Page 1

UIM-240FA, UIM-300FA

UNDERCOUNTER

CUBE ICE MACHINES

This manual contains important information regarding your Supera unit. Please read this manual thoroughly prior to equipment set-up,

operation

and maintenance. Failure to comply with regular maintenance guidelines outlined in this manual may void the warranty.

INSTRUCTION MANUAL

Page 2

INTRODUCTION

How To Use This Manual

Supera provides this manual as an aid to the service technician in installation and maintenance of

the (electro-mechanical) cube ice machines. Do not attempt to perform installation, start-up or

maintenance unless you have read and fully understand this manual.

If at any time you encounter conditions that are not addressed in this manual, contact the Supera

Service Department:

Telephone: 866-953-3288

E-mail: Service@SuperaCo.com

Any service communication must include:

• Model

• Serial Number

• A detailed explanation of the issue

Keep this manual for future reference.

The Supera Service Parts Manuals are available separately.

Supera icemakers and dispensers are not approved for outdoor installation.

WARNING: Always disconnect electrical power and shut off water supply whenever maintenance

or repairs are performed on the ice machine and related equipment.

CAUTION: Always wear protective eyewear whenever maintenance or repairs are performed on

the ice machine and related equipment.

upera September 2015 1

© S

Page 3

FREIGHT CLAIM PROCEDURE

IMPORTANT: Freight Claims

Inspect Promptly

This merchandise has been carefully inspected and packed in accordance with the carrier’s

packing specifications. Responsibility for safe delivery has been assumed by the carrier. If loss or

damage occurs, you as the consignee must file a claim with the carrier and hold the container for

carrier’s inspection.

Visible Loss or Damage

Any external evidence of loss or damage must be fully described and noted on your freight bill or

express receipt and signed by the carrier’s agent. The claim should be filed on a form available

from the carrier.

Concealed Loss or Damage

If loss or damage does not appear until merchandise has been unpacked, make a written request

for inspection by the carrier within 15 days of the delivery date. Then file a claim on a form from

the carrier.

If your unit arrives damaged, please contact your local distributor immediately.

File Claim Without Delay

Do Not Return Damaged Merchandise to Supera, LLC

© Supera September 2015 2

Page 4

INSTALLATION GUIDELINES

Installation Guidelines

For proper operation of the Supera Ice Machine, the following installation guidelines must be

followed. Failure to do so may result in loss of production capacity, premature part failures, and

may void all warranties.

Reference the installation parameters prior to installing the machine:

Ambient Operating Temperatures

Minimum Operating Temperature: 50°F (10°C)

Maximum Operating Temperature 100°F (38°C), 110°F (43°C) on 50 Hz. Models

Note: Supera icemakers and dispensers are not approved for outdoor installation.

Incoming Water Supply (See Electrical and Plumbing Diagrams for line sizing)

Minimum incoming water temperature: 40°F (4.5°C)

Maximum incoming water temperature: 100°F (38°C)

Minimum incoming water pressure: 20 psi (1.4 bar) (0,138MPa)

Maximum incoming water pressure: 60 psi (4.1 bar) (0.414MPa)

Note: If water pressure exceeds 60 psi (4.1 bar), a water pressure regulator must be installed.

Drains

All drain lines must be installed per local codes. Flexible tubing is not recommended. Route bin

drain, purge drain and water condenser drain individually to a floor drain. The use of condensate

pumps for draining water is not recommended by Supera. Supera assumes no responsibility for

improperly installed equipment.

Note: The purge drain fitting is plastic; DO NOT apply heat to the purge drain area; DO NOT

overtighten.

Water Filtration

A Supera water filter system should be installed with the ice machine.

Clearance Requirements

Self-contained air cooled ice machines must have a minimum of 6 inches (15cm) of clearance at

the rear, top, and sides of the ice machine for proper air circulation.

Stacking

Supera does not endorse stacking ice machines.

