Supermicro 6027AX-TRF-HFT2, 6027AX-72RF-HFT3, 6027AX-TRF-HFT1, 6027AX-TRF-HFT3, 6027AX-72RF-HFT1 User Manual

...

SUPER

SUPERSERVER

6027AX-TRF-HFT1

6027AX-TRF-HFT2

6027AX-TRF-HFT3

®

6027AX-72RF-HFT1

6027AX-72RF-HFT2

6027AX-72RF-HFT3

USER’S MANUAL

1.0b

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software and documentation, is the property of Supermicro and/or its licensors, and is supplied only under a license.

Any use or reproduction of this product is not allowed, except as expressly permitted by the terms

of said license.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for all

claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the manufacturer’s instruction manual, may cause harmful interference

with radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to the

State of California to cause birth defects and other reproductive harm.

Manual Revision 1.0b

Release Date: April 16, 2014

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2014 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Preface

About This Manual

This manual is written for professional system integrators and PC technicians. It

provides information for the installation and use of the SuperServer 6027AX-72RF/

TRF-HFT1/HFT2/HFT3. Installation and maintenance should be performed by

experienced technicians only.

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a checklist of the main components included with the serv-

er system and describes the main features of the X9DAX-7F/iF-HFT serverboard

and the SC829BTQ-R1K28LPB chassis, which comprise the SuperServer 6027AX72RF/TRF-HFT1/HFT2/HFT3.

Preface

Chapter 2: Server Installation

This chapter describes the steps necessary to install the SuperServer into a rack and

check out the server confi guration prior to powering up the system. If your server

was ordered without processor and memory components, this chapter will refer you

to the appropriate sections of the manual for their installation.

Chapter 3: System Interface

Refer here for details on the system interface, which includes the functions and

information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

Chapter 4: System Safety

You should thoroughly familiarize yourself with this chapter for a general overview

of safety precautions that should be followed when installing and servicing the

SuperServer 6027AX-72RF/TRF-HFT1/HFT2//HFT3.

iii

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2 User's Manual

Chapter 5: Advanced Serverboard Setup

Chapter 5 provides detailed information on the X9DAX-7F/iF-HFT serverboard,

including the locations and functions of connections, headers and jumpers. Refer

to this chapter when adding or removing processors or main memory and when

reconfi guring the serverboard.

Chapter 6: Advanced Chassis Setup

Refer to Chapter 6 for detailed information on the SC829BTQ-R1K28LPB server

chassis. You should follow the procedures given in this chapter when installing,

removing or reconfi guring SAS or peripheral drives and when replacing system

power supply modules and cooling fans.

Chapter 7: BIOS

The BIOS chapter includes an introduction to BIOS and provides detailed information on running the CMOS Setup Utility.

Appendix A: BIOS Error Beep Codes

Appendix B: System Specifi cations

iv

Notes

Preface

v

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2//HFT3 User's Manual

Table of Contents

Chapter 1 Introduction

1-1 Overview ......................................................................................................... 1-1

1-2 Serverboard Features ..................................................................................... 1-2

Processors ...................................................................................................... 1-2

Memory ........................................................................................................... 1-2

SAS ................................................................................................................. 1-2

Serial ATA ........................................................................................................ 1-2

PCI Expansion Slots ....................................................................................... 1-3

Rear I/O Ports ................................................................................................. 1-3

1-3 Server Chassis Features ................................................................................ 1-3

System Power ................................................................................................. 1-3

Hard Drive Subsystem .................................................................................... 1-3

Front Control Panel ......................................................................................... 1-3

Cooling System ............................................................................................... 1-3

1-4 Contacting Supermicro .................................................................................... 1-5

Chapter 2 Server Installation

2-1 Overview ......................................................................................................... 2-1

2-2 Unpacking the System .................................................................................... 2-1

2-3 Preparing for Setup ......................................................................................... 2-1

Choosing a Setup Location ............................................................................. 2-1

Rack Precautions ............................................................................................ 2-2

Server Precautions .......................................................................................... 2-2

Rack Mounting Considerations ....................................................................... 2-3

Ambient Operating Temperature ................................................................ 2-3

Reduced Airfl ow ......................................................................................... 2-3

Mechanical Loading ................................................................................... 2-3

Circuit Overloading ..................................................................................... 2-3

Reliable Ground ......................................................................................... 2-3

2-5 Installing the System into a Rack ................................................................... 2-4

Separating the Sections of the Rack Rails ..................................................... 2-4

Installing the Inner Rail Extension .................................................................. 2-4

Outer Rack Rails ............................................................................................. 2-6

Chapter 3 System Interface

3-1 Overview ......................................................................................................... 3-1

3-2 Control Panel Buttons ..................................................................................... 3-1

vi

Table of Contents

Power button ................................................................................................... 3-1

UID Button (Unit Identifi ed Button) ................................................................. 3-1

3-3 Control Panel LEDs ........................................................................................ 3-2

NIC2 ................................................................................................................ 3-2

NIC1 ................................................................................................................ 3-2

Informational LED ........................................................................................... 3-2

3-4 OLED Screen .................................................................................................. 3-3

3-5 Drive Carrier LEDs .......................................................................................... 3-3

Chapter 4 Standardized Warning Statements for AC Systems

4-1 About Standardized Warning Statements ....................................................... 4-1

Warning Defi nition ........................................................................................... 4-1

Installation Instructions .................................................................................... 4-4

Circuit Breaker ................................................................................................ 4-5

Power Disconnection Warning ........................................................................ 4-6

Equipment Installation ..................................................................................... 4-8

Restricted Area ................................................................................................ 4-9

Battery Handling ............................................................................................ 4-10

Redundant Power Supplies .......................................................................... 4-12

Backplane Voltage ........................................................................................ 4-13

Comply with Local and National Electrical Codes ........................................ 4-14

Product Disposal ........................................................................................... 4-15

Hot Swap Fan Warning ................................................................................. 4-16

Power Cable and AC Adapter ...................................................................... 4-18

Chapter 5 Advanced Serverboard Setup

5-1 Handling the Serverboard ............................................................................... 5-1

Precautions ..................................................................................................... 5-1

Unpacking ....................................................................................................... 5-1

5-2 Connecting Cables .......................................................................................... 5-2

Connecting Data Cables ................................................................................. 5-2

Connecting Power Cables .............................................................................. 5-2

Connecting the Control Panel ......................................................................... 5-2

5-3 Rear I/O Ports ................................................................................................. 5-3

5-4 Installing the Processor and Heatsink ............................................................ 5-4

