Page 1

WHEELCHAIR

FAUTEUIL ROULANT

ROLSTOEL

Helium &

Helium Pro

DIRECTIONS FOR USE

NOTICE D’UTILISATION

GEBRUIKSAANWIJZING

000690966.02

Page 2

IF YOU ARE VISUALLY IMPAIRED, THIS DOCUMENT CAN BE VIEWED IN PDF

FORMAT AT WWW.SUNRISEMEDICAL.CO.UK

SI VOUS SOUFFREZ DE DÉFICIENCE VISUELLE, CE DOCUMENT PEUT ÊTRE

CONSULTÉ EN FORMAT PDF SUR WWW.SUNRISEMEDICAL.FR

ALS U VISUEEL GEHANDICAPT BENT KAN DIT DOCUMENT OOK WORDEN

GELEZEN IN PDF-FORMAAT OP: WWW.SUNRISEMEDICAL.NL

Wheelchair Components

We at SUNRISE MEDICAL have been awarded the ISO-9001 certicate, which afrms the quality of our products at every stage, from R & D to

production. This products meet the requirements in accordance with EC guidelines. Options or accessories shown are available at extra cost.

Description du fauteuil

SUNRISE MEDICAL est certié ISO -9001, une norme qui garantit la qualité des produits à toutes les étapes, de la conception à la production, en passant par la recherche et le développement. Ce produit est conforme aux directives de la Communauté européenne. Les options

ou accessoires illustrés sont disponibles moyennant un coût supplémentaire.

Rolstoelonderdelen

SUNRISE MEDICAL heeft het ISO 9001 certicaat toegekend gekregen, een bewijs van de kwaliteit van onze processen in elk stadium, vanaf

het onderzoek en de ontwikkeling tot de productie. Deze producten voldoen aan de eisen in overeenstemming met de EG-richtlijnen. Getoonde

opties en accessoires zijn tegen betaling verkrijgbaar.

2

EN

FR

NL

Helium-Rev.7.0

Page 3

2

12

11

10

1

3

4

5

9

6

04

1. Push handles

2. Backrest upholstery

3. Sideguard

4. Seat sling

5. Footrest

6. Castors

7. Footboard

8. Fork

9. Quick-release axle

10. Wheel locks

11. Handrim

12. Rear wheel

29

1. Poignée de poussée

2. Toile de dossier

3. Protège-vêtement

4. Toile du siège

5. Repose-jambe

6. Roues avant

7. Plate-forme

8. Fourche

9. Axes à déverrouillage rapide

10. Freins

11. Main courante

7

8

54

1. Duwhandvatten

2. Spanbanden rug

3. Zijkant

4. Zittingbespanning

5. Voetsteun

6. Voorwielen

7. Voetplaten

8. Vork

9. Quick release assen

10. Remmen

11. Hoepel

12. Achterwiel

Helium-Rev.7.0

3

Page 4

Table of Contents

Definitions

Table of Contents 4

Definitions 4

Foreword 5

Use 5

Area of Application. 5

1.0 General safety notes and driving limits 6

ENGLISH

2.0 Handling 8

3.0 Transporting the wheelchair 8

4.0 Options 8

Step Tubes 8

Brakes 8

Suspension System 10

Hand-Bike Axle Adjustment 11

Helium centre of gravity setting 12

Helium Pro centre of gravity setting 12

Footplate Adjustment 13

Seat 13

Options - Snoll on 13

Castors 14

Wheel Alignment 14

Backrest 15

Sideguards 17

Push handle 18

Anti-tip tubes 18

Crutch Holder 19

Pelvic Restraint Belt 19

5.0 Tyres and Mounting 20

6.0 Maintenance and care 20

7.0 Disposal / Recycling of Materials 21

8.0 Trouble-shooting 21

9.0 Transportation 22

10.0 Nameplate 24

11.0 Warranty 24

12.0 Technical Data 25

13.0 Torque 28

3.1 Denitions of words used in this manual

Word Definition

Advice to the user of potential risk of

DANGER!

WARNING!

CAUTION!

NOTE: General advice or best practice

serious injury or death if the advice

is not followed

Advice to the user of a risk of injury

if the advice is not followed

Advice to user that potential

damage to equipment may occur if

the advice is not followed

Reference To Additional

Documentation

NOTE:

The wheelchairs shown and described in this user guide may

not correspond in every detail exactly to your own model.

However, all instructions are completely relevant, regardless of

possible detail differences.

The manufacturer reserves the right to alter without notice any

weights, measurements or other technical data shown in this

manual. All figures, measurements and capacities shown in this

manual are approximate and do not constitute specifications.

4

NOTE:

Please keep a note of your local service agent’s address and

t e le p h on e nu m b er i n t h e sp a ce p r ov i de d .

In the event of a breakdown, contact them and try to give all

relevant details so they can help you quickly.

Dealer signature and stamp

Helium Rev.7.0

Page 5

Foreword

Use

Dear Customer,

We are very happy that you have decided in favour of a highquality product from SUNRISE MEDICAL.

This owner's manual will provide numerous tips and ideas so

that your new wheelchair can become a trustworthy and reliable

partner in your life.

For Sunrise Medical, it is very important that we have a good

relationship with our customers. We like to keep you up-to-date

about new and current developments at our company. Keeping

close to our customers means: fast service, as little red tape as

possible, working closely with customers. When you need

replacement parts or accessories, or if you just have a question

about your wheelchair – we are there for you.

We want you to be satisfied with our products and service. At

Sunrise Medical we are constantly working to develop our

products further. For this reason, changes can occur in our

palette of products with regard to form, technology and

equipment. Consequently, no claims can be construed from the

data or pictures contained in this user’s manual.

The management system of SUNRISE MEDICAL is certified

to EN ISO 9001, ISO 13485 and ISO 14001.

As the manufacturer, SUNRISE MEDICAL,

declares that the lightweight wheelchairs

conform to the 93/42/EEC / 2007/47/EEC

guideline.

Please contact your local, authorised SUNRISE MEDICAL

dealer if you have any questions concerning the use,

maintenance, or safety of your wheelchair.

In case there is no authorised dealer in your area,

or you have any questions about product safety and product

recalls, contact Sunrise Medical either in writing or by telephone

or find the information on www.sunrisemedical.co.uk

Wheelchairs are exclusively for a user who is unable to walk or

has limited mobility, for their own personal use, when selfpropelling and being moved by a third party (pushed by

attendant) within the home and outdoors.

The maximum weight limit (includes the user and any

weight of accessories fitted to the wheelchair) is marked on

the serial number label, which is affixed to the Axle Tube

below the seat.

Warranty can only be taken on if the product is used under the

specified conditions and for the intended purposes.

The intended lifetime of the wheelchair is 5 years.

Please DO NOT use or fit any 3rd party components to the

wheelchair unless they are officially approved by Sunrise

Medical.

Area of Application.

The variety of fitting variants as well as the modular design

mean that it can be used by those who cannot walk or have

limited mobility e.g. because of:

• Paralysis

• Loss of extremity (leg amputation)

• Extremity defect deformity

• Joint contractures/joint injuries

• Illnesses such as heart and circulation deficiencies,

disturbance of equilibrium or cachexia as well as for elderly

people who still have the strength in the upper body.

ENGLISH

IMPORTANT:

DO NOT USE YOUR WHEELCHAIR UNTIL THIS

MANUAL HAS BEEN READ AND UNDERSTOOD.

Sunrise Medical

Thorns Road

Brierley Hill

West Midlands

DY5 2LD

England

Phone: 0845 605 66 88

Fax: 0845 605 66 89

www.SunriseMedical.co.uk

When considering provision, please also note the body size,

weight, physical and psychological constitution, the age of the

person, living conditions and environment.

Helium Rev.7.0

5

Page 6

1.0 General safety notes and driving limits

ENGLISH

The engineering and construction of this wheelchair has been

designed to provide maximum safety. International safety

standards currently in force have either been fulfilled or

exceeded in parts. Nevertheless, users may put themselves at

risk by improperly using their wheelchairs. For your own safety,

the following rules must be strictly observed.

Unprofessional or erroneous changes or adjustments increase

the risk of accident. As a wheelchair user, you are also part of

the daily traffic on streets and pavements, just like anyone else.

We would like to remind you that you are therefore also subject

to any and all traffic laws.

Be careful during your first ride in this wheelchair. Get to know

your wheelchair.

Before each use, the following should be checked:

• Quick-release axles on the rear wheels

• Velcro on seats and backrests

• Tyres, tyre pressure and wheel locks.

Before changing any of the adjustments of this wheelchair, it is

important to read the corresponding section of the user’s

manual.

It is possible that potholes or uneven ground could cause this

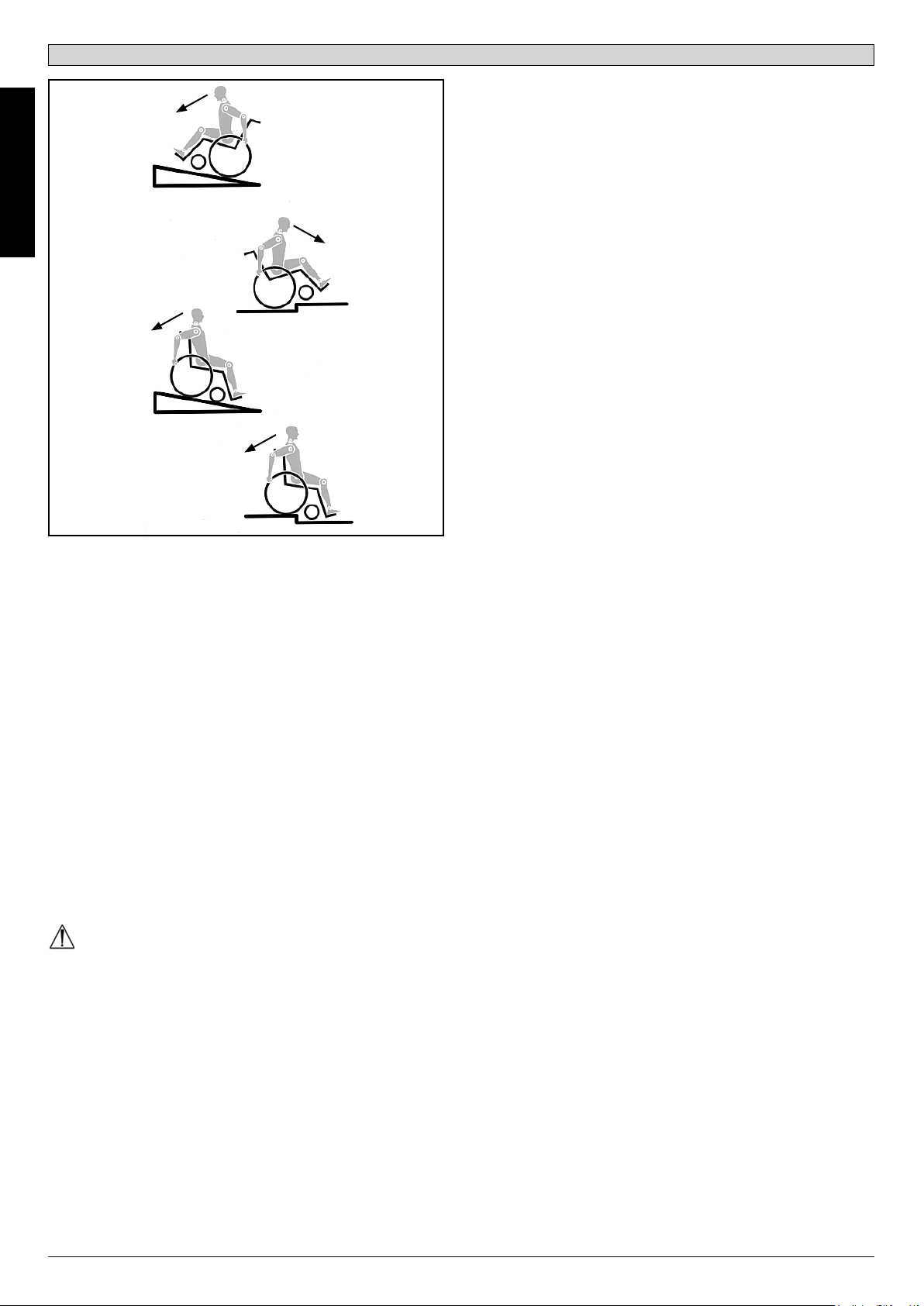

wheelchair to tip over, especially when riding uphill or downhill.

When riding forwards over a step or up an incline, the body

should be leaning forward.

DANGER!

• NEVER exceed the maximum load of 125 kg for driver plus

any items carried on the wheelchair. Please note the weight

information for lighter weight options, which are quoted

separately. If you exceed the maximum load, this can lead

to damage to the chair, or you may fall or tip over, lose

control and may lead to serious injury of the user and other

people.

