Page 1

Thank you very much for using SUNX products. Please

read this Instruction Manual carefully and thoroughly for

the correct and optimum use of this product. Kindly keep

this manual in a convenient place for quick reference.

INSTRUCTION MANUAL

Photoelectric Sensor

Adjustable Range Reflective

EQ-500 Series

1

SPECIFICATIONS

Type

Item With timer

Adjustable range (Note 1) (Note 2)

Sensing range (Setting dis-

tance maximum) (Note 2)

Hysteresis (Note 2)

Power / Current

consumption

Output

Response time

Operation indicator

Stability indicator

Distance adjuster

Sensing mode

Timer function

Automatic interference

prevention function

Protection

Ambient temperature

Ambient humidity

Emitting element

Receiving element

Material

Connection method

Cable

Cable length

Weight

Accessory

Notes: 1)

2

Model No.

Output operation

Short-circuit protection

The adjustable range stands for the maximum sensing range which can be set with the adjuster.

2)

The adjustable range, the sensing range and the hysteresis are specified for white non-glossy paper (200200mm) as the object.

3)

When the sensors are mounted closely, use them in the interference prevented area, as shown below.

3

2

1

Lmm

Setting range (m)

or more

06020 8040

Note that the detection may be unstable depending on the mounting conditions or the sensing object. In the state where this product is mounted, be sure to check the operation with the actual sensing object to be used.

Mounting interval L (mm)

INFORMATION RELATING TO

EQ-501

EQ-501T

0.2 to 2.5m 0.2 to 1.0m

24 to 240V AC r 10% or 12 to 240V DC r 10%

Ripple P-P 10% or less

AC: 4VA or less (With timer: 5VA or less)

DC: 3W or less (With timer: 4W or less)

Relay contact 1a

Switching capacity: 250V AC 3A (resistive load)

Electrical life: 100,000 or more operations

Mechanical life: 50,000,000 or more operations

20ms or less (Depends on the timer setting period for EQ-50غT)

Interference

prevented

LOW VOLTAGE DIRECTIVE

(Multi-voltage type only)

Item

Impulse withstanding voltage

Rated conditional protective device

Note: Each condition for use that the standards require is under

less than 2,000m above sea level.

3

CAUTIONS

٨

This product has been developed / produced for industrial use only.

Make sure that the power supply is off while wiring and adjusting.

٨

Take care that wrong wiring will damage the sensor.

٨

Verify that the supply voltage variation is within the rating.

٨

If power is supplied from a commercial switching reg-

٨

ulator, ensure that the frame ground (F.G.) terminal

of the power supply is connected to an actual ground.

FUSE 5A FAST BLOWShort-circuit protective device

Multi-voltage

Short sensing range

EQ-502

EQ-502T

10% or less of operation distance

30V DC 3A (resistive load)

(switching frequency 1,200 times/hour)

(switching frequency 18,000 times/hour)

Switchable either Detection-ON or Detection-OFF

㧙

Orange LED (lights up when the output is ON)

Green LED (lights up under stable operating condition)

2-turn mechanical adjuster with pointer

㧙

EQ-5غT: Selectable from ON-delay and OFF-delay (0.1 to 5 sec. variable)

-25to+55 (No dew condensation or icing allowed), Storage: -30 to +70

Enclosure: ABS, Front cover: Polycarbonate, Display cover: Polycarbonate

Extension up to total 100m is possible with 0.3mm

100g approx. 85g approx.

Description

IEC 60947-5-2: 1998Refering standard

AC-12/DC-12Utilaization category

2.5kV

3Pollution degree

25HzFrequency of operation cycle

20msTurn off time

12%Excess gain

100A

35 to 85% RH, Storage: 35 to 85% RH

Infrared LED (modulated)

2-segment photodiode

Screw-on terminal connection

Suitable for round cable Ǿ9toǾ11mm

Adjusting screwdriver: 1 pc.

Lmm

or more

٨٨Never use this product as a sensing

device for personnel protection.