Installing an Xeon E5-2600 Processor ........................................................... 5-4

Installing a Passive CPU Heatsink ................................................................. 5-7

Removing the Heatsink ................................................................................... 5-7

5-5 Installing Memory ............................................................................................ 5-8

Memory Support .............................................................................................. 5-8

vii

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

DIMM Installation ............................................................................................ 5-8

5-6 Adding PCI Add-On Cards ............................................................................ 5-12

5-7 Serverboard Details ...................................................................................... 5-13

X9DAX-7F/iF-HFT Quick Reference ............................................................. 5-14

5-8 Connector Defi nitions ................................................................................... 5-16

5-9 Jumper Settings ............................................................................................ 5-23

5-10 Onboard Indicators ........................................................................................ 5-26

5-11 SATA Ports .................................................................................................... 5-27

5-12 Installing Software ......................................................................................... 5-28

SuperDoctor III .............................................................................................. 5-29

5-13 Onboard Battery ............................................................................................ 5-31

Chapter 6 Advanced Chassis Setup

6-1 Static-Sensitive Devices .................................................................................. 6-1

Precautions ..................................................................................................... 6-1

6-2 Control Panel .................................................................................................. 6-2

6-3 Accessing the Inside of the System................................................................ 6-3

6-4 System Fans ................................................................................................... 6-4

System Fan Failure ......................................................................................... 6-4

Hard Drive Installation ..................................................................................... 6-6

6-6 Power Supply .................................................................................................. 6-9

Power Supply Failure ...................................................................................... 6-9

Chapter 7 BIOS

7-1 Introduction ...................................................................................................... 7-1

Starting BIOS Setup Utility .............................................................................. 7-1

How To Change the Confi guration Data ......................................................... 7-2

Starting the Setup Utility ................................................................................. 7-2

7-2 Main Setup ...................................................................................................... 7-2

7-3 Advanced Setup Confi gurations...................................................................... 7-4

7-4 Overclocking ................................................................................................. 7-24

7-5 Event Logs .................................................................................................... 7-26

7-6 IPMI ............................................................................................................... 7-28

7-7 Boot ............................................................................................................... 7-31

7-8 Security ......................................................................................................... 7-32

7-9 Save & Exit ................................................................................................... 7-33

Appendix A BIOS Error Beep Codes

Appendix B System Specifi cations

viii

Chapter 1: Introduction

Chapter 1

Introduction

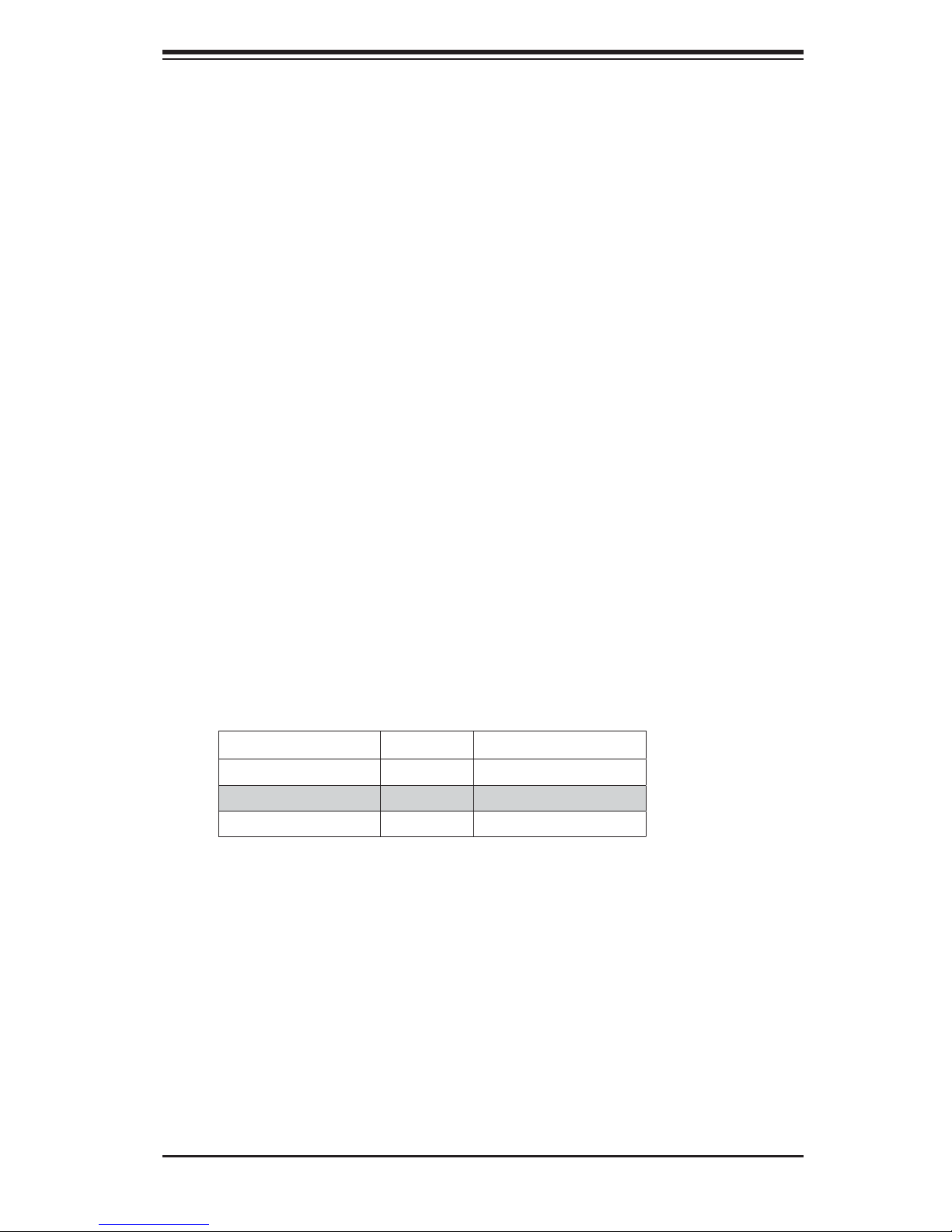

1-1 Overview

The SuperServer 6027AX-72RF/TRF-HFT1/HFT2/HFT3 is a high-end server comprised of two main subsystems: the CSE-829BTQ-R1K28LPBP 2U chassis and

the X9DAX-7F/iF-HFT dual processor serverboard. Please refer to our web site for

information on operating systems that have been certifi ed for use with the system

(www.supermicro.com). For processor specifi cs, please see the following page.

