Superior Sofia Instructions For Installation, Use And Maintenance Manual

INSTRUCTIONS FOR

INSTALLATION, USE AND

MAINTENANCE

Pellet Stove

SOFIA

The instruction manual is an integral part of the product.

SUPERIOR

®

English

2

SUPERIOR

®

Dear client,

We thank you for choosing one of our products, the result of technological expertise and continued research in pursuit of a superior

product in terms of safety, reliability and features.

In this manual you will find all the information and useful advice necessary to get the most out of your appliance in total safety.

DT2010001-01

See the guarantee certificate enclosed with the product for the terms, limitations and exclusions.

In line with its policy of constant product improvement and renewal, the manufacturer may make changes without notice.

This document is the property of Gruppo Piazzetta S.p.A.; no part of it may be disclosed to third parties without the written permission of Gruppo

Piazzetta S.p.A. All rights reserved by Gruppo Piazzetta S.p.A..

• This instruction booklet has been prepared by the manufacturer and is an integral part

of the product. In the event of sale or relocation of the product make sure this booklet

accompanies it, since the information contained in it is intended for the purchaser and

for anyone involved in the installation, use and maintenance of the product.

• Read the instructions and the technical information contained in this booklet carefully

before proceeding with installation, use or any repairs.

• The observance of the instructions and technical information in this instruction booklet

guarantees the safety of persons and property; it also ensures more efficient operation

and an increased lifespan.

• Gruppo Piazzetta S.p.A. cannot be held responsible for damage or injury due to failure

to comply with the instructions for installation, use and maintenance given in this

booklet, or due to unauthorised alterations or to the use of other than original spare

parts.

• Appliance installation and use must conform with the manufacturer’s instructions as

well as with European and national legislation and local regulations.

• Installation, electrical connection, checks, maintenance and repairs are operations

which must be carried out exclusively by qualified and authorised personal with

specialised knowledge of the product.

• The wall against which the product is to be placed must not be of wood or any other

flammable material. For correct installation it is also important to comply with the

section entitled “Safety distances”.

• Before installing the product read all instruction booklets relevant to the cladding, the

ventilation kit and any other accessory.

• Check that the floor where the product is to be installed is perfectly level.

• When handling the steel parts of the cladding it is advisable to use clean cotton gloves

to avoid leaving fingerprints that are difficult to remove at first time of cleaning.

• The stove must be assembled by at least two persons.

• Connect the pellet stove to the electricity supply only after it has been connected by

an expert to the flueway.

• The plug at the end of the power cable must be easily accessible after installation.

• Use only recommended wood pellets in the pellet stove (refer to section entitled “FUEL”).

• Never use liquid fuels to light the pellet stove or to relight the embers.

• Ensure that the area where the stove is installed is properly ventilated while the stove

is lit.

• In the event of malfunctioning the fuel supply will be stopped. Restart the stove only

after having eliminated the cause of the malfunction.

• Stop using the product in the event of fault or malfunctioning.

• Do not remove the protective grille from the pellet hopper.

• Any build-up of unused pellets in the burner left over from repeated failed ignitions

must be removed before attempting to light the stove again.

• Stove operation can result in surfaces, handles, flue pipe and glass becoming

extremely hot. When the stove is in operation, only touch these parts if wearing

protective clothing otherwise use suitable tools.

• Because of the build-up of heat on the glass, take care that those who are unfamiliar

with stove operation do not linger near the stove.

• This appliance must not be used by persons (including children) with reduced physical,

sensory or mental capacities, or lack of experience or knowledge unless they are

supervised or instructed on use of the appliance by the person who is responsible for

its safety.

• Creaking may be heard while the stove is in operation or cooling down. This is not to

be considered a defect, but is a consequence of thermal expansion of the component

materials.

• The product you have purchased may different slightly from the one illustrated in this

booklet since the pictures are only given as an indication and not an exact portrayal.

In the event of difficulties or if you are unable to understand the instruction

booklet, contact your local dealer.

Do not place objects which are not heat-resistant on top of the stove or

within the recommended minimum safety area.

Do not open the door while the stove is in operation or operate the stove

when the glass is broken.

EN 14785 Residential space heating appliances fired by wood pellets. Requirements and test methods

EN 832 Thermal performance of buildings - Calculation of energy use for heating - Residential buildings

UNI 10683 Heat generators fired by wood or other solid biofuels - Installation requirements

UNI 10847 Single flue systems for liquid and solid fuel generators - Maintenance and inspection - Guidelines

and procedures

UNI 7129 Gas installations for domestic use fired by mains gas supply. Design, installation and maintenance.

DIN 51731 class HP2 Fuels

ÖNORM M7135 Fuels

CEI EN 60335-1 Safety of household and similar electrical appliances.

Safety. Part 1: General requirements

CEI EN 50165÷1997 Electrical equipment of non-electric appliances for household and similar purposes – Safety

requirements

EN 1856-1 Chimneys - Requirements for metal chimneys - Part 1: System chimney products

EN 1856-2 Chimneys - Requirements for metal chimneys - Part 2: Metal liners and connecting flue pipes

EN 1443 Chimneys – General requirements

IMPORTANT INFORMATION

DT2010208-07

REFERENCE STANDARDS

DT2010209-05

H07022850 / DT2000426 - 00

English

3

SUPERIOR

®

This booklet code H07022850 / DT2000426 Rev. 00 (01/2009) comprises 40 pages.

CONTENTS

DT2010187-00

Section Title Page

1.0 GENERAL RULES 4

1.1 Single flueway or chimney 5

1.2 Soot inspection 5

1.3 Chimney stack 6

1.4 Fresh air intake 7

1.5 Installation environment 7

1.6 Capacity load of the floor 8

1.7 Heating capacity 8

1.8 Minimum safety distances 9

1.9 Flueway 9

1.10 Connecting to a conventional chimney 11

1.11 Using an external flue 12

1.12 Prevention of domestic fires 12

2.0 TECHNICAL CHARACTERISTICS AND SPECIFICATIONS 13

2.1 Features 13

2.2 Technical data 13

2.3 Product identification data 14

2.4 Dimensional diagram 14

2.5 Wiring diagram 15

3.0 FUEL 16

4.0 PREPARING FOR INSTALLATION 16

5.0 INSTALLATION 17

5.1 Electrical connection and the room sensor connection 17

5.2

Installing the external thermostat

17

6.0 USE 18

6.1 Control panel 18

6.2 Lighting for the first time 19

6.3 Startup and normal operation 19

6.4 Remote control 22

6.5 Timer 23

6.6 Safety devices 28

6.7 Opening the door 31

6.8 Disposal of ashes 31

7.0 MAINTENANCE 32

7.1 Cleaning the grate and the grate support 32

7.2 Cleaning the ash drawer 32

7.3 Cleaning the firebox 32

7.4 Cleaning the smoke chamber 33

7.5 Cleaning the flue system 33

7.6 Cleaning the ceramic cladding 33

7.7 Cleaning the enamelled metal parts 33

7.8 Cleaning the glass (DAILY) 34

7.9 Replacing the window 34

7.10 Replacing the remote control battery 34

7.11 Cleaning the fans 34

7.12 When not in use 34

7.13 Extraordinary maintenance 34

8.0 TROUBLESHOOTING 35

8.1 Replacing the fuses 38

Declaration of conformity Pellet Stove Sofia 39

H07022850 / DT2000426 - 00

English

4

SUPERIOR

®

DT2030321-00

Ensure that the installation of your product conforms to all the indications given below.