• When it is dark, please wear light clothing or clothing with

reflectors, so that you can be seen more easily. Make sure

that the reflectors on the side and back of the wheelchair

are clearly visible. We would also recommend that you fit

an active light.

• To avoid falls and dangerous situations, you should first

practice using your new wheelchair on level ground with

good visibility.

• When getting on or off the wheelchair, do not use the

footboards. These should be flipped up beforehand and

swung to the outside as far as possible. Always position

yourself as close as possible to the place where you wish

to sit.

• Only use your wheelchair properly. For example, avoid

travelling against an obstacle without braking (step, kerb

edge) or dropping down gaps.

• The wheel locks are not intended to brake your wheelchair.

They are only there to ensure that your wheelchair does

not begin rolling unintentionally. When you stop on uneven

ground, you should always use the wheel locks to prevent

such rolling. Always apply both wheel locks; otherwise,

your wheelchair could tip over.

• Explore the effects of changing the centre of gravity on the

behaviour of the wheelchair, for example on inclines,

slopes, all gradients or when overcoming obstacles. Do this

with the secure aid of a helper.

• With extreme settings (e.g. rear wheels in the most forward

position) and less than perfect posture, the wheelchair may

tip over even on a level surface.

• Lean your upper body further forward when going up

slopes and steps.

• Lean your upper body further back when going down

slopes and steps. Never try to climb and descend a slope

diagonally.

• Avoid using an escalator which may lead to serious injury

in the event of a fall.

• Do not use the wheelchair on slopes > 10°. The Dynamic

safe slope is dependent on the chair configuration, the

user#s abilities and the style of riding. As the user’s abilities

and style of riding cannot be pre-determined then the max

safe slope cannot be determined. Therefore this must be

determined by the user with the assistance of an attendant

to prevent tipping. It is strongly recommended that

inexperienced users have anti-tip tubes fitted.

• It is possible that potholes or uneven ground could cause

this wheelchair to tip over, especially when riding uphill or

downhill.

• Do not use your wheelchair on muddy or icy ground. Do not

use your wheelchair where pedestrians are not allowed.

• To avoid hand injuries do not grab in between the spokes

or between the rear wheel and wheel lock when driving the

wheelchair.

• In particular when using lightweight metal handrims, fingers

will easily become hot when braking from a high speed or

on long inclines.

• Riding sideways on to a slope or incline, increases the

possibility of the wheelchair tipping over sideways.

• Only attempt stairs with the help of an attendant. There is

equipment available to help you, e.g. climbing ramps or

lifts, please use them. If there is no such equipment

available, then the wheelchair must be tipped and pushed,

never carried, over the steps (2 helpers). We recommend

that users over 100 kg in weight do not use this stairway

manoeuvre!

• In general, any anti-tip tubes fitted must be set beforehand,

so that they cannot touch the steps, as otherwise this could

lead to a serious tumble. Afterwards the anti-tip tubes must

be set back to their correct position.

• Make sure that the attendant only holds the wheelchair

using securely mounted parts (e.g. not on the footrests or

the sideguards).

• This wheelchair is not designed to be used whilst weight

training and/or when using dumbbells. Only use equipment

specifically designed for this purpose.

• Do not lift or carry the wheelchair by the backtubes or the

pushhandles.

• When using the lifting ramp make sure that the anti-tip

tubes fitted are positioned outside the danger area.

• Secure your wheelchair on uneven ground or when

transferring, e.g. into a car, by using the brakes.

6

Helium Rev.7.0

Page 7

• If and whenever possible, during a journey in a specially

fitted vehicle for disabled people, vehicle occupants should

use the seats in the vehicle and the appropriate restraint

system. This is the only way to ensure that occupants will

have the maximum protection if there is an accident. When

using safety elements offered by SUNRISE MEDICAL and

using a specially designed safety system, lightweight

wheelchairs can be used as a seat when being transported

in a specially fitted vehicle. (See the Chapter on

“Transportation”).

• Depending on the diameter and setting of the castors, as

well as the centre of gravity setting of the wheelchair, the

castors may begin to wobble at high speeds. This can lead

to the castors being blocked and the wheelchair may tip

over. Therefore, please make sure that the castors are

adjusted correctly (see the Chapter "Castors"). In particular,

do not travel on an incline without brakes, travel at a

reduced speed. We recommend that novice users use antitip tubes.

• Anti-tip tubes should prevent the chair tipping over

backwards unintentionally. Under no circumstances should

they take the place of transit wheels, and be used to

transport a person in a wheelchair with the rear wheels

removed.

• When reaching for objects (which are in front of, to the side

or behind the wheelchair) make sure that you do not lean

too far out of the wheelchair, as if you change the centre of

gravity there is a risk of tipping or rolling over. The hanging

of additional load (back pack or similar items) onto your

chair backposts can affect the rearward stability of your

chair, especially when used in combination with recliner

backrests. This can cause the chair to tip backwards

causing injury.

• Adjustments to your wheelchair, particularly to safetyrelated components must be carried out by an approved

dealer. This applies to adjustments to wheel locks, anti-tip

tubes, backrest angle and height, lower leg length, COG,

lap belt, rear wheel toe-in and camber, seat height as well

as toe-in and directional stability of the castor fork.

• When using mobility accessories fitted to the wheelchair

such as handbikes, electronic power assist, etc, make sure

that your wheelchair is fitted with the appropriate castor

forks, approved for this use. Please contact your dealer if

you have any questions.

• Do not fit any unauthorized electronic equipment, powered

or mechanically operated mobility drives, hand-bike or any

other device that changes the intended use or the structure

of the wheelchair.

• Any combination with other medical devices requires the

approval of Sunrise Medical.

• Please note that in certain configurations the wheelchair

may exceed a width of 700 mm. If this is the case, under

certain circumstances, it may not be possible to use some

or all of the available escape routes from a building. It may

be more difficult or impossible to travel on public transport.

• For thigh amputees you must use anti-tip tubes.

• Before setting off, check that your tyre pressure is correct.

For rear wheels it should be at least 3.5 bar (350 kPa). The

max. pressure is indicated on the tyre. The knee-lever

brakes will only work if there is sufficient tyre pressure and

if the correct setting has been made (see the Chapter on

“Brakes”).

• If the seat and back sling are damaged, you must replace

them immediately.

• Be careful with fire, in particular with burning cigarettes.

Seat and back slings can be set alight.

• If the wheelchair is subject to direct sunlight for a long

period of time, then parts of the wheelchair (e.g. frame,

legrests, brakes and sideguard) may become hot (>41°C).

• Always make sure that the quick-release axles on the rear

wheels are set properly and lock in. If the button on the

quick-release axle is not pressed in, the rear wheel cannot

be removed.

WARNING!

• The effect of the knee-lever brake as well as the general

driving characteristics are dependent on tyre pressure. The

wheelchair is significantly lighter and easier to manoeuvre

when the rear wheels are pumped up correctly and both

wheels have the same pressure.

• Make sure that your tyres have sufficient tread! Please note

that you are subject to any and all traffic laws when driving

in public traffic.

• Always be careful with your fingers when working or

adjusting the wheelchair!

WARNING!

CHOKING HAZARD – This mobility aid uses small parts which

under certain circumstances may present a choking hazard to

small children.

The wheelchairs shown and described in this user guide may

not correspond in every detail exactly to your own model.

However, all instructions are completely relevant, regardless of

possible detail differences.

The manufacturer reserves the right to alter without notice any

weights, measurements or other technical data shown in this

manual. All figures, measurements and capacities shown in this

manual are approximate and do not constitute specifications.

Sunrise Medical is ISO 9001 certified, which ensures quality at

all stages of the development and production of our products.

This product complies with the standards set forth in EU

directives. Optional equipment and accessories are available at

extra charge.

ENGLISH

Helium Rev.7.0

7

Page 8

2.0 Handling

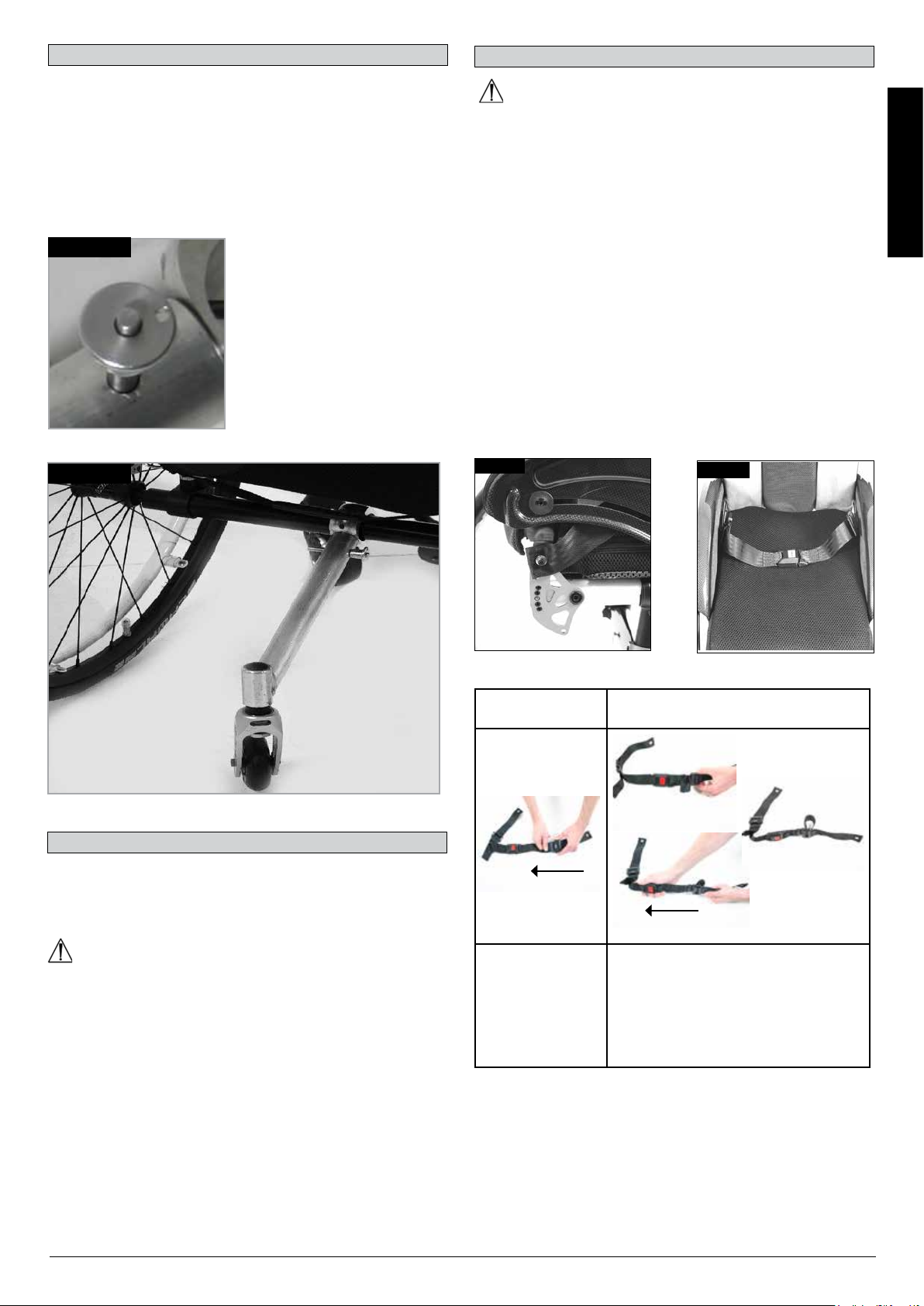

Quick-release axles on rear

wheel

The rear wheels are equipped with

quick-release axles.

The wheels can thus be installed or

removed without using tools.

To remove a wheel, simply depress

the quick-release button on the axle

ENGLISH

(1) and pull it out (Fig. 2.1).

CAUTION!

Hold the quick-release button on the axle depressed when

inserting the axle into the frame to mount the rear wheels.

Release the button to lock the wheel in place. The quick-release

button should snap back to its original position.

Fig. 2.1

1

3.0 Transporting the wheelchair

Transporting the wheelchair

Removing the rear wheels will keep the wheelchair as compact

as possible. The backrest can be folded down by pulling the cord

(1) (see picture 3.2) located on the backrest (Fig. 3.1 and 3.2).

Getting into your wheelchair on your own

• Push the wheelchair to a wall or a solid piece of furniture

• Apply the brakes

• The user can lower themselves into the wheelchair

• Then position the feet in front of the heel straps

(Fig. 4.1).

Getting out of your wheelchair on your own

• Apply the brakes

• With one hand on the wheel or side guard, the person should

lean forwards slightly, to transfer the body weight to the front

edge of the seat and then push up to an upright position with

both feet firmly on the floor and one foot behind the other (Fig.

4.2).

Fig. 4.1

Fig. 4.2

Fig. 3.1

In this state the wheelchair can be lifted by the frame tubes and

the seat sling. When transporting the unoccupied wheelchair in

a vehicle, it should be tied down or strapped in.

