Superior DS-36RN, DS-36RP, DSR-HTK, ELB-45, DSR-EXT12 Installation And Operating Instructions Manual

...Page 1

Installation

And Operating

Instructions

For Superior's

Discovety Series

Sealed Combustion

WARNING: IMPROPER

INSTALLATION

ADJUSTMENT,

ALTERATION,

SERVICI

OR

MAINTENANCE

CAN

CAUSE

INJURY

OR

PROPERTY

DAMAGE. REFER

TO

THIS

MANUAL.

FOR

ASSISTANCE

OR

AODI.

TIONALINFORMATION

CONSULTAIIUALI-

FIE0

INSTALLER,

SERVICE

AGENCY

OR

THE

GAS

SUPPLIER.

FOR YOUR

SAFETY

Natural Gas Models

DS-36RN

Propane Models

DS-36RP

Decorative Gas

Appliance

And Termination

Components

DSR-EXT12

DSR-EXT6

DSR-HTK

EL

B-45

What to do if you smell gas:

11-

Do not try to light any appliance.

I

Do not touch any electrical

switches. Do not use any phone in

your building.

Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instruc-

tions.

If you cannot reach your gas sup-

plier, call the fire department.

Do notstoreoruse gasoline

orother

flammable vapors or liquids in the

vicinity of this or any other appliance.

PLACES

ARE

VENTED

DECORATIVE

GAS

APPLIANCES.

DO

NOT

BURN

WOOD

OR

Due to high temperatures, the appliance should be located out of

traffic and away from furniture or

drapes. Do not place clothing or

other materials on or near the appliance.

I

PLEASE

RETAIN

THlS MANUAL

FOR

FUTURE

REFERENCE.

I

f i r e - p a r t s . c o m

Page 2

I

TABLE

0,F

CONTENTS

-

......................................

lntroduct~on page

2

.........................

General information page 2

Location and clearances

..................

page

3

Installation

.....................................

a

3

Framing dimensions

........................

page 3

......................

Appliance dimensions page

5

..................

Outside wall termination page 6

Gas connections

...........................

-...page

8

....................

High elevation derating page

8

....................

Finishing requirements page 10

......................................

Accessories page

11

...........................

Operation and care page 11

Maintenance age 11

Partslcomponents

..........................

page 12

Troubleshooting guide

.....................

page 13

Replacement parts list

.....................

page 14

.......................

Liahtino instructions paqe 16

. .

Warranty.

-I

I

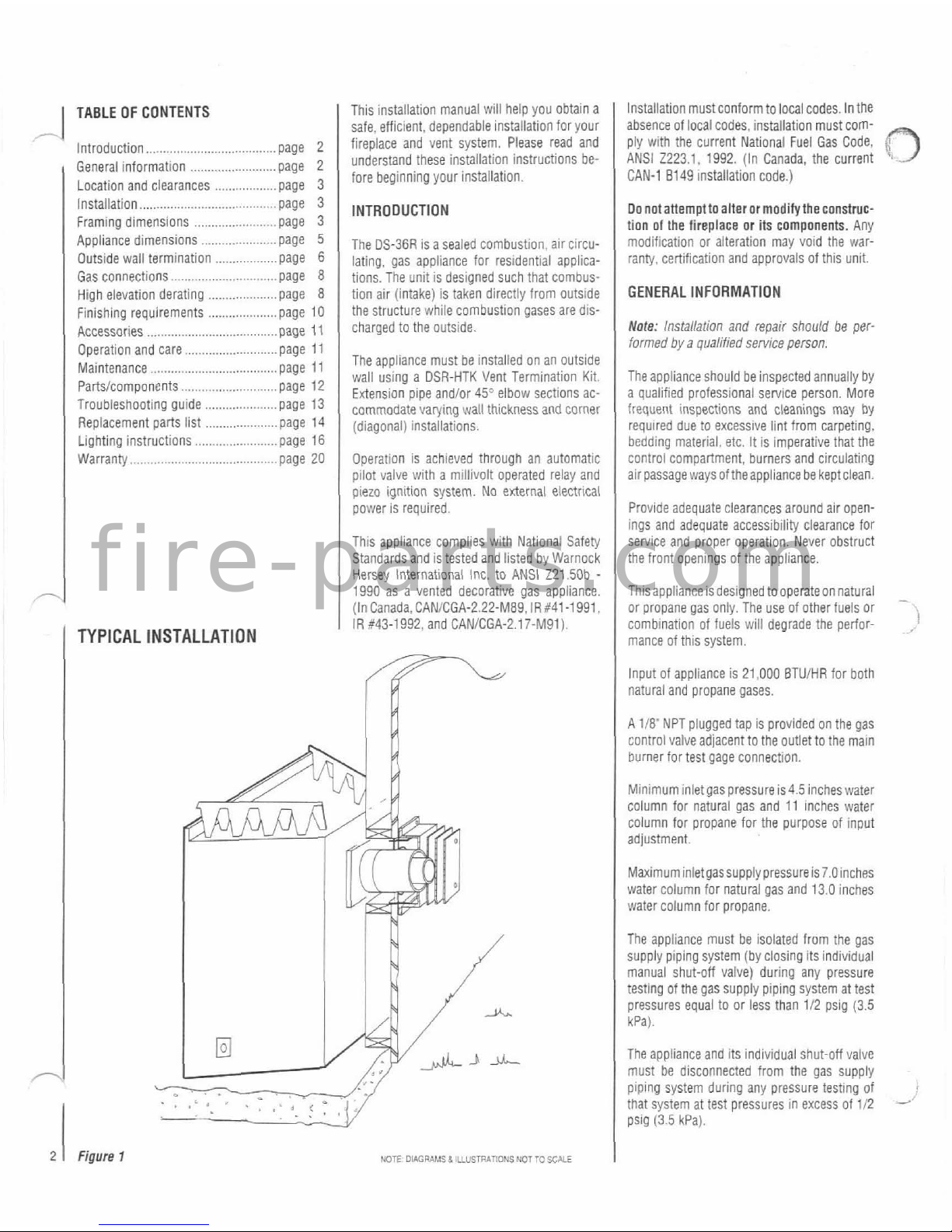

TYPICAL

INSTALLATION

This installation manual will help you obtain a

safe,

efficient,

dependable installation for your

fireplace and vent system. Please read and

understand these installation instructions before beginning your installation.

INTRODUCTION

The DS-36R is a sealed combustion,

alr circu-

lating, gas appliance for residential applica-

tions. The unit is designed such that combus-

tion air (intake) is taken directly from outside

the structure while combustion gases are discharged to the outside.

The appliance must be installed on an

outslde

wall using a DSR-HTK Vent Termination Kit.

Extension pipe

andlor 45Vlbow sections ac-

commodate varying wall thickness

and

corner

1

(diagonal) installations.

Operation is achieved through an automatic

pilot valve with a millivolt operated relay and

piezo ignition system. No external electrical

power is required.

This appliance complies with National Safety

Standards and is tested and listed by Warnock

Hersey International

lnc. to ANSI

Z21.50b

-

1990 as a vented decorative gas appliance.

(In

Canada,CAN/CGA-2.22-M89.lR:41-1991

IR 643-1992, and CANICGA-2.17-M91).

2

1

Figure

1

NOTE DiAcRAMs 8 UusrnArIoUs UoT

To

SCALE

Installation must conform to local codes. In the

absence of local codes, installation must comply with the current National Fuel Gas Code,

3

ANSI 2223.1. 1992. (In Canada, the current

CAN-1

8149 installation code.)

Donotanempttoalterormoditytheconstmc-

tion of the fireplace or its components. Any

modification or aiteration may void the warranty, certification and approvals of this unit.

GENERAL INFORMATION

Note:

Installation

and repair should be

per-

formed

by a qualified sennce person.

The appiiance should be inspected annually by

a oualified orofessionai service oerson. More

frequent

lnipections and cleanings may

by

required due to excessive lint from carpeting,

bedding

material. etc.

It

is imperative that the

control compartment, burners and circulating

air passage ways

oftheappllance be keptclean.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Thlsappliance 1s deslgned tooperateon natural

-

or propane gas only The use of other fuels or

comb~nat~on of fuels

will

degrade the perfor-

.

mance of thls system

Input of appliance is 21,000

BTUiHR for both

natural and propane gases.

A 118' NPT plugged tap is provided on the gas

control valveadjacent to the outlet to the main

burner for test gage connection.

Mtn~mum inlet gas pressure is4.5 incheswater

column for natural gas and 11

Inches water

column for propane for the purpose of input

adjustment.

Maximum inletgassupply pressure

is7.Oinches

water column for natural gas and 13.0 inches

water column for propane.

The appliance must be isolated from the gas

supply

plping system (by closing its individual

manual shut-off valve) during any pressure

testing of the gas supply

piplng system at test

pressures equal to or less than 112 psig (3.5

kPa).

The appliance and its individual shut-off vaive

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 112

-'

psig

(3.5

kPa).

f i r e - p a r t s . c o m

Page 3

Do not use this appliance if any part has been

-

under water, Immediately call a qualified service technician to inspect the appliance and to

replace any pans of the control system that

have been under water.

ASSEMBLY STEPS

The typical sequence of installation foilows.

however,each installation isunique resultingin

variations to those described.

This appliance must be vented through an

1.

