Page 1

Workshop Manual

ELITE XS 3 & 4 WHEEL,

ONYX

ENGLISH

Scooters

Page 2

Page 3

ELITE XS, ONYX

WORKSHOP MANUAL

The ELITE XS range is a rear wheel drive, three or four - wheeled electric powered

scooter with pneumatic tyres, rake adjustable

tiller, upholstered seat with folding back and flip up-wid th adjust able

armrests, shopping basket, horn, battery gauges

and security key on/off switch.

Sunrise Medical is ISO 9001 certified, which ensures quality at all stages of the

development and production of this Scooter.

This product is manufactured to comply with the requirements of

EEC directives 89/336/EEC

CE

TITLE CONTENTS P AGES

Safety 1 to 2

Recommended T ools 3

Service & Inspection 4

T echnical S pecifications 5 to 7

Programme 8

Bumper, Brakes & Wheels

Front Bumper (3W). 9

Front Wheel & Brake (3W) 10 to 12

Rear Wheel Elite XS 13 to 14

Front Wheel Onyx, XL8 15

Rear Wheel Onyx, XL8 16

T yres & Tube Onyx, XL8 17 to 19

T yres & Tube Elite 20

Front Brake Elite (4W), Onyx, XL8 21 to 22

Seat, Batteries & Rear Panel

Seat Removal (All) 23

Seat Post Removal (All) 24

Seat Assembly (All) 25 to 29

Batteries & Battery Charger (All) 30 to 31

Rear Panel (All) 32

Rear Lights & Indicators 33 to 35

Rear Chassis

Brake Lever/Loom 36

Panels & Bolts 37 to 40

Transaxle 41 to 43

Suspension Struts 44

Struts/Stabilisers 45

Stabilisers/Bumper 46

Bumper/Frame 47

Main Fuse 48

Main Fuse/Fuse Panel/Programme Skt. 49

Main Control Box 50 to 51

Page 4

IMPORTANT

It is potentially hazardous to fit or use any parts other than genuine

Sunrise Medical parts.

The company disclaims all liability for the consequences of such use,

which in addition voids the machine warranty .

This scooter is for the carriage of

ONE PERSON

And must not be used for any other purpose.

ELITE XS, ONYX

WORKSHOP MANUAL

TITLE CONTENTS P AGES

Tiller Fascia Panel 52

Tiller Fascia Panel & Tiller Back Panel 53 to 54

Hand Brake & Tiller Front Panel 55

Tiller Front & Top Panel 56

Tiller Horn & Reflector 57

Tiller-Indicators-Bulbs 58

Tiller Charging Socket 59

Tiller Loom 60

Tiller Adjustment & Weld Assy. 61 to 62

Tiller Bracket 63

H’lamps, Fnt Body Panel & Main Loom

Gaiter & Front Bumper 64

Headlamp & Bulb (4-Wheel) 65 to 66

Headlamp (3-Wheel) 67

Fnt. Body Panel (4-Wheel) 68

Fnt. Body Panel (3-Wheel) 69

Main Loom 70 to 72

Front Suspension & Steering

Stub Axles 73 to 75

Steering Rods 76 to 77

Front Suspension Struts 78

Swinging Arm 79

Steering Head (4-Wheel) 80 to 81

Steering Head & Forks 82 to 83

Page 5

Page 6

SAPPHIRE

GENER AL SAFETY

Whilst working on powered mobility products, it is essential to observe good

working practice.

Below are a series of safety guidelines and recommendations.

Please note that these precautions are intended to serve only as a guide and are

not intended to supersede or replace any safety statute, NHS or other safety

regulations.

General

•

Always wear suitable protective clothing when handling batteries.

•

Always wear s u it a b le e ye protection w h e n d r illin g or inspec tin g .

•

When safe to do s o, wear p rote ctive gloves whe n h and ling the run n ing gea r

or batteries, as these parts are exposed to paths, parks etc.

•

If the drive wheels have to be raised of the floor, always use a pair of axle

stands to secure the vehicle correctly.

Batteries

All work carried out on batteries or battery boxes should demand a degree of

extra caution.

•

Always make sure that the batteries are disconnected from the vehicle before

commen cing work.

•

Always check that the battery charger is disconnected from the vehicle /

batteries before comm encing work.

•

Do not smoke.

•

Keep batteries away from all sources of ignition.

•

Do not place objects on the battery tops.

•

Always try to k e ep so m e o n e within e ar shot of your work area so that they

may come to your assistance if needed.

•

Always wear personnel protection when handling batteries including, eye /

face protection and gloves.

•

Make sure there is easy acce ss to soap and wa ter in case of acid spills.

•

Avoid touching eyes or unprotected parts of the body while working on

batteries.

•

Remember that none sealed batteries can contaminate any packaging,

housing, or boxes they may have been transported in, so handle all

packaging with care especially when disposing of.

•

If battery acid should come into contact with bare skin or clothing, be sure to

wash immediately using plenty of soap and water. If battery acid enters the

•

eyes, flush with running cold water for as long as possible while medical help

is sought.

ELITE/ONYX

SAFETY

1

Page 7

SAPPHIRE

GENERAL SAFETY

Batteries

· When the tops of batteries are exposed, take extra care when working on or around the

terminals.

· Do not allow metal tools to drop on to or touch the exposed terminals of the batteries or

other exposed connections as this could cause a short circuit, which may result in an

explosion.

· Remove personnel items of jewellery such as rings, watches, chains etc. before

commencing work on batteries. If such items were to cause short circuit whist being

worn, very serious burns would result.

· Batteries are constructed using very heavy materials, because of this it is essential that

correct lifting techniques be employed when moving batteries around. It is also

recommended that safety footwear be worn.

· When disposing of old batteries, please ensure that correct disposal procedures are

followed. Contact your local authority for their recommendations.

Battery Chargers

· Remember battery chargers are Mains Driven Units.

· Always observe all guidelines and laws relating to mains-connected installations and

equipment.

· Never operate the battery charger in wet or damp conditions.

· If you suspect that the charger has been exposed to water or excessive damp, do not

use it. Return the unit back to the dealer/supplier for inspection.

· If the battery charger is suspected of being defective or is visibly damaged, return the

unit back to the dealer for inspection.

2

ELITE/ONYX

SAFETY

Page 8

RECOMMENDED TOOLS

1. Metric socket set.

2. Imperial socket set.

3. Hexagon wrenches, (imperial & metric).

4. 3.5 - 8mm flat screwdriver.

