Superior GRD-5000N, GHC-5000N, GRD-5000L, GHC-5000L Installation And Operating Instructions Manual

Page 1

"INSTALLER.THESE

INSTRUCTIONSMUSTBE

CONVEYEDTOHOMEOWNER"

GHC-5000N.L

Installation

AndOperating

Instructions

ForSuperior's

VentedType

Decorative

GasAppliance

NaturalGasModels

GRD-5000N

GHC-5000N

PropaneGasModels

GRD-5000L

GHC-5000L

!r({J89y(

@

ThisinstaDationmanualwillhelpyouobtainasale,

efficient,dependableinstallationforyourfireplace

andventsystem.Pleasereadandunderstand

theseinstallationinstructionsbeforebeginningyour

installation.

WARNING:THEGRDAND GHCSERIESFIRE.

PLACES ARE VENTED DECORATIVEGAS

APPLIANCES.DONOTBURNWOODOROTHER

MATERIALIN THESEAPPLIANCES.

Do not attempt to after or modify the construction of

thefll'eplace or it'scomponents. Any modification or

alterationof constructionmay void the warranty,

certification and approvals of these units.

FORYOURSAFETY

Ifyou smell gas:

1.Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4.Immediately call your

gas supplier.

FOR

YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

DUETOHIGHTE

ES,THEAp.

PUANCESHOUl rEDOUTOF

TRAFFICANDA1

FURNITURE

ORDRAPERIES.

DONOTPLACE OROTHER

MATERIALSON

THEAPPU.

ANCE.

PLEASERETAINTI

FORFUTURE

REFERENCE

Page 2

~

GENERALINFORMATION

Thisappliance compUeswithNational SafelyStan-

dards and is tested and listed by Underwriters

Laboratories, Inc. to ANSI Z21.50-1986 as a vented

decorative gas appliance.

Installation must conform to local codes. In the

absence of local codes installation must conform

with the current National Fuel Gas Code, ANSI

Z223.1. Theappliance,when installed,must be

electricallygroundedinaccordance withlocalcodes,

withthe National ElectricalCode, ANSIINFPANo.

70-1984.

Note:Installationandrepairshouldbe donebya

qualifiedserviceperson.Theapplianceshouldbe

inspectedannually

byaprofessionalserviceper-

son.Morefrequentinspectionslc/eaningsmaybe

requireddw toexcessive/intfromcarpeting,bed-

dingmaterial,etc.Itisimperativethatthecontrol

compartment,burnersandcirculatingairpassage

waysoftheappliancebekeptclean.

Provide for adequate ventilation.

~

Provide adequate clearances around air openings

and adequate accessibility dearance for service

and proper operation. Never obstruct the front

opening ofthe fireplace.

Minimumclearances to combustibles are:

Sides 112', Floor 0', Back 112', Ceiling 41 112',

Sidewall O', Vent Surfaces 1'.

Minimum inlet gas pressure is 4.5 inches water

columnfornatural gas and 11 inches water column

propane forthe purpose of input adjustment.

Maximuminlet gas supply pressure is 7.0 inches

water columnfornatural gas and 13.0 inches water

column for propane.

Input is 18,000 aTUMR

A 1/8' N.P.T. plugged tapping is provided on the

gas control along side of the outlet to the main

burner fora test gage connection.

This apptiance must oot be connected to a chimney

flue servicing a solid fuel burning appliance.

The appliance must be isolated from the gas supply

piping system by dosing its individual manual shut-

off valve during any pressure testing of the gas

supply piping system altest pressures equal to or

more than 112 psig.

2

INTRODUCTION

The GHC-SOOOis a heat circulating system that

utilizing a miUivok gas control valve and a piezo

ignition system. Glass doors, trim kits and a forced

air fan assembly are optional equipment.

The GRD-SOOO

is a radiantheat system that utiliz-

ing a millivoh gas control valve and a piezo ignition

system. Glass doors are optional equ~ment.

ASSEMBLYSTEPS

1.Position appliance prior to framing or into pre-

pared framing.

2.Route gas line to firebox compartment and install

m~livoh waD switch.

3. Install vent system.

4. Field wire main power supply to appliance junc-

tion box (only if optional fan assembly is to be

installed aI a later time).

5. Complete finished wall malerial and trim.

6. Install controls and burner assembly. Connect to

gas supply.

7. Wife remote millivolt wall switch to control valve.

8. Attach horizontal louvers andlor optional \rim

pieces.