In case of using sensing devices for personnel pro-

WARNING

Incorporated (Note 3)

٨

tection, use products which meet laws and standards,suchasOSHA,ANSIorIECetc.,forpersonnel protection applicable in each region or country.

DC-voltage

EQ-511

EQ-511T

0.2 to 2.5m 0.2 to 1.0m

0.1 to 2.5m 0.1 to 1.0m0.1 to 2.5m 0.1 to 1.0m

12 to 24V DCr10%˴Ripple P-P 10% or lessSupply voltage

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less (between output and 0V)

Residual voltage: 1V or less (at 100mA sink current)

PNP open-collector transistor

Maximum source current: 100mA

Applied voltage: 30V DC or less (between output and +V)

Residual voltage: 1V or less (at 100mA source current)

2ms or less (Depends on the timer setting period for EQ-51غT)

IP67 (IEC)

Lmm

or more

0.4V or less (at 16mA source current)

Switch either BGS or FGS function

2

, or more, cabtyre cable

Lmm

or more

Short sensing range

45mAorless

0.4V or less (at 16mA sink current)

Incorporated

3

2

1

Setting range (m)

0

Mounting interval L (mm)

Do not run the wires together with high-voltage lines or

power lines or put them in the same raceway. This can

cause malfunction due to induction.

٨

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this

product, connect the frame ground (F.G.) terminal of

the equipment to an actual ground.

Take care that the sensor is not directly exposed to fluores-

٨

cent light from a rapid-starter lamp, a high frequency lighting

device or sunlight etc. as it may affect the sensing performance.

If an external surge voltage exceeding 4kV (DC-voltage:

٨

1kV) is impressed, the internal circuit will be damaged,

and a surge suppressing element should be used.

Do not use during the initial transient time (50ms) after

٨

the power supply is switched on.

٨

This sensor is suitable for indoor use only.

A mechanical structure is employed for the distance ad-

٨

juster of this product. Take care not to drop the product.

Do not use this sensor in places having excessive va-

٨

por, dust, etc., or where it may come in direct contact

with water, or corrosive gas.

٨

Take care that the sensor does not come in contact

with water, oil, grease, organic solvents, such as, thinner, etc., strong acid or alkaline.

٨

This sensor cannot be used in an environment containing inflammable or explosive gases.

٨

Never disassemble or modify the sensor.