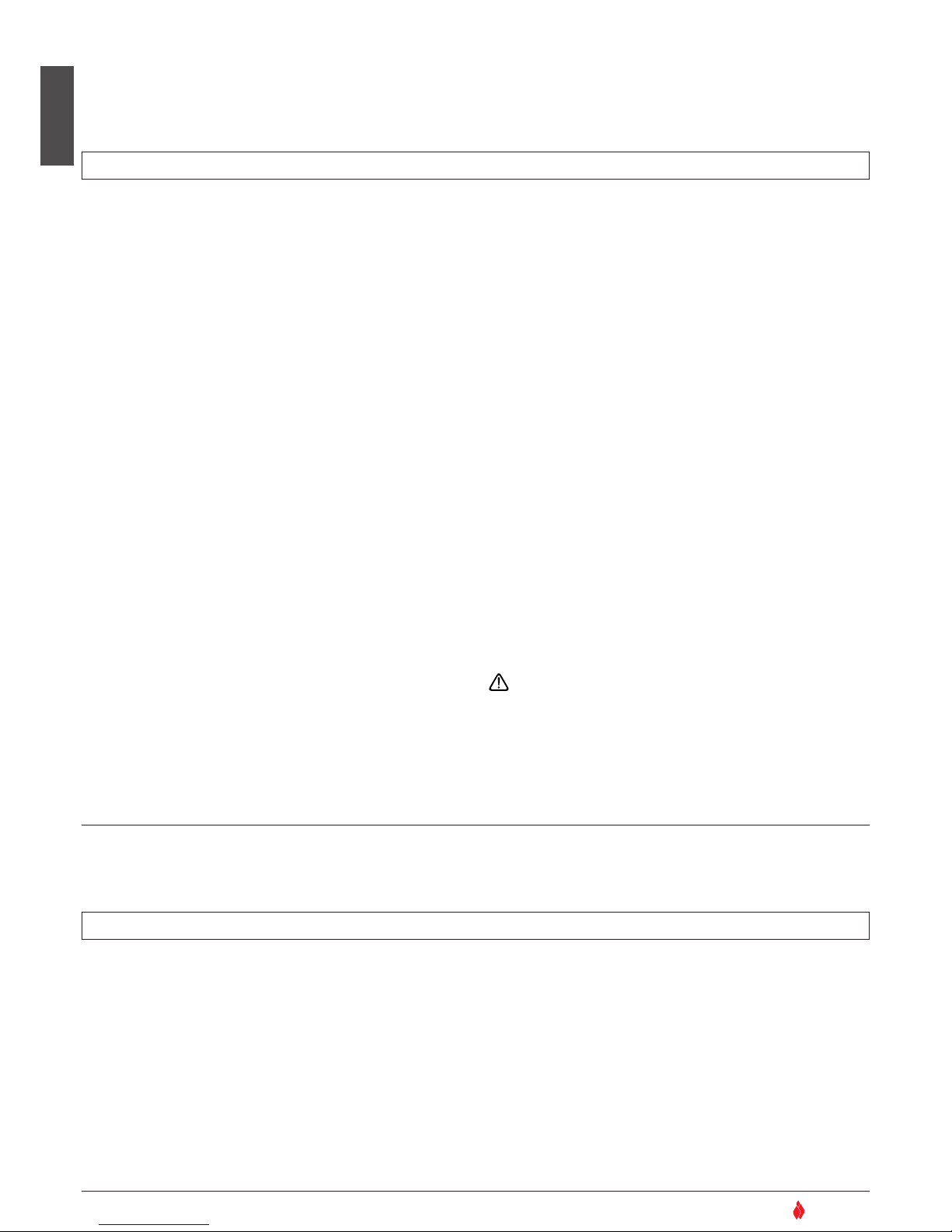

Fig. 1

CHIMNEY STACK

SINGLE FLUEWAY

OR CHIMNEY

CONNECTION TO FLUE

SOOT INSPECTION

APERTURE

FRESH AIR INTAKE

MINIMUM SAFETY DISTANCES

CAPACITY LOAD

OF THE FLOOR

END ELBOW WITH

INSPECTION WINDOW

1.0 GENERAL RULES

DT2010216-04

H07022850 / DT2000426 - 00

English

5

SUPERIOR

®

NO

X

Minimo 3,5 m

MAX 45°

NO

NO

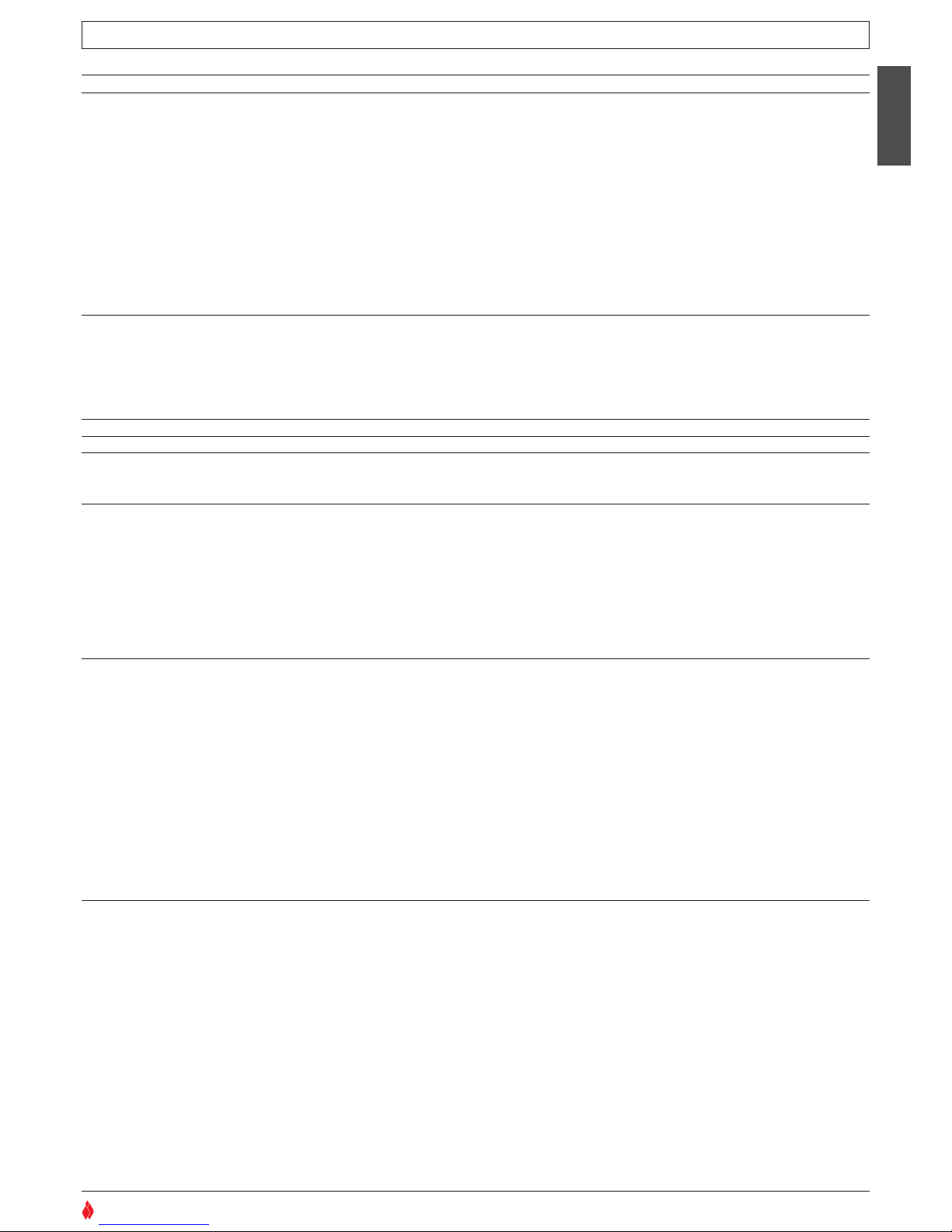

Every appliance must have a vertical flue pipe operating by natural

draught to discharge the combustion gases outdoors.

The flue must:

- comply with regulations in force in the place of installation of the

appliance;

- be tight to the products of combustion, waterproof, suitably insulated,

made with materials resistant to corrosion by the gases and to stress;

- be connected to just one stove, fireplace or extraction hood (Fig. 2);

- be properly sized, with constant free internal section, equal to or

greater than the diameter of the flue pipe of the stove and at least 3.5

m in length (Fig. 2);

- be mainly in a vertical position with a deflection from the axis of no

more than 45° (Fig. 2);

- be at a suitable distance from combustible or flammable materials,

ensured by an air gap or suitable insulating material;

- be of uniform internal section, preferably round. Square or

rectangular sections must have rounded corners with a radius of at

least 20mm and a maximum ratio between the sides of 1.5 (Fig. 3-4-

5). The walls must be smooth if possible and without narrowing.

Bends must be regular and without discontinuity (Fig. 6).

It is forbidden to make fixed or mobile apertures on the flue

pipe to connect appliances other than the one to which it is

already connected.

It is forbidden to pass other air ducts or service pipes inside

the flue pipe, however large it is.

If the flue pipe is an incorrect size or installed other than in

compliance with the above instructions, Gruppo Piazzetta

S.p.A. cannot be held liable for malfunctioning of the product,

damage to property or injury to persons or animals.

