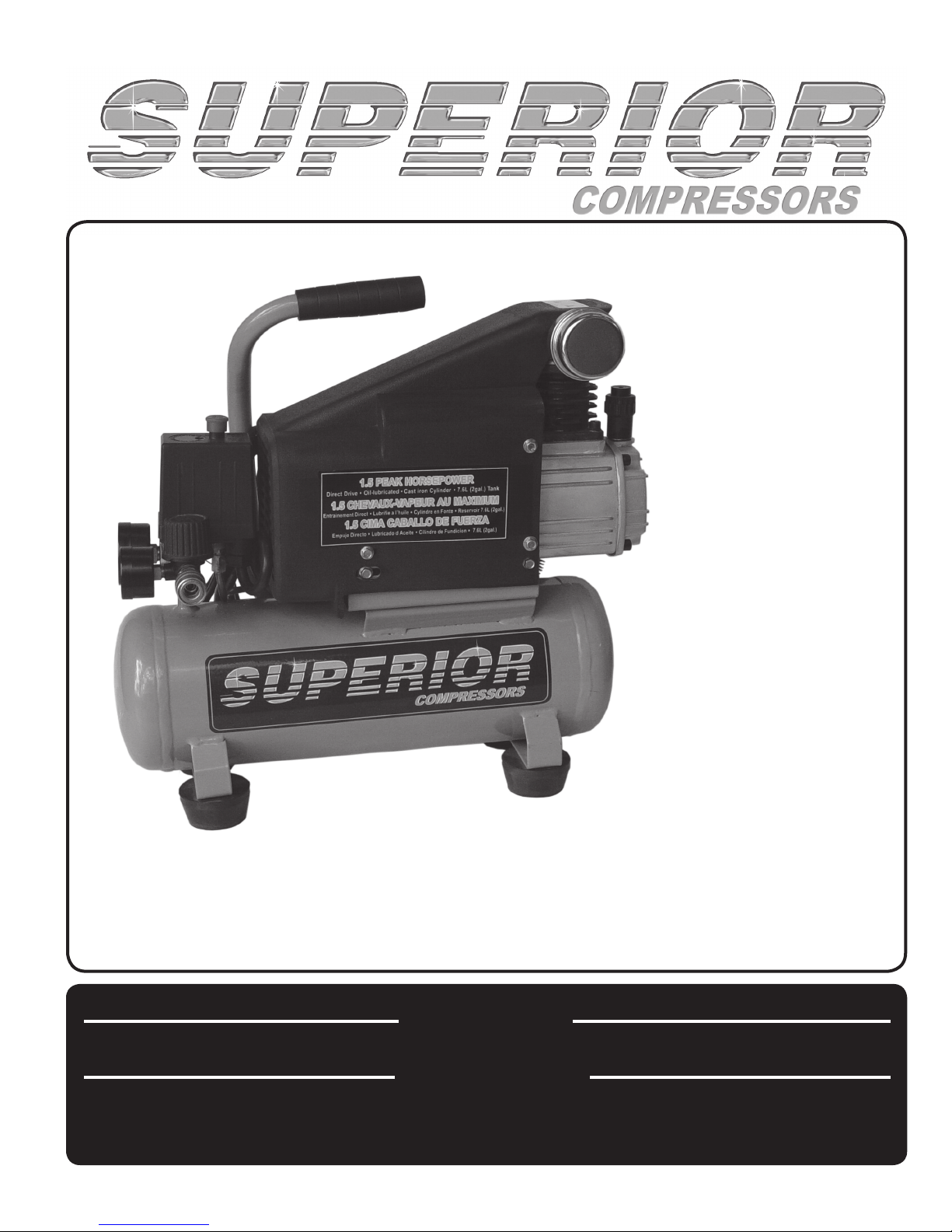

Superior SPT290 Operator's Manual

Model / Modèle : SPT290

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Vous aurez besoin de ce guide pour les instructions de sécurité, les procédures d’utilisation et la garantie.

Conservez-le dans un endroit sûr et sec pour référence future.

1-1/2 hp Air Compressor

Operator’s Manual (p.2)

Compresseur à air 1-1/2 CV

Manuel de l’opérateur (p.7)

SAVE THIS MANUAL

CONSERVEZ CE GUIDE

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electrical and pneumatic equipment such as this, basic

safety precautions should always be followed to reduce the risk of personal

injury. Please familiarize yourself with the following information to prevent

damage to your equipment and injury to the operator, property damage, or

death

READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT

We strongly recommend that this tool not be modied and /or used for any

application other than that for which it was designed. If you have any questions

relative to its application, do not use the equipment until you have consulted us and

ENGLISH

we have advised you.