EQ-512

EQ-512T

Interference

prevented area

150 20050250100

4

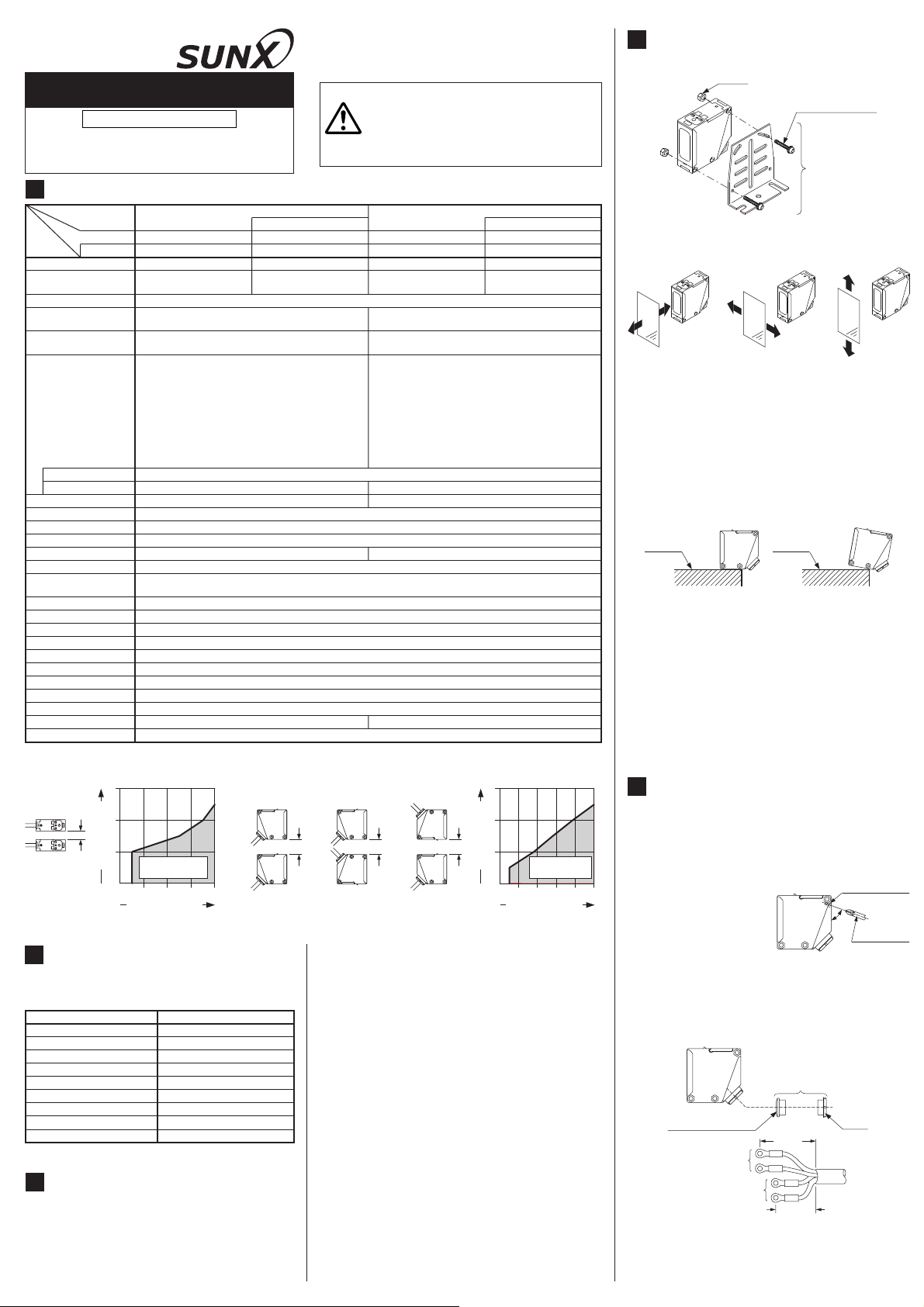

MOUNTING

٨ The tightening torque should be 0.8N㨯morless.

M5 PWV

M5 (length 32mm)

screw with washers

Sensor

mounting

bracket

MS-EQ5-01

(Optional)

٨

Care must be taken regarding the sensor mounting direction with respect to the object's direction of movement.

Good

Sensing object

Good

Sensing object

Not good

Sensing object

Do not make the sensor detect an object

in this direction because it may cause

unstable operation.

٨٨When detecting a specular object (aluminum or copper

foil, etc.) or an object having a glossy surface or coating, please take care that there are cases when the

object may not be detected due to a small change in

angle, wrinkles on the object surface, etc.

When a specular body is present below the sensor, use the

sensor by tiling it slightly upwards to avoid wrong operation.

Not good

Specular

face

٨

If a specular body is present in the background, wrong

Specular

face

Good

Tilt

operation may be caused due to a small change in the

angle of the background body. In that case, install the

sensor at an inclination and confirm the operation with

the actual sensing object.

This product is not easily affected by the reflected light inten-

٨

sity since this sensor is the adjustable range reflective type.

When the reflected light intensity is remarkably low, the

sensing range may be affected. In that case, mount the sensor, while checking light-up of the stable indicator (green).

Mounting screws of the terminal cover and display

٨

cover should certainly be tightened to maintain the water tight rating, however, the tightening torque of the

screws should be of 0.3 to 0.5N㨯m.

5

WIRING CONNECTIONS

٨٨Check all wiring before applying power since incorrect

wiring may damage the internal circuit.

Also, carefully tighten the terminal screws so that the

wires of adjacent terminals do not touch.

The mounting hole for screw the terminal cover fixing

inclines 70 degrees to the

terminal cover, as shown

in the figure below.

To avoid damaging this

product or a screw, take

care when tightening or

loosening a screw.