Fig. 3.2

1

4.0 Options

Step Tubes

Step Tubes

Step tubes are used by attendants to push a wheelchair over an

obstacle. Simply step on the tube to push a wheelchair, for

example, over a kerb or step.

WARNING!

Sunrise Medical strongly recommends the use of a step tube on

any model where attendant use is the predominant intended

use. Damage to the backposts may occur if you constantly use

the backpost without a step tube, as a lever to pull back on to tip

the wheelchair.

Brakes

Fig. 4.3

CAUTION!

Braking power can be

affected by incorrect fitting and

adjustment of the brakes, as well as tyre pressure which is too

low.

Wheel Locks

Your wheelchair is equipped with two wheel locks. They are

applied directly against the tyres. To engage, press both wheel

lock levers forward against the stops. To release the locks, pull

the levers back to their original positions.

Braking power will decrease with:

• Worn tyre tread

• Tyre pressure that is too low

• Wet tyres

• Improperly adjusted wheel locks.

Fig. 4.4

3.0 mm

8

Helium Rev.7.0

Page 9

Brakes...

The wheel locks have not been designed to be used as brakes

for a moving wheelchair. The wheel locks should therefore never

be used to brake a moving wheelchair. Always use the handrims

for braking. Make sure that the interval between the tyres and

wheel locks complies with given specifications. To readjust,

loosen screw and set the appropriate interval. Then re-tighten

the screw, (Fig. 4.3 and 4.4).

CAUTION!

After each adjustment of the rear wheels, check the interval to

the wheel locks and readjust if necessary.

Brake lever extension

The longer lever helps to minimize the effort needed to set the

wheel locks.

The brake lever extension is screwed to the brakes. By raising

this, it can be flipped forward (Fig. 4.5).

CAUTION!

Mounting the wheel lock too close towards the wheel will result

in a higher effort to operate. This might cause the brake lever

extension to break!

The One-arm Wheel Lock

The one arm wheel lock is underneath the seat sling and is

operated by pulling the brake lever, which is located on the left

or right side, towards the rear, in the direction of the tyre. For

the brakes to work properly, this must be pulled until it reaches

the stop, (Fig. 4.6.1)

Adjustment

To adjust the brake, loose the screws (1) and mount the wheel

lock where it will work in a proper way (Fig. 4.6.2).

ENGLISH

CAUTION!

Incorrect mounting of the one arm wheel lock can lead to

serious injury of the user and other people.

Fig. 4.6.1

Leaning onto the brake lever extension while transferring will

cause the lever to break! Splashing water from tires might cause

the wheel lock to malfunction.

CAUTION!

Incorrect mounting of the wheel lock will result in a higher effort

to operate.

This might cause the wheel lock extension lever to break!

Compact Wheel Lock

Compact wheel locks are underneath the seat sling and are

operated by pulling the wheel locks towards the rear, in the

direction of the tyre. For the brakes to work properly, this must

be pulled until it reaches the stops, (Fig. 4.6).

CAUTION!

The mounting bolts for the brakes must not be loosened and/or

re-tightened.

Fig. 4.5

Fig. 4.6

Fig. 4.6.2

1

Helium Rev.7.0

9

Page 10

Suspension System

CAUTION!

WARNING!

Rear suspension can affect the stability of the wheelchair. To

avoid a fall, use a spotter and/or anti-tip tubes when becoming

familiar with new equipment.

1. Tuning the 4-Link Rear Suspension

ENGLISH

a. to stiffen the suspension, turn the spring preload adjustor (E)

clockwise (looking up at the suspension system from

underneath the wheelchair).

b. to soften the suspension, turn the spring preload adjustor (E)

counter-clockwise (looking up at the suspension system from

underneath the wheelchair).

2. Alignment of Suspension Link Arms

Do not adjust the link arms (F, Fig. 4.10). These are set at the

factory to ensure proper tracking and performance of the 4-Link

suspension system.

(see next page).

Setting the toe-in/toe-out to zero (using the factory fitted

adjuster)

Loosen the Allen screws (G), (2 per side), that

secure the axle tube on both sides. Observe the ball in the

transparent adjuster in the centre of the axle tube, then turn the

axle tube (C), until the ball is exactly centred at the lowest point

of the adjuster. The toe is now set at zero (Fig. 4.7, 4.10).

When turning the 4-Link Rear Suspension, make one change at a

time and write down each change. This takes patience, but allows

you to understand how each change affects the ride of the

wheelchair in conjunction with rear suspension.

NOTE– The lower shock mount is designed to have a loose feel,

this is by design to allow for proper suspension travel.

CAUTION!

Under no circumstances, loosen the screw connection between

the axle clamp and the shock absorber.

3. Maintenance

The maintenance requirements listed below should be followed

along with general wheelchair maintenance shown in Section 6.0.

a. do not apply lubrication to shock end bushings or coils.

b. you can apply lubrication to the link ends after cleaning with a

mild soap and soft

brush.

c. use a soft brush to clear any dirt or debris from coil system.

d. never use a high-powered washer for cleaning the 4-Link Rear

Suspension.

Before re-tightening the screws (G), check that

the flat surfaces of the camber adapter in the axle tube protrude

outside the axle tube clamp. The end of the cylindrical camber

adapter should be flush with the end of the axle tube. Tighten

the screws to a torque of 7 Nm

Setting the toe-in/toe-out to zero (using a 90° setting gauge)

Place the entire wheelchair on a flat

horizontal table or ground surface. Loosen the Allen screws (G)

(2 per side) which hold the axle tube on both sides of the axle

tube.

Then put the setting gauge at an angle of exactly 90° (e.g. a

carpenter’s square) on the flat surfaces of the camber adapter

(D) (Fig. 4.8, Fig. 4.9). Then turn the axle tube until the wrench

surfaces are exactly parallel to the upper surface of the setting

gauge (Fig. 4.8).

Before re-tightening the screws (G), check that

the flat surfaces of the camber adapter in the axle tube protrude

outside the axle tube clamp. The end of the cylindrical camber

adapter should be flush with the end of the axle tube. Tighten

the screws to a torque of 7 Nm

C

BALL

Fig. 4.7

Fig. 4.9

Fig. 4.8

D

B

Fig. 4.10

10

C

D

F

E

Helium Rev.7.0

PAR ALLEL

H

I

G

Page 11

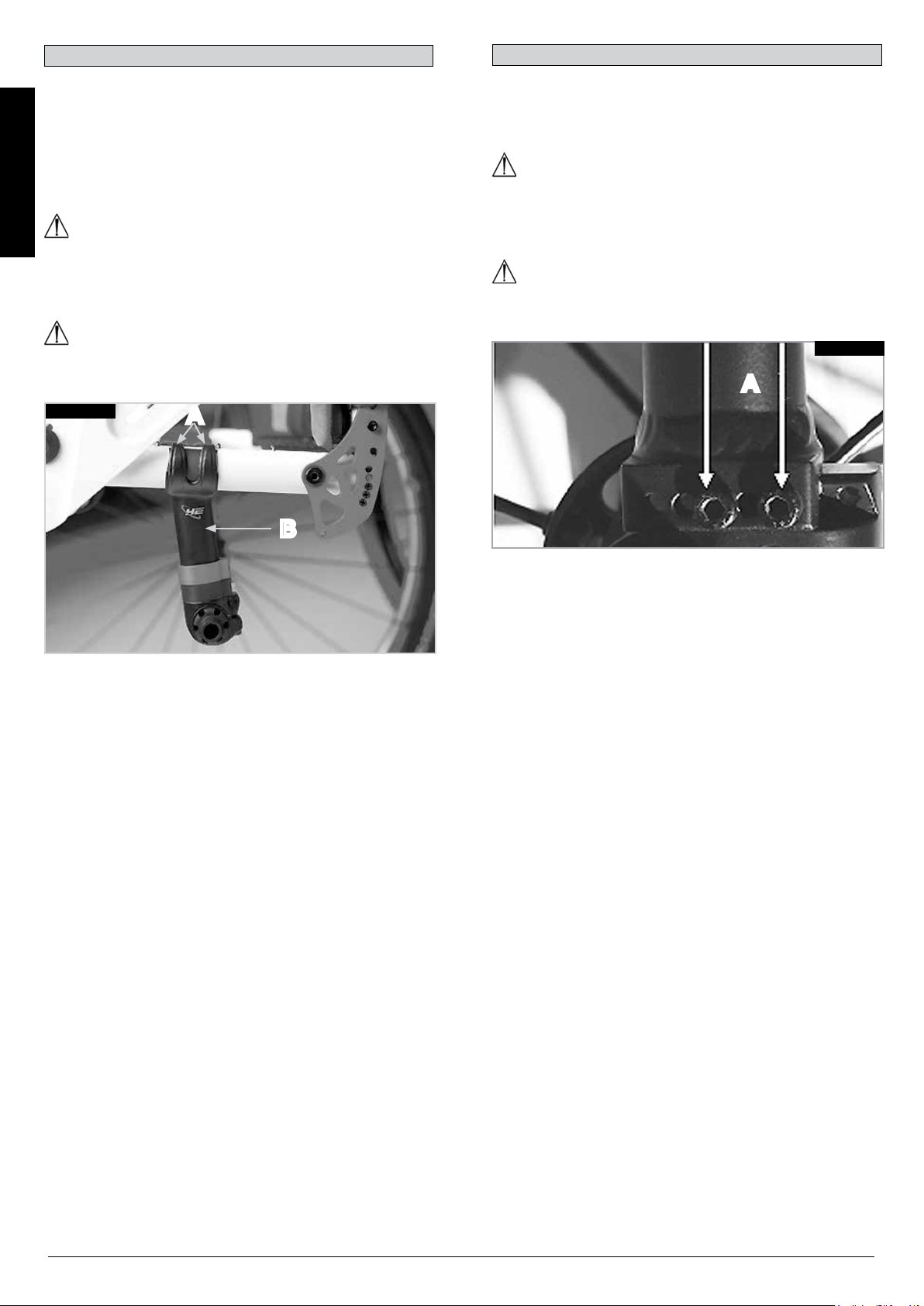

Hand-Bike Axle Adjustment

Hand-Bike-Axle

It is necessary to adjust the hand-bike axle to bias the centre of

gravity rearwards. This allows safe use of a hand-bike

accessory, (Fig. 4.10.1).

Fig. 4.10.2

DANGER!

Using a hand-bike without the hand-bike axle makes the

wheelchair unstable and can lead to serious injury of the user

and other people.

Fig. 4.10.1

ENGLISH

Fig. 4.10.3

Fig. 4.10.4

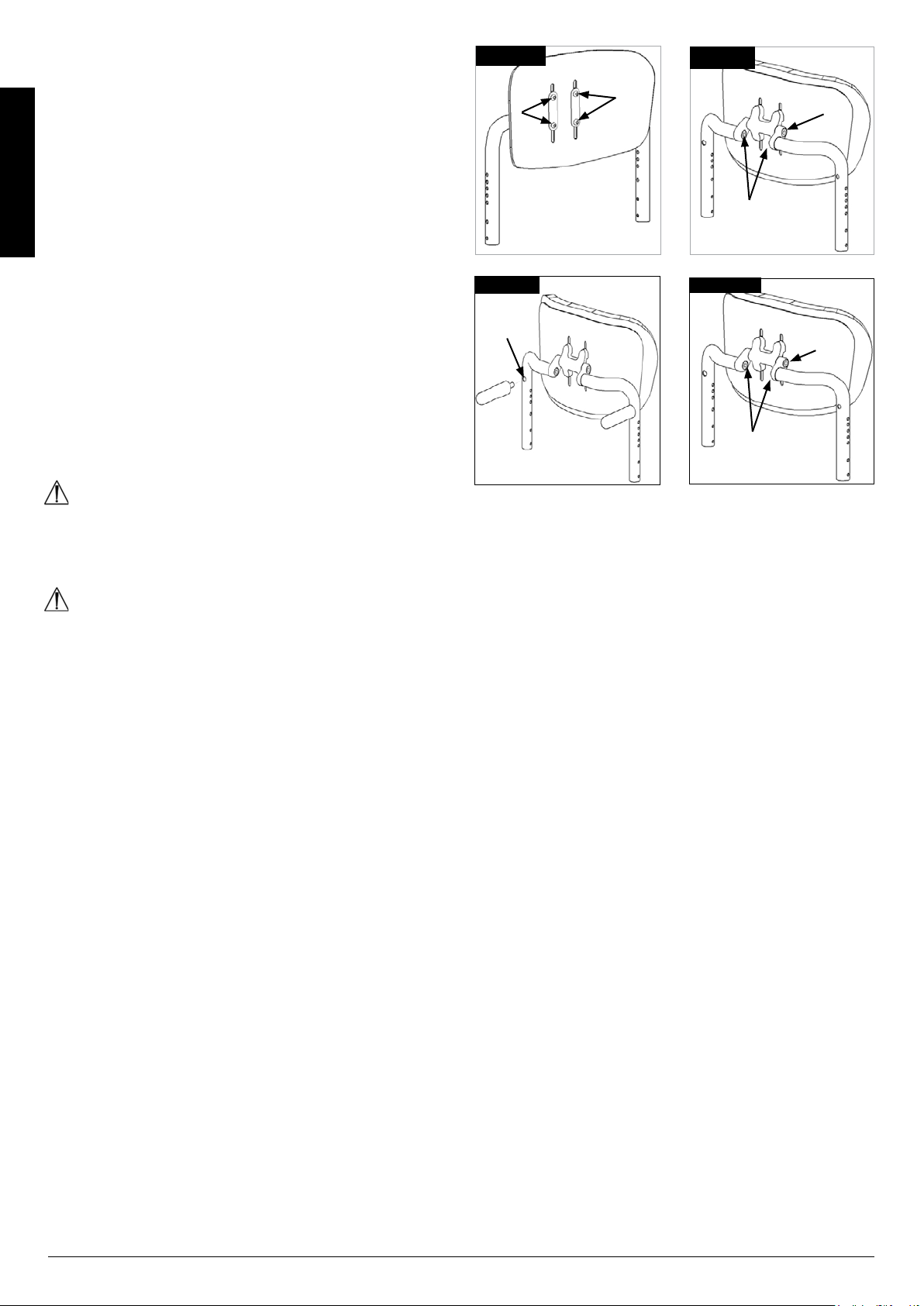

Hand-Bike Reinforcement Kit

To assemble the hand-bike reinforcement kit:

• Insert the nipple at one end of the cable into the receptor

at the front of the frame, (Fig. 4.10.2).

