IP Address 192.168.100.100

Default Gateway Address 0.0.0.0

Default Subnet Mask 255.255.255.0

Default username ADMIN

Default password ADMIN

4-11

Page 42

SuperBlade User’s Manual

Home Page

Figure 4-7 and Table 4-6 respectively display the WEB-BASED MANAGEMENT UTILITY

H

OME PAGE and its controls.

Figure 4-7. Home Page

1 2

4

3

6

5

Table 4-6. Home Page Controls

Item Description

1 Home: Click this icon to return to the Home Page.

2

3

4 Logout: Click on this icon to log out.

5 Refresh: Click on this icon to refresh the remote console preview screen.

6

Console: Click this icon to open the Remote Console Screen. (KVM must first be initialized

either with the KVM button or via management software).

Remote Console Screen: The active screen from the remote console is displaye d here.

Clicking on this window also accesses the remote console.

Main Menu Icons: Used to initiate the various functions in the Web-based Management

Utility.

NOTE: For more information on the Web-based Management Utility, see the

Web-based Management Utility User’s Manual on the CD-ROM included with

your SuperBlade system.

4-12

Page 43

Chapter 4: System Modules

4-2 Double-Wide Modules

Most modules in the SuperBlade fit into single-wide bays. The InfiniBand module and

some other modules however (such as the 10GbE Pass-through module), require a

double-wide bay and can only be installed in such a bay created by combining the two

right most bays. The enclosure's module bays are designed to be easily modified from

single to double-wide by following the procedure below.

Modifying an Enclosure’s Module Bays for Double-wide Modules

1. Remove the four screws that secure the inner enclosure to the main enclosure.

Slide the inner enclosure outward, depressing the locking tabs on both sides to pull

it completely out.

2. Remove any single-wide modules that are occupying the bays you wish to modify to

a double-wide bay.

3. In the module bay you wish to expand to double wide, remove the two screws that

secure the center support to the inner enclosure then take out the center support.

See Figure 4-9, Step 1 for details.

4. Remove the two screws from the underside of each of the two horizontal spacers

(as shown in Figure 4-8). See Figure 4-9, Step 2 for details.

5. Using four screws, install the long horizontal spacer to the same space where the

two short spacers were removed. See Figure 4-10, Step 3 for details.

6. You can now install a double-wide module into the bay. See Figure 4-10, Step 4 for

details.

NOTE: This procedure describes modifying two right most single-wide bays

located at the top of the inner enclosure. The same procedure applies to the two

right most single bays located at the bottom of the enclosure, but note that the

horizontal spacers in the bottom bays use a guide pin and are not

interchangeable with the upper bay spacers (see Figure 4-8 for details).

Modules in the upper bays will have their release handles on the bottom, while

modules in the lower bays will have their release handles on the top.

Placing modules in an “upside-down” orientation in the upper-left corner (only)

does not affect their operation.

NOTE: Only one double-wide module can be installed in an enclosure since

each enclosure requires at least one CMM module. The bottom location is

recommended.

If using the AOC-IBH-002 single-port InfiniBand mezzanine card, the InfiniBand

switch MUST be installed in the bottom location.

4-13

Page 44

SuperBlade User’s Manual

Figure 4-8. Horizontal Spacers for Single Bays

MCP-560-00012-1N (for top bay)

MCP-560-00009-1N (for bottom bay)

4-14

Page 45

Chapter 4: System Modules

Figure 4-9. Modifying for a Double-Wide Module Bay (Steps 1 & 2)

Step 1

Center Support

Screws (2)

Center

Support

Step 2

Horizontal Sp acer

Screws (4)

Horizontal Spacers (2)

(MCP-560-00012-1N)

4-15

Page 46

SuperBlade User’s Manual

Figure 4-10. Modifying for a Double-Wide Module Bay (Steps 3 & 4)

Step 3

Horizontal Spa cer

Screws (4)

Horizontal

Spacers (1)

Step 4

Double-Wide

(InfiniBand) Module

4-16

Page 47

Chapter 5

Power Supply Modules

The SuperBlade enclosure comes standard with one CMM module (see the Chapter 4

for details on the CMM module) and either two or four power supplies. See Appendix A

for summary specification details on the power supplies available to the SuperBlade

enclosure.

NOTE: The SBE-710E enclosure may use either 2000W or 1600W power

supplies. The SBE-714D/E enclosure can only use 1400W power supplies.