Screw for terminal

cover fixing

70q

Screwdriver

٨To maintain a watertight performance, the cable should

have an outer diameter between Ǿ9toǾ11mm with a

smooth covering material that allows the accessory conduit connector to be securely tightened, however, the

tightening torque of the screw should be of 1.5 to 2.0N㨯m.

Composition of a conduit connector, and processing of a cable

Conduit connector

Gland packing (Note)

37mm

Power

Output

25mm

When assembling the conduit connector, take care of the

Note:

direction of the gland packing.

Furthermore, in order to maintain a watertight performance, fit the

gland packing such that the seating surface of the gland packing

contacts the packing holder part of the terminal cover evenly.

Gland

Page 2

٨If pressure terminals are to be used, affix the connect-

ed pressure terminals to a terminal (M3.5 screw).

Dimensions of the suitable crimp terminals

(Unit: mm)

Round type Y-shaped type

Ǿ3.6

or more

7.5

or less

22 or less

10

or less

17

or less

(After crimping)

7

or less

Ǿ3.6

or more

7.5

or less

22 or less

10

or less

17

or less

(After crimping)

7

or less

The tightening torque of the terminal screws should be

0.3to0.5N㨯m.

6

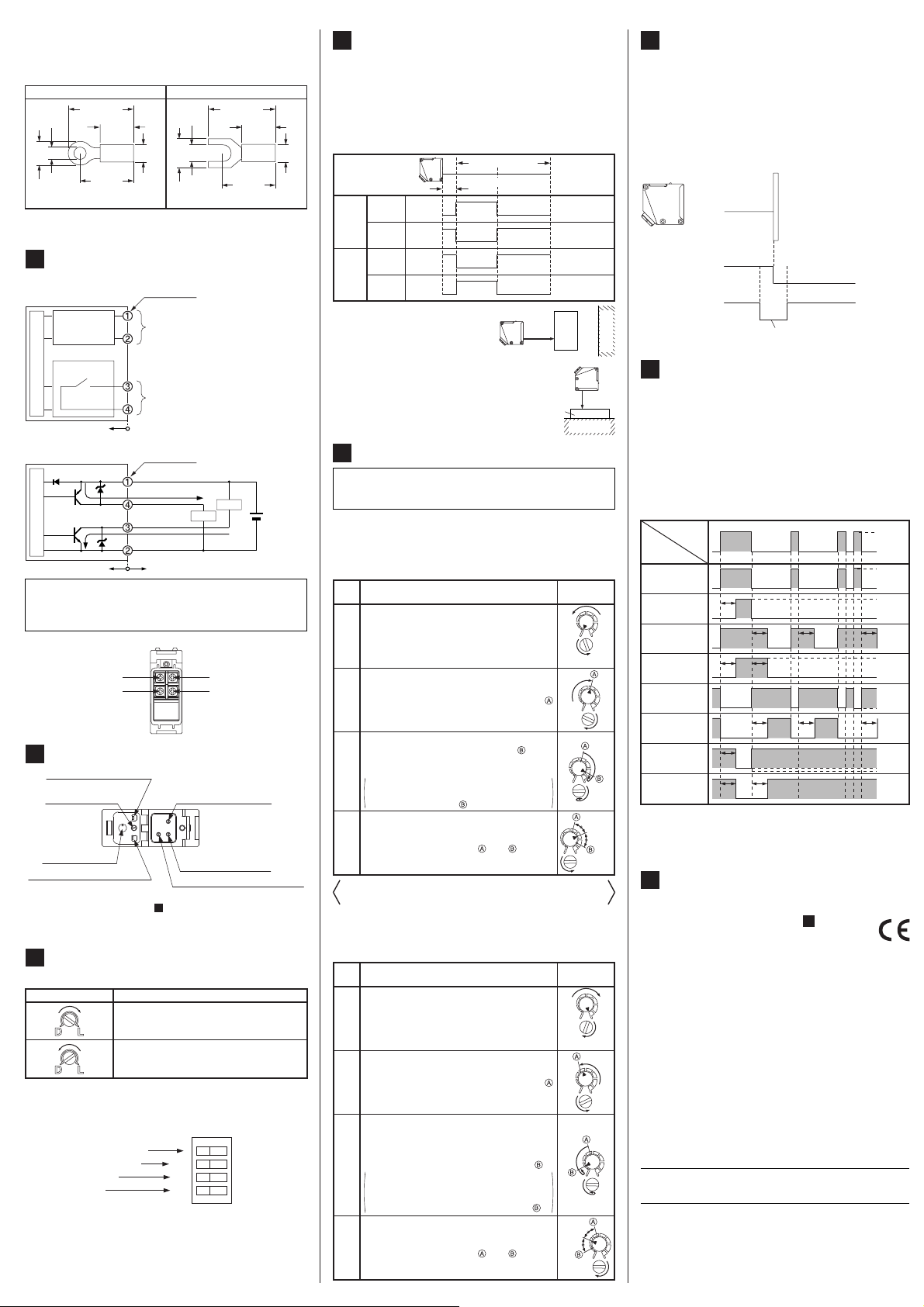

I/O CIRCUIT DIAGRAMS

٨ Multi-voltage type

Multi-voltage

circuit

Output relay

Sensor circuit

Internal circuit

٨ DC-voltage type

D

Tr2

Sensor circuit

Tr1

Internal circuit Users' circuit

Symbols...

D: Reverse supply polarity protection diode

D1,ZD2: Surge absorption zener diode

Z

r1: NPN output transistor

T

r2: PNP output transistor

T

ZD2

ZD1

Terminal No.

Power supply

24 to 240V ACr10%

or

12 to 240V DCr10%

Relay contact

(1a)

Terminal No.

V

+

100mA max.

Output (PNP)

Output (NPN)

0V

Load

Load

100mA max.

+

-

12 to 24V DC

r10%

٨ Terminal position

Ԙ

Ԛ

7

PART DESCRIPTION

Stability indicator (Green)

