Page 1

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures,

and warranty. Put it and the original sales invoice in a safe, dry place for

future reference.

CONSERVEZ CE GUIDE

Vous aurez besoin de ce guide pour les instructions de sécurité, les

procédures d’utilisation et la garantie. Conservez-le dans un endroit sûr et

sec pour référence future.

v

Model / Modèle : FCN50

060515

2” Flooring Cleat Nailer

Operator’s Manual (p.2)

Marteau cloueur à plancher 2 po

Guide d’utilisation (p.14)

Page 2

ENGLISHFRANÇAIS

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using pneumatic tools, basic

safety precautions should always be followed to

reduce the risk of personal injury.

READ ALL INSTRUCTIONS BEFORE USING THIS

TOOL

This tool was designed for installing 3/4” tongue and

groove hardwood ooring. We strongly recommend

that this tool not be modied and /or used for any

application other than that for which it was designed.

If you have any questions relative to its application, do

not use the tool until you have written us and we have

advised you.

SAFETY GLASSES: To prevent eye injuries, the

tool operator and all persons in the work area

must wear approved safety glassesto ANSIZ87.1

specications with permanently attached, rigid side

shields.

EAR PROTECTION: Wear ear protection to

safeguard against possible hearing loss.

DRESS SAFELY. Protective gloves and non-skid

footwear or safety shoes are recommended while

working with and operating this tool. Do not wear

loose clothing or jewelry. Contain long hair.

USE CLEAN, DRY, REGULATED, COMPRESSED

AIR at 70 to 90 psi / 488 to 621 kPa / 4.88 to 6.2

bar.

DO NOT CONNECT TOOL to pressure which

potentially exceeds 200 psi / 1379 kPa / 13.8 bar.

AIR HOSE: Use only hose that is rated for a

minimum working pressure of 150 psi or 150%

of the maximum system pressure, whichever is

greater. Check that connections are tight..

NEVER USE OXYGEN, CARBON DIOXIDE,

combustible gases or any other bottled gas as a

power source for this tool. Explosion and serious

personal injury could result.

COUPLINGS: Connect tool to air supply hose with

a 1/4” NPT coupling that removes all pressure from

the tool when the coupling is disconnnected.

DISCONNECT TOOL FROM AIR SUPPLY HOSE

before doing any disassembly, maintenance,

1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 3

FRANÇAIS

ENGLISH

3

clearing a jammed fastener, leaving the work area,

moving the tool to another location, or handing the

tool to another person.

EXTENSION CORDS: Observe warnings that

accompany air compressors concerning the use

of the correct gauge and insulation on extension

cords used out of doors.

NEVER USE A TOOL that is leaking air, has

missing or damaged parts, or requires repair.

Make sure all screws and caps are securely

tightened.

CHECK FOR DAMAGED PARTS. Never use

a tool if safety, trigger, or spring are inoperable,

missing or damaged. Do not alter or remove

safety, trigger, or springs. Make daily inspections

for the free movement of trigger and safety

mechanism.

REPLACEMENT PARTS: When servicing, use

only identical Superior replacement parts and

fasteners recommended by us.

CONNECT TOOL TO AIR SUPPLY BEFORE

loading fasteners to prevent fasteners from

ring during connection. The fastener driving

mechanism may cycle when the tool is connected

to the air supply.

ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS. Keep it pointed away from yourself

and others at all times. No horseplay. Respect the

tool as a working implement.

DO NOT LOAD FASTENERS with the hammer

face depressed. The tool may unintentionally re a

fastener.

DO NOT DEPRESS THE HAMMER FACE when

not driving fasteners. Never carry tool while

touching on the hammer face trigger mechanism:

tool may re an unwanted fastener.

DON’T OVERREACH. Keep proper footing and

balance at all times. Do not reach over or across

machines which are running.

GRIP TOOL FIRMLY to maintain control while

allowing the tool to recoil away from the work

surface as the fastener is driven.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

IMPORTANT SAFETY INSTRUCTIONS

Page 4

ENGLISHFRANÇAIS

4

DO NOT DRIVE FASTENERS on top of other

fasteners, or with the tool at too steep an angle:

the fasteners can ricochet causing personal injury.

FIRE FASTENERS INTO WORK SURFACE

ONLY. Do not drive cleat nails nor attempt to do

so, into hard or brittle materials such as steel,

concrete, or tile.

DO NOT DRIVE FASTENERS too close to the

edge of the workpiece. The workpiece is likely to

split, allowing the fasteners to y free or ricochet

causing personal injury.

STAY ALERT. Keep hands and body away from

the path of any potential red fastener. Watch

what you are doing & use common sense. Don’t

operate any tool when you are tired or under the

inuence of drugs or alcohol. Check prescriptions

to determine if there could be a problem.

GUARD AGAINST ELECTRIC SHOCK. Prevent

body contact with grounded surfaces: pipes,

radiators, ranges, and refrigerator enclosures.

Before driving fasteners into walls, oors,

or wherever “live” electrical wires may be

encountered, try to ascertain whether there is a

danger of shock.

KEEP WORK AREA CLEAR of obstructions.

STORE IDLE EQUIPMENT. When the tool is not

being used, it should be cleaned, and stored in a

clean dry place out of the reach of children.

EMPLOYERS must enforce compliance with the

safety warnings and all other instructions in this

manual. Keep it available for use by everyone

assigned to use this tool.

WARNING: The warnings, cautions, and

instructions detailed in this manual cannot cover

all possible conditions and situations that occur. It

must be understood by the operator that COMMON

SENSE AND CAUTION ARE FACTORS that

cannot be built into this product, but MUST BE

SUPPLIED BY THE OPERATOR.

20.

21.

22.

23.

24.

25.

26.

27.

IMPORTANT SAFETY INSTRUCTIONS

Page 5

FRANÇAIS

ENGLISH

5

UNPACKING

Check immediately that all parts and accessories are

included:

Cleat Nailer 1

Hammer 1

Spacer for 1/2” ooring 1

S3 Hex Key 1

S4 Hex Key 1

S5 Hex Key 1

Air Tool Oil 1

Manual 1

If anything is missing or broken, contact your retailer

or call toll-free 1.888.267.7713.

SPECIFICATIONS

Shoots standard 15-1/2 ga. “L” shaped ooring

cleat nails minimum 1-1/2” (38mm) long to a

maximum length of 2” (50mm)

Operating pressure: 70-90 psi / 488 to 621 kPa /

4.88 to 6.2 bar (max. 120 psi / 827 kPa / 8.3 bar)

Air consumption: 5 cfm @ 80 psi / 552 kPa

Cleat nail capacity: 100

Air Inlet: 1/4” NPT

Tool weight: 5.2 kg (11.5 lb)

Pkg. weight: 10.5 kg (23.2 lb)

OPERATING PROCEDURES

SET UP

Your Superior FCN50 Cleat Nailer is fully assembled

when you receive it. See the recommended air

system setup below. Be sure that the couplers are set

up so that the air hose is depressurized when adding

or removing components from the system.

Cleat Nailer

Quick-Connector

Oiler Filter Air Supply

Air Hose

Regulator

Page 6

ENGLISHFRANÇAIS

6

AIR SOURCE

The FCN50 is designed to operate on clean, dry,

compressed air, regulated at 70 to 90 psi / 488 to

621 kPa / 4.9 to 6.1 bar. The preferred system

would include a lter, a pressure regulator, and

an automatic oiler located as close to the tool as

possible (within 5 meters (15 feet) is ideal). Do

not use bottled air or gases.