5. No. 0 cross-head screwdriver.

6. No. 1 cross-head screwdriver.

7. No. 2 cross-head screwdriver.

8. Metric combination spanner set 5 - 25mm

9. Imperial combination spanner set 1/8 - 1”

10. Mole grips.

11. Long nose pliers.

12. Adjustable S panner .

13. Combination pliers.

14. Ciclip pliers.

15. Hammer , (small & large).

16. Soft hammer,(rubber , hide or nylon).

17. Feeler gauges, (metric & imperial).

18. St anley knife.

19. Pin punches.

20. Electric drill, (mains/battery).

21. Drill bits, (metric & imperial).

22. Hacksaw , (standard & junior).

23. T oque wrench.

24. Steel engineering rule.

25. Tape measure.

26. T yre pump.

27. Tyre pressure gauge.

28. Personal safety gear.

29. Wire strippers/cutters.

30. Tag crimper .

31. Multi-meter.

32. Battery tester.

33. Hand held electronic programmers.

34. Parts manuals & wokshop manuals.

35. Tyre levers.

3

Page 9

Service & Inspection

ANNUAL

Controller Electrical

• On/off Switch • Loom

• PCB Plug Connections • Connections

• Operation • Lights/Indicators

• Dynamic Braking

• Programmable Settings, (where applicable).

• T est Run

Drive

Batteries • Forwards

• Reverse

• Physical Inspection . • Emergency Stop

• Connections • Left Turn

• Discharge T est • Right Turn

• Up/Down Slope • Over Obstacles

• Parking Brake

Wheels & Tyres

• Wear

• Pressure, (Pneumatic Only).

• Bearings, (Where appropriate).

• Wheel Nuts

• Castors, (Where appropriate).

• Stub Axles

Motors

• Wiring

• Noise

• Connections

• Brake

• Brushes.

Chassis

• Condition, (W elded Joints etc.).

• Steering, (T wists etc.).

Upholstery / Seat

• Seat

• Back

• Arm pads

• Seat Slide Mechanism, (where fitted).

• Set Post Assy .

4

Page 10

TECHNICAL SPECIFICATIONS

maximum range* 57 km

forward speed maximum 12 km/h

reverse speed maximum 5 km/h

turning circle 115 cm

incline 1:4 (25%), max. user weight 115 kg

incline 1:5 (20%), max. user weight 150 kg

total weight (excl. batteries) 82 kg

total length 138 cm

total width 67 cm

weight heaviest part 64 kg

batteries 74 AH

weight batteries each (74 AH) 26.5 kg

adjustable seat height 48 - 55 cm

backrest height 52 cm

seat depth 43 cm

seat width 51 cm

Elite XS 3-Wheel

* Range is calculated under test conditions. Weight, terrain and weather conditions can

affect range and speed.

5

Page 11

maximum range* 57 km

forward speed maximum 12 km/h

reverse speed maximum 5 km/h

turning circle 162 cm

incline 1:4 (25%), max. user weight 115 kg

incline 1:5 (20%), max. user weight 150 kg

total weight (excl. batteries) 87 kg

total length 138 cm

total width 67 cm

weight heaviest part 69 kg

batteries 74 AH

weight batteries each (74 AH) 26.5 kg

adjustable seatheight 48 - 55 cm

backrest height 52 cm

seat depth 43 cm

seat width 51 cm

Elite XS 4-Wheel

* Range is calculated under test conditions. Weight, terrain and weather conditions can

affect range and speed.

TECHNICAL SPECIFICATIONS

6

Page 12

TECHNICAL SPECIFICATIONS

ONYX

*Range given represents test conditions. Please note that temperature,

user weight, terrain and battery capacity may affect overall performance.

Overall Length 54" / 138 cm

Overall Width 26" / 67 cm

Max.user weight 330 lbs / 150 kg / 23.5 st

Max.Gradient (1) 14 degrees - 115 kg user weight

Max.Gradient (2) 11 degrees - 150 kg user weight

Range* 24 m / 37 km

Speed 8 mph / 12 kph

T urning Radius 63" / 162 cm

Weight (excluding batteries) 190 lbs / 87 kg

Battery Capacity 50 AH

Adjustable seat height 19" - 23" / 48 cm - 58 cm

Front wheel diameter 12" / 31 cm

Rear wheel diameter 12" / 31 cm

7

Page 13

Function Fast Slow 8kph 6kph

Forward acceleration 25 25

Forward deceleration 15 15

Reverse acceleration 20 20

Reverse deceleration 20 20

Forward speed with 2K5 resistor 100 100 66 50

Reverse speed 35 35

Invert throttle polarity yes

Power down timer 0 m

Accessible only with SP1b v2.2

Current limit 1 10A 1 10A

Motor compensation 60m&! 60m&!

Hold factor/hold comp 180% 180%

Mid current 0s

mid time 0%

Brake time 15

ISO tests on **

Bridge hold time 20

Throttle gain 100

Pulse reverse alarm yes

Wig-wag throttle yes

Low battery flash inhibit yes

Soft stop yes

Throttle deadband 10%

Output voltage 25V

Trucharge cable resist ance 40m&!

Trucharge cal 100

Max charge amps 30

Min charge amps *

Accessible only with SP1e To p Bottom

Profile 1 80

PROGRAMME FOR ELITE, ONYX

Accessible with SP1

8

Page 14

ELITE-ONYX

FRONT BUMPER ELITE XS (3W)

1. The front bumper is secured at

each end by two hex stud bolts.

2. The nuts are between the outer

chassis member and the edge of the

foot board.

3. Use a 10.00mm open spanner and

a 5.00mm hex key , to undo the bolts.

4. Remove all four bolts.

5. Finally , remove the bumper.

6. Note that the bumper has a smooth

curved profile on the top surface and

an angled profile underneath.

9

Page 15

ELITE-ONYX

FRONT WHEEL/BRAKE ELITE XS (3W)

1. With the bumper removed it is

easier to access the front brake.

2. Use a 4.00mm hex driver to release

the brake anchor stud.

3. The Brake Anchor Stud & W ashers. 4. Turn the brake adjuster and locking

wheel to align their slots with the slot

in the bracket.

5. Pull the brake cable cap out of the

adjuster.

6. Drop the cable through the slots.

10

Page 16

ELITE-ONYX

11

FRONT WHEEL/BRAKE ELITE XS (3W)

7. Free the cable & it’s spring from

the bracket.

