Superior SLBV-40NE, SLBV-35NE, SLBV-35NM, SLBV-35PM, SLBV-40PM User Manual

...

P/N 506009-02 Rev. B 06/2011

AVERTISSEMENT : Assurez-vous de bien suivre les

instructions données dans cette notice pour réduire au

minimum le risque d’incindie ou d’explosion ou pour

éviter tout dommage matériel, toute blessure ou la mort.

WARNING: If the information in these instructions

is not followed exactly, a fire or explosion may

result, causing property damage, personal injury,

or death.

WARNING /AVERTISSEMENT/AVISO

• HOT GLASS WILL CAUSE

BURNS.

• DO NOT TOUCH GLASS

UNTIL COOLED.

• NEVER ALLOW CHILDREN

TO TOUCH GLASS.

• UNE SURFACE VITRÉE CHAUDE

PEUT CAUSER DES BRÛLURES.

• LAISSER REFROIDIR LA SURFACE

VITRÉE AVANT D'Y TOUCHER.

• NE PERMETTEZ JAMAIS À UN ENFANT

DE TOUCHER LA SURFACE VITRÉE.

• EL VIDRIO CALIENTE

CAUSARÁ QUEMADURAS.

• USTED DEBE NUNCA

TOCAR EL VIDRIO CALIENTE.

• LOS NIÑOS DEBEN NUNCA

TOCAR EL VIDRIO.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

- Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

- Ne pas entreposer ni utilizer d’essence ni d’autres vapeurs

ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ :

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous servir des

téléphones se trouvant dans le bâtiment où vous trouvez.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service des incindies.

- L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifié ou par le

fournisseur de gaz.

This manual is one of a set of two supporting this product.

Refer to P/N 506010-02 for Care and Operation Instructions.

Ce manuel est disponible en francais, simplement

en faire la demande. Numéro de la pièce 506223-19.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

INSTALLATEUR : Laissez cette notice avec l'appareil.

CONSOMMATEUR : Conservez cette notice pour

consultation ultérieure.

INSTALLATION INSTRUCTIONS

B-Vent Gas Fireplaces

SLBV 35/40 Models

MODELS

SLBV-35NM

SLBV-35PM

ITS Report No. 100017854

Please read and understand these instructions

MILLIVOLT:

SLBV-40NM

SLBV-40PM

BEFORE starting installation.

ELECTRONIC:

SLBV-35NE

SLBV-40NE

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Packaging .........................................Page 2

Introduction ......................................Page 2

General Information ..........................Page 2

Gas Pressure Requirements ..............Page 4

Orifice Sizes ......................................Page 4

Gas Valve Diagrams ..........................Page 4

Requirements for the Commonwealth

of Massachusetts .......................Page 4

New York City Approval .....................Page 4

Cold Climate Insulation .....................Page 5

Location ............................................ Page 5

Vent Termination Clearances:

Multiple Terminations.....................Page 6

Gas Vent Rule ................................Page 6

Minimum Clearances to Combustibles:

Appliance and Vent Clearances ......Page 7

Hearth Extension ............................Page 7

Wall Finishes / Surrounds /

Mantels .......................................Page 7

Pre-Installation Steps (Remove

Glass Enclosure Panel) ...............Page 8

Typical Installation Sequence ............Page 8

Detailed Installation Steps:

Step 1. Construct Appliance

Framing ............................Page 8

Fireplace and Framing

Specifications ...................Page 9

Step 2. Route the Gas Line ..............Page 11

Step 3. Install Venting System and

Exterior Termination .........Page 11

Step 4. Install Field Wiring ..............Page 12

Wiring Diagrams .................Page 13

Step 5. [Optional] Install Outside

Combustion Air Kit ............Page 14

Installation Accessories ......Page 14

Step 6. Connect the Gas Line ..........Page 15

Step 7. Verify Appliance

Operation .........................Page 16

Step 8. Install Volcanic Stone, Glowing

Embers, and Logs ........... Page 17

SLBV-35 Log Placement .....Page 18

SLBV-40 Log Placement .....Page 19

Step 9. Install the Glass Enslosure

Panel ...............................Page 20

Step 10. Burner Air Shutter

Adjustments .....................Page 20

Step 11. Perform Spillage Test ..........Page 22

Manually-Reset Safety Limit

Switch ..............................Page 22

Step 12. Install Hood .........................Page 23

Step 13. Finishing Requirements ......Page 23

Step 14.

Warnings ...................................... Page 24

Gas Conversion Kits .........................Page 25

2

Attach Safety-in-Operation

PACKAGING

The assembled vented gas replace is packaged

with the following items:

1 - One log set located in rebox area.

2 - One envelope containing the literature

package which consists of the care and

operations manual, installation instructions, safety-in-operation warning labels

and warranty; envelope is located in the

control compartment.

3 - One hood located behind the glass enclo-

sure panel assembly.

4 - One bag of decorative volcanic stone located

in the lower control compartment.

5 - One bag of glowing embers located in the

lower control compartment.

INTRODUCTION

The Millivolt appliances have a millivolt gas

control valve with piezo ignition system.

The Electronic appliances have a battery

backed-up electronic intermittent pilot ignition

system. No external electrical power is required

to operate these appliances; however, 120V

AC is recommended (see Step 4, “Install Field

Wiring,” on Page 12).

Use Only These Approved Vent Components:

These vented gas fireplaces are designed for

residential applications. They must be installed

with approved Type-B double-wall vent pipe

systems and a listed vent termination routed

to the outside atmosphere. Use only the proper

size listed below.

• 4" B-Vent for 35" models and 5" B-Vent for

40" models.

GENERAL INFORMATION

WARNING

B-Vent appliances are

not designed to operate

in negatively pressured

environments (pressure within

the home is less than pressures

outside). Significant negatively

pressured environments caused

by weather, home design, or

other devices may impact the

operation of these appliances.

Negative pressures may result

in poor flame appearance,

sooting, damage to property

and/or severe personal

injury. Do not operate these

appliances in negatively

pressured environments.