Construct appliance framing

outside wall and must not be connected to a

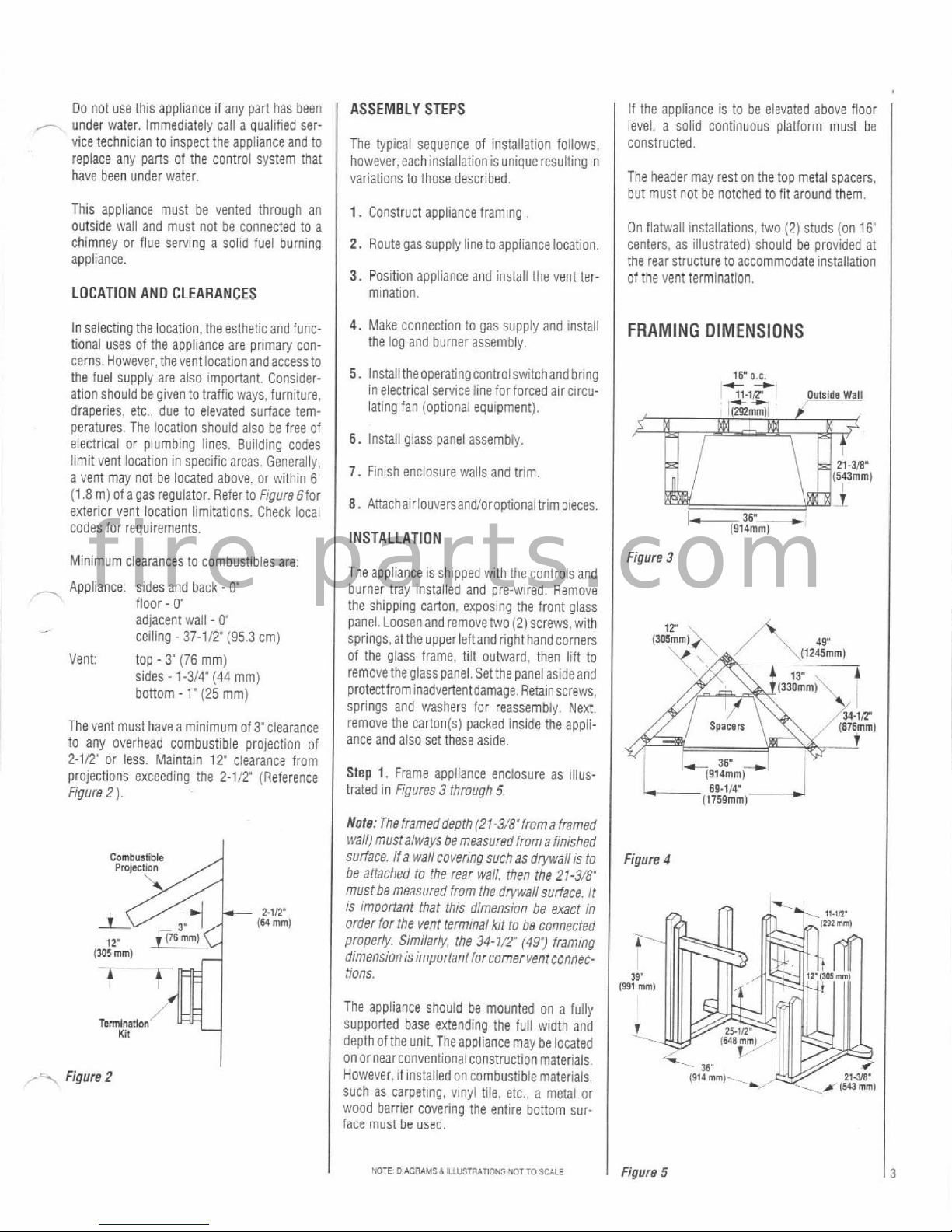

If the appliance is to be elevated above floor

level, a soiid continuous platform must be

constructed.

chimney or flue

sewing a soiid fuel burning

appliance.

LOCATION AND CLEARANCES

The header may rest on the top metal spacers.

but must not be notched to fit around them.

2.

Routegas supply line toappliance location.

3.

Position appliance and install the vent termination.

On

flatwall installations. two (2) studs (on

16'

centers. as illustrated) should be provided at

the rear structure to accommodate installation

of the vent termination.

In selecting the location, the esthetic and

func-

4.

Make connection

gas Supply and install

FRAMING DIMENSIONS

tional uses of the aonliance are orimaw con-

the log and burner assembly.

,

.

,

~~

cerns. However, thevent location and access to

the fuel supply are also important. Consideration should be given to

traffic ways, furniture.

draperies, etc., due to elevated surface temperatures. The location should also be free of

electrical or plumbing lines. Building codes

limit vent location in specific areas. Generally,

a Vent may not be located above. or within

6'

(1.8 m) of a gas regulator. Refer to

FigureGfor

exterior vent location limitations. Check local

codes for requirements.

Minimum clearances lo combustibles are:

,-

Appliance sides and back - 0"

floor - 0"

adjacent wall - 0'

celiing - 37-112'

(95

3

cm)

Vent

top

-

3'

(76

mm)

sides

-

1-314"

(44

mm)

bottom

-

1'

(25

mm)

The vent must have a minimum

Of3"Clearance

to any overhead combustible projection of

2-112" or less. Maintain

12'

clearance from

projections exceeding the

2-112" (Reference

Figure 2

)

.

+-.

Figure

2

5.

Install theoperating controlswitchand bring

in electrical service line for forced air circulating fan (optional equipment).

6.

install giass panel assembly.

7.

Finish enclosure walls and trim.

8.

Anachairlouversandioroptionaltrimpieces.

INSTALLATION

The appliance is shlpped with the controis and

burner tray instailed and pre-wired. Remove

the shipping carton. exposing the front glass

panel. Loosen and remove two (2) screws. with

springs,atthe

upperieftandrighthandcorners

of the glass frame, tiit outward. then lilt to

removethe glass panel.

Setthe panel asideand

protectfrom inadvertentdamage. Retainscrews.

springs and washers for

reassembly. Next.

remove the

carton(s) packed inside the appii-

ance and also set these aside.

Step

1.

Frame appliance enclosure as illus-

trated in

Figures 3 through

5,

Note: The frameddeprh (21-3i8"froma framed

wall) mustalways be measured from a finished

surface. If a wall covering such as

drywall is to

be

attached to the rear wall, then the 21-3/8~

must be measured from the drywall surface. It

is important that this dimension be exact in

order far the vent

term~nal kit to be connected

properly.

Similarly. the 34-71.?

(491

framing

dimension is important forcorner

ventconnec-

t10ns.

The appliance should be mounted on a fully

supported base extending the full width and

depth

ofthe unit. Theappliance may be located

on or nearconventional construction materials.

However, if installed on combustible materials,

Such as carpeting, vinyl tile, etc.. a metal or

wood barrier covering the entire bottom sur-

face

must

be

used.

15.

O.C.

l%.,i?

m*

+

Outside

Wall

Figure

3

Figure

4

I

NOTE

OWGRAMSb

ILIU5TR*mONS

WTTO

SCALE

I

Figure

5

f i r e - p a r t s . c o m

Page 4

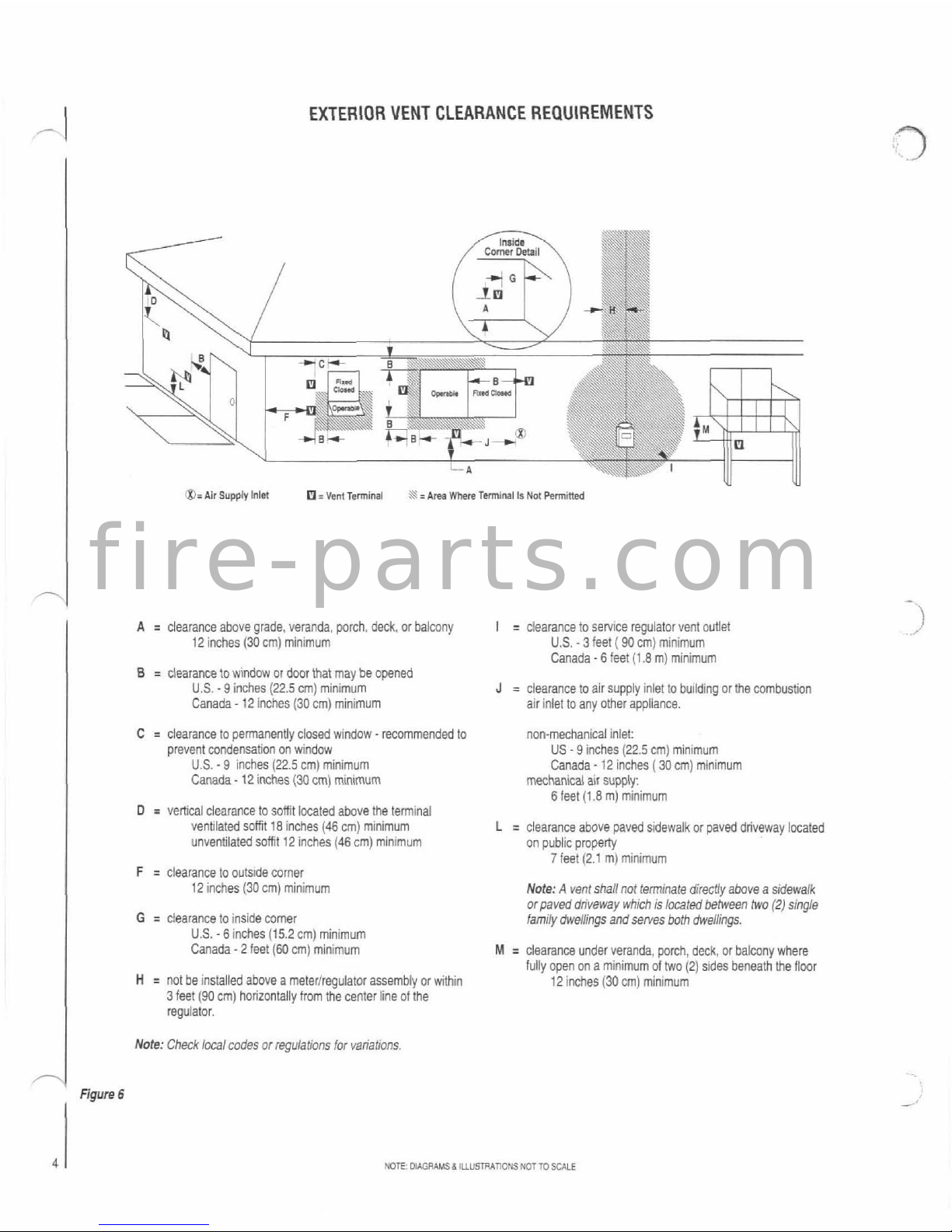

EXTERIOR VENT CLEARANCE REQUIREMENTS

a=

Air

Supply Inlet

Cl=

Vent

Terminal

A

r

Area

W)ma

Tminal Is

Not

Pennmed

I

A = clearance above grade, veranda, porch, deck, or balcony

12 inches (30 cm) minimum

B

=

clearance to window or door that may be opened

U.S.