9. Install the optional glass doors.

INSTALLATION

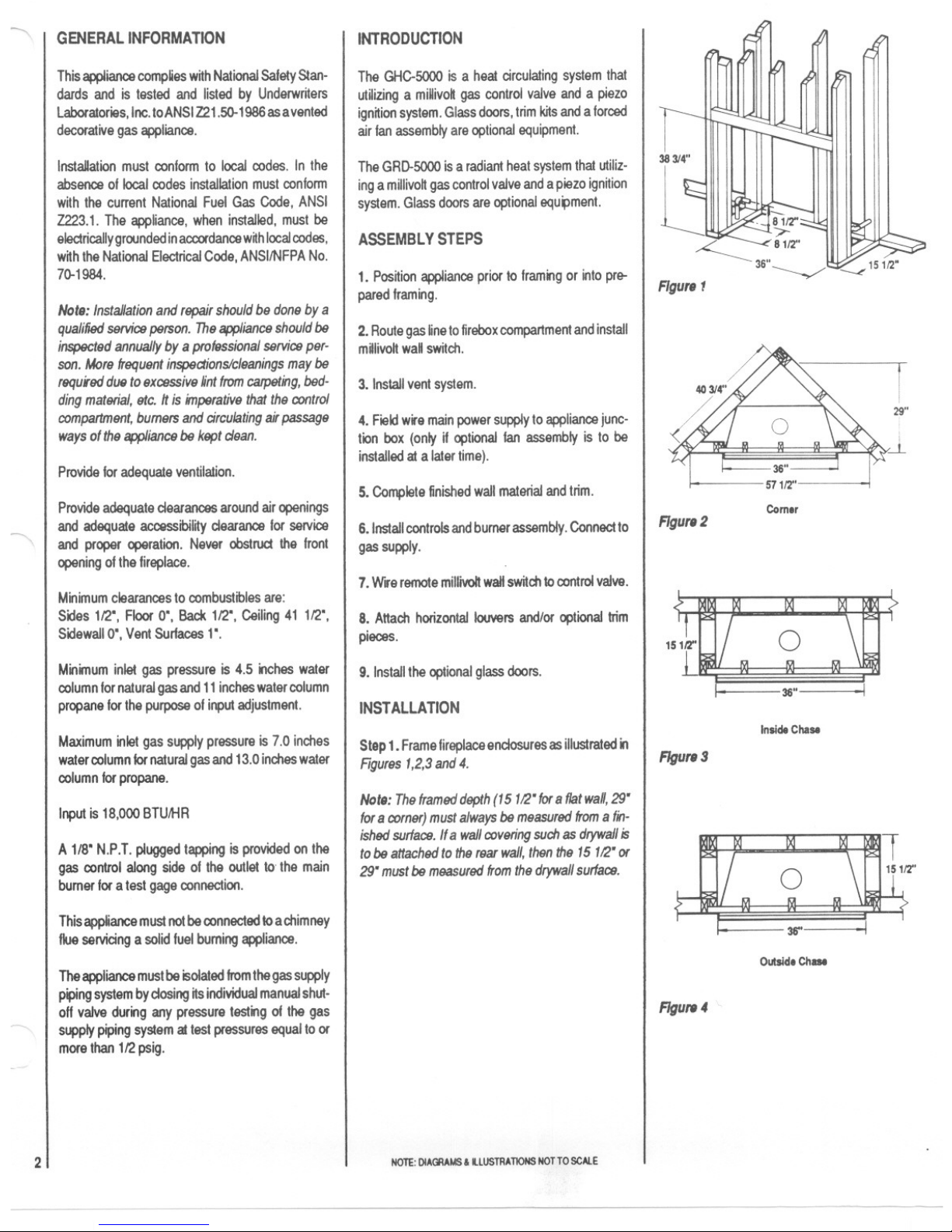

Step1. Frame fireplace endosures as illustrated in

Rgures1,2,3and4.

Note:Theframeddepth(15112"for8flatwall,29"

for8corner)mustalwaysbemeasuredfromafin-

ishedsurface.Ifa wallcoveringsuch

as drywallis

tobeattachedtotherearwall,thenthe15112"or

29"mustbemeasuredfromthedrywallsurface.

NOTE:DIAGRAMS& illUSTRATIONS NOTTO SCAlE

~

r

29"

i

~

Comer

FIgure2

36"

Inside Chase

FIgure 3

mt

36" I

Outside Chase

FIgure4

Page 3

~

Step2.Routea112"NPTbiackirongasline8112"

abovethefloorsurface(iffireplacewillberestingon

thefloor)and8112"behindthefaceattherough

framing(Figure5).

~81fl'

Figure5

Note:Itisprefe"edtoroutethegaslineontheright

sideofthefireplace,however,thegaslinemaybe

routedtoeitherside.Thisgaslineshouldextendat

least2"intothecontrolcompartment(FIgure6).