Ø

DT2030050-00

DT2030049-00

Fig. 3

P

R (min. 20)

L (≤ 1,5 x P)

Accumulo di Creosoto

DT2030189-00

Fig. 5

R (min. 20)

Accumulo di Creosoto

DT2030188-00

Fig. 4

Fig. 2

DT2030190-00

Fig. 6

3.5 M MINIMUM

Deposit of Creosote

Deposit of Creosote

1.1 SINGLE FLUEWAY OR CHIMNEY - Fig. 2 / 6

DT2010024-02

1.2 SOOT INSPECTION - Fig. 1

DT2010031-01

We recommend that the flue must have a chamber for collecting solid matter and any condensate located below the connection and which may

be easily inspected by means of an airtight door. (Fig.1)

H07022850 / DT2000426 - 00

English

6

SUPERIOR

®

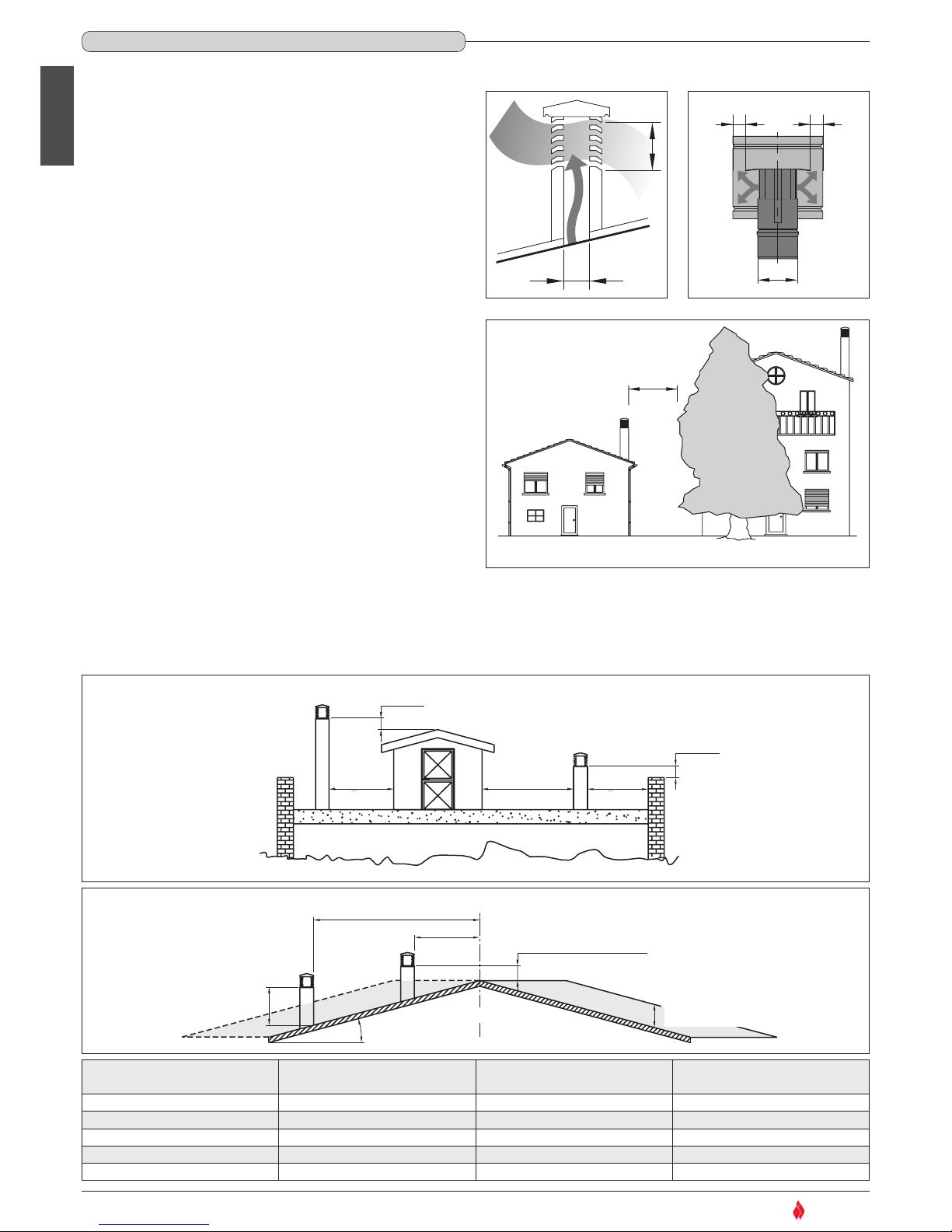

The chimney stack is a device fitted on the top of the chimney that is designed to

aid dispersion of the products of combustion in the atmosphere.

The chimney stack must comply with the following requirements:

- it must have an internal section and shape the same as the flue (A);

- it must have a useful outlet section (B) of not less than twice that of the flue (A);

- the part of the chimney that emerges from the roof or remains in contact with the

outside (e.g. in the case of a flat roof), must be covered with brick or tile elements

and in any case well insulated;

- It must be built in such a way as to prevent the penetration of rain, snow and

foreign matter into the flue and to ensure that in the event of winds from all

directions and angle, discharge of the combustion products is assured (chimney

stack with down-draught cowl).

Recommended distances for correct chimney operation.

To ensure trouble-free operation of the chimney and allow correct dilution of the

products of combustion in the air, the chimney stack must be installed at the

distances given below:

- 6 - 8 metres from any buildings or other obstacles that are higher than the

chimney stack;

- 50 centimetres higher than any obstacles located at a distance less than 5 metres;

- outside the reflux area. The size and shape of this area differ according to the angle

of inclination of the roof and it is therefore necessary to adopt the minimum

heights shown below.

Example: Check the slope of the roof (column

α

), and the anticipated distance of

the chimney stack from the axis of the ridge (column A); if the distance is greater

than “A” the height of the chimney stack may be read in (column H); if the distance

is less than “A” the chimney stack must rise above the ridge by 0.5 metres.

6-8 m

DT2030052-00

Fig. 9

TETTO PIANO

0.50 m

0.50 m

maggiore 5 m

pari o minore

5 m

pari o minore

5 m

DT2030053-00

Fig. 10

TETTO PIANO

TETTO INCLINATO

0.50 m

0.50 m

0.50 m oltre il colmo

altezza zona di

reflusso Z

asse colmo

distanza maggiore A

α

H min.