8. Aline the cable with the slot in the

actuator lever.

9. Pull the brake cable & nipple out of

the actuator lever.

10. Use a 10.00mm cranked hex key

to loosen the front axle.

1 1. Use a 19.00mm. socket to secure

the other end of the front axle.

12. Once the axle is loosened, jack the

front wheel up until it clears the floor.

Page 17

ELITE-ONYX

12

FRONT WHEEL/BRAKE ELITE XS (3W)

13. Undo the dome nut and washer

using finger pressure.

14. Turn the other side ant-clockwise

and pull the axle slowly out.

15. Be careful not to lose the two shim

washers as the axle retreats through

the wheel.

16. Remove the large spacer as the

axle withdraws from the wheel and

fork.

17. With the axle removed, lift the

front wheel clear of the forks.

18. Lift the brake assembly out from

the centre of the wheel.

Page 18

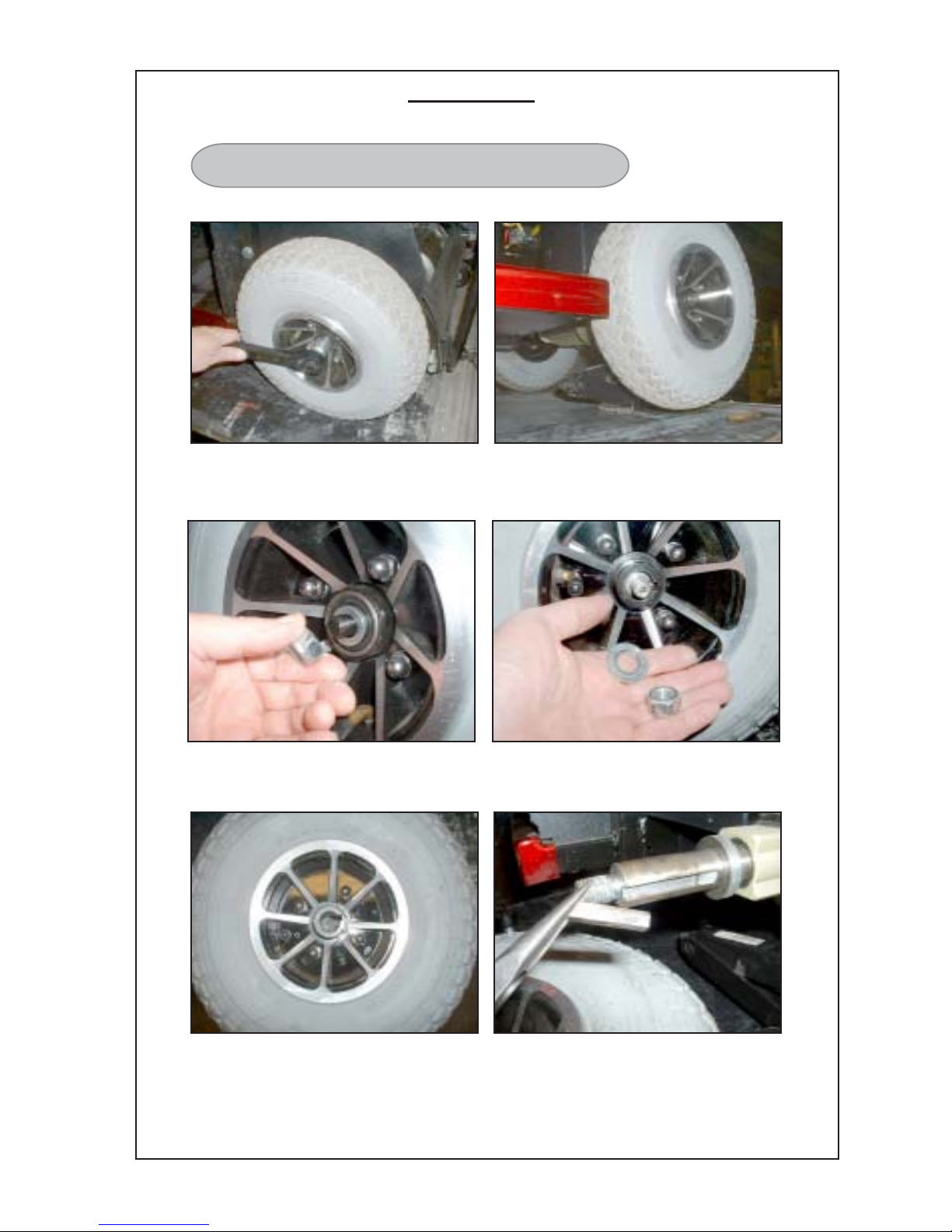

ELITE-ONYX

REAR WHEELS ELITE XS

1. Use a small flat-blade screw driver

to get under the hub cap tag.

2. Carefully prize the hub cap off.

3. Use a 19.00mm socket to loosen

the hub nut.

4. Use a jack or blocks to lift the rear

wheel. Note that the jack should only

be placed under the chassis box

sections, not the flat panels.

5. Use the socket with hand pressure,

to undo the hub nut fully .

6. Remove the hub nut.

13

Page 19

ELITE-ONYX

REAR WHEELS ELITE XS

7. Remove the large washer.

8. Because the rear wheel is keyed to

the drive shaft, a small ammount of

force may be carefully applied to

loosen the wheel.

9. Remove the wheel. 10. Remove the drive key .

1 1. Remove the spacer . Note that

there is a rebate cut into the end of the

inside face of the spacer .

12. The locating circlip that the spacer

rebate encloses. This circlip correctly

positions the rear wheel on the drive

shaft.

14

Page 20

ELITE-ONYX

15

FRONT WHEELS ONYX

1. View of the front wheel.

2. With the wheel on the ground, use

a 19.00mm socket to loosen the

centre self-locking nut

3. Once the centre nut is loosened,

raise the wheel using a jack or axle

stands/blocks.

4. Remove the centre nut using finger

pressure only .

5. Remove the washer.

6. Carefully remove the wheel.

Page 21

ELITE-ONYX

16

REAR WHEELS ONYX

1. Using a 19.00mm socket, loosen

the rear wheel while it is still on the

ground.

2. Use a jack or axle stands/blocks, to

elevate the wheel.

3. Use finger pressure to remove the

centre nut.

4. Remove the nut and washer.

5. Note that there is a key way cut in

the centre of the rear wheel.

6. Remove the corresponding key

from the drive shaft.