WARNING

Young children should be carefully supervised when they are

in the same room as the appliance. Toddlers, young children

and others may be susceptible

to accidental contact burns.

A physical barrier is recommended if there are at risk

individuals in the house. To

restrict access to a fireplace

or stove, install an adjustable

safety gate to keep toddlers,

young children and other at

risk individuals out of the room

and away from hot surfaces.

AVERTISSEMENT

Les jeunes enfants devraient être

surveillés étroitement lorsqu’ils

se trouvent dans la même pièce

que l’appareil. Les tout petits,

les jeunes enfants ou les adultes

peuvent subir des brûlures s’ils

viennent en contact avec la surface chaude. Il est recommandé

d’installer une barrière physique

si des personnes à risques habitent la maison. Pour empêcher

l’accès à un foyer ou à un poêle,

installez une barrière de sécurité; cette mesure empêchera les

tout petits, les jeunes enfants et

toute autre personne à risque

d’avoir accès à la pièce et aux

surfaces chaudes.

Children and adults should be alerted to

the hazards of high surface temperature

and should stay away to avoid burns or

clothing ignition.

Les enfants et les adultes devraient

être infor-més des dangers que posent

les températures de surface élevées

et se tenir à distance afin d’éviter des

brûlures ou que leurs vêtements ne

s’enflamment.

DO NOT ATTEMPT TO ALTER OR

MODIFY THE CONSTRUCTION OF THE

APPLIANCE OR ITS COMPONENTS. ANY

MODIFICATION OR ALTERATION MAY

VOID THE WARRANTY, CERTIFICATION,

AND LISTINGS OF THIS UNIT.

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

(continued)

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury

or property damage. Refer to

this manual. For assistance or

additional information consult

a qualied installer, service

agency or the gas supplier.

WARNING

Failure to comply with these

installation instructions will

result in an improperly installed

and operating appliance, voiding its warranty. Any change to

this appliance and/or its operating controls is dangerous.

WARNING

Clothing or other ammable

material should not be placed

on or near the appliance.

AVERTISSEMENT

On ne devrait pas placer de

vêtements ni d’autres matières

inammables sur l’appareil ni à

proximité.

WARNING

Any safety screen or guard

removed for servicing the appliance must be replaced prior to

operating the appliance.

AVERTISSEMENT

Tout écran ou protecteur retiré

pour permettre l’entretien de

l’appareil doit être remis en

place avant de mettre l’appareil

en marche.

WARNING

Improper installation or use

of this appliance can cause

serious injury or death from

re, burns, explosion or

carbon monoxide poisoning.

Note: Installation and repair should be done

by a qualified service person. The appliance

should be inspected before use and at least

annually by a professional service person.

More frequent cleaning may be required due

to excessive lint from carpeting, bedding

material, etcetera. It is imperative that control

compartments, burners and circulating air

passageways of the appliance be kept clean.

Remarque : L’installation et la réparation devrait être confiées à un technicien

qualifié. L’appareil devrait faire l’objet

d’une inspection par un technicien professionnel avant d’être utilisé et au moins

une fois l’an par la suite. Des nettoyages

plus fréquents peuvent être nécessaires si

les tapis, la literie, et cetera produisent

une quantité importante de pous-sière.

Il est essentiel que les compartiments

abritant les commandes, les brûleurs

et les conduits de circulation d’air de

l’appareil soient tenus propres.

Do not use these appliances if any part

has been under water. Immediately call a

qualified, professional service technician

to inspect the appliance and to replace

any parts of the control system and any

gas control which have been under water.

Ne pas utiliser cet appareil s’il a été

plongé, même partiellement, dans

l’eau. Appeler un technicien qualifié

pour inspecter l’appareil et remplacer

toute partie du système de commande

et toute commande qui a été plongée

dans l’eau.

Only trim kit(s) supplied by the manufacturer

shall be used in the installation of this appliance.

Seules les trousses de garniture fournies

par le fabricant doivent être utilisées pour

l’installation de cet appareil.

These appliances comply with National Safety

Standards and are tested and listed by ITS

(Report No. 100017854) to ANSI Z21.50 (in

Canada, CSA-2.22) and to CAN/CGA-2.17-M91

in both USA and Canada (latest editions at time

of manual publication) as vented gas replaces.

Both millivolt and electronic versions of

these appliances are listed by ITS for installation in bedrooms in the United States (not

approved in Canada).

These appliances must not be connected to a

chimney or flue serving a separate solid fuel

burning appliance.

Installation must conform to local codes, or, in

the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition), or the Natural Gas and Propane Installation Code, CAN/CSA B149.1 (latest edition).

The appliance, when installed, must be electri-

cally grounded and wired in accordance with

local codes or, in the absence of local codes, with

the USA National Electrical Code, ANSI/NFPA

70 (latest edition) or, in Canada, the Canadian

Electrical Code, CSA C22.1 (latest edition).

Provide adequate clearances around air open-

ings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front opening of the appliance.

These appliances are designed to operate on

natural or propane gas only. The use of other

fuels or combination of fuels will degrade

the performance of this system and may be

dangerous.

These fireplaces are designed as supplemental

heaters; therefore, it is advisable to have an

alternate primary heat source when installed

in a dwelling.

MILLIVOLT MODELS: The millivolt appliances

are manually controlled and feature a spark

igniter (piezo) that allows the appliance's pilot

gas to be lit without the use of matches or batteries. This system provides continued service

in the event of a power outage.

ELECTRONIC MODELS: The electronic appliances are manually controlled and feature an

electronic intermittent pilot ignition system.

External electrical power is required to operate

these units.

ALL MODELS: Both millivolt and electronic

models come standard with a manuallymodulated gas valve; flame appearance and

heat output can be controlled at the gas valve.

BTU input rates for all models are listed in

Table 1, below.