Electrical Specifications

Refer to the serial plate at the rear of the ice machine to make sure proper voltage and circuit

breaker size have been supplied. Make sure the machine is on a dedicated circuit. European

installations require that the electrical supply fixed wiring must be provided with a disconnect

means having a separation of at least 3mm in all poles. The ice machines are provided without an

electrical cord set and are designed and agency approved to be permanently connected.

The 115 volt Undercounter ice makers are supplied with an electrical cord, all other ice makers will

need to be installed and wired per local electrical codes.

© Supera September 2015 3

Page 5

Caution: Electrical connection must be made or a cord installed by a qualified electrician or

there is danger of an electrical fire.

Adjustments

.

Level the machine within 1/8 inch in all directions. Check the bin control for proper adjustment.

Check the water in the water trough for proper level. Check the ice bridge for proper thickness.

Check the water regulating valve adjustment if water cooled

© Supera September 2015 4

Page 6

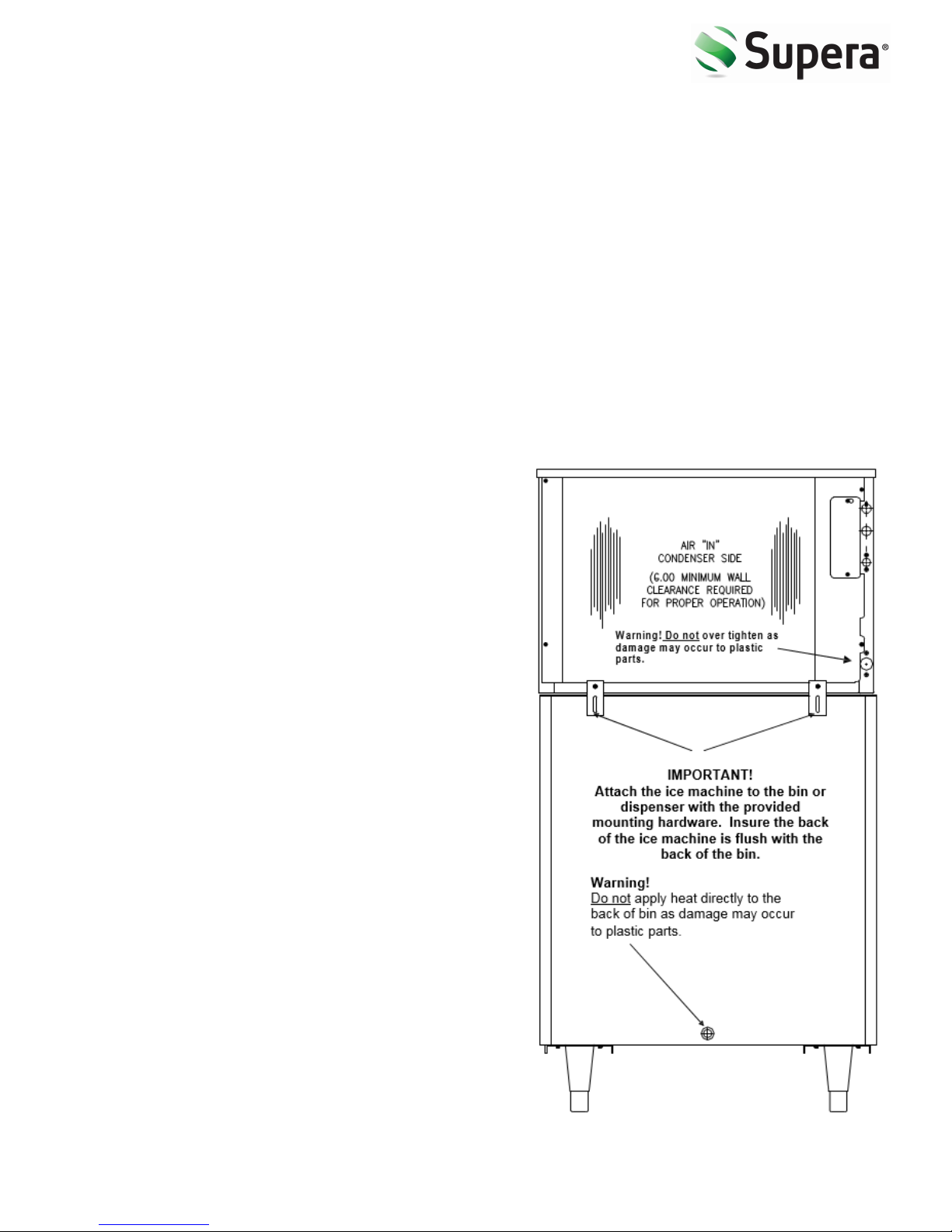

INSTALLATION GUIDELINES

Important!

Warning!

Do not apply heat directly to the back of bin as

damage may occur to plastic parts.

Do not over tighten the purge drain fitting as

damage may occur to plastic parts.

Remove the bin carton and tip the bin on its back to remove the skid and attach the bin legs.

Secure the machine on top of the bin or dispenser.

Attach the ice machine to the bin with the mounting straps provided with the bin or dispenser.

Insure that the back of the ice machine is flush with the back of the bin. Proper functioning of the

bin door requires the bin door, when it is opened, to be in a stable position.

If the ice machine is too far forward on the bin, the opened door may not be stable, resulting in an

unexpected closing of the bin door. If the ice machine is to be mounted on a bin or dispenser

other than a Supera, refer to the manufacturer instructions for machine mounting. Supera will not

be responsible for damage or injury that results from unexpected closing of the bin door as a

result of the ice machine being too far forward on the bin.

A water filtration system should be installed with all ice machines. Check the filter manufacturer's

