Page 1

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures,

and warranty. Put it and the original sales invoice in a safe, dry place for

future reference.

CONSERVEZ CE GUIDE

Vous aurez besoin de ce guide pour les instructions de sécurité, les

procédures d’utilisation et la garantie. Conservez-le dans un endroit sûr et

sec pour référence future.

v

Model / Modèle : FCN1590

15

o

Framing Coil Nailer

Operator’s Manual (p.2)

Marteau pneumatique pour

clous en rouleau à 15 degrés

pour la charpente

Manuel de l’utilisateur (p.17)

060816

Page 2

ENGLISHFRANÇAIS

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using pneumatic tools, basic

safety precautions should always be followed to

reduce the risk of personal injury.

READ ALL INSTRUCTIONS BEFORE USING THIS

TOOL

We strongly recommend that this tool not be modied

and /or used for any application other than that for

which it was designed. If you have any questions

relative to its application, do not use the tool until you

have written or called us and we have advised you.

SAFETY GLASSES: To prevent eye injuries, the

tool operator and all persons in the work area

must wear approved safety glasses to ANSIZ87.1

specications with permanently attached, rigid side

shields.

EAR PROTECTION: Wear ear protection to

safeguard against possible hearing loss.

DRESS SAFELY. Protective gloves and non-skid

footwear or safety shoes are recommended while

working with and operating this tool. Do not wear

loose clothing or jewelry. Contain long hair.

USE CLEAN, DRY, REGULATED, COMPRESSED

AIR at 70 to 120 psi / 483 to 827 kPa / 4.8 to 8.3

bar.

DO NOT CONNECT TOOL to pressure which

potentially exceeds 180 psi / 1241 kPa / 12.4 bar.

AIR HOSE: Use only hose that is rated for a

minimum working pressure of 150 psi or 150%

of the maximum system pressure, whichever is

greater. Check that connections are tight.

NEVER USE OXYGEN, CARBON DIOXIDE,

combustible gases or any other bottled gas as a

power source for this tool. Explosion and serious

personal injury could result.

COUPLINGS: Connect tool to air supply hose with

a 1/4” NPT coupling that removes all pressure from

the tool when the coupling is disconnected.

DISCONNECT TOOL FROM AIR SUPPLY HOSE

before doing any disassembly, maintenance,

clearing a jammed fastener, leaving the work area,

moving the tool to another location, or handing the

tool to another person.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 3

FRANÇAIS

ENGLISH

3

EXTENSION CORDS: Observe warnings that

accompany air compressors concerning the use

of the correct gauge and insulation on extension

cords used out of doors.

NEVER USE A TOOL that is leaking air, has

missing or damaged parts, or requires repair.

Make sure all screws and caps are securely

tightened.

CHECK FOR DAMAGED PARTS. Never use

a tool if safety, trigger, or spring are inoperable,

missing or damaged. Do not alter or remove

safety, trigger, or springs. Make daily inspections

for the free movement of trigger and safety

mechanism.

REPLACEMENT PARTS: When servicing, use

only identical Superior replacement parts and

fasteners recommended by us.

CONNECT TOOL TO AIR SUPPLY BEFORE

loading fasteners to prevent fasteners from

ring during connection. The fastener driving

mechanism may cycle when the tool is connected

to the air supply.

ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS. Keep it pointed away from yourself

and others at all times. No horseplay. Respect the

tool as a working implement.

DO NOT LOAD FASTENERS with the hammer

face depressed. The tool may unintentionally re a

fastener.

DO NOT DEPRESS THE TRIGGER when not

driving fasteners. Never carry tool while touching

the trigger mechanism: tool may re an unwanted

fastener.

DON’T OVERREACH. Keep proper footing and

balance at all times. Do not reach over or across

machines which are running.

GRIP TOOL FIRMLY to maintain control while

allowing the tool to recoil away from the work

surface as the fastener is driven.

DO NOT DRIVE FASTENERS on top of other

fasteners, or with the tool at too steep an angle:

the fasteners can ricochet causing personal injury.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

IMPORTANT SAFETY INSTRUCTIONS

Page 4

ENGLISHFRANÇAIS

4

FIRE FASTENERS INTO WORK SURFACE

ONLY. Do not drive nails nor attempt to do so, into

hard or brittle materials such as steel, concrete, or

tile.

DO NOT DRIVE FASTENERS too close to the

edge of the workpiece. The workpiece is likely to

split, allowing the fasteners to y free or ricochet

causing personal injury.

STAY ALERT. Keep hands and body away from

the path of any potential red fastener. Watch

what you are doing & use common sense. Don’t

operate any tool when you are tired or under the

inuence of drugs or alcohol. Check prescriptions

to determine if there could be a problem.

GUARD AGAINST ELECTRIC SHOCK. Prevent

body contact with grounded surfaces: pipes,

radiators, ranges, and refrigerator enclosures.

Before driving fasteners into walls, oors,

or wherever “live” electrical wires may be

encountered, try to ascertain whether there is a

danger of shock.

KEEP WORK AREA CLEAR of obstructions.

STORE IDLE EQUIPMENT. When the tool is not

being used, it should be cleaned, and stored in a

clean dry place out of the reach of children.

EMPLOYERS must enforce compliance with the

safety warnings and all other instructions in this

manual. Keep it available for use by everyone

assigned to use this tool.

WARNING: The warnings, cautions, and

instructions detailed in this manual cannot cover

all possible conditions and situations that occur. It

must be understood by the operator that COMMON

SENSE AND CAUTION ARE FACTORS that

cannot be built into this product, but MUST BE

SUPPLIED BY THE OPERATOR.

UNPACKING

Check immediately that all parts and accessories are

included in the case:

FNC1590 Framing Coil Nailer 1

Safety Glasses (pr) 1

Air Tool Oil (bottle) 1

21.

22.

23.

24.

25.

26.

27.

n

n

n

IMPORTANT SAFETY INSTRUCTIONS

Page 5

FRANÇAIS

ENGLISH

5

S3 Hex Key 1

S4 Hex Key 1

S5 Hex Key 1

S6 Hex Key 1

Manual 1

If anything is missing or broken, contact your retailer

or call toll-free 1.888.267.7713.

SPECIFICATIONS

TOOL

Operating pressure: 70 - 120 psi / 483 to 827 kPa /

4.8 to 8.3 bar (max. 120 psi / 827 kPa / 8.3 bar)

Air consumption: 0.17 cu. ft. / cycle @ 100 psi /

(4.77 litres / cycle @ 690 kPa

Air Inlet: 1/4” NPT

Tool weight: 3.7 kg (8.2 lb)

Pkg. weight: 7 kg (15.4 lb)

FASTENERS

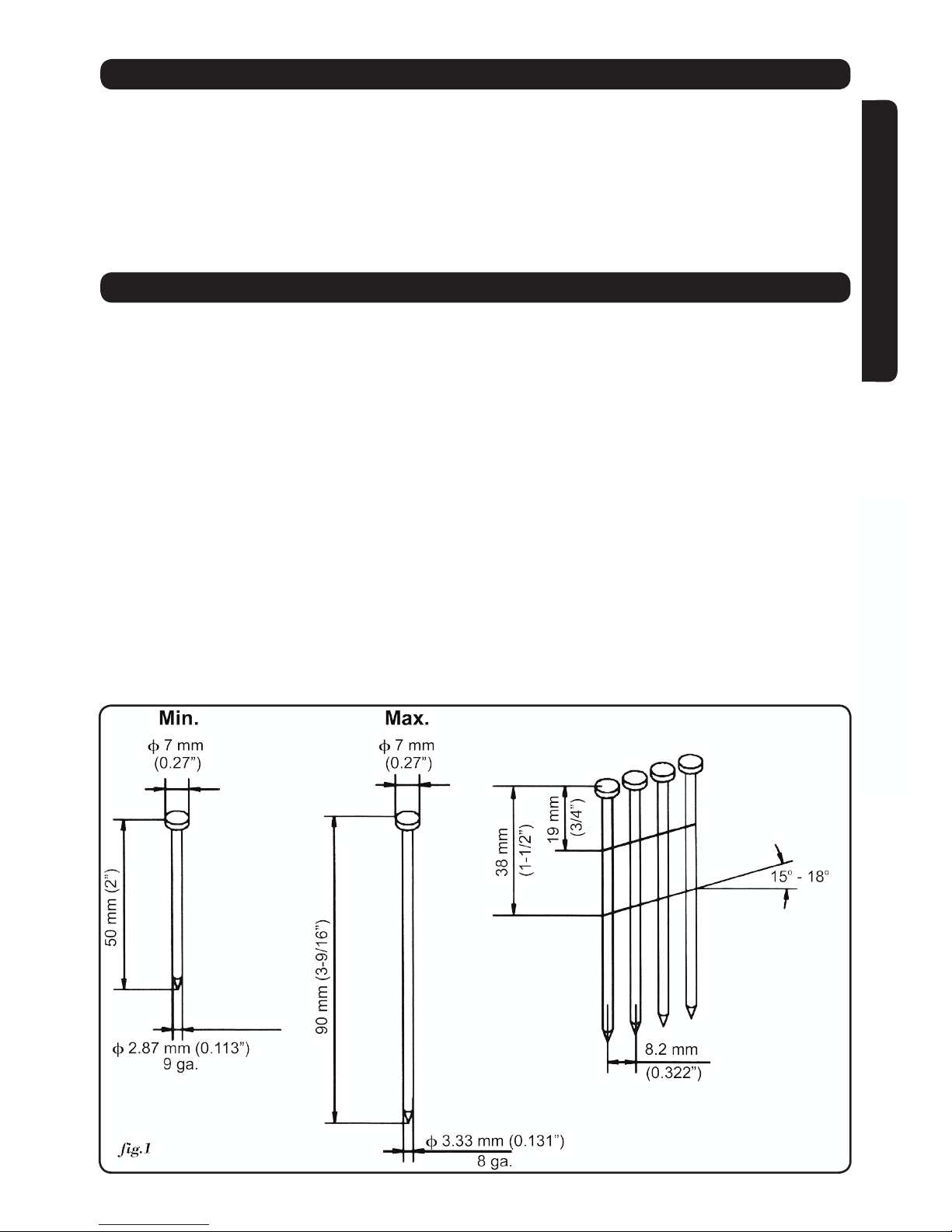

The FNC1590 is a light duty, coil fed, pneumatic

nailer, using compressed air as a power source. It is

designed to install 50 mm - 90 mm (2”– 3-9/16”) 9 ga.