In addition to the serverboard and chassis, various hardware components have been

included with the 6027AX-72RF/TRF-HFT1/HFT2/HFT3, as listed below:

• Four 8-cm system fans (FAN-0118L4)

• SAS/SATA accessories

One SAS/SATA backplane (BPN-SAS-829BTQ)

Ten drive carriers (MCP-220-00075-0B)

• One rackmount kit (MCP-290-00053-0N)

• Two passive CPU heatsinks (SNK-P2048P)

• Each model comes with specifi c types of CPUs and memories.

Server Model CPU Memory

6027AX-72RF/TRF-HFT1 E5-2687W 8 X 8GB DDR3 (1600MHz)

6027AX-72RF/TRF-HFT2 E5-2643 8 X 4GB DDR3 (1600MHz)

6027AX-72RF/TRF-HFT3 E5-2687WV2 8 X 8GB DDR3 (1866MHz)

Note: For your system to work properly, please follow the links below to download

all necessary drivers/utilities and the user's manual for your server.

• Supermicro product manuals: http://www.supermicro.com/support/manuals/

• Product drivers and utilities: ftp://ftp.supermicro.com

• If you have any questions, please contact our support team at support@su-

permicro.com

Note: a complete list of safety warnings is provided on the Supermicro web site at

http://www.supermicro.com/about/policies/safety_information.cfm

1-1

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

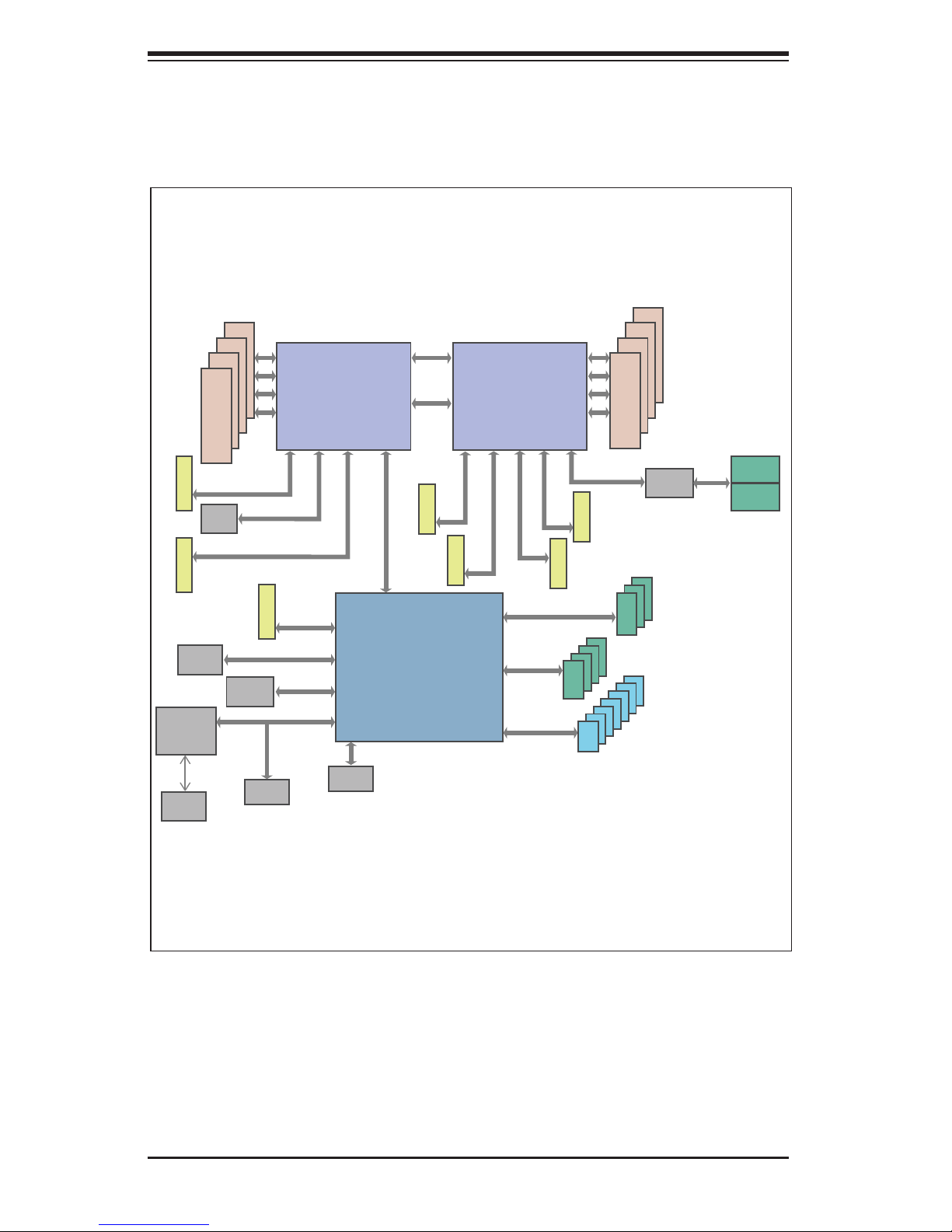

1-2 Serverboard Features

The SuperServer 6027AX-72RF/TRF-HFT1/HFT2/HFT3 is built around the X9DAX7F/iF-HFT, a dual processor serverboard based on the Intel C602 chipset and

designed to provide maximum performance. Below are the main features of the

X9DAX-7F/iF-HFT. (See Figure 1-1 for a block diagram of the chipset).

Processors

The X9DAX-7F/iF-HFT supports dual Intel® Xeon® processors in LGA 2011 sockets

(Socket R).

Server Model Supported Processor

6027AX-72RF/TRF-HFT1 Intel Xeon Processor E5-2687W, Socket R (LGA 2011)

6027AX-72RF/TRF-HFT2 Intel Xeon Processor E5-2643, Socket R (LGA 2011)

6027AX-72RF/TRF-HFT3 Intel Xeon Processor E5-2687WV2, Socket R (LGA 2011)

Please refer to the serverboard description pages on our web site for a complete

listing of supported processors (www.supermicro.com).

Memory

The X9DAX-7F/iF-HFT has 16 DIMM slots that can support up to 512 GB of RDIMM,

ECC LRDIMM or up to 128 GB of Unbuffered (UDIMM) ECC/non-ECC UDIMM

DDR3-1866/1600/1333/1066/800 MHz type memory. See Chapter 5 for details.

SAS

A total of eight SAS 2.0 ports are provided with an LSI 2208 SAS controller. RAID

levels 0, 1, 5, 10, 50 and 60 are supported.