1. KEEP WORK AREA CLEAR of obstructions and well ventilated. Cluttered

areas invite injury.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use electrical tools in damp

or wet locations. Don’t expose your tool to rain. Keep the work area well lit.

Don’t use tools in the presence of ammable gases or liquids. Atomized uids

like paints and solvents can be highly ammable. Do not spray them near this

equipment.

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extensions

cords. Visitors can be a distraction and are difcult to protect from injury.

4. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of reach

of children.

5. GUARD AGAINST ELECTRIC SHOCK. Do not use the compressor without

connection to a properly grounded outlet of the specied voltage and fuse

protection. Grounded tools must be plugged into an outlet that itself is prop-

FRANÇAIS

erly installed and grounded. Grounding provides a low-resistance path to

carry electricity to ground away from the operator, should the tool malfunction

electrically. Do not remove the grounding prong from the plug or alter the plug

in any way. If in doubt as to whether the outlet is properly grounded according to code, check with a qualied electrician. Extension cords must also be

equipped with grounded (three prong) plugs.

6. SAFETY GLASSES To prevent eye injuries, the operator and all persons in the

work area must wear approved safety glasses with permanently attached, rigid

side shields. Always wear safety glasses or goggles when spraying air. Do not

aim or spray air at people or animals. Severe skin damage can result.

7. STAY ALERT. Watch what you are doing & use common sense. Don’t operate

any tool when you are tired.

8. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across machines which are running.

9. DO NOT ABUSE THE CORD. Never pull on the cord to unplug it. Protect the

cord from potential sources of damage: heat, oil & solvents, sharp edges, or

moving parts. Replace damaged cords immediately.

10. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

ESPAÑOL

CORD. An extension cord rated for outdoor use must be marked “W-A” or “W”.

11. DO NOT EXPOSE ELECTRICAL EQUIPMENT TO MOISTURE. Rain or wet

conditions can cause water to enter the tool and lead to electric shock.

12. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

Recommended Minimum Wire Gauge for Extension Cords

Amps from Nameplate 25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use

!

13. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF position before plugging in.

2

IMPORTANT SAFETY INSTRUCTIONS

14. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING KEYS

OR WRENCHES before turning the tool on. Left attached, these parts can y

off a rotating part and result in personal injury.

15. DO NOT USE THE COMPRESSOR IF IT CANNOT BE SWITCHED ON OR

OFF. Have it repaired before using it.

16. DISCONNNECT THE PLUG FROM POWER BEFORE MAKING ANY ADJUSTMENTS. Changing attachments or accessories can be dangerous if the

tool could accidentally start.

COMPRESSED AIR CAUTIONS

1. COMPRESSED AIR FROM THIS UNIT MAY CONTAIN CARBON MONOXIDE. The air produced is neither suitable for breathing nor food processing

without ltering and testing to all applicable legal standards.

2. AIR ONLY: Use this compressor for compressing air only. Do not compress

other gases.

3. BREATHING PROTECTION: Always use a respirator when spraying paint or

chemicals.

4. MAINTAIN TOOLS WITH CARE.

ance. Follow instructions for lubricating and changing accessories. Keep dry,

clean and free from oil and grease.

5. NEVER USE THIS EQUIPMENT if it is leaking air; has missing or damaged

parts, guards, or shields; or requires repair. Make sure all screws and caps are

securely tightened.

6. DO NOT USE THE AIR HOSE to move the compressor. Release the pressure

in the storage tank before moving.

7. DO NOT ATTEMPT ANY MAINTENANCE OR ADJUSTMENT with the compressor in operation, the power connected, or air under pressure in the system.

8. CHECK FOR DAMAGED PARTS. Make frequent inspections for the correct

function of components and safety mechanism.

9. REPLACEMENT PARTS. When servicing, use only identical Superior replacement parts and fasteners recommended by us.

10. EMPLOYERS must enforce compliance with the safety warnings and all other

instructions in this manual. Keep it available for use by everyone assigned to

use this equipment.

