Page 1

The Fireplace Compcny

For

Superior

j

HC

Series Fireplaces

1

Model

HC-3320

Model

HC-3820

And

Hearthstar

B

Series

Fireplace

Model

385

This installation manual will

help you obtain a safe, effi-

'cient, dependable installation

for your fireplace and chimney

sysiem. Please read and

understand these installation

instructions before beginning

your installation.

Do not attempt to modify or

alter the construction of the

fireplace or its components.

Any modification or aitaration

of construction may void the

'warranty, listings and appro-

vals of this system.

The name Superior

is

used

synonymously with the name

Hearthstar throughout this

Installation Instruction

manual.

Page 2

L

I

RULES

TO FOLLOW

1

10.

Alwavs keeo flue damner I

'

PRECAIITlnNS

I

~.

. . .

-

-

. .

-

.

.

-

.

.

-

FOR

SAFETY

open whiie heat is present in

fireplace.

The most imoortant

ar~zr

nf

1.

Before starting your fireplace installation, read and

understand these safety tips

and installation instructions

:~carefully. Failure to follow

them couid cause a fireplace

malfunction resulting in serious bodily injury

and/or pro-

perty damage.

2.

Always check your local

building codes. The installation must comply

with their

regulations.

3.

Connect this model fire-

place to a Superior Model

TF8

.Thru Flow Chimney System

'(8"

inside diameter) residen.

tial type appliance chimney

only and vent to the outside

!of the building.

1

4.

To maintain top effi-

iciency, and to prevent build.

up

of soot and creosote,

inspect and clean the fireplace and chimney prior to

use and periodically during

,the heatina season.

'11.

Before servicing, allow

fireplace to cool. Always shut

off any electricity and gas (if

used) to fireplace whiie work-

ing on it. This will prevent

electrical shocks or burns.

12.

This fireplace is not

intended to heat an entire

home. Its use

shou!d be for

supplemental

heat in^

only.

13.

Ensure an adequate

supply of cornbustion air to

prevent hazards due to poor

combustion and to avoid

affecting other

fuel burning

appliances.

TOOLS

AND

BUILDING

SUPPLIES NORMALLY

REQUIREO

Tools should include:

Phillips screwdriver

Slot styie screwdriver

Hammer

Saw

andior Sabersaw

6.

Do NOT use

gas

is

used:

This fuel gives

bon monoxide fumes. Pipe cutter

-

!

5.

Use solid wood fuel only.

DO NOT use artificial logs,

'chemical chimney cleaners,

:coal or flame colorants in

your fireplace.

7.