instructions for proper installation.

All water supply lines must be installed per local codes. Use 1/4 inch O.D. minimum on air cooled

machines. On water cooled machines 3/8 inch O.D.

minimum tubing must be run to the condenser. The

water supply for the float can “T” off from the

condenser line using 1/4 inch

O.D. minimum tubing. Make 2 coils of extra tubing so

that the machine can be pulled away from the wall if

service is needed.

All drain lines must be installed per local codes. The

purge drain should be a minimum of 5/8 inch O.D.

tubing. The condenser drain on water cooled units

should be 3/8 inch O.D. minimum. The drain line

fittings on Supera bins are 3/4 FPT. The bin drain

should be a minimum of 3/4 inch O.D. Cold water

drains should be insulated to prevent condensation

from forming.

Connect power supply to the terminal block in the

control box or at the rear junction box if equipped.

Ensure the machine is level within 1/8 inch in all

directions.

Remove any shipping or packaging material.

Once the machine has been installed, follow the startup procedures.

© Supera

September 2015 5

Page 7

ELECTRICAL AND PLUMBING REQUIREMENTS

ON-OFF-WASH Switch is located in

Note: This unit does not have a splash curtain.

UIM-240FA

This mo

in place of a mechanical bin switch.

the control box.

Remove the grill screws to access the

control box.

© Supera

del utilizes a thermostatic bin control

September 2015 6

Page 8

ELECTRICAL PLUMBING REQUIREMENTS

Note: This unit does not have a splash

ON-OFF-WASH Switch is located

UIM-300FA

curtain.

This model utilizes a thermostatic bin

control in place of a mechanical bin

switch.

in the control box.

Remove the grill screws to access

the control box.

© Supera September 2015 7

Page 9

HOW THE ICE MACHINE WORKS

A general

description of how the Supera Cubers works is given below. With the ICE/OFF/WASH

switch in the ice position, the compressor, water pump and condenser fan motor (when

applicable) will energize starting the freeze cycle.

During the freeze cycle, water is circulated over the evaporator(s) where the ice cubes are

formed. When the suction pressure has pulled down to the proper cut-in pressure of the timer

initiate (pressure control), the contacts will close and energize the time delay module (timer). At

this time, the cubes will be close to completion.