-

9 inches

(22.5

cm) minimum

Canada

-

12 inches

(30

cm) minimum

C

=

clearance to permanently closed window - recommended to

prevent condensation on window

U.S.

-

9

inches (22.5 cm) minimum

Canada

-

12

inches (30 cm) m!nlmum

D

=

vertical ciearance to soffit located above the terminal

verlaled sorl

18

rcnes 146

CT)

ntnlmm

~nvent ate0

SOY

'2

ncpes

(46 cn, T n

~1-n

F

=

clearance to outside comer

12 inches (30

cm) minimum

G

=

clearance to inside comer

U.S.

-

6

inches (15.2 cm) minimum

Canada

-

2 feet

(60

cm) minimum

H

=

not be installed above a metedregulator assembly or within

3 feet (90 cm) horizontally from the center line of the

regulator.

I

Note:

Check

local codes or regulations for variations.

I

=

clearance to service regulator vent outlet

U.S.

-

3

feet ( 90 cm) minimum

Canada

-

6

feet (1.8 m) minimum

J

=

clearance to air supply inlet to building or Vle combustion

air inlet to any other appliance.

non-mechanical inlet:

US

-

9

inches (22.5 cm) minimum

Canada - 12 inches ( 30 cm) minimum

mechanical air supply:

6

feet (1.8 m) minimum

L

=

clearance above paved sidewalk or paved driveway located

on public

propeq

7

feet (2.1 m) minimum

Note:

A

vent shall

not

terminate directly above a sidewalk

or paved dnveway which is located between two

(2)

single

tami/y dwellings andserves

both

dwellings.

M = clearance under veranda, parch, deck, or balcony where

fully open on a minimum of two (2) s~des beneath the floor

12 inches (30

cm) minimum

-1

Figure

6

NOE.

OIAGRkLISd

IUUSTUATIOIIS

NOTTO

SCALE

f i r e - p a r t s . c o m

Page 5

-

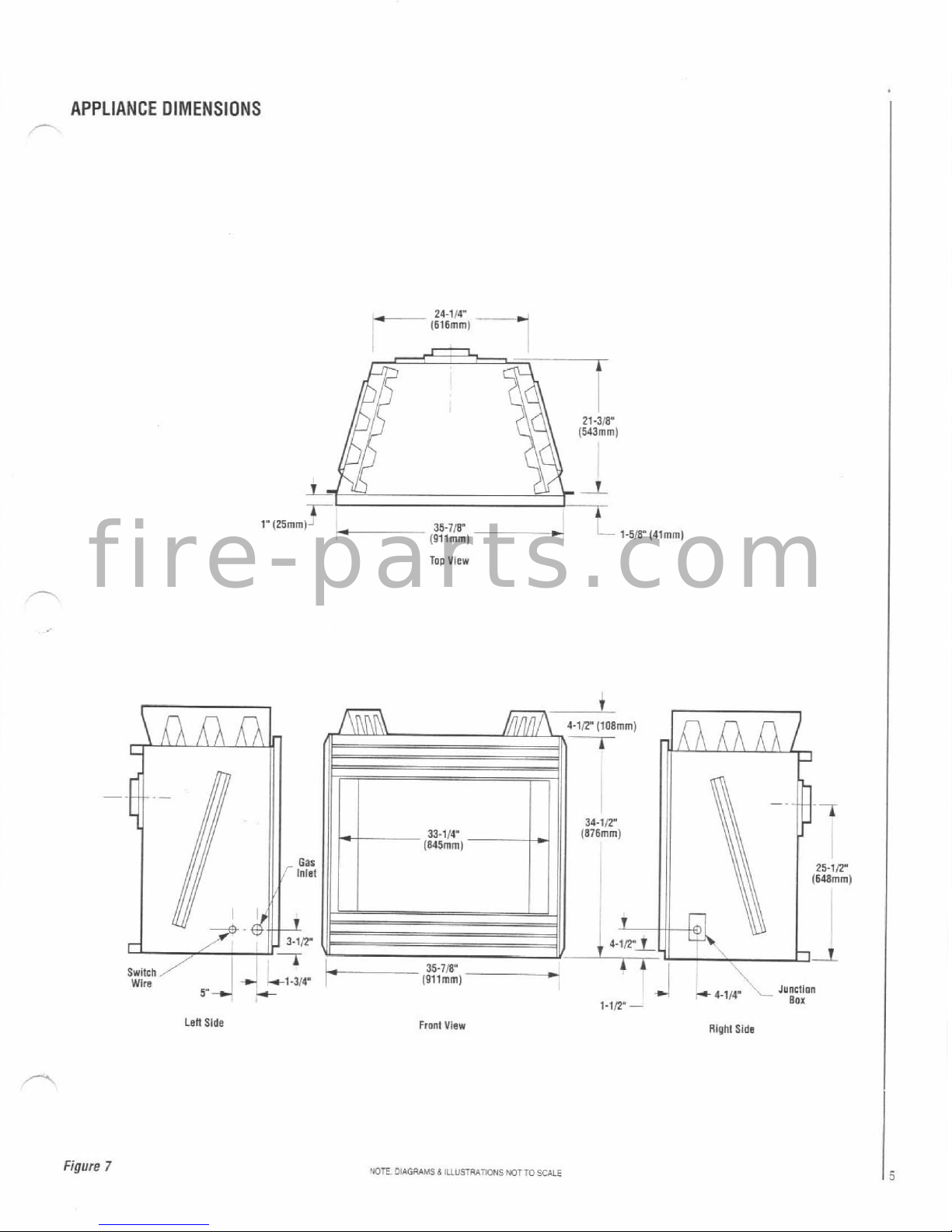

APPLIANCE DIMENSIONS

Too

View

,

4.1,4'

,--

Junction

1-l,Y

-

BOX

Len

Side

FmnI

View

Rlphl

Side

Figure

7

NOTE

OlAGRAMS

&

ILLUSBATIONS

NOTTO

SCALE

f i r e - p a r t s . c o m

Page 6

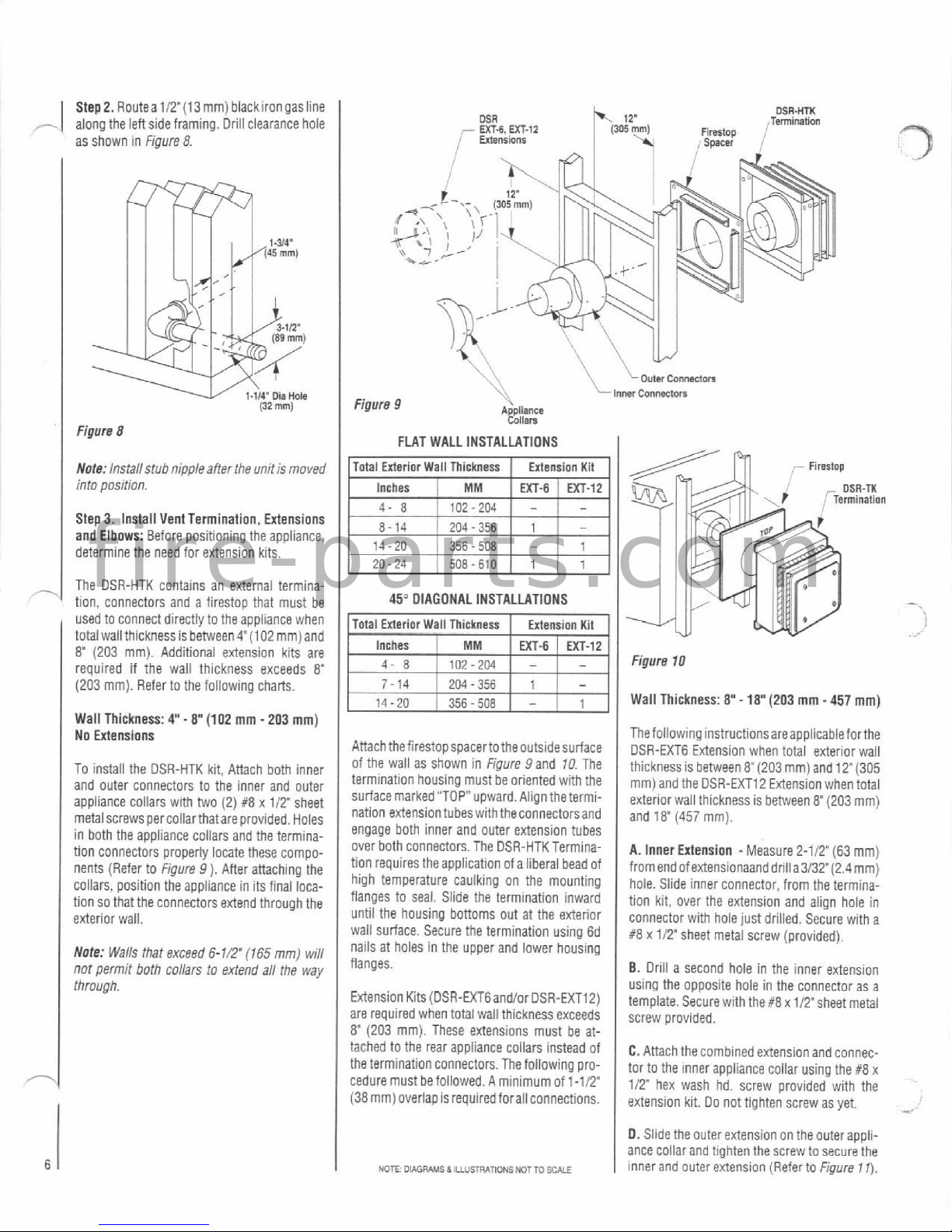

Step2. Routea112'(13mm) blackirongasline

-

along the leftsideframing. Driii clearance hole

as shown in

Figure

8.