Note: The operating system you use must have RAID support to enable the hotswap capability and RAID function of the SAS drives.

Serial ATA

A SATA controller is also integrated into the chipset to provide two SATA 3.0 (6/

Gbps) and four SATA 2.0 (3 Gbps) ports, which are RAID 0, 1, 5 and 10 supported.

The SATA drives are hot-swappable units.

Note: The operating system you use must have RAID support to enable the hotswap capability and RAID function of the SATA drives.

1-2

Chapter 1: Introduction

PCI Expansion Slots

The X9DAX-7F/iF-HFT has two PCI-Express 3.0 x16 slots, four PCI-E3.0 x8 slots

and one PCI Express 3.0 x 4 in x8 slot. PCI slots are controlled by CPUs: both

CPUs must be installed to utilize all slots. See Chapter 5 for details.

Rear I/O Ports

The color-coded I/O ports include one COM port, a VGA port, two USB 3.0 ports,

four USB 2.0 ports (additional USB headers are included on the serverboard) and

two 1 Gb Ethernet ports. A dedicated IPMI LAN port is also included.

1-3 Server Chassis Features

The CSE-829BTQ-R1K28LPB is an EATX form factor chassis designed to be used

in a 2U rackmount confi guration. The following is a general outline of the main

features of the SC829BTQ-R1K28LPB server chassis.

System Power

The CSE-829BTQ-R1K28LPBP features a redundant 1280W power supply composed of two separate power modules. This power redundancy feature allows you

to replace a failed power supply module without shutting down the system.

Hard Drive Subsystem

The CSE-829BTQ-R1K28LPBP chassis was designed to support ten hot-swap

SATA or SAS hard drives.

Front Control Panel

The control panel on the CSE-829BTQ-R1K28LPBP provides you with system

monitoring and control. LEDs indicate system power, HDD activity, network activity,

system information and power supply failure. A main power button and a system

reset button are also included. As an option, two USB ports may be incorporated

into the control panel to provide front side USB access.

Cooling System

The CSE-829BTQ-R1K28LPBP chassis has an innovative cooling design that includes four 8-cm hot-plug system cooling fans located in the middle section of the

chassis. The power supply module also includes a cooling fan.

1-3

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

#1-4

#1-3

#1-2

Intel E5-2600

8 SNB CORE

DDR3

#2 #1 #3

P0

P1

DMI2

LAN

X540

USB 3.0

(REAR)

COM1

internal

1394

SPI

BMC

WPCM450

VGA

USB 3.0

LANE1/2/3/4

LANE6

PCH

C602

LANE7

LANE8

PCI

#0~#3

#0~#3

#0~#7

SCU

DMI2

4 GB/s

DMI2

3.0 Gb/S

(FRONT)

SAS2208

PCI-E X16 G3

PCI-E X8 G3

PCI-E X4

PCI-E X8 G3

PCI-E X8 G3

PCI-E X16 G3

QPI

8G

Intel E5-2600

8 SNB CORE

DDR3

#3A #3B #2A #2B #1

SAS2

#1-1

DDR3

PCI-E X16

SLOT 2

PCI-E X8

SLOT 3

PCI-E X8 G3

PCI-E X8 G3

PCI-E X8 G3

PCI-E X8

SLOT 7

PCI-E X8

SLOT 5

PCI-E X8

SLOT 6

PCI-E X16

SLOT 1

PCI-E X4

SLOT 4

800/1066/1333

#0-4

#0-3

#0-2

#0-1

DDR3

800/1066/1333

QPI

8G

3.0 Gb/S

6.0 Gb/S

For Port 0/1

USB 2.0

4 Rear

2 Front

1 Type-A

PCI-E X1

PCI-E X1

PCI

P0

P1

SAS

Ports 0~3

SAS

Ports 4~7

SATA

SATA2

USB

Figure 1-1. Intel C602 Chipset (PCH A):

System Block Diagram

Note: This is a general block diagram. Please see Chapter 5 for details.

1-4

Chapter 1: Introduction

1-4 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site:

www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacifi c

Address: Super Micro Computer, Inc.

3F, No. 150, Jian 1st Rd.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site:

Technical Support:

Email: support@supermicro.com.tw

Tel: +886-(2) 8226-3990

Chung-Ho Dist., New Taipei City 235

Taiwan

www.supermicro.com.tw

1-5

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

Notes

1-6

Chapter 2: Server Installation

Chapter 2

Server Installation

2-1 Overview

This chapter provides a quick setup checklist to get your SuperServer 6027AX72RF/TRF-HFT1/HFT2/HFT3 up and running. Following these steps in the order

given should enable you to have the system operational within a minimum amount

of time. This quick setup assumes that your system has come to you with the

processors and memory preinstalled. If your system is not already fully integrated

with a serverboard, processors, system memory etc., please turn to the chapter or

section noted in each step for details on installing specifi c components.

2-2 Unpacking the System

You should inspect the box the SuperServer 6027AX-72RF/TRF-HFT1/HFT2/HFT3

was shipped in and note if it was damaged in any way. If the server itself shows

damage you should fi le a damage claim with the carrier who delivered it.

Decide on a suitable location for the rack unit that will hold the SuperServer 6027AX72RF/TRF-HFT1/HFT2/HFT3. It should be situated in a clean, dust-free area that is

well ventilated. Avoid areas where heat, electrical noise and electromagnetic fi elds

are generated. You will also need it placed near a grounded power outlet. Read the

Rack and Server Precautions in the next section.

2-3 Preparing for Setup

The box the SuperServer 6027AX-72RF/TRF-HFT1/HFT2/HFT3 was shipped in

should include two sets of rail assemblies, two rail mounting brackets and the

mounting screws you will need to install the system into the rack. Follow the steps

in the order given to complete the installation process in a minimum amount of time.

Please read this section in its entirety before you begin the installation procedure

outlined in the sections that follow.

Choosing a Setup Location

• Leave enough clearance in front of the rack to enable you to open the front door

completely (~25 inches) and approximately 30 inches of clearance in the back

of the rack to allow for suffi cient airfl ow and ease in servicing.

2-1

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

• This product is for installation only in a Restricted Access Location (dedicated

equipment rooms, service closets and the like).

• This product is not suitable for use with visual display work place devices

acccording to §2 of the the German Ordinance for Work with Visual Display

Units.

2-4 Warnings and Precautions

Rack Precautions

• Ensure that the leveling jacks on the bottom of the rack are fully extended to

the fl oor with the full weight of the rack resting on them.