Distance adjuster

(2-turn)

Adjuster indicator

Operation indicator (Orange)

Notes: 1)2)The operation mode switch of the DC-voltage type is the

DIP switch. Refer to ' OPERATION MODE SWITCH'for

details.

Incorporated on EQ-5غT only.

8

OPERATION MODE SWITCH

8

ԙ

ԛ

OFF-delay timer switch

(Note 2)

ON-delay timer switch

(Note 2)

Operation mode switch (Note 1)

٨ Multi-voltage type (L-ON / D-ON mode only)

Operation mode switch

Detection-ON mode is obtained when the

switch is turned fully clockwise.

Detection-OFF mode is obtained when the

switch is turned fully counterclockwise.

Note: Turn the operation mode switch gradually and lightly with the

attached screwdriver. If the distance adjuster is over turned or

pressed heavily, it may be damaged.

Description

٨ DC-voltage type

L-ON / D-ON mode

BGS / FGS mode

Timer mode

Not used

LD

BGS FGS

OFF

Timer ON

N.C.N.C.

9

BGS / FGS FUNCTION

(DC-voltage type only)

٨٨This sensor incorporates BGS / FGS function. Select

either BGS or FGS function depending on the positions of the background and sensing object.

BGS / FGS function is set with the operation mode switch.

Depends on a selection of either BGS or FGS function, the output operation changes as follows.

Sensing range

Non-detectable area

L-ON

BGS

D-ON

L-ON

FGS

D-ON

<BGS function>

٨

This function is used when

the sensing object is apart

from the background.

<FGS function>

٨ This function is used when the sens-

ing object contacts the background

or the sensing object is glossy, etc.

10

DISTANCE ADJUSTMENT

For DC-voltage type, be sure to set the BGS / FGS function

before distance adjustment. If the setting is done after the

distance adjustment, the sensing area is changed.

٨٨Turn the distance adjuster gradually and lightly with

the attached screwdriver. If the distance adjuster is

over turned or pressed heavily, it may be damaged.