Keep tools clean for better and safer perform-

ENGLISH

FRANÇAIS

SAFETY PRECAUTIONS SPECIFIC TO COMPRESSOR

1. TANK SAFETY VALVE: This valve prevents damage to the air receiver if a

malfunction in the compressor pump occurs. It is factory pre-set at a limit specic to your particular model and adjustment. Do not tamper with it. This will

automatically void your warranty.

2. PRESSURE SWITCH: The air pressure switch is factory pre-set for optimum

performance. Do not bypass or remove this switch. Serious damage to equipment or personal injury could result from too high an air pressure.

3. MOTOR AND COMPRESSOR PUMP: Air compressors get hot during operation. Do not touch the motor, discharge tubing, or compressor while it is run-

ning.

The compressor turns itself on automatically while the power is connected.

4. AIR TANK: Over-pressurizing the air receiver, piping or tank could cause

it to explode or burst. To protect from over-pressurizing, the compressor is

equipped with a factory preset safety valve. Do not remove, make adjustments

to or substitutions for this valve. Perform a test of the valve from time to time:

pull the ring on the valve to make sure that it operates freely. If the valve does

not operate freely, replace it before further use. Never weld to, drill into, or

change the air receiver in any way.

5. TAMPERING: If any of the components above are found to have been changed

or tampered with, the warranty will be made void. When servicing, we recom-

mend using only identical Superior replacement parts and any replacement

parts used must have the same specication as the original equipment.

ESPAÑOL

3

SPECIFICATIONS

Your 1-1/2 hp ‘Hotdog’ Air Compressor:

= Light weight: 22 lb / 10kg

= Oil lubricated for durability and long life.

= Extremely quiet operation

= Includes air line regulator & gauge- set your exact line pressure (may require

attachment to compressor)

= Oil breather cap (may require attachment to compressor)

= 115 volt, 60 hz, 10 amps

= 3400 rpm

= 2.5 cfm @ 90 psi

ENGLISH

= Maximum pressure: 115 psi

= Lubrication oil: SAE20 or SAE30 weight non-detergent oil

INSTALLATION AND OPERATING INSTRUCTIONS

Your new air compressor can be used for operating paint, weed killer, and

insecticide sprayers, air tools, grease & caulking guns, sandblasters, ination, etc.,

although you should compare the air demands of the tool against this compressor’s

2.5 c.f.m. output (at 90 psi). A tool with a higher air demand than this compressor

can produce may either not function, or not function well. It may also cause the

compressor to run without stopping for long periods of time, trying to maintain

pressure in the tank. This can cause the either the motor or compressor pump to

overheat and damage them. Be sure the requirements of your tools can be met by

the compressor.

To compress air, the piston in the pump moves up and down in the cylinder. On

the down stroke, air is drawn in through the inlet valve. Since the discharge valve

remains closed, as the piston goes up, the air in the cylinder is compressed. The

inlet valve closes and compressed air is forced out into the air receiver. A check

FRANÇAIS

valve prevents it from going back into the pump. Working air is not immediately

available. The pump continues to add air until the air receiver pressure builds to

above that required at the regulator.

INSTALLATION AND LOCATION

= Locate the compressor in a clean, dry and well-ventilated area, on a rm level

surface.

= It should be located 30 to 45cm / 12 to 18 inches from a wall or any other ob-

struction that would interfere with the air ow. It is equiped with heat dissipation

ns that allow for proper cooling. Keep them and other parts free of dust or dirt

that could interfere with cooling. A clean compressor runs cooler and provides

longer service.

= Do not place anything on top of the compressor.

= Do not use lead-tin solder to join pipes and ttings. It can melt at the tempera-

tures of the compressor’s air discharge and cause the piping to burst.

ESPAÑOL

EXTENSION CORDS

If you plan to use an extension cord when operating your air compressor, please

note:

= Maximum length: not to exceed 15m / 50 ft.

= Minimum wire size: 14 gauge.

If the extension cord is too long or the wire size is too small, the air compressor will

not start.

COMPRESSOR LUBRICATION

= CHECK THE OIL quantity and quality before operating the compressor. Do not

add or change oil while the compressor is in operation. Use only oil with the

correct specications. With the air compressor on level surface, the oil level

should be at the red dot on the oil level sight glass.

= If oil level is low, remove oil ll plug/breather cap, add enough oil to bring level

to the red dot. Do not over-ll.

4

Loading...

Loading...