• In single rack installation, stabilizers should be attached to the rack. In multiple

rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the

rack.

• You should extend only one component at a time - extending two or more si-

multaneously may cause the rack to become unstable.

Server Precautions

• Review the electrical and general safety precautions in Chapter 4.

• Determine the placement of each component in the rack before you install the

rails.

• Install the heaviest server components on the bottom of the rack fi rst, and then

work up.

• Use a regulating uninterruptible power supply (UPS) to protect the server from

power surges, voltage spikes and to keep your system operating in case of a

power failure.

• Allow any hot plug drives and power supply modules to cool before touching

them.

• Always keep the rack's front door and all panels and components on the servers

closed when not servicing to maintain proper cooling.

2-2

Chapter 2: Server Installation

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack environment may be greater than the ambient temperature of the

room. Therefore, consideration should be given to installing the equipment in an

environment compatible with the manufacturer’s maximum rated ambient temperature (Tmra).

Reduced Airfl ow

Equipment should be mounted into a rack so that the amount of airfl ow required

for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not

arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might have

on overcurrent protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply connections other than the direct connections to the branch circuit (i.e. the use of power

strips, etc.).

Warning! To prevent bodily injury when mounting or servicing this unit in a

rack, you must take special precautions to ensure that the system remains

stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in

the rack.

• When mounting this unit in a partially fi lled rack, load the rack from the bottom

to the top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

2-3

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

2-5 Installing the System into a Rack

This section provides information on installing the SC8298 chassis into a rack unit

with the quick-release rails provided. There are a variety of rack units on the market,

which may mean the assembly procedure will differ slightly. You should also refer to

the installation instructions that came with the rack unit you are using.

Note: This rail will fi t a rack between 26" and 33.5" deep.

Warning! Stability hazard. The rack stabilizing mechanism must be in

place, or the rack must be bolted to the fl oor before you slide the unit out

for servicing. Failure to stabilize the rack can cause the rack to tip over.

Separating the Sections of the Rack Rails

The chassis package includes two rail assemblies in the rack mounting kit. Each

assembly consists of two sections: an inner fi xed chassis rail that secures directly

to the server chassis and an outer fi xed rack rail that secures directly to the rack

itself.

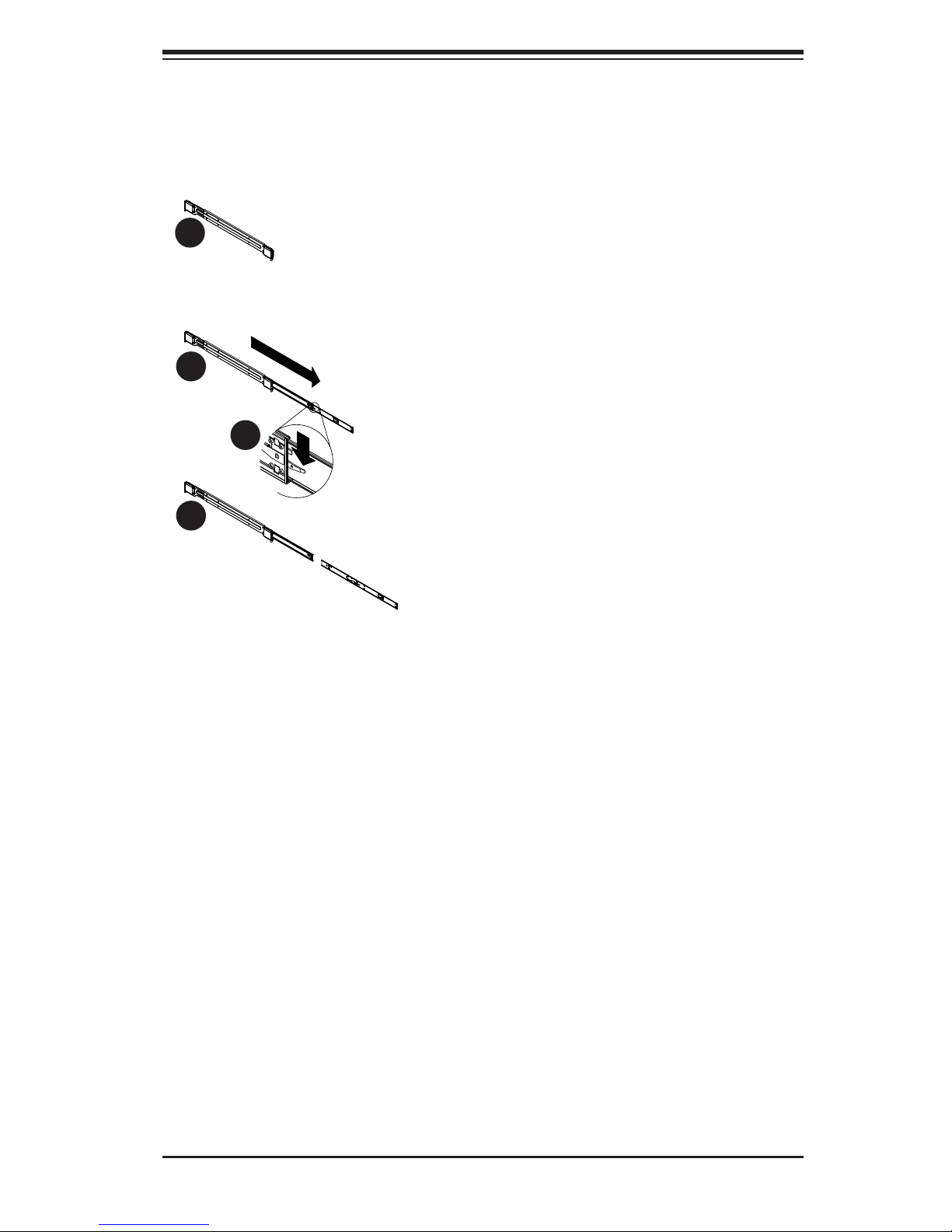

Installing the Inner Rail Extension

The SC8298 chassis includes a set of inner rails in two sections: inner rails and

inner rail extensions. Inner rail extensions are attached to the inner rails to mount

the chassis in the rack.

Installing the Inner Rails

1. Place the inner rail extensions on the side of the chassis aligning the hooks

of the chassis with the rail extension holes. Make sure the extension faces

"outward" just like the pre-attached inner rail.

2. Slide the extension toward the front of the chassis.

3. Secure the chassis with 2 screws as illustrated. Repeat steps for the other

inner rail extension.