distanza

min. uguale A

maggiore 5 m

pari o minore

5 m

pari o minore

5 m

Fig. 11

A

B*

* B equivale al

doppio di A

DT2030051-00

Fig. 7

A

B

B

DT2030191-00

Fig. 8

DT2030192-00

* B it is twice

of to A

FLAT ROOF

5 m

or less

5 m

or less

over 5 m

SLOPING ROOF

distance more than A

distance

at least A

ridge axis

0.50 above the ridge

height of

reflux area Z

Pitch of the roof

Horizontal width of reflux

area from ridge axis

Minimum height of

outlet from roof

Height of reflux

area

αα

A H min Z

15° 1,85 m 1,00 m 0,50 m

30° 1,50 m 1,30 m 0,80 m

45° 1,30 m 2,00 m 1,50 m

60° 1,20 m 2,60 m 2,10 m

REFLUX AREA

1.3 CHIMNEY STACK - Fig. 7 / 11

DT2010025-03

H07022850 / DT2000426 - 00

English

7

SUPERIOR

®

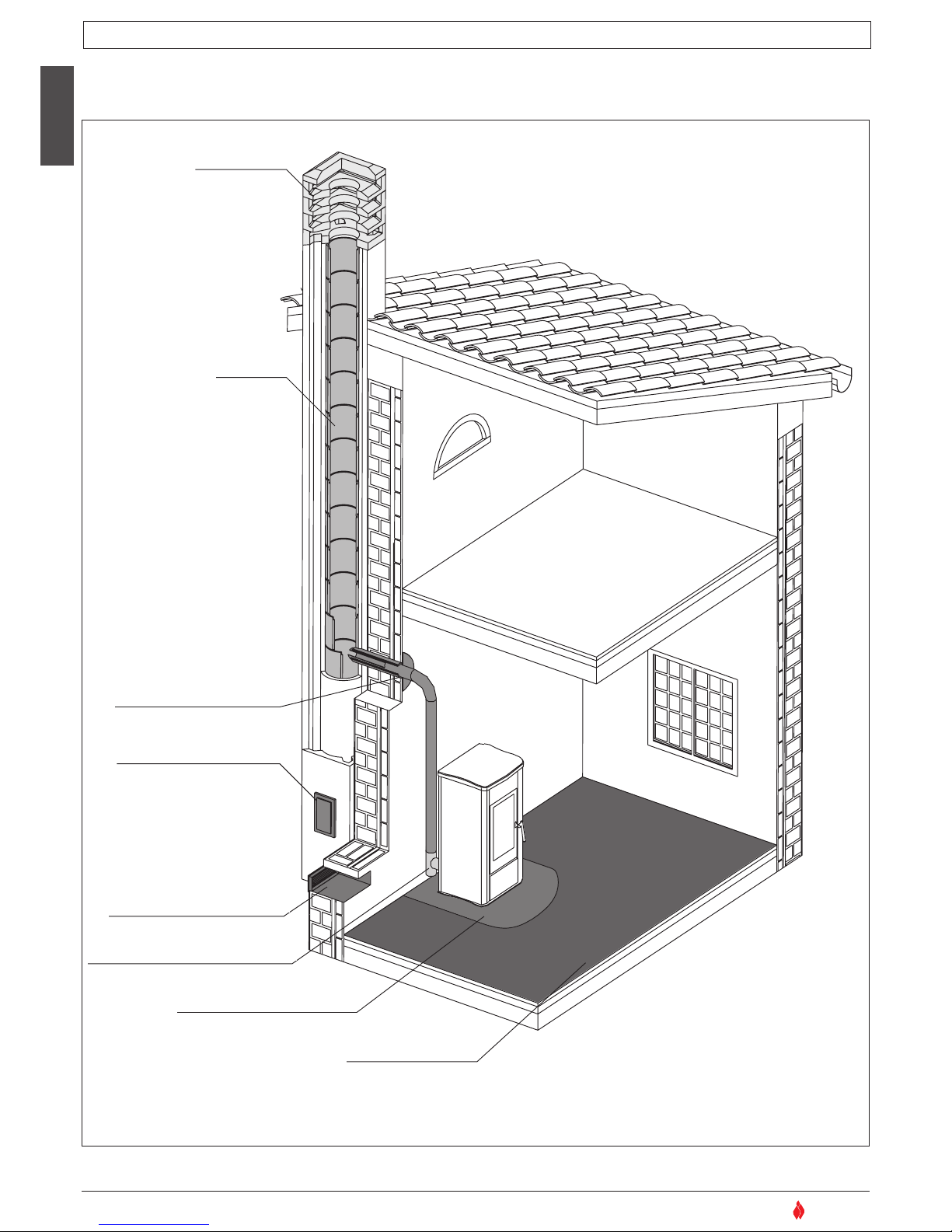

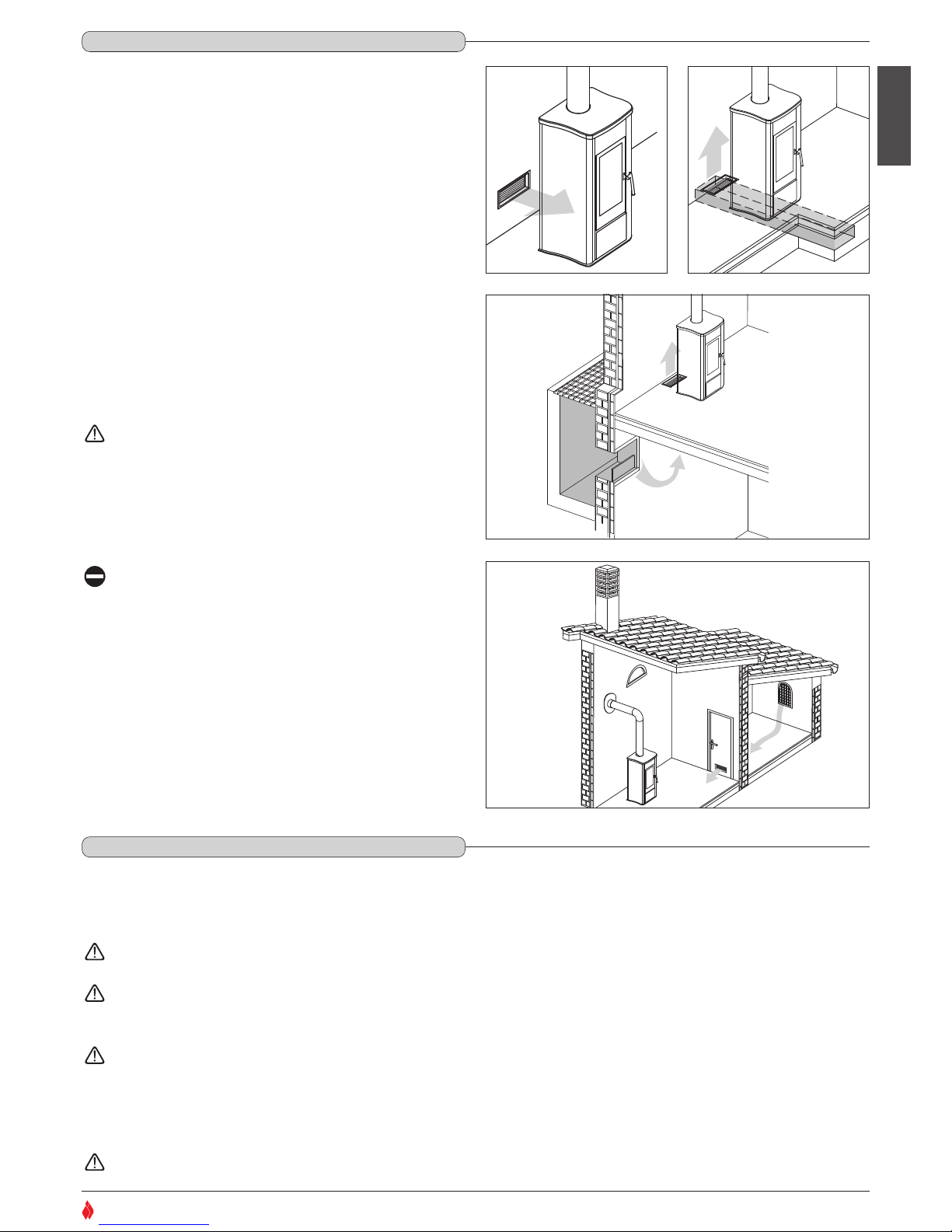

To ensure trouble-free operation the stove/fireplace must have the

necessary air available for combustion and this is provided through the

fresh air intake.

The fresh air intake must:

- have a total free cross section at least equal to the size given in the

paragraph “TECHNICAL DATA”;

- be protected by a grille or suitable guard provided it does not reduce

the minimum recommended section;

- be in a position whereby it cannot be obstructed.

The airflow necessary for the fire may be obtained in different ways:

- through a fresh air intake direct into the room of installation;

- with ducting through pipes direct to the room of installation, increasing

the recommended minimum free cross section by at least 15%;

- from an adjacent room to the place of installation provided this air flows

freely through permanent apertures communicating with the outside.

The adjacent room from which air is taken must not have a low

pressure compared to the exterior due to a counter draught

caused by the presence in that room of another appliance in

use or of a suction device.

The permanent apertures in the adjacent room must comply

with the requirements given above.

Combustion air must not be taken from adjacent rooms used

as a garage or a combustible materials store or for activities

posing a fire hazard.

DT2030054-00

Fig. 12

DT2030194-00

Fig. 14

DT2030195-00

Fig. 15

DT2030193-00

Fig. 13

1.4 FRESH AIR INTAKE - Fig. 12 / 15

DT2010539-03

1.5 INSTALLATION ENVIRONMENT

DT2010033-01

The appliance should be installed in a location which allows safe and convenient use as well as easy maintenance. If the product being installed

requires an electrical socket, the room must also be provided with an earthed power supply in accordance with current regulations.

The room where the appliance is to be installed must comply with the following requirements:

they must not be used as a garage, store for combustible material or for activities with a risk of fire.

They must not be in a vacuum in relation to the outside environment due to the effect of contrary draught caused by the presence in

the room where the fi replace is installed of another appliance or an extractor device.

Do not use two stoves, a fireplace and a stove, a stove and a wood-fired cooking range, etc. in the same environment, since the draught

of one could affect the draught of the other.

- Devices suitable for cooking food with relative hoods without an extractor fan may only be used in kitchens.

- Gas appliances of type C are allowed (refer to current legislation and regulations in the place of installation)

Gas appliances of type B are not allowed (refer to current legislation and regulations in the place of installation)

H07022850 / DT2000426 - 00

English

8

SUPERIOR

®

The stove or fireplace must not be used simultaneously with collective type ventilation ducts with or without extractor fan, other devices

or other appliances such as: forced ventilation systems or other heating systems using ventilation to change the air. Such systems could

cause a vacuum in the environment of installation even if installed in adjoining or communicating rooms.

The stove or fireplace must not be used: in stairwells except in buildings with no more than two apartments; in corridors for common

use; in bedrooms; in bathrooms or shower-rooms.