Input (BTU/hr) Manually-Modulated

Gas Valves (all models)

Models

SLBV-35

SLBV-40

Table 1

Input Rate (BTU / HR)

Nat. Gas Prop. Gas

17,000 high

13,000 low

22,000 high

17,000 low

17,000 high

14,000 low

20,000 high

15,500 low

3

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

GAS PRESSURE REQUIREMENTS

(All Models)

Tables 2 and 3 show the appliances' inlet and

manifold gas pressure requirements:

Inlet Gas Supply Pressure

(All models)

Fuel # Minimum Maximum

Natural Gas

Propane

4.5" WC

(1.12 kPa)

11.0" WC

(2.74 kPa)

Table 2

Manifold Gas Supply Pressure

(All models)

Fuel # Low High

Natural

Gas

Propane

(Lo) 2.2" WC

(0.55 kPa)

(Lo) 6.3" WC

(1.57 kPa)

Table 3

Test gauge connections are provided on the

front of the gas control valve, identied IN for

the inlet and OUT for the manifold side (see

Figures 1 and 2).

Propane tanks are at pressures that will cause

damage to valve components. Verify that the

tanks have step-down regulators to reduce the

pressure to safe levels.

These appliances must be isolated

from the gas supply piping system (by

closing their individual manual shut-off

valve) during any pressure testing of

the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5 kPa).

These appliances and their individual

shut-off valves must be disconnected

from the gas supply piping system

during any pressure testing of that

system at pressures greater than 1/2

psig (3.5 kPa).

4

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

(Hi) 3.5" WC

(0.87 kPa)

(Hi) 10.0" WC

(2.49 kPa)

ORIFICE SIZES

Sea Level to High Altitude

(All Models)

These appliances are tested and approved for

installation at elevations of 0–4500 feet (0–1372

meters) above sea level using the standard

burner orice sizes (marked with an asterisk

(*) in Table 4, below).

For elevations above 4500 feet, contact your

gas supplier or a qualified service technician.

Deration

At higher elevations, the amount of BTU fuel

value delivered must be reduced by either:

• using gas that has been derated by the gas

company,

• changing the burner orice to a smaller size

as regulated by the local authorities having

jurisdiction and by the (USA) National Fuel Gas

Code NFPA 54/ANSI Z223.1 - latest edition or,

in Canada, the CAN/CSA-B149.1 codes - latest

edition.

Install the appliance according to the regulations

of the local authorities having jurisdiction and,

in the USA, the National Fuel Gas Code NFPA

54 / ANSI Z223.1 - latest edition or, in Canada,

the CAN/CSA-B149.1 - latest edition.

NOTE: Flame appearance will diminish

4% per thousand feet of altitude.

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

Series

SLBV-35

SLBV-40

Table 4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Nat.Gas

drill size (inches)

#48 (0.076")*

drill size (inches)

#56 (0.046")*

H1236•

#43 (0.089")*

#55 (0.052")*

99K75•

Standard size installed at factory.

*

• Part /Catalog Number.

Propane

62L37•

19L52•

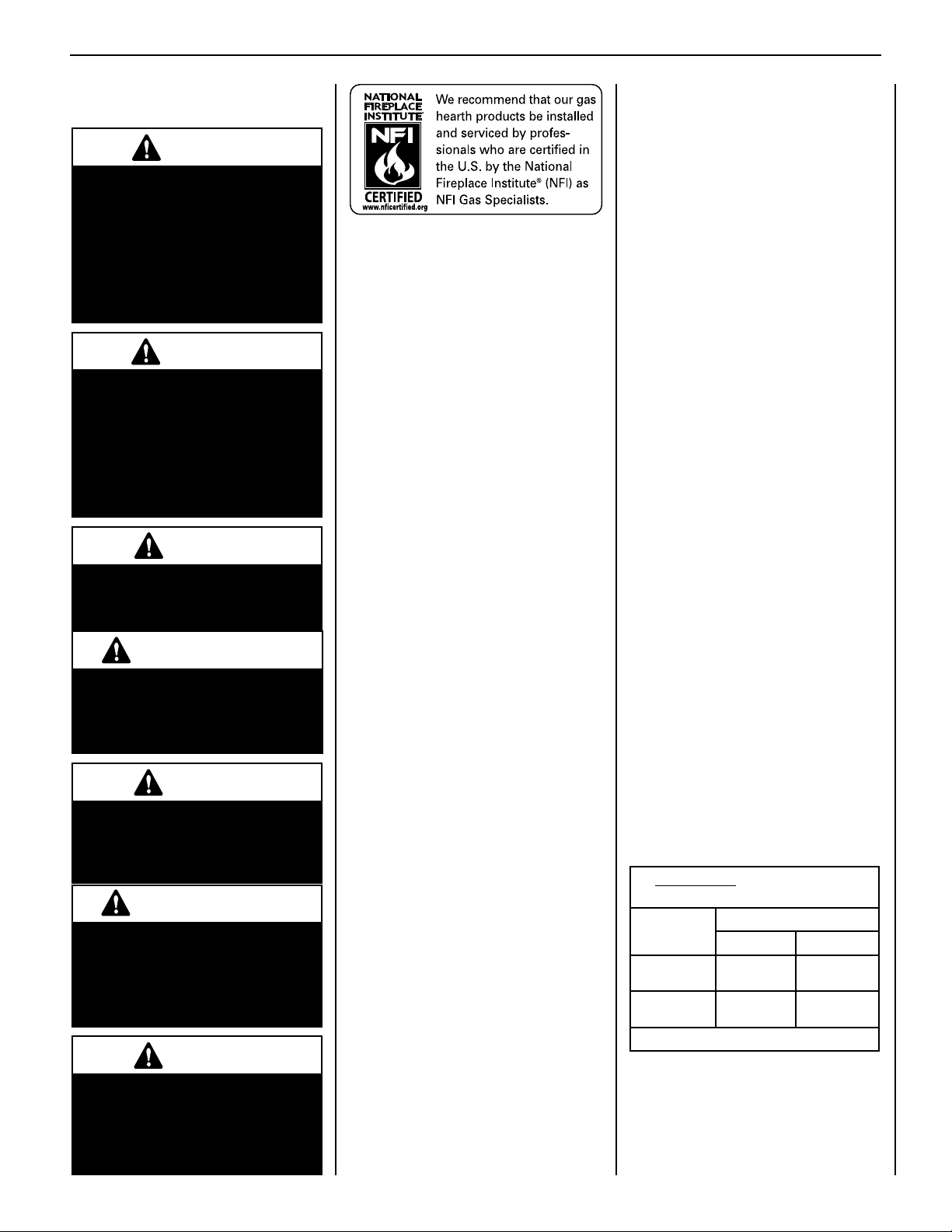

GAS VALVE DIAGRAMS

See Figure 1 for millivolt models and Figure 2

for electronic models.