~

jX'J

L

~~

FIgure6

Step3.Positiontheapplianceintopreparedfram-

ing,naifingwith6dnailsthroughthenailingftange

holes.

Not,:Thenailingflangeandtheareadirectlybe-

hindthenailingflangeareex9l1lptfromtheclear-

ancesdescn'bedontheclearancelabel.

Step4.Installtheremotewallswitchinaconven-

ientlocationandroutethe18gagemilivotwire

throughtheoppositegaslineaccessholeintothe

controlcompartment.Atleast15"ofwireisrequired

inthecontrolcompartment.

Connecta 5"typeB-ventsystemtothefireplace

flueoutercoUarwithtwo(2)No.8 sheetmetal

screwsandinstalltheremainderofthistypeB-vent

to theoutside.Minimumheightof theventand

fireplaceshouldbe12feel.

LYBTYpe Vlnt

8-.

FlulCo"ar

Assembly

" .

FlUIOIII

11

II""

Collar "

"

".."

FIgure

7

Note:RefertotheventmanufacturersinstaHation

instructionsforvariationsofventingtechniques.If

commonventingofseveralunitsiscontemplated,it

shouldbediscussedwithanarchitectandthelocal

BuildingDepartment.

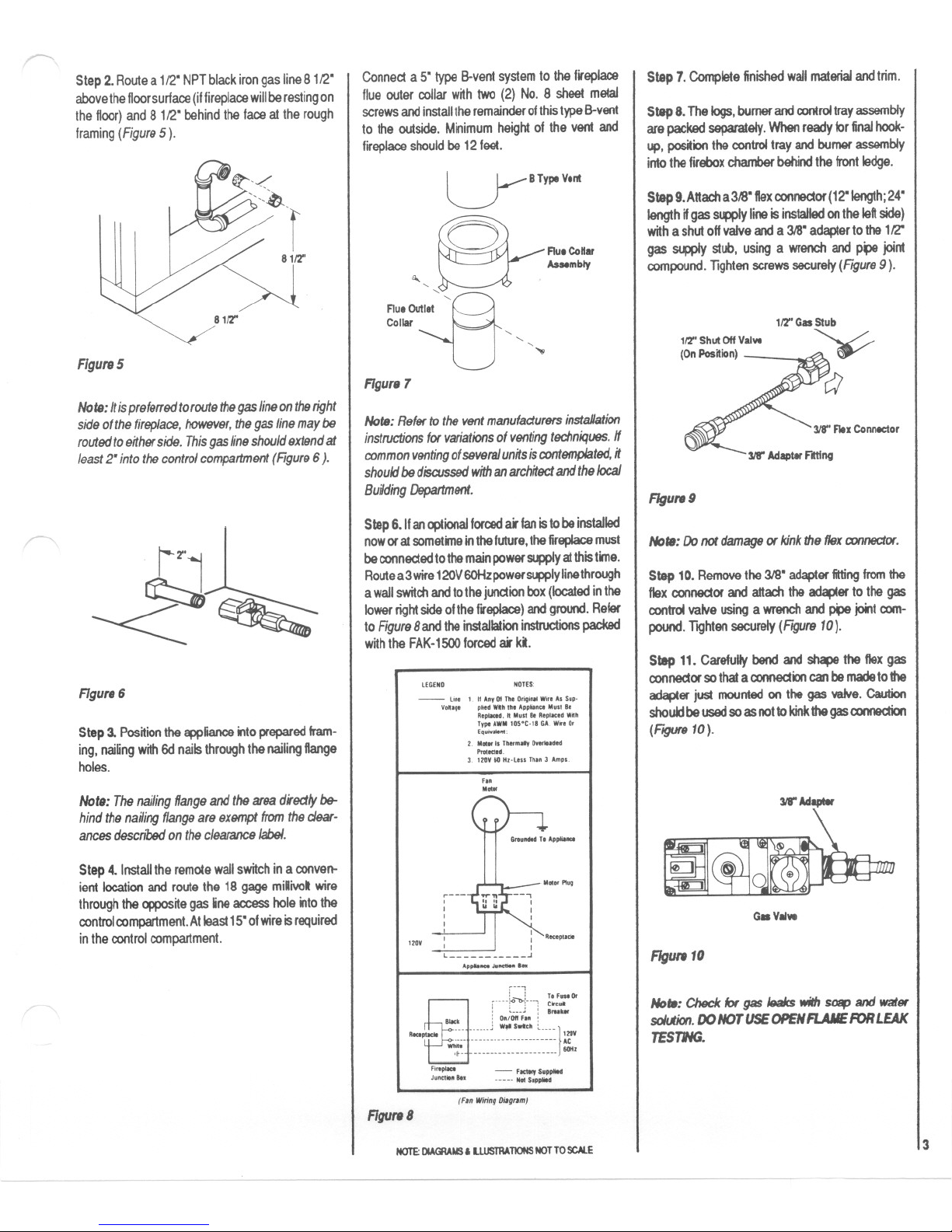

Step6.11anoptionalforcedairfanistobeinstalled

noworatsometimeinthefuture,thefireplacemust

beconnectedtothemainpowersupplyatthistime.