MR

OSR-HTK

Termlnahon

-

UT4.

UT-12

Firertop

I

,'

Enensloor

r

Spacer

(32

mm)

Figure

8

Note:

Installstub nipple affer the unit is moved

into position.

Step3. Install Vent Termination, Extensions

and Elbows: Before positioning the appliance,

determine the need for extension kits.

The DSR-HTK contains an external termination, connectors and a

firestop that must be

-sed to clnnec: a~recrly :o 1-15 applarc? Nhen

I

lural wall thlcrtness s oerween @ 102

nrr,

ano

8'

(203 mm). Additional extension kits are

required if the wall thickness exceeds

8"

(203 mm). Refer to the following charts.

Walt Thickness:

4'-

8'

(102

mm

-

203

mm)

No Extensions

To install the DSR-HTK kit, Attach both inner

and outer connectors to the inner and outer

appliance collars with two

(2)

#8

x

112'

sheet

metal screws per collarthatare provided. Holes

in both the appliance collars and the termination connectors properly

locate these compo-

nents (Refer to

Figure 9 ).

After attaching the

collars, position the appliance in its final loca-

tion so that the connectors extend through the

exterior wall.

Note:

Walls that exceed

6-I/.

(765

mm) will

not permit

both

collars to extend aN the way

through.

\\

Louts

ConMdor.

Figure

9

'+\

lmr

~onnecmn

A

pllance

!011am

FLAT WALL INSTALLATIONS

Total Exterior Wall Thickness Extension Kit

Inches

EXT-6

EXT-12

204

-

356

14-20

356-

508

-

20-24 508 - 610

45"

DIAGONAL INSTALLATIONS

1

Inches

1

MM

I

MT-fi

EXT-12

4

8

1

in?-7M

I

-

I

-

Attach thefirestopspacerto theoutsidesurface

of the wail as shown in

Figure

9

and 10 The

termination housing must

be

oriented with the

surfacemarked "TOP" upward. Align

thetermi-

nation

extensiontubeswiththeconnectorsand

engage both inner and outer extension tubes

over both connectors. The

DSR-HTKTermination requires the application of a liberal bead of

high temperature caulking on the mounting

flanges to seal. Slide the termination inward

until the housing bottoms out at the exterior

wall surface. Secure the termination using 6d

nails at holes in the upper and lower housing

flanges.

Extension Kits

(DSR-EXTGandlor DSR-EXT12)

are required when total wall thickness exceeds

8"

(203 mm). These extensions must be at-

Figure

10

Wall Thickness:

8"

-

18"

(203

mm

-

457

mm)

1

Thefoliowing

instructionsareapplicableforthe

DSR-EXT6 Extension when total exterior wall

tached to the rear appliance collars instead of

the termination connectors. The following procedure must befollowed. A minimumof

1-11?

(38 mm) overlap is requiredforall connections.

Ihll:klless s o:?Neen 8'(203 mm! ano

12'(305

mm an0 !he DSZ-EX72 Extels on wnen tnra

.

exterlorwall thlcknessis between 8"(203 mm)

and

18'

(457

mm).

A.

Inner Extension -Measure 2-112" (63 rnm)

from endof

extensionaanddriIia3/32"(2.4mm)

hole. Slide inner connector, from the termination kit, over the extension and align hole in

connector with hole just drilled. Secure with a

R8 x 112' sheet metal screw (provided).

B.

Drill a second hole in the inner extension

using the opposite hole in the connector as a

template. Secure with

the#8xtITsheet metal

screw provided.

C.

Attach the combined extensionand connec-

tor to the inner appliance collar using the

#8

x

112' hex wash hd. screw provided with the

extension kit. Do not tighten screw as yet.

*

D. Slide the outer extension on the outerappliance collar and tighten the screw to secure the

inner and outer extension (Referta

Figure

11).

f i r e - p a r t s . c o m

Page 7

Figure

11

E. Measure2-114'(57 mm) from theend ofthe

outer extension and drill a 3132' (2.4 mm) hole.

Slide outer connector, from termination kit.

over the outer extension and align hole in

connector with hole just drilled in extension.

Secure

with #8 x 112'sheet metal screw.

Note: When installing more than one extension

to the appliance. the second extension connects to the first extension in the same manner

as the first

extensfon connects to !he appliance

collars.

Installing Elbows

For corner installations, install Model ELB-45

Elbow at the rear collar before positioning

applianceintoframing. Slide innerelbow overthe

inner collar, orienting to align hole in bracket

with the upper hoie on the collar (Figure 12).

Step

4.

Install Remote Wall Switch - The

applianceis shipped

withall the internal wiring

completed at the

factoly. Seiect a convenient

location

forthe remote wall switchand connect

the wiring found at the appliance (Figure 14

1.

F.

Drill 3/32 hole in oppositesideof extension,

using connector hole as template. Secure with

#8 x 112'sheet metal screw.

G.

Follow same procedure as was outlined in

Step 3 for installing termination.

WallThiCkneSS:

12"-24"(305

mm

-

610

mm)

CAUTION: 00 NOT CONNECT THE REMOTE

SWITCH TO

A

120V

SUPPLY.

Figure

12

Note: The elbow has two (2) brackets, one for

rightside offsetand the other for theleftside.

Align hole in the upper bracket, install a X8-15

x

1/T sheet metal screw to hold the ~iece~

Figure

14

Step

5.

A junction box is provided for the

installation of the FAK-1500 Forced Air Kit

(optional). Electrical power must be provided

together (not

necessaw totighten). ~ei, slide

to support the fan.

ThefollowinginstructionsareaPPlicableforthe

the outer elbow onto the outer collar, aligning

DSR-EXT6 Extension when total exterior wail

the slot with the oreviouslv installed screw

R0utea3-wire, l20VAC powerlinewithcontrol

thickness is between 12" (305

mm) and

14'

(356 mm) and the DSR-EXT12 Extension when

the total exterior wail thickness is between

18"

(457

mm) and 24" (508 mm)

A.

Inner Extension - Slide inner connector,

from the termination kit, overthe extension and

align hole in connector with hole located

112'

(13 mm)from the end of extension. Align holes

and secure with

two (2) 88 x 112' sheet metal

screws provided.

8.

Attach the combined extension and connec-

tor in the innerappliance collar using

the#-1 5

x

112' hex wash hd. screw provided with the

extension kit.

Do not tighten screw as yet.

C. Slide the outer extension on the outer appli-

ance collarand tighten

thescrew to secure the

inner and outer extension (Refer to Figure

11).

When thetotal outside wallthickness is greater

thanF? (203 mm).installappropriate extension

tubes at the elbow in similar manner as described for fiat wall applications in Step

3.

figure 13

~ ~

~

,

-~~~~

--

.. . .~.

Loosen screw suftjciently to permit the elbow

to slip under the screw head. With outereibow

in position and bottomed at the screw, tighten

screw to secure the assemblv.

Rnpm

lvma

sox

L

an

Wiring

Diagram

Figure

15

switch to the lower right side of the appliance.

Makeconnectionstothereceptacleasshownin

Figure 15.

The appliancemust beelectricallvarounded in

appliance installation

or at any time thereafter,

E.

Follow Same procedure as was outlined in

Follow the instructions provided with the kit.

Step 3 for installing termination.

VCTE

OIAGRAMS

A

LLUSTRAPONS

NO7

TO

SCALE

0.

Slide outer connector, from termination kit.

over outer extension and align with holes,

lo-

-

cated 114'

(6

mm) from end of extension.

Secure with two (2)

#8

x 112' sheet metal

screws.

,

. . .

. . . . .

,

UNng

45':

Elbar

And

Extensions

13

accordance with local codes or. iniheabsence

of local codes. withthe National EiectricalCode.

ANSIINFPA 70-1987. (In Canada. the current

CSA

C22-1 Canadian Electrical Code.)

Thc

far~ed

air

fan

mav

be inuuritrd

at

initial

f i r e - p a r t s . c o m

Page 8

Step

6.

Connecting Gas Line -All codes re-

,

-.

quire a shut-off valve mounted in the supply

iine. Figure

17illustrates two (2) methods for

connectingthegassupply.Theflex-linemethod

is acceptable in the

U.S.,

however. Canadian

requirements vary depending on locality. Installation must be in cornpiiance with

local

codes.

The gas control valve is located under the

refractory shelf.

If previously installed, remove

the two

(2)

bottom louvers by unsnapping

the bottom edge at each end and set aside

(Figure

16).