to 8 ga. spiral, ring or smooth wire-collated nails with

a collation angle of 15 degrees (g.1). The tool is

made with a magnesium alloy body and cylinder cap

to provide light weight while maintaining high strength

and rigidity.

n

n

n

n

n

n

n

n

n

n

UNPACKING

Page 6

ENGLISHFRANÇAIS

6

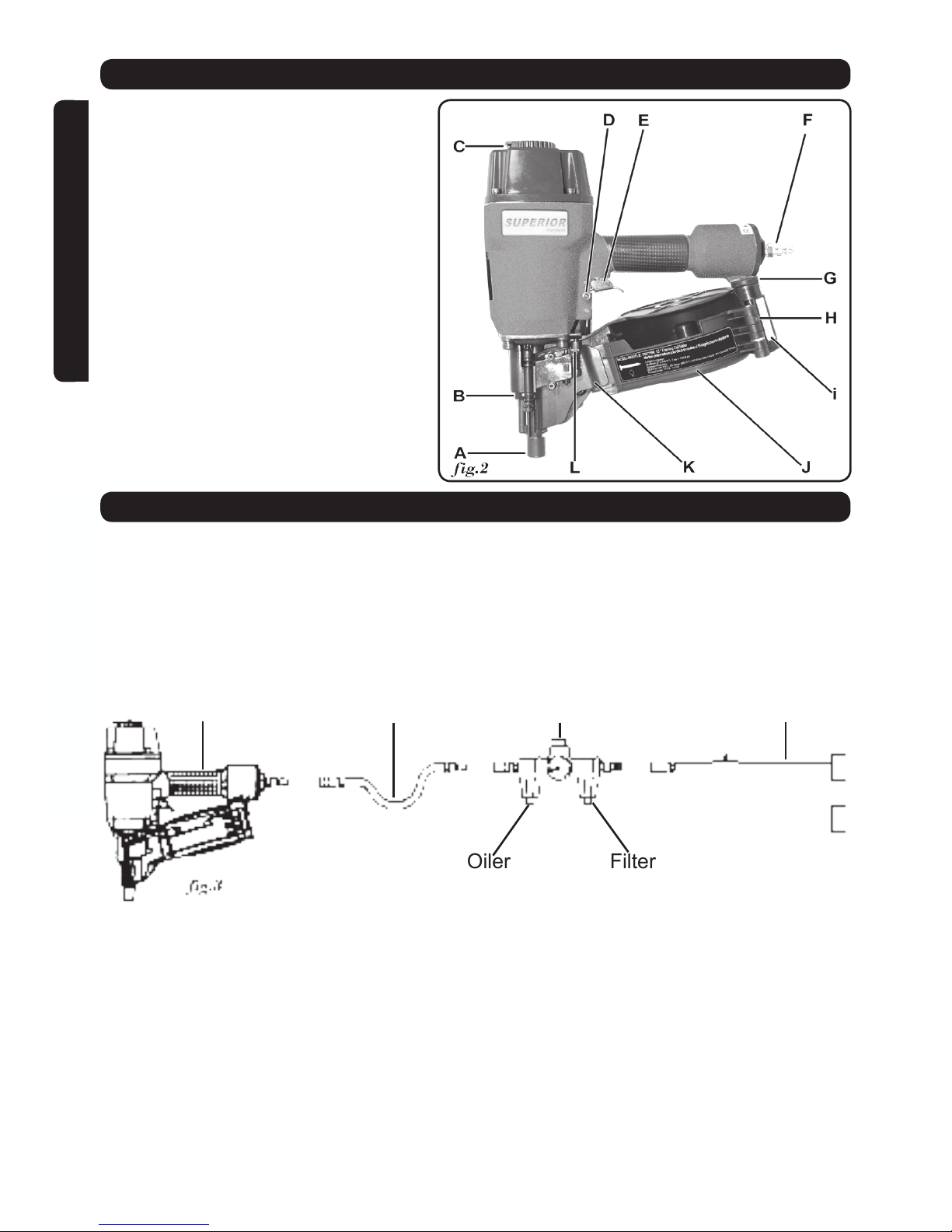

Figure 2 names the major components of the FNC1590:

A. Contact tip

B. Depth adjustment knob

C. 360 degree re-directable

exhaust port

D. Trigger mode selector

E. Trigger

F. Male quick-connect tting

G. Magazine height adjustment

knob

H. Magazine height indicator

I. Magazine height scale

J. Lower magazine

K. Feed cover plate

L. Cover plate latch

OPERATING PROCEDURES

SET UP

Your Superior FNC1590 Framing Coil Nailer is

fully assembled when you receive it. See the

recommended air system setup (g.3) below. Be sure

that the couplers are set up so that the air hose is

depressurized when adding or removing components

from the system.

AIR SOURCE

The FNC1590 is designed to operate on clean,

dry, compressed air, regulated at 70 - 120 psi /

483 to 827 kPa / 4.8 to 8.3 bar (max. 120 psi /

827 kPa / 8.3 bar). The preferred system (g.3)

would include a lter, a pressure regulator, and

an automatic oiler located as close to the tool as

possible (within 5 meters (15 feet) is ideal). Do not

use bottled air or gases.

Determine if it is necessary to lubricate. All

compressed air contains moisture and other

n

n

FUNCTIONAL DESCRIPTION

Nailer Air Hose Regulator Air Supply

FilterOiler

Page 7

FRANÇAIS

ENGLISH

7

contaminants that can harm the internal

components of the tool. An air line lter will

remove most of these and signicantly prolong the

life of the tool. If you are using an in-line automatic

oiler, check and add oil if necessary. If an in-line

oiler is not available, place 5 or 6 drops of oil into

the tool’s quick-connect tting (g 2, F) at the

beginning of each workday. More than this will be

expelled from the tool’s exhaust during ring.

PREPARING THE TOOL

Air Fitting: The FNC1590 is equipped with a 1/4”

NPT male plug for a ‘quick connector’. To prevent

accidental cycling even though disconnected, the

tool must always be connected to the air supply

in such a way that all air pressure in it is released

when the coupling is disconnected.

CAUTION:

All air line components (including hoses, pipe,

connectors, lters, & regulators, etc.) must be

rated for a minimum working pressure of 150 psi

/ 1034 kPa / 10.3 bar or 150% of the maximum

system pressure, whichever is greater. Please

try to use a hose of ID 3/8” connecting nailer with

compressor.

Do not connect this tool to a system with maxi-

mum potential pressure greater than 180 psi

(1241 kPa, 12.4 bar)

Disconnect your air line from your nailer using the

quick connect on the air hose. Do not unscrew

the air inlet from the nailer with your air hose connected.

Disconnect tool from air supply before performing

maintenance, clearing a jammed fastener, leaving work area, moving tool to another location, or

handing the tool to another person.

LOADING FASTENERS

1. After reading and understanding this entire

manual, connect tool to the air supply.

CAUTION:

Keep tool pointed away from yourself and others

at all times.

n

OPERATING PROCEDURES

Page 8

ENGLISHFRANÇAIS

8

Always connect tool to air supply before loading

fasteners

Do not load fasteners with trigger or safety

pressed.

Always wear approved safety glasses, and hear-

ing protection when preparing or operating the

tool.

Never use a tool that leaks air or needs repair.