Routea3wire120V OOHzpowersupplylinethrough

awallswitchandtothejunctionbox(locatedinthe

lowerrightsideofthefU'epIace)andground.Refer

toFIgure8andtheinstallationinstructionspacked

withtheFAK-1500forcedai' ki.

LEGEND NDTES,

Step7.Completefinishedwallmaterialandtrim.

Step8.Thelogs,burnerandcontroltrayassembly

arepackedseparately.Whenreadyforfinalhook-

up,positionthecontroltrayandburnerassembly

intothefireboxchamberbehindthefrontledge.

Step9.Attacha318"flexconnector(12"length;24"

lengthifgassupplylineisinstalledonthe leftside)

witha shutoff valve and a 318"adapter to the 112"

gassupplystub,usinga wrenchandp~ joint

compound.TIghtenscrewssecurely(Figure9).

112"ShutOffValve

(OnPos~ion)

FIgure 9

Note:Donotdamageor kinktheflexconnector.

Step 10. Removethe 318"adapter fittingfromthe

flex connectorand attachthe adapterto the gas

controlvalveusinga wrenchand ~ jointcom-

pound. Tighten securely(Figure10).

Step 11. Carefullybend and shape theflexgas

connector so that a connection can be madetothe

adapterjustmountedonthegasvalve.Caution

shouki be used so as not to kinkthegas connection

(FtgUf8 10).

W' Adlpllr

G. VII.

FIgure10

No,.: Check lor gas leaks with SOIipand water

soWon.DONOTUSEOPENFLAMEFORLEAK

TESTING.

3

- U.. 1 "A', 01Th.D", W", A. S",.

, ,"d WIh." A.."", M."..

"_d.hM."..'ep',,"Whh

T,peAWMIOS.C A we. D'

E,."...",.

2 M ,. Th..mOlyD d"

""'_d.

,. 12DY" N..lou Th" , Am,..

",

M""

M""~,,

12DY

~---

,

I

,

I

~ Ii""""'"

l ~

A" , ...

~

cnnl~';:L T"'.....

,: :,Ce,..

BIle, :D';Oti-:."i."""

-- --- hm.J WoO"",Lnu

~f -~~~~:::::---~~~:::::::}:r.

FI..-

"'d." ... - 'oc:1WyS......

no-. ... S...",

(F.n WiringO;.g""'1

FIgure8

NOTE:DlAGlAMS' LlUSTRAllONS NOT TO SCAlE

Page 4

r--

Aftergas lineinstallation iscomplete, use insulation

(not provided) to pack space where gas line pene-

trates the appliance. Pack insulation tightly from

outside the appliance tocompletely seal this space.

Step12.RemoteMIllivoltWallSwitchWiring.

Attach one wire !rom the remote miUivolt wall switch

to the "TH" terminal on the gas control valve.

Conned the otherwire from the remote millivok wall

swftch to "TH TP" terminal at the gas control valve

(Figure11).

r ~-

I

I

I

I

I

I

I

I

I

I

I

I

I

I

,

;:~

,

-I -I

~::I:

II~

r~:mo~~tfj-+-[2

GasVllve

To Remote Mllivol

Wall SwItch

Rgure11

CAUTION:DO NOT WIRE REMOTEWALL

r'~, SWITCHTOAMAINPOWERSUPPLY.

Figure12

Figure13

4

HROIZONTALTRIMINSTALLATION

On the GHC Model, remove the four (4) black

louvers and the two (2) antique brass cover pieces

from the protective container and fasten onto the

face ofthe fireplace. The louver str~ snap onto the

louver pegs wnhoutthe need fortools. T 0 assemble

the louver str.,s, tilt the str., on top of the pegs and

snap lower edge to lock in place. The antique brass

cover pieces are mounted over the support bars

directly over and below the fireplace opening. They

also snap into place. Keep the locking dimples on

the bottom side of the covers when installing.

FLAMECOLORIZATIONDEVICES

The burner assembly is equ.,ped with a special

flame enhancement rod located between the lower

logs and a mineral fiber llame enhancement strip

across from the (lower) burnerparts. These devices

colorize the gas flame and produce the "ember

effect".

In normal operation, these devices will provide

many hours ofsatisfadory performance. Overtime,

the orange color wUldiminish in intensity and it will

be necessary to purchase a replacement rod and/

or mineral fiber flame enhancement device. These

devices are available at nominal charge from your

local distributor/dealer or directly form Superior.