The control valve has a 318' NPT

thread inlet port.

Plan the connections accord-

ingly.

Figure

76

Secure all joints tightly using appropriate tools

andsealing compound.

Leakchecktheinstalla-

tion with a soapy water solution.

I

Do not use open flame for leak test.

I

HIGH

ELEVATION OERATING

This unit has been tested for installation at high

altitudesinaccordance

withCanadian teststan-

dard CANICGA-2.17.

Higher aititudes affect the atmospheric pres-

sure and heat

value of gaseous fuels. When

installing this unit at high altitudes, the rated

input wili be lower than that at sea level. The

lowered oxygen content in the air and lowered

gas density require installation of a different

orifice to achieve efficient. clean combustion at

the burner assembly. Refer to the chart in

Fipure 18andIor the rating plate on the appii-

ance for proper orifice size.

Figure

17

Order and install the appropriate high altitude

orifice kit perthechart below. Be suretoattach

the conversion stickerto the rating

piateon the

appliance.

l~;e~o;ri~~ig~~t~

1

Size Orl. Kit Elevation

0

-

2000'

Natural

(0-610

m)

U.S.

per

ANSI 2223.1-1992

Canada

per

CANICGA 2.17-M91.

Figure

18

Step7. Loglnstallatian-The logs, screenand

embers

kitare packaged ina separateshipping

container. Remove the mineral fiber rnateriai

frornits packagingandspread acrossthe burner

tray, covering the

hole pattern area.

NOTE

OIAORAMSd ILLUSTRATIWS

NOTTOSCALE

I

Carefully position and centerthe fiber logs onto

the burnerwith thelongerioginfront.

Placethe

two (2) smaller fiber logs across the two (2)

lower

log sin the manneriilustrated (Figure

19).

The flames should not impinge on the logs.

v

Figure

19

Step

8.

Checking the System - With gas iine

installed and the remote switch connected, run

initial system checkout before closing up the

front of the unit. Follow the pilot lighting in-

struction on page

16.

Note:

lnstructlonsarealso foundon thepuliout

panel located

on

the bottom surface of the

appl~ance

I'

f i r e - p a r t s . c o m

Page 9

When first lighting the appliance, it will take a

.-

few minutes for the line to purge itself of air.

Once purging iscomplete, the pilot and burner

will

lightand operateas indicated inthe instruction manual. Subsequent lightings of the appliance will not require such purging. Inspect the

pilotflame(removelogs, if necessary, handling

carefully).

The

flame slould oe steady, no' tltlng or llrat-

~na.Flameshot~~o be,-~~e~~icolor wlh

Pxe?

cl

orange at the outer edge

The top 3i8'

(10

mm) at the pilot generator

(thermopile) should be engulfed in the pilot

flameand the flame should project

1'

(25

mm)

beyond the hood on both sides

(Figure20). In

Canada only, the flame switch sensor must be

engulfed in the pilotflame.

Figure

20

Replace logs if removed for pilot inspection.

To light the burner; turn "ON" the remote wall

switch, manually depress and hold the door

safetyswitch

(FigureZl) and rotate thecontrol

knob counterclockwise to the

"ON"

posltion

("ON"

will be at the bottom side of the valve).

Wale: Thesafetyswitch mustbe held closed for

burner operation.

I

Comml

Kmb

-

Figure

21

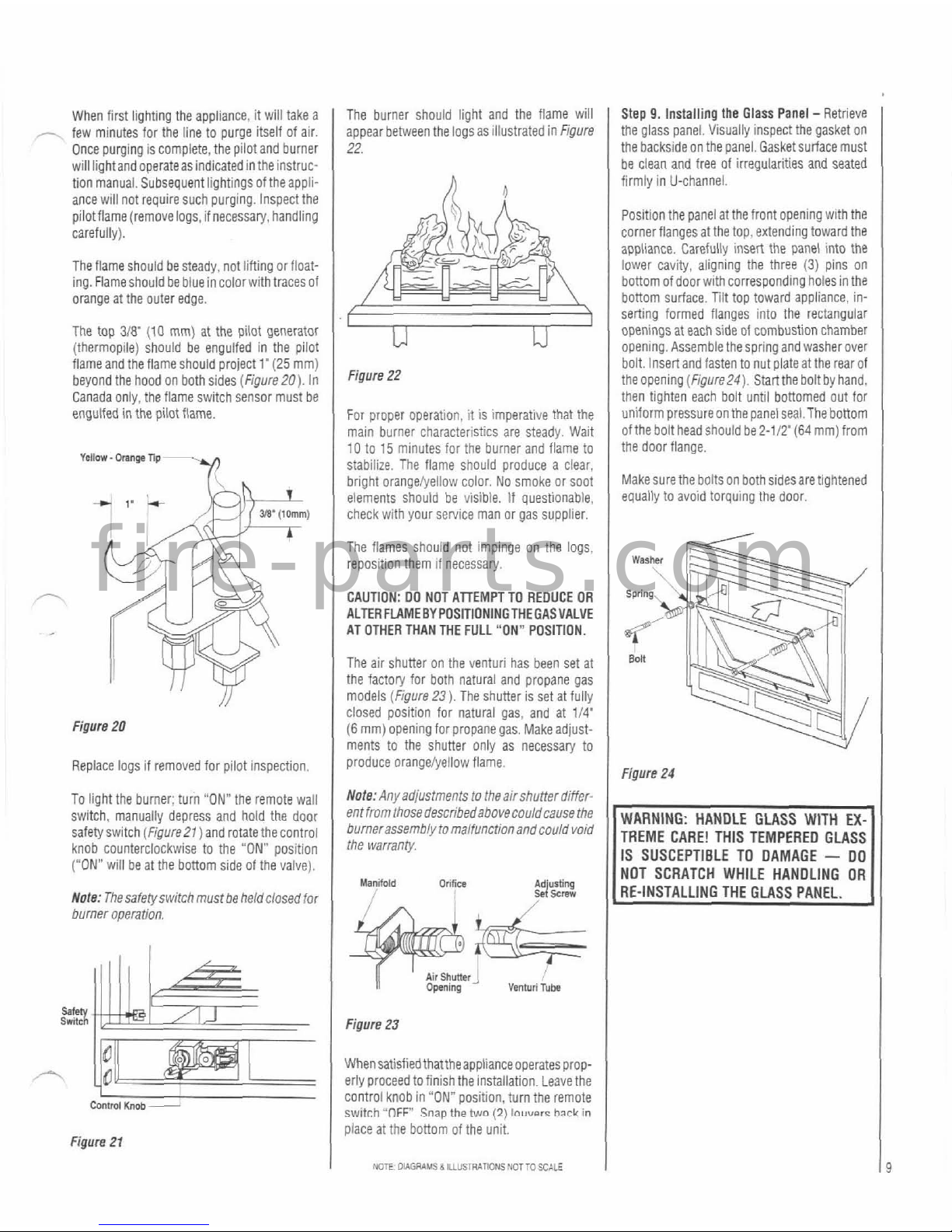

The burner should light and the flame will

appear between the logsas iilustrated in

Figure

22.

Figure

22

For proper operation,

it

is imperative that the

main burner characteristics are steady. Wait

10

to 15 minutes for the burner and flame to

stabilize. The flame should produce a clear,

bright orangeiyellow color. No smoke or soot

elements should be visible. If questionable,

check with your service man or gas supplier.

The flames should not impinge on the logs.

reposition them if necessary.

CAUTION:

DO NOT ATTEMPT TO REDUCE OR

ALTER

FLAMEBY POSITIONINCTHEGASVALVE

AT OTHER THAN THE FULL "ON" POSITION,

The air shutter on the venturi has been set at

the factory for both natural and propane gas

models

(Figure23). The shuner is set at fully

closed position for natural gas, and at

114"

(6

mm) opening for propane gas. Makeadjustments to the shuner only as necessary to

produce orangeiyellow flame.

Note: Any adjustments to

theair shutter differ-

entfrom

thosedescribedabovecouldcause

the

burnerassembly

to

malfunction andcouid void

the warranty

Figure

23

I

Whensatisfiedthattheappliance

operatesprop-

erly proceed to finish the installation. Leavethe

control knob in

"ON"

position, turn the remote

switch

"OFF

Sna~

the

two

(2)

lauuerr

hack

in

piace at the bottom of the unit.

NOTE:

OAGRAMS

d

ILLUSTRATIONS

NOTTO

SCALE

I

Step

9.

Installing the Glass Panel - Retrieve

the glass

panel. Visually inspect the gasket on

the backside on the panel. Gasket surface must

be

clean and free of irregularities and seated

firmly in

U-channel.

Position the panel at the front opening with the

corner flanges at the top, extending toward the

appliance. Carefully

insert the panel into the

lower cavity, aligning the three

(3)

pins on

bottom of door

wlth

corresponding

holes in the

bottom surface. Tilt top toward appliance, inserting formed flanges into the rectangular

openings at each side of combustion chamber

opening. Assemble the spring and washer over

bolt. Insert and fasten to nut

plateat the rear of

the opening (Figure24). Startthe boltby hand,

then tighten each bolt until bottomed out for

uniform pressure

onthe panel seal. The bottom

of the bolt head should be

2-112'(64 mm) from

the door flange.

Make sure the

boltson bothsides are tightened

eauaily to avoid torquing the door.

Figure

24

TREME

CARE! THIS TEMPERED GLASS

IS SUSCEPTIBLE TO DAMAGE

-

DO

NOT

SCRATCH WHILE HANDLING OR

9

f i r e - p a r t s . c o m

Page 10

I

Step

10.