Determine if it is necessary to lubricate. All

compressed air contains moisture and other

contaminants that can harm the internal

components of the tool. An air line lter will

remove most of these and signicantly prolong the

life of the tool. If you are using an in-line automatic

oiler, check and add oil if necessary. If an in-line

oiler is not available, place 2 drops of oil into the

tool’s Air Plug (FCN50-46) at the beginning of each

workday. More than this will be expelled from the

tool’s exhaust during ring.

Air Fitting: The FCN50 is equipped with a 1/4”

NPT male plug for a ‘quick connector’. To prevent

accidental cycling even though disconnected, the

tool must always be connected to the air supply

in such a way that all air pressure in it is released

when the coupling is disconnected.

CAUTION:

=All air line components (including hoses, pipe,

connectors, lters, & regulators, etc.) must

be rated for a minimum working pressure

of 150 psi / 1034 kPa / 10.3 bar or 150%

of the maximum system pressure, whichever

is greater.

=Disconnect the tool from the air supply before

performing maintenance, clearing a jammed

fastener, leaving the work area, moving the tool to

another location, or handing it to another person.

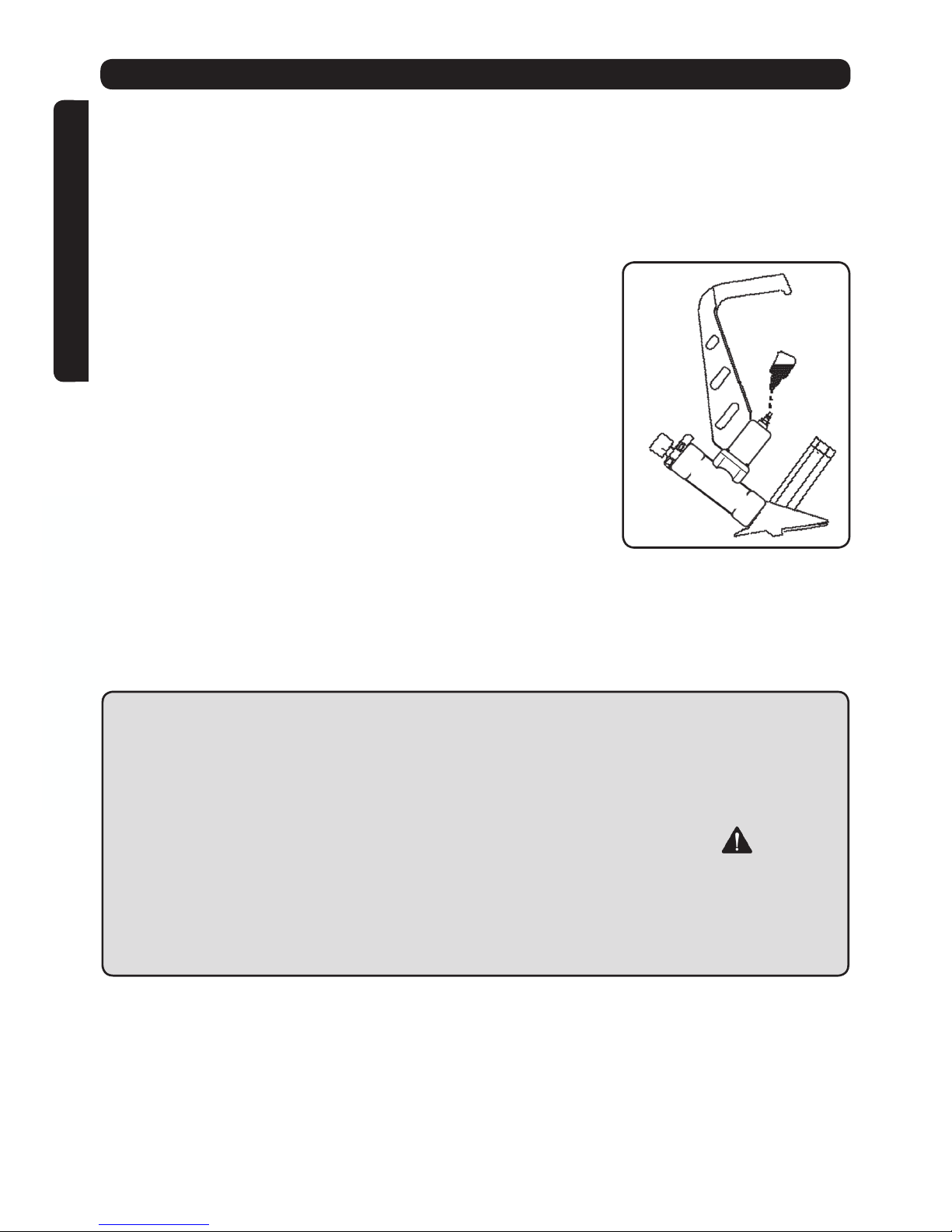

PREPARING THE TOOL

Be sure that the spacer (FCN50-25) attached to

your tool is suitable for the thickness of ooring.

The tool comes with a spacer attached designed

for 20 mm (25/32”) thick (nominally 3/4”) ooring.

If the ooring you are installing is 12.5 mm (1/2”)

thick, remove the three screws (FCN50-26) and

1.

2.

OPERATING PROCEDURES

Page 7

FRANÇAIS

ENGLISH

7

the spacer from the bottom of the shoe (FCN50-

24).

Replace the spacer with the other spacer included

and attach it with the three screws (FCN50-26).

After reading and understanding this entire

manual, connect tool to air supply.

Turn on the air compressor and adjust the

regulator to the proper pressure for the fastener

size you are using. (See Using the Tool, below

with regard to adjusting this.)

CAUTION:

=Keep the tool pointed away from yourself and

others at all times.

=Always connect the tool to air supply before

loading fasteners.

=Do not load fasteners with safety or trigger

depressed.

=Always wear approved safety glasses and

hearing protection when preparing or operating

this tool.

=Never use a tool that leaks air or needs repair.