NEVER light a fire with

gasoline, kerosene or lighter

fluid because of the danaer of

1

Level

,

~~~~~~i~~

tape

:

Plumb line

!

Electric drill and bits

I

Pliers

Square

Pipe threader

Pipe joint compound

Pipe key valve

explosion. Keep all

volatTle

I

'Building supplies:

liquids away from fireplace.

Framinq materials

8.

DO

NOT INSTALL FIRE.

Wall

f16shing materials

PLACE IN A BEDROOM OF

A

Caulking materials

MANUFACTURED HOME.

(noncombust~ble)

-~

9.

NEVER leave children

:unattended when there is a

.fire burning in the fireplace

Fireplace surround and

hearth extension materials

(noncombustibie)

F~

-,

concern dealing with the

installation of Zero clearance

fireplaces are clearances to

combustible materials, secure

assembiy of component parts,

height of chimney system, the

proper use of accessory

equipment, and the techniques employed in using finishing materials applied to

fireplace surrounds, hearth

extensions and wall shields.

Each of these topics will be

covered in great detail

throughout this manual.

Please give each your special

attention as you progress with

your installation.

Page 3

INTRODUCTION

General Information

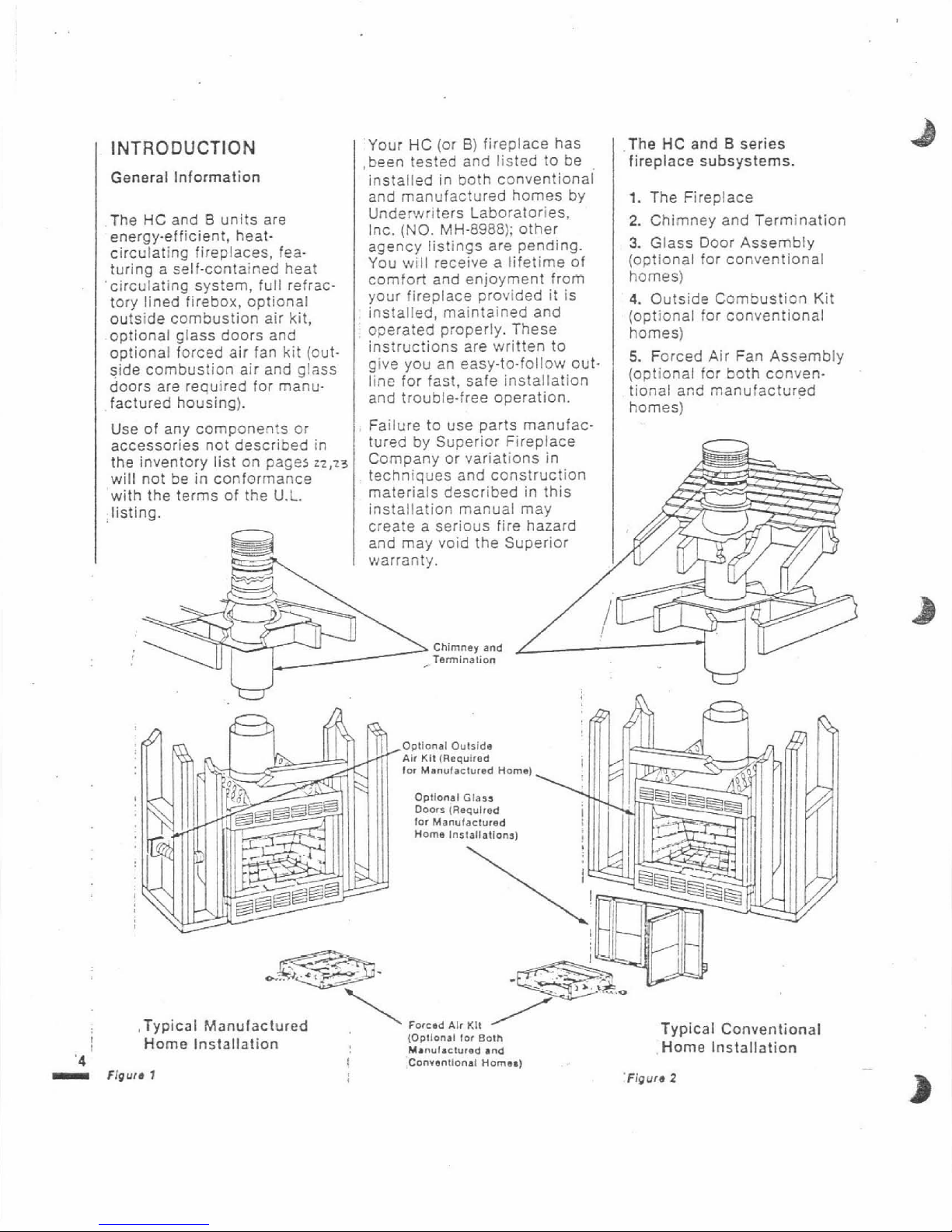

The HC and B units are

energy-efficient, heatcirculating fireplaces,

fea.

turing a self-contained heat

circulating system, full refrzctory lined firebox, optional

outside combustion air kit,

optional glass doors and

optional forced air fan kit (outside combustion air and glass

doors are required for manufactured housing).

Your

HC

(or

8)

fireplace has

,been tested and listed to be

,

installed in both conventional

and manufactured homes by

Underwriters Laboratories,

Inc. (NO.

MH-8988);

other

agency listings are pending.

You will receive a lifetime of

comfort and enjoyment from

your fireplace provided it is

installed, maintained and

1

operated properly. These

instructions are written to

give you an easy-to-follow

out.

line for fast, safe installation

and trouble-free operation.

The

HC and B series

fireplace subsystems.

1.

The Fireplace

2.

Chimney and Termination

3.

Glass Door Assembly

(optional for conventional

homes)

4.

Outside Combusticn Kit

(optional for

conventional

homes)

5.

Forced Air Fan Assembly

(optional for both conventional and manufactured

homes)

Optional

Outside

Air

Kit

(Required

for

Manufactured

Home)

Opltonai

Glass

Doors

(Required

lor

Manulactured

Home

Installatton.)

!

\

.Typical Manufactured

Forcad

AIC

KII

(Optionat

lor

BOI~

Typical Conventional

Home Installation

~.~~~~~t~~~d

and

Home Installation

I

Conrsnllonal

Homal)

Figure

1

'Figure

2

Use of any components or

I Failure to use parts rnanufac-

accessories not described in

the inventory list on pages

~2,~~

will not be in conformance

with the terms of the

U.L.

listing.

tured by Superior Fireplace

Company or variations in

techniques and construction

materials described in this

installation manual may

create a serious fire hazard

and may void the Superior

warranty.

Chimney

and

Termination

Page 4

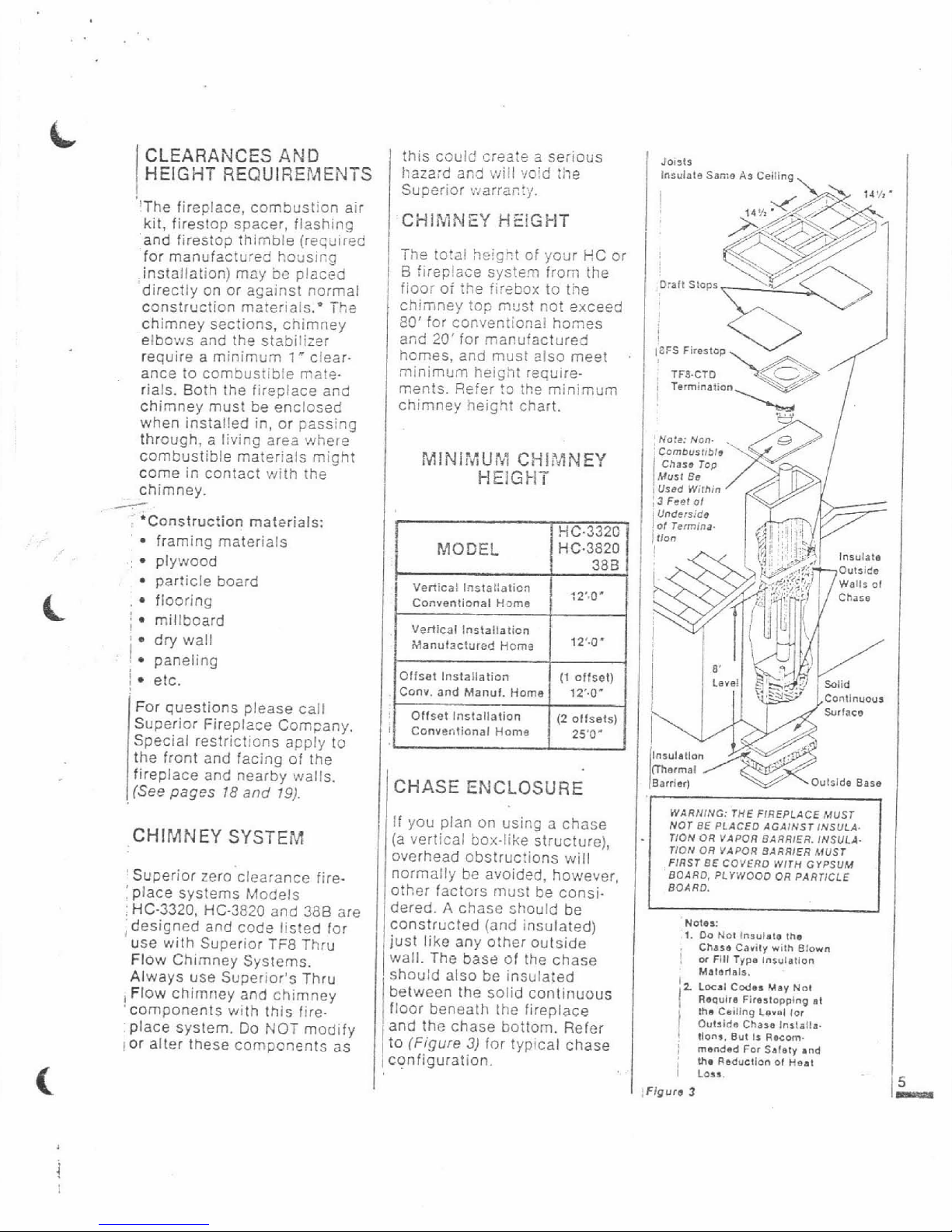

CLEARANCES

AND

this could srea!e a serious

loilto

HEIGHT REQUIEEFJENTS

hazard

an3 will void the

lnsuiats

ssma

~3

Ceiling

!

Superior .v~arra;l:y.

I4

"Z

-

'The fireplace, combustion air

CHIMNEY

HSIGHT

kit, firestop spacer, flashing

'and

firestop thimble (required

for manufactured

houslcg

I

The total hei5r.t of yogr HC or

;

installation) may

be

pIac?d

1

6

fireplace system irom the

directly on or against normal

1

fioor of

:he

firebox to the

construction materials.' The

1

chmney !a? must not exceed

chimney sections, chimney

e0'

for conventional homes

elbows and the

s:abiiizer

and

20'

for manufactured

i

homes, and must also meet

require a minimum

1

*

clear.

ance to combusrlble mate

minimum

kei~ht require-

rials. Eoth the fireplace and

men:s. Pefer !o the minimum

chimney must be enclosed

chimney height chart.

when installed in, or passing

through, a living area 'where

combustible materials might

1

MINi?liU&

CHIMNEY

come in contact with the

HEIGHT

chimney.

.

;

'Construction materials:

framing materials

:

plywood

particle board

Vertical

Installation

,

flooring Conventional

H'>rna

j

millboard

Vertical

Installation

:

dry wall

Manufactured

Homa

12''0*

'

paneling

i

I

etc.

Offset

Installatioil

(1

offset)

Conv.

and

Manuf.

Home

12'4'

!

For questions please call

Surlacs

Superior Fireplace Com;any.

,

,,,,,,

ianal

I

5.0.

Special restrictions apply

to

the front and facing of the

fireplace

and nearby walls.

I

CHASE ENCLOSURE

Barrier)

Outride

Base

(See pages

18

and

19).

WARNING:

THE

FIREPLaCE

MUST

If you plan on using a chase

NOT

BE

PLACED

AGAINST

INSULA.

,CHIMNEY

SYSTEM

(a vertical box.like structure),

"ON

OR

VAPOR

BARRIER.

1NSuI.A.

overhead obstructions will

TION

OR

VAPOR

YARRIER

MUST

FIRST

BE

COVER0

WITH

GYPSUM

I

Superior zero clearance fire-

normally be avoided, however,

BOARD.

PLIWOOO OR

PARTICLE

:place systems Models

other factors must be

consi.

BO4RO.

:

HC-3320, HC-3820

and

386

are

&red. A chase should be

;designed and cod- listed

for

use with Superior TFB Thru

Flow Chimney Systems.

Always use Superior's Thru

i

Flow chimney and chimney

'components with this fire.

place system. Do

NOT

modify

lor alter these components as

sl

constructed (and insulated)

,just like any other Outside

Wall. The base of the chase

should also

be insulated

between the solid continuous

floor beneath the

fireplace

'and the chase bottom. Refer

to (Figure

3)

for typical chase

1cnfiguration.

,

Notes:

I.

DO

No1

In3ulalo

Ihe

,

Chara

cavity

vim

BIOWR

1

or

FIII

Typa

insulmtion

Maloriais.

I

(2

Lmal

Cds-

May

No1

Rwuira

Firaslopping

at

the

Csdlng

L~W~I

lor

j

Outside

Chara

lnrlslla.

!

tlon*.

But

1%

Reca.

I

mended

For

Sa1.v

and

:

I

me

Lo,,.

Reduction

oi

neat

IFigurs

3

5

Page 5