Flam. Enh8nctm.nt Rod

LogSet

Against

Back

Waft

HIGHELEVATIONDERATING

Wheninstallingthesefireplacesabove4,000feel

level, n is recommended that the fireplace bumerbe

derated by changing the existing orifice to a smaller

one. Order and install appropriate high altnude

orificekit(Figure15). .

i

~,j

1...,

~

148 Natural

158 Propane

(UseWhen

DeratingBurner)

Rgure15

ACCESSORIES

OptionalFanKIt

If the optional Ian kit, Model FAK-1500 is to be

installed on the GHC-SOOONor GHC-SOOOLgas

fireplace,refertotheinstallaiton instrudions packed

wnh the fan assembly.

The GHC-5000NandGHC-

SOOOLgas fireplacehas beenprewiredat the fac-

tory to accept the forced air kit at some later time.

The firepalce,must, however, be connected to

main

powersupplyattime of installation ifthe FAK-

1500 forced air kit is to be instaUedlater.

HorizontalTrimInstallation

There are three optional horizontal trim kits, Models

35HTK-SPS, HTK-PB and HTK-AB and two 0p-

tional vertical trim kits, Models VTK-ABR and VTK-

GOEavailableforusew~htheGHC-SOOOgas

fireplace.Refertothespecificinstallationinstruc-

tionspackedwnh eachtrimkitlortheirproper

usage.

OptionalGlassDoors

Several models of optional glass doors are avail-

able for installation on these gas fireplaces. Use

glass door Models 35G-PB, 33BF-AB, 33GOD-AS,

33GBF-PB, 33GBF-SPB, 33GBFT-SPB, 33GBF-

ABR and 35GT-SPS wnh Model GHC-SOOON,L.

ForModelGRD-SOOON,L gasfireplaces,useglass

door Models 33R-PB, 33BF-AB, 33GOD-AB,

33GBF-SPB, 33GBFT-SPB, 33GBF-ABR

and

33GBF-PB. Refer to the specific installation in-

structions packed w~h each glass door assembly

for installation

details.

Figure14

COLDCLIMATEINSULATION

If you live in a cold climate, seal all cracks around

your fireplace with non-combustible material and

wherever cold air could enter the room. It is espe-

cially importantto insulateoutside chase cav~y

between studs and under floor on which rests, if

floor is above ground level.

Surround material must be caulked where nmeets

the black metal facing of the fireplace to avoid

air

intrusion. Use non-combustible caulking material

onlyonfireplacefacingtoseal.

Do nol place insulation materials in the 1"gas vent

system clearance space.

NOTE:DIAGRAMS&LlUSTRA11ONSNOTTOSCALE

Page 5

~

GLASSDOOROPERATINGPRECAUTIONSAND

INSTRUCTIONS

.Keep wire mesh screens closed during fireplace

use.

.Never clean glass when doors are hot. Avoid over-

spray of cleaner on brass pieces.

.Glass and metal frames get hot. Use only the

wooden handles to open and close doors.

CAUTION:THEFIREPLACESHOULDONLYBE

OPERATEDWITHTHEGLASS DOORSFULLY

OPENORFULLY CLOSED.

-$-

Figure16

Bi.Fold

Glass Doors

-$-

~-T"~"'-"'--

1 ' '---'

AIl-Glassl'M'And Twin-Pan.

GlassDoors

Figure17

FIREPLACESPECIFICATIONSGHC.5000N,L

~

273/4"

~

357~'

!

41/4"

~

I

I

Top

Figure18

331/4"

I

341'rt'

U

I

21"

I

1112"

-'-~

.-

Rgure19

PJ

-i !-

~

4F~_.

8E . ilt D' ~12"

L

7~~

i

10" I

'6"~lilrt,T ~16"-.J

Ilrt'

Left Right

Rgure20

Front

FIREPLACESPECIFICATIONSGRD-SOOON,L

6112"

l;

L

Figure 22

357~'

331/4"-

.-

I

I

,

I

38314"

!

lkP'f

~15,,-J

Right

5

2'"

I

Front

Left

Rgur.23

NOTE:DIAGRAMS& IlLUSTRAnoNS NOTTOSCAlE

Page 6

~

FINISHEDWALLDETAILS

" isbesttoframeyourfireplaceafter~ispositioned.

Framewith2 x 4'sorheavierlumber.Framein

accordancew~hlocalprevailingbuildingcodes.

Note: Theheadermayrestonthetopmetalspac-

ersbut mustnot benotchedtofitaroundthem.