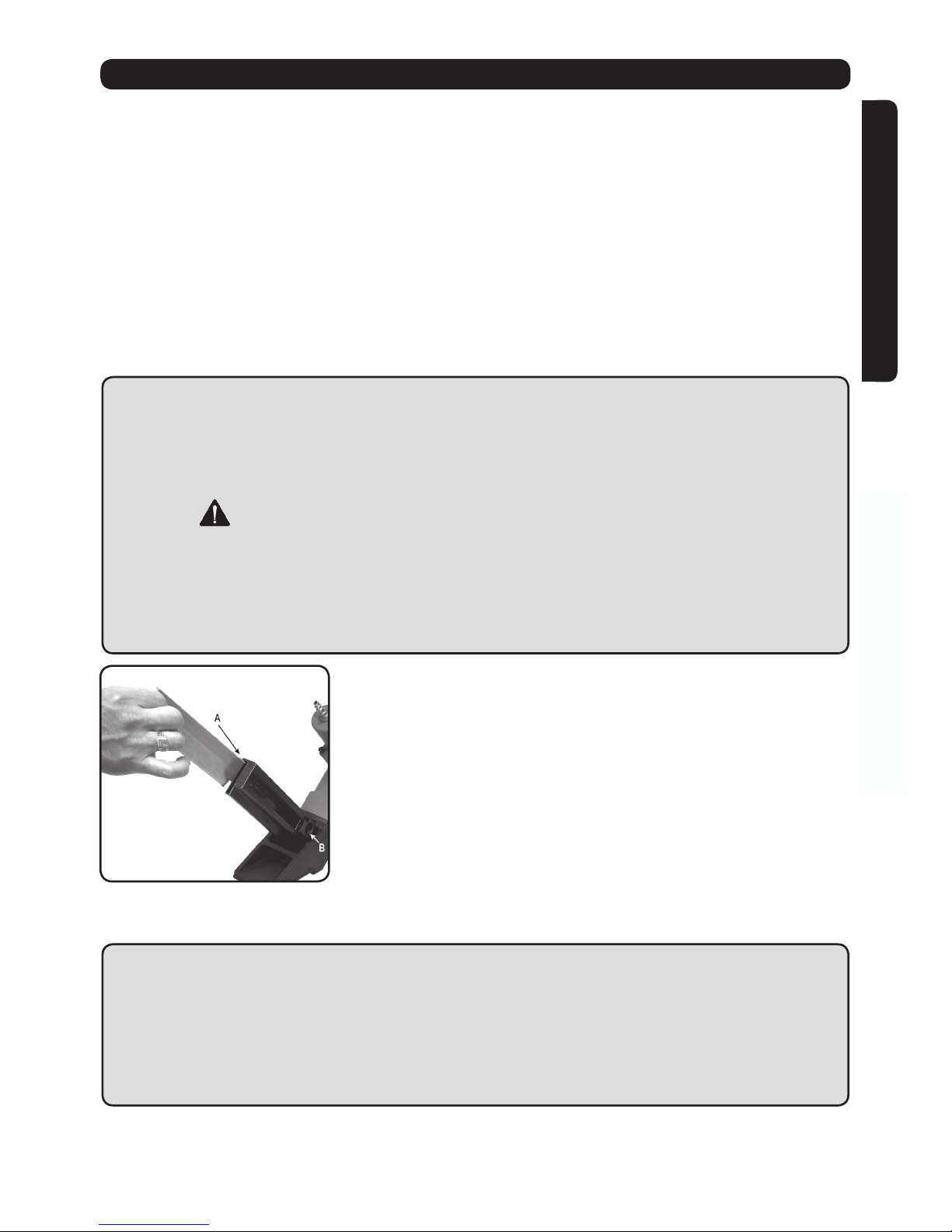

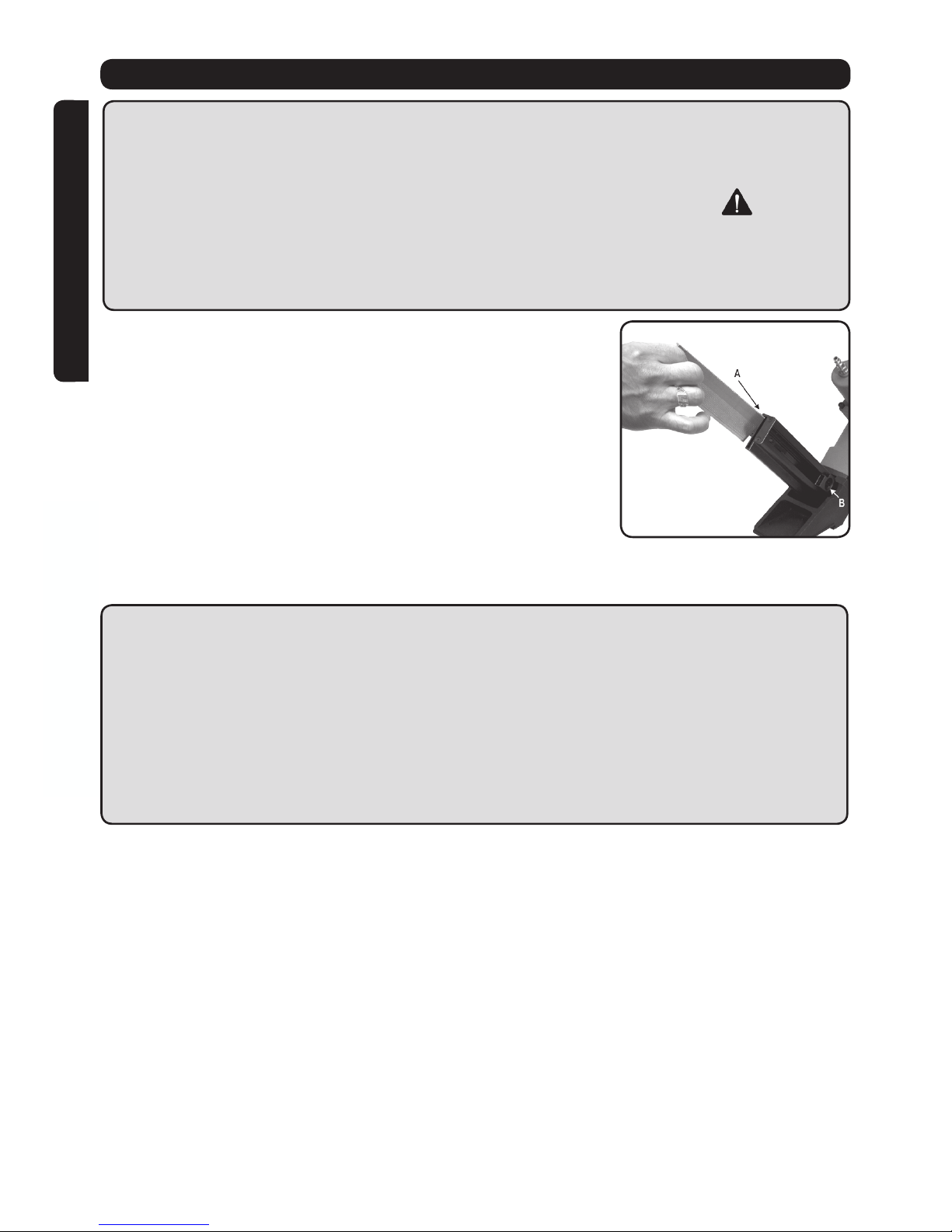

LOADING FASTENERS

Drop a stick of cleat nails into the L-shaped hole

at the back of the magazine (A). Pull back the

slide (Bracket- FCN50-39) until the feeder shoe

(FCN50-41) clicks behind the cleat nails to hold

them against the front of the magazine with the

spring.

The tool is ready to operate.

USING THE TOOL

Complete all the steps in Preparing the Tool and

Loading Fasteners, above, before using the tool.

NOTE: Use care when installing pre-nished

ooring with this tool. It is designed to install

unnished ooring and may leave marks on the

nish of pre-nished ooring. Always test re

the FCN50 on a sample piece of ooring before

starting a new job to ensure it does not damage

the oor nish.

Connect the tool with the air supply. Make sure

the air pressure is within the range given in

SPECIFICATIONS above.

3.

4.

5.

1.

2.

1.

2.

3.

OPERATING PROCEDURES

Page 8

ENGLISHFRANÇAIS

8

The depth to which a cleat nail is driven is

determined by the supplied air pressure. Test re

a cleat nail into a sample of the material you will be

working on and check its driven depth.

If a change is desired, adjust the regulator to

supply air at a higher or lower pressure.

Test re another fastener and check depth again.

Adjust as necessary.

Tightly set a piece of ooring into position.

Position the tool against the edge of the ooring

where you want the cleat nail driven.

Hold the handle (FCN50-45 ARM in the parts list)

rmly with one hand, while swinging the mallet

(FCN50-47 HAMMER) with the other.

Strike the trigger button (FCN50-10 HAMMER

FACE) rmly with the mallet (FCN50-47

HAMMER). The blow will tap the oor board more

tightly into position, while at the same time, ring a

cleat nail at the correct angle into the edge of the

board.

Lift the tool off the work surface.

CAUTION:

=Keep tool pointed in a safe direction at all times.

=Never attempt to drive cleat nails into materials

too hard to penetrate, or at too steep an angle, or

too near the edge of the workpiece. The fastener

can ricochet causing personal injury.