Check the load-bearing capacity of the floor, referring to the weight of the product given in the paragraph “TECHNICAL DATA”.

If the floor does not have a suitable load-bearing capacity, adequate countermeasures must be taken, for example, by using a sheet metal plate to

distribute the load.

Check the heating capacity of the appliance by comparing the rated power given in the paragraph “TECHNICAL DATA” with the power required by the

environment to be heated.

The energy requirement may be calculated approximately by multiplying the square metres of area by the height of the ceiling; the result is then

multiplied by a coefficient, which depends on the degree of insulation of the building, that is, on internal and external factors of the dwelling:

a) Internal factors: type of window and door frames, thickness of the insulation and walls, type of building materials, presence of stairwells, walls with

extensive glazing, high ceilings, position of the rooms to be heated in relation to other adjacent heated or unheated rooms, …

b) External factors: geographical position, average outdoor temperature, exposure, wind speed, latitude, altitude, …

Example of approximate calculation of the energy requirement to heat a fixed volume to 18/20° C:

The coefficient that is normally used is determined according to the real conditions as they occur case by case.

- From 0.04 to 0.05 kW per cubic metre in a well insulated environment

- From 0.05 to 0.06 kW per cubic metre in a poorly insulated environment.

3 rooms measuring 20m2 X (H ceiling) 2.7m = 162 m3 (volume)

In an environment with a good degree of insulation, an average value (coefficient) of 0.045 kW may be taken

162 (volume) X 0.045 (kW) = 7.3 kW necessary (6300 kcal/h)

Conversion 1kW = 860 kcal/h

Consult a heating technician or engineer for a correct check and calculation of the requirement of the environments to be heated (see

“REFERENCE STANDARDS”).

1.6 CAPACITY LOAD OF THE FLOOR

DT2010032-00

1.7 HEATING CAPACITY

DT2010130-01

H07022850 / DT2000426 - 00

English

9

SUPERIOR

®

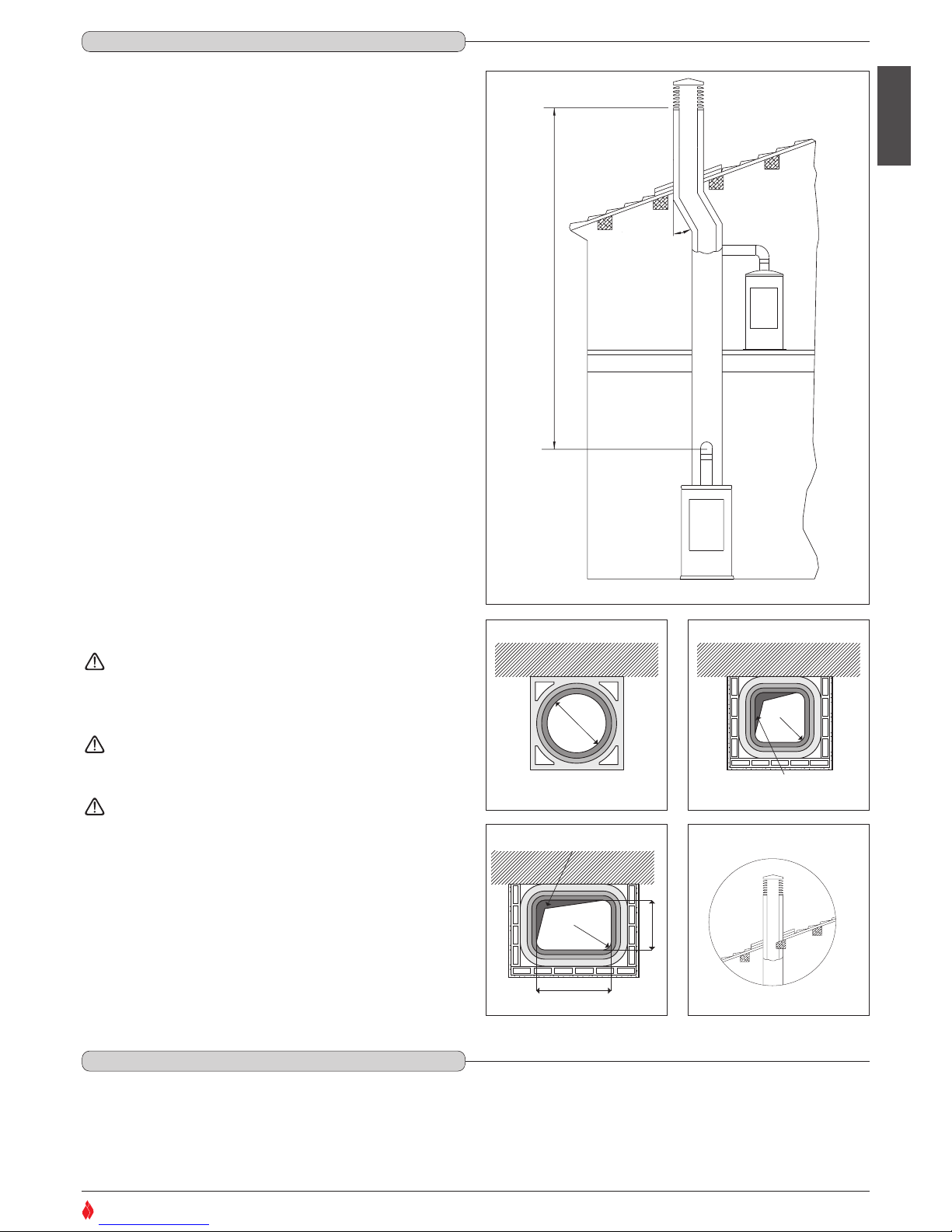

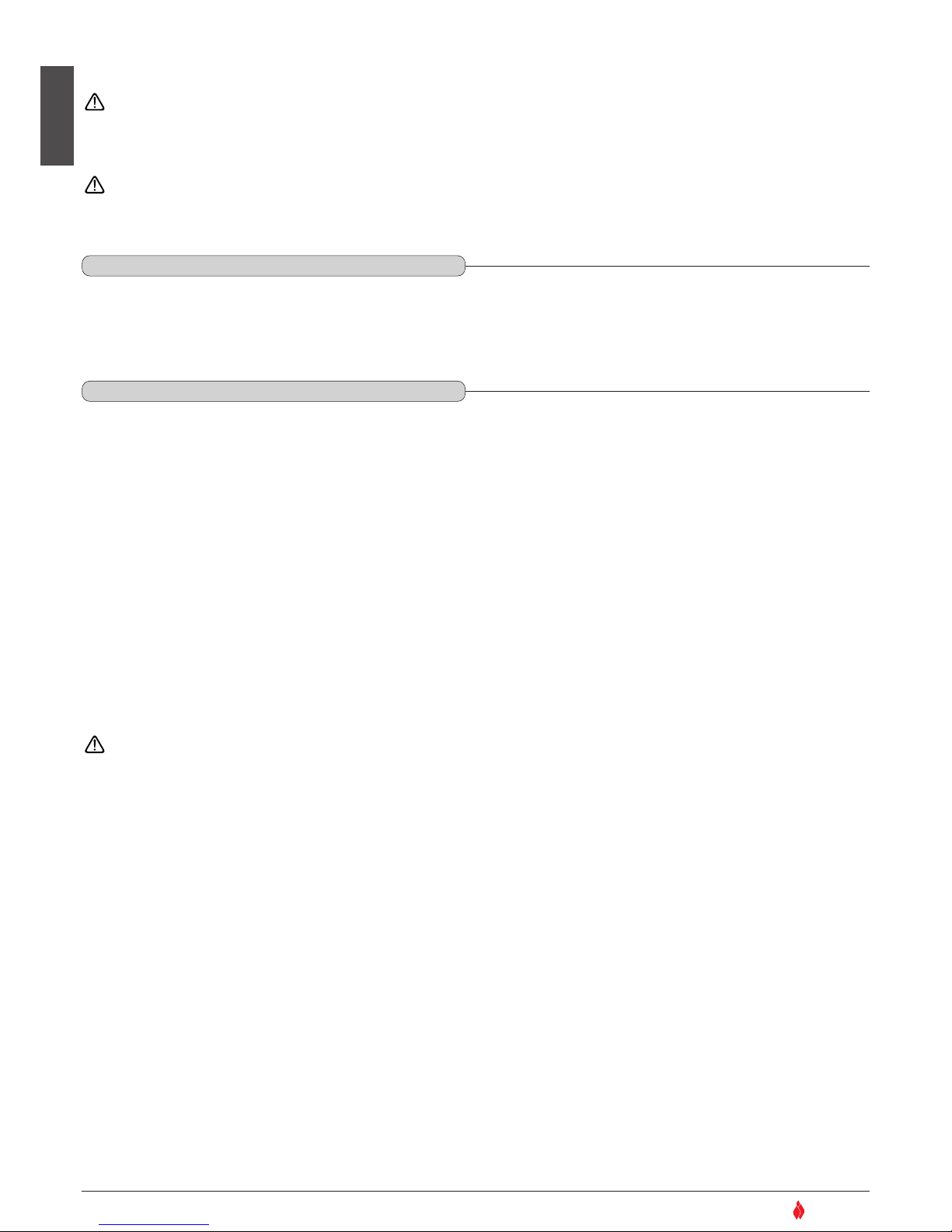

Install the product in compliance with the recommended safety

distances from heat sensitive or inflammable materials, from load

bearing and other walls and also from wooden elements, furniture, etc.