ASSEMBLY OUTLINE

Before You Start

Check your inventcry list to

be sure you have all the

necessary parts

supplieo in

good

useable condition.

Check also for any concealed

damage.

Check the operation of the

flue damper. The flue damper

handle extends

down from the

inside top of fireplace; push

in to close, puil out to open

-

takes firm pressure to lock

closed.

LOCATION OF

FIREPLACE

Carefully select the proper

location for heat circulation,

aesthetics, chimney obstructions, and clearance to side

wall. With proper prepianning,

a slight adjustment of a few

inches can save considerable

time

and

expense during

con-

struction and assembly.

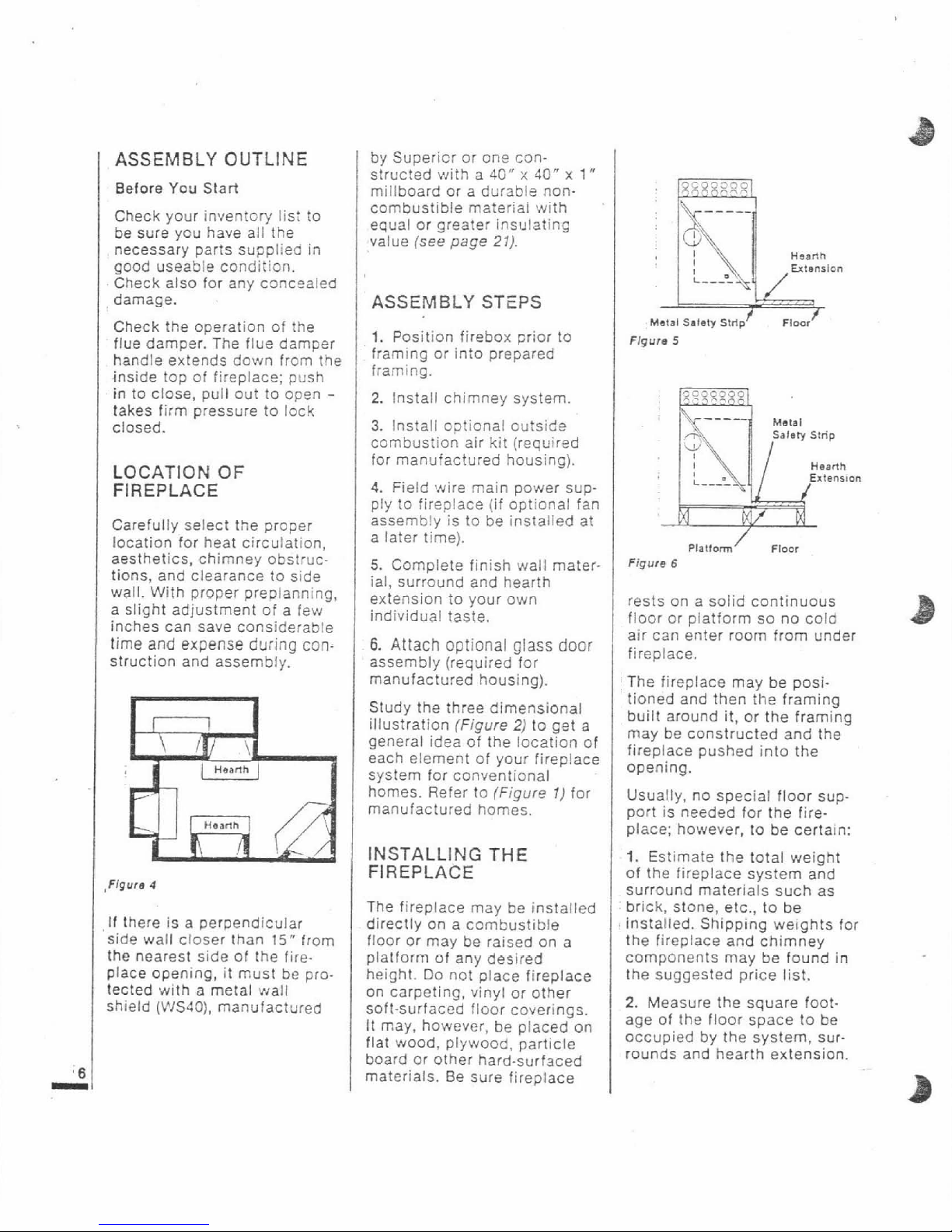

If

there is a perpendicular

;ide wall closer than

15"

from

:he nearest side of the

fire]lace opening, it must be pro.

ected with a metal

vial1

jhield

(WS4O),

manufactured

by Superior or one constructed with a

40"

x

LO"

x

1"

millboard or a durabls noncombustible rnateriai

,with

equal or greater insulating

value (see

page

21).

ASSEMBLY STEPS

I.

Position firebox prior to

framing or into prepared

framing.

2.

Install chimney system

3.

Install c?!ional cu:side

combustion air kit (required

for manufactured housing).

4.

Field wire main power supply to fireplace

(if

optional fan

assembly is to be installed at

a later time).

5.

Complete finish wall material, surround and hearth

extension to your own

individual taste.

6.

Attach

optional

glass

door

assembly (required for

manufactured housing).

Study the three

dimensional

illustration (Figure

2)

to get a

general idea of the location of

each element of your fireplace

system for conventional

homes. Refer to

(Figure

1)

for

manufactured homes.

INSTALLING

THE

FIREPLACE

The fireplace may be installed

directly on a combustible

floor or may be raised on a

platform of any desired

height. Do not place fireplace

on carpeting, vinyl or other

soft-surfaced floor coverings.

It may, however, be placed on

flat wood, plywood, particle

board or other hard-surfaced

materials. Be sure fireplace

Haanh

Plalrom

'

Floor

Figure

6

rests on a solid continuous

floor or platform so no cold

air can enter room from under

fireplace.

The fireplace may be positioned and then

the framing

built around it, or the framing

may be constructed and the

firepiace pushed into the

opening.

Usualiy, no special floor support is needed for the fireplace; however, to be certain:

1.

Estimate the total weight

of the fireplace system and

surround materials such as

brick, stone, etc., to be

installed. Shipping weights for

the fireplace and chimney

components may be found in

the suggested price list.

2.

Measure the square footage of the floor space to be

occupied by the system, surrounds and hearth extension

Page 6

3.

Note the floor construction

i.e.

2

x

6's.

2

x

8's or 2 x 10's.

single or double joists, type

and thickness of floor boards.

4.

Use this information and

consult your local building

code to determine

if

you need

,additional support.

CAUTION: DO NOT BLOCK

,

THE HEAT CIRCULATING

AIR INLETS AND OUTLETS.

DOING SO MAY RESULT IN

A POTENTIAL

FIRE

HAZARD.

.If you plan to raise the fire-

place and hearth extension,

build this platform assembly,

'then position fireplace and

;hearth extension on top.

TO

INSTALL:

Step

1:

Slide fireplace into the

prepared framing, or

positlon

fireplace

in its final location

for framing later.

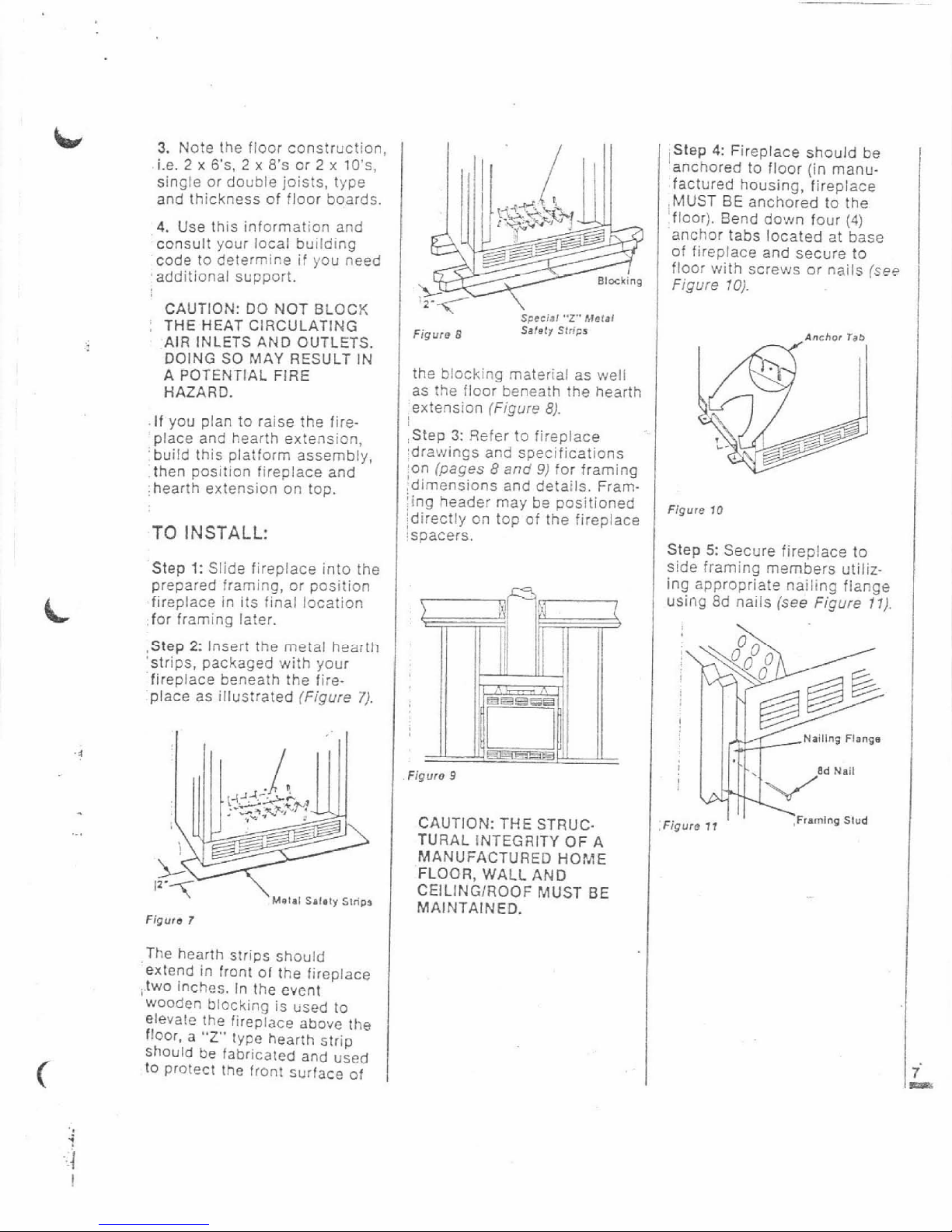

.Step

2:

Insert the metal hearth

'strips, packaged with your

fireplace beneath the fire-

place as illustrated

(Figure

7).

Figure

7

The hearth strips should

exlend in front of the fireplace

,two inches. In the event

wooden blocking is used to

elevate the fireplace above

the

floor,

a

"2"

lype hearth slrip

Should be fabricaled and used

10 protect the front surface of

the blocking material as well

as the floor beneath the hearth

extension

(Figure

8).

Step

3:

Refer to fireplace

:drawings and specifications

on

(pages

8

and

9)

for framing

dimensions and details.

Frarning header may be positioned

:directly on top of the fireplace

!spacers.

Figure

9

CAUTION: THE STRUC.

TURAL INTEGRITY OF A

MANUFACTURED

HOME

FLOOR, WALL AND

CEILINGIROOF

MUST

BE

MAINTAINED.

Step

4:

Fireplace should be

'anchored to floor (in manu-

factured housing, fireplace

.MUST

BE

anchored to the

floor). Bend

do~n four

(4)

anchor tabs located at base

of

f~replace and secure to

floor with screws or nails

(see

Figure

70).

Step

5:

Secure fireplace to

side framing members utilizing appropriate nailing

fiance

using 8d nails

(see

Figure

17).

!

Nalllng

Flange

!

:Figure

17

,Framing

Slud

Page 7

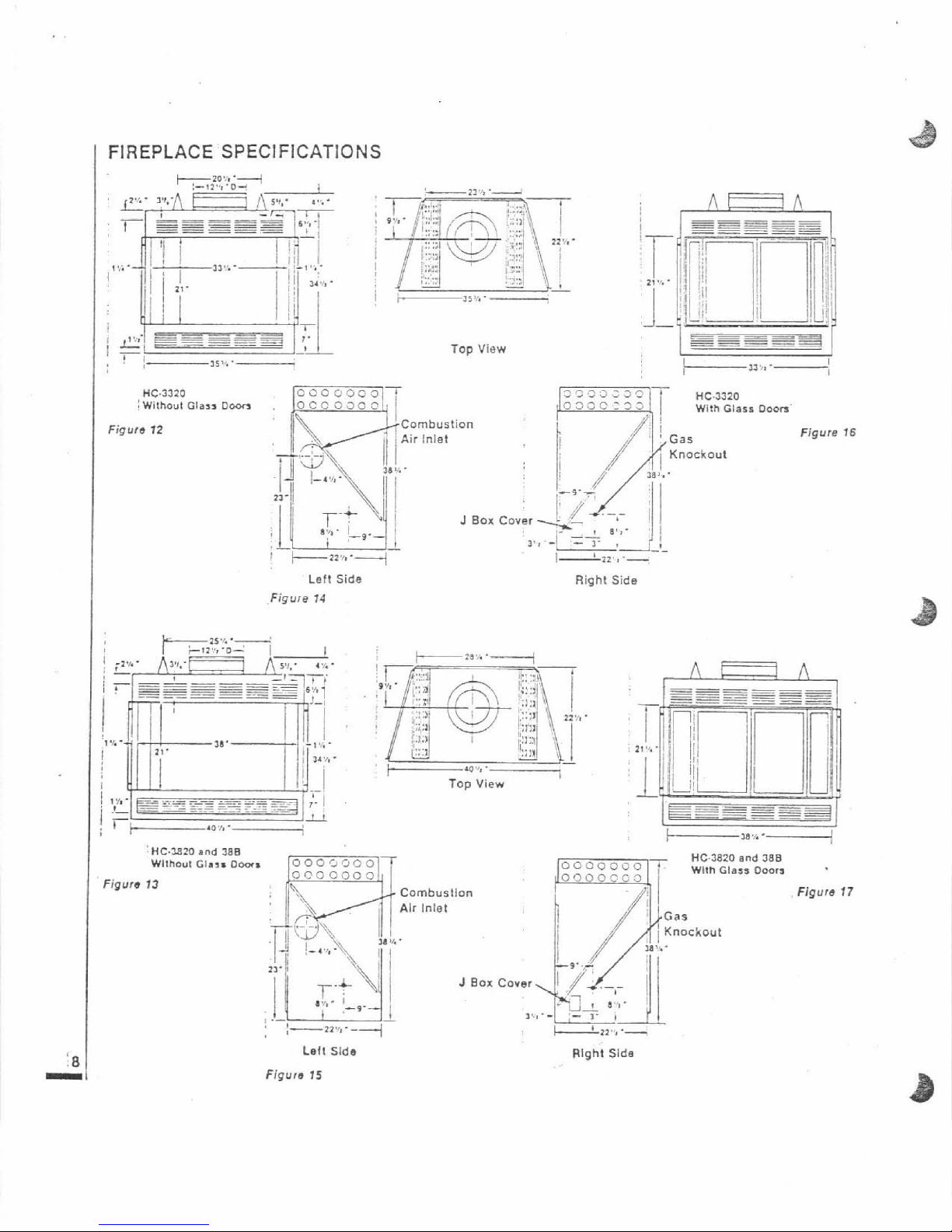

FIREPLACE

SPECIFICATIONS

?---

21

'+

'-

-----

A

i.

----

----

-

-

-

Top

View

--a

IS".'

!

I

J

Box

Left

Side

Figure

14

Figure

'HC.3820

and

388

Wltheut

Glass

Doas

,

13

HC.3320

0350333

With

Glass

I-

>>'>.-.

Doo"'

Figure

16

1C.',

Top

View

Lell Side

Flgurs

15

Right

Side

Combustion

Alr

lniet

J

Box

:

;-22,,,.-

i

HC-3820

and

28B

\

With Glass

Dm*

Right

Slda

Figure

17

Page 8

FRAMING

SPECIFICATIONS

+A--5

Fireplacs Framing

Figure

18

'If

Wall

Is

Inside

Usa

!T09.4

or

708-6

Adaolsr

AK.40,

AK.6

With

Combustion

At,

Kit

7

/

I

LA-

E-

108.4,

TOE-6

(Corner lnslallation)

I

(Oulalda

Chase)

Flgore

m

AK.4

Ol

AK-8

Combuolion

Air

KII

H

Mln.

Ceiling

Framing

(insids

Chase)

Figure

21

Figure

22

HC

AND

B

FRAMING

DIMENSIONS

40%

"

23%

"

28!&

"

11

"

14'/8"

6a'/~"

73'i,

"

34%

"

36'1,"

G

22?1

"

22

5'2

"

H

Without

3"

3"

H

With

'

8

"

8"

FRAMING DIMENSIONS

FOR CEILING

Ceiling

Opening

Type Flue

TF8,

Vanical

14'/~" 14%

"

TF8. Offset

30'

(Offset

applied

Only

to

ceiling

14'/2

"'

25"'

'Combustion

Air

Kil

I

AK-4,

AK.6

1

Figure

2.3

:FRAMING DIMENSIONS

FOR

ROOF

Roof

Opening

Page 9