2-4

Chapter 2: Server Installation

Figure 2-1: Separating the Rack Rails

1

1

2

1

3

1

4

1

Rail Assembly

Extending the Rails

Quick-

Release Tab

Separating

the Inner Rail

Extension

Separating the Inner and Outer Rails

1. Locate the rail assembly in the chassis

packaging.

2. Extend the rail assembly by pulling it

outward.

3. Press the quick-release tab.

4. Separate the inner rail extension from

the outer rail assembly.

2-5

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

3

1

1

1

2

1

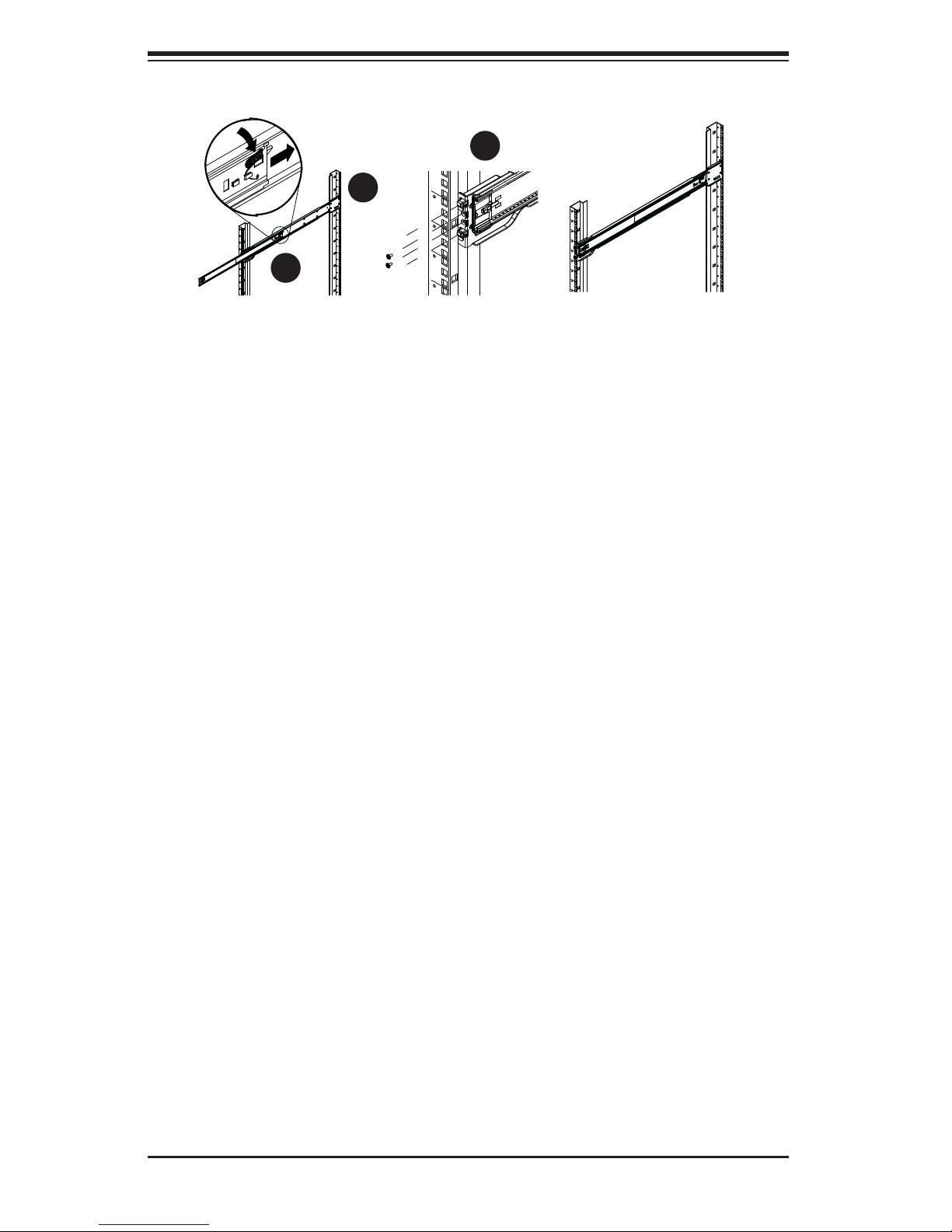

Figure 2-2. Assembling the Outer Rails

Outer Rack Rails

Outer rails attach to the rack and hold the chassis in place. The outer rails for the

SC825 chassis extend between 30 inches and 33 inches.

Installing the Outer Rails to the Rack

1. Secure the back end of the outer rail to the rack, using the screws provided.

2. Press the button where the two outer rails are joined to retract the smaller

outer rail.

3. Hang the hooks of the rails onto the rack holes and if desired, use screws to

secure the front of the outer rail onto the rack.