=Disconnect tool from air supply before doing any

disassembly, maintenance, clearing a jammmed

fastener, leaving the work area, moving the tool

to another location, or handing the tool to another

person.

=Clean and inspect the tool daily. Carefully

check for proper operation of trigger and safety

mechanism. Do not use the tool unless both the

trigger and the safety mechanism are functional,

or if the tool is leaking air or needs any other

repair.

4.

5.

6.

7.

8.

9.

10.

11.

12.

OPERATING PROCEDURES

Page 9

FRANÇAIS

ENGLISH

9

MAINTENANCE

CLEARING A JAMMED CLEAT NAIL

CAUTION: Disconnect the tool from the air supply.

Pull back the slide (Bracket- FCN50-39) and tilt

the magazine so the stick of cleat nails slides back

with the feeder shoe (FCN50-41).

Push your index nger into the hole in the slide

(Bracket- FCN50-39) and with it depress the back

end of the feeder shoe. This will lift up the front

end of the feeder shoe and allow the fasteners

to slide past it and out the back. You may have

to depress the additional magazine spring piece

(FCN50-31). Gently allow the feeder shoe to move

back to the front of the magazine.

Use a slender, soft steel rod to push the drive

blade up the blade guide to its uppermost position.

If possible, remove the jammed fastener with

needle nose pliers through the magazine side slot,

taking care not to damage the spring.

If not, it may be necessary to remove the blade

guide (FCN50-22) to access the front of the

fastener slide.

Follow instructions in Preparing the Tool to reload

fasteners.

CLEAN AND INSPECT DAILY

CAUTION: Disconnect tool from air supply before

cleaning and inspection. Correct all problems

before putting the tool back in service.

Frequent, but not excessive lubrication is required

for the best performance. Oil added through the

air line connection will lubricatethe inside parts.

An automatic oiler is recommended, but 2 drops

of oil may be added manually into the tool’s Air

Plug (FCN50-46) at the beginning of each workday

and after about every hour of continuous use.

Only a few drops at a time are necessary. More

than this will pool inside the tool and be expelled

from the tool’s exhaust during ring. USE ONLY

PNEUMATIC TOOL OIL. Do not use detergent

oil or oil with other additives, as these can cause

accelerated wear on the seals.

Use a small amount of oil on external moving parts

and pivots.

1.

2.

3.

4.

5.

6.

7.

Page 10

ENGLISHFRANÇAIS

10

Dirt and water in the air supply are major causes

of pneumatic tool wear. Use a lter/oiler for better

performance and longer tool life. Ensure the lter

ow capacity is sufcient for the tool’s air volume

use.

Wipe tool clean and inspect for wear or damage.

Use non-amable cleaning solutions to wipe

exterior of tool only if necessary. Do Not Soak

tool with cleaning solutions. Such solutions can

damage internal parts.

Inspect trigger and safety mechanism to assure

system is complete and functional: no loose or

missing parts, no binding or sticking parts.

Keep all screws tight. Loose screws can cause

personal injury or damage the tool.

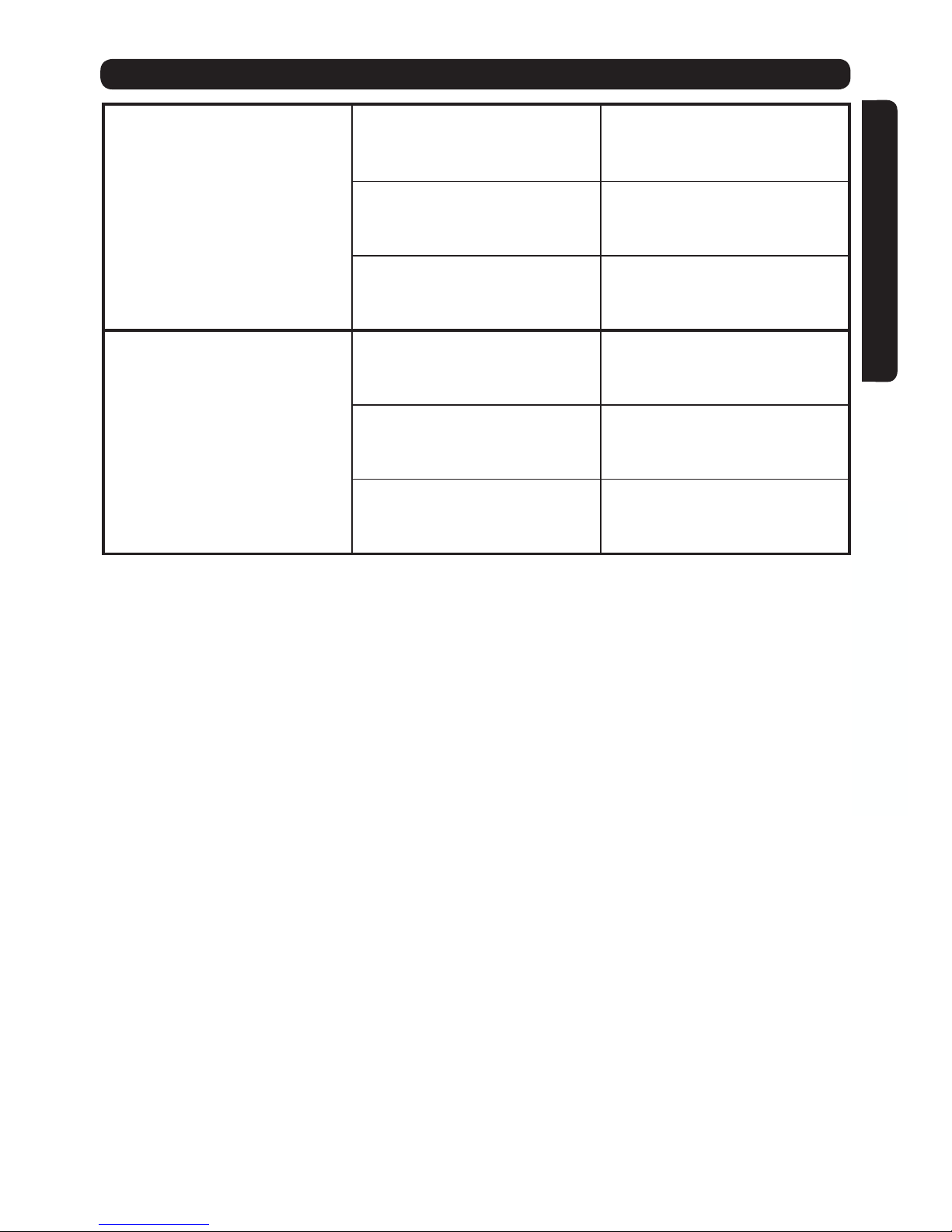

TROUBLESHOOTING

WARNING: Stop using the tool immediately if any

of the following problems occur. Serious personal

injury may result. Any repairs or replacements

must be done by qualied personnel or by an

authorized service centre only.

CAUTION:

=Disconnect the tool from air supply before

performing any service procedure.

=When inserting new or re-installing O-rings, make

sure they are clean and lubricated with an O-ring

lubricant.

MAINTENANCE

PROBLEM CAUSE SOLUTION

Air leaking in cylinder cap Loose screws in poppet

actuator (FCN50-14)

Tighten the screws and

re-check

Gasket (FCN50-17) is

cracked or worn

Replace gasket

Tool lacks power, slow to

cycle. Poor shooting and

returning performance

Tool is too dry

Add drops of lubricant as

advised

Air pressure is too low Check air supply equipment

Exhaust is blocked Clean exhaust channel

Page 11

FRANÇAIS

ENGLISH

11

Tool skips fasteners, res

intermittently

Damaged pusher spring Replace spring

Wrong size fastener Use correct fasteners: 15-

1/2 ga. L-shape cleat nails

Magazine or wear plate is

dirty

Clean magazine and nose.