Main Gas Control Knob

OFF/PILOT/ON

N

O

T

O

it

L

I

P

O

F

F

OUT

IN

Manifold Pressure Tap

Inlet Pressure Tap

Pilot Adjustment

P

W

O

L

H

I

HI/LO Variable

Flame Height

Adjustment

Screw

T

O

L

I

HTPTHTPT

Figure 1 - SIT Millivolt Gas Valve

Supply

Gas

Inlet

Pressure-Tap

(Manifold)

IN

PILOT

Pilot Gas

Outlet

Regulator

Mounting Screw

Pressure-Tap

(Inlet)

Burner Stage

Terminal

VENT

OUT

IN

HI

Ground

(TP)

LO

TH

TH

TP

Pilot Stage

Terminal

TP

Figure 2 - Dexen Electronic Gas Valve

REQUIREMENTS FOR THE

COMMONWEALTH OF

MASSACHUSETTS

These fireplaces are approved for installation in

the US state of Massachusetts if the following

additional requirements are met:

• Install this appliance in accordance with

Massachusetts Rules and Regulations 248

C.M.R.

• Installation and repair must be done by a

plumber or gas tter licensed in the Commonwealth of Massachusetts.

• The exible gas line connector used shall

not exceed 36 inches (92 centimeters) in

length.

• The individual manual shut-off must be a

T-handle type valve.

NEW YORK CITY APPROVAL

New York City, NY (MEA)

These fireplaces are approved for installation

in New York City in the US state of New York

if the following additional requirement is met:

• An Outside Combustion Air Kit (FOAK-4,

FOAK-4LD, or DK-4) must be installed. See

Step 5 on Page 14.

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

COLD CLIMATE INSULATION

For cold climate installations, seal all cracks

around your appliance with noncombustible

material and wherever cold air could enter

the room. It is especially important to insulate

outside chase cavity between studs and under

oor on which appliance rests, if oor is above

ground level. Gas line holes and other openings

should be caulked or stuffed with unfaced

berglass insulation. Check local codes for

additional requirements.

If the replace is being installed on a cement

slab in cold climates, a sheet of plywood or

other raised, insulated platform can be placed

underneath to prevent cold transfer to the

fireplace and into the room. It also may help

to sheetrock the inside surfaces and/or tape

for maximum air tightness.

LOCATION

In selecting the location, the aesthetic and

functional use of the appliance are primary

concerns. However, vent system routing to

the exterior and access to the fuel supply are

also important.

Due to high temperatures, the appliance

should be located out of traffic and away from

furniture and draperies (Figure 3).

En raison des températures élevées,

l’appareil devrait être installé dans un

endroit où il y a peu de circulation et loin

du mobilier et des tentures (Figure 3).

The location should also be free of electrical,

plumbing or other heating/air conditioning

ducting.

These appliances are equipped with an integral combustion air door and actuator arm.

Combustion air kits are optional and must be

installed before removing the securing screw

allowing the movement of the combustion air

actuator arm (see Step 5 on Page 14).

Be aware that this is a heat-producing appliance. Objects placed above the unit are

exposed to elevated temperatures.

The appliance should be mounted on a fully

supported base extending the full width and

depth of the unit. The appliance may be located

on or near conventional construction materials.

However, if installed on combustible materials,

such as carpeting, vinyl tile, etc., a metal or

wood barrier covering the entire bottom surface

must be used.

These appliances may be used for bedroom

installations in the United States and are listed

accordingly. These units may not be installed

in bedrooms in Canada.

Figure 3: Typical Locations

Note: When the unit is installed with one side

flush with a wall, see Figure 5 on Page 7.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

VENT TERMINATION

CLEARANCES

Multiple Terminations

These appliances may vent adjacent to and at

the same level with any other gas appliances

(including direct vent appliances), provided

there is at least 2 ft (0.6 m) between the proxi-

mal edges of the vent caps. These appliances

may be vented adjacent to a chimney vent

servicing a solid fuel replace, provided the

B-vent cap is at least 2 ft (0.6 m) away from the

nearest point of the chimney opening.