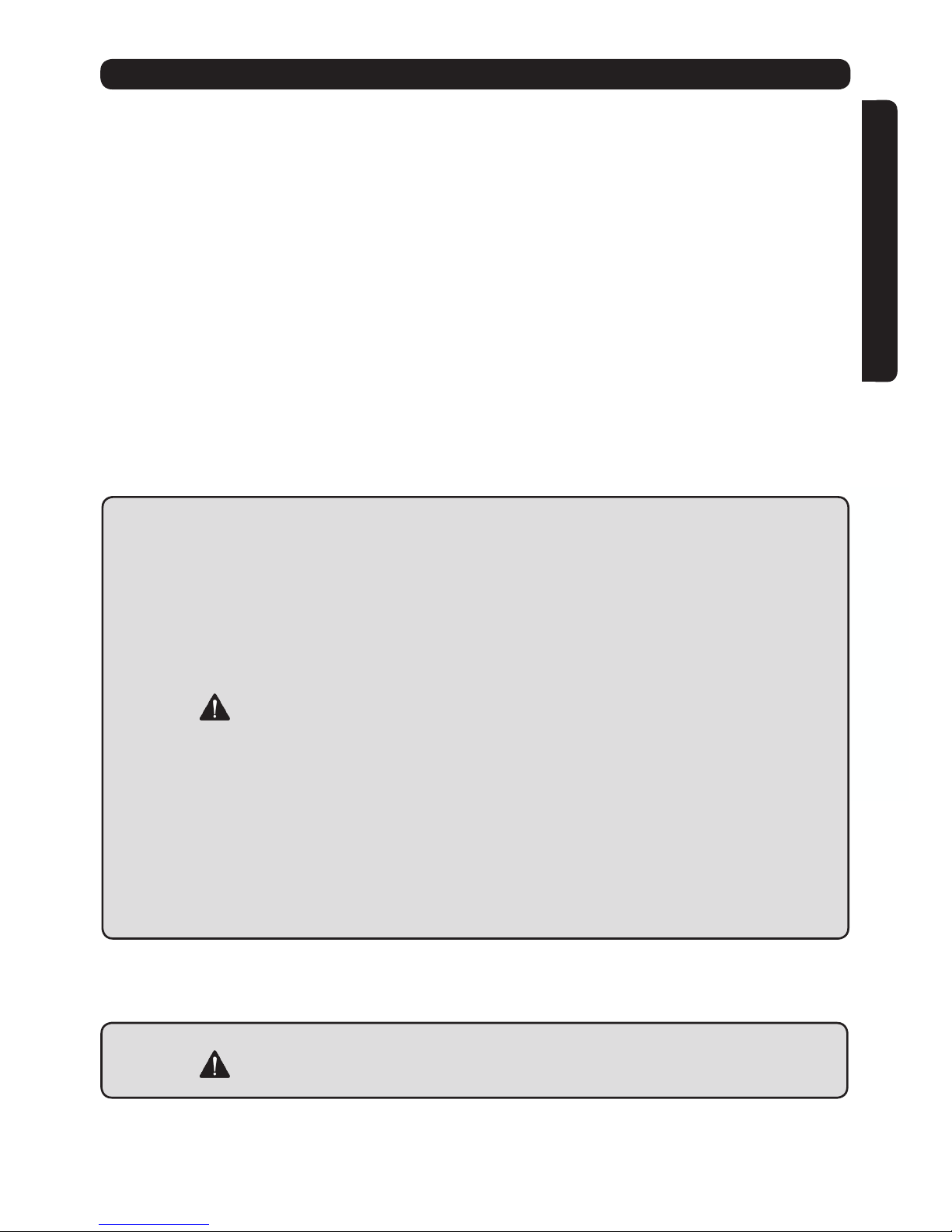

2. Depress cover-plate latch (L, g.4).

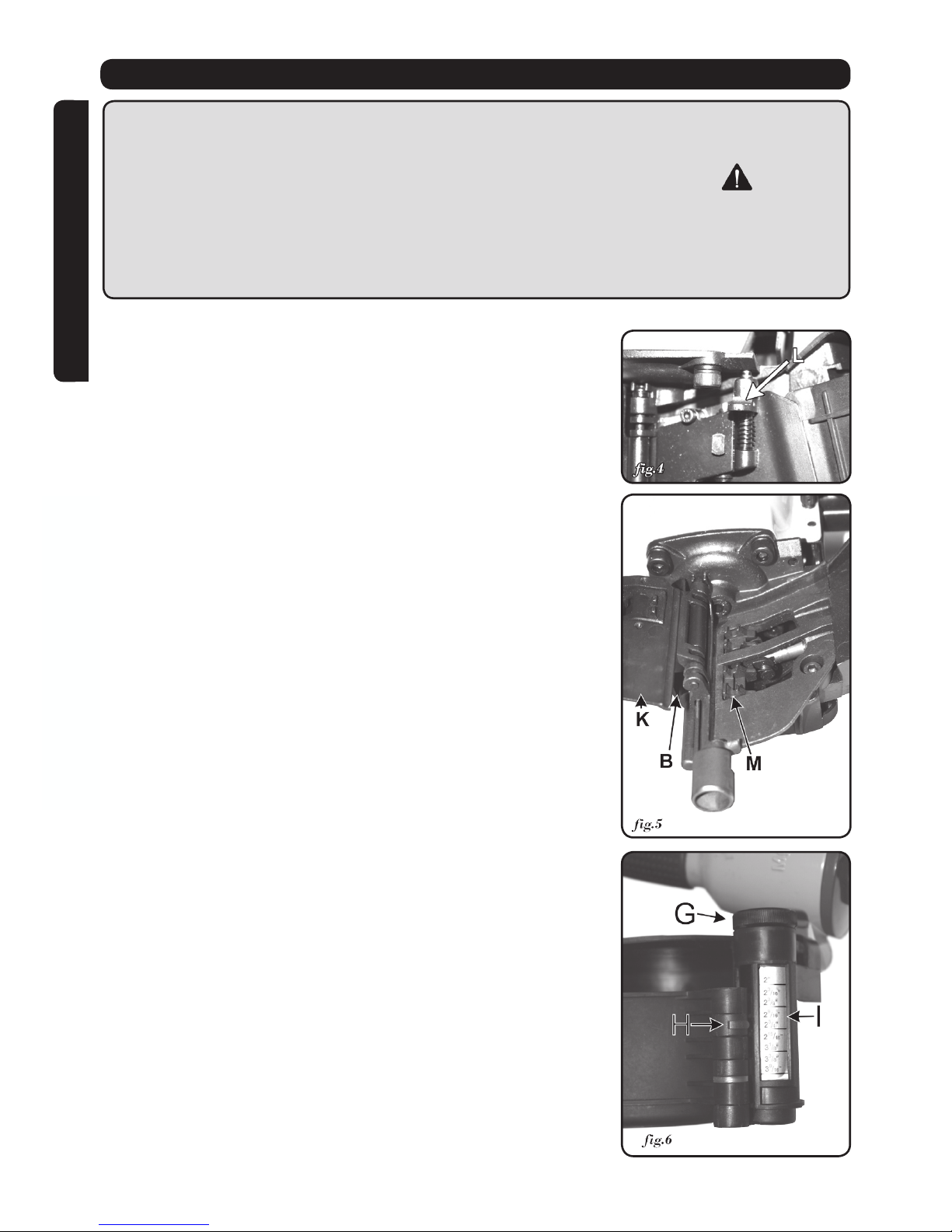

3. Open cover plate (K, g.5)

4. Open the lower magazine (J, g.2).

5. Place a coil of nails in the lower magazine.

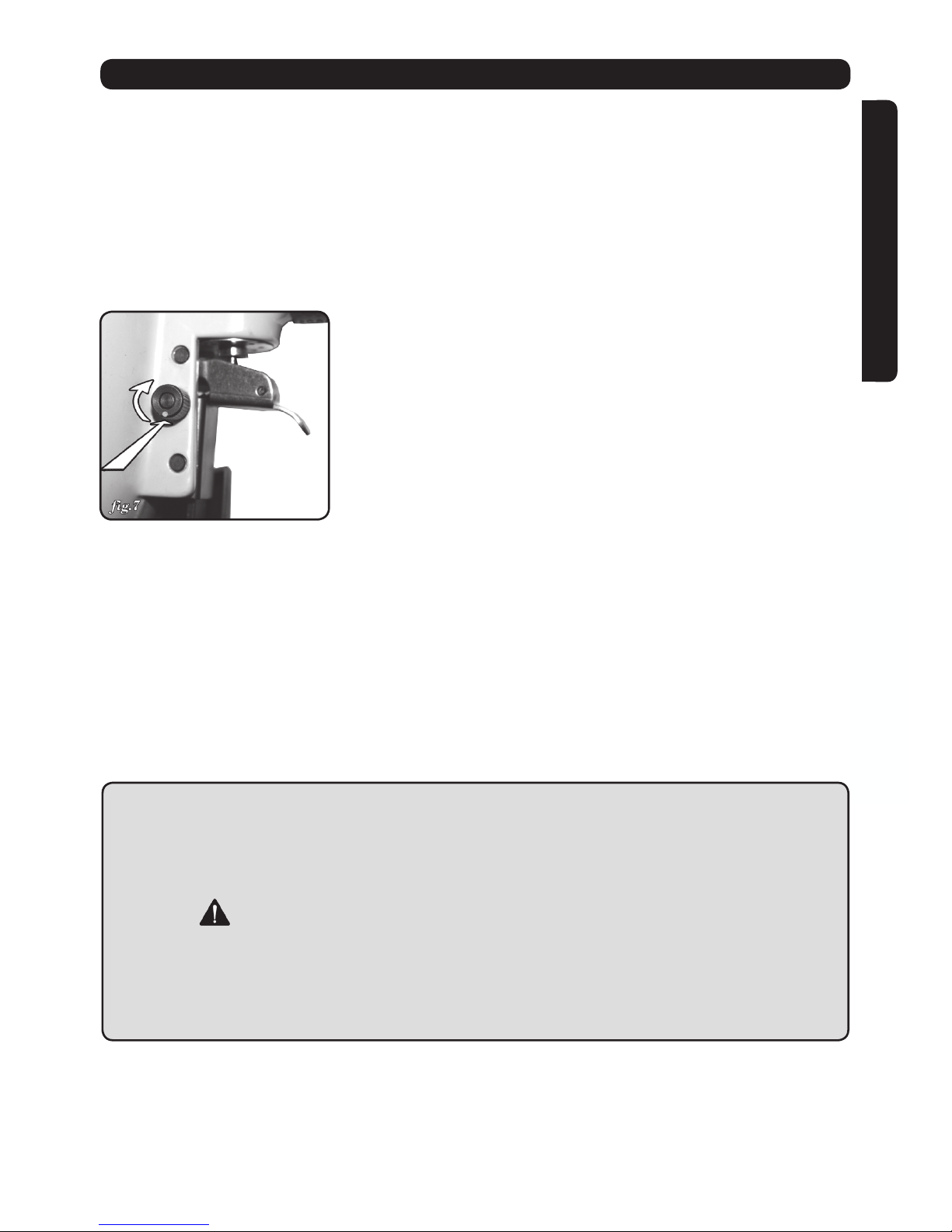

6. Rotate magzine height adjustment knob (G, g.6)

to adjust the lower magazine according to the

nails’ length. The highest position is used for 50

mm (2”) nails while the lowest position is used

for 90 mm (3-9/16”) nails. For all nails between

minimum and maximum, adjust lower magzine

accordingly.

7. Close lower magazine.

OPERATING PROCEDURES

Page 9

FRANÇAIS

ENGLISH

9

8. Draw the nails out and position the second nail on

to the feed hook (M, g.5).

9. Close cover-plate and latch (L, g.4).

10. Rotate the directional exhaust deector (C, g.2),

so that the exhaust air blast will be directed away

from the operator.

USING THE TOOL

Complete all of PREPARING THE TOOL and

LOADING FASTENERS before using.

This tool can be red in two different ways:

1. Sequential Fire:

Push in, then turn the trigger mode selector (D,

g.2) so the red dot is down.(g.7)

Put the contact tip (A, g.2) of the tool on the

working surface

Lightly push the tool toward the working surface

until the safety bracket is depressed

Press the trigger (E, g.2) to drive the fasteners.

This “trigger re” method provides the most

accurate fastener placement.

2. Bump Fire:

Push in, then turn the trigger mode selector (D,

g.2) so the red dot is up.(g.7)

Hold the contact tip (A, g.2) off the surface

Press the trigger

Keeping the trigger pressed, push the contact tip

(A, g.2) of the safety bracket against the working

surface. Once the bracket is pushed back enough,

the nail will re.

CAUTION:

Disconnect tool from air supply before performing

maintenance, clearing a jammed fastener, leaving

working area, moving tool to another location or

handing the tool to another person.

Clean and inspect tool daily. Carefully check for

proper operation of trigger and safety mechanism.

Do not use the tool unless both the trigger and the

safety mechanism are functional.

Do not use the tool if its leaking air or needs any

other repair.