5-1 Power Supply Modules

The SuperBlade enclosure has two models of power supply modules available: the

PWS-1K41-BR 1400W module (Figure 5-1) and the PWS-2K01-BR 2000W module

(Figure 5-2).

The features of these power supplies are shown in Table 5-1 and Table 5-2 below.

Figure 5-1. PWS-1K41-BR Power Supply

Table 5-1. PWS-1K41-BR Power Supply Features

Feature Description

Output 1400W

Type Redundant Module (N+1)

+12V

116A (200-240VAC input)

100A (100-140VAC input)

5-1

Page 48

SuperBlade User’s Manual

Table 5-1. PWS-1K41-BR Power Supply Features (Continued)

Feature Description

5VSB 16A

PFC Yes

Peak Efficiency 93%

Input AC Range 100-240VAC

Operating Conditions

Fan Type

Temp: -5 to 50 C

Humidity: 5 to 95% RH

2x 90mm fans

- PFC0912DE-6L38

(8000 RPM with PWM)

Figure 5-2. PWS-2K01-BR Power Supply

Table 5-2. PWS-2K01-BR Power Supply Features

Feature Description

Output 2000W

Type Redundant Module (N+1)

+12V 167A

5VSB 16A

PFC Yes

Peak Efficiency 90%

Input AC Range 200-240VAC

5-2

Page 49

Table 5-2. PWS-2K01-BR Power Supply Features

Feature Description

Chapter 5: Power Supply Modules

Operating Conditions

Fan Type

Temp: -5 to 50 C

Humidity: 5 to 95% RH

4x 90mm fans

- PFB0912DHE-6X39

(8000 RPM)

- QFR0912UHE-6F78

(8300 RPM)

Four modules are required when the full complement of 10 blade units are installed into

an enclosure. An LED on the back of a power supply will be amber when AC power is

present and green when the power is on.

When installing only two power supplies in the enclosure, they should be installed in the

lower rather than the upper power bays. This is to provide increased airflow across the

memory modules within each blade module.

The 2000W power supply modules require a 200-240V AC input and a C20 socket,

which requires a power cord with a C19 connector (see "Power Cord" below for details).

The 1400W power supply modules can work with both 110V and 220V AC input and use

a C14 socket and C13 connector.

Supermicro's high-efficiency blade system power supplies deliver continuous redundant

power at 90%+ peak efficiency. Each power supply module includes a management

module that monitors the power supplies and the power enclosure

Power Supply Failure

If a power supply or a fan in a power supply fails, the system management software will

notify you of the situation. In either case, you will need to replace the power supply

module with another identical one (part number: PWS-2K01-BR).

NOTE: Refer to www.supermicro/products/superblade for possible updates on

part numbers.

Installing a Power Supply

1. Insert a replacement unit into the empty power bay with the handle to the left.

WARNING: This left/right orientation depends on the power supply’s top or

bottom location. If you inadvertently put a power supply upside down in the lower

slots, it can be VERY difficult to remove the power supply.

2. Push unit all the way in until it is firmly seated.

3. Push the handle back into the closed position until it clicks into the locked position.

5-3

Page 50

SuperBlade User’s Manual

4. Move the locking clip away from the socket and reconnect the power cord.

Removing a Power Supply

First, make sure the power supply has been shut down. You can remove power from a

power unit via your system management software.

1. Remove the power cord from the power supply unit.

2. Release the locking clip to unlock the power supply module (see Figure 5-3).

Figure 5-3. Power Supply Module

Two-piece handle

Locking clip

AC input (C-20)

LED indicator

3. Pull out the handle and remove the unit: the two-piece handle locks into the closed

position. To release the handle, squeeze together the two metal plates of the handle

with your thumb and fingers and then pull out.

5-2 Power Supply Fans

Each power supply unit has four rear fans. These fans are not hot-swappable. If one

fails, the power supply will continue to operate but you should replace the power supply

unit at the earliest opportunity. If two or more fans fail, the power supply unit will shut

down and the LED on the back will turn amber.

5-4

Page 51

Chapter 5: Power Supply Modules

5-3 Power Components

Power components for your system’s power supplies are shown below in Figure 5-4 and

described in Table 5-3.

Figure 5-4. Power Components

2

1

3

Table 5-3. Power Components

Item Name Description

1 PDU Power Distribution Unit (MCP-520-00036-0N)