4. Repeat steps 1-3 for the remaining outer rail.

2-6

Chapter 2: Server Installation

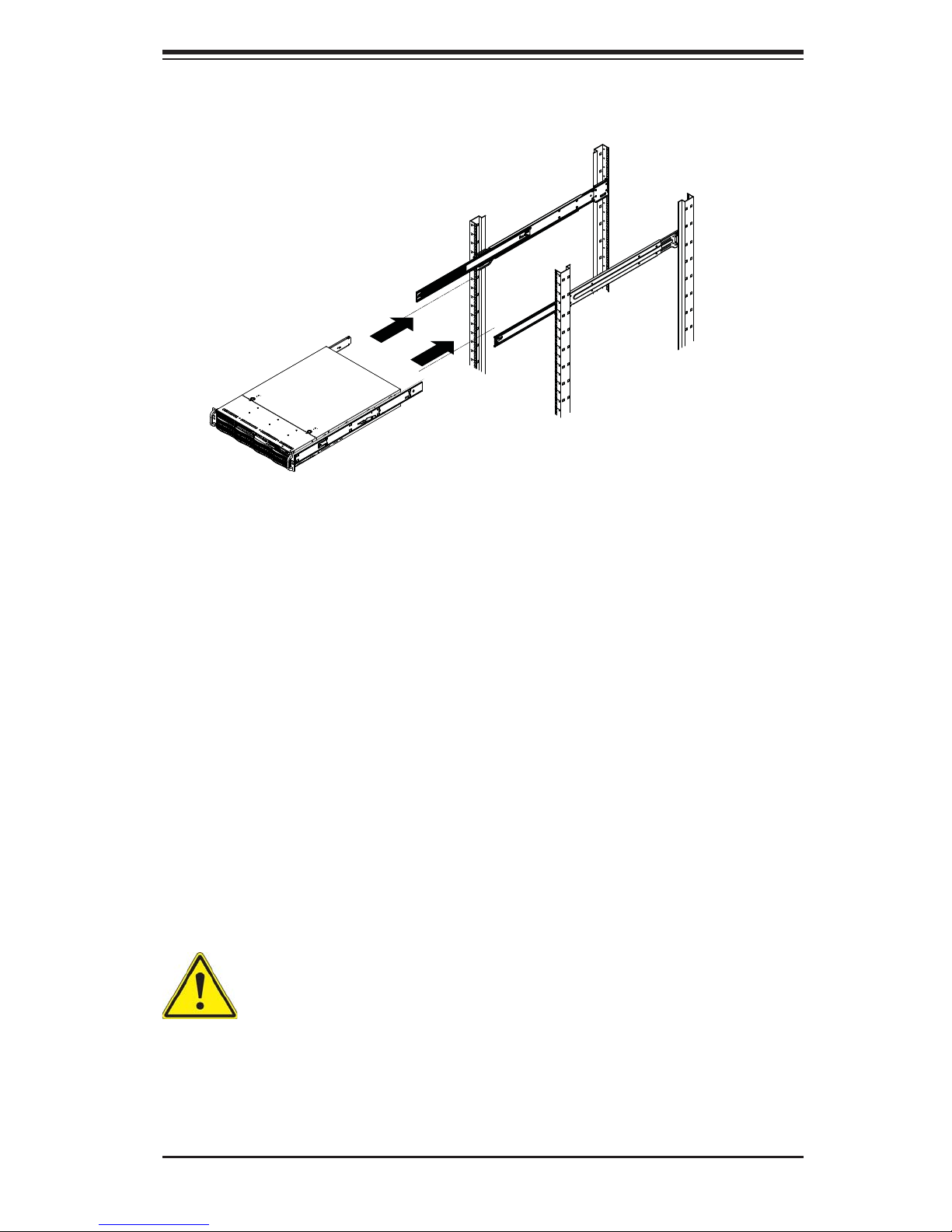

Figure 2-3. Installing the Rack Rails

Installing the Chassis into a Rack

1. Extend the outer rails as illustrated above.

2. Align the inner rails of the chassis with the outer rails on the rack.

3. Slide the inner rails into the outer rails, keeping the pressure even on both

sides. When the chassis has been pushed completely into the rack, it should

click into the locked position.

4. Optional screws may be used to secure the to hold the front of the chassis to

the rack.

Note that the fi gure above is for illustration purposes only. Always install servers to

the bottom of the rack fi rst.

Warning: do not pick up the server with the front handles. They are designed to pull the system from a rack only.

2-7

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

Notes

2-8

Chapter 3: System Interface

Chapter 3

System Interface

3-1 Overview

There are several LEDs on the control panel as well as others on the hard drive

carriers to keep you constantly informed of the overall status of the system as well

as the activity and health of specifi c components. There are also two buttons on

the chassis control panel and an on/off switch on the power supply. This chapter

explains the meanings of all LED indicators and the appropriate response you may

need to take.

3-2 Control Panel Buttons

There are two push-buttons located on the front of the chassis: a UID button and

a power on/off button.

Power button

The main power switch is used to apply or remove power from the power supply

to the server system. Turning off system power with this button removes the main

power but keeps standby power supplied to the system.

UID Button (Unit Identifi ed Button)

The main power switch is used to apply or remove power from the power supply

to the server system. Turning off system power with this button removes the main

power but keeps standby power supplied to the system.

3-1

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

3-3 Control Panel LEDs

The control panel located on the front of the SC829BTQ chassis has fi ve LEDs.

These LEDs provide you with critical information related to different parts of the

system. This section explains what each LED indicates when illuminated and any

corrective action you may need to take.

2

NIC2

Indicates network activity on LAN2 when fl ashing .

1

NIC1

Indicates network activity on LAN1 when fl ashing.

Informational LED

Continuously on and blue: UID function has been activated.

Flashing red: Fan failure.

Continuously on and red: Overheat condition. This may be caused by cables obstructing the airfl ow in the system or the ambient room temperature being too warm.

Check the routing of the cables and make sure all fans are present and operating

normally. You should also check to make sure that the chassis covers are installed.

Finally, verify that the heatsinks are installed properly. This LED will remain fl ashing

or on as long as the overheat or fan failure condition exists.

3-2

Chapter 3: System Interface

3-4 OLED Screen

A feature-rich, 1" color display screen using the latest OLED technology. OLED

displays are thinner and lighter than traditional LCD displays, providing better power

effi ciency and offering wider viewing angles with improved clarity. With four lines

of characters and 12 characters per line, the OLED screen module displays vivid

colors with 64 x 96 pixels and 16 bit color. More details are available on our web

site at

http://www.supermicro.com/lcd.

3-5 Drive Carrier LEDs

Blue: Each hard drive carrier has a green LED. When illuminated, this

green LED indicates drive activity. A connection to the backplane enables this

LED to blink on and off when that particular drive is being accessed. Please refer

to Chapter 6 for instructions on replacing failed hard drives.

Red: The red LED to indicate a hard drive failure. If one of the drives fail, you

should be notifi ed by your system management software. Please refer to Chapter

6 for instructions on replacing failed hard drives.

3-3

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

Notes

3-4

Chapter 4: Warning Statements for AC Systems

Chapter 4

Standardized Warning Statements for AC Systems

4-1 About Standardized Warning Statements

The following statements are industry standard warnings, provided to warn the user

of situations which have the potential for bodily injury. Should you have questions

or experience difficulty, contact Supermicro's Technical Support department

for assistance. Only certifi ed technicians should attempt to install or confi gure

components.

Read this appendix in its entirety before installing or confi guring components in the

Supermicro chassis.

These warnings may also be found on our web site at

about/policies/safety_information.cfm

.

http://www.supermicro.com/

Warning Defi nition

Warning!

This warning symbol means danger. You are in a situation that could cause bodily

injury. Before you work on any equipment, be aware of the hazards involved with

electrical circuitry and be familiar with standard practices for preventing accidents.