Fastener is jammed in the

tool or magazine

Driver channel is worn Replace blade guide

(FCN50-22)

Driver is broken or worn Replace driver or piston

assembly (FCN50-8)

Fasteners are bent Use undamaged standard

fasteners

MAINTENANCE

SERVICE AND REPAIRS

All quality tools eventually require some servicing

or replacement parts due to wear from normal use.

If your tool requires service, ask your retailer or

call Superior Airco Wholesale at 1(888) 267-7713

for an authorized repair centre in your area. All

repairs made by local authorized repair centres

are fully guaranteed against defective material and

workmanship.

Some user-serviceable components are described

in the Troubleshooting section. We cannot

guarantee repairs made or attempted by anyone

other than authoized agencies.

Questions? Feel free to call our technical support

department toll-free at 1(888) 267-7713. In any

communication, please be prepared to give all the

information about your tool: model number, type,

serial number, etc.

Page 12

ENGLISHFRANÇAIS

12

PARTS LIST

Please refer to the Schematic Drawing on p. 25 for the

location of parts.

ITEM DESCRIPTION ITEM DESCRIPTION

FCN50-1 Plunger FCN50-24 Shoe

FCN50-2 O-Ring 15.9×1.8 FCN50-24a Pin

FCN50-3 O-Ring 19.2×1.8 FCN50-25 Spacer for 25/32"

FCN50-4 Poppet FCN50-25 Spacer for 1/2"

FCN50-5 O-Ring 17.5×2.6 FCN50-26 Screw

FCN50-6 O-Ring 42.5×5.4 FCN50-27 Spring Washer

FCN50-7 O-Ring 57.4×3.5 FCN50-28 Screw

FCN50-8 Piston Assembly FCN50-29 Rail

FCN50-9 Cylinder Bushing FCN50-30 Magazine

FCN50-10 Hammer Face FCN50-31 Spring Piece

FCN50-11 Screw FCN50-32 Nut

FCN50-12 Cylinder Cap FCN50-33 Screw

FCN50-13 O-Ring 54.2×3.5 FCN50-34 Washer

FCN50-14 Screw FCN50-35 Magazine Cap

FCN50-15 Spring Washer FCN50-36 Screw

FCN50-16 Poppet Actuator FCN50-37 Coil Spring

FCN50-17 Gasket FCN50-38 Spring Bracket

FCN50-18 Body FCN50-39 Bracket

FCN50-19 Bumper FCN50-40 Pin

FCN50-19a Screw FCN50-41 Feeder Shoe

FCN50-19b Spring Washer FCN50-42 Torsion Spring

FCN50-19c Bafe plate FCN50-43 Seal

FCN50-20 Nose FCN50-44 Screw

FCN50-21 Screw FCN50-45 Arm

FCN50-22 Blade Guide FCN50-46 Air Plug

FCN50-23 Spring Washer FCN50-47 Hammer

Page 13

FRANÇAIS

ENGLISH

13

WARRANTY

All products distributed by Airco Superior Clarke are

warranted against manufacturers’ faults and defects

for a period of one year from the date of purchase

by the end user. The Company will REPAIR OR

REPLACE, AT ITS OWN OPTION, merchandise

deemed by the company to be defective, provided

that is has not been misused, abused, altered, or

repaired by anyone other than an authorized repair

centre. Retain proof of purchase. Consumers should

return the defective product to the place of purchase

accompanied by the receipt.

This warranty does not extend to parts deemed

consumables, such as brad and staple gun driver

blades, grinding discs, welding contact tips, etc.

All warranty claims must have prior authorization

and must be shipped prepaid to the Richmond BC

warehouse, the Mississauga ON warehouse, or to an

authorized repair depot, accompanied by a copy of

the invoice specifying the date that the item was sold

to the end user.

WARNING: Repairs should be made by an

authorized repair centre. Opening this tool could

invalidate your warranty.

Page 14

ENGLISHFRANÇAIS

14

AVERTISSEMENT : Certaines consignes de

sécurité de base doivent toujours être respectées

lors de l’utilisation d’outils pneumatiques an de

réduire les risques de blessure.

LISEZ TOUTES LES CONSIGNES AVANT

D’UTILISER CET OUTIL

Cet outil a été conçu pour installer des planches de

bois franc à rainure et à languette de ¾ po. Nous

vous recommandons fortement de ne pas modier

cet outil et de ne pas l’utiliser à d’autres ns que

celle pour laquelle il a été conçu. Si vous avez des

questions quant à cette utilisation, n’utilisez pas l’outil

tant que vous n’en ayez pas obtenu réponse de notre

part.

LUNETTES DE PROTECTION : An de

se protéger contre des blessures aux yeux,

l’utilisateur de l’outil et les personnes présentes

dans l’aire de travail doivent porter des lunettes de

protections homologuées ANSIZ787.1 avec écrans

rigides latéraux xes.

PROTÈGE-OREILLES : Portez des protègeoreilles pour prévenir la perte de l’ouïe.

PORTEZ DES VÊTEMENTS APPROPRIÉS :

Des gants de protection et des chaussures

antidérapantes ou de sécurité sont recommandés

lors du travail avec cet outil. Ne portez pas de

vêtements lâches ni de bijoux. Attachez les

cheveux longs.

UTILISEZ DE L’AIR COMPRIMÉ PROPRE, SEC

ET CONTRÔLÉ entre 70 et 90 psi / 488 et 621

kPa / 4,88 et 6,2 bar.

NE BRANCHEZ PAS L’OUTIL à une pression

potentiellement plus grande que 200 psi / 1 379

kPa / 13,8 bar.

TUYAU PNEUMATIQUE : N’utilisez que le tuyau

calibré pour une pression fonctionnement minimale

de 150 psi ou 150 % de la pression maximale du

système, soit la plus élevée des deux. Vériez que

les branchements sont bien serrés.

N’UTILISEZ JAMAIS D’OXYGÈNE, DE GAZ

CARBONIQUE, de gaz à combustion ou tout

autre gaz embouteillé comme alimentation pour

1.

2.

3.

4.

5.

6.

7.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 15

FRANÇAIS

ENGLISH

15

cet outil. Une explosion et de sérieuses blessures

pourraient en découler.

RACCORDS : Branchez l’outil au tuyau

d’alimentation pneumatique à l’aide d’un raccord

de 1/4 po TPN qui retire toute la pression de l’outil

lorsque débranché.

DÉBRANCHEZ L’OUTIL DU TUYAU

PNEUMATIQUE avant de le démonter, l’entretenir,

éliminer un clou bloqué, quitter l’aire de travail,

déplacer l’outil ou le donner à quelqu’un d’autre.

RALLONGES ÉLECTRIQUES : Respectez les

mises en garde accompagnant les compresseurs

d’air quant aux jauges et isolations appropriées

des rallonges électriques extérieures.

N’UTILISEZ JAMAIS UN OUTIL qui présente des

fuites, des pièces manquantes ou endommagées

ou qui nécessite une réparation. Assurez-vous

que toutes les vis et tous les bouchons sont bien

serrés.

VÉRIFIEZ L’ABSENCE DE DOMMAGE SUR LES

PIÈCES. N’utilisez jamais un outil si son dispositif

de sécurité, sa détente ou ses ressorts sont

manquants ou endommagés. Ne modiez pas le

dispositif de sécurité, la détente ou les ressorts.

Inspectez quotidiennement le mouvement libre de

la détente et le mécanisme de sécurité.