The remaining portion of the freeze cycle is determined by the timer setting. The timer is pre-set

at the factory to achieve the proper ice bridge thickness but may need to be adjusted upon initial

start-up.

Once the amount of time on the timer has passed, the control relay will be energized and the

machine will enter harvest. Power is now supplied to the water purge valve, hot gas valve, and the

harvest motor.

The water purge valve opens, and allows the water pump to purge the water remaining in the

water trough, removing impurities and sediment. This allows the machine to produce clear ice

cubes and keep mineral build up at a minimum.

The hot gas solenoid opens allowing hot gas to go directly to the evaporator, heating the

evaporator and breaking the bond between the evaporator and the ice slab.

The harvest assist motor, which is also energized during harvest, turns a slip clutch, which pushes

a probe against the back of the ice slab. Once the evaporator has reached approximately 40°F

(4.5°F) in temperature, the slip clutch overcomes the bonding of the ice to the evaporator and

pushes the slab of ice off of the evaporator and into the storage bin.

The clutch also actuates a switch that rides on the outer edge of the clutch. When the clutch

completes one revolution, the switch is tripped and the machine enters the next freeze cycle.

Supera models utilize a thermostatic bin control in place of a mechanical bin switch.

© Supera September 2015 8

Page 10

START UP PROCEDURE

Model

Batch Weight

UIM-240FA, UIM-300FA

3.2 – 3.5

Before starting the machine, make sure the machine is level wit

hin 1/8 inch in all directions, the bin

or dispenser leg height can be adjusted by rotating the leg foot.

Check the water level in the water trough. It should be approximately ½ inch above the top of the

water pump impeller housing. The water level can be adjusted by bending the float arm.

Move the ICE-OFF-WASH switch to the ICE position. The switch is located in the control box.

Remove the ice machine front panel or remove the lower grill on the under counter models to

access the control box.

Check for proper water flow over the evaporator(s). There should be an even flow of water over

the evaporator(s).

Check the water regulating valve (water cooled machine) for proper adjustment by measuring the

discharge pressure which should be adjusted to maintain 250 psi (17.01 bar / 1.723 MPa). Adjust

the water regulating valve as required. Water exiting the condenser should be between 100°F

(38°C) and 110°F (43°C).

As ice begins to form on the evaporators, check the freeze pattern of the ice. Ice should form

evenly across the evaporator.

Bridge Thickness and Timer Adjustment

Once the unit has gone through 1 or 2 harvest cycles, verify that the ice production is per the

chart below.

As a reference

, when ice drops off the evaporator(s) during harvest, check the bridge thickness of

the ice slab. The bridge should be approximately 3/16 of an inch on Undercounter, UIM-240FA and

UIM-300FA units. The bridge should be approximately 1/8 of an inch on all other units. If the batch

weight or bridge thickness is incorrect, the timer will need to be adjusted.

Both the Ice Batch Weight and Bridge Thickness are controlled by the freeze timer located in the

control box. To check the timer setting, add the seconds of each dipswitch turned to the “ON”

position. The number beside the each dipswitch represents seconds. To increase the Batch Weight

and bridge thickness, increase the timer setting. To decrease the Batch Weight and bridge

thickness, decrease the timer setting. The freeze timer can be adjusted by sliding one or more

switches to either the “ON” or “OFF” position to obtain the desired setting.

©

Supera September 2015 9

Page 11

START UP PROCEDURE

Bin Control Operation

The bin control is used to shut the machine off when the bin fills with ice. The bin control must be

checked upon installation or initial start-up and when performing maintenance. Adjustments are

not covered under warranty. There is one bin switch for each evaporator. The actuator arm of the

bin switch comes in contact with the splash curtain. When the bin is full of ice, the splash curtain is

held open when ice drops off of the evaporator. This releases the

pressure of the bin switch actuator arm allowing the switch to open.

Undercounter machines: A thermostatic bin control is used on the

undercounter m

odels. The bin thermostat is located in the control box

with a capillary tube, which is in a brass thermo-well mounted to the

right side of the water trough.