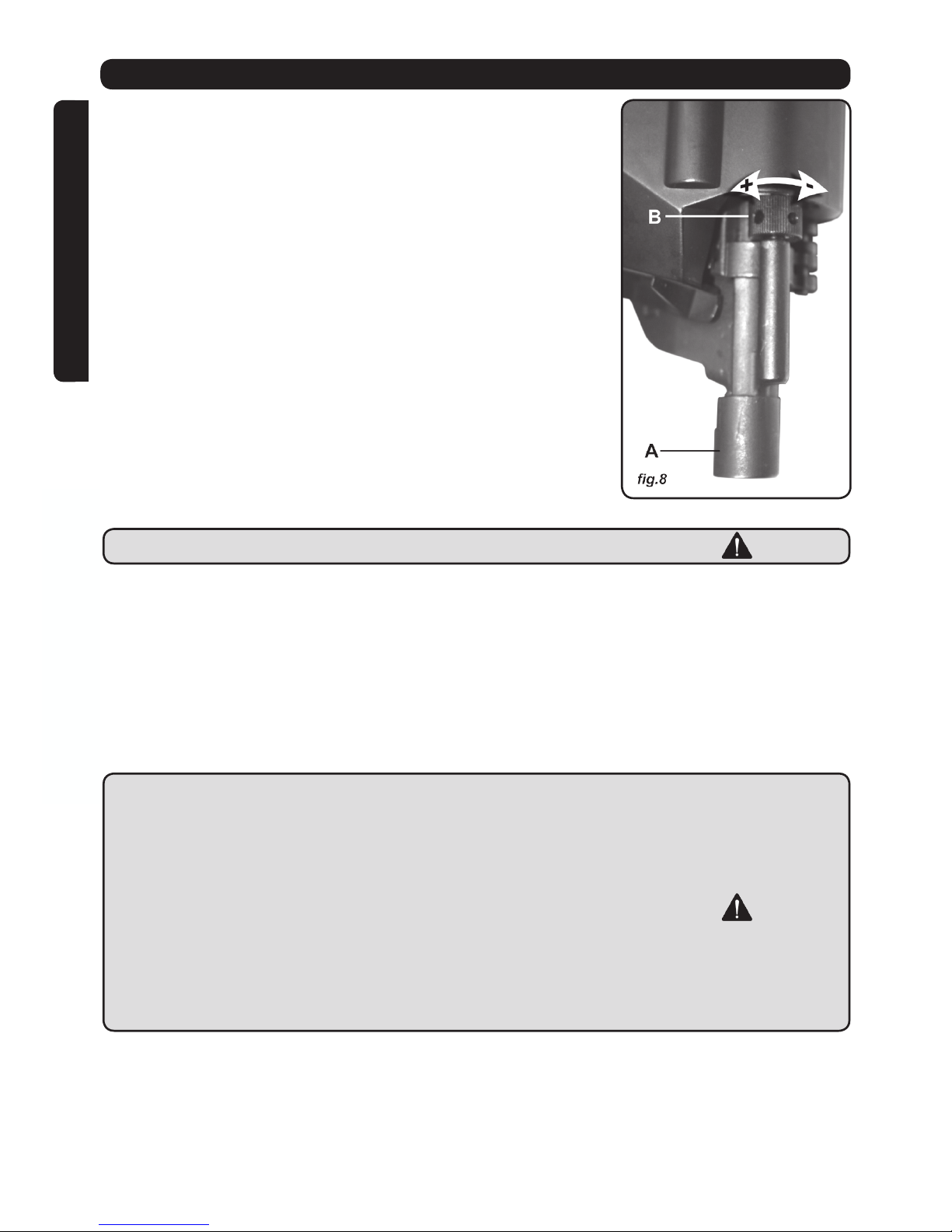

FASTENER DEPTH

Driving depth can be adjusted by rotating the depth

adjustment knob (B, g.2).

Test re a fastener into a scrap work piece and

check depth.

n

n

n

n

n

n

n

n

n

OPERATING PROCEDURES

Page 10

ENGLISHFRANÇAIS

10

If the nail is driven too deep, rotate the knob (B,

g.8) clockwise (when tool is upside-down) to

move the safety bracket downward.

If a greater depth is desired, rotate the knob

counter clockwise to adjust the safety bracket

upward.

Test re another fastener in a scrap work piece and

check the depth.

REPEAT AS NECESSARY UNTIL DESIRED

DEPTH IS ACHIEVED. The amount of air pressure

required will vary depending on the size of the

setting.

Determine the lowest setting that will consistently

perform the job at hand. Air pressure in excess of

that required can cause premature wear and/or

damage to the tool.

CLEARING A JAMMED FASTENER

CAUTION: Disconnect tool from air supply.

1. Open latch

2. Rotate lower magazine

3. Remove the nails from the magzine.

4. Use a slender; soft steel rod to drive the drive

blade to its uppermost position.

5. Use a pair of needle nose pliers to remove the

jammed fastener.

6. Follow instructions in PREPARING THE TOOL

BEFORE DRIVING to reload fasteners.

CAUTION:

Keep the tool pointed away from yourself and

others at all times.

Always connect the tool to air supply before

loading fasteners.

Do not load fasteners with safety or trigger

depressed.

Always wear approved safety glasses and

hearing protection when preparing or operating

this tool.

Never use a tool that leaks air or needs repair.

n

n

n

n

n

OPERATING PROCEDURES

Page 11

FRANÇAIS

ENGLISH

11

MAINTENANCE

CAUTION: Disconnect tool from air supply before

cleaning and inspecting the tool. Correct all problems

before operating.

CLEAN AND INSPECT DAILY

nAdd pneumatic tool oil into the oiler regularly to

assure that all moving. Frequent, but not excessive lubrication is required for the best performance. Oil added through the air line connection

will lubricate the inside parts. An automatic oiler

is recommended, but 2 drops of oil may be added

manually into the tool’s air intake at the male

quick-connect tting (F, g.1) at the beginning

of each workday and after about every hour of

continuous use. Only a few drops at a time are

necessary. More than this will pool inside the tool

and be expelled from the tool’s exhaust during

ring. USE ONLY PNEUMATIC TOOL OIL. Do

not use detergent oil or oil with other additives, as

these can cause accelerated wear on the seals.

nCheck the lter of the compressor weekly.

Open drain cock to drain all water and contaminants out of the air tank.

nWipe the tool clean.

nBlow the tool clean using high compressed air,

and then use non-ammable cleaning solutions to

wipe exterior of tool if necessary.

nDo not soak tool in cleaning solutions. Such solu-

tions can damage internal parts. The exposed

portion of the small piston rod and feed hook must

be kept clean.

nInspect trigger and safety mechanism daily to as-

sure system is complete and functional.

nKeep all screws tight. Loose screws can cause

personal injury or damage to the tool. Check if

there are worn and damaged parts. If any, please

replace immediately.

TROUBLESHOOTING

WARNING: Stop using the tool immediately if any

of the following problems occur. Serious personal

injury may result. Any repairs or replacements

must be done by qualied personnel or by an

authorized service centre only.

Page 12

ENGLISHFRANÇAIS

12

CAUTION:

Disconnect the tool from air supply before

performing any service procedure.

When inserting new or re-installing O-rings,

make sure they are clean and lubricated with an

O-ring lubricant.

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Air leaking at trigger area 1.O-ring in trigger valve stem

is worn and damaged.

1. Check/replace O-ring &

lubricate

2. O-ring in trigger valve head

is worn or damaged

2. Check/replace O-ring &

lubricate

3. Contains foreigh matter 3. Clean the tool & lubricate

Air leaking from the lower

body and the nose

1. Screw is loose at

connection between nose and

body

1. Tighten screw & re-check

2. O-ring is damaged between

body and nose

2. Check/replace O-ring &

lubricate

3. Bumper is damaged Replace the bumper

4. Foreign matter at the

contact between bumper and

body

Disassemble & clean

Air leaking from the upper

body and the nose

1. Screw is loose at

connection between cylinder

and body

1. Tighten screw & re-check

2. O-ring is damaged 2. Check/replace O-ring &

lubricate

3. Gasket is damaged Replace the gasket

Failure to start tool 1. Tool dry, lack of lubrication 1. Use pneumatic tool oil

2. Spring in the cylinder cap is

damaged

2. Replace spring in the

cylinder cap

3. Valve sticks to cylinder cap 3. Disassemble, clean &

lubricate

Blade driving fasteners too

deeply

1. Safety bracket position is

incorrect

1. Rotate depth adjustment

know to move the safety

braket down

2. Air pressure is too high 2. Decrease air pressure

Tool skips fasteners, feeds

intermittently

1. Foreign matter between

the small piston and small

cylinderDamaged pusher

spring

3. Disassemble, clean &

lubricate

2. O-ring on the small piston is

worn and damaged

2. Check/replace O-ring &

lubricate

3. Tool dry, lack of lubrication 3. Use pneumatic tool oil

4. Spring on the small piston

is damaged

4. Replace small spring

5. Air pressure too low 5. Increase air pressure, but

don't exceed120 psi (827 kPa)

Page 13

FRANÇAIS

ENGLISH

13

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

6. Body/nose connecting

screw is loose

6. Tighten all screws

7. Stop hook can't stop

fasteners

7. Replace the taper spring on

the stop hook

8. Bent fasteners 8. Use recommended

fasteners

9. Wrong size fasteners 9. Use recommended

fasteners

10. Gasket is damaged 10. Replace gasket/tighten

screw

11. Small piston is dry 11. Open nail housing, place

several drops of pneumatic

tool oil into the end cover hole

of the small piston

12. Small piston bumper is

worn and damaged

12. Replace bumper and

lubricate small piston

13. Feed hook is binding Clean feed hook and torsion

spring

14. Nail length does not

correspond with height setting

on lower magazine

14. Adjust magazine height

adjusting knob on the lower

magazine

15. Weld-wires in nail coil

broken

15. Discard coil

Runs slowly or has power loss 1. Tool dry, lack of lubrication 1.Use pneumatic tool oil

2. Spring in cylinder cap

damaged

2. Replace spring in the

cylinder cap

3. Foreign matter between the

piston assembly and cylinder

3. Disassemble, clean &

lubricate

4. Cylinder is not assembled

to home position

4. Reassemble after

disassembling

5. O-ring on the valve is dry

after disassembly

5. Lubricate and reassemble

6. Air pressure too low 6. Increase air pressure, but

don't exceed120 psi (827 kPa)

7. Driver is worn 7. Replace the piston

assembly

8. Inner diameter of hose is

too small

Use larger diameter hose

(3/8" minimum)

Fastener are jammed 1. Fasteners are wrong size 1. Use recommended

fasteners

2. Weld-wires in nail coil

broken

2. Discard coil

Page 14

ENGLISHFRANÇAIS

14

PARTS LIST

Please refer to the Schematic Drawing on p. 34 for the

location of parts.