PIÈCES DE REMPLACEMENT : N’utilisez que

les pièces de remplacement et clous Superior

identiques que nous recommandons pour la

réparation.

BRANCHEZ L’OUTIL À LA CONDUITE

PNEUMATIQUE AVANT de charger les clous, an

d’éviter qu’ils ne s’éjectent au branchement. Le

mécanisme d’expulsion des clous peut effectuer

un cycle lorsqu’il est branché à la conduite

pneumatique.

PRÉSUMEZ TOUJOURS QUE L’OUTIL

CONTIENT DES CLOUS. Pointez toujours l’outil

loin de vous et des autres personnes. Cet outil

n’est pas un jouet. Considérez-le comme un outil

de travail.

NE CHARGEZ PAS LES CLOUS lorsque le

8.

9.

10.

11.

12.

13.

14.

15.

16.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 16

ENGLISHFRANÇAIS

16

marteau est détendu. L’outil pourrait éjecter un

clou.

NE DÉTENDEZ PAS LE MARTEAU lorsque que

vous ne déchargez pas de clous. Ne transportez

jamais l’outil en touchant au mécanisme de

détente du marteau : il pourrait éjecter un clou non

désiré.

NE VOUS ÉTIREZ PAS INDÛMENT. Garder vos

pieds au sol et conservez votre équilibre en tout

temps. Ne vous étirez pas vers des machines en

fonctionnement.

AGRIPPEZ L’OUTIL FERMEMENT an de garder

le contrôle, tout en laissant l’outil s’éloigner de la

surface de travail quand le clou est enfoncé.

N’ENFONCEZ PAS LES CLOUS les uns pardessus les autres, ou à un angle trop aigu : les

clous pourraient rebondir et causer des blessures.

ÉJECTEZ LES CLOUS VERS LA SURFACE DE

TRAVAIL SEULEMENT. N’enfoncez pas de clou

dans un matériau dur ou friable tel l’acier, le ciment

ou la céramique.

N’ENFONCEZ PAS LES CLOUS trop près du

rebord du morceau à travailler. Le morceau

pourrait fendre, causant un ricochet du clou qui

risque d’entraîner des blessures.

SOYEZ VIGILANT. Gardez vos mains et votre

corps loin du chemin de tout clou potentiellement

éjecté. Regardez ce que vous faites et servezvous du gros bon sens. Ne faites fonctionner

aucun outil lorsque vous êtes fatigué, avez bu ou

consommé des drogues ou médicaments. Vériez

vos prescriptions médicales an de voir si des

médicaments peuvent causer des problèmes.

PROTÉGEZ-VOUS DES ÉLECTROCUTIONS.

Ne laissez pas l’habitacle entrer en contact

avec les surfaces mises à la terre : enceintes de

tuyaux, radiateurs, fours et réfrigérateurs. Avant

d’enfoncer les clous dans les murs, planchers ou

tout autre endroit où des ls électriques peuvent se

trouver, vériez s’il existe un risque d’électrocution.

GARDEZ L’AIRE DE TRAVAIL LIBRE de tout

obstacle.

17.

18.

19.

20.

21.

22.

23.

24.

25.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 17

FRANÇAIS

ENGLISH

17

RANGEZ LES OUTILS INUTILISÉS. Lorsque

l’outil est inutilisé, il doit être nettoyé et rangé

dans un endroit sec et propre, hors de portée des

enfants.

LES EMPLOYEURS doivent s’assurer du respect

des consignes de sécurité et de toutes les autres

consignes de ce guide. Laissez ces consignes

accessibles à toute personne devant utiliser cet

outil.

AVERTISSEMENT : Les avertissements, mises

en garde et consignes de ce guide ne peuvent

couvrir toutes les situations et conditions possibles.

L’opérateur doit reconnaître que le BON SENS

ET LA PRÉCAUTION ne peuvent être intégrés au

produit, mais qu’IL DOIT LUI-MÊME EN FAIRE

PREUVE.

DÉBALLAGE

Vériez immédiatement que toutes les pièces et

accessoires sont compris.

Marteau cloueur 1

Marteau 1

Éspaceur pour planchers de 1/2 po 1

Clé hexagonale S3 1

Clé hexagonale S4 1

Clé hexagonale S5 1

Huile à outil pneumatique 1

Guide 1

S’il manque un article ou si un article est brisé,

contactez votre détaillant ou téléphonez sans frais au

1-888-267-7713.

FICHE TECHNIQUE

Éjecte des clous à plancher de calibre 15-1/2 en

forme de « L » d’une longueur minimale de 1-1/2

po (38 mm) et d’une longueur maximale de 2 po

(50 mm)

Pression de fonctionnement : 70 à 90 psi / 488 à

621 kPa / 4,88 à 6,2 bar (max. 120 psi / 827 kPa /

8,3 bar)

Consommation pneumatique : 5 pi/min @ 80 psi /

552 kPa

Capacité de clous : 100

26.

27.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 18

ENGLISHFRANÇAIS

18

Entrée pneumatique : 1/4 po TPN

Poids de l’outil : 5,2 kg (11,5 lb)

Poids de l’emballage : 10,5 kg (23,2 lb)

PROCÉDURES D’UTILISATION

INSTALLATION

Votre marteau cloueur Superior FCN50 vous

parvient complètement assemblé. Consultez les

installations de système pneumatique recommandées

ci-dessous. Assurez-vous que les coupleurs sont

installés de façon à ce que le tuyau pneumatique soit

dépressurisé lorsque des composants sont ajoutés ou

retirés au système.

Tuyau pneumatique Régulateur

SOURCE PNEUMATIQUE

Le FNC50 est conçu pour fonctionner avec de

l’air comprimé propre et sec entre 70 et 90 psi /

488 et 621 kPa / 4,9 et 6,1 bar. Le système idéal

comprend un ltre, un régulateur de pression et

un huileur automatique situé aussi près de l’outil

que possible (idéalement à 15 pieds / 5 mètres).

N’utilisez pas d’air ou de gaz en bouteille.

Déterminez si une lubrication est nécessaire.

Tout air comprimé contient de l’humidité et autres

contaminants qui peuvent nuire aux composants

internes de l’outil. Un ltre pneumatique retirera

la plupart de ces éléments et prolongera la

durée de vie de l’outil. Si vous utilisez un huileur

automatique, vériez l’huile et ajoutez-en au

besoin. Si un huileur n’est pas disponible, versez

2 gouttes d’huile dans la che pneumatique

(FCN50-46) au début de chaque journée de travail.

Une quantité d’huile plus grande sera éjectée de

l’échappement de l’outil pendant le clouage.

Raccord pneumatique : Le FCN50 doit être doté

d’un « connecteur rapide » mâle de 1/4 po TPN.

FICHE TECHNIQUE

Marteau cloueur

Connecteur

rapide

Huileur

Filtre

Conduite

pneumatique

Page 19

FRANÇAIS

ENGLISH

19

An d’éviter tout cycle accidentel même lorsque

débranché, l’outil doit toujours être branché à la

conduite pneumatique de façon à ce que toute la

pression pneumatique à l’intérieur soit libérée au

débranchement du coupleur.

MISE EN GARDE :

=Toutes les conduites pneumatiques (y compris

les tuyaux, tubes, connecteurs, ltres,

régulateurs, etc.) doivent être calibrés pour une

pression de fonctionnement minimale de

150 psi / 1034 kPa / 10,3 bar ou 150 % de la

pression maximale du système, soit la plus

élevée des deux.

=Débranchez l’outil du tuyau pneumatique avant

de procéder à son entretien, à l’élimination d’un

clou bloqué, avant de quitter l’aire de travail, de

déplacer l’outil ou le donner à quelqu’un d’autre.