Toinstallthefireplacelacingflushwiththefinished

wallpos~ionframeworktoaccommodatethethick-

ness01thelinishedwall(Figure24,AandB).

Surroundmaterialscanbeplacedaroundthelire-

placefacingtoprovideaflushsurfacebetweenthe

surroundmaterialsandthefireplacelacing(Figure

24, C and0 ).

FinishedWill

~~,

/

11" Mln. ,

LL

GHC-5000N,L

It.

GRD-5000N,L

Non-combulllbl,

B

W8I1CoV8ring

finished Will

""Min. '

LL

GHC-5000N,L

C

FIgure 24

GRD-5000N,L

Non-combustlbl, D

WallCovering

Itisnotnecessarytoinstallahearthextensionw~h

thisgasappliance."a hearthextensionisused,do

notblockthelowerlouveredareaoftheGHC-5OOO.

Anyhearthextensionusedislorappearanceonly

andneednotconformtonormalspecifications.

Acombustiblemantelshellprojectingamaximum

018' Iromthewallmaybeinstalleda minimum

distance0111'abovethe GHC-5OOOandGRD-

5000fireplaceopening(Figure25).

6

GRD-5000 Or GHC-5000

Figure25

OPERATION

Tooperatetheappliance,relertothelightingin-

structionslocatedontheback01theIrontcover

assembly.

Yourappliancecontrolsystemisamillivotttype.It

consists01a pilotbumer,piezoign~ion,a gas

controlvalveandanONIOFFsw~ch.

Toobtainproperoperation,~isimperativethaithe

pilotandmainbumerflamecharacteristicsare

steady,notliltingorfloating,andbeblueincolor

(Figure

26 ).

Note:Forpropaneuse,airshuttermustbeopen

1/4inch(Figure30).

Naturel Of Porpana G.. Burntr

FIgure 26

Approximatelythetop3/8'atthepilotgenerator

(thermopile)shouldbeengulfedinthepilotllame

(Figure27 ).

Pilot Gtn8f8lor

(TherlllOpile)

Piezo

Ignitor

Theairshuttersontheventuritubehavebeenset

attheproperpos~ionatthefactoryforbothnatural

andpropanegasunits.Theairshutterfornatural

gashasbeensetinafullopenposition(Figures28

and29).

ManKold

8~~.

VenturiTube

NaturelG..

FIgure28

AIrShutter

1l0~\~

I~

~~3J'8"

Naturel Gas Top View

Figure29

Theairshutterforpropanehas

beensetinthehalf

open, or 1/4' opening(Figures30 and 31).

""'~ DO"

~

AirShutt'r

/ J~~ ..-

Venturi Tube

Propane Gas

Figure30

~

lJ t:.

POrpBne Gas Top VieW

Figure31

Figure27

7J

NOTE:DIAGRAMS&IlLUS1RATIONSNOTTOSCAlE

Page 7

,, ,

\

Anyvariationattheseairshuttersmayresultinan

erraticflameand/orthepossibilityofsooting,distin-

guishedbyabrightyellowflame.Anyadjustments

totheairshutterdifferentfromthatdescribedabove

couldcausetheburnerassemblyto malfunction

andcouldvoidthewarranty.

OPERATIONGUIDELINESAND

MAINTENANCEINSTRUCTIONS

1. Uponcompletingyourgaslineconnection,a

smallamountofairwillbeinthelines.Whenfirst

lightingtheappliance,~willtakeafewminutesfor

thelinesto purgethemselvesof this air.Once

purgingiscomplete,thepilotandburnerwillfight

andoperateasindicatedintheinstructionmanual.

Subsequentlightingsoftheappliancewillnotre-

quiresuchpurging.

2.When~tforthefirsttime,theappfiancewiDem~

aslightodorforanhourortwo.Thisisduetothe

"curing"ofthelogsand"burn-offofinternalpaints

andlubricantsusedinthemanufacturingprocess.

3. Keepcontrolcompartment,logs,burnersand

areasurroundingthelogscleanbyvacuumingor

brushingatleasttwiceayear.Donotvacuumthe

/"- mineralwoollocatedin the frontof theburner

assembly.

CAUTION:THE LOGSCAN GET VERYHOT-

HANDLEONLYWHENLOGSARECOOL

4.Alwaysturnoff gasto pilotbelorecleaning.

Beforere-lighting,refertothelightinginstructions.

5.Theapplianceandventingsystemshouldbe

inspectedbeforeuseor at leastannuallyby a

qualifiedserviceperson.

6.Alwayskeeptheapplianceareadearandfree

fromcombustiblematerials,gasolineandother

flammableliquids.

7.Neverobstructtheflowofventilationair.Keepthe

frontoftheappliancedearofallobstadesand

materials.