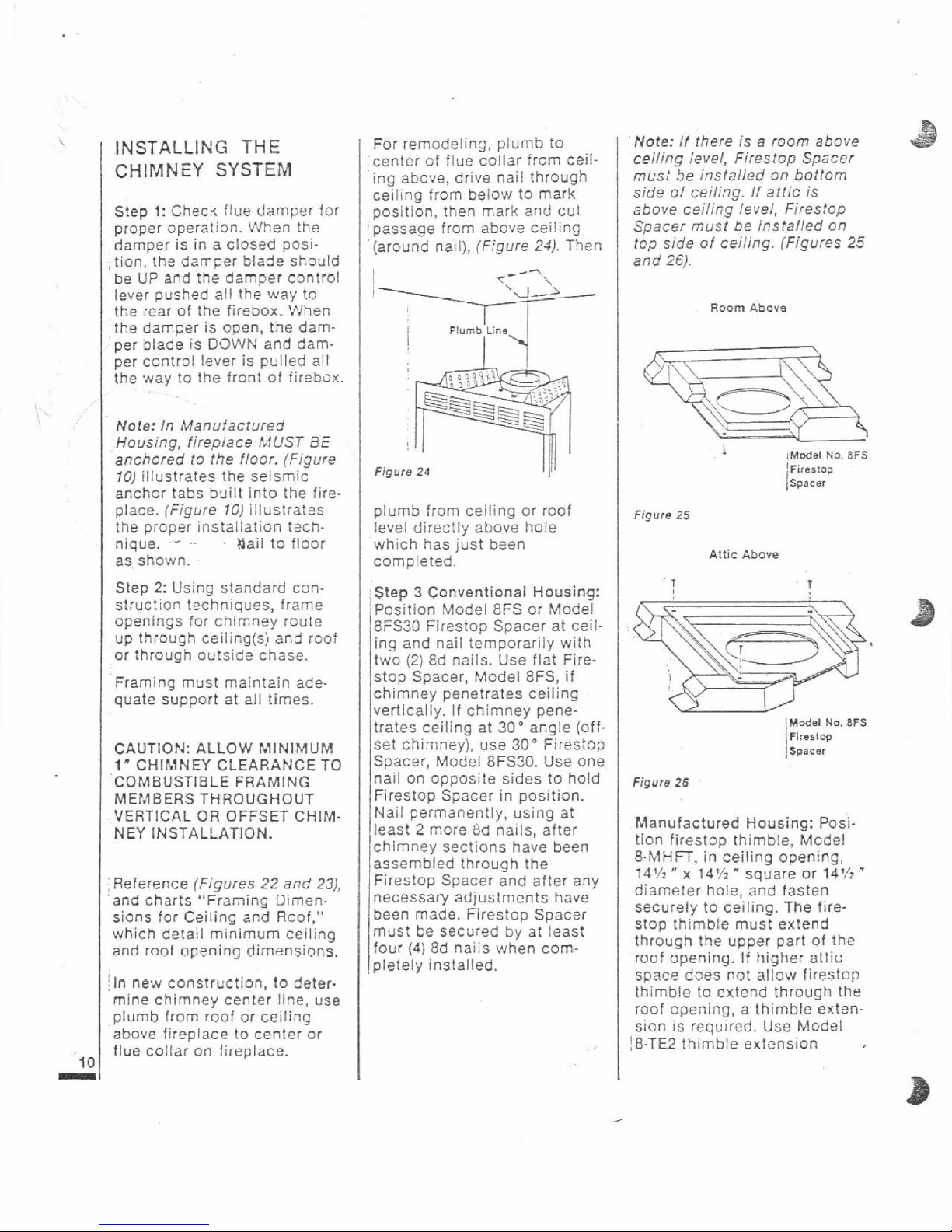

INSTALLING THE

CHIMNEY SYSTEM

Step

1:

Check flue damper for

proper operation. When the

damper is in a closed

posi-

,tion, the damper blade should

be UP and the damper control

lever pushed all the way to

the rear of the firebox. When

the damper is open, the damper blade is DOWN and damper control lever is pulled ail

the way to the front of firebox.

Note:

In

Manufactured

Housing,

lireplace

MUST

BE

anchored to the floor. (Figure

10)

illustrates the seismic

anchor tabs

built into the fire-

place. (Figure

10)

illustrates

the proper installation technique.

-

.-

.

Nail to floor

as, shown.

Step

2:

Using standard construction techniques, frame

openings for chimney route

up through

ceiling(s) and roof

or through outside chase.

Framing must maintain ade-

quate support at all times.

CAUTION: ALLOW MINIMUM

1"

CHlhlNEY CLEARANCE

TO

COMBUSTIBLE FRAMING

MEMBERS THROUGHOUT

VERTICAL OR OFFSET CHIMNEY INSTALLATION.

;Reference (Figures

22

and

231,

'and charts "Framing Dimen.

sions for Ceiling and Roof."

which detail minimum ceiiing

and

roof opening dimensions.

For

remodeling,

plumb to

center of flue collar from ceiling above, drive nail through

ceiling from below to mark

position, then mark and cut

passage from above ceiling

(around nail), (Figure

24).

Then

~n

I

--?

Plumb

Line

jln new construction, to deter.

mine chimney center line, use

plumb from roof or ceiling

above fireplace to center or

flue collar on lireplace.

plumb from ceiling or roof

level directly above

hole

which has just been

completed.

Step 3 Conventional Housing:

i~osition Model 8FS or Model

j8~~30 Firestop Spacer at ceil-

ing and nail temporarily with

two

(2)

ad nails. Use flat Fire-

stop Spacer, Model

8FS,

if

chimney penetrates ceiling

vertically.

If

chimney pene-

trates ceiiing at

30'

angle (off-

set chimney), use

30'

Firestop

Spacer, Model 8FS30. Use one

nail on opposite sides to hold

Firestop Spacer in position.

Naii permanently, using at

least

2

more 8d nails, after

chimney sections have been

assembled through the

Firestop Spacer and after any

necessary adjustments have

been made.

Firestop Spacer

I

must be secured by at least

four

(4)

8d nails when com-

pletely installed.

thimble to extend through the

roof opening, a thimble extension is required. Use Model

!8-TE2 thimble extension

Note:

If there is a room above

.&

ceiling level, Firestop Spacer

must be installed on bottom

side of ceiling. If attic is

sbove

ceilifig level, Firesfop

Spacer must be installed on

top side of ceiling. (Figures

25

and

26).

Room

Above

I

Model

No.

8FS

lFirertop

Ispacer

Figure

25

Attic

Above

lModel

Na.

BFS

Firerlw

Spacer

Figure

26

Manufactured Housing: Position

firestop thimble, Model

8.MHFT, in ceiling opening,

14%" x 14'/2"

square or

14%"

diameter hole, and fasten

securely to ceiling. The

firestop thimble must extend

through the upper part of the

roof opening. If higher

attic

saace does not allow firestop

Page 10

manufactured by Superior

Fireplace Company to extend

firestop thimble to proper

length. (Figure

27)

illustrates

typical

firestop tnimble instal.

lation. (Figure

281

shows an

installation requiring the

8-TE2 thimble extension. The

thimble extension slides over

the

firestoo thimble for a max-

imum

30"

combined height.

After determining proper

:height, fasten with four sheet

metal screws where the two

thimbles overlap (Figure

23).

Screws are provided with the

8-TE2 thimble extension.

Step

4:

Note: Chimney sec-

tions

are constructed with a

unique locking !ab design

whichi!suresan immediate,

tight

zssembly between sec-

tions. Plan your chimney

requirements

c~refully before

assembly as chimney is

difiicui: to disassemble after

installation.

The

TF8 Chimney System is a

two piece chimney, which

snaps together from the fire-

place up.

Start

viith the inner flue sec-

tion. With the hemmed end

Lacking

TrimtoFitROaf

Flashing

BMHT

Figure

27

,,,

I

Outer pipe section installs in

just the opposite way; the

hemmed end goes

UP

and

each new section goes

OVER

the outside of the previous

section installed. (Figure

30).

Note:

Assemble one complete

section of chimney at

a

time

(inner section first, then outer

seclion last) before proceed-

ing

with the next complete

section. Continue to build flue

pipe assembly up through

framed ceiling openings and

roof frame opening. Assemble

just enough to penetrate the

roof and flashing openings

(Figure

31).

Always maintain

1"

minimum clearance to

combustible materials and

always check each pipe joint

:(inner and outer) to insure pro:per engagement. Check verti,cal alignment of flue pipe so

;that it projects the roof in a

;true vertical position.Use--.

level

if

necessary~o-ks~~qrel.

'proper vertical position.

Superior chimney sections

need not

be

screwed together

for additional reinforcement.

down, snap lock it to the

matching locking flue collar

on top of fireplace. At all subsequent joints, the upper

piece fits inside of the lower

piece. Each piece snaps

togetker and locks by means

of locking tabs

(9

locking tabs

per joint). Check each piece

to

insure~proper ensagernent,

beioie

installing preceding

section by pulling slightly

from the top. If the chimney

section has been installed

correctly, it will not separate

[when you test it. Also, the

chimney joint where each

section is joined should be

;tight and flat with no gaps

(Figure

29).

Flgure

28

Page 11

Clearance

lo

Cornbusl~ble~

RJn9.

Fnr

M.nr,f2r+r,mrl

.

n+nd

t-+n.inisrrrrtte&a9L--

Housing: The chimney sec-

tions can be installed in any

sequence, by length; however,

there are two important

considerations:

71

If two sections of chimnev

rrrru iu

ur

ju~firo iuyrriirr

inside the thimble, join the

sections first before inserting

through the thimble.

2)

The height of flashing and

chimney sections which pro-

ject above the

roofline shall

not exceed