• Insert the nipple at the other end of the cable into the

receptor at the rear of the frame, (Fig. 4.10.3).

• Insert the tensioner tool, (A), into the cable receptor at the

rear of the frame, (Fig. 4.10.4).

• Move the tensioner tool, (A), upwards until the receptor

and the front tube, (B), just starts to move towards the

rear, (Fig. 4.10.5).

• Hold the cable under tension with the tensioner tool and

tighten the screw on the rear cable receptor, (Fig. 4.10.5).

• Repeat the process for the other side.

WARNING!

The tension of both cables must be checked for tightness

before and after each use of the hand-bike.

A

Fig. 4.10.5

A

B

Helium Rev.7.0

11

Page 12

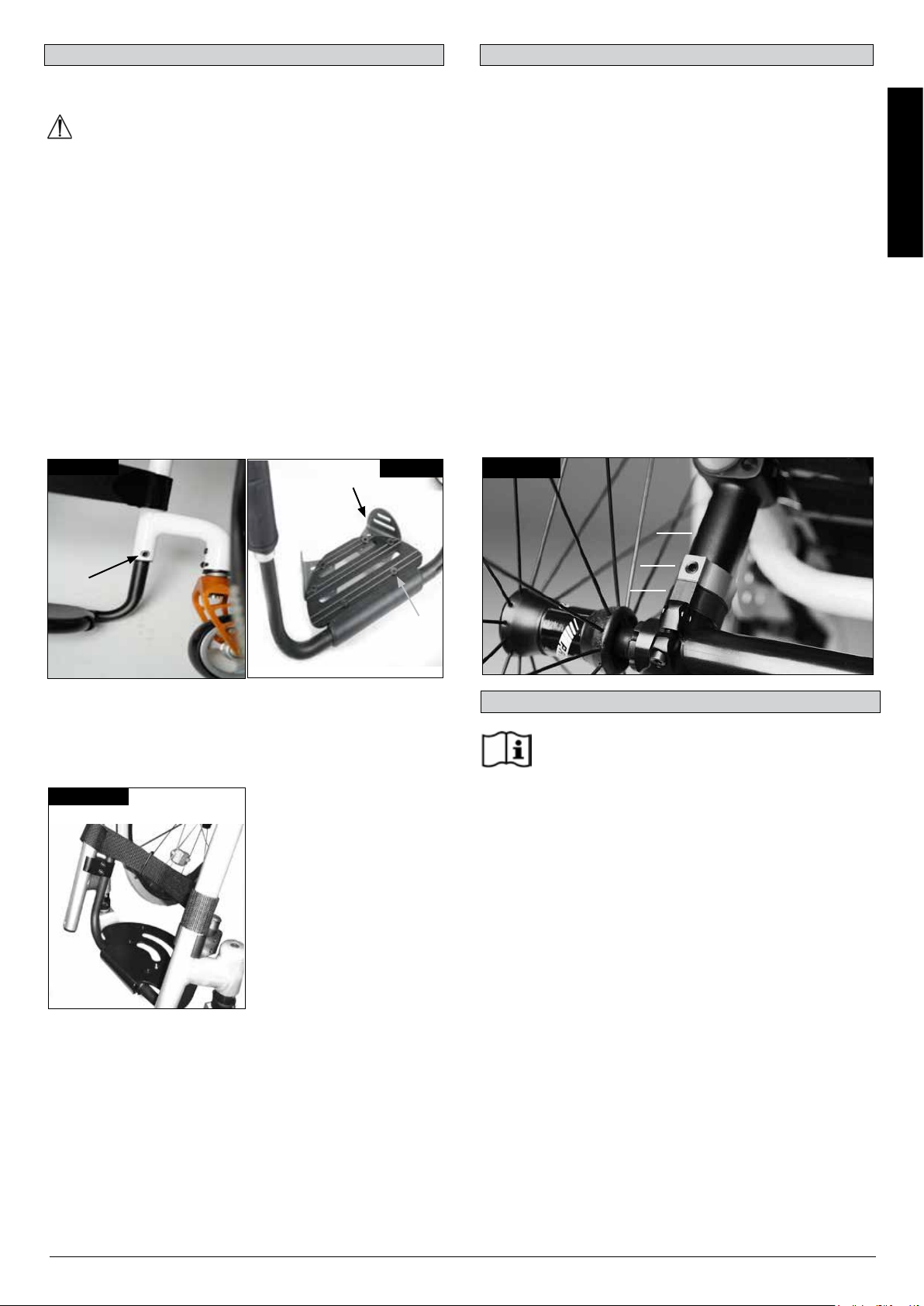

Helium centre of gravity setting

Helium Pro centre of gravity setting

Remove the rear wheels. Undo both Allen screws (A) on the

top of the axle stem (B) on both sides of the wheelchair, (Fig.

4.10.6). Then push the complete unit out of the axle and push

both axles stems forwards on the frame, (in terms of the

direction of travel), for a more active COG, or backwards for a

more passive, stable COG. Then re-tighten the screws (A) on

both sides to a torque of 5 Nm. Now adjust the side guards and

brakes to the new wheel position.

ENGLISH

CAUTION!

Please note that the tipping behaviour of the wheelchair will

change if the COG has been changed. This may mean that you

need to use anti-tip tubes.

DANGER!

The brakes must be adjusted to the new COG position.

Fig. 4.10.6

A

B

To adjust the centre of gravity (COG) remove the 2 screws, (A)

and move the bracket into preferred position, (Fig. 4.10.7). Refit

and tighten the screws (5 Nm).

CAUTION!

Please note that the tipping behaviour of the wheelchair will

change if the COG has been changed. This may mean that you

need to use anti-tip tubes.

DANGER!

The brakes must be adjusted to the new COG position.

Fig. 4.10.7

A

12

Helium Rev.7.0

Page 13

Footplate Adjustment

Adjusting The Footrest

WARNING!

• Do not stand on the footboard! Even if the user is sitting in

the chair, there is still a risk of tipping over and injury.

• When transferring, do not stand on the footboard, there is a

risk of tipping over and injury.

Releasing the screw (1) will allow you to adjust the footrest to

correspond to the length of your lower leg and re-attach the

footrest. The angle of the footrest may be individually adjusted

by loosening screws (2). The side protection (3) on the footrest

prevents the feet slipping off accidentally. Make sure that after

any adjustment work, all screws are tightened correctly (see the

page on torque) (Fig. 4.11 - 4.12).

Seat

Adjusting the seat height

To adjust the rear seat height release the Allen screws (1) (one

on each side), which fix the clamp to the axle stem (2).

Remove the spacer bracket (3), to adjust the seat height +/- 1

cm. For large adjustments, reduce the length of the axle stem

as required.

Tighten the 2 Allen screws to 7 Nm. (Fig. 4.14).

NOTE:

An adjustment to the castor angle may be necessary when

adjusting the rear seat height.

Seat Sling

To tighten the upholstery, please use the straps below the

upholstery.

ENGLISH

Fig. 4.11

3

Fig. 4.12

1

High-mount footrest

The high-mount footrest is fitted on the inner part of the frame

and permits a higher footrest position (Fig. 4.13).

Fig. 4.13

Fig. 4.14

2

1

3

2

Options - Snoll on

Please see the separate Owners' Manual for details of

the Snoll On accessory.

Helium Rev.7.0

13

Page 14

Castors

Wheel Alignment

Castor, Castor adapter, Castor fork

From time to time the wheelchair may veer slightly to the right or

left or the castors may flutter. This may be caused by the

following:

• Forward and/or reverse wheel motion has not been set

properly.

• The castor angle has not been adjusted properly.

ENGLISH

• Castor and/or rear wheel air pressure is incorrect; wheels do

not turn smoothly.

The optimum adjustment of the castors is required so that the

wheelchair runs in a straight line.

The castor plates must be re-adjusted, and the wheel locks must

be checked every time the rear wheel position has been altered.

Adjusting the castor

To ensure that both forks are set parallel, simply count the teeth

visible on both sides. After setting the castor fork, the teeth will

guarantee a secure position, allowing an adjustment of 16° in 2°

increments. Use the flat side on the front of the castor fork to

check for a right-angled position to the ground (Fig. 4.15).

The patented design allows the castor fork to be turned, so that

it can be reset at right-angles to the ground when the seat angle

is changed.

Setting the directional stability

Release the Allen screws (1) on the underside of the fork. You

can then undo the screw (2). You can now turn the black socket

(3) left or right.

Left – chair pulls to the left

Right – chair pulls to the right

Then tighten up the screw (2) again. Please set a 90° angle from

the fork to the floor.

Now tighten up the screw (1) again. (Fig. 4.16).

Fig. 4.15

Fig. 4.16

2

+8 -8

1

Adjusting the wheel alignment

Important: To achieve the very best movement, the rear wheels

must be adjusted to their optimum position, which means

correctly adjusting the wheel alignment.

To do this, measure the distance between both wheels front and

rear to ensure that they are parallel to one another.

The difference between both measurements should not exceed

5 mm.

To adjust the wheels to make them parallel, loosen the screws

and turn the axle sleeve accordingly. Make sure that after any

adjustment work, all screws are tightened correctly (see the

page on torque).

HELIUM tracking adjustment

Setting the toe-in/toe-out to zero

NOTE: A wheelchair with 0° camber cylinders cannot have toe-in

or toe-out. This setting is necessary only with 3° and 6° camber

cylinders.

The term "toe-in or toe-out" defines how well the rear wheels of

the chair are aligned in relation to the ground. This determines

how well the chair will run. Normal resistance or rolling

resistance is present when toe-in is set to zero.

To set toe-in/toe-out to zero: Loosen the Allen screw (1) (one on

each side), that secures the camber tube clamp. Check the ball

in the horizontal (2) plane and turn the angle tube (3) until the

ball is in the centre. Toe-in is now zero.

Before tightening the screws (1), check that the camber tube is

centred left-to-right. The gap should be the same on both sides,

or there should be no gap at all. Tighten the screws to 7 Nm.

(Fig. 4.17 - 4.19).

Adjusting the rear wheelbase width:

The rear wheelbase is defined as the distance between the

upper side of the rear wheels and the backrest tubes, and is

represented by factory setting (1.25 cm). This has to be

increased if a larger gap between the tyres and the optional

height-adjustable armrests has to be created (Fig. 4.20).

3

NOTE:When adjusting the rear wheelbase, adjust first one

wheel then the other. If both sides are loosened at the same

time, this will alter the toe-in/toe-out adjustment. To adjust the

rear wheelbase, the parts of the camber (4) move telescopically

into or out of the camber tube (5), and lock into place when they

reach the end. Loosen screw (6) (located closest to the camber

tube) on the left side of the chair. Move the quick-release axle

inwards or outwards to achieve the desired wheelbase. Tighten

the screws to 7 Nm. Repeat this procedure on the right side of

the chair and adjust the gap so that it is the same amount as on

the left side.

14

Helium Rev.7.0

Page 15

Fig. 4.17

Fig. 4.18

CAUTION!

When folding the backrest down, please make sure that your

fingers do not get caught.

1

Fig. 4.19

Fig. 4.20

3

5

4

6

BALL

2

Backrest

Angle-adjustable back

The backrest angle is adjusted by altering the position of the pin

in the backrest mounting. The pin (1) must be completely clicked

into place in the hole pattern on both sides, this gives you an

angle adjustment of 8.5°.