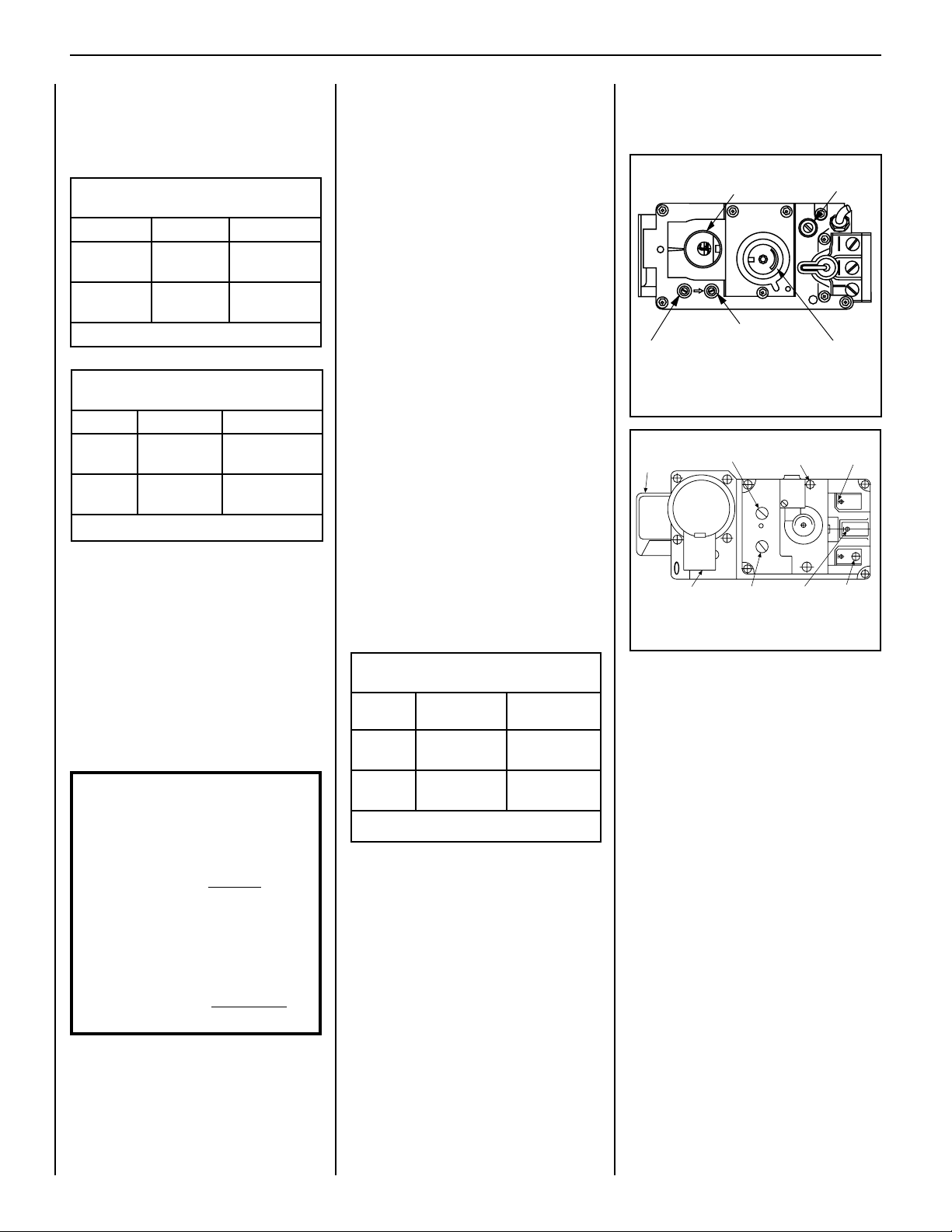

Gas Vent Rule

Gas vent caps are not permitted within 8 ft (2.4

m) of a vertical wall or similar obstruction. Gas

vent caps that are located 8 ft or more from a

portion of a building that extends at an angle

greater than 45° upward from the horizontal

may terminate in accordance with Figure 4,

provided that any discharge opening on

the cap is NEVER LESS THAN 2 ft (0.6 m)

horizontally from the roof surface (National

Fuel Gas Code ANSI Z223.1 (NFPA 54) “Gas

Vent Termination” section) (CAN/CGA B149.1).

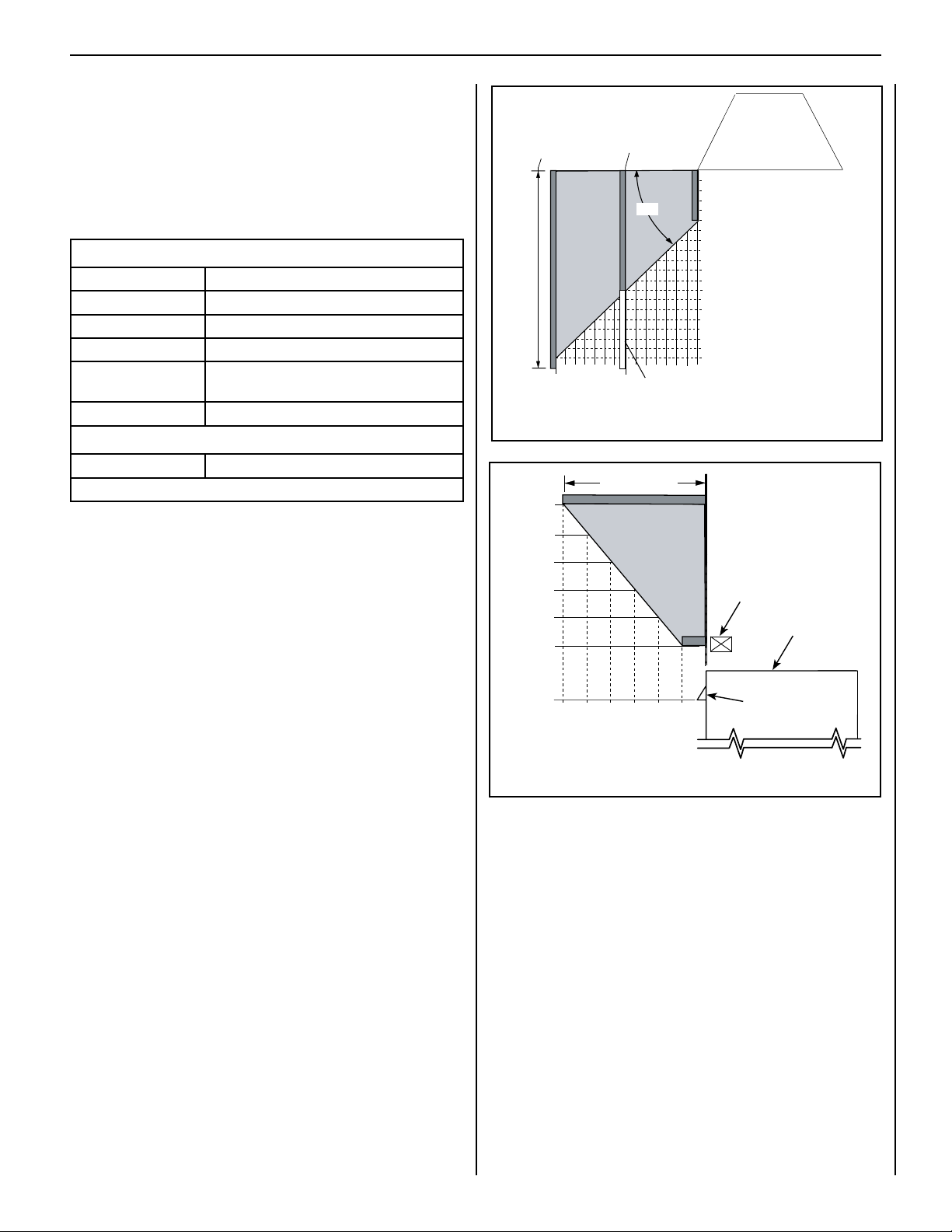

Gas Vent Rule

Figure 4

X

12

Roof Pitch is X/12

Minimum Height from Roof to

Lowest Discharge Opening

1" (25 mm)