In the case of flooring that is heat sensitive or inflammable the floor must

be protected with non-combustible insulating material, e.g. sheets of

steel plate, marble, tiles, etc.

The minimum distances are:

Connection to the flue must respect the 40 cm minimum safety

distance from heat-sensitive structural components or inflammable

materials (wood panelling, beams or ceilings, etc).

Keep any combustible product such as wooden furniture,

curtains, carpets, combustible liquids, etc. well away from

the stove when it is lit (minimum distance 80 cm).

It is advisable to leave more than the recommended 20 cm

gap at the side of the stove to facilitate any maintenance on

the appliance.

The pellet stove is not the same as other stoves. It has a forced

draught of flue gas by a fan, which keeps the firebox in a vacuum

and the entire flueway slightly pressurised. For this reason the

flue must be completely airtight and correctly installed to ensure

both trouble-free operation and user safety.

- The flueway must be made by specialised personnel or firms, as outlined

below.

- The flue must be installed in such a way as to guarantee that periodic

cleaning can be carried out without dismantling any parts whatsoever.

- Pipes should always be sealed with silicone (not cement-based sealants)

or specially adapted gaskets/seals, which retain their strength and

elasticity at high temperatures (250°C), and should be fixed with 3.9 mm

ø self-tapping screws.

Do not install dampers or valves that could block the passage of

flue gas.

Do not connect to a flueway into which other appliances (boilers,

extractor hoods, etc.) discharge fumes or vapours.

MIN 40 cm

DT2030335-00

Fig. 17

MIN 40 cm

DT2030336-00

Fig. 18

Protezione pavimento

Zona radiante dell’apertura

del focolare

Parete posteriore

Parete laterale

Parete laterale

B B

A

D

C

STUFA

E E

DT2031515-00

Fig. 16

Rear wall

Side wall

Side wall

STOVE

Heat radiation area

Floor protection

A 20 cm from the wall behind the stove

B 20 cm from the side wall

C 80cm in the heat radiation area and from the hot air fan outlet

D 50 cm floor protection

E 30 cm (measured from the internal corner of the door opening)

1.8 MINIMUM SAFETY DISTANCES - Fig. 16 / 18

DT2010536-02

1.9 FLUEWAY - Fig. 19 - 20

DT2010229-04

H07022850 / DT2000426 - 00

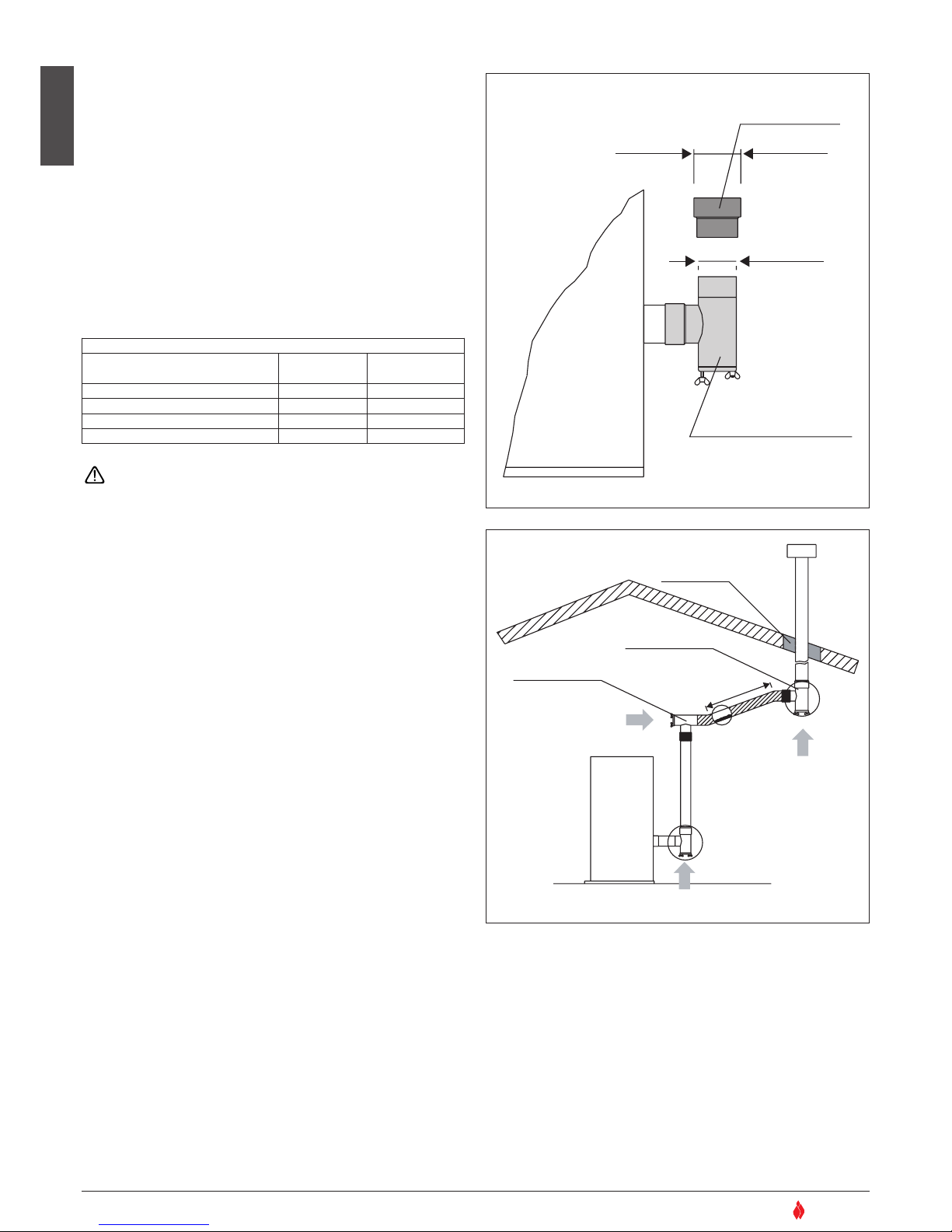

Pipes and maximum usable lengths

Pipes of painted aluminium-clad steel (minimum thickness

1.5mm), stainless steel (AISI 316) or enamelled steel (minimum

thickness 0.5mm) with a nominal diameter of 80 or 100 mm (for

pipes which run inside the flue maximum diameter 150 mm) can be

used.

The male-female connectors must have a minimum length of 50

mm.

The diameter of the pipes depends on the type of installation. The

stove was designed to take 80 mm diameter pipes but, as shown

in Table 1, in some cases the use of double-lined 100 mm diameter

pipes is recommended.

Losses in pressure associated with a 90° bend can be

compared to those incurred by one metre of pipe. An

inspectable union-tee can be considered equivalent to a 90°

bend.

EXAMPLE: : if installing a section greater than 4.5m in length with

80mm diameter pipe, calculate the maximum usable length in the

following ways:

- If a maximum of three 90° bends are used, the maximum length of

the section will be 4.5m

- If a maximum of two 90° bends are used and bearing in mind that a

90° bend can be replaced by one metre of pipe, the maximum length

of the section will be 4.5m+1m=5.5m

- If a maximum of one 90° bend is used and bearing in mind that a 90°

bend can be replaced by one metre of pipe, the maximum length of

the section will be 4.5m+1m+1m=6.5m

Where 100mm diameter pipe must be used, connect it to the stove

flue outlet with a 80mm union-tee then use a 80mm 100mm adaptor

(not supplied by Superior) (Fig. 19).

Union-tee

The use of this type of fitting must allow for the collection of

condensate mixed with soot, which builds up inside the pipe. It must

also permit periodic cleaning of the flue without the need to

disassemble the pipes.