Installing the Screens - Two

(2)

-

mesh screen paneis and mounting hardware

are packaged in the carton with the logs. Slip

the

ringson

eachscreenoverthemounting

rod.

positioning the brass pull at the formedlbent

end. Insertthestraightend into

holein sidewall

and fasten to frame with sheet metal screw

at

mountlng hole approximately 4'from each end

(Figure 25

).

Figure

25

Step

11.

lnstalling the Louvers & Trim

-

Remove the four

(4)

biack louver strips and the

two (2) brass cover pieces from the protective

container and fasten to the face of the appli-

ance. The louver strips snap onto the

louver

pegs without the need for tools. To assemble.

tiit the strip on top of the pegs and snap lower

edge to lock in place. The brass pieces are

mounted over the support bars directly above

and below the fireplace opening.

Agasvalvecoveris included

inthe homeowner's

information kit envelope to hide the gas con-

trols iocated in the iower

left louvered area.

Slidecover ontolowerlouverand position

soas

to conceal controis

(Figure

26).

U

Gas

valve

cow

.

~

Figure

26

FINISHING REQUIREMENTS

Wall

Details

Complete finished interior wall. To instail the

appliance facing flush with the finished wall,

position frameworkto accommodate the thickness of the finished wall

(Figures 27and28).

Use a non-combustible caulking at wall

and

metal facing joints to Seal all air passages.

Combusnble

Finished

Wall

Nan-Comburtibk

Wall

Covering

1blP

Min.

(

470

mm)

C

Figure

27

A hearth extension is not required with this

appliance. if a hearth extension is used, do not

block the lower louvered area.

A combustible mantel shelf projecting a maxi-

mum of

8'

from the wail may be installed at

minimum distance of

18

112" above the fire-

place opening

(Figure

29).

10

1

I

YOE

DIAORAUS

b

ILLUSTRATIONS

LnT

TO

EtALF

Side

Wali

Figure

29

Note:

For Canadian installations, 6"(152

mm)

clearance to combustible slde wall required.

COLD CLIMATE INSULATION

If you live inacoid climate, use a non-combus-

tible caulkina to seal all framing cracks and

areas

wherecold air may enter the room. ~t is

especially important to insuiate outside chase

cavttv between studs and underfloorino where

firepiace

IS

above ground. Also use insulation

to pack thespace where the gas lineenters the

appliance.

ACCESSORIES

-

Forced

Air

Kit

i

The FAK-1500 fan assembly provides forced

air circulation feature for your appliance. The

FAK-3000 fan assembly provides for a greater

air circulation. The kit mounts directly into the

lower intake chamber with electrical connec-

tion at receptacle provided. The appiiance must

havean independent 120VAC power line incorporated at the

timeof installation. See Step 5 of

the installation details and instructions supplied with the kit

(Figures 30and31

).

f i r e - p a r t s . c o m

Page 11

I

Fan

Gmundcd

TO

ApplianCB

_-

Motor

Plug

120v

,

L-------------->

Appliem

Junnion

Bar

Figure

31

Enclosure panel

The optional

35GEP-SPB Front Panel adds an

elegantappearance to

yourappliance.Thesolid

polished brass trim frames the fire and blends

withany

decor.Thepanelmountsflushwith

the

front for that custom finished look.

Horizontal Trim

Kits

-

Decorative trim kits designed to enhance the

applianceareavaiiableinthefollowingfinishes;

35HTK-PB poiished brassand35HTK-SPB solid

polished brass. The

35TT-SPB

and 35TrK-SPB

kits include polished brass filigree panels.

Remote Control

The Model RCK adds the convenience of re-

mote control for your appliance. The kit in-

cludes a wireless, hand held transmitter and a

receiver that installs in the appliance. A special

wall switch permits either manual or remote

control modes. Both receiver and transmitter

operate on standard

9

volt batteries (not included). Refer to the RCK installation instruction for specific details.

OPERATION

AN0 CARE OF YOUR

APPLIANCE

1.

Appliance operation is controlled through

the remote mounted wall switch. Adjustments

or settings at the unit are not required.

Aseparate wall switch provides independent control

of the forced air fan (optional equipment).

2.

There is a mlcro switch behind the lower left

corner oftheglass enclosure panel. This safety

4

feature prevents the burner from operating

unless the glass panel

1s in place.

3.

When lit forthe first time, the appliance will

emitaslightodorforan hourortwo.This isdue

to the "curing" of the logs and "burn-in" of

internal paintsand lubricants used

inthe manu-

facturing process.

4.

Upon each lighting of theappliance, condensation may

occurandfogthelnsideoftheglass

enclosure.Thisconditionwilldisappearshortly

as the appliance heats.

5.

Keep lower control companment clean by

vacuuming or brushing at least twice a year.

6.

Always turn off gas to pilot before cleaning.

Before re-lighting,

referto the lighting instruc-

tlonsinthismanual.

lnstructionsarealsofound

on a puli-out panel located on the floor of the

appliance (behind louvers).

7.

Always keeptheappliancearea clearand free

fromcombustiblematerials,gasolineandother

flammable liquids.

8.

Remember, this appliance has a

continuous

burning piiot flame. Exercise caution when using products with combustible vapors.

9.

Never obstruct the flow of ventiiation air.

Keep the front of the appliance clear of all

obstacles and materials.

10.

Observe caution near the glass panel. The

panel utilizes tempered glass which may shat-

ter unexpectedly or if struck with any object.

11.

CAUTION: 00 NOT OPERATETHIS APPLI-

ANCE

WITH A BROKEN

GLASS

PANEL. Where

broken glass exists. the compiete front panel

must be replaced. See the Repiacement Parts

List on page

14forcorrect parts. Panel removal

and re-assembly instructions are described on

pages

3

and 9 respectively.

12.

Clean the glass only when necessary. Wipe

surface with clean, dampened, soft cloth.

Followwith

dfy, softtowelas desired. Take care

not to scratch the glass surface. Do not use

abrasive cleaners. Never clean the glass when

it

is hot.

SHOULDBEALERTEDTOTHEHAZARDS

OF HIGH SURFACE TEMPERATURES. USE

CAUTION AROUND THE APPLIANCE TO

AVOID BURNS OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE SUPER-

VISED WHEN THEY ARE

IN

THE SAME

NOTE.

DIAGRAMS 6 ILLUSTRATIONS NOTTO SCALE

MAINTENANCE

The appliance and venting system should be

inspected before use and at least annually by a

qualified service person

IMPORTANT: TURN OFF GAS

AN0 ANY

ELEC.

TRICAL POWER BEFORESERVICING THE AP.

PLIANCE.

The main burner compartment should be inspected annually for proper operation. Remove

front panel and perform general cleaning to

remove any surface build-up on logs or pilot

and burner assembly. Wipe the piiot

nonle,

ignitor rod and hood

(Figure

20).

Avoid disturbingthe looseember material onthe baseof

the burner.

Refer to Step

9

for the front panel installation.

On re-assembly, examinethe sealing gasket on

thefrontpanelforsignsof deterioration, cracks

or hardening. Replace if any evidence is apparent. Replace oniy with material identified in

the Repiacement Parts List on page 14. When

returning to service, verify proper flame char-

acteristics as described in Step

8,

reference

Figures

20

and

22.

With proper care and maintenance, yourappliance will provide many years of enjoyment. If

you should experienceany probiem, first refer

to the trouble shooting guide in this manual. If

problem persists, contact your local service

center.

WARRANTY

Your gas fireplace is covered by

a

one year

limited warranty. You will find a copy of the

warranty on the back cover of

th~s manual.

Please read the warranty to be familiar with its

coverage.

Retain this manual. Fiie

itwith yourotherdocu-

ments for future reference.

REPLACEMENT PARTS

A

Complete parts list is found at the end of this

manual. Use only parts manufactured

andlor

approved by Superior Firepiace Company.

Normally, all parts shouid be ordered through

yourSuperiordistributorordealer.Partswill

be

shipped

at

prevailing

prices at time of order.

f i r e - p a r t s . c o m

Page 12

I

Whenordering repair parts. always give the

.

following informat~on:

1.

The model number of the appliance.

2.

The part number.

3.

The description of the part.

4.

The quantity required.

5.

The installation date of the appliance.

SUPERIOR'S ACCESSORY PARTS AND

COMPONENT LIST FOR DS-36R SERIES

FIREPLACES

Thefollowingaccessofy partsandcomponents

are to be used only with this fireplace system.

Separate installation instructions are packaged

with all forced air kits, glassdoorsandtrim kits.

If you encounter any

problems or have any

questions concerning the installation or the

application of this system, please contact your

distributor. For the name of your nearest dis-

tributor contact:

Superior Fireplace Company

4325

Artesia Avenue

Fullerton,

CA

92633

(714)

521-7302

45'Tmlnai

Elbow

Pm4

Om61

ELM5

ACCESSORIES & COMPONENTS

Hwirontal Termindm

PN

mi3

DSR-HTK

12

1

1

NOTE.

DIAGRAMS

d

ILLUSTRATIONS

NOT70

SCALE

1

PM

024474

35HTK.PB

Hodmntat

Trim

Kii

Pm

024477

3SHTK-SPB

i

'$.

Forced

Air

Kit

PR4

011781

FAK-ISM

PM

W13

DSR-EXT6

Edmdon

Kit

I

PM

034812

DSR-EXTI2

,

Traditional Louver

PN

O45651

3m-SPB

and

Trim

Kit

PJN

046091

3m-SPB

Forced

Air

Kit

PM

@39591

FAK.m

&

;.

%

-I..-r

Reme

Cmln

KII

PM m5591

RCK

HighAiutude

PM

m7m

Nlhlrai

Onfire

Kli

PR4

027967

hopne

.