13'6"

from ground

level for transporta

tion pur-

poses. In (Figure

32).

it is

assumed the floor level of the

Manufactured Home is

30"

above the ground.

Step

5:

The heignt of vertical

flue pipe supported oniy by

the fireplace must not exceed

30

feet. Flue heighls above

30

feet must be supported by a

Model 634 unitized stabilizer

installed at 30 foot intervals.

2

I

Note: The Model

8-S4

unitized

stabilizer adds

2%

inches net

effective height to the total

chimney system.

Figure

32

Install the model

8-54

stabili-

zer by fitting inner section

down into respective section

of preceding flue pipe and

locking outer stabilizer section into place over the outer

flue pipe. Position for proper

clearance through framed

opening and nail straps

securely (under tension, in

"shear") into place on framing. Use

8d

nails. Attach

successive lengths of flue

pipe directly to stabilizer

using same technique as

described

in Step

3.

Note:

Do

not apply excessive

pressure to any subsequent

chimney sections following

the stabilizer when installing.

Insure each subsequent chimney section is securely

attached, however, by testing

as noted in Step

4.

Step

6:

Select proper Superior

roof flashing, depending on

the pitch of roof. Use chart

below for selection:

[

Roof Pitch

I

Model

]

-

---z

*--I-

-L--,..L-

...A

...,

Next, slide roof flashing over

extended chimney section

that previously had been

instalied above the roof opening in Step

4.

Slide flashing

all the way down until the

fLa,s,hi!g3,?,%

r~L~,f/$?eOfl,Eh,B

position of the chimney and

the

I'

minimum clearance to

combustibles.

Figure

34

Step

7:

Secure flashing by

nailing along perimeter into

roof using

8d nails. If shingled

roof, slide upper end and

sides of flashing under

shingles (trim if necessary)

(Figure

34%

seal the top and

both sides of the flashing to

the roof with roof caulking.

Cover nail heads with roof

caulking.

Page 12

b

.Step

8:

The standard Superior

:roof flashing assemblies

;include a storm collar. Slide

jstorm collar over outer flue,

align with top surface of

flashing, insert storm tab in

I

Slot, pull tight and bend tab

i

back over slot. Seal storm

1

collar to outer flue pipe with

:roof caulking or mastic

/

around entire circumference

j

of pipe. (Also add extra roof

caulking where storm collar

meets flashing and to the

tablslot area to seal completely against water penetra.

:tion (Fioure

35).

Check all

-

joints

very

carefully

tb

insure

'no water intrusion can take

,place.

Step

9:

Superior locking

bands (Model

8LB)

may be

required

if

chimney extends

too high above the

roof1

flashing.

As

a general rule,

if

the chimney extends more

than

6

feet above the roof1

flashing, the use of locking

bands is advisable to

strengthen the chimney joints.

Ali~n locking band (one per

pipe joint) at the pipe joint

-

locking band wraps around

pipe joint, equally covering

the joint of

both 3ipe sec-

tions. Use nut provided and

TIGHTEN snugly. Do not over

tighten as this nay

damage

flue section (Figure

36).

!

Step

10

Conventional Homes:

If

using a CTD round contem-

porary termination:

1)

Hold CTD over top of last

chimney section (Figure

38).

2)

Center inner slip section

into inner flue

pipe - slip

down.

3)

Center outer locking sec

tion over outer flue nine

-

?-

iecklng

Band

push down until locking joint

snaps into position.

4)

Pull up slightly on CTD to

insure locking joint has firmly

engaged.

1

Note:

If

chimney extends

more than

s

feet above roof

line, guy wires are also

recom.

mended. Use fhree

(3)

guy

wires, attach to locking band

assembly, extend end secure

to roof in a triangular paftern

.(Figure

37).

Guy wires not sup-

plied

by

Superior.

Figure

38

w

Using a CT1 Chase

Termination

Note: Refer to specific instal-

lation instructions

~ncluded

viifh

CT7

chase termination

for

deta~is.

Manufactured Housing

Note: Complete and inspect

instaliation Steps

i

fhrough

9

as required prior to shipment

from factory. Step

10,

install-

ing the

termination, will be

completed

after the manulaclured home has arrived at the

instaliation site.

Page 13

'Always cover exposed chim.

ney sections with water proof

protection for storage and

transportation between

fac.

tory and installation site to

prevent rain and other foreign

matter from collecting inside

the fireplace and chimney.

Remove this protective covering immediately prior to

installing the termination.

Failure to do so will create a

fire hazard should the chimney sections and its cooling

system become blocked.

:The TF8-MHT mobile home

;termination adds 17%" effec.

tive height to the installation.

Use this dimension to determine

if

additional chimney

sections are required. Provide

a safe and legal

termination

height. Consult the ten foot

rule summary section on this

page for detailed information.

To install the

TFG-MHT

Manufactured Housing Ter-

mination, slip the termination

onto the preceding chimney

section. Wrap the locking

band, Model 8-MHLB, around

the joint and fasten securely

with the nut and bolt provided

'(Figure

39).

Figure

40

TEN

FOOT

RULE

MULTIPLE

SUMMARY

TERMINATIONS

The minimum chimney height

,above the roof is specified by

all major

U.S.

building codes.

If the horizontal distance from

the chimney

edce to the peak

'of ihe roof is more than 10

feet or less, the top of the

'chimney must be at least

2

feet above the peak of the

roof.

If the horizontal distance from

the chimney edge to the peak

of the roof is more than

10

feet, a chimney height refer-

ence point is established on

the roof surface

10

feet hori.

zontally from the chimney

'edge. The top of the chimney

must be at least

2

feet above

this reference point. In all

cases the chimney cannot be

less than

3

feet above the

roof at the edge of the

chimney.

!The

2'

in

10'

rule is necessary

'in the interest of safety and

Jdoes not insure.smoke-free