PRÉPARATION DE L’OUTIL

Vériez que l’espaceur (FCN50-25) sous la pied

de votre outil est conçu pour l’épaisseur de la

plancher. L’outil est muni d’un espaceur attaché

pour planchers de 20 mm (25/32 po.), 3/4 po.

nominale.

Si le plancher à installer a un épaisseur de 12.5

mm (1/2 po), retirez les 3 vis (FCN50-26) et

l’espaceur (FCN50-25) du pied (FCN50-24).

Remplacez l’espaceur avec l’autre inclus (FCN5025a) et l’attachez avec les trois vis (FCN50-26).

Après avoir lu et compris ce guide dans son

intégralité, branchez l’outil à la conduite

pneumatique.

Mettez le compresseur d’air en marche et ajustez

le régulateur à la pression adéquate pour la taille

de clou utilisée (voir Utilisation de l’outil ci-dessous

concernant ce réglage).

MISE EN GARDE :

=Pointez toujours l’outil loin de vous et des autres

personnes.

=Branchez toujours l’outil à l’alimentation

pneumatique avant de charger les clous.

1.

2.

3.

4.

5.

PROCÉDURES D’UTILISATION

Page 20

ENGLISHFRANÇAIS

20

MISE EN GARDE :

=Ne chargez pas les clous lorsque le marteau ou

la détente sont relâchées.

=Portez toujours des lunettes de sécurité et des

protège-oreilles lorsque vous préparez ou utilisez

cet outil.

=N’utilisez jamais un outil qui présente une fuite

d’air ou qui a besoin de réparations.

CHARGEMENT DES CLOUS

Déposez un tube de clous dans l’ouverture en

forme de « L » à l’arrière du magasin. Tirez sur

la glissière (Support – FCN50-39) jusqu’à ce que

le pied distributeur (FCN50-41) clique derrière les

clous, le ressort les retenant à l’avant du magasin.

L’outil est prêt à être utilisé.

UTILISATION DE L’OUTIL

Complétez toutes les étapes de la section

Préparation de l’outil et Chargement des clous

avant d’utiliser l’outil.

REMARQUE : Soyez prudent lorsque vous

installez un plancher préni à l’aide de cet outil.

Cet outil est conçu pour installer un plancher non

ni et il pourrait laisser des marques sur le vernis

du plancher préni. Testez toujours l’éjection de

clou de la FCN50 sur un échantillon du plancher

avant de commencer de nouveaux travaux, an de

vous assurer qu’il n’endommagera pas le vernis du

plancher.

Branchez l’outil à la conduite pneumatique.

Assurez-vous que la pression pneumatique se

situe à l’intérieur de l’échelle indiquée à la section

SPÉCIFICATIONS.

La profondeur d’enfoncement d’un clou est

déterminée par la pression pneumatique fournie.

Faites un essai avec un clou dans un échantillon

du matériau à travailler, et vériez sa profondeur

d’enfoncement.

Si une modication est souhaitée, ajustez le

régulateur pour qu’il fournisse l’air à une pression

plus ou moins élevée.

Faites un autre essai et revériez la profondeur.

1.

2.

1.

2.

3.

4.

5.

6.

PROCÉDURES D’UTILISATION

Page 21

FRANÇAIS

ENGLISH

21

Réglez au besoin.

Placez un morceau de plancher fermement en

place.

Placez l’outil contre le rebord du plancher, là où

vous désirez enfoncer le clou.

Tenez la poignée (BRAS FCN50-45 dans la liste

des pièces) fermement dans une main, tout en

abaissant le maillet (MARTEAU FCN50-47) de

l’autre.

Appuyez fermement sur le bouton de la détente

(FACE DU MARTEAU FCN50-10) à l’aide du

maillet (MARTEAU FCN50-47). Le coup frappera

sur la planche et la xera plus avant en position

tout en éjectant un clou au bon angle dans le

rebord de la planche.

Relevez l’outil.

MISE EN GARDE :

=Pointez toujours l’outil dans une direction sûre.

=N’enfoncez jamais de clou dans des matériaux

trop difciles à pénétrer, à un angle trop aigu ou

trop près du rebord du morceau. Le clou pourrait

rebondir et causer des blessures.

=Débranchez l’outil du tuyau pneumatique avant

de le démonter, l’entretenir, éliminer un clou

bloqué, quitter l’aire de travail, déplacer l’outil ou

le donner à quelqu’un d’autre.

=Nettoyez et inspectez l’outil à tous les jours.

Vériez que la détente et le mécanisme de

sécurité fonctionnent correctement. N’utilisez pas

l’outil à moins que la détente et le mécanisme de

sécurité soient fonctionnels. Ne l’utilisez pas s’il y

a une fuite d’air ou s’il doit être réparé.

ENTRETIEN

RETIRER UN CLOU BLOQUÉ

Mise en garde : Débranchez l’outil de la conduite

pneumatique.

Tirez sur la glissière (support – FCN50-39) et

inclinez le magasin de sorte que le tube de clous

glisse jusqu’au pied distributeur (FCN50-41).

Insérez votre index dans l’ouverture de la glissière

(support – FCN50-39) et détendez l’arrière du

7.

8.

9.

10.

11.

12.

1.

2.

3.

PROCÉDURES D’UTILISATION

Page 22

ENGLISHFRANÇAIS

22

pied distributeur, toujours à l’aide de l’index.

Ceci relèvera l’avant du pied distributeur et

permettra aux clous de glisser à l’arrière. Vous

devrez peut-être détendre le ressort de magasin

supplémentaire (FCN50-31). Laissez doucement

le pied distributeur reprendre sa place devant le

magasin.

À l’aide d’une tige métallique exible, poussez la

lame de pression dans le guide-lame, à sa position

supérieure.

Si possible, retirez le clou bloqué à l’aide de pinces

à épiler insérées dans la fente latérale du magasin,

en prenant soin de ne pas endommager le ressort.

Sinon, il pourrait être nécessaire de retirer le

guide-lame (FCN50-22) pour accéder au devant de

la glissière à clous.

Suivez les consignes de la section Préparation de

l’outil sur la recharge de clous.

MISE EN GARDE : Débranchez l’outil de la

conduite pneumatique avant le nettoyage et

l’inspection. Remédiez à tous les problèmes avant

de remettre l’outil en service.

Une lubrication fréquente mais non excessive

est nécessaire à une bonne performance.

L’huile ajoutée dans la connexion de la conduite

pneumatique lubriera les pièces internes.

Un huileur automatique est recommandé,

mais 2 gouttes d’huile peuvent être ajoutées

manuellement dans la che pneumatique (FCN50-

46) au début de chaque journée de travail et

après chaque heure d’utilisation continue. Seules

quelques gouttes à la fois sont nécessaires. Une

quantité d’huile plus grande sera accumulée

dans l’outil et éjectée de l’échappement de

l’outil pendant le clouage. N’UTILISEZ QUE DE

L’HUILE PNEUMATIQUE. N’utilisez pas d’huile à

détergent ou de l’huile contenant d’autre additifs :

ils pourraient accélérer l’usure des scellés.

Utilisez une petite quantité d’huile sur les pièces

externes mobiles et les pivots.

La saleté et l’eau de la conduite pneumatique

sont des causes majeures d’usure des outils

4.

5.

6.

7.

INSPECTION ET NETTOYAGE QUOTIDIENS

ENTRETIEN

Page 23

FRANÇAIS

ENGLISH

23

pneumatiques. Utilisez un ltre ou un huileur

pour une meilleure performance et une plus

grande durée de vie de l’outil. Assurez-vous que

la capacité de débit du ltre est sufsante pour le

volume d’air utilisé par l’outil.