Fit the black plastic pins into the unused holes. To reach a

smaller angle increment (3.5°), you open the Allen key screw (2)

and re-set the screw into the second hole. Please use the

relevant torque force (see matrix) to tighten the screw (2).

This gives you 12° change in the back angle. Then move the pin

(1) in the opposite direction to the next hole, which gives you 12°

- 8°= 3.5° change. (Fig. 4.21)

To reduce the play in the backrest, the nut (1) can be released,

then the optimal position can be set using the set screw (2).

Then re-tighten the nut (1). (Fig. 4.22).

Fig. 4.21

2

1

Fig. 4.22

1

2

Adjustable Back Sling

The adjustable back sling can be adjusted for tension by using

several straps.

The back sling upholstery can be accessed from the inside via

an opening and can be padded to suit individual tastes, (Fig.

4.23).

Height-adjustable backrest

The backrest may be set to various back heights, in 25 mm

steps. The adjustment ranges are 250 - 300 mm, 300 - 350 mm,

350 - 400 mm and 400 - 450 mm. Release the screws (1+2) and

set the backrest to the desired height. Tighten up the screws

again (see the page on torque). (Fig. 4.24)

CAUTION!

Please note that the tipping behaviour of the wheelchair will

change if the backrest angle or backrest upholstery has been

changed. This may mean that you need to use anti-tip tubes.

Fig. 4.23

Fig. 4.24

1

ENGLISH

CAUTION!

The screws must be re-tightened. Otherwise the angle

adjustment will be lost.

Folding Backrest

Release the backrest by pulling the cord. At the same time, push

it forward to fold it down. To return the backrest to its original

position, this must be pulled back as far as possible until it locks

into place on both sides.

1

Helium Rev.7.0

15

Page 16

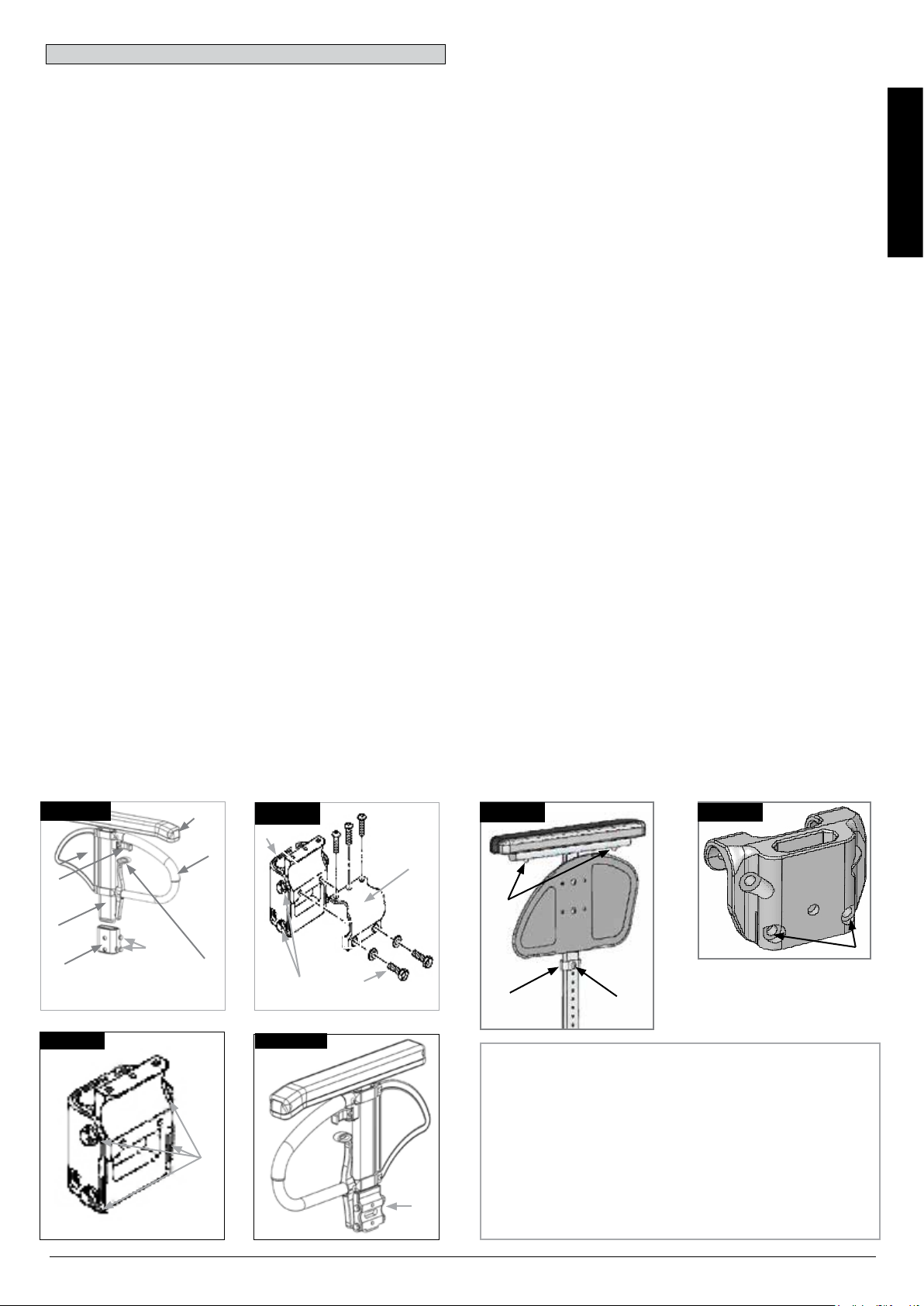

Freestyle Back

The Freestyle back can be adjusted in height, depth and angle

to provide maximum comfort and support.

Height adjustment:

Remove the back cushion to gain access to the adjustment

hardware. Loosen the 4 screws (1) using a 4 mm hex key and

move the back shell up or down to the desired height. Tighten

the screws to lock the adjustment and re-install the back

cushion.

ENGLISH

Fine Depth and Height adjustment

The Freestyle back adjustment system provides a maximum of

25 mm fine depth combined with a fine height adjustment .

Loosen the screws (2) using a 8 mm hex key and rotate the

back shell to the desired position. Tighten the screws with 20

Nm to lock the adjustment.

Angle adjustment

The Freeestyle back adjustment system allows the adjustment

of the backrest angle. Loosen the screws (3) using a 8 mm hex

key and rotate the back shell to the desired position. Tighten the

screws with 20 Nm to lock the adjustment.

Fig. 4.25

Fig. 4.27

A

Fig. 4.26

1

1

3

2

Fig. 4.28

20 Nm

In case some attendant support is required the removable push

handles can be screwed into position A.

WARNING!

Always make sure that the push handles are screwed in

completely.

WARNING!

The Freestyle back is not approved for using the wheelchair as

a seat in a car during transport.

20 Nm

16

Helium Rev.7.0

Page 17

Sideguards

Central support

Single Post Height-Adjustable Armrests

(Fig. 4.29 - 4.32).

1. Assembly

a. slide the outer armpost into the receiver mounted to the

wheelchair frame.

b. the armrest will automatically lock into place.

2. Height adjustment

a. rotate height release lever (2) to second stop.

b. slide armrest pad up or down to desired height.

c. return lever to locked position against arm post.

d. push arm pad (4) until upper arm post locks firmly into

place.

3. Removing the armrest

a. pull lever 3 and lift entire arm.

4. Replacing Armrest

a. slide armrest back into receiver until arm latches in place.

Armrest Receiver Attachment

(Fig. 4.29 - 4.32).

Adjusting Armrest Receiver Fit

To tighten or loosen the fit of the outer armpost in the receiver:

1. Loosen the four receiver adjustment bolts (9) on the sides of

the receiver.

2. With the armrest in the receiver (7), squeeze the receiver to

achieve the desired fit.

3. Tighten the four bolts (9). (16.3 Nm)

Position Adjustment

1. Loosen the two clamp bolts (10) until clamp is loose.

2. Slide armrest receiver to desired position.

3. Tighten

Installation: Slide the arm post into the receiver, located on the

wheelchair frame, until it stops

Height adjustment:

Slide the armrest post out of the receiver.

Adjust the position of the height adjustment bracket (1) by

removing the screw (2) and moving it to the desired position.

Re-fit the screw and tighten it.

Slide the arm rest post back into the receiver, (Fig. 4.32.1).

Armpad Position:

The armpad position can be adjusted by releasing the screws

(3), then moving the arm pad to the desired position. Re-tighten

the screws, (Fig. 4.32.1).

Adjusting Armrest Receiver

The tightness of the armrest receiver can be adjusted (tightened

/loosened) by means of the 2 screws (1) - (Fig. 4.32.2).

ENGLISH

Fig. 4.29

6

2

1

7

Fig. 4.31

4

Fig. 4.30

Fig. 4.32.1

Fig. 4.32.2

7

5

9

9

10

8

3

1

3

9

Fig. 4.32

9

10

1

Fig. 4.25 - 4.28 Parts key

1. Outer armpost

2. Height Release Lever

3. Release lever

4. Armrest Pad

5. Transfer bar

6. Sideguard

7. Receiver

7

8. Clamp

9. Receiver adjustment bolts

10. Clamp bolts

2

Helium Rev.7.0

17

Page 18

Push handle

Height-adjustable push handles

These handles are secured with pins to prevent them from

sliding out unintentionally. Opening the quick-release lever (1)

makes it possible to adjust the height of the push handles (2) to

meet your individual needs. As you move the lever, you will hear

a locking mechanism; you may now easily position the push

handle as desired. The nut on the tension lever determines how

tightly the push handles are clamped into place. If the nut is

ENGLISH

loose after adjusting the tension lever, the push handle will also

be too loose. Turn the push handle from side to side before use

to make sure that it is clamped securely enough into place. After

adjusting handle height, always clamp the tension lever (1)

securely into place. If the lever is not secure, injuries could result

when ascending stairs. (Fig. 4.33).

NOTE – If the height-adjustable push handles are not fitted

properly, there is a risk that these will develop "play" or that they

move out of position. Please make sure that the relevant screws

are tightened correctly.

Folding push-handles

If the push handles are not in use, they can be folded down by

depressing the button (2). When they are needed again, simply

flip them back up until they click into place. (Fig. 4.34).

2. Adjusting Anti-Tip Tubes

To achieve the correct ground clearance of approx. 1" to 2" (25

mm to 50 mm), the anti-tip tubes must be raised or lowered.

Press the anti-tip tube release button, so that both release pins

are drawn inwards. Move the inner tube up or down to slot into

the height holes provided. Release the button. Fit the second

anti-tip tube in the same way. Both wheels should be at the

same height. (Fig. 4.35).

DANGER!

Sunrise Medical Recommends Use Of Anti-Tip Tubes:

If the anti-tip tubes are not fitted, or have been fitted incorrectly,

there is a risk of tipping over and of injury.

Fig. 4.35

Fig. 4.33

Fig. 4.34

2

1

2

Anti-tip tubes

WARNING!

Sunrise Medical recommends anti-tip tubes for all chairs. When

fitting anti-tip tubes, use a torque of 7 Nm.

1. Slotting the anti-tip tubes into the clamp:

a. press the rear button on the anti-tip tube on the anti-tip tube

adaptor, so that both release pins are drawn inwards.

b. slot the anti-tip tubes (1) into the anti-tip tube adapter.

c. turn the anti-tip tubes downwards until the release pin locks

into the clamp.

d. fit the second anti-tip tubein the same way.

Active Anti-Tip tube/Flip Up

The active anti-tip tube is mounted on the left or right side of the

axle tube. By pushing it towards the axle tube, it can be flipped

downwards for operation, (Fig. 4.35.1).

WARNING!

Make sure that the anti-tip tube will lock in the final position. An

unlocked active anti-tip tube can lead to serious injury of the

user.

Fig. 4.35.1

18

Helium Rev.7.0

Page 19

Anti-tip tubes...

Pelvic Restraint Belt

Active Anti-Tip tubes For Sport

To remove the active anti-tip tubes for sport, press the button of

the quick release pin and pull it out. Now pull out the tube from

the anti-tip receiver, (4.35.2 - 4.35.3).