Minimum

Termination Heights For Vents

Above Flat Or Sloped Roofs

Ref. NFPA 54 / ANSI Z223.1

Roof Pitch * Feet * Meters

Flat to 6/12 1.0 0.3

6/12 to 7/12 1.25 0.38

7/12 to 8/12 1.5 0.46

8/12 to 9/12 2.0 0.61

9/12 to 10/12 2.5 0.76

10/12 to 11/12 3.25 0.99

11/12 to 12/12 4.0 1.22

12/12 to 14/12 5.0 1.52

14/12 to 16/12 6.0 1.83

16/12 to 18/12 7.0 2.13

18/12 to 20/12 7.5 2.29

20/12 to 21/12 8.0 2.44

Table 5

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5 (127)

8-1/4

(209)

14

(356)

12 (305)

19

(483)

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

MINIMUM CLEARANCES TO COMBUSTIBLES

Appliance and Vent Clearances

The appliance is approved with zero clearance to combustible materials

on all sides (as detailed in Table 6), with the following exception: When

the unit is installed with one side flush with a wall, the wall on the

other side of the unit must not extend beyond the front edge of the

unit (see Figure 5).

MINIMUM CLEARANCES - Inches (millimeters)

Back 0 (0) to Standoffs or Dimples

Sides 0 (0) to Standoffs or Dimples**

Top 3 in (76 mm)

Floor 0 (0)

From Bottom of Unit

to Ceiling

Vent 1 in (25.4 mm)

SERVICE CLEARANCES

Front 3 ft (0.9 m)

Table 6

**Note: See Step 1 on Page 8 for clearance requirements to the nailing

flange located at each side of the unit and any screw heads adjacent to it.

64 in (1626 mm)

At 14" minimum side

wall clearance, a

combustible wall can

project to any length.

At 8-1/4" side

wall clearance, a

combustible wall

can project 12".

o

45

Protected wall

shown in white

Top View of

Fireplace

Combustible Materials

Allowed In Shaded Area

“Safe Zone”

Combustible walls

shown in dark gray.

Combustible materials

may project beyond

one side of the

fireplace opening

as long as they are

kept within the shaded

areas illustrated here.

Inches (millimeters)

Figure 5 - Minimum Distance to Unprotected Side Wall

Mantel Depth

18 (457)

16 (406)

inches (millimeters)

Hearth Extension

A hearth extension is not required with this appliance. If a hearth extension

is used, do not block the lower control compartment door. Any hearth

extension used is for appearance only and does not have to conform to

standard hearth extension installation requirements.

Wall Finishes / Surrounds / Mantels

Note: Combustible wall finish materials and/or surround materials must

not be allowed to encroach the area defined by the appliance front face

(black sheet metal). Never allow combustible materials to be positioned

in front of or overlapping the appliance face (see Figure 5; also see

Figure 30 on Page 23).

Non-combustible materials, such as surrounds and other appliance trim,

may be installed on the appliance face with these exceptions: they must

not cover any portion of the removable glass panel.

Vertical installation clearances to combustible mantels vary according

to the depth of the mantel. See Figure 6. Mantels constructed of non-

combustible materials may be installed at any height above the appliance

opening; however, do not allow anything to hang below the replace hood.

Note: We recommend the use of high-temperature paint (rated 175°F or

higher) on the underside of the mantel.

14 (356)

12 (305)

10 (254)

8 (203)

12

(305)

10

(254)

(203)

6

8

(152)

(102)

2

4

(51)

Figure 6 - Minimum Mantel Clearances

Header

Top of

Appliance

Note - Hood shown

as positioned.

7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

Top

Standoff

Spacers*

Flush

Nailing

1/2"

Nailing

Flange

5/8"

Nailing

Flange

PRE-INSTALLATION STEPS

(Remove Glass Enclosure Panel)

The appliance is shipped with all gas controls

and components installed and pre-wired.

Note: Remove the glass enclosure panel

before installing the fireplace.

To remove the glass enclosure panel:

1. Remove the shipping carton, and then remove the shipping pad, exposing the front

glass panel.

2. Open the two latches securing the glass

panel (under the rebox oor).

3. Remove the glass panel by tilting it outward

at the bottom and lifting it up.

4. Set aside the glass enclosure panel in a

safe location to protect it from inadvertent

damage.

TYPICAL INSTALLATION

SEQUENCE

The typical sequence of installation is outlined

below, with page number references to the

related detailed instructions.

NOTE: Each installation is unique and may

result in variations to these steps.

Step 1. (Pages 8–10) Construct the appliance

framing.

Position the appliance within the

framing and secure with nailing

brackets.