Item Description

FNC1590-1 Screw

FNC1590-2 Spring Washer

FNC1590-3 Bushing

FNC1590-4 Exhaust Cover

FNC1590-5 Seal

FNC1590-6 Screw

FNC1590-7 Spring Washer

FNC1590-8 Cylinder Cap

FNC1590-9 Gasket

FNC1590-10 Washer

FNC1590-11 Valve Seat

FNC1590-12 Spring

FNC1590-13 O-Ring 57.5 x 2.6

FNC1590-14 O-Ring 72.4 x 3.5

FNC1590-15 Valve

FNC1590-16 Screw

FNC1590-17 Cylinder Seal

FNC1590-18 Collar

FNC1590-19 O-Ring 54.4 x 4

FNC1590-20 Piston Assembly

FNC1590-21 Cylinder

FNC1590-22 O-Ring 67 x 3

FNC1590-23 O-Ring 60.25 x 2.5

FNC1590-24 Restrictive Seal

FNC1590-25 O-Ring 97.5 x 3.5

FNC1590-26 Bumper

FNC1590-27 Bumper

FNC1590-28 Body

FNC1590-29 O-Ring 62.3 x 1.8

FNC1590-30 Guide Washer

FNC1590-31 Nose

FNC1590-32 Spring Washer

FNC1590-33 Screw

Item Description

FNC1590-34 Spring

FNC1590-35 Bracket Assembly

FNC1590-36 Adjuster

FNC1590-37 Safety Bracket

FNC1590-38 Seal

FNC1590-39 Pin

FNC1590-40 Safety Guide

FNC1590-41 O-Ring 8.3 x 1.8

FNC1590-42 Rotating Shaft Pin

FNC1590-43 Spring

FNC1590-44 Rotating Shaft Bushing

FNC1590-45 Spring Pin

FNC1590-46 O-Ring 20.3 x 2.5

FNC1590-47 O-Ring 20.3 x 1.5

FNC1590-48 Valve Set

FNC1590-49 O-Ring 9.5 x 1.9

FNC1590-50 O-Ring 10.3 x 1.9

FNC1590-51 Trigger Valve Head

FNC1590-52 O-Ring 12.8 x 1.9

FNC1590-53 Spring

FNC1590-54 O-Ring 5.5 x 1.5

FNC1590-55 Trigger Valve Stem

FNC1590-56 O-Ring 24.8 x 2

FNC1590-57 Trigger Valve Guide

FNC1590-58 Trigger Spring

FNC1590-59 Trigger

FNC1590-60 Spring Pin

FNC1590-61 Washer

FNC1590-62 Locking Washer

FNC1590-63 Cover

FNC1590-64 Spring

FNC1590-65 Piston Bumper

FNC1590-66 O-Ring 28.3 x 3

Page 15

FRANÇAIS

ENGLISH

15

Item Description

FNC1590-67 Piston

FNC1590-68 Torsion Spring

FNC1590-69 Pin

FNC1590-70 Feed Hook

FNC1590-71 O-Ring 14.3 x 2.5

FNC1590-72 Screw

FNC1590-73 Pin

FNC1590-74 Plate

FNC1590-75 Guard

FNC1590-76 Clear Guard

FNC1590-77 Pin

FNC1590-78 Stop Hook

FNC1590-79 Taper Spring

FNC1590-80 Screw

FNC1590-81 Spring Washer

FNC1590-82 Block Plate

FNC1590-83 Spring

FNC1590-84 Pin

Item Description

FNC1590-85 Spring Pin

FNC1590-86 Handle

FNC1590-87 Nut

FNC1590-88 Washer

FNC1590-89 Pin

FNC1590-90 Lower Magazine

FNC1590-91 Seal

FNC1590-92 Adjusting Stem

FNC1590-93 Adjusting Bushing

FNC1590-94 Seal

FNC1590-95 Upper Magazine

FNC1590-96 Adjusting Knob

FNC1590-97 Screw

FNC1590-98 Screw

FNC1590-99 Soft Grip Sleeve

FNC1590-100

O-Ring 65.4 x 2.5

FNC1590-101

End Cap

FNC1590-102

Air Plug

PARTS LIST

Please refer to the Schematic Drawing on p. 34 for

the location of parts.

SERVICE AND REPAIRS

All quality tools eventually require some servicing

or replacement parts due to wear from normal use.

If your tool requires service, ask your retailer or

call Superior Airco Wholesale at 1(888) 267-7713

for an authorized repair centre in your area. All

repairs made by local authorized repair centres

are fully guaranteed against defective material and

workmanship.

Some user-serviceable components are described

in the Troubleshooting section. We cannot

guarantee repairs made or attempted by anyone

other than authoized agencies.

Questions? Feel free to call our technical support

department toll-free at 1(888) 267-7713. In any

communication, please be prepared to give all the

information about your tool: model number, type,

serial number, etc.

n

n

n

n

Page 16

ENGLISHFRANÇAIS

16

WARNING: Repairs should be made by an

authorized repair centre. Opening this tool could

invalidate your warranty.

WARRANTY

All products distributed by Airco Superior Clarke are

warranted against manufacturers’ faults and defects

for a period of one year from the date of purchase

by the end user. The Company will REPAIR OR

REPLACE, AT ITS OWN OPTION, merchandise

deemed by the company to be defective, provided

that is has not been misused, abused, altered, or

repaired by anyone other than an authorized repair

centre. Retain proof of purchase. Consumers should

return the defective product to the place of purchase

accompanied by the receipt.

This warranty does not extend to parts deemed

consumables, such as brad and staple gun driver

blades, grinding discs, welding contact tips, etc.

All warranty claims must have prior authorization

and must be shipped prepaid to the Richmond BC

warehouse, the Mississauga ON warehouse, or to an

authorized repair depot, accompanied by a copy of

the invoice specifying the date that the item was sold

to the end user.

Page 17

FRANÇAIS

ENGLISH

17

AVERTISSEMENT : Certaines consignes de

sécurité de base doivent toujours être respectées

lors de l’utilisation d’outils pneumatiques an de

réduire les risques de blessure.

LISEZ TOUTES LES CONSIGNES AVANT

D’UTILISER CET OUTIL

Nous vous recommandons fortement de ne pas

modier cet outil et de ne pas l’utiliser à d’autres ns

que celle pour laquelle il a été conçu. Si vous avez

des questions quant à cette utilisation, n’utilisez pas

l’outil tant que vous n’en ayez pas obtenu réponse de

notre part.

LUNETTES DE PROTECTION : An de

se protéger contre des blessures aux yeux,

l’utilisateur de l’outil et les personnes présentes

dans l’aire de travail doivent porter des lunettes de

protections homologuées ANSIZ787.1 avec écrans

rigides latéraux xes.

PROTÈGE-OREILLES : Portez des protègeoreilles pour prévenir la perte de l’ouïe.

PORTEZ DES VÊTEMENTS APPROPRIÉS :

Des gants de protection et des chaussures

antidérapantes ou de sécurité sont recommandés

lors du travail avec cet outil. Ne portez pas de

vêtements lâches ni de bijoux. Attachez les

cheveux longs.

UTILISEZ DE L’AIR COMPRIMÉ PROPRE, SEC

ET CONTRÔLÉ entre 70 et 120 psi / 483 et 827

kPa / 4,8 et 8,3 bar.

NE BRANCHEZ PAS L’OUTIL à une pression

potentiellement plus grande que 180 psi / 1 241

kPa / 12,4 bar.

TUYAU PNEUMATIQUE : N’utilisez que le tuyau

calibré pour une pression fonctionnement minimale

de 150 psi ou 150 % de la pression maximale du

système, soit la plus élevée des deux. Vériez que

les branchements sont bien serrés.

N’UTILISEZ JAMAIS D’OXYGÈNE, DE GAZ

CARBONIQUE, de gaz à combustion ou tout

autre gaz embouteillé comme alimentation pour

cet outil. Une explosion et de sérieuses blessures

pourraient en découler.

1.

2.

3.

4.

5.

6.

7.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 18

ENGLISHFRANÇAIS

18

RACCORDS : Branchez l’outil au tuyau

d’alimentation pneumatique à l’aide d’un raccord

de 1/4 po TPN qui retire toute la pression de l’outil

lorsque débranché.

DÉBRANCHEZ L’OUTIL DU TUYAU

PNEUMATIQUE avant de le démonter, l’entretenir,

éliminer un clou bloqué, quitter l’aire de travail,

déplacer l’outil ou le donner à quelqu’un d’autre.

RALLONGES ÉLECTRIQUES : Respectez les

mises en garde accompagnant les compresseurs

d’air quant aux jauges et isolations appropriées

des rallonges électriques extérieures.

N’UTILISEZ JAMAIS UN OUTIL qui présente des

fuites, des pièces manquantes ou endommagées

ou qui nécessite une réparation. Assurez-vous

que toutes les vis et tous les bouchons sont bien

serrés.

VÉRIFIEZ L’ABSENCE DE DOMMAGE SUR LES

PIÈCES. N’utilisez jamais un outil si son dispositif

de sécurité, sa détente ou ses ressorts sont

manquants ou endommagés. Ne modiez pas le

dispositif de sécurité, la détente ou les ressorts.

Inspectez quotidiennement le mouvement libre de

la détente et le mécanisme de sécurité.

PIÈCES DE REMPLACEMENT : N’utilisez que

les pièces de remplacement et clous Superior

identiques que nous recommandons pour la

réparation.

BRANCHEZ L’OUTIL À LA CONDUITE

PNEUMATIQUE AVANT de charger les clous, an

d’éviter qu’ils ne s’éjectent au branchement. Le

mécanisme d’expulsion des clous peut effectuer

un cycle lorsqu’il est branché à la conduite

pneumatique.

PRÉSUMEZ TOUJOURS QUE L’OUTIL

CONTIENT DES CLOUS. Pointez toujours l’outil

loin de vous et des autres personnes. Cet outil

n’est pas un jouet. Considérez-le comme un outil

de travail.