Fig. 4.35.2

Fig. 4.35.3

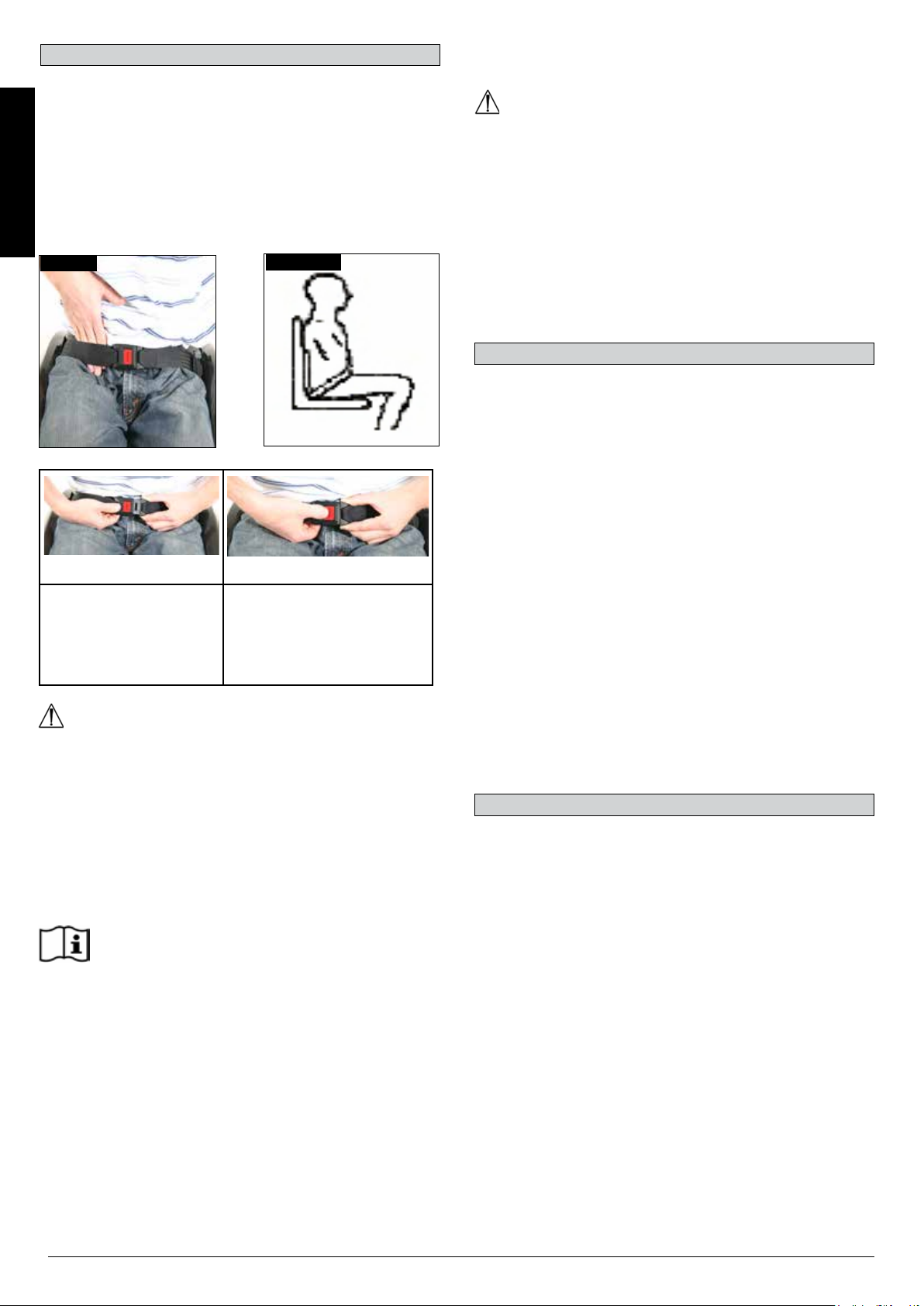

DANGER!

• Before using your wheelchair ensure the lap belt is worn.

• The lap belt must be checked on a daily

• basis to ensure it is free from any obstruction or adverse

wear.

• Always make sure that the lap strap is correctly secured

and adjusted prior to use. If the strap is too loose it could

cause the user to slip down and risk suffocation or cause

serious injury.

The lap belt is fitted to the wheelchair as shown in the

illustrations. The seat belt comprises 2 halves. They are fitted

using the existing seat stay retaining bolt fitted through the

eyelet on the belt. The belt is routed under the rear of the side

panel. (Fig. 4.36)

Adjust the belt position so buckles are in the centre of the seat.

(Fig. 4.37)

Fig. 4.36

Fig. 4.37

ENGLISH

Crutch Holder

Crutch Holder

This device permits crutches to be transported directly on a

wheelchair. It has a Velcro loop to fasten crutches or other aids.

CAUTION!

Never try to use or even remove the crutches or other aids while

moving.

Adjust lap belt to suit the user’s needs as follows:

To reduce the belt

length

Feed free belt

back through male

buckle and slide

adjusters.

Ensure belt is not

looped at male

buckle.

When fastened check space between the pelvic restraint belt

and user. When correctly adjusted it should not be possible to

insert more than the flat of the hand between the lap belt and the

user. (Fig. 4.38)

To increase the belt length

Feed free belt through slide adjusters

and male buckle to provide more belt

length.

Helium Rev.7.0

19

Page 20

Pelvic Restraint Belt...

The lap belt should be fixed so that the belt sits at an angle of 45

degrees across the user’s pelvis. The user should be upright

and be as far back as possible in the seat when correctly

adjusted. The lap belt should not allow the user to slip down in

the seat.

(Fig. 4.39)

ENGLISH

Maintenance:

Check lap belt and securing components at regular intervals for

any sign of fraying or damage. Replace if necessary.

WARNING

The lap belt should be adjusted to suit the end user as detailed

above. Sunrise Medical recommends that the length and fit of

the belt be checked on a regular basis to reduce the risk of the

end user inadvertently re-adjusting the belt to an excessive

length.

Fig. 4.38

To fasten buckle:

Firmly push male buckle

into female buckle.

Fig. 4.39

To release belt:

Press exposed sides of male

buckle and push towards

centre whilst gently pulling

apart.

5.0 Tyres and Mounting

Solid rubber tyres are standard.

With pneumatic tyres always make sure that the tyres have the

correct air pressure, as otherwise the performance of the

wheelchair may be affected. If the tyre pressure is too low, rolling

resistance will increase, requiring more effort to move the chair

forward. Low tyre pressure also has a negative impact on

manoeuverability. If the tyre pressure is too high, the tyre could

burst. The correct pressure for a given tyre is printed on the

surface of the tyre itself.

Tyres can be mounted the same way as an ordinary bicycle tyre.

Before installing a new inner tube, you should always make sure

that the base of the rim and the interior of the tyre are free of

foreign objects. Check the pressure after mounting or repairing a

tyre. It is critical to your safety and to the wheelchair’s

performance that regulation air pressure be maintained and that

tyres are in good condition.

WARNING!

• If in doubt about the use and operation of the lap belt then

ask your healthcare professional, wheelchair dealer, carer

or attendant for assistance.

• If you want to retrofit a lap belt, then please contact your

authorised Sunrise Medical dealer.

• The lap belt must be checked on a daily basis to ensure it

is adjusted correctly and free from any obstruction or

adverse wear.

• Sunrise Medical does not encourage the transportation of

any person in a vehicle using this lap belt as a method of

restraint.

Please see Sunrise Medical transit booklet for further

advice on transportation.

6.0 Maintenance and care

• Check the tyre pressure every 4 weeks. Check all tyres for

wear and damage.

• Check the brakes approximately every 4 weeks to make

sure that they are working properly and are easy to use.

• Change tyres as you would an ordinary bicycle tyre.

• All of the joints that are critical to using your wheelchair

safely are self-locking nuts. Please check every three

months to make sure that all bolts are secure (see the

section on torque). Safety nuts should only be used once

and should be replaced after use.

• Please use only mild household cleansers when your

wheelchair is dirty. Use only soap and water when cleaning

the seat upholstery.

• You should only use genuine parts approved by Sunrise

Medical. Do not use parts from other manufacturers, that

have not been by authorised by Sunrise Medical.

20

Helium Rev.7.0

Page 21

6.0 Maintenance and care...

• If your wheelchair should ever get wet, please dry it afterwards.

• A small amount of sewing-machine oil should be applied to

quick-release axles approximately every 8 weeks. Depending

on the frequency and type of use, we recommend taking your

wheelchair to your authorised dealer every 6 months to have it

inspected by trained personnel.

• If you want to store the wheelchair for a long period of time,

then no further measures are required. Make sure that the

wheelchair is stored at room temperature in a dry place which

is protected from strong sunlight. Before using it again, the

wheelchair should be checked by an authorised dealer.

CAUTION!

Sand and sea water (or salt in the winter) can damage the

bearings of the front and rear wheels. Clean the wheelchair

thoroughly after exposure.

The following parts can be removed and sent back to the

manufacturer/dealer for repair:

• Rear wheels

• Armrest

• Anti-Tip tubes

These components are available as spare parts. For further

information, please see the spare parts catalogue.

Hygiene measures when being re-used:

Prior to the wheelchair being re-used, it must be carefully

prepared. All surfaces which come into contact with the user

must be treated with a disinfection spray.

To do this, you must use a disinfectant from the DGHM list, e.g.

Antifect Liquid (Schülke & Mayr) for rapid alcohol-based

disinfection for medical products and medical devices, which

must be disinfected quickly.

Please pay attention to the manufacturer’s instructions of the

disinfectant you are using.

In general, a complete disinfection cannot be guaranteed on

seams. We therefore recommend that you dispose of seat and

back slings to avoid microbacterial contamination with active

agents according to § 6 infection protection law.

7.0 Disposal / Recycling of Materials

If the wheelchair has been made available to you free of charge,

then it does not belong to you. If it is no longer required, then

follow the instructions to return it as given by the organisation

that made the wheelchair available to you.

In the following section, there is a description of the materials

used on the wheelchair, in view of the disposal or recycling of

the wheelchair and its packaging.

Particular regulations with regard to disposal or recycling may

be in force locally and these must be taken into account when

performing disposal. (This can include the cleaning or

decontamination of the wheelchair prior to disposal).

Aluminium: Castor forks, wheels, sideguards for the chassis,

armrest frame, footrest, push handles

Steel: Fixing points, quick-release axle

Plastic: Handgrips, tube plugs, castor wheels, footplates,

armpads and 12” wheel/tyre

Packaging: Plastic bags made of soft polyethylene, cardboard

Upholstery:Woven polyester with PVC coatings and expanded

combustion modified foam.

Disposal or recycling should be done through a licensed agent

or authorised place of disposal. Alternatively your wheelchair

may be returned to your dealer for disposal.

8.0 Trouble-shooting

Wheelchair pulls to one side

• Check tyre pressure

• Check to make sure wheel turns easily (bearings, axle)

• Check the castor angle

• Check to make sure both castors are making proper contact

with the ground.

Castors begin to wobble

• Check the castor angle

• Check to make sure all bolts are secure; tighten if necessary

(see the section on torque)

• Check to make sure both castors are making proper contact

with the ground.

Wheelchair / Cross-tube assembly does not snap into

position in the seat saddle

• Chair is still new, i.e., the seat or backrest upholstery is still

very stiff. This will improve with time.

Wheelchair is difficult to fold up:

• Adjustable backrest upholstery is too stiff. Loosen it

accordingly.

Wheelchair squeaks and rattles

• Check to make sure all bolts are secure; tighten if necessary

(see the section on torque)

• Apply small amount of lubrication to spots where movable parts

come into contact with one another

Wheelchair begins to wobble

• Check angle at which castors are set

• Check tyre pressure

• Check to see if rear wheels are adjusted differently.

ENGLISH

Helium Rev.7.0

21

Page 22

9.0 Transportation

DANGER!

There is a risk of serious injury or death if this advice is ignored!

Transportation of your wheelchair within a vehicle:

A wheelchair secured in a vehicle will not provide the equivalent

level of safety and security as a vehicle seating system. We

recommend that the user transfers to the vehicle seating. It is

ENGLISH

recognised that this is not always practical for the user to be

transferred and in these circumstances where the user must be

transported whilst in the wheelchair the following advice should

be followed:

DANGER!

• Confirm that your chair is crashtest suitable (see nameplate

or crashtest bracket at the rear of the chair (Fig. I)

• Confirm that the vehicle is suitably equipped to transport a

passenger in a wheelchair, and ensure the method of

access/egress is suitable for your wheelchair type. The

vehicle should have the floor strength to take the combined

weight of the user, the wheelchair and accessories.

• Sufficient space should be available around the wheelchair

to enable clear access to attach, tighten and release the

wheelchair and occupant tie down restraints and safety

belts.