Page 22

ELITE-ONYX

17

TYRES & TUBES ONYX

1. Remove the dust cap from the tyre

valve.

2. Depress the valve pin. T o release

as much of the air as possible,

squeeze the tyre.

3. Using a soft face hammer , carefully

tap around the circumference of the

back of the tyre.

4. Then tap around the front. This

action helps to break the seal on the

rims to aid removal.

5. The front face of the wheel has

4-dome nuts securing the hub.

6. The rear face of the wheel has 4 corresponding captured studs.

Page 23

ELITE-ONYX

18

TYRES & TUBES ONYX

7. With the air out, loosen the four hub

nuts using the opposites sequence,

but don’t take them off.

8. Once the hub nuts are loosened,

use the socket shaft and finger pressure to fully remove them.

9. Remove the hub nuts.

10. Remove the washers.

1 1. Turn the wheel over . 12. Lift the hub away from the rims.

Page 24

ELITE-ONYX

19

TYRES & TUBES ONYX

13. Lift the inner rim away from the

tyre. A non-corrosive release agent

will help.

14. Turn the wheel over and repeat for

the outer rim. Note; Be careful if using

metal tyre levers as excessive force

on the rim edge may cause fracture.

15. With the rims removed, reach into

the tyre and gently pull the tube out.

16. The Hub, Hub Nuts, W ashers and

Centre Wheel nut.

17. The Outer & Inner Rims.

18. The Tyre & T ube.

Page 25

ELITE-ONYX

TYRES & TUBES ELITE XS

1. The five rim studs are accessed

from the back of the wheel.

The Elite XS has different types of wheel rims to the Onyx. The outer rim has

an integrated hub, but the basic process is the same.

2. Remove the valve dust cap and deflate the tyre as previously described.

3. Squeeze as much of the air out of

the tyre as is possible. At this st age,

use a non-corrosive releasing agent

between the tyre & rim.

4. Remove the five recessed rim

studs using a 4.00 mm hex key/driver.

5. Remove the inner rim from the tyre.

6. Lift the outer rim from the tyre & proceed as before to remove the tube. Note

that the outer rim has an integrated hub.

20

Page 26

ELITE-ONYX

21

FRONT BRAKE ELITE XS(4) & ONYX

1. With the wheel removed the front

brake can be accessed.

2. Locate the brake actuator lever.

3. Push the brake actuator lever, so

that it releases the tension on the

cable.

4. Push the Nipple on the end of the brake

cable, out of the actuator lever.

5. Carefully turn the brake adjuster

until the slots line up with the slot in

the bracket.

6. Release the end of the brake cable.

Page 27

ELITE-ONYX

22

FRONT BRAKE ELITE XS(4) & ONYX

7. The brake assembly is secured by

two bolts either side. The nuts are

visible from the front.

8. The bolt heads are accessed from

behind the brake assembly .

9. Use a 13.00mm open spanner on

the nuts.

10. Use a 13.00mm ring spanner on

the bolt heads.

1 1. Access is easier if the fingers are

used when the nuts are loose enough

to remove. Repeat for the other side.

12. Finally , remove the brake assembly

from the stub axle.

Page 28

ELITE-ONYX

23

SEAT ASSEMBLY REMOVAL ELITE XS & ONYX

The seat removal process is the same for the Onyx and the Elite XS seats.

1. Lift the armrests up. 2. Pull the backrest lever up.

3. Fold the backrest forward.

4. Stand behind the seat, lif t the seat

swivel lever up and lift the seat off the

seat post.

5. The complete seat assembly

removed.

Page 29

ELITE-ONYX

SEAT POST REMOVAL ELITE XS & ONYX

2. Remove the seat and rear panel to

access the seat post bolt, (see previous

and next page).

1. The seat post in situ.

3. Use two 17.00 mm spanners to

loosen the seat post bolt.

4. T ake the nut and washer of f using

finger pressure.

5. Hold the top of the seat stem to

prevent it from falling when the bolt is

withdrawn.

6. Lift the seat stem out. Note the

height positioning holes in the seat

stem.

24

Page 30

ELITE-ONYX

25

SEAT ASSEMBLY ELITE XS & ONYX

1. Turn the seat over to access the two

armrest width adjuster knobs.

2. Loosen both knobs.

3. Withdraw the armrests.

4. There are four nuts securing the

seat plate assembly .

5. Use a 13.00 mm socket to undo the

four seat plate securing nuts.

6. Lift the seat plate assembly off the

four seat rail studs.

Page 31

ELITE-ONYX

SEAT ASSEMBLY ELITE XS & ONYX

7. The seat plate assembly removed.

8. There are four hex bolts securing

the two seat rails top and bottom.

9. Slide the seat rails forward to

expose the bottom bolts and use a

5.00 mm hex key to undo them.

10. Depress the seat slide and slide

the rail back to expose the top two

bolts. Note that the other rail slides

freely .

1 1. Undo the top two bolts.

12. Lift the seat rails off the seat

assembly .

26

Page 32

ELITE-ONYX

27

SEAT ASSEMBLY ELITE XS & ONYX

CAUTION!

The seat swivel lever assembly uses a strong locating spring. When

working on this assembly , always wear suitable eye protection.

13. The seat swivel lever showing the

position of the spring.

14. For safety , use a strong tie wrap to

secure the spring as shown above.

15. Use a second tie wrap, adjusted

slightly looser to catch the spring if it

flies up.

16. Use a 5.00 mm hex key and a

13.00 mm socket, to undo the fulcrum

nut.

17. Carefully remove the fulcrum bolt.

18. With the fulcrum bolt removed, cut

the first tie wrap.

Page 33

ELITE-ONYX

SEAT ASSEMBLY ELITE XS & ONYX

19. Lift up the lever to relieve the

spring pressure and then cut the

second tie wrap.

20. Remove the spring by pulling the

two coiled sections off the lever fulcrum.

21. The lever & spring assembly .

22. The lever can be fitted to either

side of the seat plate, providing left or

right-hand operation.

23. The lever & spring showing the

correct orientation of the spring ready

for refitting.

24. Squeeze the two ends of the

spring into the two holes whilst holding

the lever vertically . The angled end of

the lever should face away from the

seat post.

28

Page 34

ELITE-ONYX

SEAT ASSEMBLY ELITE XS & ONYX

25. Ease the lever down so that the

fulcrum lines up with the pressing on

the seat plate. Use a screwdriver to

line up the holes.