When ice comes in contact with the capillary tube thermo-well, the bin

thermostat opens and the machine will shut off.

Bin Control Adjustment

All Models (Except Undercounter Models): Check the bin switch for

proper adjustment by swinging the bottom of the curtain away from the

evaporator. Slowly bring the curtain towards the evaporator. The switch

should close when the bottom edge of the curtain is even with the outer

edge of the water trough. Adjust the switch by loosening the nuts that

hold the switch in place. Move the switch to the proper position and

retighten the nuts. Recheck the adjustment. Adjustments are not

covered under warranty.

Undercounter Models

The Bin Thermostat used on these Self Contained Ice Cuber Machines is

a sensitive device influenced by ambient conditions including altitude

and temperature. The machine is set up to operate properly at the

factory for 70°F at sea level. If your ice machine shuts off early, bin half

full, or doesn’t shut off, bin overflowing, please follow these instructions

to set the bin thermostat.

Supera September 2015

©

10

Page 12

1. These instructions are best followed on a full ice bin with at

least 3 inches of ice resting against the brass thermal well.

The machine must be running to perform this adjustment;

follow step two if the machine is off.

2. Turn the thermostat adjustment screw clockwise until it

stops; this is the max cold setting and will prevent the

machine from shutting off.

3. Hold a minimum of 3 inches of ice against the middle of the

brass thermal well for 3-4 minutes. It is imperative that

enough ice be used for the

4. Slowly turn the adjustment screw counter- clockwise until the

machine shuts off. If the screw is turned too quickly, the

thermostat could be set to too warm a temperature. Turn

slowly.

5. Remove the ice from the well and warm the brass with your hand; the machine should turn

back on.

The ice machine is now set for ambient conditions. If the ice machine location experiences

significant changes in ambient temperatures, this procedure will need to be followed again.

Adjustments are not covered under warranty.

© Supera September 2015 11

Page 13

GENERAL MAINTENANCE

Electrical shock and/or injury from moving parts inside this machine can cause serious injury.

Disconnect electrical supply to machine prior to performing any adjustments or repairs.

Failure to perform the required maintenance at the frequency specified will void warranty

coverage in the event of a related failure.

General Maintenance Procedure

To insure economical, trouble free operation of your machine, it is recommended that the

following maintenance be performed every 6 months.

1. Clean the ice-making section per the instructions

minimum of

ev

ery

6 months. Local water conditions may require that cleaning be

below. Cleaning should be performed a

performed more often.

2. Check ice bridge thickness.

3. Check water level in trough.

4. Clean the condenser (air-cooled machines) to insure unobstructed air flow.

5. Check for leaks of any kind: Water, Refrigerant, Oil, Etc.

6. Check the bin control switch for proper adjustment.

7. Check the water regulating valve (water cooled machine) for proper adjustment by

measuring the discharge pressure which should be adjusted to maintain 250 psi (17.01

bar / 1.723 MPa). Adjust the water regulating valve as required. Water exiting the condenser

should be between 100°F (38°C) and 110°F (43°C).

8. Check all electrical connections.

9. Oil the fan motor if the motor has an oil fitting. (Self-contained air-cooled models only)

10. Check the water filter (if applicable) and replace if dirty or restricted.

11. Inspect the evaporator water distribution tube to insure even distribution of water across

the face of the evaporator.

© Supera September 2015 12

Page 14

CLEANING PROCEDURE

Supera Ice Machine Cleaning and Sanitizing Instructions

Note: Electrical power will be ON when performing the following cleaning instructions.

It is the USER’S RESPONSIBILITY to see that the unit is properly maintained. It is always

preferable and less costly in the long run, to avoid possible down time by keeping it clean and

adjusted as needed; and by replacing worn components before they can cause failure. The

following is a list of recommended maintenance that will help keep the machine running with a

minimum of problems.

Maintenance and Cleaning should be scheduled at a minimum of twice per year.