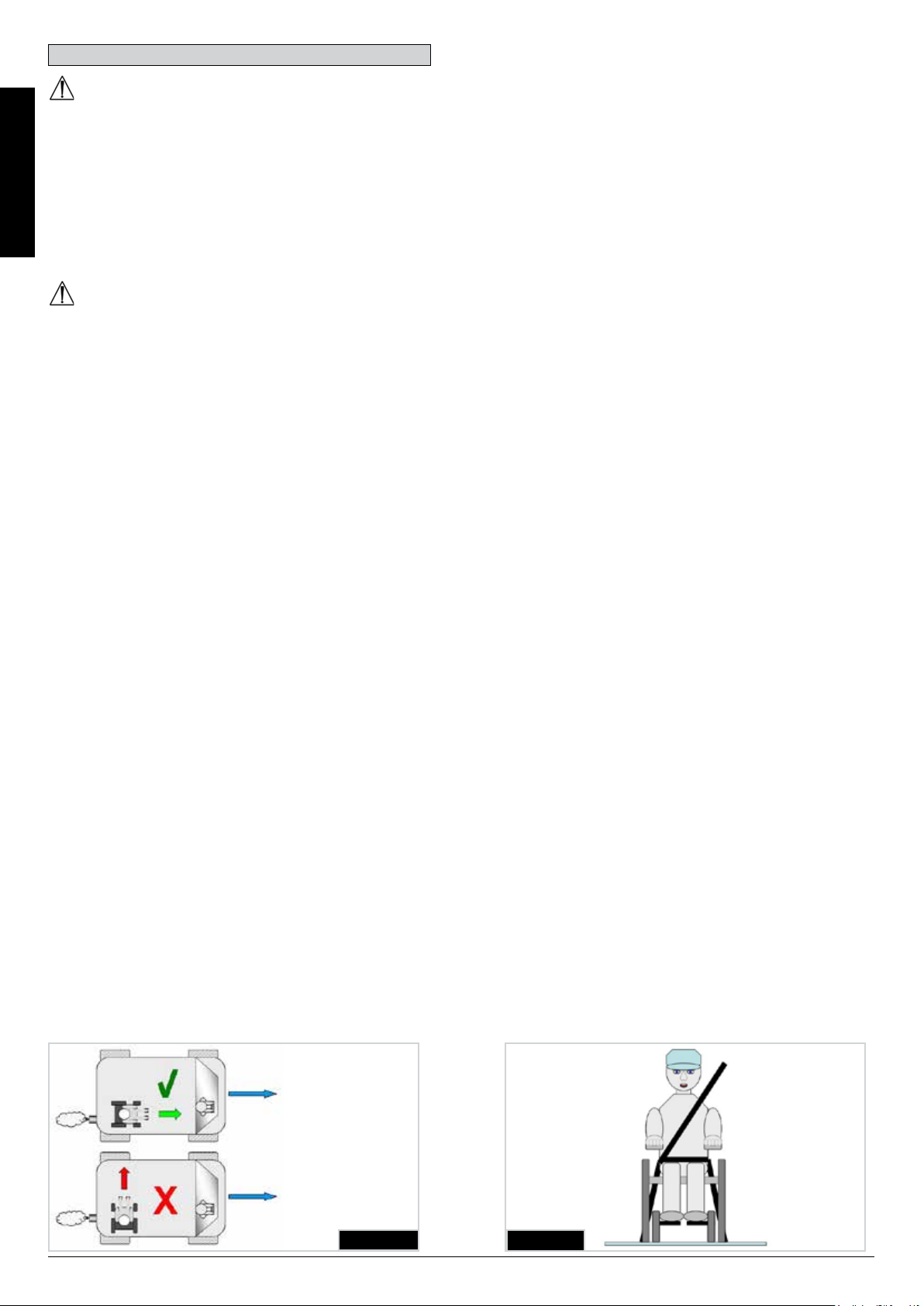

• The occupied wheelchair must be located in a forward

facing position and secured by the wheelchair tie down and

occupant restraint straps (WTORS tie downs meeting the

requirements of ISO 10542 Part 2 or SAE J2249) in

accordance with the WTORS manufacturer’s instructions.

• The wheelchair’s use in other positions within a vehicle has

not been tested e.g. transportation in a side facing position

must not be carried out under any circumstances (Fig. A).

• The wheelchair should be secured by a Tie Down Restraint

system, conforming to ISO 10542 or SAE J2249 with nonadjustable front straps and adjustable rear straps, which

typically use Karabiner clips/S hooks and tongue and

buckle fittings. These restraints generally comprise of 4

individual straps that are attached to each corner of the

wheelchair.

• The tie-down restraints should be fitted to the main frame of

the wheelchair as indicated in the diagram on the following

page, and not to any attachments or accessories, e.g. not

around the spokes of wheels, brakes or footrests.

• The tie–down restraints should be attached as close as

possible at an angle of 45 degrees and tightened securely in

accordance with the manufacturer’s instructions.

• Alterations or substitutions must not be made to the wheelchair

tie down points or to structural and frame or components

without consulting the manufacturer. Failure to do so will

invalidate the ability of a Sunrise Medical wheelchair to be

transported within a vehicle.

• Both pelvic and upper torso restraint belts must be used to

restrain the occupant to reduce the possibility of head and

chest impacts with the vehicle components and serious risk of

injury to the user and other vehicle occupants. (Fig. B) The

upper torso restraint belt should be mounted to the vehicle “B”

pillar - failure to do so will increase the risk of serious

abdominal injuries to the user.

• A head restraint suitable for transportation (see label on

headrest) must be fitted and suitably positioned at all times

during transportation.

• Postural supports (lap straps, lap belts) should not be used or

relied on for occupant restraint in a moving vehicle unless they

are labelled as meeting the requirements specified in ISO

7176-19:2001 or SAE J2249.

• The safety of the user during transportation depends upon the

diligence of the person securing the tie-down restraints and

they should have received appropriate instructions and/or

training in their use.

• Wherever possible remove and stow safely away from the

wheelchair all auxiliary equipment, for example:

• Crutches, Loose cushions and Tray Tables.

• Articulating/elevating legrest should not be used in the elevated

position when the wheelchair and user are being transported

and the wheelchair is restrained using Wheelchair Transport

and Occupant Restraints.

• Reclining backrests should be returned to an upright position.

• The manual brakes must be firmly applied.

• Restraints should be mounted to the vehicle “B” pillar and

should not be held away from the body by wheelchair

components such as armrest or wheels.

22

Fig. A

Fig. B

Helium Rev.7.0

Page 23

Transportation...

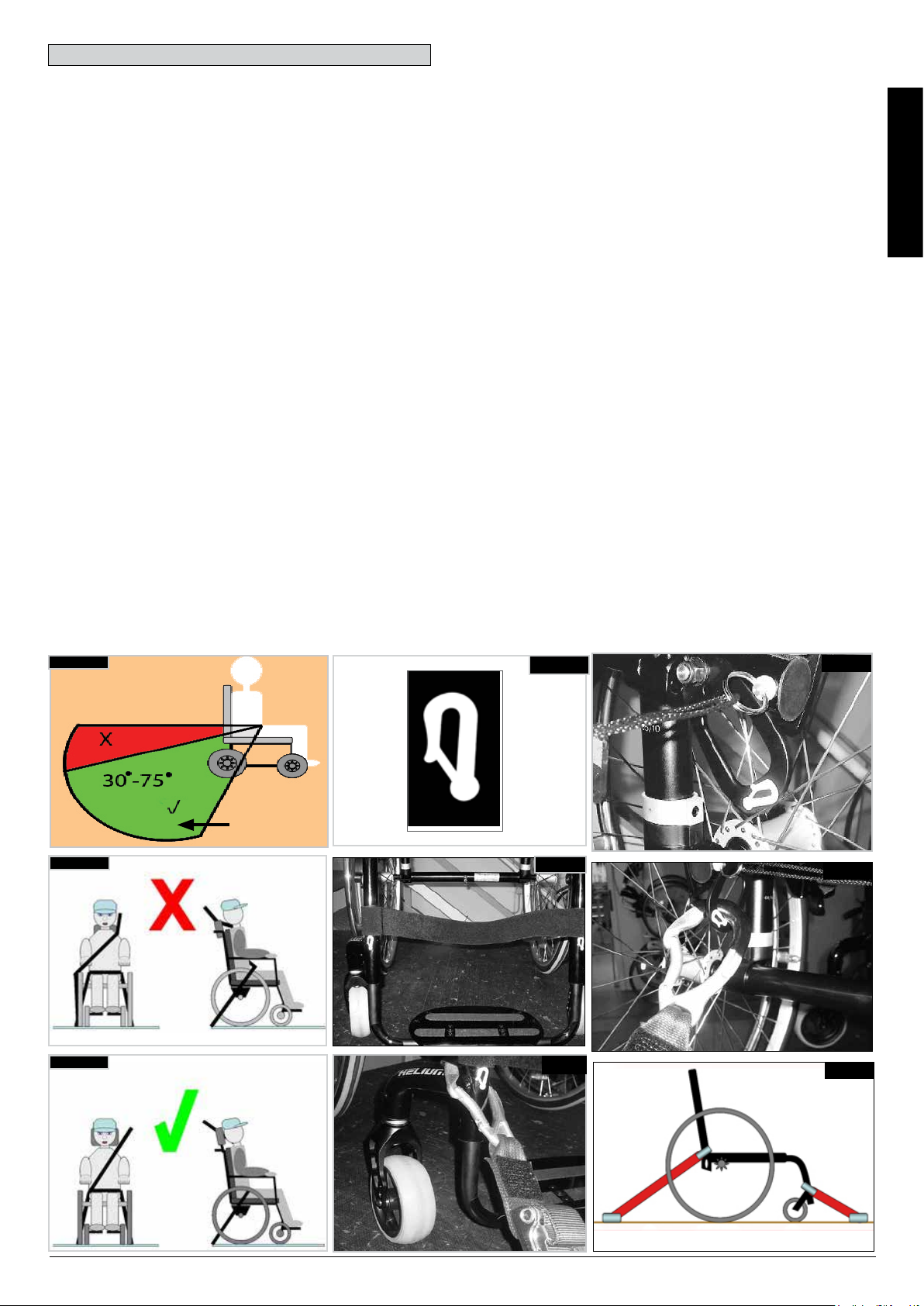

Occupant Restraints Instruction:

1. The pelvic restraint belt must be worn low across the front of

the pelvis so that the angle of the pelvic belt is within the

preferred zone of 30 to 75 degrees to the horizontal.

A steeper (greater) angle within the preferred zone is desirable

i.e. closer to, but never exceeding 75°. (Fig. C)

2. The upper torso restraint belt must fit over the shoulder and

across the chest as illustrated Fig. D and E.

Restraint belts must be adjusted as tightly as possible

consistent with user comfort.

Restraint belt webbing must not be twisted when in use.

The upper torso restraint belt must fit over the shoulder and

across the shoulder as illustrated in Fig. D and E.

3. The attachment points to the chair are the inner front side

frame just above the castor, and the rear side frame. The straps

are fitted around the side frames at the intersection of the

horizontal and vertical frame tubes. (See Figs G-H-I)

4. The tie down symbol (Fig. F) on the wheelchair frame

indicates the position of the wheelchair restraint straps. The

straps are then tensioned after the front straps have been fitted

to secure the wheelchair.

USER WEIGHT LESS THAN 22 kg

When the user being transported is a child, less than 22 kg mass

and the vehicle involved has less than eight (8) seated passengers

it is recommended that they be transferred to an UNCE Regulation

44 compliant child restraint system (CRS).

This type of restraint system provides a more effective occupant

restraint system than the conventional 3 point occupant restraint

system and some CRS systems also include additional postural

supports to assist in maintaining the position of the child when

seated.

Parents or care providers may consider the option, in some

circumstances, for their child is to remain in their wheelchair whilst

in transport due to the level of posture control and comfort

provided by the set up in the wheelchair.

We would recommend in such circumstances that a risk

assessment be carried out by your attendant and relevant

competent persons.

Positioning of wheelchair tie down restraints on wheelchair:

1. Location of the front and rear tie down labels (Fig. G - H).

2. Position of the front, (Fig. I) and rear, (Fig. J), wheelchair tie

down restraint and the tie down label.