Essuyez l’outil et inspectez-le pour toute usure

ou dommage. Utilisez une solution de nettoyage

ininammable pour essuyer l’extérieur de l’outil,

seulement si nécessaire. Ne trempez pas l’outil

dans un produit de nettoyage. De tels produits

peuvent endommager les pièces internes.

Inspectez la détente et le mécanisme de sécurité

an de vous assurer qu’ils sont complets et

fonctionnels : aucune pièce manquante ou lâche,

aucune pièce collante.

Serrez bien toutes les vis. Les vis lâches peuvent

causer des blessures ou endommager l’outil.

DÉPANNAGE

AVERTISSEMENT : Cessez immédiatement

d’utiliser l’outil si l’un des problèmes suivants

survient. Des blessures graves pourraient résulter

du défaut de respecter cette consigne. Toute

réparation ou remplacement doit être effectué par

le personnel qualié ou par un centre de service

agréé.

MISE EN GARDE :

=Débranchez l’outil de la conduite pneumatique

avant de procéder à tout entretien ou réparation.

=Lorsque vous insérez ou réinstallez des joints

toriques, assurez-vous qu’ils sont propres et

lubriés à l’aide d’un lubriant à joint torique.

ENTRETIEN

PROBLEM CAUSE SOLUTION

Fuite d’air dans le chapeau

de cylindre.

Vis déserrée dans le

champignon (FCN50-14)

Serrez la vis et vérier

Joint (FCN50-17) usé ou

endommagé

Remplacez le joint

Page 24

ENGLISHFRANÇAIS

24

L'outi fonctionne lentement

ou manque de puissance.

Lubrication insufsante Ajoutez gouttes d'huile tel

qu'indiqué

Alimentation d'air

insufsante

Vériez la source d'air

L'orice d'échappement du

chapeau de cylindre est

obstrué.

Nettoyez l'orice

d'échappement

L'outil saute des pièces de

xation.

Ressort (FCN50-17) du

poussoir est endommagé.

Remplacez le ressort du

poussoir.

Pièces de xation de la

mauvais dimension

Utilisez uniquement des

pièces reommandées :

clous à plancher en forme

de « L » de cal. 15-1/2

Saletés dan la plaque avant

ou magasin

Nettoyez la canal

d'entraînement de la plaque

avant et le magasin

Pièces de xation coincées

dans l'outil ou le magasin.

Le canal d'entraînement de

la plaque avant est usé ou

endommagé.

Remplacez la guide-lame

(FCN50-22)

La lame poussoir est

endommagé

Remplacez l'ensemble de

piston (FCN50-8)

Pièces de xation

endommagées.

Utilisez uniquement des

pièces reommandées et

non-endommmagées.

DEPANNAGE

SERVICE ET RÉPARATIONS

Tous les outils de qualité nécessitent

éventuellement un entretien ou un remplacement

de pièces, suite à une usure en cours d’utilisation

normale.

ENTRETIEN

Page 25

FRANÇAIS

ENGLISH

25

Si votre outil doit être réparé, adressez-vous

auprès de votre détaillant local ou téléphonez à

Superior Airco Wholesale au 1 (888) 267-7713

pour trouver le centre de réparation agréé de votre

secteur. Toutes les réparations effectuées par les

centres de réparation agréés sont entièrement

garanties contre toute défectuosité matérielle ou

de main-d’œuvre.

Certains composants pouvant être entretenus par

l’utilisateur sont décrits à la section Dépannage.

Nous ne pouvons garantir les réparations

effectuées par toute autre personnel que celui d’un

centre de réparation agréé.

Des questions? N’hésitez pas à téléphoner à notre

centre de soutien technique, au numéro sans frais

1 (888) 267-7713. Soyez toujours prêt à donner

les renseignements suivants concernant votre

outil : numéro du modèle, type, numéro de série,

etc.

GARANTIE

Tous les produits distribués par Airco Superior Clarke

sont garantis contre les défauts de fabrication et les

défectuosités pour une période d’un an à compter

de la date d’achat par l’utilisateur nal. La société

RÉPARERA OU REMPLACERA, À SA SEULE

DISCRÉTION, toute marchandise que la société

considère être défectueuse, pourvu qu’elle n’ait pas

subi un usage inapproprié ou abusif, et qu’elle n’a été

modiée ni réparée par une personne autre que le

personnel d’un centre de service autorisé. Conservez

la preuve d’achat. Le consommateur devrait retourner

le produit défectueux, accompagné du reçu de caisse,

au lieu d’achat.

Cette garantie ne s’applique pas aux pièces qui

doivent être remplacées périodiquement, telles

que les lames d’entraînement des agrafeuses et

des cloueuses, les disques à poncer, les becs de

soudage, etc. Toutes les demandes de réclamation

doivent avoir une autorisation préalable et les produits

doivent être expédiés, port payé, à l’entrepôt de

Richmond (Colombie-Britannique) ou de Mississauga

(Ontario), ou à un dépôt de service après-vente

autorisé, accompagné d’une copie de la facture

indiquant la date de vente de l’article à l’utilisateur

nal.

ENTRETIEN

Page 26

ENGLISHFRANÇAIS

26

LISTE DES PIÈCES

Consultez le schéma de la p.27 pour l’emplacement des pièces.

ARTICLE DESCRIPTION ARTICLE DESCRIPTION

FCN50-1 Plongeoir FCN50-24 Pied

FCN50-2 Joint torique 15.9 x 1.8 FCN50-24a Goupille

FCN50-3 Joint torique 19.2 x 1.8 FCN50-25 Espaceur (pour 25/32 po)

FCN50-4 Champignon FCN50-25a Espaceur (pour 1/2 po)

FCN50-5 Joint torique 17.5 x 2.6 FCN50-26 Vis

FCN50-6 Joint torique 42.5 x 5.4 FCN50-27 Rondelle ressort

FCN50-7 Joint torique 57.4 x 3.5 FCN50-28 Vis

FCN50-8 Ensemble de piston FCN50-29 Tranche

FCN50-9 Bague cylindrique FCN50-30 Magasin

FCN50-10 Face à marteau FCN50-31 Ressort

FCN50-11 Vis FCN50-32 Écrou

FCN50-12 Capuchon cylindrique FCN50-33 Vis

FCN50-13 Joint torique 54.2 x 3.5 FCN50-34 Rondelle

FCN50-14 Vis FCN50-35 Capuchon de magasin

FCN50-15 Rondelle ressort FCN50-36 Vis

FCN50-16 Actuateur de champignon FCN50-37 Fil à ressort

FCN50-17 Joint FCN50-38 Support à ressort

FCN50-18 Habitacle FCN50-39 Support

FCN50-19 Pare-choc FCN50-40 Goupille

FCN50-19a Vis FCN50-41 Pied distributeur

FCN50-19b Rondelle ressort FCN50-42 Ressort tordeur

FCN50-19c Plaque déecteur FCN50-43 Garde

FCN50-20 Bec FCN50-44 Vis

FCN50-21 Vis FCN50-45 Bras

FCN50-22 Guide-lame FCN50-46 Fiche pneumatique

FCN50-23 Rondelle ressort FCN50-47 Marteau

AVERTISSEMENT : Toutes les réparations doivent

être exécutées par le personnel d’un centre de

service autorisé. Si vous ouvrez cet outil, vous

risquez d’annuler la garantie.

Page 27

FRANÇAIS

ENGLISH

27

SCHEMATIC DRAWING / SCHÉMA

Superior Airco Wholesale Ltd., Richmond, BC, Canada V6X 1X5

Tel: 1-888-267-7713 www.superiorairco.com

Loading...

Loading...