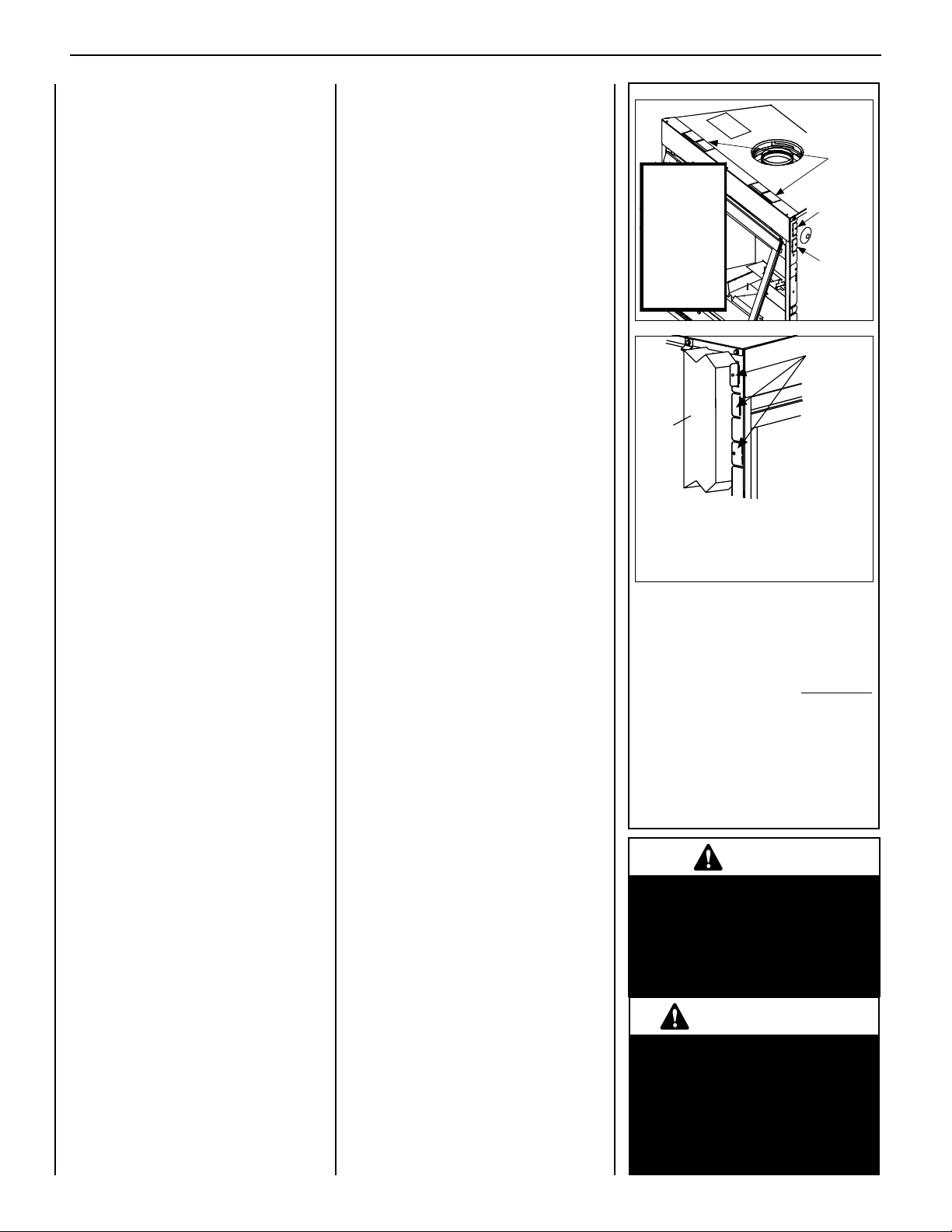

IMPORTANT! Bend up the appropri-

ate top standoff spacers for the

drywall/finish material thickness to

be used (see Figure 7). Bend up the

outer pair for 1/2" ma terials and the

inner pair for 5/8" materials.

Bend up the outer pair for 1/2" ma-

terials and the inner pair for 5/8"

materials.

Bend out the appropriate nailing

flanges for the drywall/finish material

to be used.

Nailing flanges are provided for flush

framing, 1/2 inch and 5/8 inch framing depths (see Figure 7).

Step 2. (Page 11) Route the gas supply line

to the appliance location.

Step 3. (Page 11) Install the vent system and

exterior termination.

Step 4. (Page 12) Install field wiring.

a. Millivolt Appliances: Install the

operating control switch (not factory

provided).

b. Electronic Appliances: Field wire

8

and install operating control switch.

Step 5. (Page 14) [OPTIONAL]: Install

outside supplemental combustion

air kit.

Step 6. (Page 15) Make connection to gas

supply.

Step 7. (Page 16) Verify appliance operation.

Step 8. (Page 17) Install the logs, decorative

volcanic stone, and glowing embers.

Step 9. (Page 20) Install the glass enclosure

panel.

Step 10. (Page 20) Adjust burner air shutter

to ensure proper flame appearance.

Step 11. (Page 22) Perform spillage test.

Step 12. (Page 23) Install hood.

Step 13. (Page 23) Complete finished interior

wall.

Step 14. (Page 24) Attach "Safety-in-

Operation" warnings.

DETAILED INSTALLATION STEPS

Step 1. Construct Appliance

Framing

Frame the appliance as illustrated in Figures

8-1 and 8-2. All framing details must allow for

a minimum clearance to combustible framing

members as shown in Table 6, Page 7.

If the appliance is to be elevated above oor

level, a solid continuous platform must be

constructed below the appliance.

Headers may be in direct contact with the appli-

ance top standoff spacers when they are bent

up vertically, maintaining the 3" clearance to

the replace top, but must not be supported

by them or notched to fit around them. All

construction above the appliance must be

self-supporting. DO NOT use the appliance

for structural support.

Secure the fireplace to the side framing mem-

bers using the unit's nailing anges — one top

and bottom on each side of the replace front.

See Figure 7. Use 8d nails or equivalent.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Header

Spacing

Top

Standoffs

*IMPORTANT!

Bend up the

Top Standoff

Spacers before

installation.

Use outer pair

for 1/2" materials

and inner pair

for 5/8" materials.

Side

Framing

(Left side front corner of fireplace shown.

NOTE: The nailing anges, combustible

members, and screw heads in areas directly

adjacent to the nailing anges are EXEMPT

from the 1/2” clearance to combustible

requirements for the rebox outer wrapper.