26. Hold the lever steady and insert the

fulcrum bolt.

27. Drive the bolt through the fulcrum

using a hex driver.

28. Tighten the nut & bolt, but do not

over-tighten.

29. The angle on the lever head

should be facing downwards, towards

the seat plate.

30. Operate the lever several times to

ensure it does not stick. If it is stiff,

loosen the fulcrum nut and bolt slightly

until a smooth action is obtained.

29

Page 35

ELITE-ONYX

BATTERIES & CHARGER ELITE XS & ONYX

1. Unlock the boot using the ignition

key .

2. Lift out the battery charger and cords.

3. Lift up the two plastic battery cover

clips.

4. Carefully lift the rear panel tags out

of the two location slots in the floor

panel.

5. Pull the panel forwards. 6. Finally , lift the panel away from the

scooter.

30

Page 36

ELITE-ONYX

31

BATTERIES & CHARGER ELITE XS & ONYX

7. The two batteries. Note that the

battery size is 50A/h on the Onyx &

74A/h on the Elite.

8. Disconnect the two Anderson

battery connectors.

9. Undo each of the velcro retaining

straps.

10. Use the correct lifting technique to

remove the batteries.

1 1. Remove the batteries one at a time.

12. The battery compartment.

Page 37

ELITE-ONYX

32

REAR PANEL REMOVAL ELITE XS & ONYX

1. Unscrew the Parking Brake knob.

2. The rear panel is held in place by

two screws.

3. Remove the two screws.

4. Lift the front of the panel up to

access the rear lighting loom plugs.

5. Unplug the rear lighting loom.

6. Lift the panel clear of the scooter .

Page 38

ELITE-ONYX

33

REAR LIGHTS & INDICATORS ELITE XS & ONYX

1. Remove the rear panel as described earlier.

2. Flip the pane up to expose the

underside and loom.

3. Cut the small tie wrap located on

the bottom of the storage compartment.

4. Cut the next tie wrap situated just

below the first.

5. Cut the tie wrap next to the right

hand light cluster.

6. Cut the tie wrap next to the left hand

cluster.

Page 39

ELITE-ONYX

34

REAR LIGHTS & INDICATORS ELITE XS & ONYX

7. The two rubber bulb holders at the

back of the light cluster.

8. T wist and turn the holder to remove

it from the back of the light cluster.

9. Carefully pull the bulb out of the

holder. All rear bulbs are 24V - 5W

Capless type.

10. Both bulb holders removed.

1 1. The rear lighting loom removed. 12. View of the flexi-clip on the light-

ing cluster body ..

Page 40

ELITE-ONYX

REAR LIGHTS & INDICATORS ELITE XS & ONYX

13. Use a flat blade screwdriver to

gently prise the flexi-clip through the

panel.

14. Lift the light cluster part way out.

15. Withdraw the light cluster taking

care not to break the straight locating

tab.

35

Page 41

ELITE-ONYX

REAR CHASSIS - BRAKE LEVER/LOOM

1. The brake lever is secured to the

motor brake handle.

2. Use an 8.00mm socket & X-head

screw driver to undo the nut and bolt.

3. Lift the brake lever out of the bottom

mount.

4. Slide the top of the brake lever out

the “P” clip.

5. Unplug the small white molex plug.

6. Unplug the main motor loom plug

from main control box.

36

Page 42

REAR CHASSIS - PANELS & CHASSIS BOLTS

1. Undo the two screws on the rear

splash panel.

2. Remove the splash panel.

3. Repeat for the other side. Note that

the upper screws are larger than the

lower screws.

4. Remove the rear wheel as previously

described.

5. This exposes the rear wheel back

panel.

6. Undo the screws.

37

ELITE-ONYX

Page 43

ELITE -ONYX

REAR CHASSIS - PANELS & CHASSIS BOLTS

7. Loosen the nut and bolt but do not

remove it yet.

8. It is a good idea to place the screws

back into the frame for safe keeping.

9. There are two bolts found at each

side of the rear frame.

10. Use a 17.00mm socket & spanner

to remove the nuts.

1 1. Note that the bolt will not normally

come out of the frame using the

socket.

12. Use a soft faced hammer to carefully tap the bolts through the frame.

38

Page 44

ELITE-ONYX

REAR CHASSIS - PANELS & CHASSIS BOLTS

13. Be aware that there is a washer

between the left & right, rear chassis

struts.

14. The top chassis bolt.

15. Use a 10.00mm hex key &

19.00mm spanner , to undo and

remove the top bolt.

16. Carefully pull the drive assembly

away from the main chassis.

17. Retrieve the washers & don’t

forget to fit them back when reassembling the scooter.

18. Place the drive assembly on a work

bench for easier access.

39

Page 45

ELITE-ONYX

REAR CHASSIS - PANELS & CHASSIS BOLTS

19. Lift the splash panels out of the

bottom bolts taking care not to break

the slots.

20. Remove the two self-tapping

screws from the rear valance.

21. Remove the rear valance by

carefully feeding the brake release

lever through the slot in the valence.

22. It’s a good idea to put the screws

back in the frame for safe keeping.

23. There are four , transaxle mounting

bolts. T wo on the left hand side.

24. T wo on the right hand side.

40

Page 46

ELITE-ONYX

REAR CHASSIS - TRANSAXLE

1. View of the four nylok transaxle

securing nuts, located on top of the

assembly.

2. View of the four transaxle securing

studs, located under the assembly .

3. For easy access to the nuts &

studs, turn the drive assembly so that

it rests on the stabiliser wheels.

4. Use a 13.00mm socket & 6.00mm

hex key to loosen the studs, but do not

remove them yet.

5. Repeat for the lower stud. 6. Turn the drive assembly around to

access the other set of studs.

41

Page 47

ELITE-ONYX

REAR CHASSIS - TRANSAXLE

7. Repeat for the upper stud. 8. And finally , the lower stud.

9. Remove the nuts using finger pressure.

10. Don’t forget to remove the washers also.

1 1. Some studs may drop out of the

frame quite easily .

12. Some studs may require tapping

out with a soft face hammer .

Caution! The transaxle may suddenly move when the studs are removed. Ensure that the drive assembly is in a stable work area and that

your fingers are clear of the frame & work top.

42

Page 48

ELITE-ONYX

REAR CHASSIS - TRANSAXLE

13. Lift the “U” brackets off the

transaxle.

14. Carefully lift the transaxle out of the

drive assembly frame.