'ALL4LASs'-'

Enclosure

Panel

PN

043.552

3SGEPSPB

f i r e - p a r t s . c o m

Page 13

TROUBLE SHOOTING THE GAS CONTROL SYSTEM

MODEL

DS-36R

Note:

Before trouble shooting the gas control system. be sure external gas shut off valve (located at gas supply inlet) is in the

"C

-

A

CORRECTIVE ACTION

Check for sparkat electrode and p~lot; if no sparkand electrode

wire is properly connected, replace ignitor.

Using a match. light pilot. If pilot lights, turn off pilot and trigger

the red button again.

If pilot lights, an Improper gas mixture

caused the bad

lhghting and a longer purge period is recom-

mended. If pilot will not light -check gap at electrode and pilot

-

should be 1/8'to have a strong spark. If okay, replace pilot

(Figure

20).

Check piiot flame, it must impinge on pilot generator

(Frgure

20

).

Clean and/or adjust pilot for maximum flame

impingement

on generator.

Be sure wire connections from generalor at gas valve terminals

are tight and generator

1s fully nserled into pilot bracket.

One of the wall

swltch wlres may be grounded. Remove wall

switch wiresfromvaive terminals.

If pilot nowstay slit, tracewall

switch wiring for ground. May be grounded to appliance or gas

Supply.

Check piiot generator with millivolt meter. Take reading at

generator terminals of gas valve. Should read

325

millivolts

minimum while

holdlng valve knob depressed in pilot position

and

wall switch

"OFF".

Replace faulty pilot generator it reading

is below specified minimum.

Turn valve knob

to

"ON,

place wall switch to "ON. Miilivolt

metershould

readgreaterthan100mv. Ifthe reading isokay and

the burner does not come on, replace the gas

valve.

Check wall switch and wires for proper connections. Jumper

wireacrossterminalsatwallswitch. if burner

corne~on. replace

defective wall switch. If okay, jumper wires across wail

switch

wires at valve, if burner comes on, wires are faulty or connections are bad.

Re-check Symptom

X2.

Check burner orifice for stoppage and remove.

-

~p

Remove glass panel (see instructions).

Remove Two

(2)

screws from switch mounting bracket. pull

switch

out.

Jumper wlre across

terminals

of switch.

if burner comes on, switch defective.

Repiace.

c;ieananaioraa~ustp~lotflameformax~mumflameimpingement

on pilot generator (Figure

20).

position.

SYMPTOM

1.

Spark ignitor will not light pilot

after repeated

triggering

of red

button.

2.

Pilot will not stay lit after

carefuily following the lighting

instructions.

3.

Pilot burning, no

gas

to burner,

Valve knob "ON", Wall Switch

"ON.