operation. Trees, buildings.

adjoining rooflines, adverse

wind conditions, etc.. may

require a taller chimney

should the fireplace not draft

properly (see Figure

40).

If more than one termination

is located on the same chase

or within the same general

proximity, we suggest they

'should be separated in dis-

tance at least

24"

horizontally

from

flue center to flue center

and stacked, or soldiered

vertically at least 18" apart, from

termination smoke exit to

termination smoke exit. See

(Figure

41)

for detail.

:This suggestion is in the

inter,est of better satisfactory oper:ation and use.

If

terminations

!are located too close to each

other, smoke may migrate

from one flue into the other.

I

Figura 41

Page 14

.TF8 CHIMNEY

'COMPONENT

iCALCULAilONS

I

iMinimum installed height of

'the

HC

and B series fireplace

!systems (including fireplace

!and chimney components) is

!12'0" in conventional homes

:and 12'0" in manufactured

.housing. The maximum height

:is

80' in conventional hones

and 20'0" in manufactured

,housing.

lation. This

dimension

is the

,distance

from the

FLOOR

the

fireplace

Sets on to the point

where smoke exits from the

term~nation.

.2.

Determine the number of

:chimney components required,

except chimney sections. This

would include firestops,

stabi-

I

lizers, roof flashing, etc.

3.

The effective heights of the

components are:

HCand

B

Series

Fireplaces

=

38"

4.

Determine amount of chim;ney height required by sub*tracting total combined height

I

!of all preselected components

(fireplace and chimney com-

ponents) from total desired

i

height.

Reference Vertical Elevation

Chart and determine number

:of chimney sections (quantity

,and length) required.

I

MANUFACTURED

HOUSING

VERTICAL ELEVATION CHART

CONVENTIONAL HOMES

:To determine the number of

chimney sections and chimney components required,

;follow these steps:

7.

Determine total vertical

[height of the fireplace

instal-

jorder separately.

'C~~~ermination

=

4"

CTi Termination

=

18"

'54

S!abilizer

(required for every

30'

of vertical chim-

:ney and 10'of

(offset chimney

=

21/>

Use Model TFB.MHCP.1 which

'contains all chimney

compon-

Ients and chimney sections

fo;

typical manufactured housing

,installations. It provides for

;an installed height

of

12'2".

If

;additional chimney sections

!or components are required,

Page 15

I

'OFFSET CALCULATIONS

1.

Use Offset Charts to deter-

mine amount

of horizontal off-

set

(A)

and height

(B)

for

various flue pipe section

assemblies.

2.

Use "Height of Flue Only"

column on Vertical Elevation

Chart to determine combinations of pipe used above

return elbow to achieve

desired heights. Reference

components effective height

chart in vertical elevation

chart section.

,

,

3.

To use Elevations Chart as

job estimator only; add

neces.

sary firestop spacers and stabilizers, as required.

Firestop

spacers must be used as

shown in

(Figures

25

and

26)

and stabilizers as shown in

(Figure

33).

*

I

TFO.E30

111

Refurn

Elbow

I

Chmnay

Sections

Ollsel

Elbow

I

OFFSET ELEVATION

CHART

Page 16

Q

OFFSET

INSTALLATIONS

Special Offset Instructions

To clear any overhead

obstructions, you may offset

your chimney system using

Suoerior

30"

offset and return

elbows (Models

TFB-30 and

TFB-E30).

Use two elbows - an offset

.elbow to initiate the offset

and a return elbow to

terni-

nate it.

The offset and return elbows

may be attached together, or

a section or sections of chimney in between may be used,

but do not exceed

20'

in total

length between elbows (see

Figur2

43).

If

sections of pipe

exceed

i0'

between elbows, a

chimney stabilizer must be

used at the

10'point. The sta-

bilizer

support straps must

be

securely attached under ten.

sion (in shear)

!o structural

framing members above (see

Figure

d3).

Vlhen two sets of

elbows are used, the

maimum combined lsngth of

chimney used

between each

set of elbows cannot exceed

20'

(see Figures

44

and

45).

Example: If

C,

=

iO'then

C,

'cannot exceed

10'.

A

30" off-

set elbow, angling in any

direction, may be the first

component used off the top of

the

fire~lace flue collar.

~

~~

needed for your

Maximum offset of chimney

and purchase

system is

30".

TVJO offset

1,

before beginning insfaliation.

'elbows must not be assem,bled to form a

60°

offset.

Figure

43

I

Figure 44

Figurs 45

However, two sets of offset

and return elbows

nay be

used in

a

single flue system,

provided the total

heigh: of

the system exceeds

25'.

1

Return elbow support straps

must

be securely attached

under tension (in shear) to

structural framing members

:above (Figure

46

Page

78).

Note: The TF8-MHCP-1 Manu-

'faclured Housing Chimney

Pack does not contain any

offset or return elbows

to

i

facilitate offset chimney

!

instailation. Calcuiate the

!additional

chimnev com-

1

Page 17

TO INSTALL

OFFSETS

First. review chimney offset

elevation chart and Figure

42

on page

76

for reference.

:step

1:

Determine the offset

distance where flue is to pass

through the first ceiling

-

dimension

"A".

To find lhis

point on your ceiling, first

determine the centerpoint for

'a vertical chimney following

the instructions for vertical

installation.

Measure height to the ceiling

from top of fireplace

-

dimen-

sion

"0".

Use offset Elevation

Chart to find dimension "A".

Mark point where you

will

drive your nail to show the

centerpoint for your offset

ceiling cut.

Step

2:

Proceed by using the

Straight Up

Instailation

lnslructions for cutting and

framing ceiling and roof

openings.

Note: See

Fram~ng and

Dimension Chart for the sizes

of the ceiling and roof openings. The size of the roof

opening varies with the

degree of the pitch of the

roof.

OFFSET ELBOW

ASSEMBLY

IFBE30

Return

Elbow

18

-

Figure

46

Offset elbows install the

same as chimney sections.

First, snap the inner section

INTO the preceding inner sec-