Caution! The transaxle is heavy. Use proper lifting techniques. When

resting the transaxle on the bench, be sure that fingers & thumbs are

clear of the assembly .

15. Remove the spacers.

16. Note that two of the transaxle

mounting studs cannot be removed at

this stage, due to a clash with the

suspension struts.

17. The transaxle removed from the

drive assembly frame.

18. It is a good idea to put the studs/

brackets back onto the frame for safe

keeping.

43

Page 49

ELITE-ONYX

REAR CHASSIS - SUSPENSION STRUTS

1. The two rear suspension struts.

2. The struts are adjustable by turning

the large adjustment wheel with mole

grips. Both struts must be evenly

tensioned.

3. The struts are secured by two

concentric studs. Use two 5.00mm

hex keys/drivers, to undo them.

4. Repeat the process for the top studs.

5. Note the use of thread-lock on the

inner concentric studs.

6. Withdraw the outer concentric stud.

This process can be carried out with the transxle still in place, if required.

44

Page 50

ELITE-ONYX

REAR CHASSIS - STRUTS & STABILISERS

7. Drop the strut out of the top mounting.

8. Remove the lower concentric stud.

9. Lift the suspension strut out of the

frame, (the transaxle stud described

previously , can now be removed).

10. The stabiliser wheels are secured

by a nylok nut.

1 1. Use 8.00mm hex key ........

12. and a 17.00mm socket to undo the

axle studs.

45

Page 51

ELITE-ONYX

REAR CHASSIS - STABILISERS & BUMPER

13. Remove the nut. 14. Slide the stabiliser wheel off the

axle stud.

15. Slide the spacer off the axle stud. 16. Withdraw the axle stud from the

frame. Repeat the process for the

other stabiliser .

17. The rear bumper is secured by the

stabiliser axle studs, (that have just

been removed), and a further two

studs.

18. Use the 8.00mm hex key and

17.00mm socket to undo these studs.

46

Page 52

ELITE-ONYX

REAR CHASSIS - BUMPER & FRAME

19. Remove the studs on both sides. 20. Lift the bumper off.

21. Use a 17.00mm socket and a

13.00mm spanner , to undo the rear

frame pivot bolts.

22. T ake extra care when loosening/

removing the pivot bolts as the frame

can drop down suddenly .

23. Lift the two halves of the frame

apart.

24. The two halves of the rear frame.

47

Page 53

ELITE-ONYX

MAIN FUSE

1. Disconnect & remove the batteries

to expose the main 150A fuse holder .

2. Be careful when removing the

plastic fuse cover as it is easy to

break the four locating lugs.

3. Use an 8.00mm socket/spanner to

undo the fuse ring-tag connectors.

4. Remove the ring tags.

5. The main fuse is held on the two

studs.

6. Use fingers to remove the main fuse.

48

Page 54

ELITE-ONYX

MAIN FUSE, FUSE PANEL & PROGRAM SKT.

7. The main 150A fuse and cover.

8. Fuses for the lights, indicators, front

remote control and battery charger, are

located under the black plastic cover.

9. Carefully unclip the cover and

remove it to access the fuses.

10. There are six blade fuses in total,

each have the rating in amps marked

on the body .

1 1. T o remove the fuse, carefully pull

the body using finger force only ,

(not pliers). always replace fuses with

the correct value and type.

12. The programming socket is located

next to the fuse panel on the Elite only .

The Onyx is programmed directly into the

Egis main control box.

49

Page 55

ELITE-ONYX

MAIN CONTROL BOX

1. The main control box is located

behind the fuse panel.

2. Disconnect the main loom plug.

3. Remember to squeeze the locking

tab to release the plug. Be careful not

to pull the wires.

4. Release the square molex programming plug next.

5. Use the locking tag to release the

programming plug.

6. Finally , squeeze the end tabs to

release the power & motor looms.

50

Page 56

ELITE-ONYX

MAIN CONTROL BOX

7. The main control box is secured by

two screws located in a recess at

each side.

8. Use a cross-head screwdriver to

undo the screws.

9. Be careful when withdrawing the

screws as white compound may cover

the ends of the thread.

10. Carefully pull the main control box

away from the rear of the fuse panel

plate.

1 1. The rear of the main control box is coated with sticky white heatsink compound.

Avoid contact with the skin and clothing.

It is important that more heatsink compound is applied when fitting a new main control box.

The heatsink compound is available from electronics stockists, ( RS Components, Maplin).

51

Page 57

ELITE-ONYX

TILLER FASCIA PANEL

1. Carefully lift the base of the T iller

Fascia Panel using a flat blade

screwdriver. It is a push fit.

2. Lift the fascia up to expose the

plugs on the underside.

3. Locate the large white molex plug.

4. Press the plastic catch on the plug

to remove it from the PCB.

5. Next, locate the smaller white and

orange plugs.

6. Press the catch down on these two

plugs to remove them from the PCB.

52

Page 58

ELITE-ONYX

TILLER FASCIA PANEL & TILLER BACK PANEL

7. Remove the two plugs.

8. Use the same procedure to remove the blue plug.

9. When the plugs are disconnected,

remove the fascia and store it in a

safe place for reuse, or fit new one.

10. Location of tiller back panel screws.

1 1. Unscrew the Tiller Adjust Handle &

remove it.

12. Undo the six screws in the tiller

back panel.

53

Page 59

ELITE-ONYX

TILLER BACK PANEL

13. Lift away the tiller back panel to

expose the looms behind it.

14. Unclip and disconnect the orange

plug.

15. Do the same with the green plug.

16. Finally , unclip and disconnect the

white plug.

17. Remove the tiller back panel.

54

Page 60

ELITE-ONYX

HAND BRAKE & TILLER FRONT PANEL

1. Loosen the hand brake, but do not

remove it yet.

2. Squeeze the hand brake, grab the

brake cable, let the brake handle go

and at the same time pull firmly on the

cable.

3. The brake cable should pop out of

the location groove.

4. It may be easier to rotate the hand

brake to gain access to the cable

retaining rebate.

5. Release the brake nipple from the

handle.

6. Feed the brake cable back through

the hole in the tiller front panel. Remove the Handbrake if required.

55

Page 61

ELITE-ONYX

TILLER FRONT & TOP PANEL

1. Undo the two Basket Bracket

screws.

2. Remove the Basket Bracket.

3. Undo the two Tiller T op Panel

screws.