4.

~~~~~~~t pilot

outage

problem,

POSSIBLE CAUSES

A.

Defective ignitor

(no spark at electrode).

B.

Defective or misaligned electrode at

pilot (spark at electrode).

A.

Defective p~iot generator (thermopile)

or

remote wail swltch.

8.

Defective automaticvalve operator.

A.

Wall switch or wlres defective.

8.

Pilot generator may not

be

generating

sufficient

millivoltage.

C.

Plugged burner orlfice~

-

0.

Defective glass micro switch [located

at lower left corner of glass panel).

A.

~ilut flame may

oe

too low or blowing

(high) causing the piiot safety to drop

out.

f i r e - p a r t s . c o m

Page 14

REPLACEMENT PARTS

LIST

GAS

CONTROLS

I/

0s-36RN

1-

No. DESCRIPTION

Gas Valve - Robertshaw 20.

1

009737

04771

1

21.

1

Piezo laniter

1

/

ns13ni I I

1

22.

Orifice Fitting -Standard

Orifice

-

High

Altitude

23.

1

Flame Switch

24.

1

Thermopile

Pilot Assembly

Bulkhead Union

28.

Fitting 094499

f i r e - p a r t s . c o m

Page 15

Detail

A

.

.

,

,

/

ir

.,-,

/

',,

/

y-..,

1,

22

1'

,d'

F-.;

25

,:

27

-~J

\__i

WIRIWG

DIIGRAW

15

f i r e - p a r t s . c o m

Page 16

I

LIGHTING INSTRUCTIONS

A. This appliance has a pilot which must

be

lighted by hand. When Immediately mil your gas supplier from a neighbor's

lighting the pilot, follow these instructions exactly.

phone. Follow the gas

supplieh insl~caons.

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

I

0.

BEFORE OPERATING smell all around he appliance area for If you cannot reach your gas supplier, call the fire

gas. Be sure to smell next to the floor because some gas is

depamnent.

heavier than air and wiil settle

on

the floor.

WHATTO DO IF YOU SMELL GAS

*Do nottly to light any appliance.

C. Use only your hand to push in or

tum the gas control knob. Never

use tools,

If the knob will not push in or tum by hand, do not

try

to

repair it, call a qualified service technician. Force or attempted

repafr may result in a fire or an explosion.

.Do not touch any electric switch; do not use any phone in

your building.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and any

gas control which has been under water.

111

LIGHTING INSTRUCTIONS

-

1.

STOP! Read the safely information above on this page.

2.

Turn remote wall switch to "OFF".

3.

Remove access lowers.

4.

Venly main line shut-off valve is open.

5.

Push in gas control knob slightly and tum ciockwise

fi

lo "OFF.

6.

Wah five

(5)

minutes to ciear olrt any gas. If you then smell gas,

STOP! Follow

"8"

in the safety information above on lhis page. If

you do not

smell gas, go to the nerd step.

7.

Turn knob on gas control counterclockwise

h

to 'PILOT'.

I

8.

Push in control knob all the way and hold in. Immediately light the

piiot

by

triggering the spa* ignitor (pushing red button) until pilot

lights. Continue to hold the control knob in for about

1

li;!

minutes

afterthe piiot is lit. Release knob and it

will

pop back up. Pilol should

remain lit. If it goes out, repeat

sleps 5 through

8.

If knob does not pop up when released, stop and immediately

cail your service technician or gas supplier.

I

If pilot will not slay

lit

after several tries, turn the control knob

to 'OFF' and call your service technician or gas supplier.

I

9.

Turn gas control knob counterclockwise

h

to "ON".

Note:

Knob

cannot

be

turned

from

"PILOT

to

"OFF"

unless Me knob is

pushed

in

slighUy.

Do

not

force.

10.

Replace access louvers.

1.

Tgrn remote

,+la

I

s;*d~tch

'OFF".

The pilot wiil remain lit for

4.

Depress gas conlrol knob slightly and turn clockwise

normal

sewice.

to "OFF". Do not force.

I

1

2.

For complete shut-down, turn remote wall sw~tch to

"OFF"

5

R~plaro

access

louvers

I

.-'

I

I

3.

Remove lower louvers.

16

f i r e - p a r t s . c o m

Page 17

INSTRUCTIONS

D'ALLUMAGE

AVERTISSEMENT: SI VOUS NE SUIVEZ PAS EXACTEMENT CES INSTRUCTIONS, UN FEU OU UNE EXPLOSION

POURRA CAUSER DOMMAGE DE

PROPI$TE, BLESSURE PERSONNELLE OU PERTE DE VIE.

b.

Cet appareil a un pilote qui doit 6tre allume a la main. Quand vous

allumez le pilole, suivez exactement les instructions.

8.

AVANT O'ALLUMER sentez autour de I'appareil pour le gaz.

Assurez vous de la senteur pres du plancher parce que celtain gaz

est plus

pesant que I'air et se deposera sur le plancher.

QUO1 FAIRE S1 VOUS SENTU

LE

GAZ:

N'essayez

pas

d'allumer I'appareil

*

Ne

touchez

pas

aucun connecteur electrique; ne vous

servez pas d'aucun telephone dans votre

dike.

Appelez votre foumisseur de gaz immediatement d'un

teleohone voisin. Survez les instruction du foum~sseur de qaz.

Si vous ne pouvez pas atteindre votre foumisseur de gaz.

appelez

le depaltement d'incendie.

C. Se~ez vous seulement de votre main pour engager ou toumer le

bouton de reglage a gaz. N'employez jamais doutils. Si le bouton

n'engage pas ou tome pas a lamain. nessayez pas de le reparer.

appelez un technicien de smice qualiie.

Force

et essai de

reparage peut aboutir a un feu ou a une explos~on.

D. Ne vous servez pas de cel appareil si une partie a tramp4 dans

I'eau. Appelez un technicien de service qualifie immdiatement

pour inspecter I'appareil el remplacer n'imporle quelle parhe du

sysleme de

commande et n'imporle quel commande a gaz qui on

ete

sous I'eau.

1.

ARRETEZ! Lsez I rionai:sr de 3;rere au dessus decette

etquene.

2.

Toumez le telerupteur a "FERME

3.

Retirer les volets d'acces.

1.

Vefier que la vanne d'arret principale de gaz est ouverfe

5.

Engagez le bouton de reglage a gaz Ikgerement et tournez dans le

;ens des aiguilles d'une montre

a

"FERME'.

Note:

Le

booton

ne doitpas

&tre

tourne de

"PILOTE"

a

FERME"

a

rnoins que

le

bouton

soit legeremen1 engage. Ne forcupas.

5.

Attendez

(5)

minutes pour IiMrer le gaz. Si vous senlez du gaz,

"ARRETET. Poursu~ez

'B"

dans I'information de sdret6 au dessus

de

cette etiquette. Si vous ne senlez pas de gaz, allez donc au

prochain qmdin.

7.

Tournez le bouton sur le reglage a gaz

en sens

inverse des aiguilles d'une montre

a

'PILOTE.

8.

Engage le bouton de reglage a gaz tout le long et retenez. Allumez

le pilote irnm6diatement avec une allurnette allumete ou en

declanchant

I'etinceleuse (engagant le bouton rouge) avant que le

pilote s'allume. Continuez se retenir le bouton de reglage pour

a

peu pres

1

112

minutes apres que le pilote est allume. Relachez le

bouton el ll va se relever sueitement. Le pilote devra rester allume.

Si el s'eteinl. repetez le gradin 5 jusqu'

a

8.

Si le bouton ne se releve pas apres avor

Be

relache, arr6tez

immediatement et telkphonez votre technicien de service ou

votre fournisseur de

gaz.

SI 5 p~lore ne

reur

pas rester a lure aprej cLe ques esa s.

Toumez

.e mton oe reglage 1 gaz

a

a

posr

CI

'FEP'AE el

telephonez votre technicien de service ou votre foumisseur de

LIZ.

9.

Toumez le bouton de reglage a gaz en sens inverse des aiguilles

d'une monlre

h

a

"OUVERT.

10.

Replacez les volets d'acces

1.

Tournez ie teEruoteur nural a FERME". Le pilote va reste

4.

Engagez le bouton de reglage a gaz leoerement et taurnez

allume jusqu au relour du service normal.

dans

le sens des aiguilles d'une montree

a

TERME". Ne forcez pas.

2.

Pour une feneture complete, toumez le telerupteur mural

a

"FFRM~.

5.

Replacez les volets

d'acces.

3.

Retirer les volets inferieurs.

f i r e - p a r t s . c o m

Page 18

Superior DS-36 Direct Vent Gas Fireplace

THE WARRANTY

Limited Warranty 1 Year

SUPP~IO~

hreClaCB Cornpaw

warrants

Ihls

OS.36 Saner

Dacoranve

Gag

Appllase

'0

be

'reg

riam

defects

n

materials

and rarkmanrhlp

at

the time of manutaemre

REMEDY AND EXCLUSIONS

ihcco~emgeofthiiWarrinri~r!mnRlloallrom~onanliotthednonbvauarapolanccmanufa~redbySuperiarfireplaleCompany,a~thibeexcebonotflamerolan~~~ondcncer.

cement

ogr.

2nd

Svatrar

wis

enclosure

prnpl.

Thll

'Warlamb

0°F

covali

Supenor dacoistlva

gar

aopllanirr nstailed m tnc

Unted

Stater

or

Canada

Ilthevenle0a~rativt~asaool~ancccaueredbvlh1sWamn@Iataund~abedel~:ivew~thmone~eartromfhedateofnshlut~an~reeSv~eror'r

nyhtotinverilgal~~noutl~ned

below!.

SYO~~OIUI, stat6

ootion.

RDZBC~

or

reoalr

delenlve

cnrnoonenlr

ai

rhs

decorallwe par applunta manufactured

w

Sulierlor

Firemlace

Company

at

no

ehrrgesnd all ara pav

for

~lal~naole labor

carrr

ncorreo

'n

reDlaclng

9r

rapa8nng

sivCh

Componaalr

It

repati

or

rpplasament s not

conrnerc:anl

oramrat

j~perior nil,

at

ifr opL8on refund

the

purchase

pilce otllc SoDer8or

oecoia'lve

gaa

ao~lancl

Nth

rsrwcl

to:he glarr enclosure pane :he r?med#ei oltS8r paragraph

are

av9.8-e

e

ror

90

days

imm

me

aate

ol

nrallaron

This

WarranIvrwerr

on1'i~amrand;aOor iuproudedaoove. tnnOCa~rhal1

Eu~erlor

ilreplaceCompamaenrp~ns~blef~r

~aleralr.comoonents,ar

cansructlon

wnlcharr not

manuhctureb

or

iuprrliad

by

Superlor

ireplace Cdmosnv, orforthe labor

sereirav

lo instal.

reoar

or

remove

such

maienar. compenents

or

:onrtmcron

All

reo,acement

or

repar

cornaanents.~~~

be

inload

FOE

:he

nearert

suienor

ilre~acecornpa~y tanory~

OUALlFlCATlONS TO THE WARRANlY

Toe

vented decoiatve gar aFp1iance

YIarranV

3uOined

B~M

k

f~rth~i~~olac! to

me

!allaw#ng 0uallicananr:

fli

Tbe

uenfeo

CrrORtive gal dPPlanCe

mist

be

n~falled m

lcmrmnce

vilth

Suoeoai

Freolace Companv inrtalation nrhunionr

an0

locdl bu!ldng coder

me

Wanany

on

thtr

SUCD~OT

vented

CPeolllre

Far

aoalianccioverr

only

thecomaanent

Darts

manufacured 31,

Sulieror

Firepiace Company

7ie

use

olcomoonentraanulacturm

by

athers

~8th

th~ Super8cr rentee aecocalve 015300llance except torartedvenlingr~~tamai pieirrbW n

lh0!mulla!~on~nrtwoonsicouldcreate

ienouistely~aaior,

mayrev,,

,n

the

uanal

otcelllhc11

or.

hi.

rr:~~nz:d

Pallon*

ialeNagenc:er and

cauld

3e

n

u,u'at,an

o~'acl1

ludng codes :hslVarranPg

oosr

ro:rovera~;

aamayar

orcurrng

rmn

$ha

use

11

3n~

COI~UO'I~P::

not

mrlr!arured

or

ropo.en

ov

Succnor Freclac~iompa~~i

12)

ne

Su~e~nr'~er:!brrcorar8'~e

gaEi>cl,aoce

mur: 1elu>s::?bIanarmll

.>st

Thsderoratlve yrrapoliancer ar8aertgnW lo

burnellher

nauralorpropanagasonh/ Burning

conuso!

ow

P1~3laie

f~es

s3:n

ds~0011,

-0aI

3,

anv

olaer

10'C

fuel

i,,~

muse

oamage

10

me

cecoiatlve

gas apprnc8~1II produce emersruetem3eralures

and

r~ll

result in

.

LIMITATION ON LIABILIN

It

IS

~IDRUIY

allreed and unaemood ma1 Supetior flnplars Conpaw'l soic

obligation

and purrhanr's axrlvrirr remedy underthis

wmm,

under my

o!lrrnnmy,

LxOntfLd 0rrrn~lted,

or

In Lootract. lor(

or

othanita, rhrll

be

limtlad to nplrnmenf. replr,

or

iewnd,

sr

rpciifiad ahaue.

In~~event~aII S~perlorflnplars Com~sm

bainp0nribl~tataminridrmllor~onrc~ucmli~

damaqnr

caned

by d8lerls lnitspmducb. WhmtOarsuohalm~qa

occu=or

kdlxovarea

bafarr

or

aner

rsplaramantor repail, and whnher

or

nrrvrh damage Is cauJcd

br

Superior

Finplac8Company'~ne(lipenrc.

Some

rtatcr donot allor

me

lirl~1~0n0rllmilali~n ol nridentalot ronre~uenlbl aams~sr.rolhe

above

limitation

or

sirlullanmaynolapOlytoyou.

Thsdwral8on olmy Implied wairanhwah

rmper!

lothisSup~r#or 0~~01aI1w 11aPappli8nce

is

ilmtledlo

the

dutati~nofthetonpe~ngvananh

Soma

slates do

no!

ailowI#mltationr

on

how long

an

8rnpll~d wamnh lass,

so

Ihcahovcmay nolapplylayou.

INVESTIGATION OF CLAIMS AGAINST WARRANN

Su~e'nr

Frr~IzciCompaov

,eiemes

the

nont-o

nver!qateawandall tlaimr

agannmis

WarranNandtoderideu~on methad of senlement

SUPERIOR FIREPLACE COMPANY NOT RESPONSIBLE FOR WORK DONE WITHOUT WRITEN CONSENT

Superior :~replarr

Carnoany

mail

in

ra

eu%t

be

resooli#ble'or

anylvamnni

work dona wtfho~

I~~SI

obfanng Saneror s vrmen

consenr.

OEPiLERS HAVE NO AUTHORITYTO ALTER THIS WARRANN

Sucsrtsl=~rtn~rce

Conoany s emoloveer

anc

beaters

bare

9:

lvfiorPIt0

make

any

warnnneE

notto

aumonzc

any

rameder

.n

aaa#t#onto

or

ncanrlrtentwm those itatdabova

HOW TO REGISTER A CMIM AGAINST WARRANN

In

OrCer

lo:

any

clalm

un0rr:he

',Varrrnh:a

OD

rafl

StiDmor fireplace

Company

must

bo

nollfied atthe calmed cmtm

wrrt8ng

or

by tele~none

la

Su~erlor

Rvapuce cornoaw.

aWen!>an

Customer

Sc~ce

Oeganment 1325

anei8a

Av?nue

fwllenon. Caiilornla92633, ielaohane 714-52;.;302

ai

soon

ar

resronabig

lw$#blraner:na dclcctts dlrcovend

Clalns gmst

:nawarranV

n

'wrm!!ng

rEoiiM

,iiduce!1*

dat.01 nsmllat.on, and a Jercrlpllan 01 lha dstect.

Superior reservesthe right to make changes at anytime, w~thoulnotice.

In

design. mater~als. specrfications, pricesand alsotodiscont~nue colors. swlesand products. Consult your

local distributor for fireplace code information,

I

Distributed

By:

The

Fireplace

Company

Pll"lL0

8"

USA,

B

1993

wSuper>or

Rreolace

Company

P/N

098122

REV.

B

7193

4325

Artesia

Avenue

Fullerton.

CA

92633

Plants

In

Fullerton. CA

Unlon City.

TN

f i r e - p a r t s . c o m

Loading...

Loading...