Multi-voltage type, DC-voltage typeBGS select

<When a sensing object moves horizontally to the sensor>

Step

Turn the distance adjuster fully counterclockwise to the minimum sensing range position.

Ԙ

(0.2m approx.)

Please an object at the required distance

from the sensor, turn the distance adjuster

gradually clockwise, and find out point

ԙ

where the sensor changes to the light received condition.

Remove the object, turn the distance adjuster

further clockwise, and find out point where

the sensor changes to the light received condition again with only the background.

Ԛ

When the sensor does not go to the light received condition even if the adjuster is fully

turned clockwise, point is this extreme point.

The optimum position to stably detect objects

ԛ

is the center point between and .

When a sensing object is approaching / moving

away from the sensor.

Follow only steps Ԙ and ԙ. Since the sensing point

٨

may change depending on the sensing object, be sure

to check the operation with the actual sensing object.

٨ DC-voltage typeFGS select

Step

Turn the distance adjuster fully clockwise to

the maximum sensing range position. (2.5m

Ԙ

approx., 1.0m approx. for EQ-512غ

In the state where the sensor detects the

background, turn the distance adjuster gradually counterclockwise, and find out point

ԙ

where the sensor changes to the undetecting

condition.

Place an object at the required distance from the sensor, turn

the adjuster counterclockwise further until the sensor goes into the undetecting condition again. Once it has entered, turn

the adjuster backward a little until the sensor returns to the

Ԛ

detecting condition. That position is designated as point .

When the sensor does not go into the undetecting condition even if the adjuster is fully turned

counterclockwise, the position where the adjuster was fully turned is regarded as the point .

The optimum position to stably detect objects

ԛ

is the center point between and .

Adjusted distance

Description

Description

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Sensing object

Sensing

object

Background

Distance

adjuster

Turn fully

Distance

adjuster

Turn fully

Optimum

position

Optimum

position

11

STABILITY INDICATOR

٨ Since the EQ-500 series use a 2-segment photo-

diode as its receiving element, and sensing is done

based on the difference in the incident beam angle

of the reflected beam from the sensing object, the

output and the operation indicator (orange) operate

according to the object distance.

Further, the stability indicator (green) shows the

margin to the setting distance.

Setting distance

Sensing object

Output

(operation indicator)

(In case of Detection-ON)

Stability indicator

Background

12

٨

Stable

operating

condition

TIMER FUNCTION (EQ-5غTonly)

An OFF-delay timer, which is useful when the re-

Stable operating

condition

Unstable operating

condition

sponse of the connected device is slow, etc., an

ON-delay timer, which is useful when the input

specifications of the connected device require a signal of a fixed width, are possible with EQ-5غT.

٨

The OFF-delay timer and the ON-delay timer can

be used at the same time.

٨

For DC-voltage type, set the DIP switch for the

timer selecting to 'Timer ON' side.

<Time chart>

Sensing

condition

Operation

Light-received

normal operation

Light-received

ON-delay

Light-received

OFF-delay

Light-received

ON/OFF-delay

Light-interrupted

normal operation

Light-interrupted

ON-delay

Light-interrupted

OFF-delay

Light-interrupted

ON/OFF-delay

Note: Turn the timer switch gradually and lightly with the attach-

ed screwdriver. If the distance adjuster is over turned or

pressed heavily, it may be damaged.

13

INTENDED PRODUCTS FOR

T

T

TT

TT T

T

TT

TT

Timer period: T = 0.1 to 5s (variable)

CE MARKING

The models listed under ' SPECIFI-

٨

CATIONS' come with CE Marking.

As for all other models, please contact our

office.

1

SUNX Limited

Overseas Sales Dept. (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

Europe Headquarter: Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

Phone: +49-8024-648-0

US Headquarter: Panasonic Electric Works Corporation of America

629 Central Avenue New Providence, New Jersey 07974 USA

Phone: +1-908-464-3550

PRINTED IN JAPAN

ON (lights up)

OFF (lights off)

Lights up

Lights off

Beamreceived

Beaminterrupted

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

URL : sunx.jp

Loading...

Loading...