tions of chimney. Check connection by pulling slightly to

insure a tight fit. Next, the

outersection snap locks

OVER the preceding outer

section of chimney. Again,

'check outer

sectlon by pulling

'slightly to insure proper

connection is made.

RETURN

ELBOW

ASSEMBLY

Return eibows ins!ail the

same as stabilizers and round

contemporary terminations.

Follov~ these easy steps:

1)

Hold unitized return elbow

over top of last chimney

section.

2)

Center inner slip section

into inner flue pipe

-

slip

down.

3)

Center outer locking sec-

tion over outer flue pipe

-

push down until iocking joint

snaps into position.

4)

Pull upsljghtly on return

elbow-to

insu~Velocking joint

has firmiy engaged.

Remember, all offset and

return elbows and any chimney in between must be

installed to maintain at least

1"

clearance to combustibie

materials.

Note: Do not apply excessive

pressure to any subsequent

chimney sections following

return elbow assembly when

Installing. Insure each subsequent chimney section is

securely attached, however,

by testing as noted above.

CHIMNEY

OFFSET

30'

THRU FLOOR OR

CEILING

It may be necessary to construct the chimney at

30"

when passing through the

floor or ceiling area.

Use

30"

angled firestops as shown in

(Figures

47

and

43).

Support

the chimney at floor or ceiling

penetration

with stabilizer if

distance below the ceiling is

10'

or more. Maintain

1"

mini-

mum clearance to

conbust.

ibies from chimney sections.

Attic

space

BFS30

8%

Slabilirer

10:

Mar.

/

30'

Fire9lop

And Altic

Above

Figure

47

-,

10'

Max.

/

30'

Firattop

and

Rocm

Abors

Figure

48

Page 18

ACCESSORIES

Glass Doors Optional For

Conventional Homes

-

Required For Manufactured

Housing

If glass doors are to be

installed on this fireplace,

refer to specific installation

instructions packed with glass

doors. Superior glass doors.

-.::

'Model Numbers 33HGD-AB,

:38HGD and 38HGD-A9 are for

'use only on certain Superior

factory-built fireplaces.

Use on

any other fireplace may con-

'stitute a potential fire hazard.

Glass and metal frames

get

hot - always use wood

'handles to

oaen and close.

Glass doors are required for

installation in all manufactured home installations to

.cornply with Federal HUD

Q

:requirements.

COMBUSTION

(FRESH)

'AIR

SYSTEM

OPTIONAL

'FOR

i

CONVENTIONAL

-

:REQUIRED

FOR

MOBILE

;HOME INSTALLATION

-?

In Conventional Homes:

Use Combustion Air Kit Model

AK.4

with Superior HC and

B

fireplaces.

In Manufactured Housing:

Combustion Air Kit Model

AK-6 must be installed with

the Superior HC or

8

fireplace

to comply with Federal HUD

'requirements.

i

GENERAL

INFORMATION

Outside alr drawn into the

fireplace

suppltes alr to the

fire for combustion. Only one

combustion air duct on left

side of the fireplace is

required, if

ins:alled.

Figure

49

1

If additional length of duct is

:required, use locally available

;U.L.

Class

1,

aluminum

iducting. The duct may be

!extended

up

to

50'

in any

/direction.

I

I

Note: Do not terrn~nate corn-

bustion air kit rn attic space.

'There

is

one hand operated

shut-off damper at the left of

the firebox opening inside the

'fireplace. To open, pull out all

:the way. The combustion air

'damper should be fully open

/when the fireplace is being

:operated. When the fireplace

'is

not in use, fully close the

combustion air damper to pre-

;vent cold air from entering

your home.

TO INSTALL:

Reference installation instruc-

tions supplied with Models

,

AK-4 or AK-6.

Never locate inlet where it

can be blocked by shrubs,

snow drifts, etc. Never locate

in garage or any area where

.

there is another fuel burnlng

appliance or products emit-

tlng combustible gases such

I

as Paint, gasoline, etc. In cold

cltmales, it is recommended

that the combustion air duct

be insulated.

Outside combustion air

ducting may be installed

upwards, or vertically, through

framing and ceiling joists,

with the hood installed

through an outside wail or

ducting may be installed

downwards, through floor

joists, and under the floor of

the home. Ducting may be

installed into a basement

area, not considered part of

the living area or the home.

Figure

50

Figure

51

FORCED AIR KIT

If you are installing a Superior

Forced Air Kit. Model

FAK-1500, see the instruction

sheet provided in the kit for

electrical wiring requirements.

The fireplace has been prewired at the factory to accept

the forced air kit at some later

time. The fireplace must, however, be connected to main

power supply at time of installation

if

the FAK-1500 is to be

installed later.

Page 19

FIREPLACE FINISHES,

HEARTH

EXTENSIONS,

WALL

SHIELDS

I

FRAMING

Ilt's best to frame your fire!place after it is positioned.

:the chimney and the

ccmbus.

tion air kit,

if

applicable, is

/installed. Frame with

2

x 4's

:(or heavier) lumber. Frame in

accordance with local

prevaii-

ing building codes.

Note:

The header may rest on

!he top metal spacers, but

must

not be notched to lit

around them.

No clearance is required

,between the framing and

f~re.

'place and thimble (for manu-

factured housing use only).

However, remember a

1

"

clearance is required between

framing and the chimney.

To install the fireplace facing

flush with the finished

\vall,

position framework to accommodate the thickness of the

finished wall (Figures

52.

A,

5

I

'and

C).

To insta!l the fire?!ace facin~

flush vit3 sur:ou-d materials.

0osi:ion framework to accorn-

'modate the thickness of the

final

surroun materials

(Figure

52

D).

\

Flnirh

Wall

Oimenrion

Figure

53

GAS LINE

This provision

is

intended for

connection to a decorative

gas appliance only, in accordance

wirh the National Fuel

Gas Code,

ANSi Z 223.1-i960.

If you're installing a gas line,

concect it now. The gas

knock out location is determined by a

1

118"

round

indentation located at the

bottom and slightly off center

on the side refractories. THE