1. Remove the ice machine front panel.

2. Make sure that all the ice is off of the evaporator. If ice is being made, wait for cycle

completion then turn the machine “OFF” at the ICE/OFF/WASH selector switch.

3. Remove or melt all ice in the storage bin.

4. Add recommended amount of approved nickel safe ice machine cleaner to the water

trough according to label instructions on the container.

5. Initiate the wash cycle at the ICE/OFF/WASH switch by placing the switch in the “WASH”

position. Allow the cleaner to circulate for approximately 15 minutes to remove mineral

deposits.

6. Depress the purge switch and hold until the ice machine cleaner has been flushed down the

drain and diluted by fresh incoming water.

7. Terminate the wash cycle at the ICE/OFF/WASH switch by placing the switch in the “OFF”

position. Remove the splash curtain and inspect the evaporator and water spillway to

ensure all mineral residue has been removed.

8. If necessary, wipe the evaporator, spillway and other water transport surfaces with a clean

soft cloth to remove any remaining residue. If necessary, remove the water distribution

tube, disassemble and clean with a bottlebrush. Reassemble all components and repeat

steps 4 through 7 as required to remove residue.

9. Turn OFF ice machine water supply and clean the water trough thoroughly to remove all

scale or slime build-up. If necessary, remove the water trough to reach all splash areas and

float.

10. Use an EPA approved food equipment sanitizer at the solution mix recommended by the

sanitizer manufacturer.

11. Add enough sanitizing solution to fill the water trough to overflowing and place the

ICE/OFF/WASH switch to the “WASH” position and allow circulation to occur for 10

minutes and inspect all disassembled fittings for leaks. During this time, wipe down all other

ice machine splash areas, plus the interior surfaces of the bin, deflector and door with the

remaining sanitizing solution. Inspect to insure that all functional parts, fasteners,

thermostat bulbs (if used), etc. are in the correct position.

12. Depress the purge switch and hold until sanitizer has been flushed down the drain. Turn ON

the ice machine water supply and continue to purge to the diluted sanitizing solution for

another 1 to 2 minutes.

13. Place the ICE/OFF/WASH switch to the “ICE” position and replace the front panel.

14. Discard the first two ice harvests. DO NOT USE any ice produced from the cleaning

solution.

© Supera September 2015

13

Page 15

CABINET CARE

Cleaning Stainless Steel

Commercial grades of stainless steel are susceptible to rusting if not properly maintained. It is

important that you properly care for the stainless steel surfaces of your ice machine and bin to

avoid the possibility of rust or corrosion. Use the following recommended guidelines for keeping

your stainless steel looking like new:

1. Clean the stainless steel thoroughly once a week. Clean frequently to avoid build-up of

hard, stubborn stains. Also, hard water stains left to sit can weaken the steel's corrosion

resistance and lead to rust. Use a nonabrasive cloth or sponge, working with, not across, the

grain.

2. Don't use abrasive tools to clean the steel surface. Do not use steel wool, abrasive sponge

pads, wire brushes or scrapers to clean the steel. Such tools can break through the

"passivation" layer - the thin layer on the surface of stainless steel that protects it from

corrosion.

3. Don't use cleaners that use chlorine or chlorides. Don't use chlorine bleach or products like

Comet to clean the steel. Chlorides break down the passivation layer and can cause rusting.

4. Rinse with clean water. If chlorinated cleansers are used, you must thoroughly rinse the

surface with clean water and wipe dry immediately.

5. Use the right cleaning agent. The table below lists the recommended cleaning agents for

common stainless steel cleaning problems:

Cleaning Activity Cleaning Agent Method of Application

Routine Cleaning Soap, Ammonia, Windex, or

detergent with water. Fantastik,

409, Spic ‘nSpan Liquid are also

approved for Stainless Steel

Removing grease or fatty acids Easy-off or similar oven cleaners Apply generously, allow to stand

Removing hard water spots and

scale

Vinegar Swab or wipe with clean cloth.