NE CHARGEZ PAS LES CLOUS lorsque le

déclencheur est détendu. L’outil pourrait éjecter un

clou.

8.

9.

10.

11.

12.

13.

14.

15.

16.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 19

FRANÇAIS

ENGLISH

19

NE DÉTENDEZ PAS LE DÉCLENCHEUR

lorsque que vous ne déchargez pas de clous.

Ne transportez jamais l’outil en touchant au

mécanisme du déclencheur : il pourrait éjecter un

clou non désiré.

NE VOUS ÉTIREZ PAS INDÛMENT. Garder vos

pieds au sol et conservez votre équilibre en tout

temps. Ne vous étirez pas vers des machines en

fonctionnement.

AGRIPPEZ L’OUTIL FERMEMENT an de garder

le contrôle, tout en laissant l’outil s’éloigner de la

surface de travail quand le clou est enfoncé.

N’ENFONCEZ PAS LES CLOUS les uns par-

dessus les autres, ou à un angle trop aigu : les

clous pourraient rebondir et causer des blessures.

ÉJECTEZ LES CLOUS VERS LA SURFACE DE

TRAVAIL SEULEMENT. N’enfoncez pas de clou

dans un matériau dur ou friable tel l’acier, le ciment

ou la céramique.

N’ENFONCEZ PAS LES CLOUS trop près du

rebord du morceau à travailler. Le morceau

pourrait fendre, causant un ricochet du clou qui

risque d’entraîner des blessures.

SOYEZ VIGILANT. Gardez vos mains et votre

corps loin du chemin de tout clou potentiellement

éjecté. Regardez ce que vous faites et servezvous du gros bon sens. Ne faites fonctionner

aucun outil lorsque vous êtes fatigué, avez bu ou

consommé des drogues ou médicaments. Vériez

vos prescriptions médicales an de voir si des

médicaments peuvent causer des problèmes.

PROTÉGEZ-VOUS DES ÉLECTROCUTIONS.

Ne laissez pas l’habitacle entrer en contact

avec les surfaces mises à la terre : enceintes de

tuyaux, radiateurs, fours et réfrigérateurs. Avant

d’enfoncer les clous dans les murs, planchers ou

tout autre endroit où des ls électriques peuvent se

trouver, vériez s’il existe un risque d’électrocution.

GARDEZ L’AIRE DE TRAVAIL LIBRE de tout

obstacle.

17.

18.

19.

20.

21.

22.

23.

24.

25.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 20

ENGLISHFRANÇAIS

20

RANGEZ LES OUTILS INUTILISÉS. Lorsque

l’outil est inutilisé, il doit être nettoyé et rangé

dans un endroit sec et propre, hors de portée des

enfants.

LES EMPLOYEURS doivent s’assurer du respect

des consignes de sécurité et de toutes les autres

consignes de ce guide. Laissez ces consignes

accessibles à toute personne devant utiliser cet

outil.

AVERTISSEMENT : Les avertissements, mises

en garde et consignes de ce guide ne peuvent

couvrir toutes les situations et conditions possibles.

L’opérateur doit reconnaître que le BON SENS

ET LA PRÉCAUTION ne peuvent être intégrés au

produit, mais qu’IL DOIT LUI-MÊME EN FAIRE

PREUVE.

DÉBALLAGE

Vériez immédiatement que toutes les pièces et

accessoires sont compris.

FNC1590 Marteau pneumatique pour clous en

rouleau à 15 degrées pour la charpente 1

Lunettes de protection (paire) 1

Huile à outil pneumatique en bouteille 1

Clé hexagonale S3 1

Clé hexagonale S4 1

Clé hexagonale S5 1

Clé hexagonale S6 1

Guide 1

S’il manque un article ou si un article est brisé,

contactez votre détaillant ou téléphonez sans frais au

1-888-267-7713.

FICHE TECHNIQUE

Pression de fonctionnement : 70 à 120 psi / 483 à

827 kPa / 4,8 à 8,3 bar (max. 120 psi / 827 kPa /

8,3 bar)

Consommation d’air : 0.17 pi3/ cycle @ 100 lb/po2

(4.77 litres / cycle @ 690 kPa

Entrée pneumatique : 1/4 po TPN

Poids de l’outil : 3,7 kg (8,2 lb)

Poids de l’emballage : 7 kg (15,4 lb)

26.

27.

n

n

n

n

n

n

n

n

n

n

n

n

n

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 21

FRANÇAIS

ENGLISH

21

Éjecte des clous à plancher de calibre 15-1/2 en

forme de « L » d’une longueur minimale de 1-1/2

po (38 mm) et d’une longueur maximale de 2 po

(50 mm)

CLOUS

Le FNC1590 est un marteau cloueur pneumatique de

service léger et alimenté au rouleau, qui utilise l’air

comprimé comme source de puissance. Il est conçu

pour installer des clous de 2 po à 3 9/16 po (calibre

11-1/4 à calibre 10-1/4) vrillés, annelés ou lisses

avec un angle de regroupement de 15 degrés (g.1).

L’outil est fabriqué d’un boîtier et d’un capuchon de

cylindre en alliage de magnésium pour un poids léger

tout en conservant une forte résistance et la rigidité.

n

FICHE TECHNIQUE

Page 22

ENGLISHFRANÇAIS

22

DESCRIPTION DES FONCTIONS

La gure 2 identie les composantes

principales de la FNC1590:

A. Poussoir de contact

B. Molette à réglage de profondeur

C. Déecteur d’échappement ori-

entable à 360 degrés

D. Sélecteur de mode du

déclencheur

E. Déclencheur

F. Fiche pneumatique mâle

G. Molette de reglage de la maga-

sin

H. Indicateur de hauteur de la

magasin

I. Échelle de hauteur

J. Magasin inferieur

K. Plaque-couvercle d’alimentation

L. Cheville à ressort

PROCÉDURES D’UTILISATION

INSTALLATION

Votre marteau cloueur Superior FNC1590 vous

parvient complètement assemblé. Consultez les

installations de système pneumatique recommandées

ci-dessous (g.3). Assurez-vous que les coupleurs

sont installés de façon à ce que le tuyau pneumatique

soit dépressurisé lorsque des composants sont

ajoutés ou retirés au système.

Tuyau pneumatique Régulateur

SOURCE PNEUMATIQUE

Le FNC1590 est conçu pour fonctionner avec

de l’air comprimé propre et sec entre 70 et 120

psi / 483 et 827 kPa / 4,8 et 8,2 bar. Le système

idéal (g.2) comprend un ltre, un régulateur de

pression et un huileur automatique situé aussi

près de l’outil que possible (idéalement à 15 pieds

/ 5 mètres). N’utilisez pas d’air ou de gaz en

bouteille.

n

Marteau cloueur

Connecteur

rapide

Huileur

Filtre

Conduite

pneumatique

Page 23

FRANÇAIS

ENGLISH

23

PROCÉDURES D’UTILISATION

Déterminez si une lubrication est nécessaire.

Tout air comprimé contient de l’humidité et autres

contaminants qui peuvent nuire aux composants

internes de l’outil. Un ltre pneumatique retirera

la plupart de ces éléments et prolongera la

durée de vie de l’outil. Si vous utilisez un huileur

automatique, vériez l’huile et ajoutez-en au

besoin. Si un huileur n’est pas disponible, versez

5 ou 6 gouttes d’huile dans la che pneumatique

(F, g.2) au début de chaque journée de travail.

Une quantité d’huile plus grande sera éjectée de

l’échappement de l’outil pendant le clouage.

Raccord pneumatique : Le FNC1590 doit être doté

d’un « connecteur rapide » mâle de 1/4 po TPN.

An d’éviter tout cycle accidentel même lorsque

débranché, l’outil doit toujours être branché à la

conduite pneumatique de façon à ce que toute la

pression pneumatique à l’intérieur soit libérée au

débranchement du coupleur.

MISE EN GARDE :

Toutes les composantes en ligne (boyaux, con-

necteurs, ltres, régulateurs, etc.) doivent pouvoir

soutenir 150 % de la pression maximum du système. Essayez d’utiliser un boyau d’un diamètre

intérieur de 3/8 po pour connecter la cloueuse au

compresseur.

Ne connectez pas cet outil à un système avec une

pression maximale potentielle supérieure à 180

psi (1241 kPa, 12,3 bar).

Déconnectez la conduite d’air de la cloueuse à

l’aide du connecteur à action rapide du boyau

d’air. Ne dévissez pas la prise d’air de la cloueuse

avec le boyau d’air connecté.

Débranchez l’outil de la source d’alimentation d’air

avant de procéder à l’entretien, à l’enlèvement

d’un clou coincé et avant de quitter le lieu de tra-

vail, de déplacer l’outil d’un endroit à l’autre ou de

passer l’outil à une autre personne.

CHARGEMENT DES CLOUS

1. Après avoir lu attentivement ce guide au complet,

branchez l’outil à la source d’alimentation d’air.

MISE EN GARDE :

Ne dirigez jamais la sortie de l’outil vers vous-

même ou vers une autre personne.

n

n

Page 24

ENGLISHFRANÇAIS

24

PROCÉDURES D’UTILISATION

Débranchez toujours l’outil de la source

d’alimentation d’air avant de charger les clous

dans l’outil.

Ne chargez pas les clous quand le déclencheur ou

le dispositif de sécurité sont enfoncés.

Portez toujours des lunettes de protection et une

protection des oreilles approuvées en préparant

et en utilisant cet outil.

Ne pas utiliser l’outil s’il y a une fuite d’air ou s’il

requiert toute autre réparation.

2. Appuyer sur la cheville à ressort (L, g.4)

3. Ouvrir la plaque-couvercle d’alimentation (K,

g.5).

4. Ouvrir la magasin inferieur (J, g.2).

5. Placer le rouleau de clous à l’intérieur.

6. Pivoter la molette de reglage de la magasin (G,

g.6) pour régler le boîtier de clous inférieur à la

longueur des clous. La position la plus élevée

est utilisées pour les clous de 50 mm (2 po) et la

position la plus basse est utilisée pour les clous

de 90 mm (3 9/16 po). Pour tous les clous entre

2 po et 3 9/16 po, régler le boîtier inférieur en

conséquence.