警告の定義

この警告サインは危険を意味します。

人身事故につながる可能性がありますので、いずれの機器でも動作させる前に、

電気回路に含まれる危険性に注意して、標準的な事故防止策に精通して下さい。

此警告符号代表危险。

您正处于可能受到严重伤害的工作环境中。在您使用设备开始工作之前,必须充分

意识到触电的危险,并熟练掌握防止事故发生的标准工作程序。请根据每项警告结

尾的声明号码找到此设备的安全性警告说明的翻译文本。

此警告符號代表危險。

您正處於可能身體可能會受損傷的工作環境中。在您使用任何設備之前,請注意觸

電的危險,並且要熟悉預防事故發生的標準工作程序。請依照每一注意事項後的號

碼找到相關的翻譯說明內容。

4-1

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

ןונקת תורהצהאהרהז

Warnung

WICHTIGE SICHERHEITSHINWEISE

Dieses Warnsymbol bedeutet Gefahr. Sie befi nden sich in einer Situation, die zu

Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit den

Gefahren elektrischer Schaltungen und den üblichen Verfahren zur Vorbeugung

vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung angegebenen

Anweisungsnummer nach der jeweiligen Übersetzung in den übersetzten

Sicherheitshinweisen, die zusammen mit diesem Gerät ausgeliefert wurden.

BEWAHREN SIE DIESE HINWEISE GUT AUF.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este símbolo de aviso indica peligro. Existe riesgo para su integridad física. Antes

de manipular cualquier equipo, considere los riesgos de la corriente eléctrica y

familiarícese con los procedimientos estándar de prevención de accidentes. Al

fi nal de cada advertencia encontrará el número que le ayudará a encontrar el texto

traducido en el apartado de traducciones que acompaña a este dispositivo.

GUARDE ESTAS INSTRUCCIONES.

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant entraîner des blessures ou des dommages corporels. Avant

de travailler sur un équipement, soyez conscient des dangers liés aux circuits

électriques et familiarisez-vous avec les procédures couramment utilisées pour

éviter les accidents. Pour prendre connaissance des traductions des avertissements

fi gurant dans les consignes de sécurité traduites qui accompagnent cet appareil,

référez-vous au numéro de l'instruction situé à la fi n de chaque avertissement.

CONSERVEZ CES INFORMATIONS.

ןה תואבה תורהצהא ינפמ שמתשמה תא ריהזהל תנמ לע ,היישעתה ינקת יפ לע תורהז הלבח

ה וא תולאש שיו הדימב .תירשפא תיזיפי ,יהשלכ היעבב תולקתרוציל שי הכימת תקלחמ םע רשק

רידגהל וא ןיקתהל םיאשר דבלב םיכמסומ םיאנכט .ורקימרפוס לש תינכט תאה .םיביכר

תרדגה וא תנקתה ינפל ואולמב חפסנה תא

אורקל שי .ורקימרפוס יזראמב םיביכרה

4-2

Warning Statements for AC Systems

. ﻲﻓ ﻚﻧﺍ ﻥﺃ ﻦﻜﻤﻳ ﺔﻟﺎﺣ ﻲﻓ ﺐﺒﺴﺘﺗ ﺔﺑﺎﺻﺍ ﺔﻳﺪﺴﺟ ﺰﻣﺮﻟﺍ ﺍﺬﻫ ﻲﻨﻌﻳ ﺮﻄﺧ !ﺮﻳﺬﺤﺗ

ﻥﺃ ﻞﺒﻗ ﻱﺃ ﻰﻠﻋ ﻞﻤﻌﺗ ﺕﺍﺪﻌﻣ،ﻛﻢﻠﻋ ﻰﻠﻋ ﻦ ﻦﻋ ﺔﻤﺟﺎﻨﻟﺍ ﺮﻁﺎﺨﻤﻟﺎﺑ ﺮﺋﺍﻭﺪﻟﺍ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ

ﻛﻭﺔﻳﺍﺭﺩ ﻰﻠﻋ ﻦ ﺭﺎﻤﻤﻟﺎﺑﺕﺎﺳ ﺔﻴﺋﺎﻗﻮﻟﺍ ﻟ ﻊﻨﻤﻉﻮﻗﻭ ﻱﺃﺙﺩﺍﻮﺣ

ﻢﻗﺭ ﻡﺪﺨﺘﺳﺍ ﻥﺎﻴﺒﻟﺍ ﺹﻮﺼﻨﻤﻟﺍ ﺔﻳﺎﻬﻧ ﻲﻓ ﺮﻳﺬﺤﺗ ﻞﻛ ﺭﻮﺜﻌﻠﻟ ﺎﻬﺘﻤﺟﺮﺗ

안전을 위한 주의사항

경고!

이 경고 기호는 위험이 있음을 알려 줍니다. 작업자의 신체에 부상을 야기 할 수

있는 상태에 있게 됩니다. 모든 장비에 대한 작업을 수행하기 전에 전기회로와

관련된 위험요소들을 확인하시고 사전에 사고를 방지할 수 있도록 표준

작업절차를 준수해 주시기 바랍니다.

해당 번역문을 찾기 위해 각 경고의 마지막 부분에 제공된 경고문 번호를

참조하십시오

BELANGRIJKE VEILIGHEIDSINSTRUCTIES

Dit waarschuwings symbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat werken,

dient u zich bewust te zijn van de bij een elektrische installatie betrokken risico's

en dient u op de hoogte te zijn van de standaard procedures om ongelukken te

voorkomen. Gebruik de nummers aan het eind van elke waarschuwing om deze te

herleiden naar de desbetreffende locatie.

BEWAAR DEZE INSTRUCTIES

4-3

SUPERSERVER 6027AX-72RF/TRF-HFT1/HFT2/HFT3 User's Manual

Installation Instructions

Warning!

Read the installation instructions before connecting the system to the power source.

設置手順書

システムを電源に接続する前に、設置手順書をお読み下さい。

警告

将此系统连接电源前,请先阅读安装说明。

警告

將系統與電源連接前,請先閱讀安裝說明。

Warnung

Vor dem Anschließen des Systems an die Stromquelle die Installationsanweisungen

lesen.

¡Advertencia!

Lea las instrucciones de instalación antes de conectar el sistema a la red de

alimentación.

Attention

Avant de brancher le système sur la source d'alimentation, consulter les directives

d'installation.

אורקל שי רוקמל תכרעמה רוביח ינפל הנקתה תוארוה תאחתמ.

ﻟﺍ ﺕﺍﺩﺎﺷﺭﺇ ﺮﻗﺍﺐﻴﻛﺮﺘ ﻞﻴﺻﻮﺗ ﻞﺒﻗ ﻰﻟﺇ ﻡﺎﻈﻨﻟﺍ ﺔﻗﺎﻄﻠﻟ ﺭﺪﺼﻣ

시스템을 전원에 연결하기 전에 설치 안내를 읽어주십시오.

Waarschuwing

Raadpleeg de installatie-instructies voordat u het systeem op de voedingsbron

aansluit.

4-4

Loading...

Loading...