3. Side view of tie down straps, (Fig. K).

ENGLISH

Fig. C

Fig. D

Fig. E

PREFERRED

ZONE

Fig. F

Fig. G

Fig. H

Fig. I

Fig. J

Fig. K

Helium Rev.7.0

23

Page 24

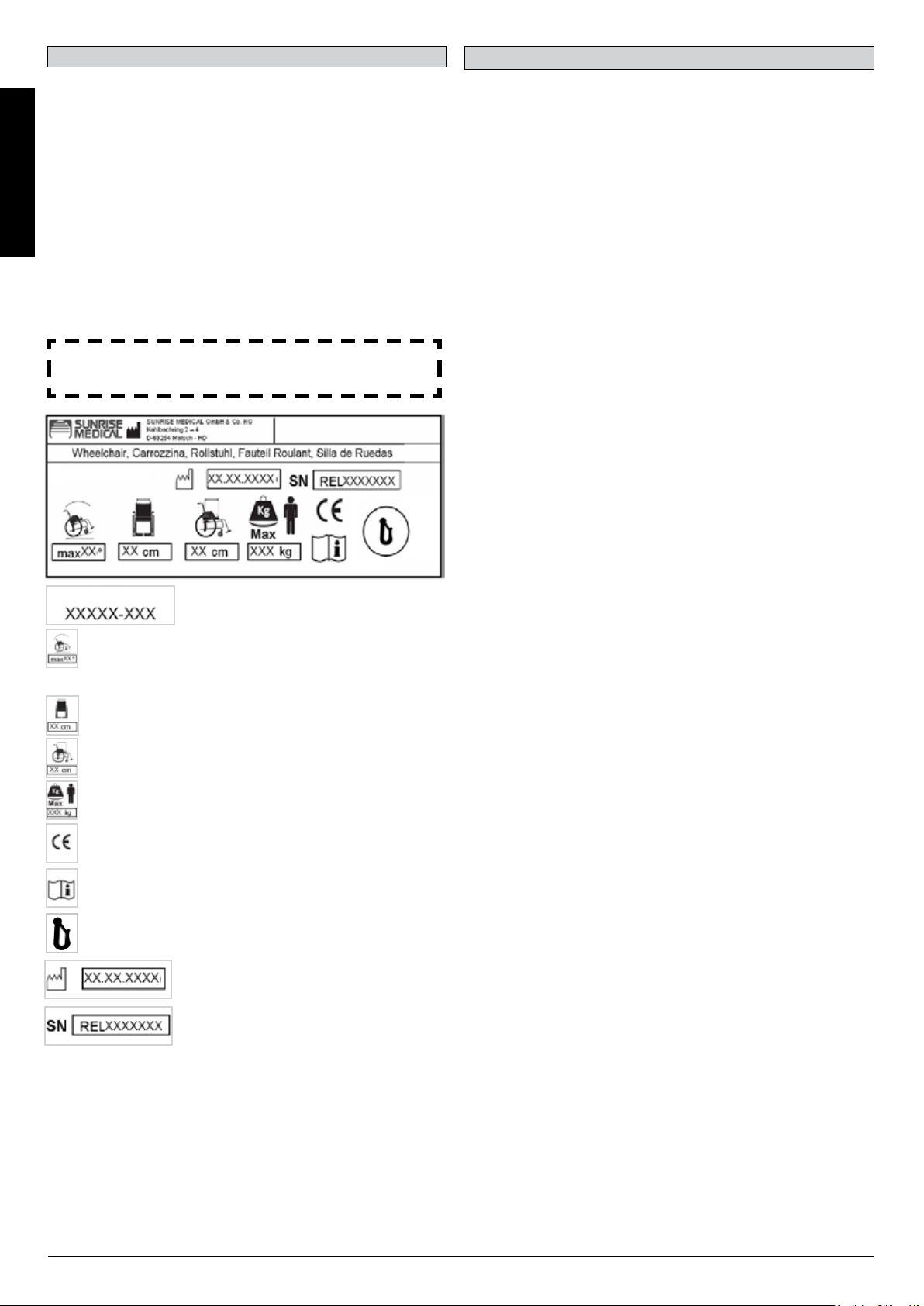

10.0 Nameplate

Name Plate

The nameplate is located on either the cross-tube assembly or

the transverse frame tube, as well as on a label in the owner’s

manual. The nameplate indicates the exact model designation

and other technical specifications. Please provide the following

pieces of information whenever you have to order replacement

parts or to file a claim:

ENGLISH

• Serial number

• Order number

• Month/Year

SAMPLE

Helium

Helium

Product Name/SKU Number.

Maximum safe slope with anti-tip tubes fitted,

Depends on wheelchair setting, posture and

physical capabilities of the user.

Seat width.

Depth (maximum).

Load Maximum.

CE Mark

11.0 Warranty

Warranty

THIS IN NO WAY AFFECTS YOUR STATUTORY RIGHTS.

Warranty conditions

1) Repair or replacement is carried out by the authorised Sunrise

Medical dealer.

2) To fulfil the guarantee conditions, should servicing need to be

carried out on your wheelchair under this agreement, contact the

designated Sunrise Medical customer service agent immediately,

with precise details on the type of difficulty. Should you be using

the wheelchair outside the area covered by the designated Sunrise

Medical customer service agent, the work will be carried out under

"guarantee conditions" by another agency as designated by the

manufacturer.

3) Should any part of the wheelchair require repair or replacement,

as a result of a specific manufacturing or material defect, within 24

months (5 years on frame and cross brace) from the date on which

the possession of the product was transferred to the original

purchaser, and subject to it remaining within that ownership, the

part or parts will be repaired or replaced completely free of charge

if returned to the authorised service agent.

Note: This guarantee is not transferable.

4) The guarantee also covers all repaired or replaced parts for the

remaining period of the guarantee for the wheelchair.

5) For spare parts which are fitted after the start of the original

guarantee, we give a further 24-month guarantee.

6) Consumable parts are normally excluded from the guarantee,

except in the case that premature wear of the part is the direct

result of a manufacturing fault. These parts include, amongst

others, upholstery, tyres, inner tubes and similar parts.

7) The above warranty conditions apply to all product parts for

models purchased at full retail price.

8) Normally we do not accept responsibility if a repair or

replacement of the wheelchair is required for one of the following

reasons:

a) The product or part has not been maintained or serviced in

accordance with the manufacturer's recommendations as shown in

the User Instructions and/or the Service Instructions. Accessories

have been used which are not specified as original accessories.

b) The wheelchair or a part of the wheelchair was damaged

through neglect, accident or improper use.

c) Alterations to the wheelchair or parts, which are not in

accordance with the manufacturer’s specifications or the carrying

out of repairs before informing the customer service agent.

24

User's Guide.

Crash Tested

Date of manufacture.

Serial number.

Helium Rev.7.0

Page 25

12.0 Technical Data

Total width:

With 25" standard wheels, incl. handrims with 6° camber: SW + 300 mm

Overall length: 910 mm with SD 48

Total height: 1120 mm with BH 45

Weight in kg: from 6.4 kg

Maximum load:

Helium 125 kg

Seat heights:

The choice of frames, forks and castors, as well as the rear wheel size (24”, 25”) determines the seat heights which can be achieved.

Norm Min. Max. Norm Min. Max.

Overall length with

footrest

Overall Width 620 mm 760 mm Effective seat depth 340 mm 480 mm

Folded length N/A N/A Effective seat width 320 mm 460 mm

Folded width N/A N/A Seat surface height at

Folded Height N/A N/A Backrest angle 59° 105°

Total Mass 6.4 kg 13.0 kg Backrest height 250 mm 450 mm

Slope for the use of

the wheel locks

Mass of the heaviest

part

Static stability

downhill

Static stability uphill

with anti-tip tubes

Static stability

sideways

Dynamic stability uphill power

consumption

770 mm 1050 mm Seat surface angle 0° 15°

front edge

0° 7° Turning radius 670 mm

- 2.1 kg with

24" rear wheel

*

10° 10° Angle from leg to seat 92° 100°

10° 10° Distance from the

10° 10° Front location of

N/A N/A Handrim diameter 540 mm 567 mm

Distance from the

footrest to the seat

armrest to the seat

armrest structure

430 mm 550 mm

220 mm 520 mm

N/A N/A

N/A N/A

ENGLISH

Overcoming

obstacles

*Standard wheel with stainless steel handrim

The wheelchair conforms to the following standards:

a) Requirements and tests for static strength, impact resistance and fatigue strength (ISO 7176-8) Yes.

b) Drive and control systems for power wheelchairs, requirements and test (ISO 7176-14) n.a.

c) Environmental test in accordance with ISO 7176-9 n.a.

d) Flammability resistance of upholstered parts in accordance with ISO 7176-16 (EN 1021-1/2) Yes.

Helium Rev.7.0

N/A N/A Horizontal location

of axle

+ 56 mm + 11 mm

25

Page 26

Technical Data >>>

Castor Fork Frame Type Front seat height

in mm

430 430 - 300

ENGLISH

low

98 mm x 32 mm

440 440- 310

450 450 - 320

470 470 - 340

high

480 480 - 350

490 490 - 360

3" (76.2 mm)

440 440 - 310

low

450 450 - 320

460 460 - 330

111 mm x 32 mm

480 480 - 350

high

490 490 - 360

500 500 - 370

440 440 - 310

low

450 450 - 320

460 460 - 330

98 mm x 32 mm

480 480 - 350

high

490 490 - 360

500 500 - 370

450 450 - 320

low

460 460 - 330

470 470 - 340

111 mm x 32 mm

490 490 - 360

high

500 500 - 370

510 510 - 380

450 450 - 320

4" (101.6 mm)

low

460 460 - 330

470 470 - 340

111 mm x 45 mm

490 490 - 360

high

500 500 - 370

510 510 - 380

450 450 - 320

460 460 - 330

low

470 470 - 340

480 480 - 350

123 mm x 45 mm

490 490 - 360

500 500 - 370

high

510 510 - 380

520 520 - 370

Rear seat height

in mm

26

Helium Rev.7.0

Page 27

Technical Data ...

Castor Fork Frame Type Front seat height

in mm

460 460 - 330

low

470 470 - 340

98 mm x 32 mm

500 500 - 370

high

510 510 - 380

460 460 - 330

low

470 470 - 340

480 480 - 350

111 mm x 32 mm

500 500 - 370

high

510 510 - 380

520 520 - 390

470 470 - 340

5" (127 mm)

low

480 480 - 350

111 mm x 45 mm

high 510 510 - 380

520 520 - 390

470 470 - 340

480 480 - 350

low

490 490 - 360

500 500 - 370

123 mm x 45 mm

510 510 - 380

520 520 - 390

high

530 530 - 400

540 540 - 410

500 500 - 370

low

510 510 - 380

6" (152.4 mm) 123 mm x 45 mm

540 540 - 410

high

550 550 - 420

Rear seat height

in mm

ENGLISH

Helium Rev.7.0

27

Page 28

13.0 Torque

ENGLISH

Torque.

20 Nm

20 Nm

NOTE: Wherever torque settings are specified, it is strongly recommended that a torque meter (not included), is used to verify correct

torque specification is achieved.

If no other information is given, the generic torque for M6 screws is 7 Nm.

CAUTION: Some of the screws that are used during manufacture are fitted with threadlock, (blue dot on the thread) and can be undone

and re-tightened up to three times before they must be replaced with new screws and threadlock. Alternatively, you can put Loctite™

243 threadlock on the screws and re-fit them.

28

Helium Rev.7.0

Page 29

Sommaire

Définitions

Sommaire 29

Définitions 29

Avant-propos 30

Utilisation 30

Champ d'application. 30

1.0 Consignes générales de sécurité et

limites de conduite 31

2.0 Manipulation 33

3.0 Transport du fauteuil 33

4.0 Options 33

Leviers de basculement 33

Freins 33

Mécanisme de suspension 35

Réglage du support d'axe pour handbike 36

Réglage du centre de gravité de l'Helium 37

Réglage du centre de gravité de l'Helium Pro 37

Réglage de la palette 38

Siège 38

Options - Snoll on 38

Roues avant 39

Alignement des roues 39

Dossier 40

Protège-vêtements 42

Poignée de poussée 43

Roulettes anti-bascule 43

Porte-canne 44

Ceinture pelvienne 44

5.0 Pneus et montage des pneus 45

6.0 Maintenance et entretien 45

7.0 Mise au rebut / Recyclage des matériaux 46

8.0 Dépannage 46

9.0 Transport 47

10.0 Plaque signalétique 49

11.0 Garantie 49

12.0 Caractéristiques techniques 50

13.0 Couple réel 53

3.1 Dénitions des termes employés dans le manuel

Terme Définition

Indication d'un risque

potentiel de blessures

DANGER !

AVERTISSEMENT !

ATTENTION !

REMARQUE :

sérieuses ou de mort en

cas de non-respect des

consignes

Indication d'un risque de

blessure en cas de nonrespect des consignes

Indication que le matériel

peut être endommagé si le

conseil fourni n'est pas suivi

Conseil d'ordre général ou

pratique recommandée

Référence faite à d'autres

manuels

FRANÇAIS

REMARQUE :

Il est possible que les fauteuils illustrés et décrits dans le

présent manuel ne soient pas complètement identiques au

modèle que vous avez acheté. Toutefois, toutes les instructions

fournies dans le présent manuel sont valables pour votre

matériel, malgré d'éventuelles différences minimes.

Le fabricant se réserve le droit de modifier sans préavis les

poids, mesures et autres données techniques indiquées dans

le présent manuel. Tous les chiffres, dimensions et capacités

indiqués dans ce manuel sont approximatifs et ne constituent

pas des caractéristiques.

Helium Rev.7.0

REMARQUE :

Il vous est conseillé de noter dans l’encadré prévu ci-dessous

les coordonnées du technicien chargé de votre service aprèsvente.

En cas de panne, contactez-le en lui donnant le plus

d’informations possible sur la nature de la panne pour qu’il

puisse vous aider efficacement et rapidement.

Tampon et signature du revendeur

29

Page 30

Avant-propos

Utilisation

Chère cliente, cher client,

Vous avez choisi un produit de SUNRISE MEDICAL de grande

qualité. Nous nous en réjouissons.

Ce manuel d’utilisation vous fournira de nombreux conseils et

suggestions de sorte que votre produit deviendra pour vous un

partenaire familier digne de confiance.

Pour Sunrise Medical, être proche de nos clients est une