WARNING:CHILDRENANDADULTSSHOULD

BE ALERTED TO THE HAZARDS OF HIGH

SURFACETEMPERATUREANDSHOULDSTAY

AWAYTO AVOIDBURNSOR CLOTHINGIGNI.

TION.YOUNGCHILDRENSHOULDBESUPER-

VISEDWHENTHEY AREINTHESAMEROOM

~ . ASTHEAPPUANCE.

MAINTENANCE

IMPORTANT:Turnoffgasandelectricalpower

beforeservicingappliance.Itisrecommendedthat

acompetentservicemanperformthesecheckups

atthebeginningofeachheatingseason.

In orderto properlycleantheburnerandpilot

assembly,removetheglassenclosure,thelogs

andexposetheburnerandpilotassembly.

CleaningBurnerAnd

Pilot

Cleanallforeignmaterialsfromtopofburnerand

frombottompanelbelowburner.Checkto make

surethatburnerorificeisclean.

Visuallyinspectpilot.Brushorblowawayanydust

or lint accumulations.If pilotorificeisplugged,

disassemblymayberequiredtoremoveanyfor-

eignmaterialfromorificeortubing.Whenappliance

isputbackinservice,checkpilotflamepatterns

w~hRgure27.

WARRANTY

Yourgasfireplaceiscoveredbyaoneyearlimned

warranty.Youwitlfindacopyofthewarrantyinthis

manual.Pleasereadthewarrantytobefamifiarwnh

n'svaluablecoverageandfileRwRhothersyou

saveforfuturereference.

MILLIVOLTCONTROLLIGHTING

INSTRUCTIONS

1.Turnremotewalls~ch to"Off".Tumgasvalve

knobto"pilor,depressandturnto"011".Waitfive

minutes.

2.Turngasvalveknobto"pilot".

3.HoldindepressedposRionandlightpilotby

triggeringthesparkign~er(pushingredbutton)until

pilotlights.Continueholdingknobdepressedfor

approximately1112minutesuntilpilotremainsIn

whenknobisreleased.

4.Turngasvalveknobto"an".Tumremoteswnch

to"On".Burnerwincomeon.

SHUTDOWNINSTRUCTIONS

1.Theburnermaybeturnedoffbyturningremote

sw~ch"Off".ThepilotwillremainInfor returnto

normalservice.

2. Forcompleteshutdown:Tumremotesw~ch

.olr. Depressandturngasvalveknooto"Off'.

NO~:DIAGRAMS&illUSTRATIONSNOTTOSCAlE

PILOTBURNERADJUSTMENTS

1.Removepilot adjustmentcaponmainvalve.

2.Adjustpilotscrewtoprovideproperlysizedflame

(Figure27).

3.Replacepilotadjustmentscrew.

TROUBLESHOOTING

WrthproperinstaJlationandmaintenance,yournew

gasfireplaceshouldprovideyearsoftroublefree

service.Ifyoudoexperiencea problem,trouble

shootingguidesareprovidedinthismanual.These

guideswillassistyouoraqualifiedserviceperson

inthediagnosisof problemsandthecorrective

actiontobetaken.

REPLACEMENTPARTS

Contactthefactoryforquestionsconcerningprices

andpoliciescoveringreplacementparts.Partswill

besh"pedatprevailingprices.Normally,allparts

canbeorderedthroughyourSuperiordistributoror

dealer.

Whenorderingrepairparts,alwaysgivethefollow-

inginformation:

1.Themodelnumberoftheappliance

2.Thepartnumber

3.Thedesaiptionofthepart.

4.Theinstallationdateoftheappliance.

Ifyouhaveanyquestionsorproblems,contactyour

localdistributorldealeror:

Superior FIreplace Company

4325ArteslaAvenue

FuHerton,CA 92633

(714) 521-7302

7

Page 8

REPLACEMENTPARTSLIST

.~

ROBERTSHAWCONTROLS

8

*Note:Item21intendedforhighaltitudeinstallation.Item23includesitems14and22inasinglekit.

GHC.SOOON GRD.SOOON

GHC.SOOOL

GRD.SOOOL

NO.

DESCRIPTION

PARTNO. CTY

PARTNO. CTY

1

GasFireplaceAssembly

024711

1

024712

1

2

Bar,Louver

024501

4

-

3

Bar,Top

024491

1

-

4

Trim,Upper/Lower

024151 2

-

5

Panel,Screen/Pull

090083

2

090083

2

6

Rod,Screen

011381

2 011381

2

7

Refractory,Bottom

024931

1 024931

1

8

FrontCoverAssy.