This type of fitting can be bought at Superior retail outlets together

with the pipes.

An example is given below of a flueway connection, which allows

complete cleaning without having to disassemble the pipes (Fig 20).

English

10

SUPERIOR

®

TABLE 1 – LENGHT PIPES

TYPE OF INSTALLATION

WITH 80mm Ø PIPE

WITH DOUBLE-WALLED

100mm Ø PIPE

Maximum length (with three 90° bends) 4.5 m 8 m

For installations more than 1200m above sea level

- Required

Maximum number of bends 3 4

Length of horizontal sections with minimum 3% gradient

2 m 2 m

RACCORDO A T CON TAPPO

A CHIUSURA ERMETICA

RACCORDO

ø 80 > ø 100

ø 80mm

ø 100mm

DT2030337-00

Fig. 19

ISOLANTE

RACCORDO A T

RACCORDO A T

DIREZIONE

DI PULIZIA

DIREZIONE DI PULIZIA

Max 2m

(min. 3%)

DIREZIONE DI PULIZIA

DT2030338-00

Fig. 20

Straight reducer

ø 80 > ø 100

Tee with sealing plug

Insulating material

Tee

Tee

Direction of

cleaning

Direction of cleaning

Direction of cleaning

H07022850 / DT2000426 - 00

English

11

SUPERIOR

®

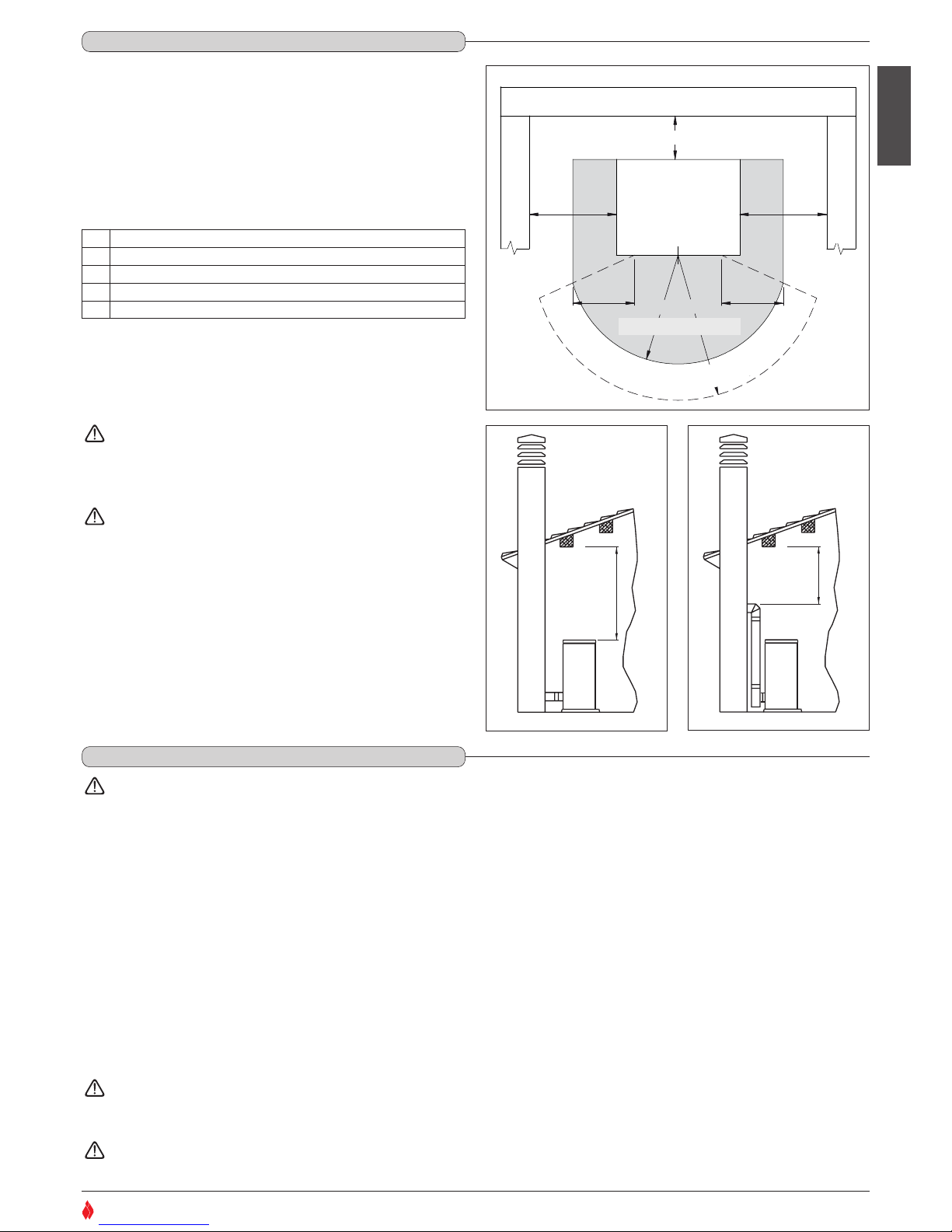

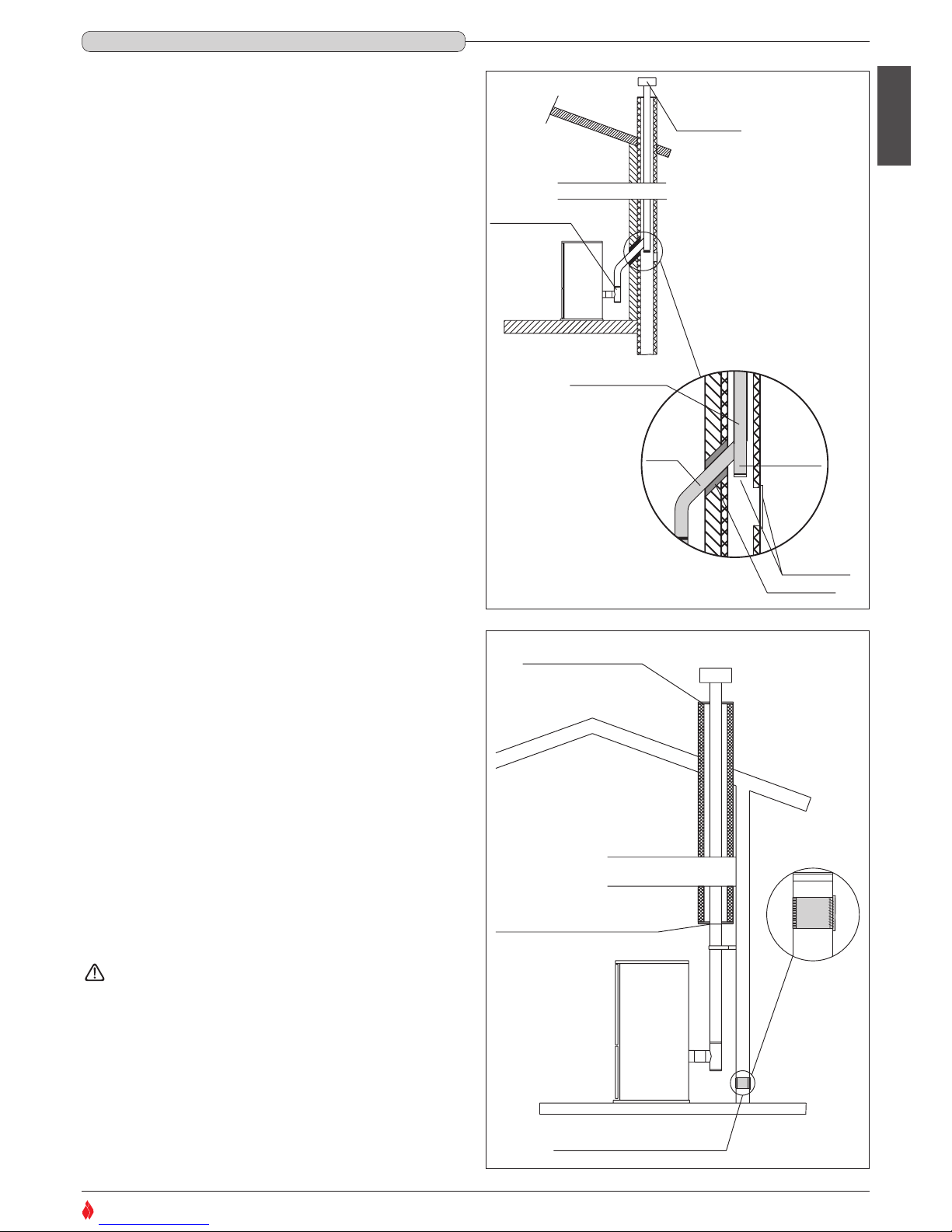

If you wish to use an existing chimney it is strongly recommended that

you have it checked by a professional chimneysweep to ensure that it

is completely airtight. The reason for this is that the smoke, because it

is slightly pressurised, can infiltrate any cracks in the flue and escape

into living spaces. If upon inspection you find that the chimney is not

completely sound, it is recommended that you insert piping made of

new material. If the existing chimney is wide enough we recommend a

pipe with a maximum diameter of 150mm. It is also recommended that

you insulate the chimney flue (Fig. 21-22).