Combustible framing may be in direct contact

with the nailing anges and may be located

closer than 1/2” from screw heads and the

rebox wrapper in areas adjacent to the

nailing flanges.

Frame the opening to the exact dimensions

specified in the framing details in this manual.

Figure 7

~

Nailing flanges are

provided at all four

corners at 5/8", 1/2",

and flush settings.

Fireplace secured to framing

by nailing flanges

Right side requirements are the same.)

5/8”

Nailing

Flange

1/2”

Nailing

Flange

Fireplace

Nailing

Flanges

WARNING

Failure to position the parts in

accordance with these diagrams

or failure to use only parts specifically approved with this appliance

may result in property damage or

personal injury.

AVERTISSEMENT

Risque de dommages ou de

blessures si les pièces ne sont

pas installées conformément à

ces schémas et ou si des pièces

autres que celles spécifiquement

approuvées avec cet appareil sont

utilisées.

SUPERIOR® B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

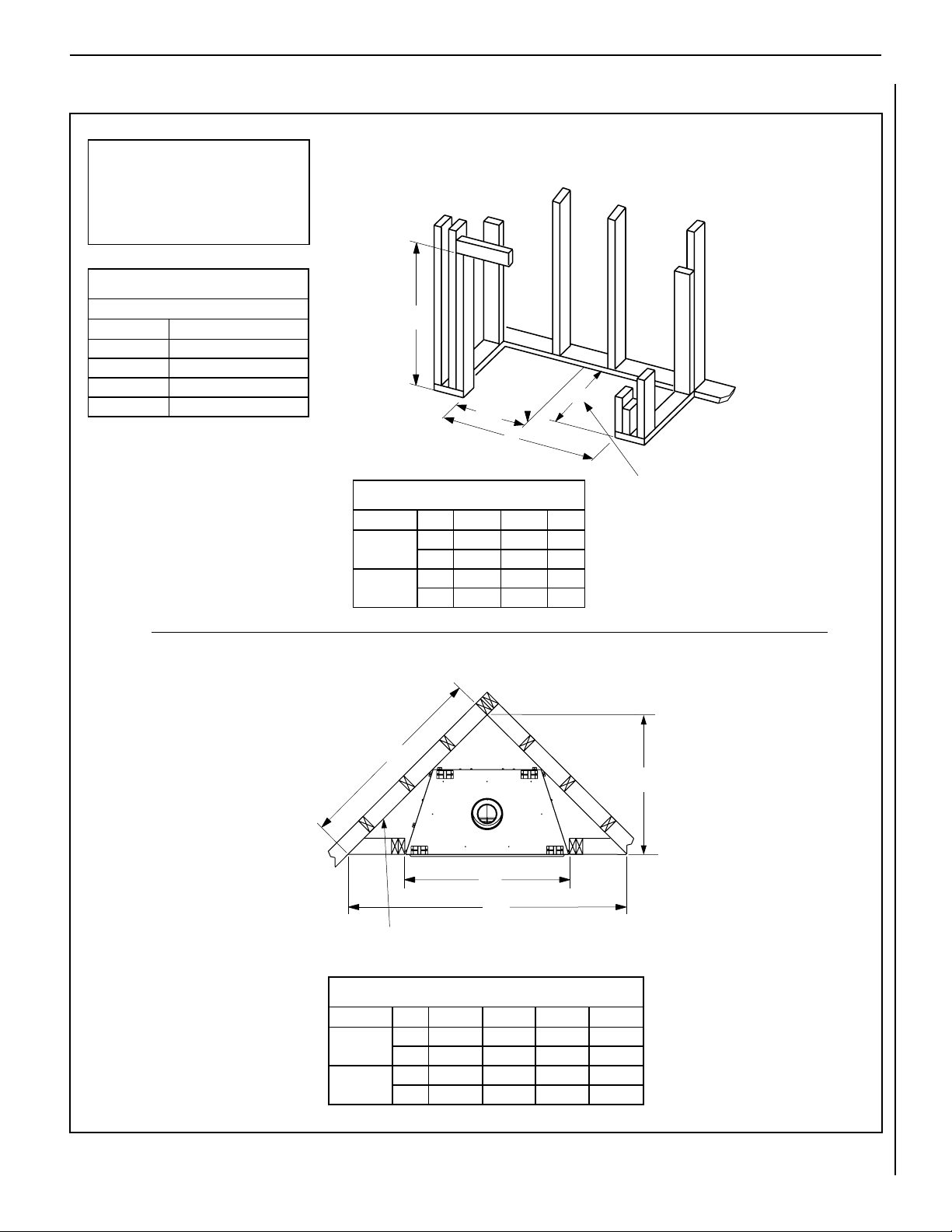

FIREPLACE AND FRAMING SPECIFICATIONS

NOTE: Diagrams, illustrations and

photographs are not to scale. Product

designs, materials, dimensions,

specifications, colors, and prices are

subject to change or discontinuance

without notice.

Input (BTU/HR) - MV & Electronic

Natural & Propane Gas

Models Input Rate (BTU/hr)

SLBV-35N 17,000

SLBV-35P 17,000

SLBV-40N 22,000

SLBV-40P 20,000

FIREPLACE FRAMING SPECIFICATIONS

Construct framing with 2x4 or larger lumber.

B

C

1/2

A

A

Framing Dimensions

Model No. A B C

SLBV-35

SLBV-40

in. 35-1/4 35-1/4 16

mm 895 895 406

in. 40-1/4 40-1/4 16

mm 1022 1022 406

“C” is the required framing depth dimension

when the finish material (drywall) thickness

is 1/2 in. (13mm).

Figure 8-1

CORNER FRAMING DIMENSIONS

F

D

E

Back wall of chase/enclosure

(including any finishing materials)

Corner Framing Dimensions

Model No. D E F G

SLBV-35

SLBV-40

in. 35-1/4 57-1/2 40-5/8 28-3/4

mm 895 1461 1032 730

in. 40-1/4 61-13/16 48-11/32 30-11/16

mm 1022 1554 1101 779

G

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Loading...

Loading...