4. Withdraw the Tiller T op Panel.

5. Make sure all of the remaining plugs

are disconnected & remove the Tiller

Front Panel.

6. The three tiller panels removed.

56

Page 62

ELITE-ONYX

TILLER - HORN & REFLECTOR

1. The Horn or Audible Warning Device, (AWD), is located on the T iller

Front Panel.

2. The horn, (AWD), is secured by one

of the Reflector fixing screws.

3. Undo the screw to remove the Horn,

(AWD).

4. Undo the remaining three screws.

5. Lift the Reflector off the mounting

posts.

6. The AWD & Reflector .

Note that the longer screw secures the horn.

57

Page 63

ELITE-ONYX

TILLER - INDICATORS - BULBS

1. The front Indicators are retained by

plastic clips on the Tiller Front Panel.

2. There are two retaining clips per

indicator, acting as a bayonet fixing.

3. T o release the Indicator unit, twist

the indicator body untill the clips align

with the square cut out section.

4. Feed the whole assembly through

the cut out in the panel.

5. The bulb holder is a push-fit, simply

pull it out from the lense.

6. The bulb is also a push-fit, to release it, carefully pull on the glass

bulb. 24V 5W Capless.

58

Page 64

ELITE-ONYX

TILLER - CHARGING SOCKET

1. The Charging Socket is located on

the front of the Tiller Front Panel.

2. Slide the socket cover over to the

side to expose the two mounting

screws for removal.

3. The sprung cover screw is located

at the back of the socket, unscrew this

with care as it could pop out suddenly .

4. Carefully remove the Charging

Socket from the front of the panel.

5. Be careful not to lose the tiny spring. 6. The Charging Socket and screw .

59

Page 65

ELITE-ONYX

TILLER LOOM.

1. Unclip the metal cable tag located

half way up the Tiller stem.

2. Undo the Rubber Gaiter securing

screw.

3. Carefully roll the rubber gaiter back

to expose the tiller bracket.

4. Note that the lower cable tag holds

the loom clear of the mobile joint.

5. Release the cable tag. 6. Check the cables for chaffing or splits.

60

Page 66

ELITE-ONYX

TILLER ADJUSTMENT & WELD ASSY.

1. Use 6.0mm Hex key to partially

undo the top cylinder mounting studs.

2. With the studs still together but

screwed almost out, gently tap the

standard stud to push through the

sleeved stud.

3. Remove the standard stud and

carefully lower the cylinder. Remove

the sleeved stud.

4. The lower cylinder bracket.

5. The lower cylinder bracket requires

a 12.0mm and a 10.0mm spanner /

socket to undo it.

6. Lift the Cylinder T iller Adjuster away .

61

Page 67

ELITE-ONYX

TILLER ADJUSTMENT & WELD ASSY.

7. Unclip any remaining loom ties.

8. Unplug any remaining connectors.

9. Move the cables clear of the Tiller

Bracket.

10. Use a 12.0mm socket & 10.0mm

spanner to undo the T iller Bracket

bolts.

1 1. Carefully lift the T iller Weld Assembly out of the Tiller Bracket.

12. Remove the Tiller W eld Assy .

62

Page 68

ELITE-ONYX

TILLER BRACKET

1. Unplug any remaining connectors

that may be under the rubber gaiter.

2. Remove any disconnected looms.

3. Clear the remaining looms out of

the way to expose the Tiller Bracket

Fixing Stud.

4. Use a 13.0mm socket to undo the

stud, but be aware that the steering

may turn onto the steering stop.

5. Lift the T iller Bracket out from the

Steering Head.

6. Note the serrations at the bottom of

the bracket assy . When refitting the

bracket, ensure the steering is

aligned parallel and straight ahead.

63

Page 69

ELITE-ONYX

GAITER & FRONT BUMPER (4-Wheel)

1. Carefully feed the rubber gaiter

over the remaining looms and brake

cables to remove it.

2. Cut the last remaining plastic tie wrap.

3. The two Front Bumper fixing studs

are located directly beneath the

bumper mounting bracket.

4. Use a 5.0mm hex key to undo the

two studs.

5. Remove the Front Bumper.

64

Page 70

ELITE-ONYX

HEADLAMP & BULB - (4-Wheel)

1. Access to the headlamp is improved if the left-hand, front wheel, is

removed.

2. The headlamp is secured by two

hex studs.

3. Use a 5.0mm hex key or driver, to

undo the two studs.

4. Carefully remove the Headlamp unit

taking care not to damage the rubber

beading attached to the panel.

5. When refitting, slide the headlamp

unit tight up against the rubber beading. Note the mounting bracket has

elongations to facilitate this.

6. The headlamp bulb is accessed

through the back plastic cover at the

rear of the headlamp unit.

65

Page 71

ELITE-ONYX

HEADLAMP & BULB - (4-Wheel)

7. Press the clip down on the re-useable tie wrap to release it and pull the

black rubber cover back to expose the

lamp holder.

8. There may be two redundant wires

inside the rubber cover, these are not

used, but check that they are insulated.

9. The bulb holder is a bayonet type.

Twist and pull to release it.

10. Withdraw the bulb. 24V - 15W.

1 1. The Headlamp unit components.

66

Page 72

ELITE-ONYX

HEADLAMP - (3-Wheel)

1. Undo the two screws located just

above the headlamp.

2. The Headlamp can then be withdrawn from the cowling as a complete

unit. Don’t forget to disconnect the

headlight loom from the main loom.

3. Unclip the reusable tie wrap. 4. Pull the rubber cover back.

5. T wist and turn the bayonet-fit terminal cover.

6. Remove the 24V - 15W bulb.

67

Page 73

ELITE-ONYX

FRONT BODY PANEL (4-Wheel)

1. Undo the two self-tapping screws

at the front of the body panel.

.

.

.

.

2. There are four further screws located

in the foot mat.

3. Unscrew all four self tapping screws.

4. Lift the body panel up from the front.

5. Note that there is a velcro pad

under each wheel arch and corresponding chassis member.

6. The 4-wheel Front Body Panel.

68

Page 74

ELITE-ONYX

FRONT BODY PANEL (3-Wheel)

Remove the Tiller using the same procedure as the 4-wheel scooter .

Remove the bumper as previously described.

Please note that the photographs below do not show the foot mat.

The screws can be accessed without removing the foot mat, exactly

the same as the 4-wheel version.

1. Unscrew the left-hand front self

tapping screw

2. and the right-hand screw.