Pipes and bends made by Gruppo Piazzetta S.p.A. are recommended

for connection to the flueway, since they are sized to fit the flue outlet

of the appliance.

Other pipes may be applied after adaptation and checking of the

compatibility of the coupling, taking into account that the pipes and

bends must be made in compliance with current regulations. In this

case, however, Gruppo Piazzetta S.p.A. only guarantees trouble-free

operation for parts that it manufactures and that are used according to

specifications.

Connection to the flue must respect the 40cm minimum safety

distance from heat-sensitive structural components or inflammable

materials (wood panelling, beams or ceilings, etc). (See figures 17-18).

- If the connector has to pass through partitions or walls of inflammable

or heat-sensitive materials, or through load-bearing walls, create:

an insulating barrier equal to or greater than 10cm around the

connector using mineral-based insulating material (rock wool,

ceramic fibre) with a nominal density greater than 80kg/m3.

- If the connector has to pass through non-flammable partitions or

walls, create:

an insulating barrier equal to or greater than 5cm around the

connector using mineral-based insulating material (rock wool,

ceramic fibre) with a nominal density greater than 80kg/m3.

- Check that the connection to the flueway is gas/smoke-tight, since

the appliance operates in a vacuum.

- Check that the pipe does not penetrate too far into the flueway,

thereby choking the pipe for the passage of smoke and combustion

gases.

Ensure that all installation work is carried out to professional

standards.

COMIGNOLO

RACCORDO A T

CON CANNA FUMARIA

NON INTEGRA

INSERIMENTO DI

UN TUBO

SPORTELLI PER

ISPEZIONE

ISOLANTE

Max ø150 mm

ø 80 mm

DT2030339-01

Fig. 21

FLANGIA DI CHIUSURA

FLANGIA DI CHIUSURA ERMETICA

IN ACCIAIO INOX O ALLUMINATO

PRESA D'ARIA ESTERNA

CON GRIGLIA NON RICHIUDIBILE

DT2030340-00

Fig. 22

Insulating material

Tee

Chimney stack

Pipe insertion

With damaged flue

Inspection

windows

Closing flange

Sealing flange in stainless

steel or aluminium

Fresh air intake with

non-closable grille

1.10 CONNECTING TO A CONVENTIONAL CHIMNEY - Fig.21 - 22

DT2010230-02

H07022850 / DT2000426 - 00

English

12

SUPERIOR

®

PRESA D'ARIA ESTERNA CON

GRIGLIA NON RICHIUDIBILE

d

DT2030341-00

Fig. 23

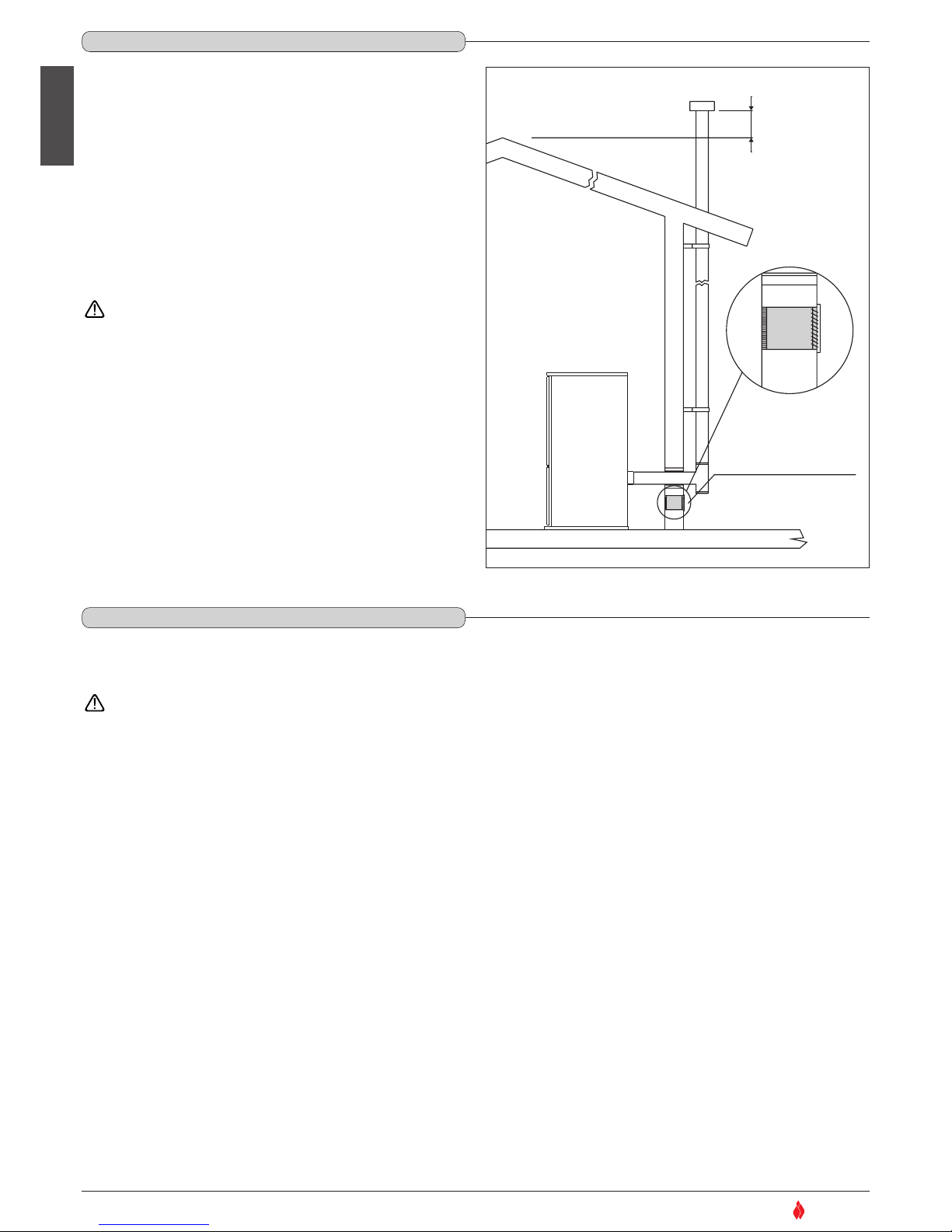

An external flue can be used provided it complies with the following

requirements:

- use only insulated stainless steel pipes (double-lined) fixed to the

outside wall of the building (Fig. 23);

- there must be an inspection opening at the base of the flue to permit

periodic checks and maintenance;

- the flue must be fitted at the top with a chimney stack with downdraught cowl, also ensuring compliance with the safety distance from

the roof ridge as outlined in the section entitled “GENERAL RULES”,

under “CHIMNEY STACK”.

Ensure that all installation work is carried out to professional

standards.

Fresh air intake with

non-closable grille

1.11 USING AN EXTERNAL FLUE - Fig. 23

DT2010232-02

1.12 PREVENTION OF DOMESTIC FIRES

DT2010027-02

The product must be installed and used in compliance with the manufacturer’s instructions and European and national standards as well as local

regulations.

When a flue pipe passes through a wall or a ceiling, special installation methods must be applied (protection, thermal insulation,

distances from heat-sensitive materials, etc.) See the paragraph “FLUEWAY”

- It is also recommended that all elements made of combustible or inflammable material, such as beams, wooden furniture, curtaining, flammable

liquids, etc. be kept outside the heat radiation range of the stove and in any case at a distance of at least 80 cm from the heating block.

- For other information, see the paragraph “MINIMUM SAFETY DISTANCES” and “CONNECTION TO A CONVENTIONAL CHIMNEY”.

- The flue pipe, chimney stack, chimney and fresh air intake must always be free of obstructions, clean and checked periodically, that is, at least

twice during the seasonal period from the lighting of the stove and during its use. When the stove has not been used for some time it is advisable

to carry out the checks mentioned above. For further information, consult a chimneysweep.

- Only use recommended fuels (See section “FUEL”).

H07022850 / DT2000426 - 00

Loading...

Loading...