025831

1 025833

1

9

Log,Main

028121

1 028121 1

10

Log,TopRight

028141

1 028141 1

11

Log

,TopLeft

028151

1 028151 1

12

Cover,ScreenRod

011351

1

011351

1

13 WallSwitchKit

025971

1

025971

1

14

FrontFlameEnhancementStrip

032631

1

032631

1

22

FlameColorizationRod

032351

1

032351

1

*23 FlameEnhancementKit

033711

1

033711

1

GHC.SOOON GHC.SOOOL

GRD.SOOON GRD.SOOOL

NO. CONTROLDESCRIPTION

PARTNO. CTY

PARTNO.

CTY

15

Valve,GasControl(#7000MVRLC)

009737 1 093771

1

16

Orifice,#46(natural),#56(propane)

092751

1 092752 1

17

Igniter,Mini

091301

1 091301 1

18

PilotGenerator(Thermopile-TP-75)

094699

1 094699 1

19

PilotAssembly

093761

1

093762

1

20

BurnerAssembly

024981

1 024981 1

*21

HighAltitudeOrificeKit

027961

1

027962

1

Page 9

c._.

iI.

°1 ~

00

13

NOTE:DIAGRAMS&ilLUSTRATIONSNOTTOSCAlE

~

GHC-5000N,L

0

GRD-5000N,L

9

Page 10

~

TROUBLESHOOTINGTHEELECTRICPIEZOIGNITOR

ANDGASCONTROLSYSTEM

MODELSGHC-5000N,GHC-5000L,GRD-5000N,GRD-5000L

Note:Beforetroubleshootingtheeleetriepiezoignitorsystem,besureexternalgasshutoffvalve,locatedatthegassupplyinlet,isinthe"ON"position.

~

10

NOTE:DIAGRAMS&ilLUSTRATIONSNOTTOSCAlE

SYMPTOM

POSSIBLECAUSES

CORRECTIVEACTION

1.Sparkignor willnotlightpilotafter

A.Defectiveignor 1.Checkforsparkatelectrodeandpilot;ifnospark

repeatedtriggeringofredbutton.

(nosparkatelectrode). andelectrodewireisproperlyconnected,replace

theignor.

B.Defectiveormisalignedelectrodeatpilot

1.Usinga match,lightpilot.Ifpilotlights,tumoff

(Sparkatelectrode). pilotandtriggertheredbuttonagain.Ifpilotlightsan

impropergasmixturecausedthebadlightinganda

longerpurgeperiodisrecommended.Ifpilotwillnot

light-checkgapatelectrodeandpilot

-shouldbe

1/8inchtohaveastrongspark.IfOK,replacepilot

assembly(Figure27).

2.PilotwillnotstayI aftercarefullyfollowing

A.Defectivepilotgenerator(thermopile)or

1.Checkpilotflame.1tmustimpingeonpilotgen-

lightinginstructions.

remotewallswitchwiring. erator(Figure27). Cleanand/oradjustpilotfor

maximumflameimpingementongenerator.

2.Besurewireconnectionsfromgeneratoratgas

valveterminalsaretightandgeneratoris fully

insertedintopitotbracket.

3.Oneofthewallswitchwiresmaybegrounded.

Removewallsch wiresfromvalveterminals.If

pilotnowstaysm,tracewallswch wiresfora

ground.Maybegroundedtofumaceorgassupply.

4.Checkpilotgeneratorwh miltivohmeter.Take

readingatgeneratorterminalsofgasvalve.Should

read325miltivoltsminimumwhileholdingvalve

knobdepressedin pilotposion andwallswitch

"OFF".Replacefauhygeneratorifreadingisbelow

specifiedminimum.

B.Defectiveautomaticvalveoperator. 1.Turnknobto"ON",placewallswitchto "ON"

mlivoltmetershouldreadgreaterthan100MV.If

thereadingisOKandtheburnerdoesnotcomeon,

replacethegasvalve.

3.Pot burning,nogastoburJlftr,valveknob

A.Wallswitchorwiresdefective.

1.Checkwallswitchandwiresforproperconnec-

"ON",wallswitch"ON". tions.Jumpwiresforproperconnections.Place

jumperwireacrossterminalsat wallsch. If

burnercomeson,replacedefectivewaDswitch.If

OK,placejumperwiresacrosswallsch wiresat

gasvalve.Ifburnercomeson,wires

aredefective

orconnectionsarebad.

B.Pot generatormaynotbegenerating

1.Re-checkSymptom#2.

sufficientmivohage.

C.Pluggedburnerorifice. 1.Checkburnerorificeforblockag9andremove.

4.Frequentpilotoutageproblem.

A.Pilotflamemaybetooloworblowing(high) 1.Clean/adjustpilotflametormaximumflame

causingthepilotsafetyto dropout.

impingementonpilotgenerator(FIgUf927).

Loading...

Loading...