Apply with a clean cloth or

sponge. Rinse with clean water

and wipe dry.

for 15-20 minutes. Rinse with

clean water. Repeat as required.

Rinse with clean water and dry.

© Supera September 2015

14

Page 16

WINTERIZING PROCEDURE

Important!

Whenever the ice machine is taken out of operation during the winter months, the procedure

below must be performed. Failure to do so may cause serious damage and will void all warranties.

1. Turn off water to machine.

2. Make sure all ice is off of the evaporator(s). If ice is being made, initiate harvest or wait for

cycle completion.

3. Place the ICE/OFF/WASH switch to the “OFF” position. The switch is located in the control

box.

4. Disconnect the tubing between the water pump discharge and water distribution tube.

5. Drain the water system completely.

6. On water cooled machines, hold the water regulating valve open by prying upward on the

water valve spring with a screwdriver while using

compressed air to blow all the water out of the

condenser.

7. Remove all of the ice in the storage bin and discard.

© Supera September 2015 15

Page 17

Service History

Model Number Serial Number Date Installed

Page 18

www.SuperaCo.com

LIMITED WARRANTY

SUPERA ICE MACHINE EQUIPMENT MODELS:

Undercounter Ice Machines [UIM-240FA, UIM-300FA]

Modular Ice Machines [MIM-500FA, MIM-650FA, MIM-900FA, MIM-1000FA]

Combination Ice Machines [MIM-500FA_IB-350, MIM-500FA_IB-500, MIM-650FA_IB-350, MIM-650FA_IB-500, MIM-900FA_IB-500,

MIM-1000FA_IB-500]

Claims: All claims for parts or labor must be made directly through SUPERA, LLC. All claims should include: model number of the unit, the serial

number of the cabinet, proof of purchase, date of installation, and all pertinent information supporting the alleged defect. In case of compressor

replacement under warranty, either compressor or compressor tag must be returned to SUPERA, LLC along with above listed information. Failure to

comply with warranty policies will result in voiding claims. Any service provided without authorization from Supera, LLC will not be covered by Supera,

LLC.

Three-Year Parts & Labor Warranty: SUPERA, LLC warrants all new refrigerated components, the cabinet and all parts, to be free from defects in

materials or workmanship, under normal and proper use and maintenance service as specified by SUPERA, LLC and upon proper installation (indoor

building only) and start-up in accordance with the instruction packet supplied with each SUPERA, LLC unit. SUPERA, LLCʼs obligation under this

warranty is limited to a period of three (3) years from the date of original purchase.

Any part, covered under this warranty that is determined by SUPERA, LLC to have been defective within three (3) years of original installation date

is limited to the repair or replacement, including labor charges, of defective parts or assemblies. The labor warranty shall include ONLY pre-authorized

time and up to sixty miles of travel for the service company.

Additional Five-Year Compressor Warranty: In addition to the three (3) year warranty stated above, SUPERA, LLC warrants its hermetically sealed

compressor to be free from defects in both material and workmanship under normal and proper use and maintenance service for a period of five (5)

additional years from the date of original installation, but not to exceed five (5) years and three (3) months after purchase.

Compressor determined by SUPERA, LLC to have been defective within this extended period will, at SUPERA, LLCʼs discretion, be either repaired or

replaced with a compressor or compressor parts of similar design and capacity.

The five (5) year extended compressor warranty applies only to hermetically sealed parts of the compressor and does not apply to any other parts or components, including,

but not limited to, cabinet, paint finish, temperature control, refrigerant, metering device, driers, motor starting equipment, fan assembly or and other electrical components,

etcetera.

Compressor Warranty: The five-year compressor warranty detailed above will be void if the following procedure is not carefully adhered to:

Not Covered Under This Warranty: SUPERA, LLCʼs sole obligation under this warranty is limited to either repair or replacement of parts, subject to

the additional limitations below. This warranty neither assumes nor authorizes any person to assume obligations other than those expressly covered

by this warranty. Warranty does not cover service requests for free replacement and/or recall parts.