7. Fermer le boîtier de clous.

Page 25

FRANÇAIS

ENGLISH

25

PROCÉDURES D’UTILISATION

8. Déroulez quelques clous du rouleau et placez la

deuxième sur la crochet d’alimentation (M, g.5).

9. Refermer la plaque-couvercle d’alimentation (K,

g.5).et le mécanisme de verrouillage (L, g.4)

10. Régler le déecteur directionnel de l’échappement

(C, g.2), pour diriger les soufes d’air de

l’échappement à l’écart de l’utilisateur.

UTILISATION DE L’OUTIL

Complétez toutes les étapes de la section

PRÉPARATION DE L’OUTIL et CHARGEMENT DES

CLOUS avant d’utiliser l’outil.

Cet outil peut être utilisé de deux façons :

1.

Coup par coup (séquentielle)

Appuyez, et puis tournez vers la bas, la pointe

rouge du sélecteur du déclencheur (D, g.2) pour

sélecter la mode coup par coup.(g.7)

Placez la pointe poussoir de contact (A, g.2) sur

la pièce.

Appuyez légèrement sur la cloueuse pour enfoncer

le dispositif de sécurité

Appuyez sur le déclencheur pour planter les clous.

La méthode de déclenchement manuel coup par

coup est la façon la plus précise de placer les

clous.

2.

Déclencheur gardé enfoncé et actionné par

coup

Appuyez, et puis tournez vers la haut, la pointe

rouge du sélecteur du déclencheur (D, g.2) pour

sélecter la mode. (g.7)

Tenez la pointe de contact (A, g.2) à l’écart de la

surface.

Appuyez sur le déclencheur

Puis d’enfoncer le dispositif de sécurité en

appuyant la pointe de la cloueuse (A, g.2)

sur la surface. Lorsque le dispositif de sécurité

est sufsamment enfoncé, la cloueuse sera

déclenchée et plantera un clou.

MISE EN GARDE :

Débranchez l’outil de la source d’alimentation d’air

avant de procéder à l’entretien, à l’enlèvement

d’un clou coincé et avant de quitter le lieu de travail, de déplacer l’outil d’un endroit à l’autre ou de

passer l’outil à une autre personne.

Nettoyez et inspectez l’outil à tous les jours.

Vériez soigneusement le fonctionnement du

déclencheur et du mécanisme de sécurité.

n

n

n

n

n

n

n

n

Page 26

ENGLISHFRANÇAIS

26

ENTRETIEN

N’utilisez pas l’outil si le déclencheur ou le mé-

canisme de sécurité ne fonctionne pas correctement

N’utilisez pas l’outil si l’outil a une fuite d’air ou s’il

doit être réparé.

PROFONDEUR DES CLOUS

La profondeur du clouage peut être réglée en pivotant

lla molette de réglage de la profondeur (B, g.2):

Décocher un clou d’essai dans un morceau de bois

de rebut et vériez la profondeur.

Si le clou est trop enfoncé, pivotez la molette dans

le sens des aiguilles d’une montre (quand l’outil

est à l’envers) pour déplacer le support de sécurité

vers le bas.

Si le clouage plus profond est requis, pivotez la

molette dans les sens contraire des aiguilles d’une

montre pour régler le support de sécurité vers le

haut.

Faites l’essai d’un clou dans un morceau de bois

de rebut pour vérier la profondeur.

RÉPÉTEZ L’AJUSTEMENT SI NÉCESSAIRE

JUSQU’À CE QUE VOUS ATTEIGNIEZ LA

PROFONDEUR DÉSIRÉE. La quantité de

pression d’air requise dépendra du réglage.

Déterminez le réglage minimum qui produira des

résultats constants. Une pression d’air supérieure

à celle réellement requise causera une usure

prématurée ou des dommages à la cloueuse.

DÉGAGEMENT D’UN CLOU COINCÉ

MISE EN GARDE : Déconnecter l’outil de la source

d’air comprimé.

1. Ouvrir le mécanisme de verrouillage

2. Pivoter le boîtier de clous inférieur

3. Retirer les clous hors du boîtier inférieur.

4. Utiliser une tige d’acier mince et douce pour

repousser la lame de commande à sa position

supérieure extrême.

5. Utiliser une paire de pinces pointues pour retirer le

clou coincé.

6. Observer les directives de la section PRÉPARATION DE L’OUTIL AVANT LE CLOUAGE pour

recharger les clous.

n

n

n

n

n

n

Page 27

FRANÇAIS

ENGLISH

27

ENTRETIEN

MISE EN GARDE :

Ne dirigez jamais la sortie de l’outil vers vous-

même ou vers une autre personne.

Branchez toujours l’outil à la source

d’alimentation d’air avant de charger les clous

dans l’outil.

Ne chargez pas les clous quand le déclencheur

ou le dispositif de sécurité sont enfoncés.

Portez toujours des lunettes de protection et une

protection des oreilles approuvées en préparant

et en utilisant cet outil.

Ne pas utiliser l’outil s’il y a une fuite d’air ou s’il

requiert toute autre réparation.

MISE EN GARDE : Débranchez l’outil de la conduite

pneumatique avant le nettoyage et l’inspection.

Remédiez à tous les problèmes avant de remettre

l’outil en service.

NETTOYEZ ET INSPECTEZ L’OUTIL À

TOUS LES JOURS.

Ajouter régulièrement une huile pour outil

pneumatique au huileur de l’outil pour assurer

que toutes les pièces mobiles de cet outil soient

adéquatement lubriées. Une lubrication

fréquente mais non excessive est nécessaire à

une bonne performance. L’huile ajoutée dans la

connexion de la conduite pneumatique lubriera

les pièces internes. Un huileur automatique est

recommandé, mais 2 gouttes d’huile peuvent être

ajoutées manuellement dans la che pneumatique

(F, g.2) au début de chaque journée de travail et

après chaque heure d’utilisation continue. Seules

quelques gouttes à la fois sont nécessaires. Une

quantité d’huile plus grande sera accumulée

dans l’outil et éjectée de l’échappement de

l’outil pendant le clouage. N’UTILISEZ QUE DE

L’HUILE PNEUMATIQUE. N’utilisez pas d’huile à

détergent ou de l’huile contenant d’autre additifs :

ils pourraient accélérer l’usure des scellés.

Vérier le ltre du compresseur sur une base

hebdomadaire.Ouvrir le robinet de vidange pour

vider l’eau et les contaminants hors du réservoir

d’air.

Essuyer l’outil pour le nettoyer.

Soufer l’outil pour le nettoyer en utilisant l’air

n

n

n

n

Page 28

ENGLISHFRANÇAIS

28

comprimé, utiliser ensuite une solution de

nettoyage ininammable pour essuyer l’extérieur

de l’outil si nécessaire.

Ne pas tremper l’outil dans la solution de

nettoyage. Ces liquides peuvent endommager les

pièces internes. La section exposée de la petite

tige de piston et le crochet d’alimentation doivent

être conservés propres.

Examiner la détente et le mécanisme de sécurité

quotidiennement pour vous assurer que le système

soit complet et fonctionnel.

Conserver toute les vis resserrées à fond. Des

vis relâchées peuvent causer des blessures

corporelles ou des dommages à l’outil. Vérier

l’outil pour des pièces usées et endommagées. Si

présentes, les remplacer immédiatement.

DÉPANNAGE

AVERTISSEMENT : Cessez immédiatement

d’utiliser l’outil si l’un des problèmes suivants

survient. Des blessures graves pourraient résulter

du défaut de respecter cette consigne. Toute

réparation ou remplacement doit être effectué par

le personnel qualié ou par un centre de service

agréé.

MISE EN GARDE :

=Débranchez l’outil de la conduite pneumatique

avant de procéder à tout entretien ou réparation.

=Lorsque vous insérez ou réinstallez des joints

toriques, assurez-vous qu’ils sont propres et

lubriés à l’aide d’un lubriant à joint torique.

n

n

n

ENTRETIEN

Page 29

FRANÇAIS

ENGLISH

29

DEPANNAGE

PROBLEM CAUSE SOLUTION

Fuite d’air autour de la détente. 1. Le joint torique de la tige de

soupape de détente est usé et/ou

endommagé.

1. Vérier et/ou remplacer le joint

torique / lubrier

2. Le joint torique de la soupape

de tête de la détente est usé et/ou

endommagé.

2. Vérier et/ou remplacer le joint

torique / lubrier

3. Renferme des corps étrangers. 3. Nettoyer l’outil / lubrier

Fuite d’air à la section inférieure

du boîtier et à la partie avant.

1. La vis est dévissée sur la

section de raccordement de la

partie avant et du boîtier.

1. Resserrer la vis / vérier de

nouveau.

2. Le joint torique entre la

partie avant et le boîtier est

endommagé.

2. Vérier et/ou remplacer le joint

torique / lubrier

3. Le butoir est endommagé 3. Remplacer le butoir.

4. Renferme des corps étrangers

à la section de contact entre le

butoir et le boîtier.

4. Désassembler et nettoyer.

Fuite d’air à la section supérieure

du boîtier et à la partie avant.

1. La vis est dévissée sur la

section de raccordement de la

partie avant et du boîtier.

1. Resserrer la vis / vérier de

nouveau.

2. Le joint torique est endommagé 2. Vérier / remplacer le joint

torique / lubrier.

3. Le joint étanche est

endommagé.

3. Remplacer le joint étanche.

Impossibilité d’actionner l’outil. 1. Outil sec, manque de

lubrication

1. Utiliser l’huile pour outil

pneumatique.

2. Le ressort du capuchon de

cylindre est endommagé.

2. Remplacer le ressort à

l’intérieur du capuchon de

cylindre.

3. La soupape est collée au

capuchon de cylindre.

3. Désassembler / vérier /

lubrier.

La lame enfonce les clous trop

profondément.

1. La position de support de

sécurité est incorrecte.

1. Pivoter le bouton de réglage

de profondeur pour déplacer le

support de sécurité vers le bas.

2. La pression d’air est trop

élevée.

2. Diminuer la pression d’air.

Manquement de clous /

alimentation intermittente.

1. Présence de corps étrangers

entre le petit piston et le petit

cylindre.

1. Désassembler / nettoyer /

lubrier.

2. Le joint torique sur le petit

piston est usé et endommagé.

2. Vérier / remplacer le joint

torique / lubrier.

3. Outil sec et manque de

lubrication.

3. Utiliser l’huile pour outil

pneumatique.