3. Undo the two self tapping screws

at the rear of the foot board.

.

.

.

.

4. Lift the Footboard clear of the frame.

69

Page 75

ELITE-ONYX

MAIN LOOM

1. Start at the back of the scooter .

2. Unclip the two square molex plugs.

3. Unclip the small molex plug. 4. Cut the plastic tie wrap.

5. Unclip any remaining plugs.

6. Make sure the loom is free of cable

ties and connections.

70

Page 76

MAIN LOOM

7. Prop up the back of the scooter

frame.

8. The lower splash guard has to be

removed.

9. Undo the two screws located directly below the splash guard.

10. Remove the splash guard.

1 1. It is a good idea to screw the

screws back into the frame for safe

keeping.

12. Release the cable clip at the base

of the flat form loom.

71

ELITE-ONYX

Page 77

ELITE-ONYX

MAIN LOOM

13. Turn the chassis on it’ s side for

easier access.

14. Start by undoing the wire clip at

the rear end of the loom.

15. The loom runs inside a metal

channel. There are a further three

clips to undo along this channel.

16. The final clip is located at the front

of the channel.

17. Gently feed the loom out of the

channel.

18. The Main Loom.

72

Page 78

STUB AXLE (4-Wheel)

1. The S tub Axle assembly can be

removed with or without dismantling

the Steering rods first. This example

shows removal with the steering still

in place.

2. Use a 6.0mm hex key on the securing stud.

3. Use a 13.0mm socket on the nut

below the securing stud.

4. With the nut removed, unscrew the

securing stud, as it is threaded inside

the bracket.

5. Use a 19.0mm spanner on the top

stub axle bolt.

6. Use a 19.0mm socket on the lower

stub axle nut.

73

ELITE-ONYX

Page 79

STUB AXLE

7. After removing the locking nut, use

a 19.0mm spanner to release the

second securing nut.

8. The plain nut is refitted first, followed by the self-locking nut.

9. Use care when lifting the pivot bolt

out, as there are bushes and spacers

which can fall out of the assembly .

10. Remove the Stub Axle, again

taking care not to lose the spacers

and bushes.

1 1. The top and bottom brass spacer

bushes.

12. The top sleeved bush.

74

ELITE-ONYX

Page 80

STUB AXLE

13. Remove the bottom sleeved bush.

14. Finally , remove the internal spacer .

15. The Stub Axle assembly .

16. View of the bushing order; Brass Bush,

Sleeved Bush, Spacer , Sleeved Bush and

Brass Bush.

17. The stub axle component parts.

18. The remaining stub axle is a

“mirror image” of the previous one and

is removed using the same process.

75

ELITE-ONYX

Page 81

STEERING RODS

1. Use an 8.0mm hex key and a

17mm spanner , to release the steering rod outer stud.

2. It is only possible to remove the

lock nut not the stud.

3. Lift the steering rod up, until the stud

is clear of the stub axle.

4. The second nut is permanently

attached to the stud and acts as a

spacer.

5. The other end of the steering rod is

connected to the Steering Head.

6. Use an 8.0mm hex key and a

17mm spanner , to release the steering rod inner stud in exactly the same

way .

76

ELITE-ONYX

Page 82

STEERING RODS

7. The steering rod removed.

8. Use exactly the same process for

the other steering rod.

9. If the stub axle has been removed

before the steering rod, the stub axle

pivot bracket will have to be removed

from the steering rod.

10. Note that the two Steering Rods

are identical.

1 1. Each end of the steering rods have grease nipples to aid the application of lubricant.

77

ELITE-ONYX

Page 83

FRONT SUSPENSION STRUTS

1. The lower strut studs require two

5.0mm hex keys for removal. Because of interference with the swinging arm, a ball-end 5.0mm key is

required on the outside stud.

2. View of a ball-end hex key .

3. The studs are concentric and thread

into each other. The blue colour is

thread-lock.

4. The upper studs are removed in the

same way as the lower studs.

5. Remove the front suspension strut

and repeat the process for the other

strut if required.

6. One of the Front Suspension Strut s

showing the concentric studs. Note

that the strut can be adjusted using the

tension ring at the bottom.

78

ELITE-ONYX

Page 84

SWINGING ARM

1. The swinging arm is secured to the

main chassis by a pivot bolt.

2. Use a 13.0mm socket and a

13.0mm open spanner , to release the

pivot bolt.

3. Withdraw the long pivot bolt.

5. There is a bush in each end of the

swinging arm pivot.

4. There is an inner sleeve within the

swinging arm. Use long nose pliers to

pull this out.

6. The Swinging Arm assembly .

79

ELITE-ONYX

Page 85

STEERING HEAD (4-Wheel)

1. Use an adjustable spanner to

loosen the steering head securing

nut.

2. It is a good idea to wedge the

bottom of the steering head to stop it

turning, here a screw driver is used.

3. The steering head securing nut

should loosen quite easily .

4. As the steering head has a fine

thread it is quicker to remove the

securing nut, using the fingers.

5. Next, remove the spacer ring.

6. Again, use an adjust able spanner to

release the Steering bearing retaining

nut.

80

ELITE-ONYX

Page 86

STEERING HEAD (4-Wheel)

7. Again, use finger pressure to undo

the nut.

8. Removing the nut, exposes the top

steering bearing race.

9. Use thin nose pliers to lift the top

bearings out.

10. With the top bearings removed,

lower the steering head to expose the

bottom bearing race.

1 1. Feed the lower bearing race, up

and over the top of the steering head.

12. The 4-Wheel Steering Head Assy .

81

ELITE-ONYX

Page 87

STEERING HEAD & FORKS (3-Wheel)

1. Use an adjustable spanner to loosen

the steering head nut.

2. As this nut has a fine thread, it is

better to use fingers to undo it all the

way .

3. Remove the nut and the washer.

4. The steering bearing nut.

5. Use the adjustable spanner to

loosen the steering bearing nut also.

6. Undo the nut the rest of the way

using finger pressure.

82

ELITE-ONYX

Page 88

STEERING HEAD & FORKS (3-Wheel)

7. The top steering bearings usually

come away with the nut.

8. Steering top bearing and retaining

nut.

9. Withdraw the front fork assembly

from the steering head.

10. The lower steering bearing will

come away with the fork assembly .

1 1. View of the S teering bearings,

retaining nut and Front Fork assembly .

83

ELITE-ONYX

Page 89

NOTES

Loading...

Loading...