No replacement will be made for any part or assembly which (I) has been subject to an alteration or accident; (II) was used in any way which, in

Supera’s opinion, adversely affects the machines performance; (III) is from a machine on which the serial number has been altered or removed; or, (IV)

uses any replacement part not authorized by Supera. This warranty does not apply to destruction or damage caused by unauthorized service, using

other than Supera authorized replacements, risks of transportation, damage resulting from adverse environmental or water conditions, accidents,

misuse, abuse, improper drainage, interruption in the electrical or water supply, charges related to the replacement of non-defective parts or

components, damage by fire, flood, or acts of God.

Equipment warranty is valid only when installation, service, and preventive maintenance are performed by a Supera authorized distributor, a Supera

authorized service agency, or a Supera Regional Manager, or are in compliance with Supera’s specifications. Supera, LLC reserves the right to refuse

claims made for ice machines or bins no longer installed in the original location. The Limited Warranty does not cover normal maintenance,

adjustments, cleaning or coverage of purchased ice due to equipment failures.

SUPERA, LLC HAS FINAL DESCRETION ON ALL WARRANTY REQUESTS. NO CONSEQUENTIAL DAMAGES. SUPERA, LLC IS NOT RESPONSIBLE FOR ECONOMIC

LOSS; PROFIT LOSS; OR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES, SERVICE TECHNICAN ERRORS, OR

DAMAGES ARISING FROM FOOD OR PRODUCT SPOILAGE REGARDLESS OF WHETHER OR NOT THEY RESULT FROM REFRIGERATION FAILURE. WARRANTY IS

NOT TRANSFERABLE, This warranty is not assignable and applies only in favor of the original purchaser/user to whom delivered. ANY SUCH ASSIGNMENT OR

TRANSFER SHALL VOID THE WARRANNTIES HEREIN AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR LABOR COVERAGE FOR COMPONENT FAILURE OR OTHER THE WARRANTY PACKET PROVIDED WITH THE UNIT. ALTERATION,

NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE, FOOD, ACTS OF GOD. SUPERA, LLC is not responsible for the repair or

replacement of any parts that SUPERA, LLC determines have been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during

transit or installation, fire, flood, or act of GOD. IMPROPER ELECTRICAL CONNECTIONS. SUPERA, LLC IS NOT RESPONSIBLE FOR THE REPAIR OR REPLACEMENT

OF FAILED OR DAMAGED COMPONENTS RESULTING FROM ELECTRICAL POWER FAILURE, THE USE OF EXTENSION CORDS, LOW VOLTAGE, OR VOLTAGE

DROPS TO THE UNIT. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE; THERE ARE NO OTHER WARRANTIES,

EXPRESSED, IMPLIED OR STATUTORY, EXCEPT THE THREE (3) YEAR PARTS & LABOR WARRANTY AND THE ADDITIONAL FIVE (5) YEAR COMPRESSOR

WARRANTY AS DESCRIBED ABOVE. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY AND

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. Outside U.S. and Canada; This warranty does not apply, and SUPERA, LLC is not responsible for, any warranty claims made on products sold or used outside the

continent of the United States and Canada. Installation in a residential application will void all warranties.

1. This system contains R404A or R134a refrigerant and Polyol Ester lubricant. The Polyol Ester lubricant has rapid moisture absorbing

qualities.

2. Drier replacement is very important and must be changed when a system is opened for servicing. A620 copper drier or better is highly

recommended.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must be obtained.

4. When compressor is grounded, suction drier and 620 drier or better must be replaced.

5. Compressor must be obtained through SUPERA, LLC, unless otherwise specified in writing, through SUPERA, LLCʼs warranty department.

© SUPERA, 2015 Version 1 | September 2015

Page 19

Supera Customer Care Toll-Free Service Line:

1-866-953-3288

For additional product and warranty

information, please visit our website at:

www.SuperaCo.com

Loading...

Loading...