KNOCK OUT

IS

ALWAYS TO

BE

REMOVED

FROM

INSIDE

THE FIREBOX.

If

removal is

attempted

!rom the outer

wrapper

into the firebox, side

'refractory damage may occur.

With a medium-sized hammer,

lightly tap the surface of the

indentation. The refractory

material is very thin in the

area of the indentation, and

can be easily removed. Once

a small hole is made in the

knock out, continue to tap

lightly until the desired diameter is obtained. The knock out

area can be removed to a

total diameler of

1

118"; however, the entire knock out

does not have to be removed.

With the refractorv knock out

removed

:o the disired diarneter, remove knock out on

outer wrapper and install gas

line. Use only

'/2"

black iron

pipe through fireplace wall for

cocnection to a

106 lighter or

gas log unit inside

the firebox. Outside, the iron pipe

connects to a gas shut

o:i

valve recessed flush into a

wall or floor and controlled by

a removable valve key for

safety.

Always plumb gas line instal-

lation pe: state and local

codes. Check all connections

with soa9 suds; leaks will

bubble. Never test any gas

line connections with a match

or open flame.

IMPORTANT: Re-pack

insuiation in square hole around

gas line to seal.

CAUTION: WHEN USING THE

DECORATIVE GAS APPLI-

ANCE.

THE FIREPLACE

DAMPER MUST BE SET IN

:THE FULLY OPEN

POSiTlON.

COLD CLIMATE

INSULATION

If

YOU

live in a cold climate,

seal

all cracks around fire.

place with

non-combustib!e

material and wherever cold air

could enter room. It's espe-

cially important to insulate

outside chase cavity

Setsveen

studs and under floor on

which fireplace rests, if floor

of outside is above ground

level. Surround material must

be caulked where it meets

[he

black metal face of the fireplace to avoid air intrusion.

Use non-combustible caulking

mater~al only on fireplace

facing, to seal. Also the out.

side air inlet duct should be

insulated to minimize formation

of

condensation.

Page 20

HEARTH EXTENSIO NSI

WALL SHIELDS

*A hearth extension must be

installed with all

firep!aces. It

.is required !o protect :he floor

in front of the fireplace from

both radiant heat and sparks.

-The hearth extension must

extend beyond the front and

both sides of the fireplace

opening per the dimensions in

the chart

accompanyir,g (Fig-

ure

54).

Use either the metal

hearth extension

(Modsl HE-33

for HC-3320 or Model HE-36 for

.HC-3820 and 368) manufac;lured by Superior Fireplace

Company, or a

'It

"

thickness

!of millboard or a durable non-

combustible material

with

equal or greater insuiatirg

value. These materials may be

covered by a decorative

nan-

combustible veneer.

CAUTION: FIREPLACE MUST

BE RAISED IF HEIGHT OF

:HEARTH EXTENSION

EXCEEDS

I'll"

ABOVE

:BOTTOM OF FIREPLACE

:(FIGURE

55).

'*If

fireplace is installed on a

,combustible floor, use

:he

,metal safety strips (provided)

on the floor, extending half

'under the fireplace and half

under the hearth extension.

BETWEEN THE FIREPLACE

AND HEARTH

EXTFNSIAN

I

NON-COMBUSTIBLE

MATERIAL.

I

INSTALLING THE HEARTH

EXTENSION

BE

CAREFUL

*Secure the hsarth extension

to the floor to prevent

possi-

;

ble

shifting.

-If a side wall is closer than

15"

to the fireplace opening, a

wall shieid is reauired. Use

metal

wall shields (Model No.

:

WS4C)

manufactured by

Superior Fireplace Company or

construct

ia;i:h a

40" x 40"

x

1"

millboard cr a durable non-

combustible material

with

equal or Greater insulating

value. The wall shields may

b~

covered with a decorative non-

I

.

combustible veneer.

-

8

Figure

54

HEARTH EXTENSION

DIMENSIONS

Models

Letter HC.3300 HC.3800

'38"

I

8"

I

*If firepIace 1s Installed

dia-

,gonally, across a 90" corner,

Iflo wall sh~elds are requlred

((F~gure

12)

*For information regarding

non-combustible materials and

construction detaiis, contact

:Superior

Fireplace Company,

Customer

Senice Depar:ment.

Fi

PJlSH

TO

YOUR

TASTE:

There are a wile variety of

"finished looks" for your

'Superior fireplace

-

from for-

:ma1 ?.fall treatments to man

tels to rustic !.~ood paneling

to

warm brick facings.

I If you are uslng a combust.

i

ible material, do not overlap

the black

fireolace facing

(Fig.

,

ure

52)

I

I

FACING

AND

WALLSUR.

ROUNDS WITH A NON.

I

COMBUSTIBLE MATERIAL.

Max.

Thickness

ol

Hesnh

Extension

when

Figure

55

Fireplace

1s

on

FIOO~

Non.comtustible materials,

like tile, stone, brick, etc., may

overlap

the edge of the fire-

place opening,

thweon.r---

..

-

pletely-hiding the blackfire-

i

'placefacing; but be sure not

!to interfere with the operation

;of the glassdoor: See (Flgures

+16-md1-7)

for minimum front

facing dimensions if glass

doors are to be installed.

Page 21

SUPERIOR ACCESSORY

PARTS COMPONENTS

LIST

The following accessory parts

and components are to be

used only with your Superior

fireplace system. Separate

installation instructions all

packaged separately with all

glass doors, combustion air

Chimney

Ssst>on

TF8.35

Chimney

Ssclion

TF.18

Chimney

Secllon

TFB12

kits, forced air

fan

kits.

&ki~neytop terrnina:ions and the

manufactured hone

cF,imney

pack.

If you encounter any problem:

or have quesiions concerning

the installation or application

of this system, please

contact:

:

Fireslop

Spacer

(35'1

8FS3

Ollsal

Elbow

TFB30

Return

Elbow

TFBEIO

SUPERIOR FIREPLACE

COMPANY

Special Services Coordinator

4325

Artesia Ave.

Fullerton. California

92633

714-521.7302

Locking

B.t,td

8LB

Fleshing

Round

Te#rnlnatlon

TFbCTP

Page 22

Chase Terminallan TF8CTl

Thimble Ertenrlon BTE2

Chlmnay

Pack

Manulaclured

Hams

TF8.MHCP.l

Forced

Air Kil FAK.1500

t5

1 . TF8.CTD

Z

Firestop Thimble

(IHHFT

AK.4

Comburllon

AIr

Kit AK.6

Chimney

Pack

Canvanlidnai

TFa.CP7

108-4

Take

011

Boo1 Toe-6

3BHGD

33HGD.AB

Glars

Doers

33HGD.AB

Hearlh Extensions

HE46

Wall Shield

WS40

Relraclory Palch Kit

RPK

ReIra~twy Trlm

KI~

RTK

Loading...

Loading...