4. Le ressort sur le petit piston

est endommagé.

4. Remplacer le ressort du petit

piston.

Page 30

ENGLISHFRANÇAIS

30

PROBLEM CAUSE SOLUTION

5. Pression d’air trop basse. 5. Augmenter la pression d’air

sans excéder une pression de

120 lbf/po2 (8,3 bars).

6. La vis est dévissée sur la

section de raccordement de la

partie avant et du boîtier.

6. Resserrer toutes les vis.

7. Le crochet d’arrêt ne peut pas

retenir les clous.

7. Remplacer le ressort conique

du crochet d’arrêt.

8. Clous pliés. 8. Utiliser les clous

recommandés

9. Grosseur de clous incorrecte 9. Utiliser les clous

recommandés.

10. Le joint étanche est

endommagé.

10. Remplacer le joint étanche /

resserrer la vis.

11. Le petit piston est sec. 11. Ouvrir le boîtier de clous,

verser plusieurs gouttes d’huile

pour outil pneumatique dans

l’orice du couvercle du bout du

petit piston.

12. Le butoir du petit piston est

usé et endommagé

12. Remplacer le butoir et

lubrier le petit piston

13. Le crochet d’alimentation se

coince.

13. Nettoyer le crochet

d’alimentation et le ressort de

torsion.

14. La longueur de clou ne

correspond pas à l’espace de

chargement du boîtier des clous

14. Régler l’écrou de réglage

sur la partie inférieure du boîtier

de clous selon la longueur des

clous

15. Les ls de soudure du

rouleau de clous sont brisés.

15. Cesser l’usage.

Fonctionne lentement ou

éprouve des pertes depression.

1. L’outil est sec, manque de

lubrication.

1. Utiliser l’huile pour outil

pneumatique.

2. Le ressort à l’intérieur du

capuchon de cylindre est

endommagé.

2. Remplacer le ressort à

l’intérieur du capuchon de

cylindre.

3. Des corps étrangers ont

pénétré entre l’assemblage du

piston et le cylindre.

3. Désassembler / nettoyer /

lubrier.

4. Le cylindre n’est pas

assemblé à la position initiale.

4. Réassembler après le

désassemblage.

DEPANNAGE

Page 31

FRANÇAIS

ENGLISH

31

PROBLEM CAUSE SOLUTION

5. Le joint torique sur la soupape

est sec après le désassemblage.

5. Réassembler après la

lubrication.

6. La pression d’air est trop

basse.

6. Augmenter la pression d’air

sans excéder une pression de

120 lbf/po2 (8,3 bars).

7. Le marteau est usé. 7. Remplacer l’assemblage de

piston.

8. Le diamètre interne du boyau

pneumatique est trop petit.

8. Utiliser un boyau pneumatique

de diamètre interne plus gros.

Les clous sont coincés. 1. Les clous de dimensions

incorrectes.

1. Utiliser les clous

recommandés.

2. Les ls de soudure du rouleau

de clous sont brisés.

2. Cesser l’usage.

DEPANNAGE

LISTE DES PIÈCES

Consultez le schéma de la p.34 pour l’emplacement

des pièces.

ITEM DESCRIPTION

FNC1590-1 Vis

FNC1590-2 Rondelle à ressort

FNC1590-3 Douille

FNC1590-4 Couvercle d’échappement

FNC1590-5 Joint

FNC1590-6 Vis

FNC1590-7 Rondelle à ressort

FNC1590-8 Chapeau de cylindre

FNC1590-9 Joint statique

FNC1590-10 Rondelle

FNC1590-11 Siège de soupape

FNC1590-12 Ressort

FNC1590-13 Joint torique 57.5 x 2.6

FNC1590-14 Joint torique 72.4 x 3.5

FNC1590-15 Soupape

FNC1590-16 Vis

FNC1590-17 Joint de cylindre

FNC1590-18 Collet

FNC1590-19 Joint torique 54.4 x 4

ITEM DESCRIPTION

FNC1590-20 Ensemble de piston

FNC1590-21 Cylindre

FNC1590-22 Joint torique 67 x 3

FNC1590-23 Joint torique 60.25 x 2.5

FNC1590-24 Joint reducteur

FNC1590-25 Joint torique 97.5 x 3.5

FNC1590-26 Butoir

FNC1590-27 Butoir

FNC1590-28 Corps

FNC1590-29 Joint torique 62.3 x 1.8

FNC1590-30 Rondelle de guidage

FNC1590-31 Nez

FNC1590-32 Rondelle à ressort

FNC1590-33 Vis

FNC1590-34 Ressort

FNC1590-35 Ensemble de support

FNC1590-36 Organe de réglage

FNC1590-37 Support de sécurité

FNC1590-38 Joint

Page 32

ENGLISHFRANÇAIS

32

AVERTISSEMENT : Toutes les réparations doivent

être exécutées par le personnel d’un centre de

service autorisé. Si vous ouvrez cet outil, vous

risquez d’annuler la garantie.

ITEM DESCRIPTION

FNC1590-39 Goupille

FNC1590-40 Guide de sécurité

FNC1590-41 Joint torique 8.3 x 1.8

FNC1590-42 Goupille d'arbre tournant

FNC1590-43 Ressort

FNC1590-44 Douille d'arbre tournant

FNC1590-45 Goupille à ressort

FNC1590-46 Joint torique 20.3 x 2.5

FNC1590-47 Joint torique 20.3 x 1.5

FNC1590-48 Ensemble de soupape

FNC1590-49 Joint torique 9.5 x 1.9

FNC1590-50 Joint torique 10.3 x 1.9

FNC1590-51 Tête de la soupape déclencheur

FNC1590-52 Joint torique 12.8 x 1.9

FNC1590-53 Ressort

FNC1590-54 Joint torique 5.5 x 1.5

FNC1590-55 Tige de la soupape déclencheur

FNC1590-56 Joint torique 24.8 x 2

FNC1590-57 Guide de soupape du déclencheur

FNC1590-58 Ressort de déclencheur

FNC1590-59 Déclencheur

FNC1590-60 Goupille à ressort

FNC1590-61 Rondelle

FNC1590-62 Rondelle frein

FNC1590-63 Couvercle

FNC1590-64 Ressort

FNC1590-65 Butoir de piston

FNC1590-66 Joint torique 28.3 x 3

FNC1590-67 Piston

FNC1590-68 Ressort de torsion

FNC1590-69 Goupille

FNC1590-70 Crochet d'alimentation

ITEM DESCRIPTION

FNC1590-71 Joint torique 14.3 x 2.5

FNC1590-72 Vis

FNC1590-73 Goupille

FNC1590-74 Plaque

FNC1590-75 Protection

FNC1590-76 Protection transparent

FNC1590-77 Goupille

FNC1590-78 Crochet d'arrêt

FNC1590-79 Ressort conique

FNC1590-80 Vis

FNC1590-81 Rondelle à ressort

FNC1590-82 Plaque d'arrêt

FNC1590-83 Ressort

FNC1590-84 Goupille de verrouillage

FNC1590-85 Goupille à ressort

FNC1590-86 Butée effacable au pouce

FNC1590-87 Écrou

FNC1590-88 Rondelle

FNC1590-89 Goupille

FNC1590-90 Magasin inferieur

FNC1590-91 Joint

FNC1590-92 Tige de réglage

FNC1590-93 Douille de réglage

FNC1590-94 Joint

FNC1590-95 Magasin superieur

FNC1590-96 Écrou de réglage

FNC1590-97 Vis

FNC1590-98 Vis

FNC1590-99 Manchon de prise souple

FNC1590-100 Joint torique 65.4 x 2.5

FNC1590-101 Chapeau d’embout

FNC1590-102 Fiche pneumatique

LISTE DES PIÈCES

Page 33

FRANÇAIS

ENGLISH

33

SERVICE ET RÉPARATIONS

Tous les outils de qualité nécessitent

éventuellement un entretien ou un remplacement

de pièces, suite à une usure en cours d’utilisation

normale.

Si votre outil doit être réparé, adressez-vous

auprès de votre détaillant local ou téléphonez à

Superior Airco Wholesale au 1 (888) 267-7713

pour trouver le centre de réparation agréé de votre

secteur. Toutes les réparations effectuées par les

centres de réparation agréés sont entièrement

garanties contre toute défectuosité matérielle ou

de main-d’œuvre.

Certains composants pouvant être entretenus par

l’utilisateur sont décrits à la section Dépannage.

Nous ne pouvons garantir les réparations

effectuées par toute autre personnel que celui d’un

centre de réparation agréé.

Des questions? N’hésitez pas à téléphoner à notre

centre de soutien technique, au numéro sans frais

1 (888) 267-7713. Soyez toujours prêt à donner

les renseignements suivants concernant votre

outil : numéro du modèle, type, numéro de série,

etc.

GARANTIE

Tous les produits distribués par Airco Superior Clarke

sont garantis contre les défauts de fabrication et les

défectuosités pour une période d’un an à compter

de la date d’achat par l’utilisateur nal. La société

RÉPARERA OU REMPLACERA, À SA SEULE

DISCRÉTION, toute marchandise que la société

considère être défectueuse, pourvu qu’elle n’ait pas

subi un usage inapproprié ou abusif, et qu’elle n’a été

modiée ni réparée par une personne autre que le

personnel d’un centre de service autorisé. Conservez

la preuve d’achat. Le consommateur devrait retourner

le produit défectueux, accompagné du reçu de caisse,

au lieu d’achat.

Cette garantie ne s’applique pas aux pièces qui

doivent être remplacées périodiquement, telles

que les lames d’entraînement des agrafeuses et

des cloueuses, les disques à poncer, les becs de

soudage, etc. Toutes les demandes de réclamation

doivent avoir une autorisation préalable et les produits

doivent être expédiés, port payé, à l’entrepôt de

Richmond (Colombie-Britannique) ou de Mississauga

(Ontario), ou à un dépôt de service après-vente

autorisé, accompagné d’une copie de la facture

indiquant la date de vente de l’article à l’utilisateur

nal.

n

n

n

n

Page 34

ENGLISHFRANÇAIS

34

SCHEMATIC DRAWING / SCHÉMA

Superior Airco Wholesale Ltd., Richmond, BC, Canada V6X 1X5

Tel: 1-888-267-7713 www.superiorairco.com

Loading...

Loading...